Patents

Literature

39results about How to "Reduce oil return" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

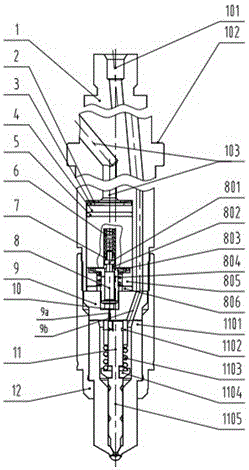

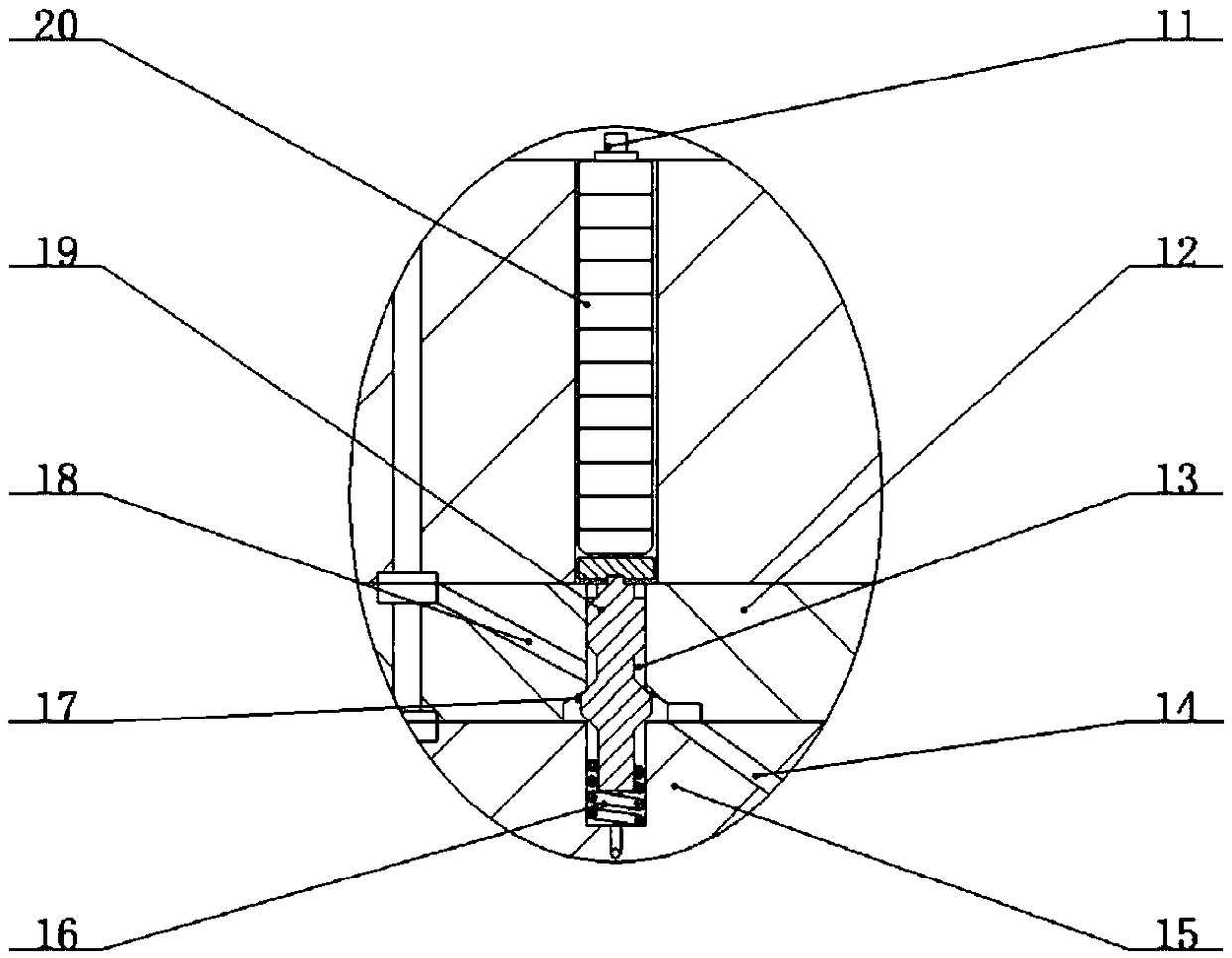

Middle hole pressure storage static leakage-free oil sprayer

ActiveCN104314725ASimple structureImprove sealingFuel injection apparatusMachines/enginesSolenoid valvePlunger

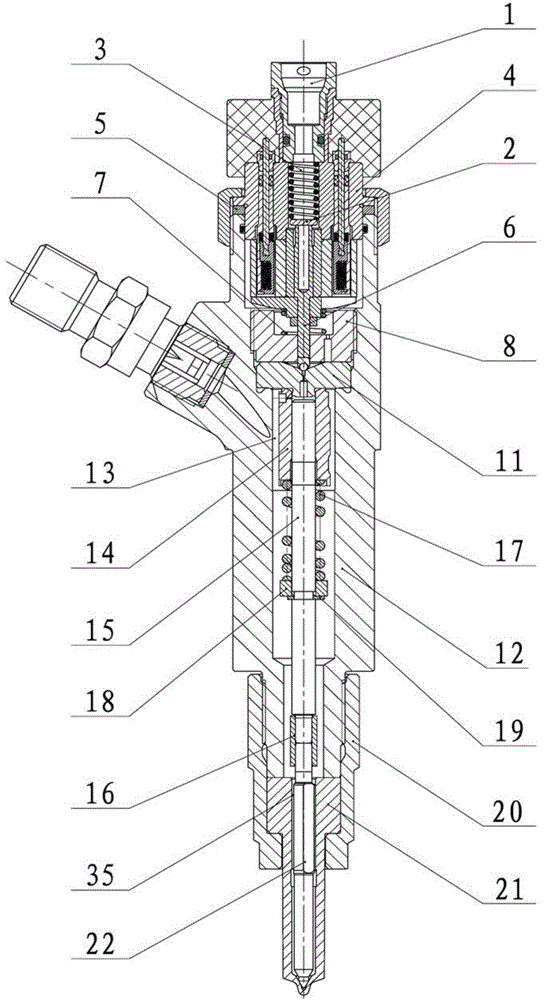

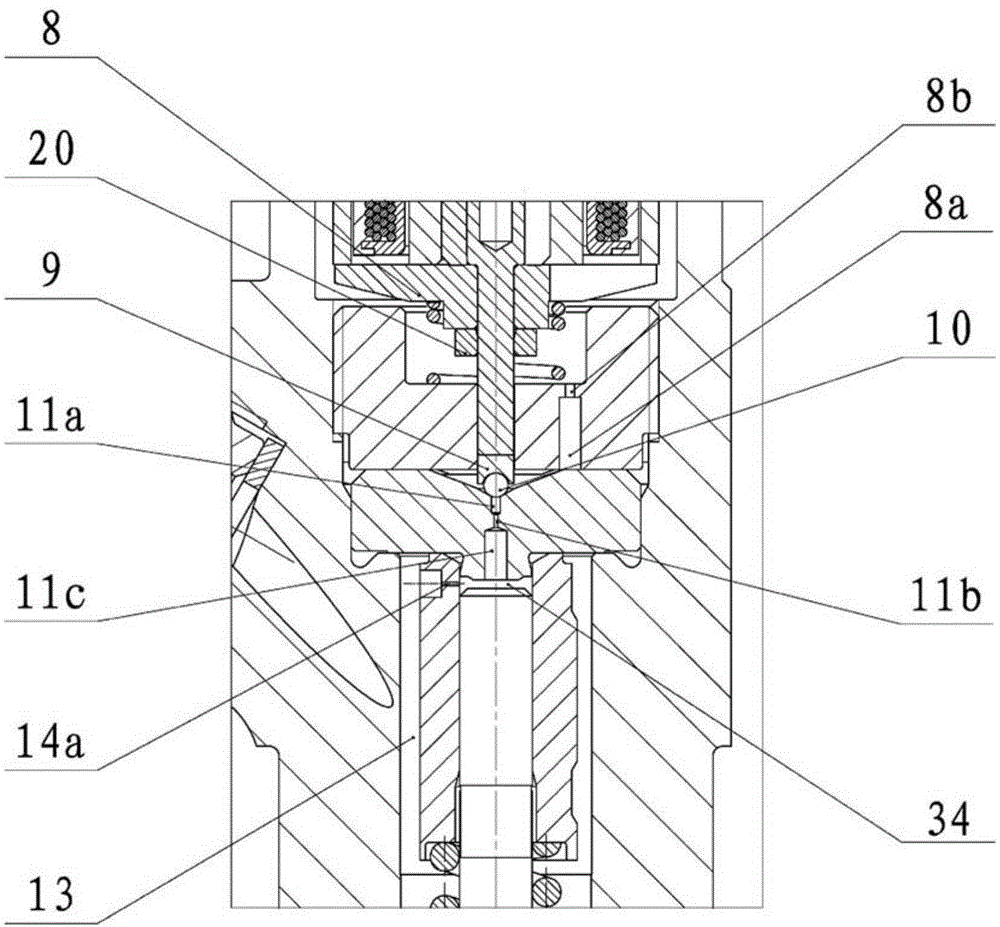

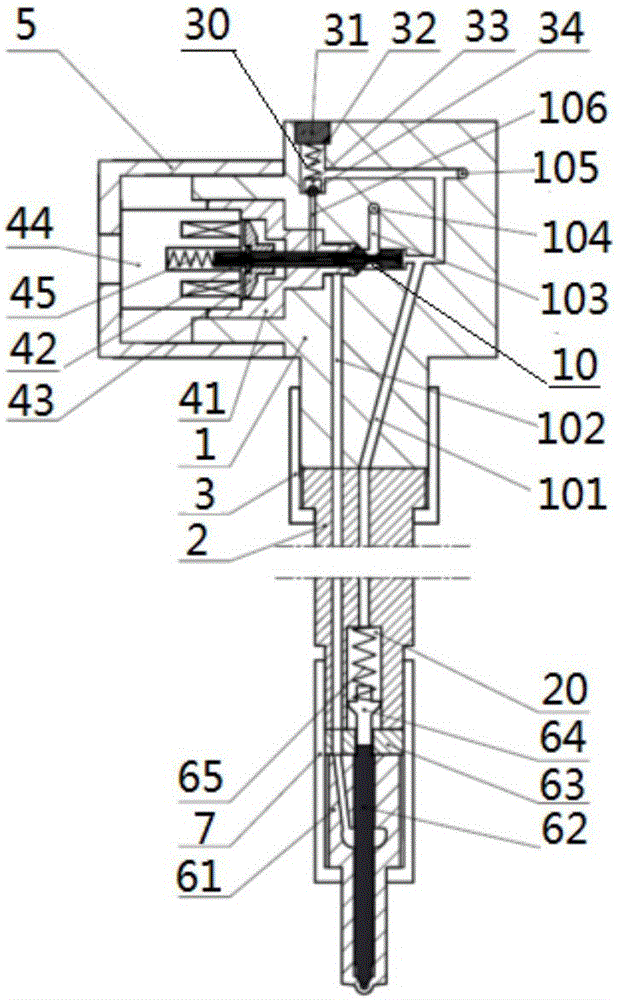

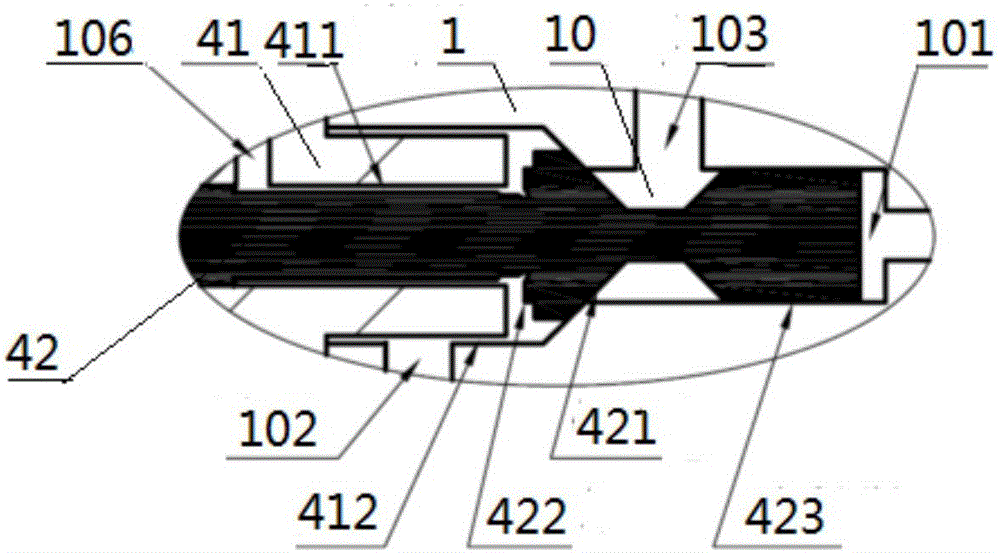

The invention discloses a middle hole pressure storage static leakage-free oil sprayer, comprising a high speed solenoid valve, a locking screw sleeve, a tapered surface ball valve type switch valve, a control plunger and barrel assembly, an oil sprayer spring, a spring seat, an opening check ring, an oil sprayer body, an oil sprayer assembly and an oil nozzle locking cap; the tapered surface ball valve type switch valve is arranged in a concave cavity in the upper end of the oil sprayer body; the upper end of the oil sprayer body is connected with the high speed solenoid valve by a locking nut; the lower end of the oil sprayer body is connected with the oil nozzle assembly by the oil nozzle locking cap; the control pole plunger and barrel assembly is arranged in a central hole formed along the axis of the oil sprayer body; the central hole of the oil sprayer body and the control pole plunger and barrel assembly form a middle hole pressure storage cavity. The oil sprayer is simple in structure, low in machining cost and convenient to mount, so the production efficiency and product percent of pass are improved.

Owner:钧风电控科技(大连)有限责任公司

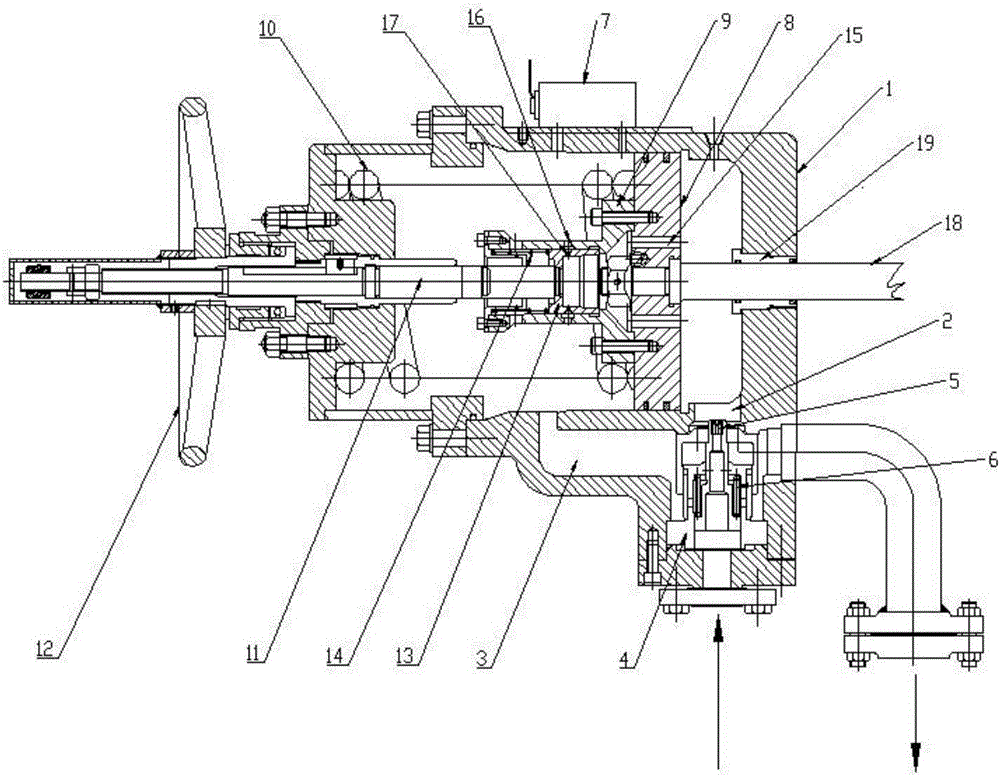

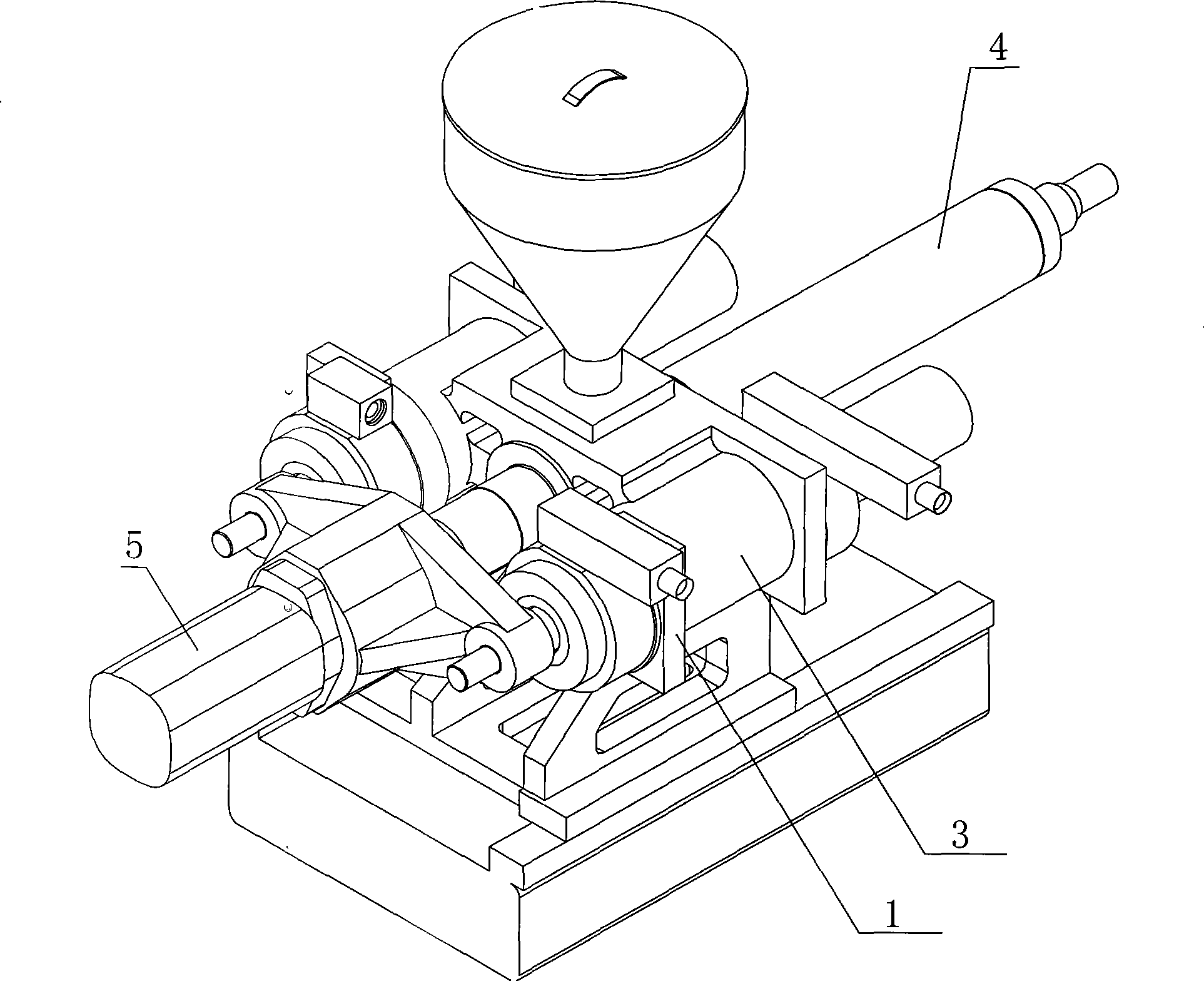

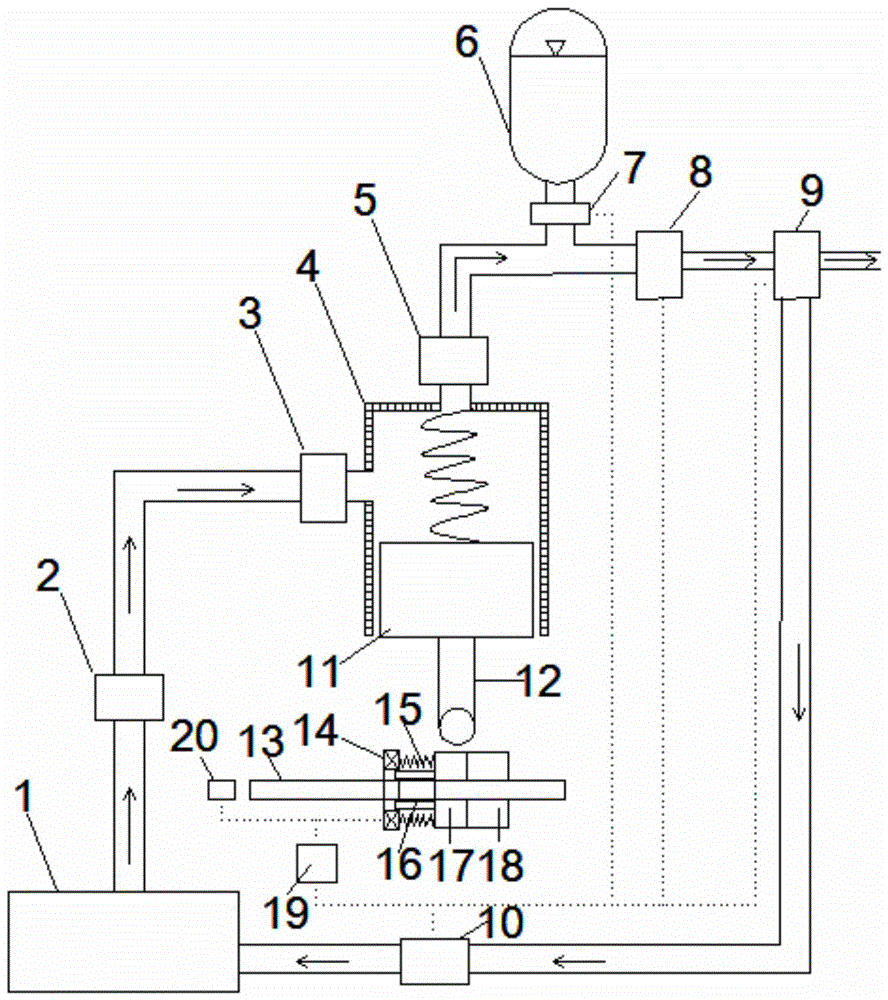

Electromagnetic variable cam mechanism and small-fluctuation variable-flow oil supply device

InactiveCN104791211AImprove fuel delivery efficiencyGood orientationPositive displacement pump componentsPiston pumpsInjectorFuel oil

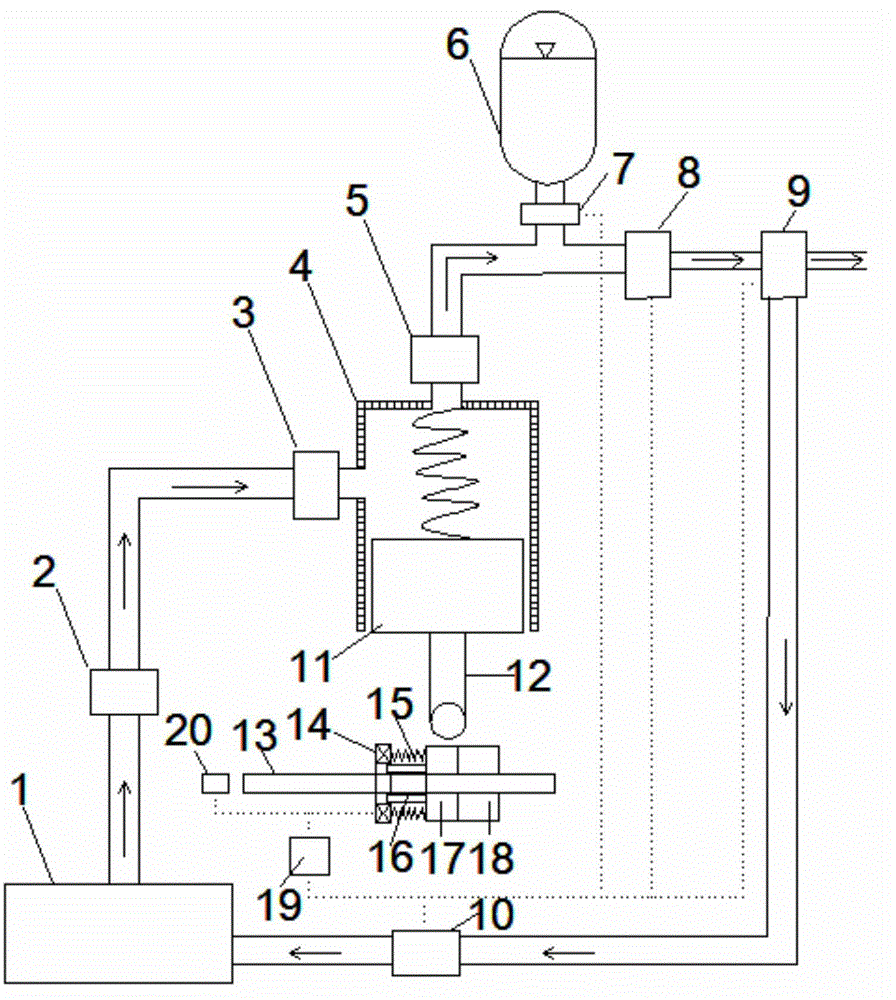

The invention discloses an electromagnetic variable cam mechanism and a small-fluctuation variable-flow oil supply device. The small-fluctuation variable-flow oil supply device comprises an oil tank and an oil pump, wherein the oil pump is composed of a cylinder body and a piston, an oil inlet of the cylinder body is communicated with the oil tank through an oil inlet valve and a filter, an oil outlet of the cylinder body is communicated with an oil inlet of an electric-control oil injector through an oil outlet valve and a pressure sensor, an oil return port of the electric-control oil injector is connected with an oil return port of the oil tank through an oil return control valve, the lower end of the piston makes contact with a single-action cam or a multi-action cam, and the pressure sensor, the electric-control oil injector, an electromagnetic coil and the oil return control valve are connected with a power source and a controller. According to the small-fluctuation variable-flow oil supply device, the single-action cam or the multi-action cam is selected to be used for changing the oil supply capacity of the oil pump in real time according to the rotating speed working condition and the load working condition of an engine, the amount of returned oil is controlled through the oil return control valve, the amount of returned oil of the oil pump is reduced, and fuel oil supplying efficiency is improved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

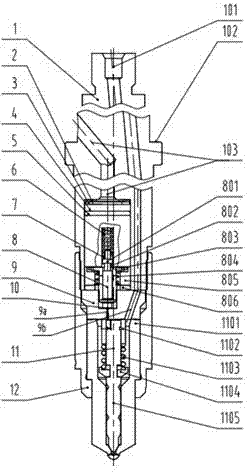

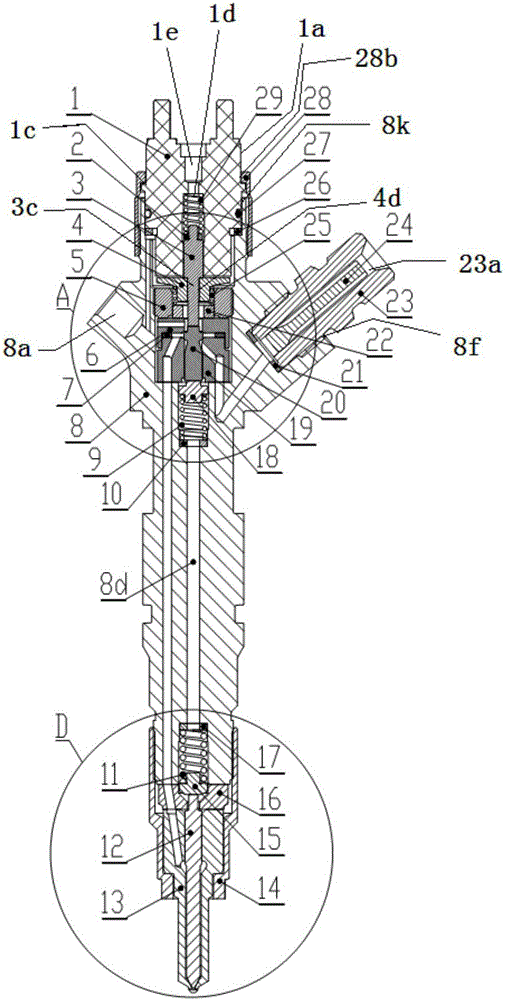

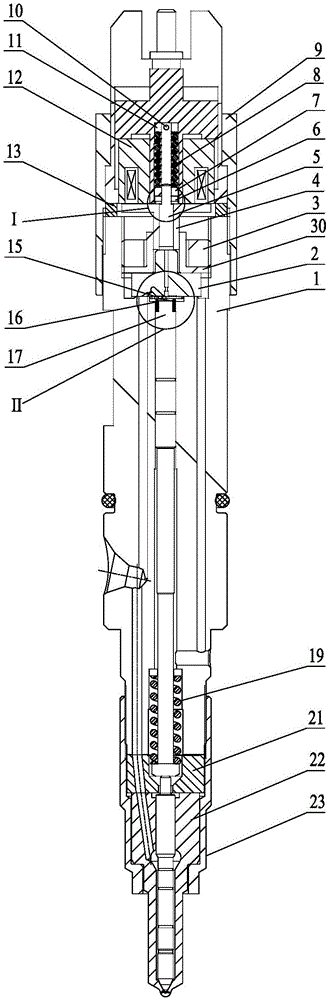

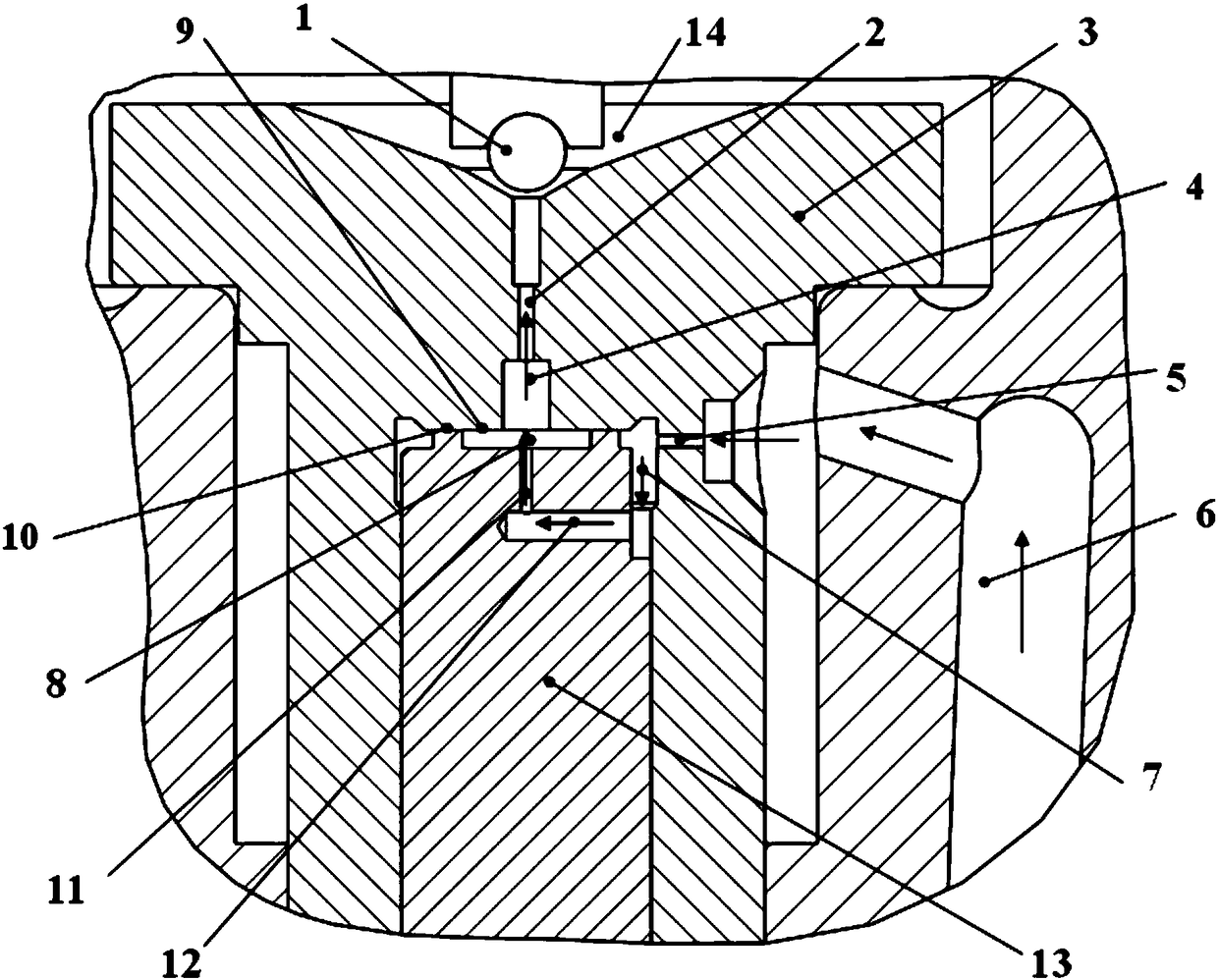

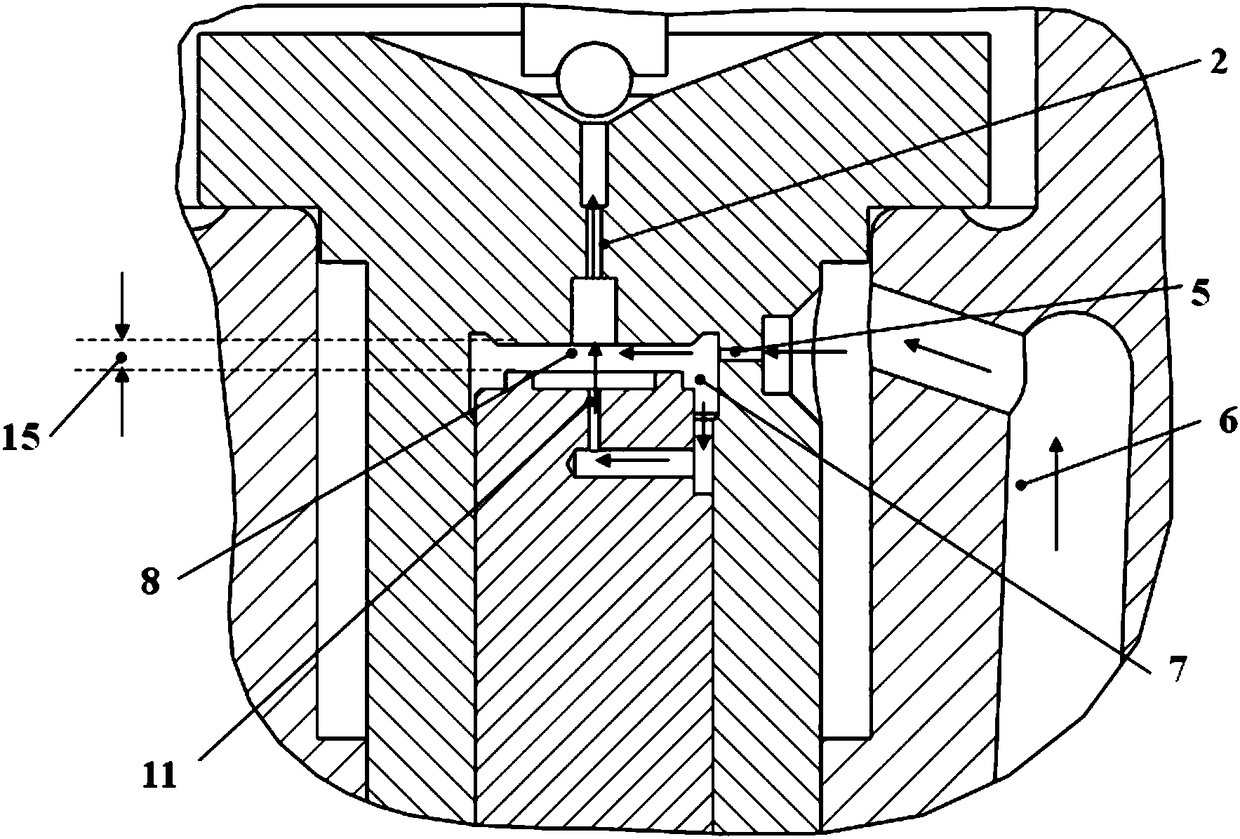

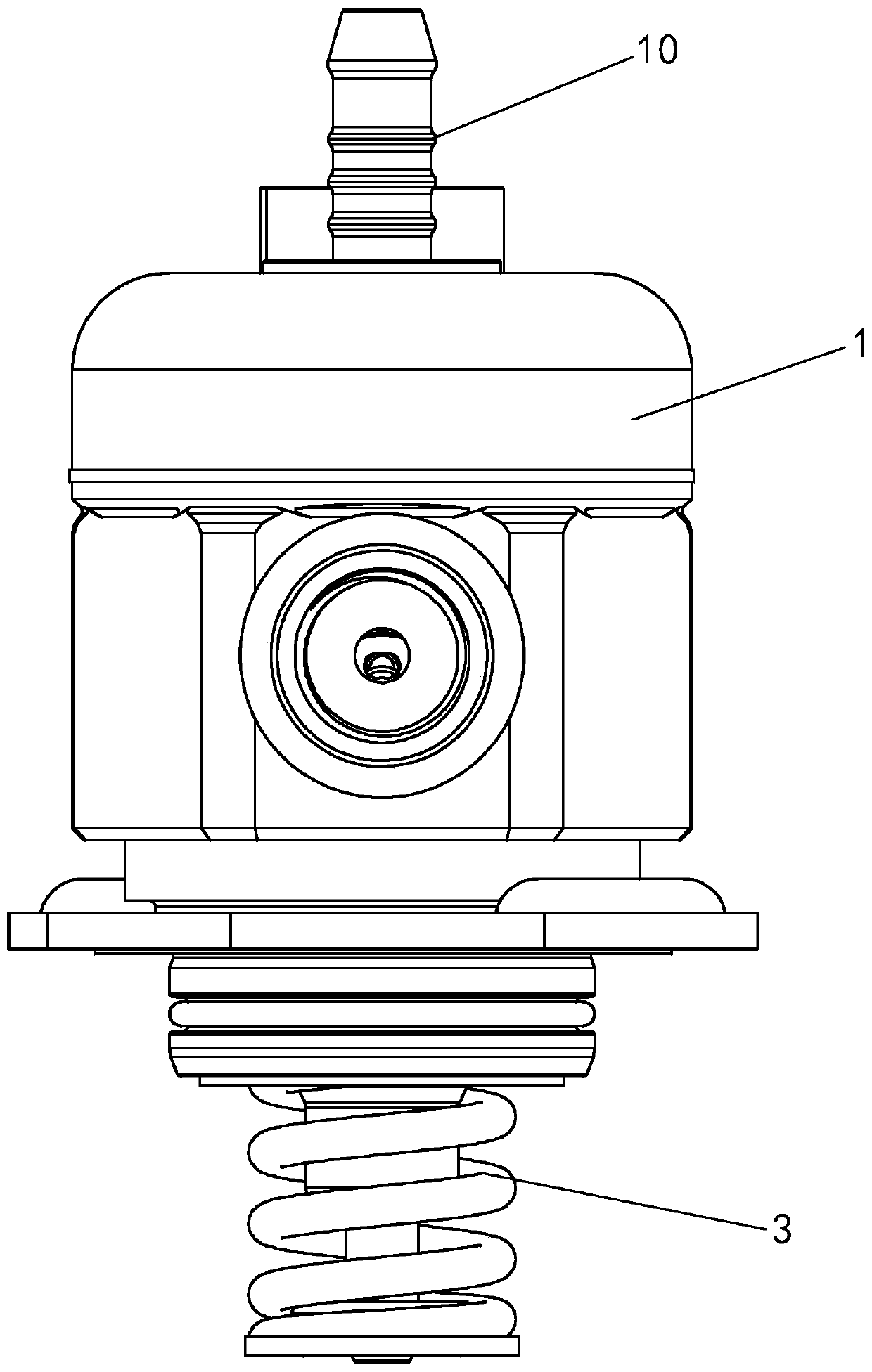

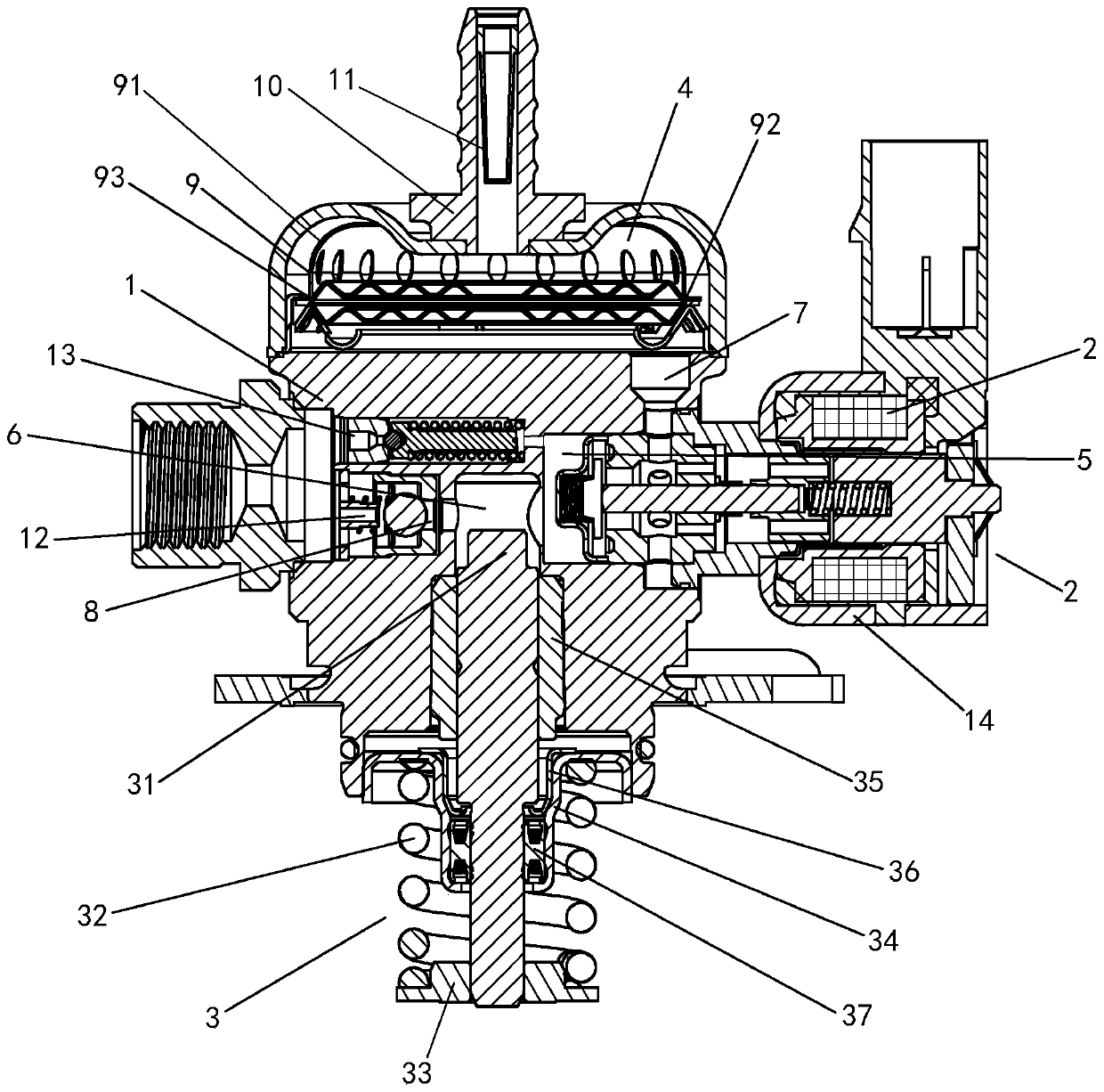

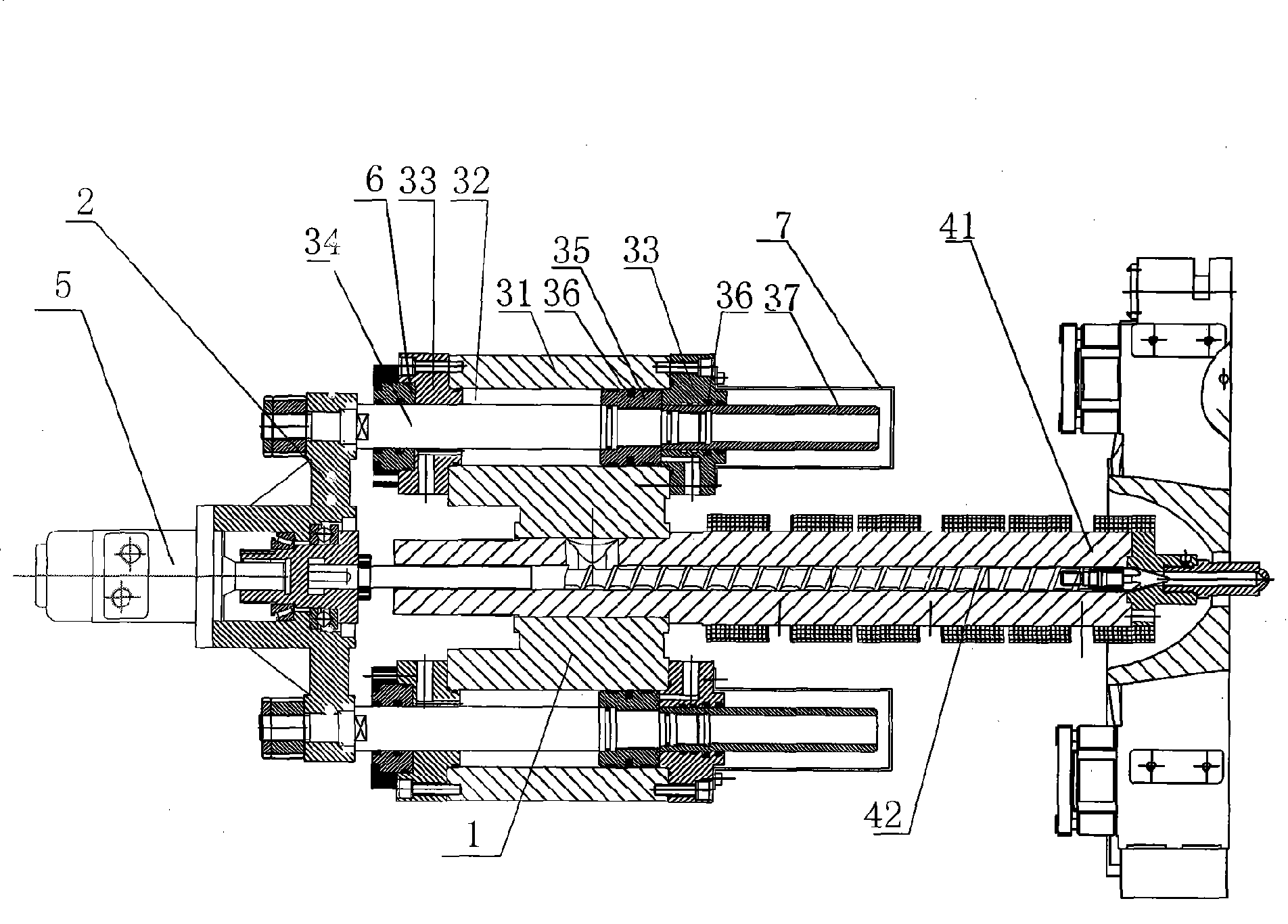

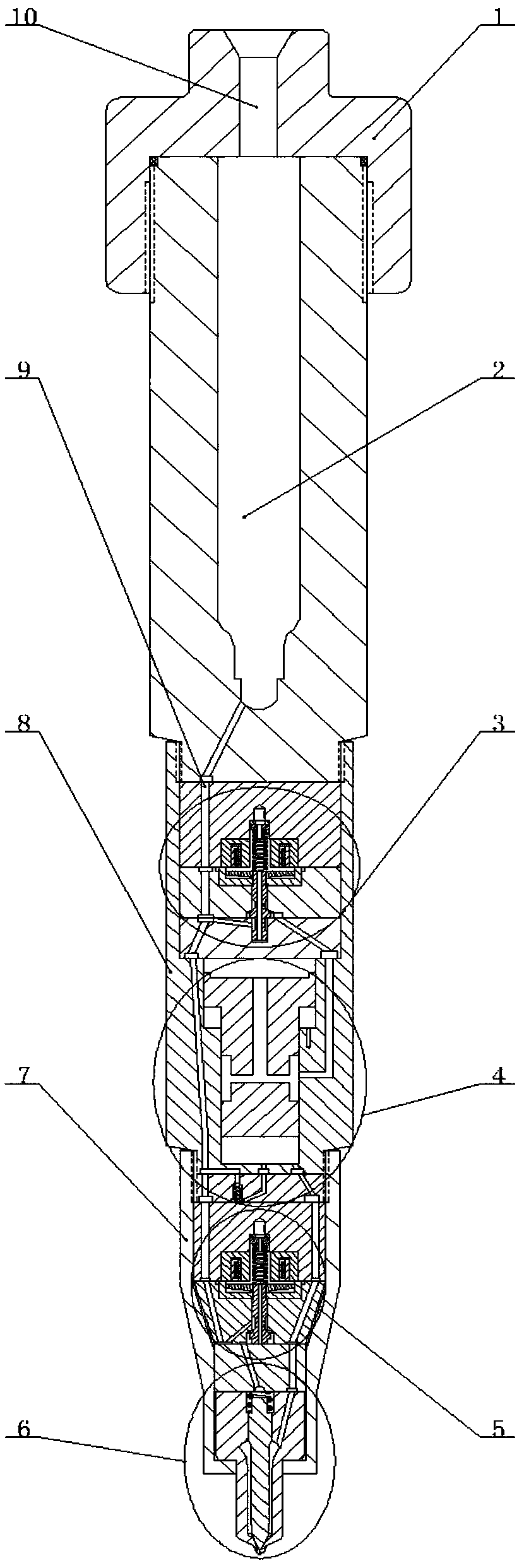

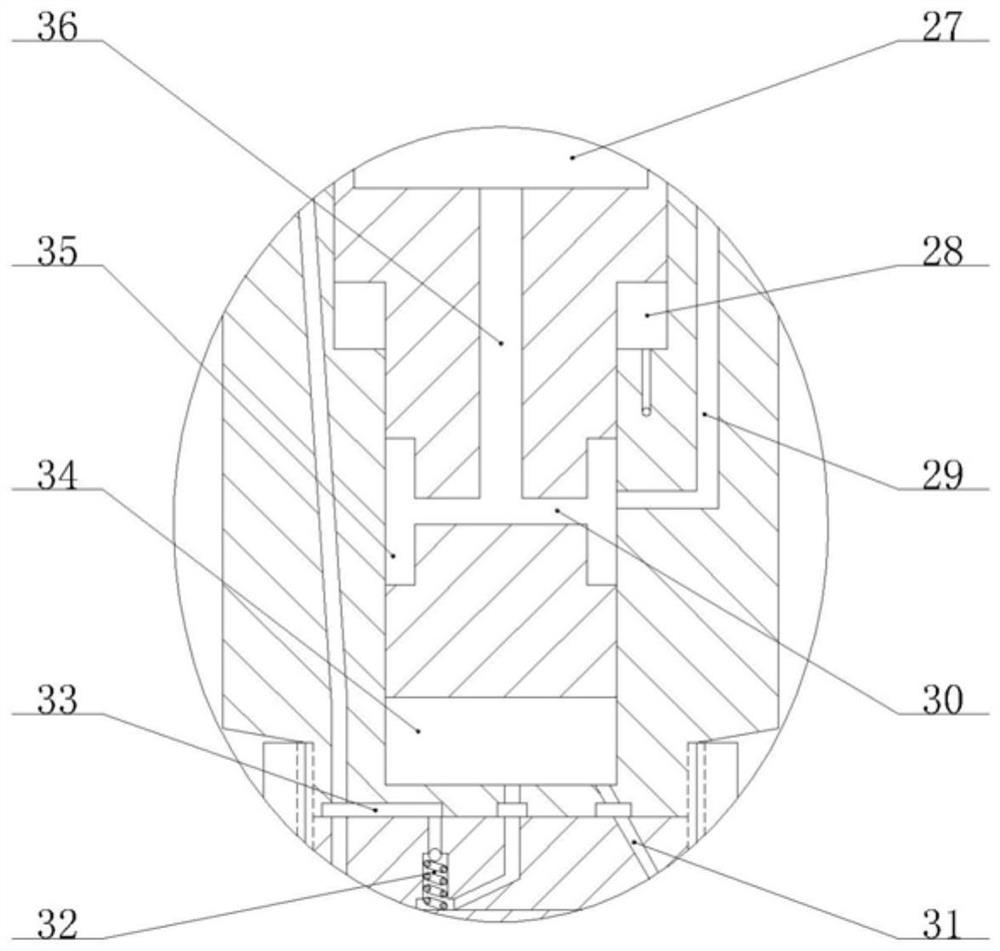

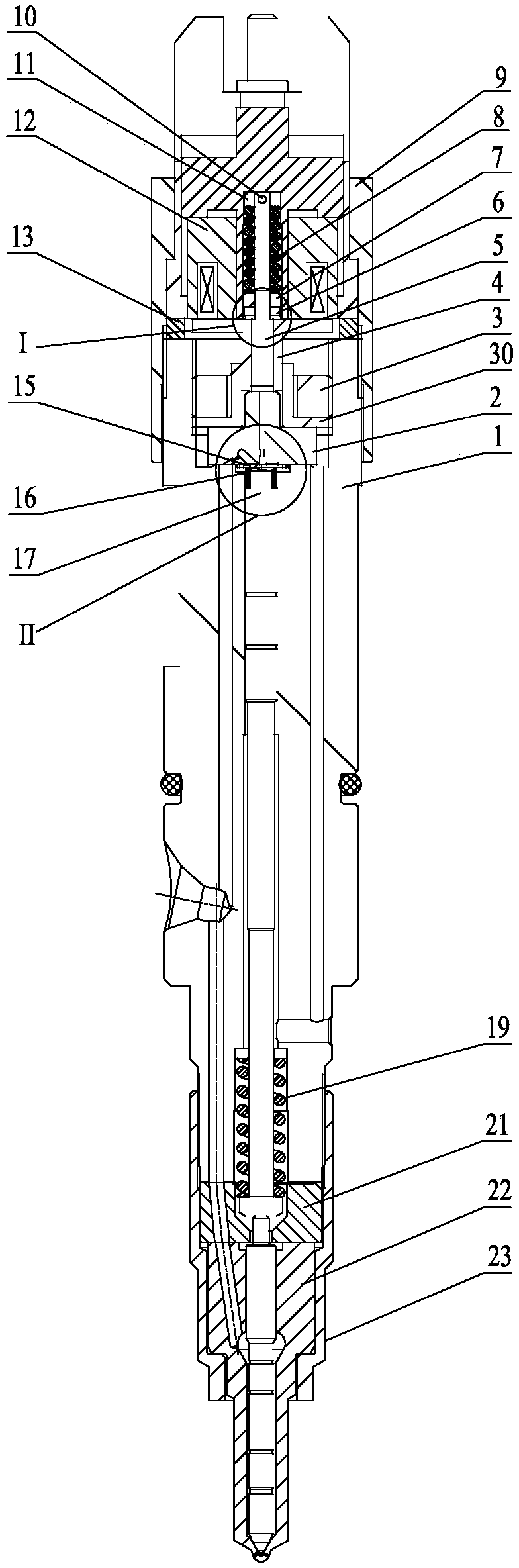

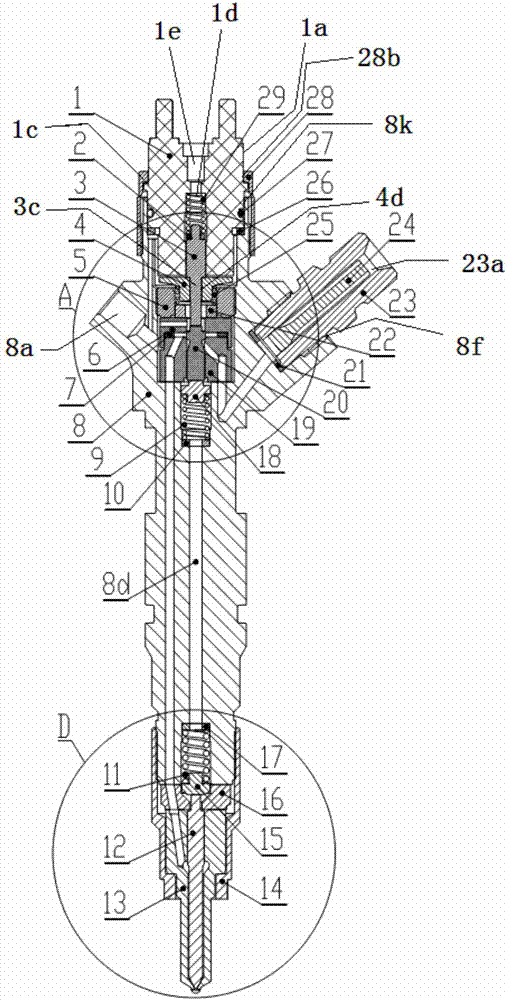

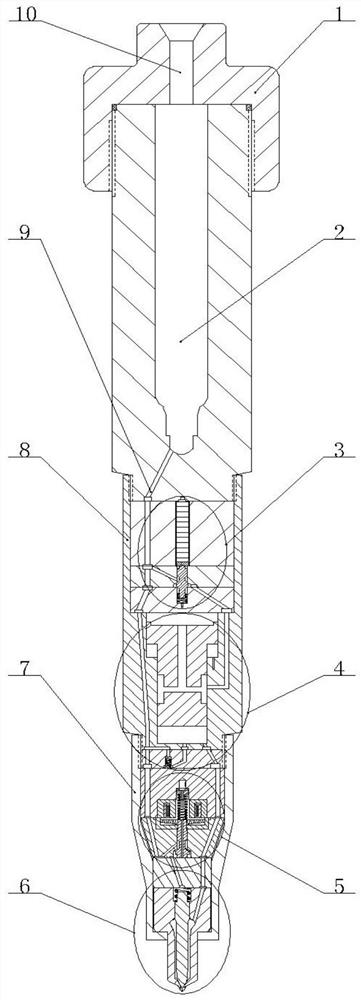

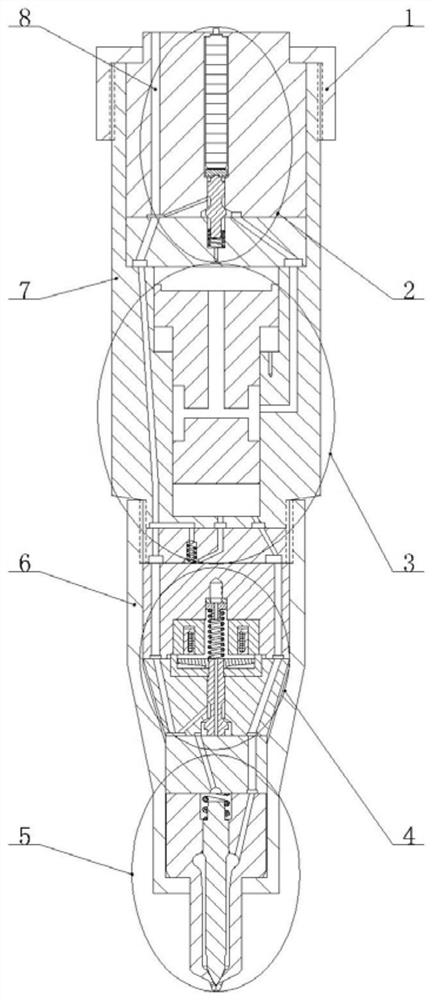

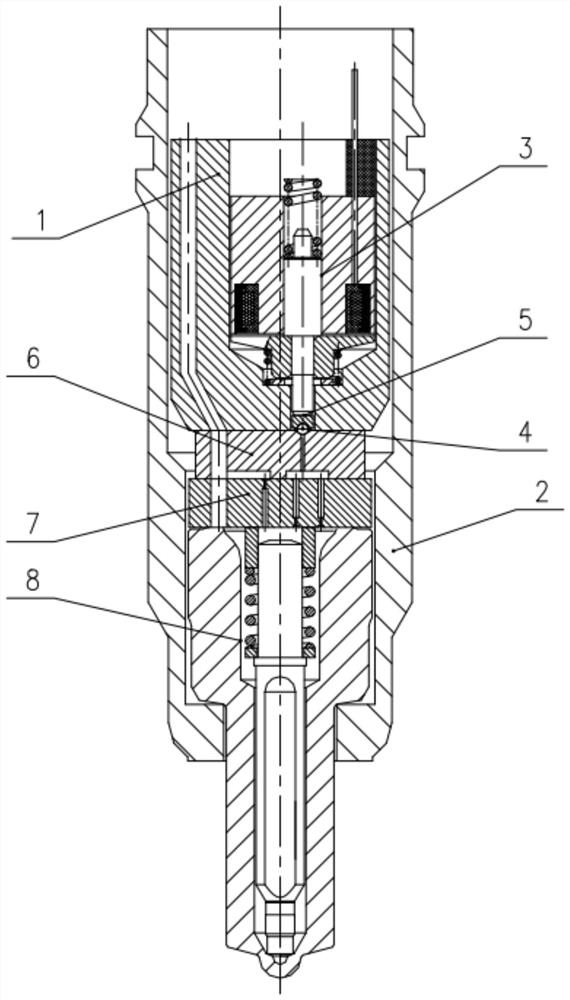

Energy-saving high-pressure common-rail electronic-control oil injector

ActiveCN104500297ASimple structureQuick responseFuel injection apparatusMachines/enginesSolenoid valveCommon rail

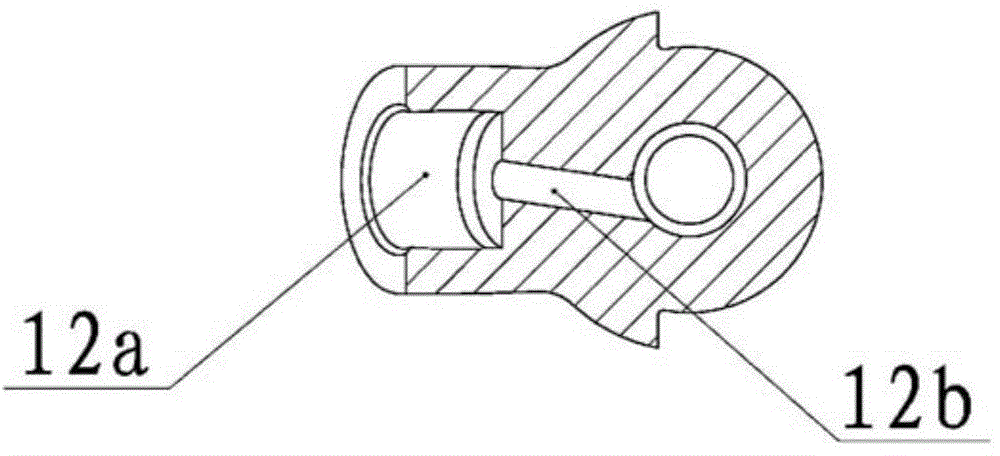

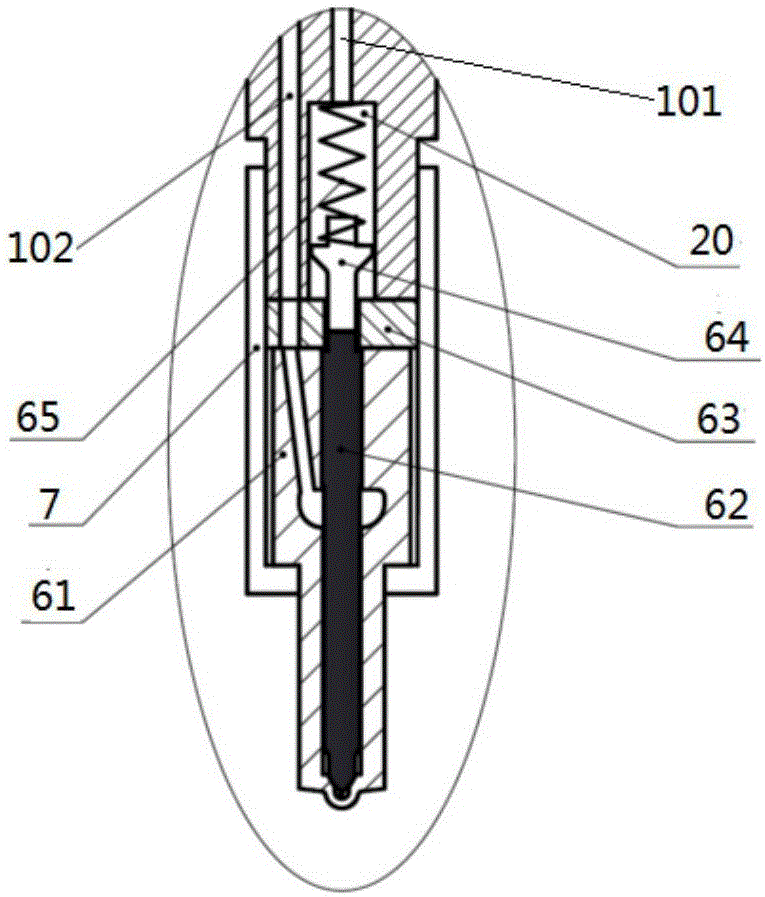

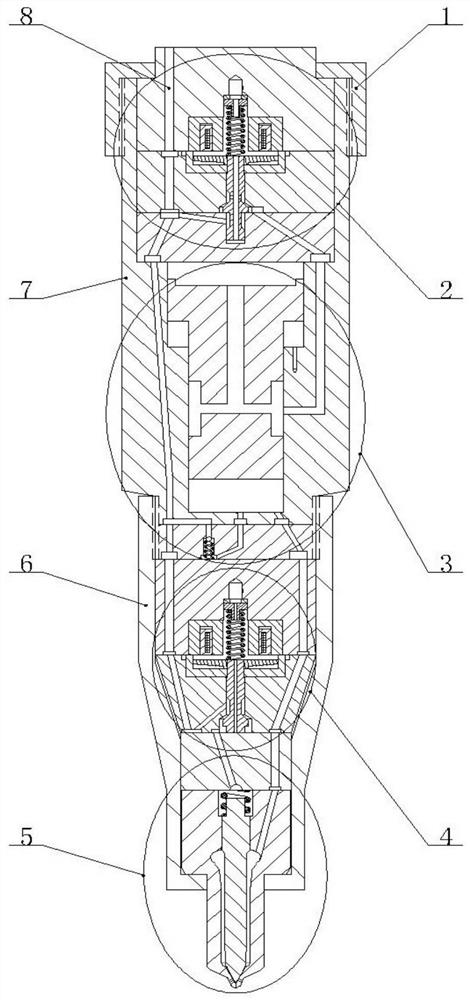

The invention discloses an energy-saving high-pressure common-rail electronic-control oil injector. The energy-saving high-pressure common-rail electronic-control oil injector is characterized in that a high-speed electromagnetic valve is of a built-in structure and is compressed by a butterfly spring, and compressing force on the high-speed electromagnetic valve can be adjusted by the aid of an adjusting gasket; a hydraulic servo mechanism is positioned on the lower portion of the high-speed electromagnetic valve and is mounted inside an oil injector body; a control valve is provided with a positioning plane and a high-pressure sealing spherical surface, so that influence of accumulated machining errors on components can be reduced; a needle valve assembly comprises a needle valve body, a needle valve, a clip type spring seat, a spring and a sleeve. The energy-saving high-pressure common-rail electronic-control oil injector has the advantages that the needle valve body has an oil-passage-free character, and accordingly the production cost can be reduced; a large conical surface is arranged on the top of the needle valve, throttle holes and a circular groove are formed in the upper portion of the needle valve, a small cylinder is arranged in the middle of the needle valve, a spiral groove is formed in the lower portion of the needle valve, a throttle hole is formed in the sleeve, and the sleeve, the needle valve and the needle valve body are matched with one another, so that the electronic-control oil injector is quick in response, free of leakage and low in oil return, power consumption and fuel oil consumption of a high-pressure common-rail diesel engine can be reduced, emission of the diesel engine can be improved, and the energy-saving high-pressure common-rail electronic-control oil injector is particularly applicable to repeated injection common-rail diesel engines.

Owner:CHONGQING HONGJIANG MACHINERY

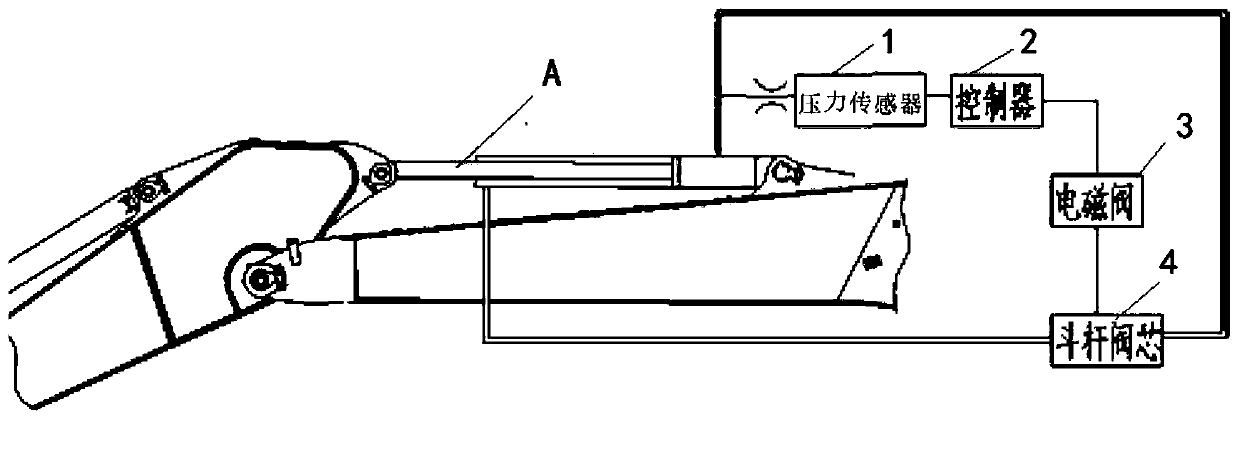

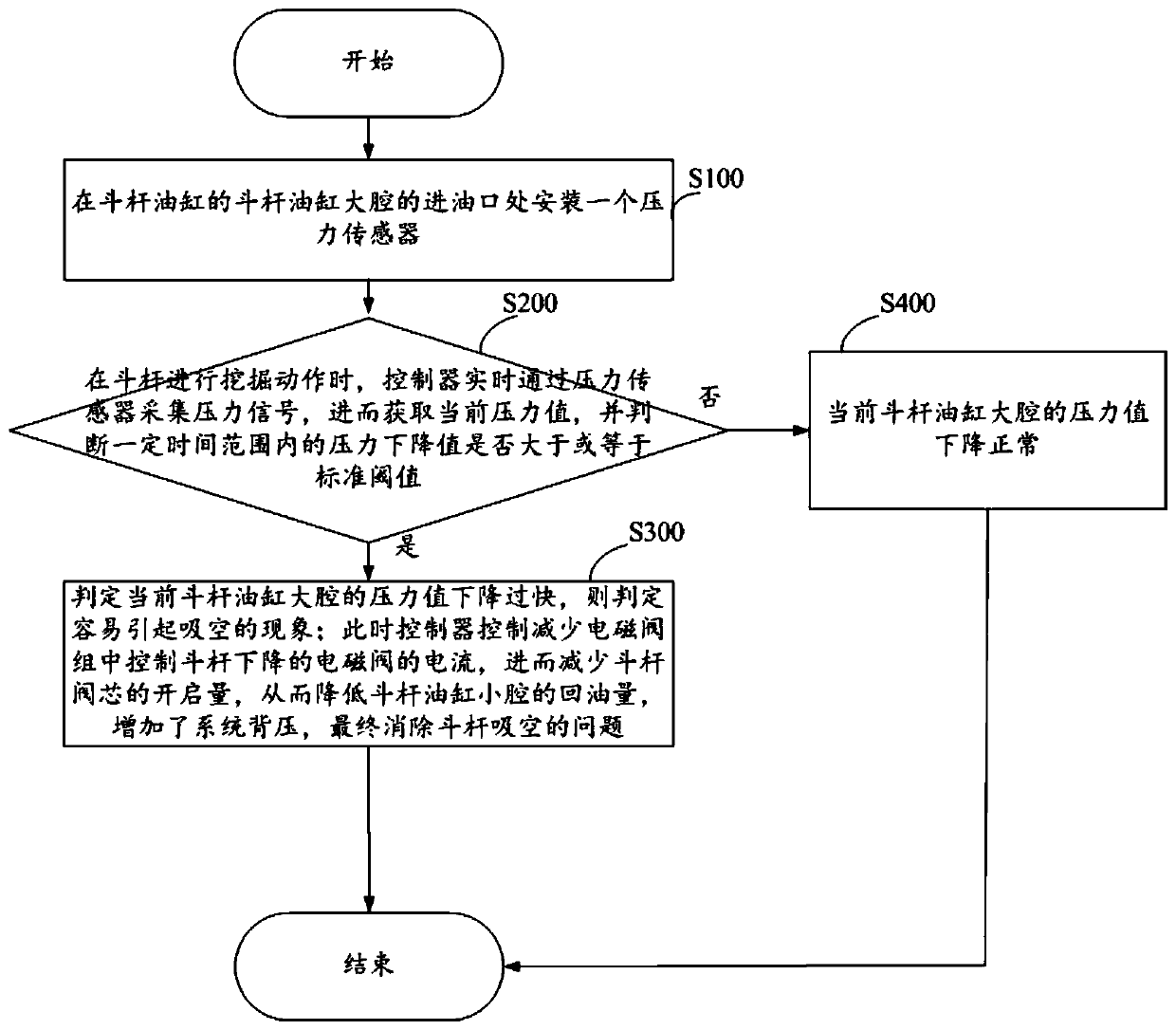

Energy-saving control device and control method for controlling bucket rod of excavator to descend

InactiveCN109736373ASolve the problem of suctionSmall currentMechanical machines/dredgersTime rangePower flow

The invention relates to an energy-saving control device and control method for controlling a bucket rod of an excavator to descend. The energy-saving control device for controlling the bucket rod ofthe excavator to descend comprises a pressure sensor, a controller, an electromagnetic valve for controlling the bucket rod to descend, and a bucket rod valve core. The controller is used for collecting pressure signals in real time through the pressure sensor when the bucket rod carries out excavation action, then the current pressure value is obtained, and whether the pressure descending value within the preset time range is larger than or equal to the standard threshold value or not is judged; if the pressure descending value within the current preset time range is larger than or equal to the standard threshold value, it is judged that the pressure value of a large cavity of a current bucket rod oil cylinder is descended too fast, and it is determined that the phenomenon of air suctionis caused easily; and at the moment, the controller controls to reduce currents of the electromagnetic valve for controlling the bucket rod to descend in an electromagnetic valve set, then the openingamount of the bucket rod valve core is reduced, thus the oil amount of a small cavity of the bucket rod oil cylinder is reduced, the system back pressure is increased, and finally the problem of airsucking of the bucket rod is eliminated.

Owner:SHANGHAI SANY HEAVY IND

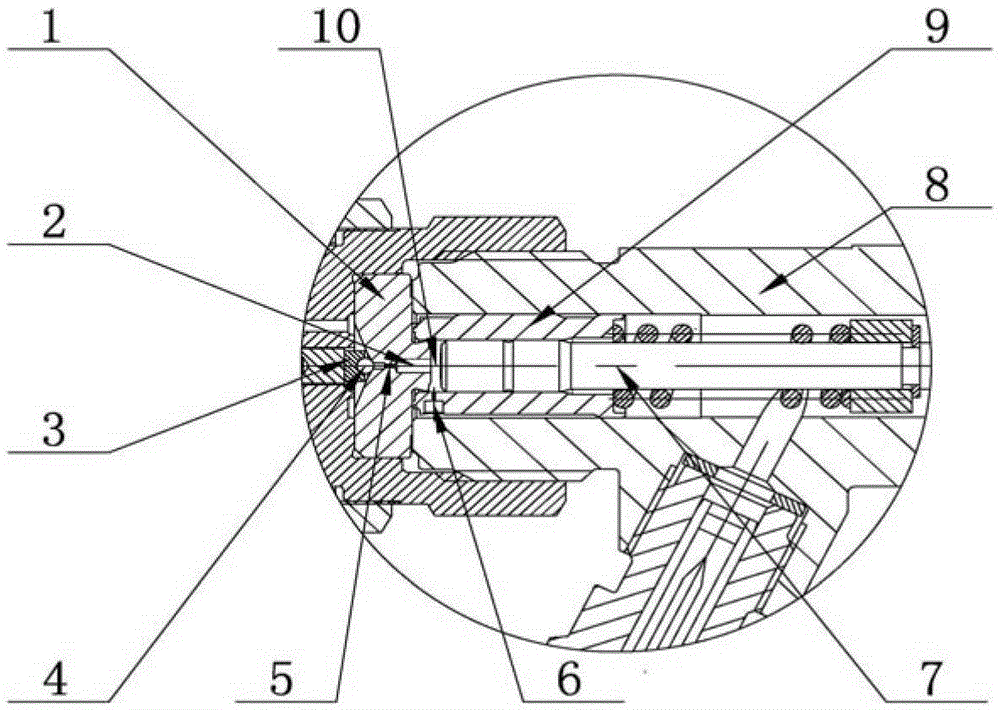

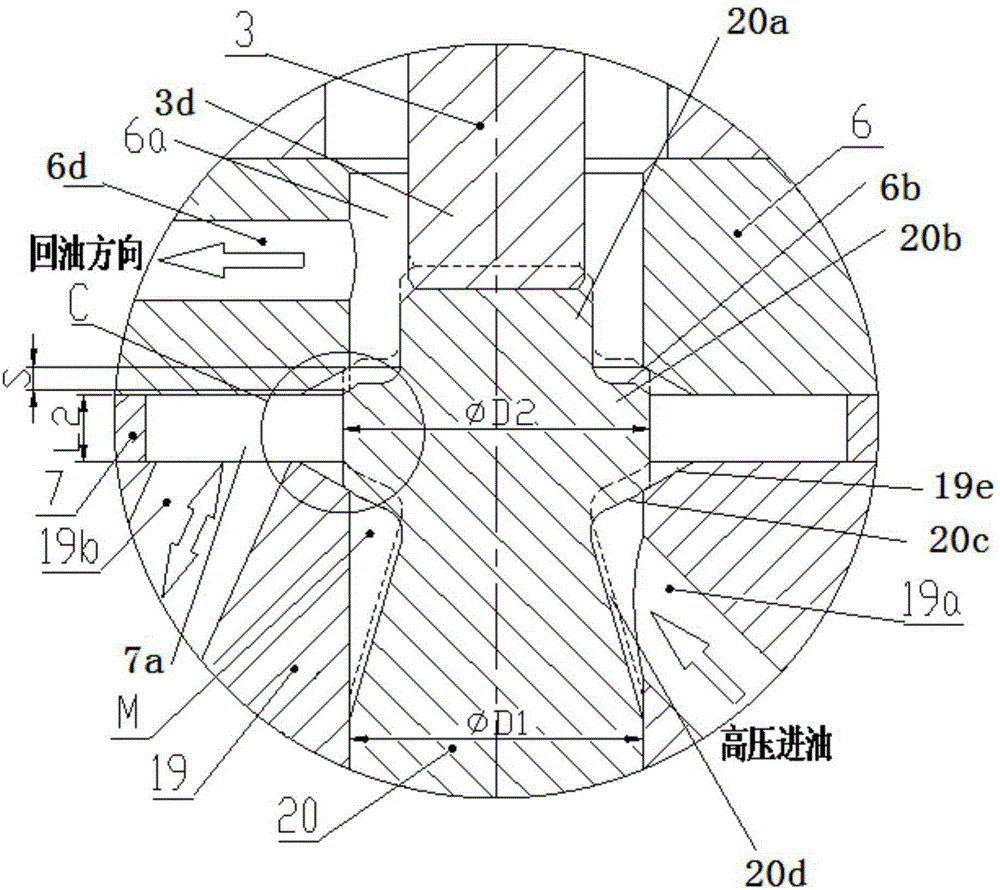

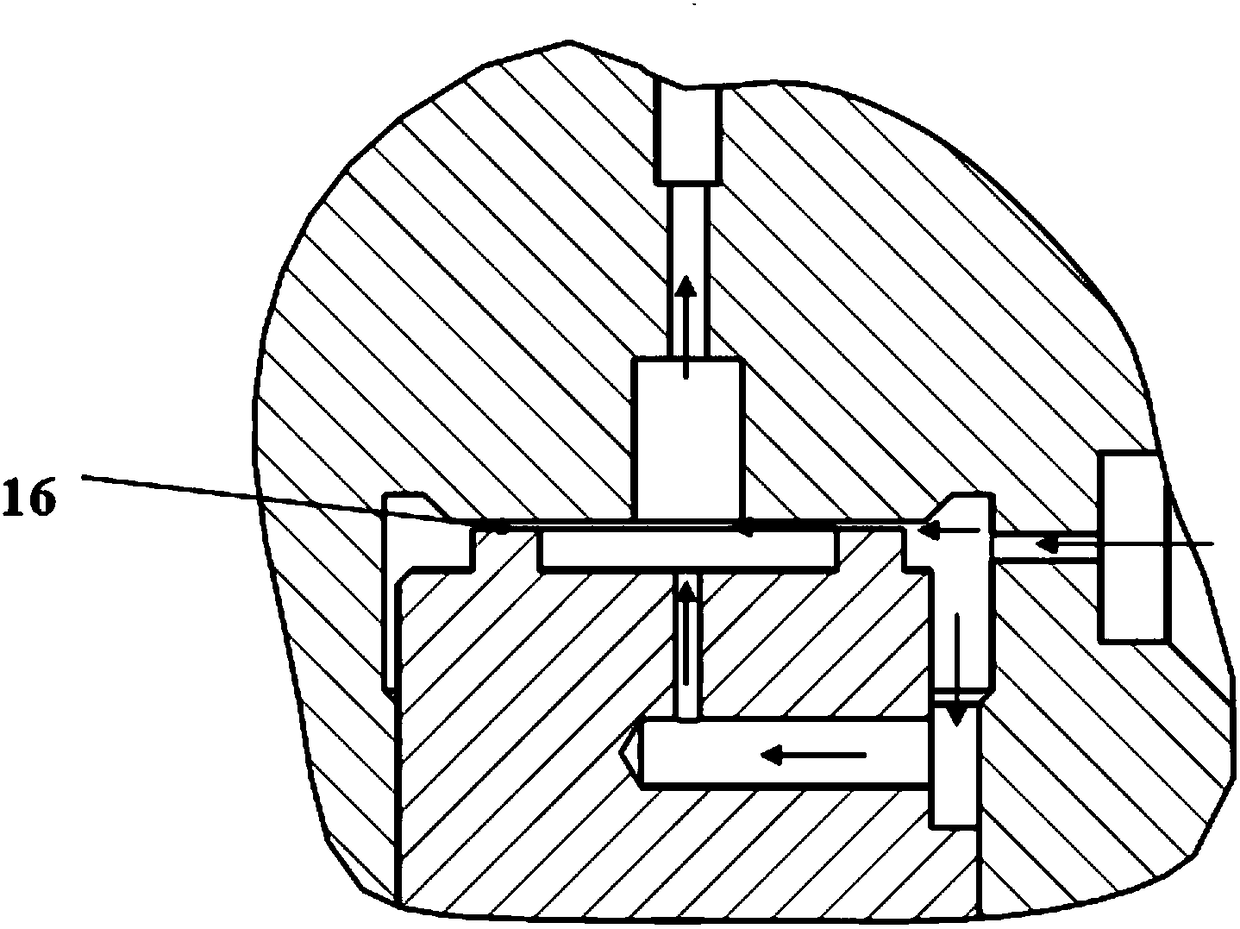

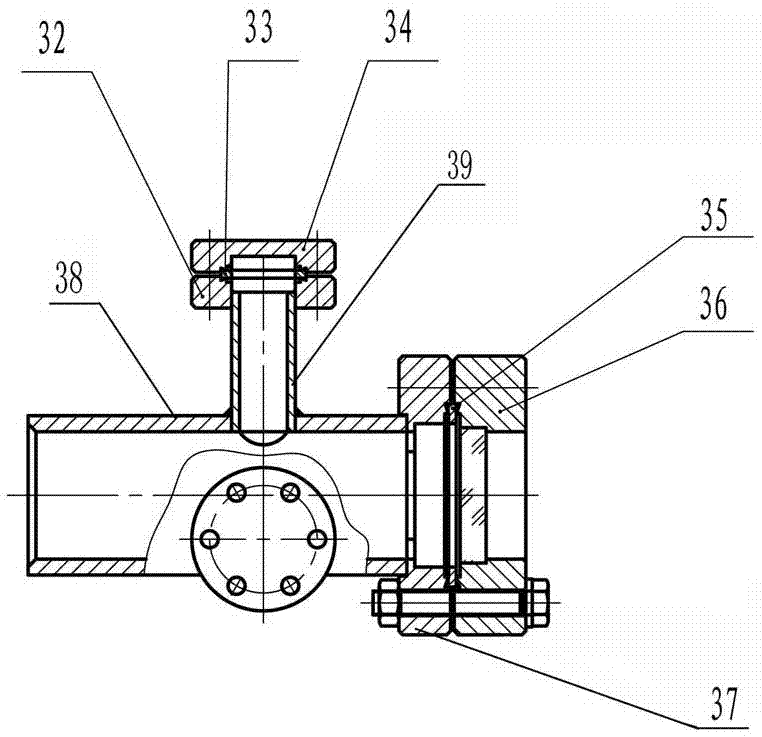

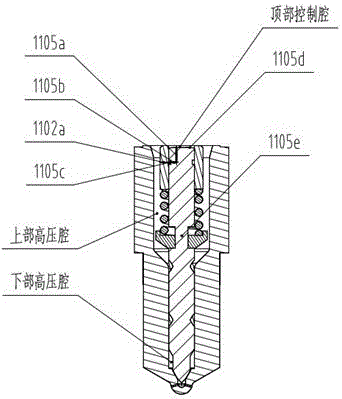

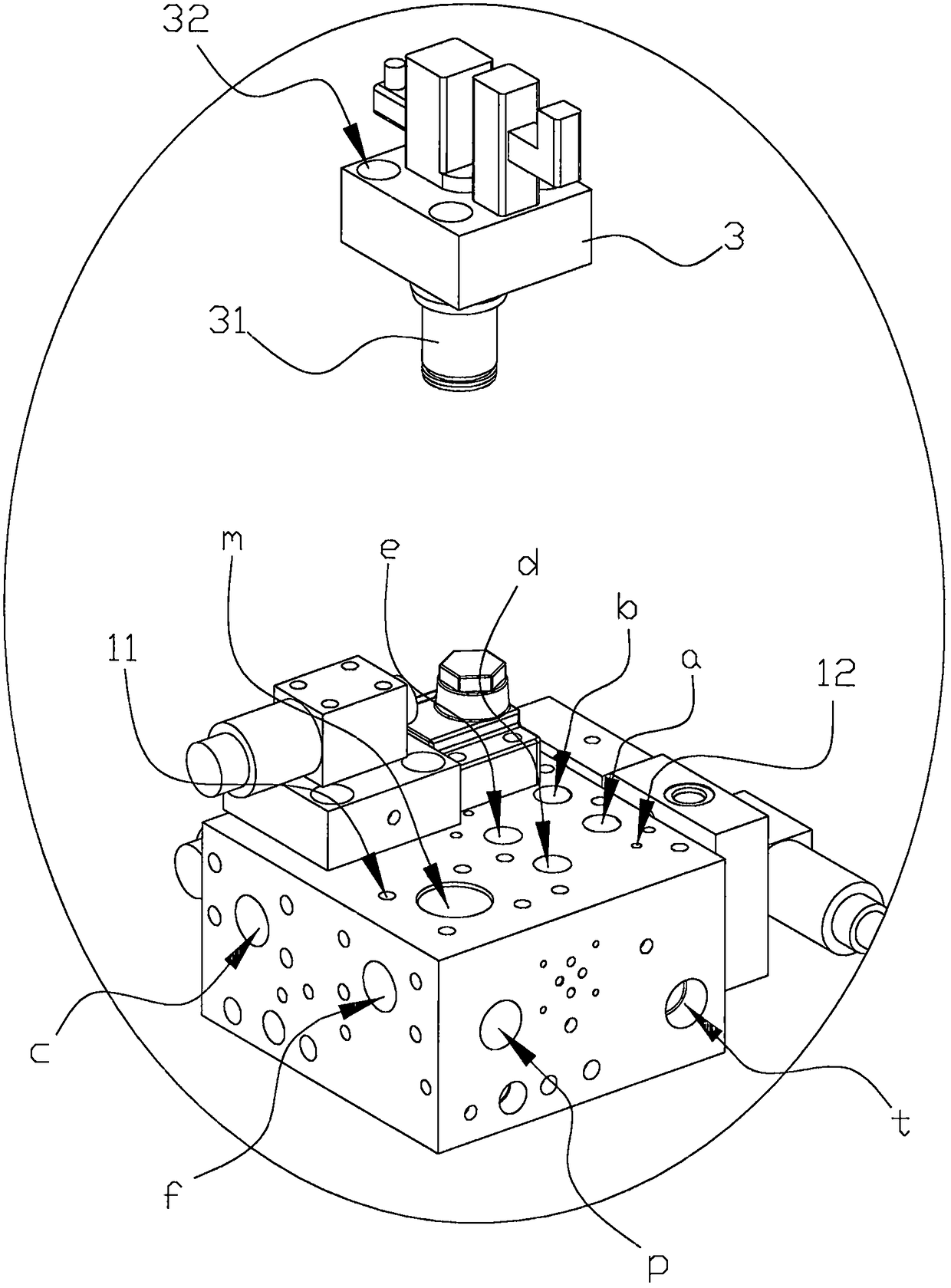

A hydraulic controller for common rail fuel injector with middle hole pressure accumulation

ActiveCN103967666BImproves sealing reliabilityReduce sensitivityFuel injection apparatusMachines/enginesCommon railControl theory

Owner:钧风电控科技泰州有限责任公司

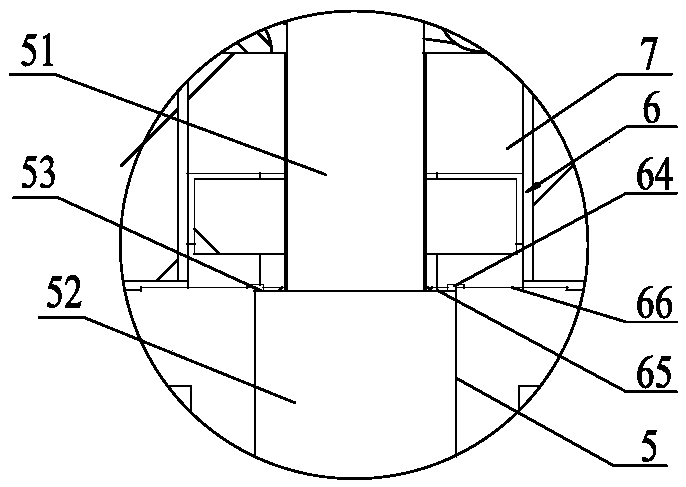

Novel common-rail fuel injector

ActiveCN105201716AVary the amount of fuel injected per cycleIdeal fuel injection timingFuel injection apparatusMachines/enginesSolenoid valveEngineering

The invention discloses a novel common-rail fuel injector. The common-rail fuel injector comprises a fuel injector body component, an electromagnetic valve component and a fuel injection nozzle component, wherein the electromagnetic valve component and the fuel injection nozzle component are mounted at upper and lower ends of the fuel injector body component respectively. The fuel injection control function is realized in such a manner that the two-position three-way electromagnetic control valve component and the fuel injection nozzle component with adjustable opening pressure are combined, the fuel injector is simpler in structure, and the initial fuel injection point and the fuel injection quantity can be controlled flexibly. An electromagnetic control valve core of the fuel injector is designed to adopt a fuel pressure self-balancing structure, the fuel injection starting response speed can be significantly increased, the driving current of an electromagnet can be significantly reduced, the service life of the electromagnet is effectively prolonged, and the reliability of the electromagnet is effectively improved. The common-rail fuel injector is free of pressure control chamber structures, outgoing fuel throttling hole control ball valves and control piston couple pairs of other traditional common-rail fuel injectors, so that precise parts and components with great machining technology difficulty are not required, the machining difficulty is greatly reduced, and the technological cost is correspondingly reduced.

Owner:NANYUE FUEL INJECTION SYST CO LTD

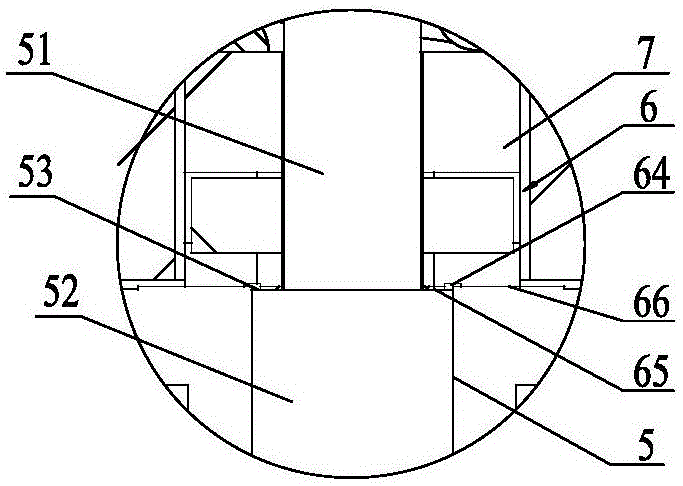

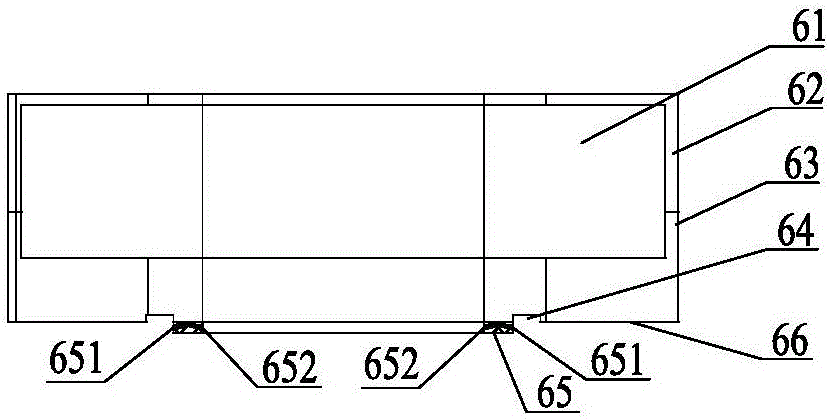

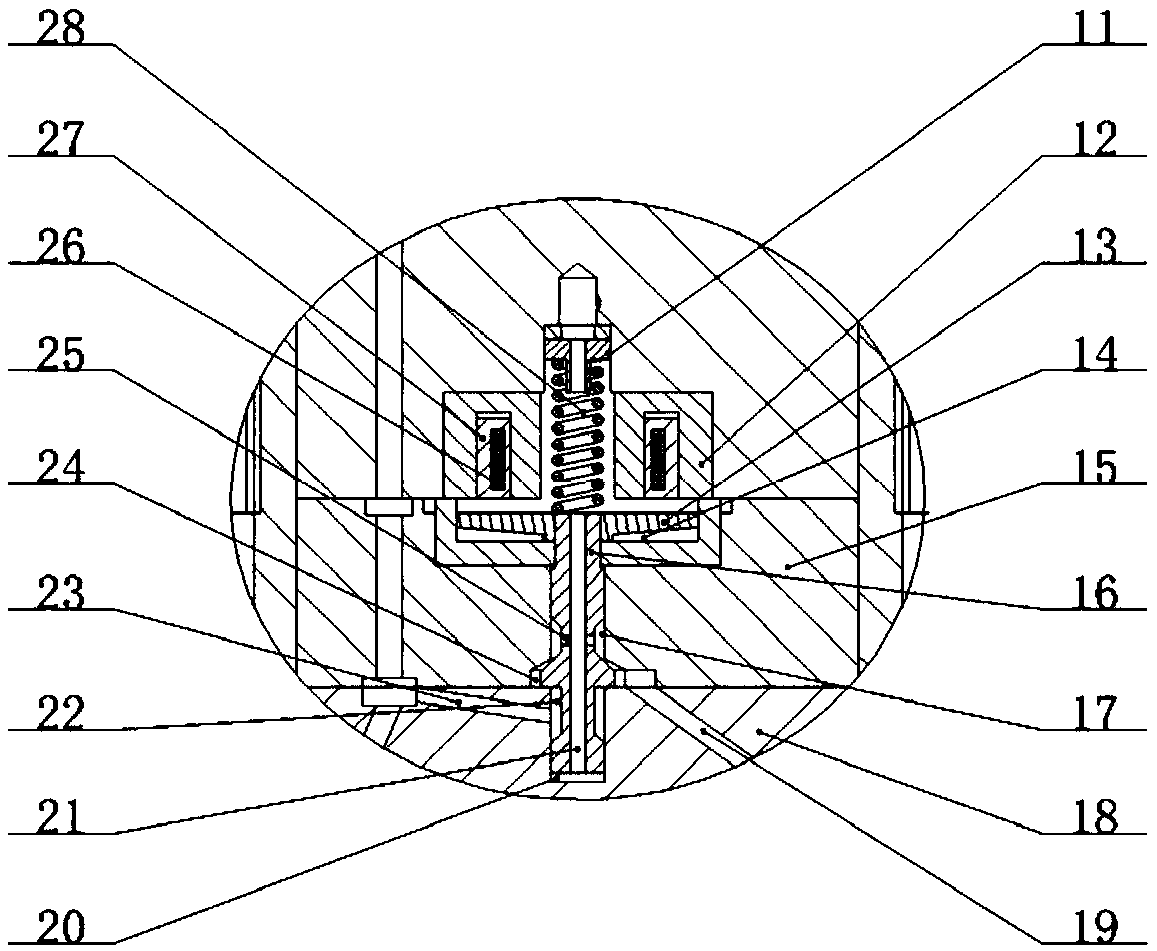

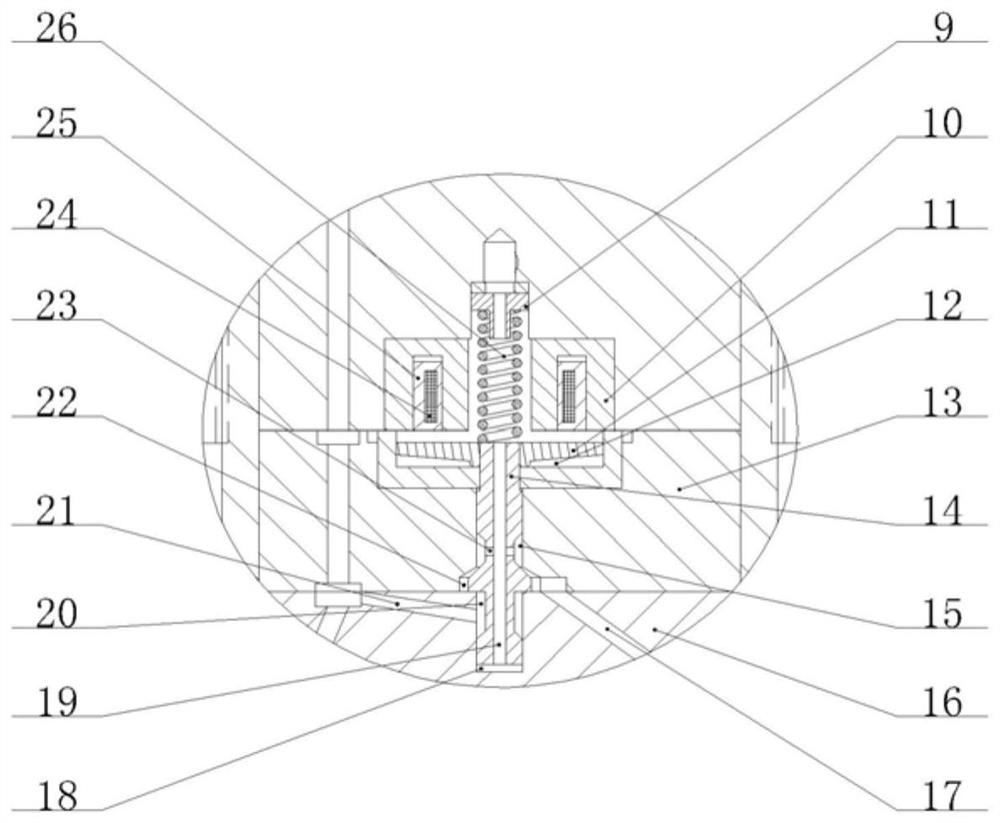

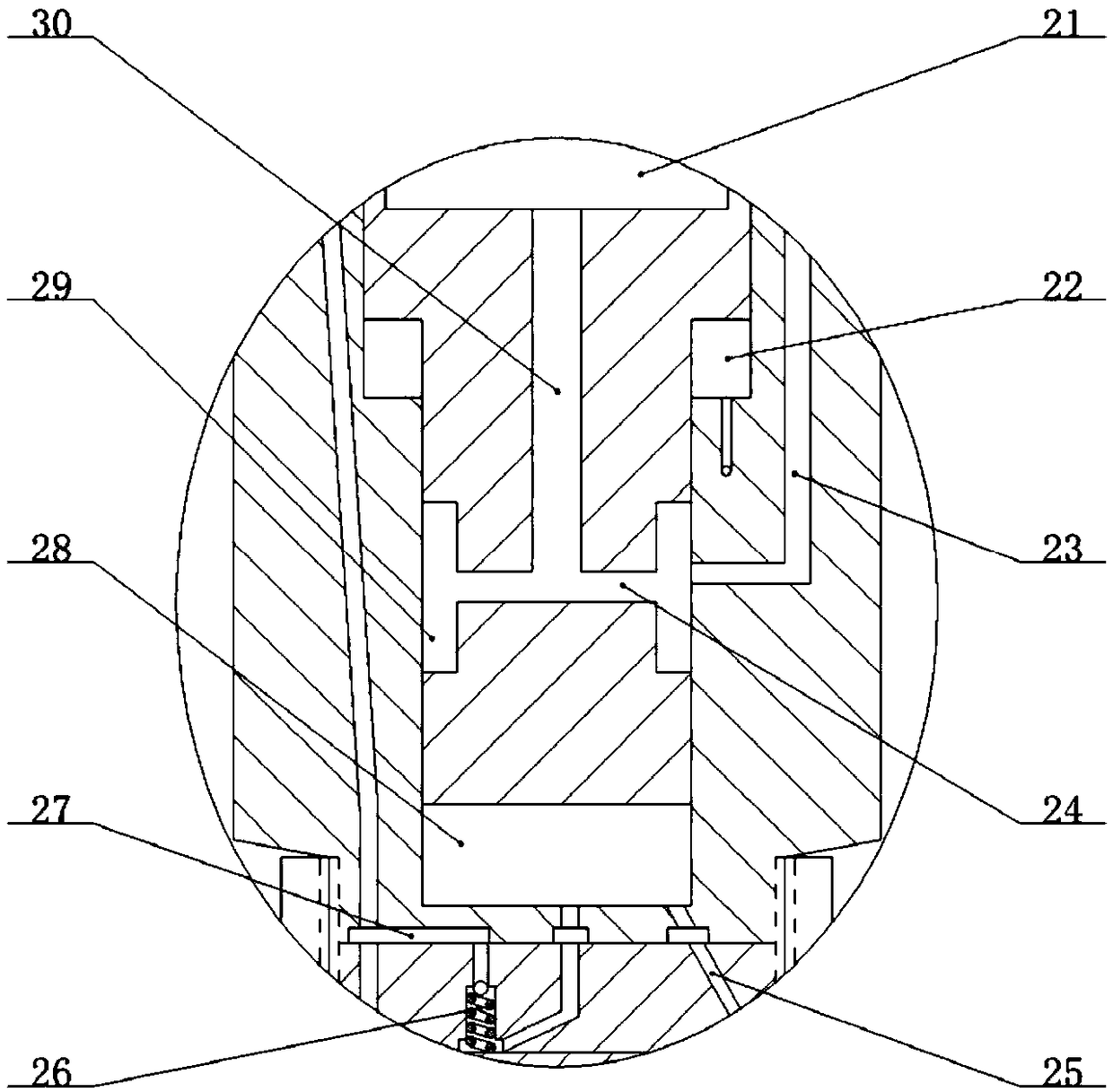

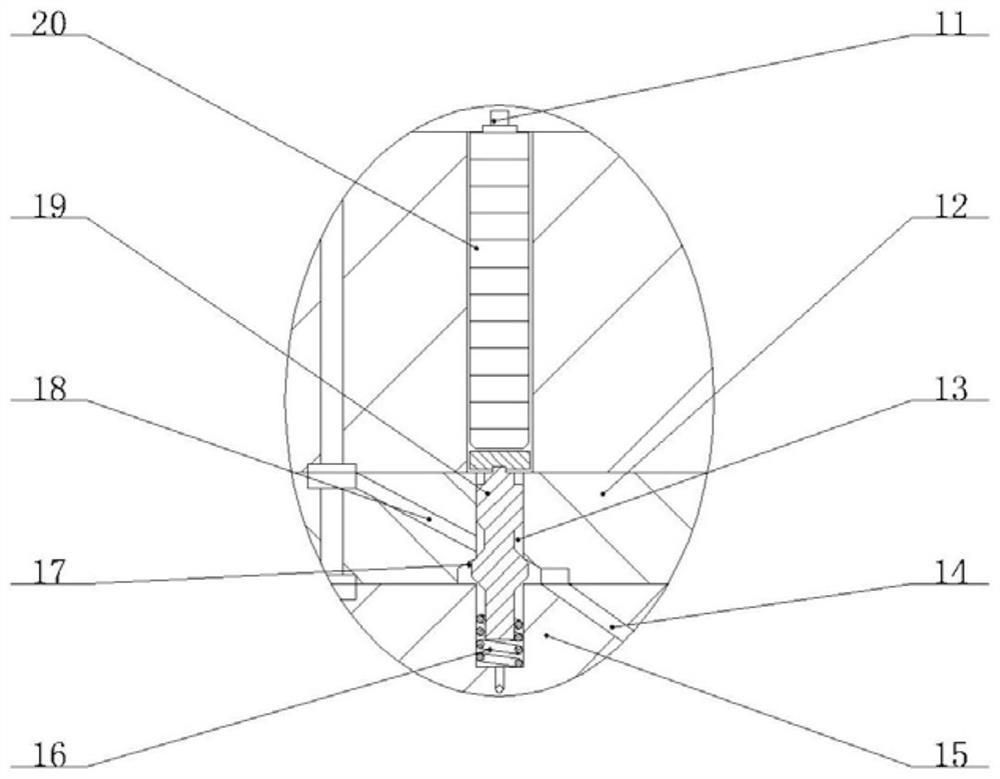

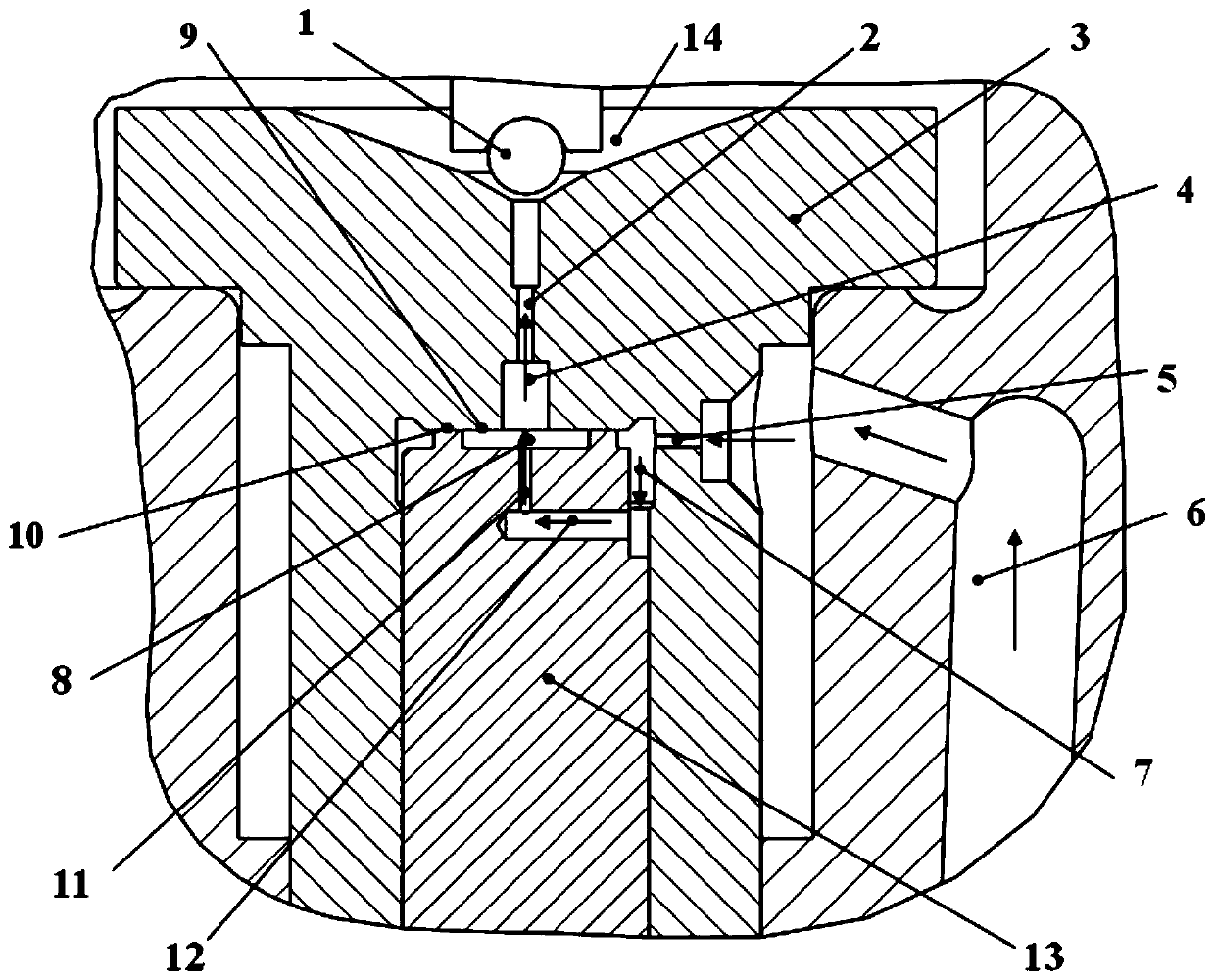

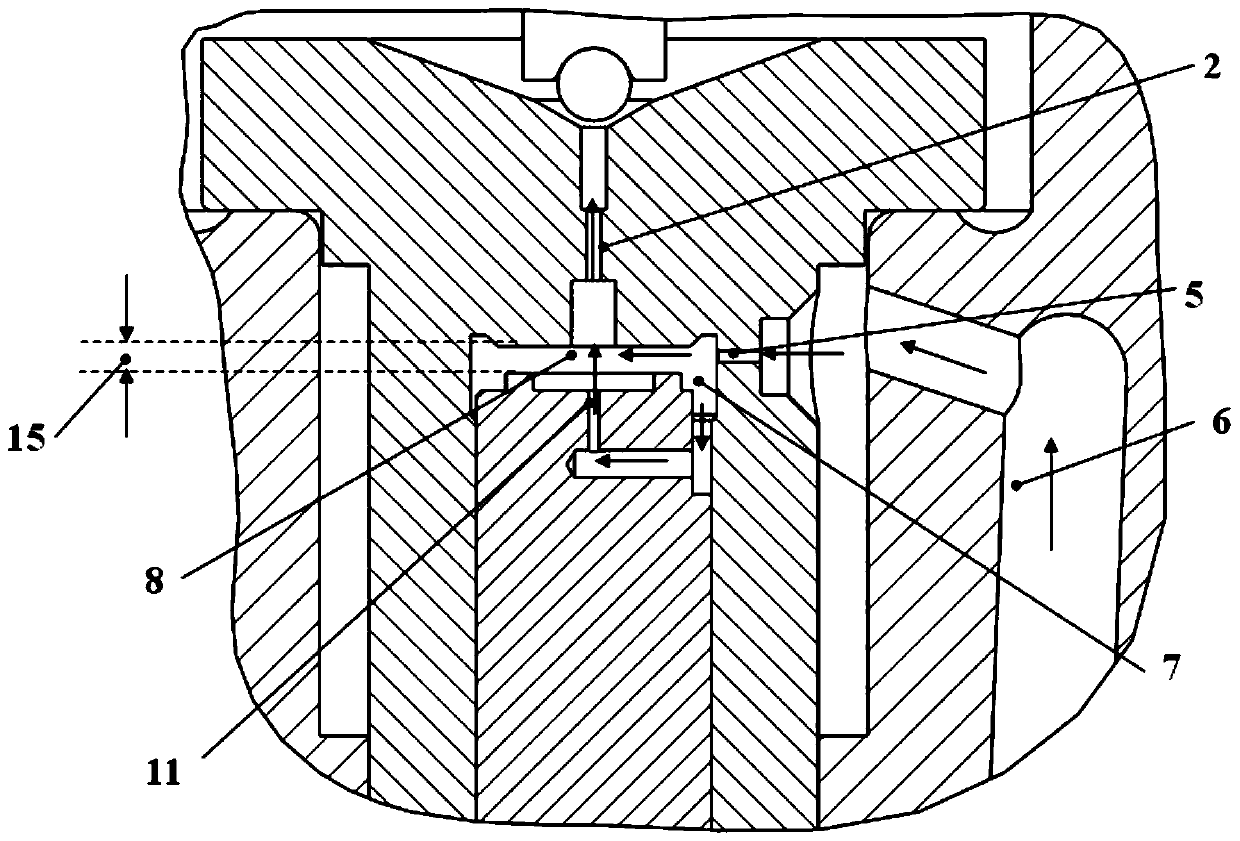

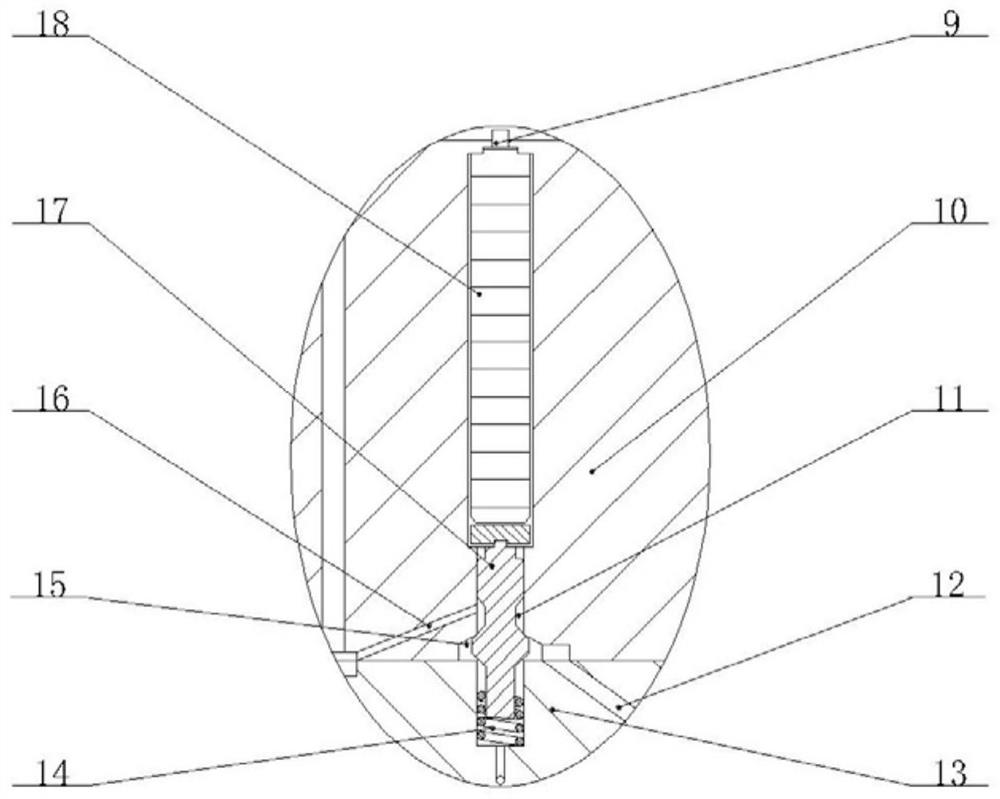

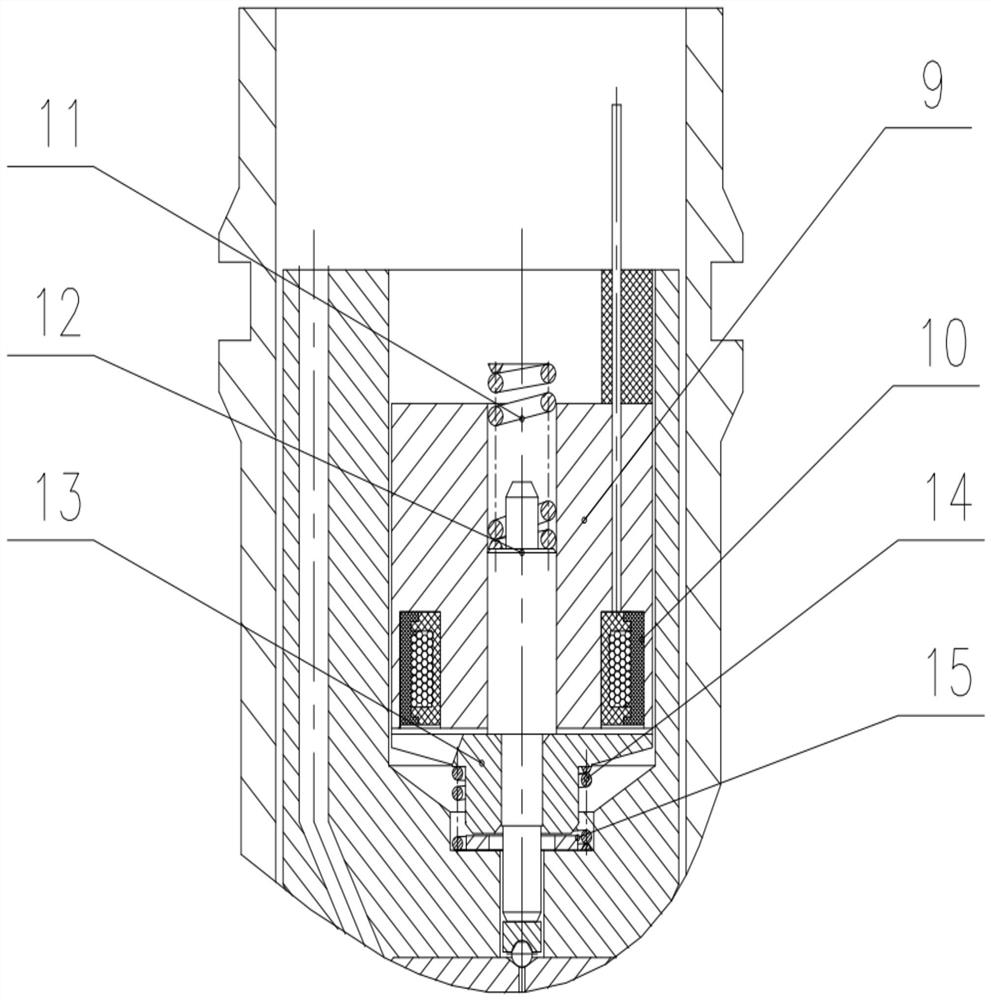

Weak leakage oil return preventing fuel injection device

ActiveCN106704067AExtended service lifeImprove reliabilityMachines/enginesFuel injection with fuel accumulatorsEngineeringHigh pressure

The invention relates to a weak leakage oil return preventing fuel injection device. The weak leakage oil return preventing fuel injection device comprises an oil injector body, a throttle orifice plate, a control valve seat, an armature, a valve core, an adjusting gasket, an armature pre-tightening spring, an electromagnet tightening cap, an electromagnet assembly, a stroke adjusting ring, a control piston, a pre-tightening spring, a transition block, an oil nozzle matching part and an oil nozzle tightening cap. The weak leakage oil return preventing fuel injection device is characterized by further comprising a sealing pad, a control disc, a control disc pre-tightening spring and an armature guide sleeve; the sealing pad is arranged on the upper portion of the valve core in a sleeving mode and located below the adjusting gasket; an annular step is arranged on a circumferential ring at the head of the control piston; the control disc pre-tightening spring is arranged on the annular step at the head of the control piston in a sleeving mode; the control disc is arranged on the upper portion of the control disc pre-tightening spring; and the upper surface of the control disc is in contact fit with the throttle orifice plate. According to the weak leakage oil return preventing fuel injection device, the problem that the sealing leakage quantity is increased due to abrasion caused by movement of a control valve can be solved; the service life of an electronic control oil injector is prolonged; and meanwhile, the oil return quantity of the electronic control oil injector is decreased, the high-pressure energy consumption loss is reduced, and the mechanical efficiency is improved.

Owner:CHINA FIRST AUTOMOBILE

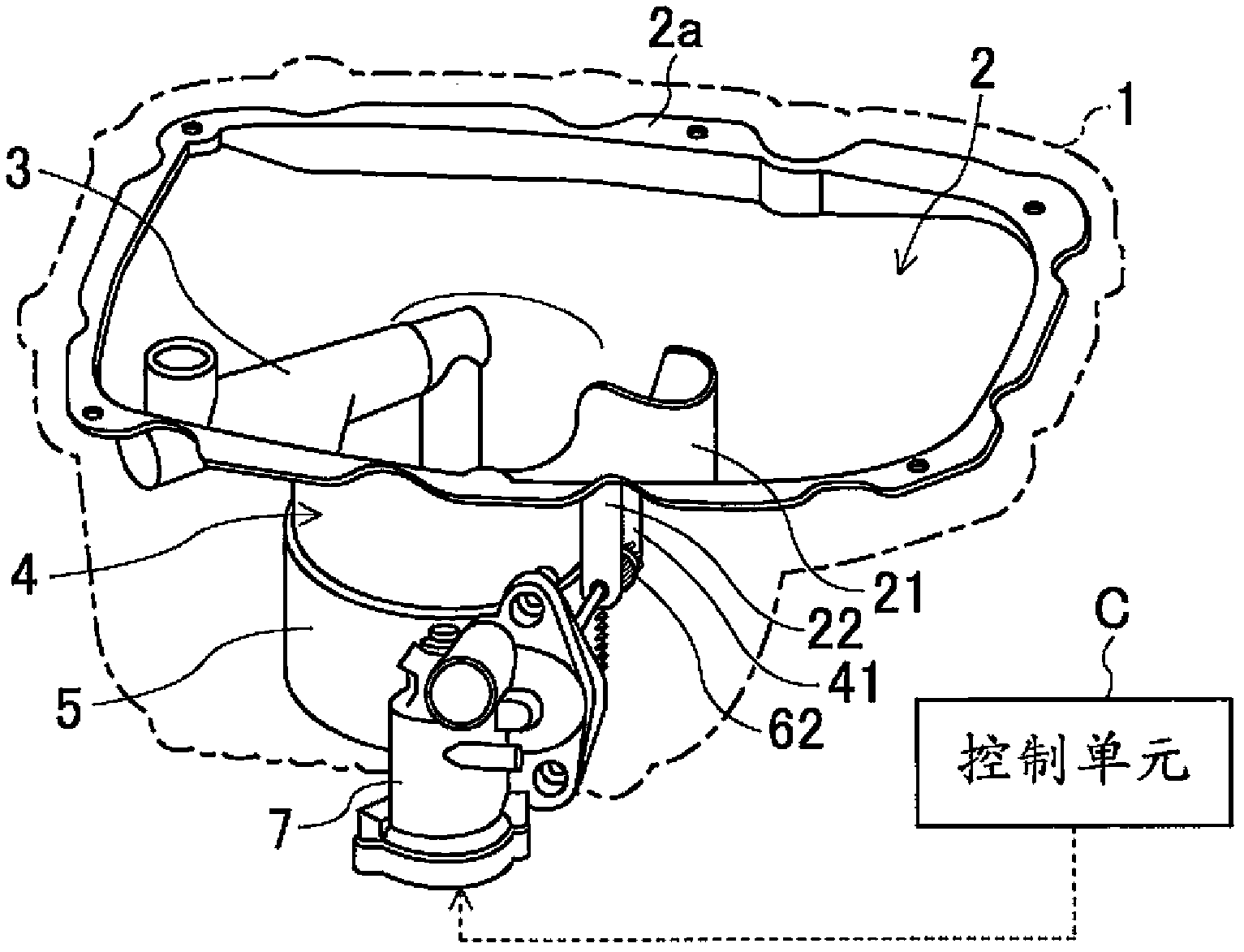

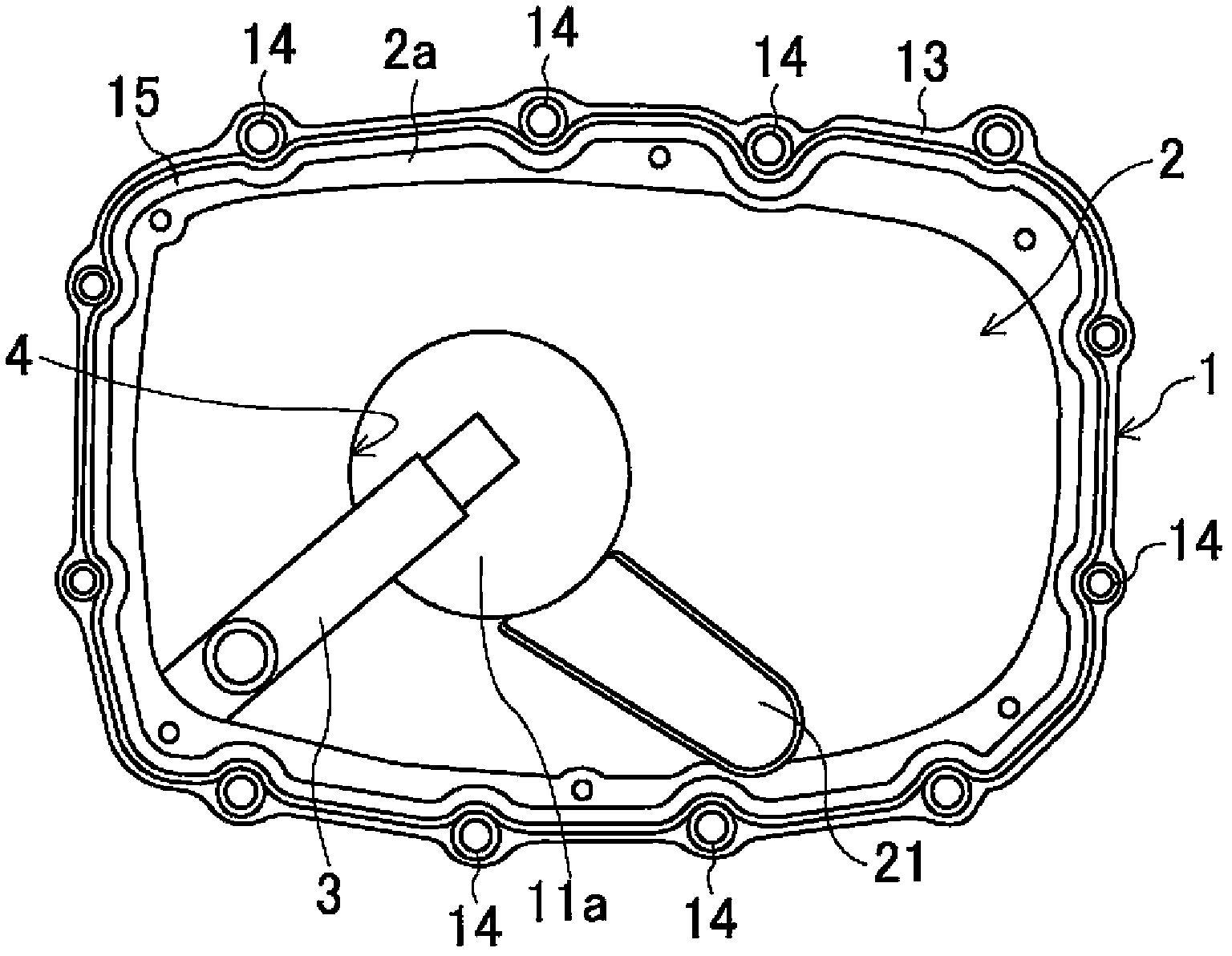

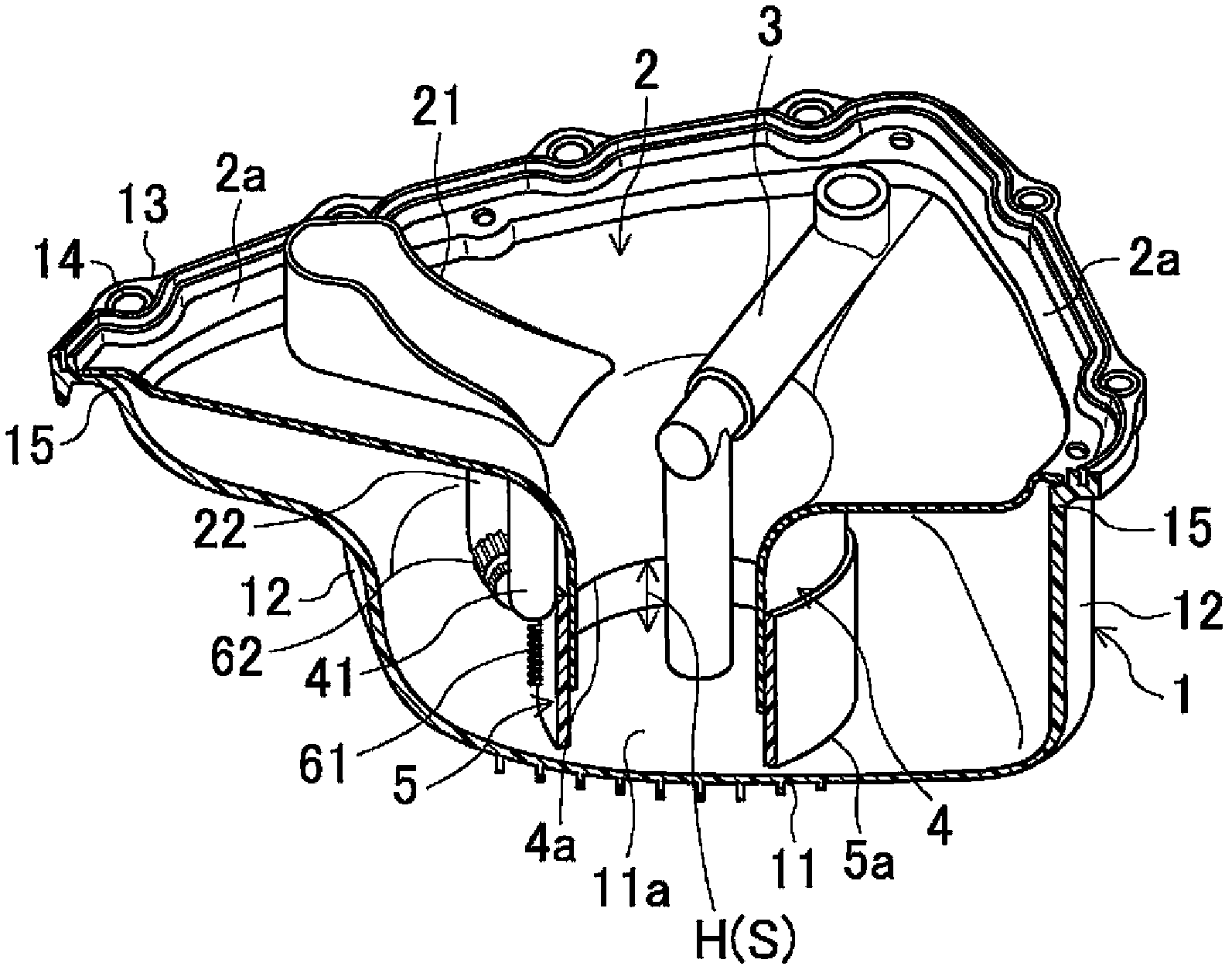

Oil pan structure

InactiveCN102619587AWell mixedReduce oil returnMachines/enginesEngine lubricationOil canInterior space

Disclosed is an oil pan structure for an engine. The internal space of the oil pan structure is divided into a first engine oil storage chamber and a second engine oil storage chamber by a cylindrical engine oil channel body. A circulating port is arranged between the engine oil channel body and the oil pan to make the engine oil circulate between the first engine oil storage chamber and the second engine oil storage chamber. The opening size of the circulating port can be adjusted according to the operating state of the engine. A minimum opening size is ensured for incomplete obstruction of the circulation of the engine oil in the circulating port. Therefore, the time for the operation of the heating of turbine can be shortened when the engine is in the refrigerating state, with reduced oil consumption, and the temperature of the engine oil can rise rapidly. The fuel cut-off phenomenon during the time when the engine speed rises sharply can be avoided.

Owner:DAIKYONISHIKAWA CORP

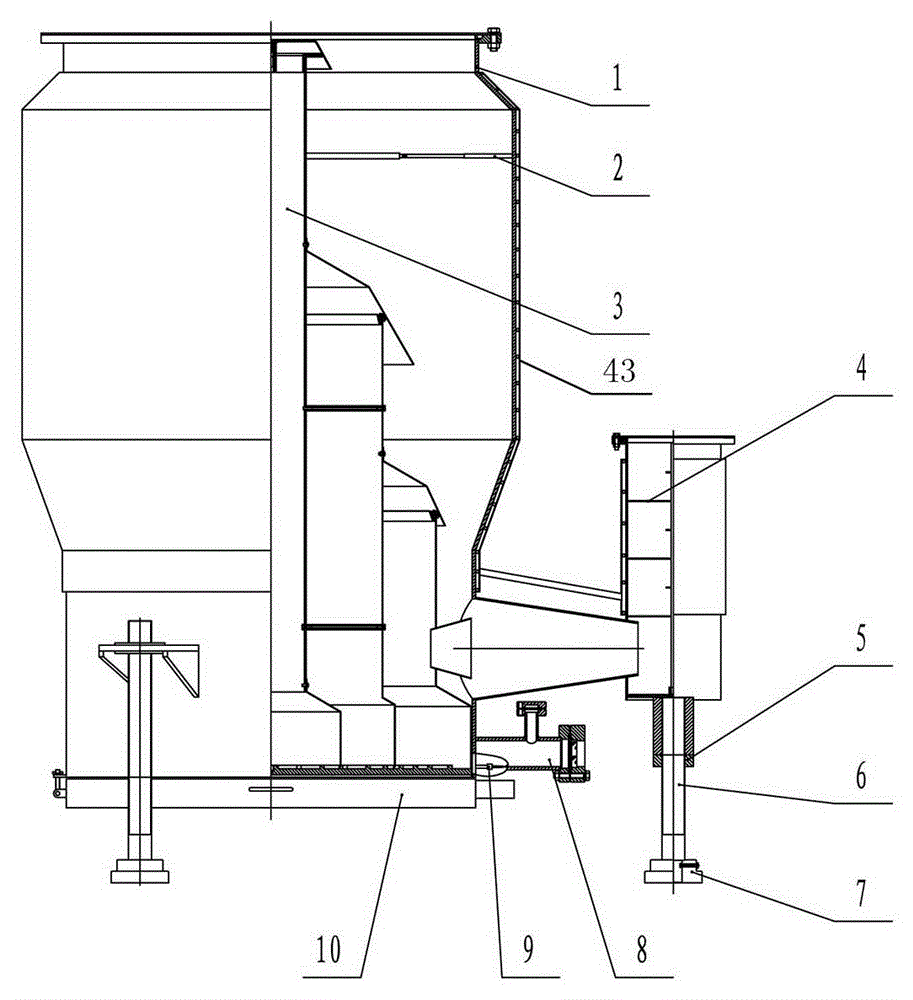

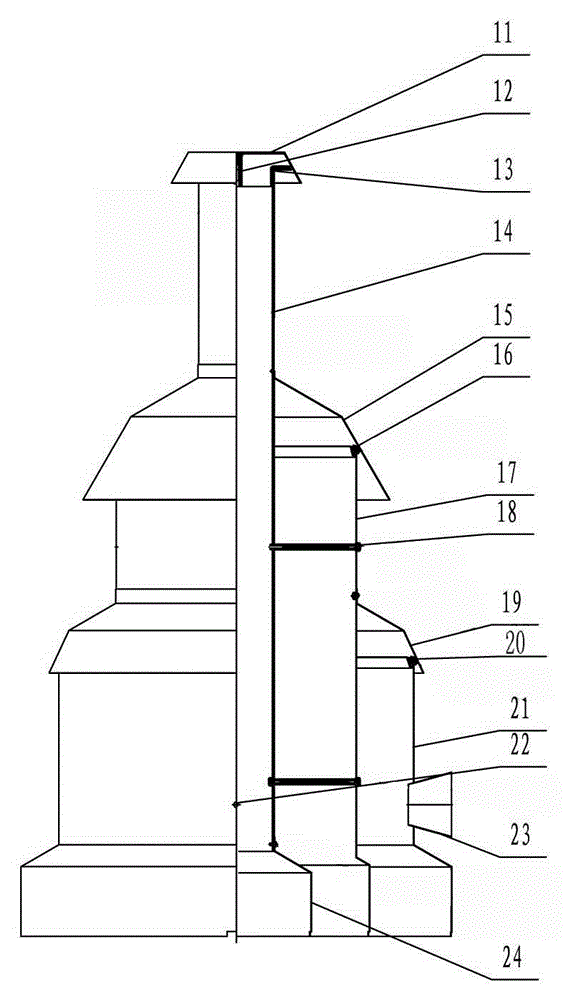

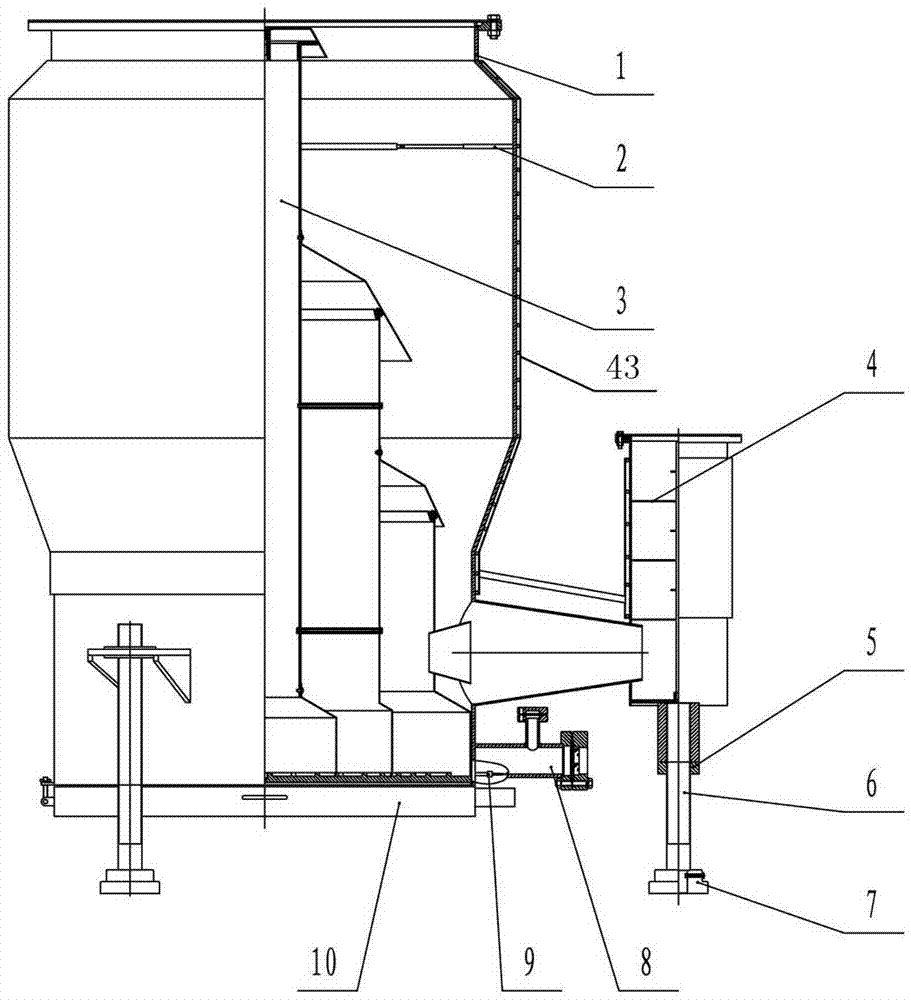

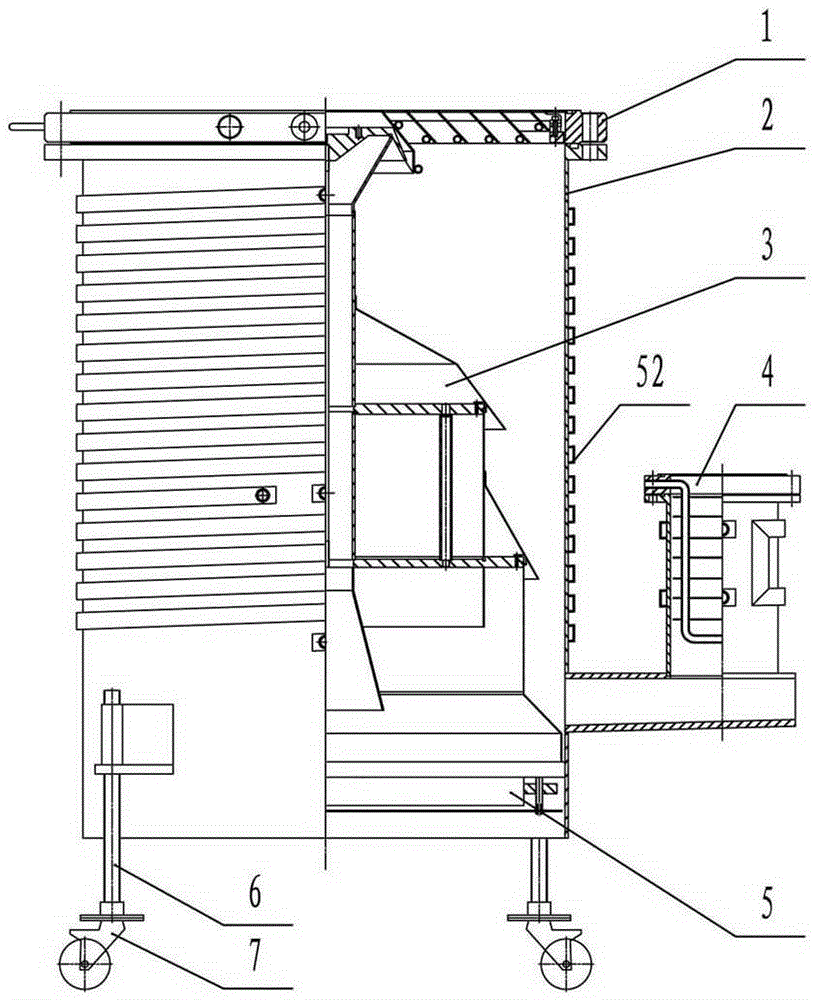

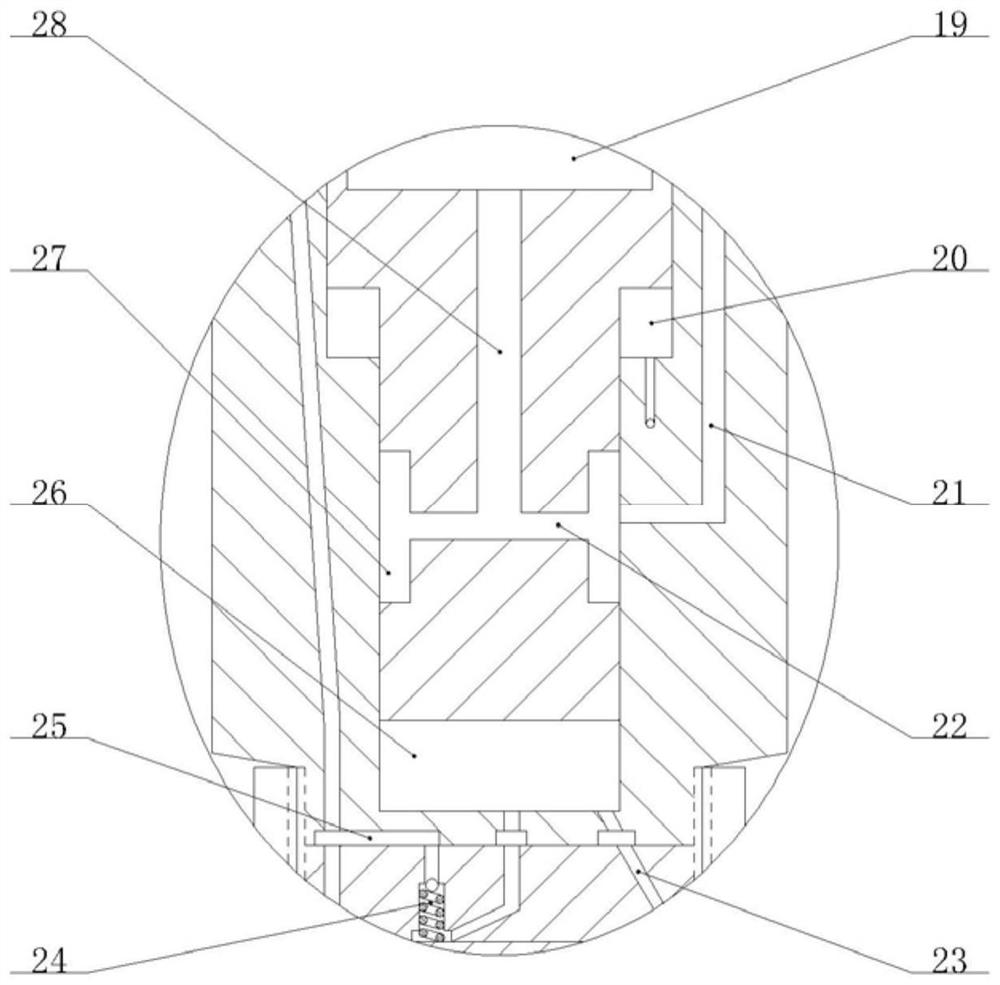

Large-caliber high vacuum oil diffusion pump

ActiveCN104989679ACompact structureShort heating timeMachines/enginesDiffusion pumpsElectricityCore component

The invention discloses a diffusion pump, and particularly relates to a large-caliber high vacuum oil diffusion pump, which is suitable for a vacuum furnace and a vacuum coating machine. The large-caliber high vacuum oil diffusion pump comprises a pump body, and a pump core component arranged in the pump body, wherein a heater is arranged at the bottom of the pump body; an oil stop device is arranged in an exhaust port of the pump body; the pump body adopts a convex cavity structure; the pump core component is vertically mounted in a center oil tank in the pump body, and is formed into an integral structure by a first-stage guide pipe, a second-stage guide pipe and a third-stage guide pipe arranged in sequence from inside to outside; umbrella cap-shaped diffusion nozzles are respectively arranged at the upper parts of all the guide pipes; a spraying nozzle is vertically welded at the bottom of the third-stage guide pipe; the first-stage guide pipe is higher than the second-stage guide pipe; and the second-stage guide pipe is higher than the third-stage guide pipe. The large-caliber high vacuum oil diffusion pump has the characteristics of large caliber, high limit vacuum degree, high pumping rate, low oil return rate and low electricity consumption.

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

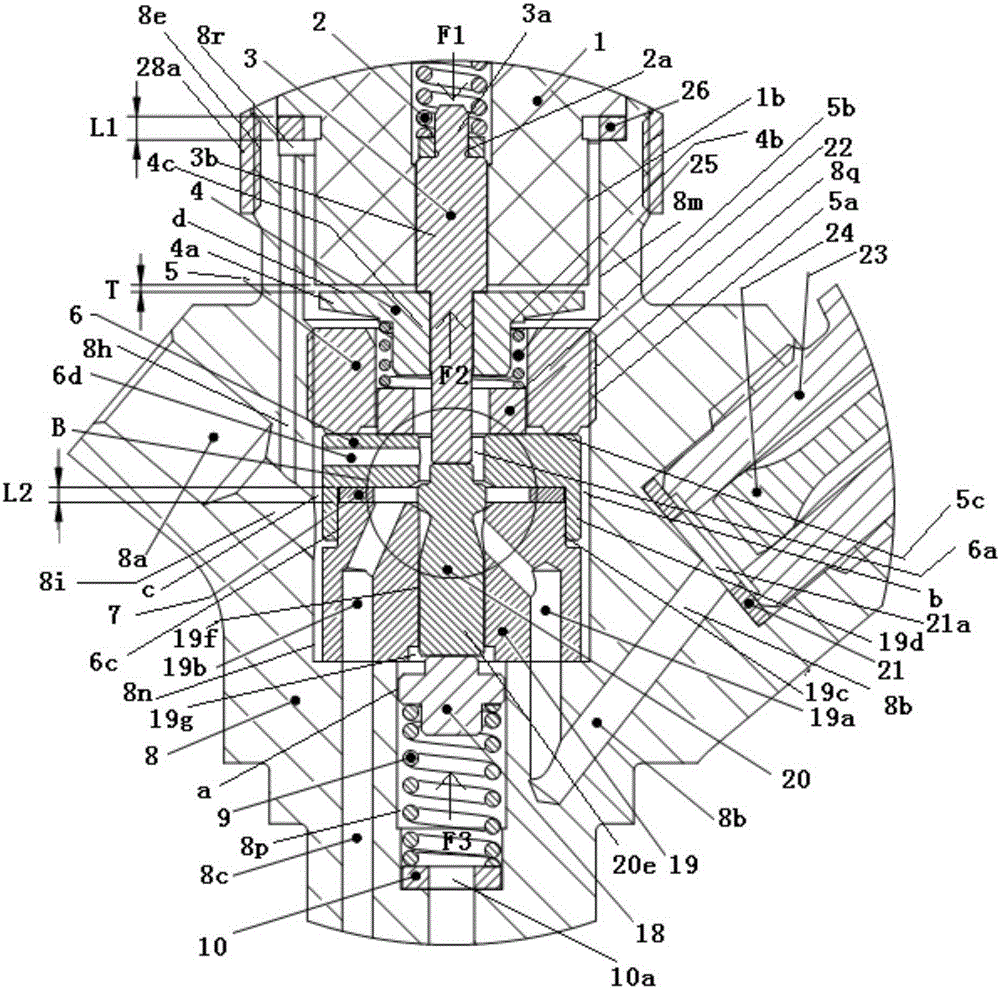

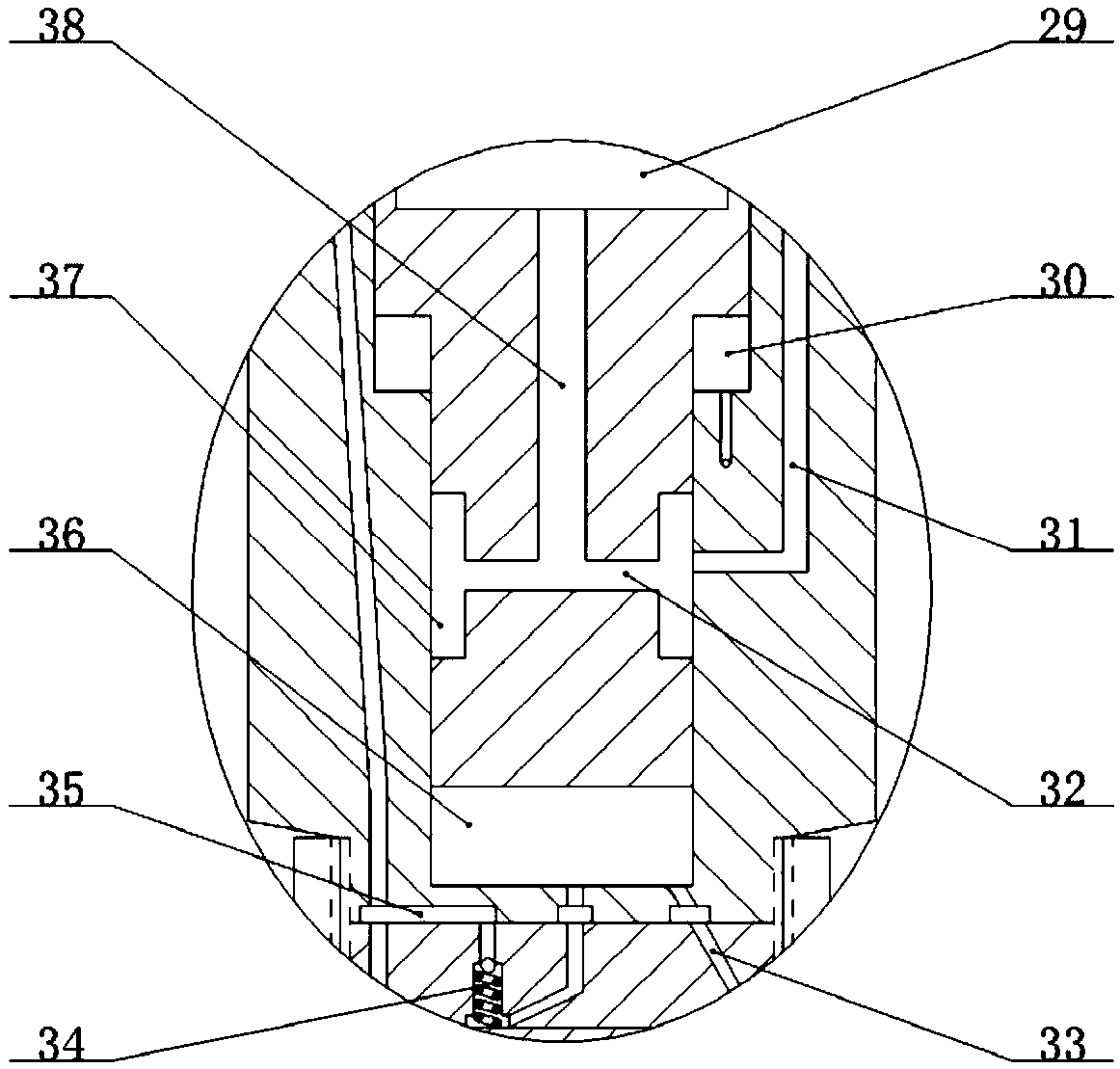

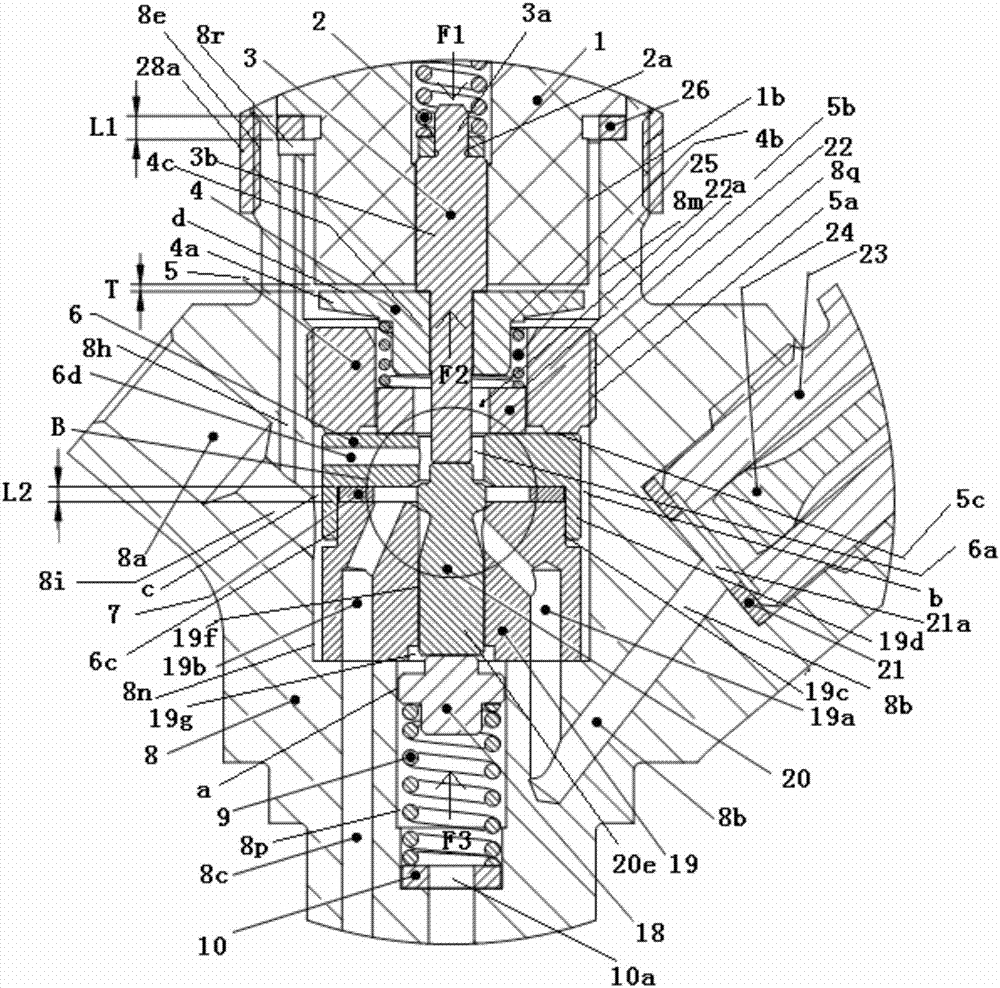

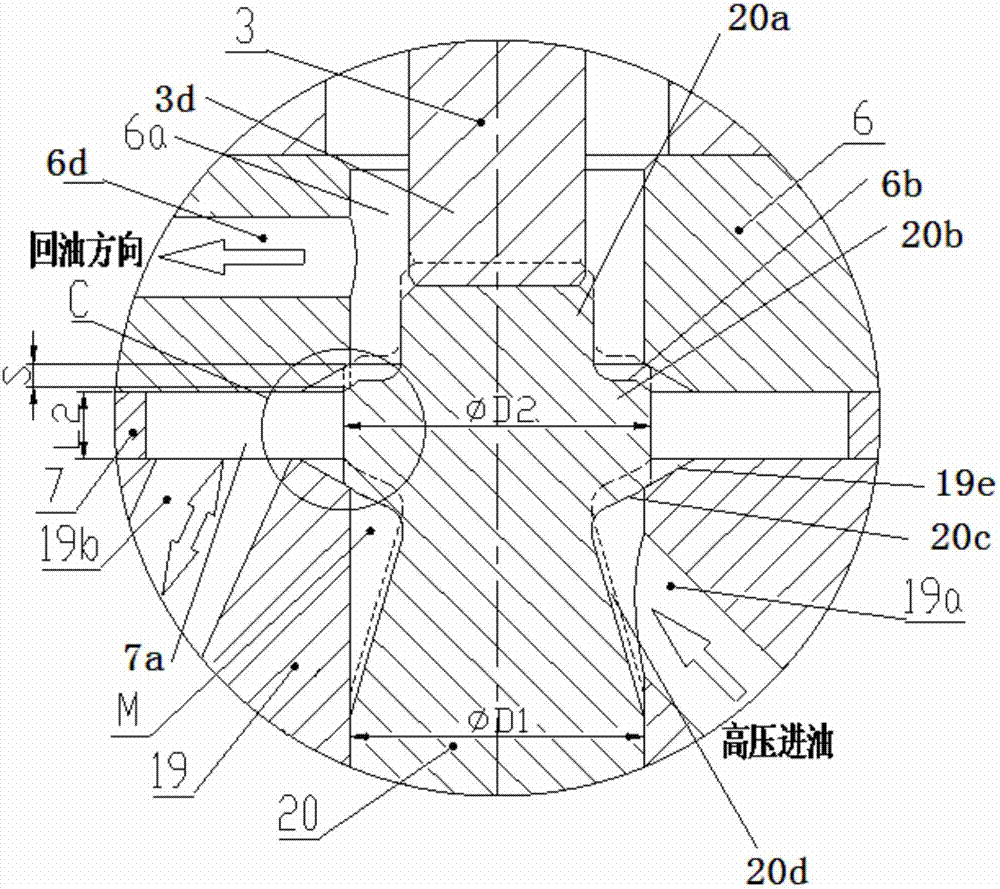

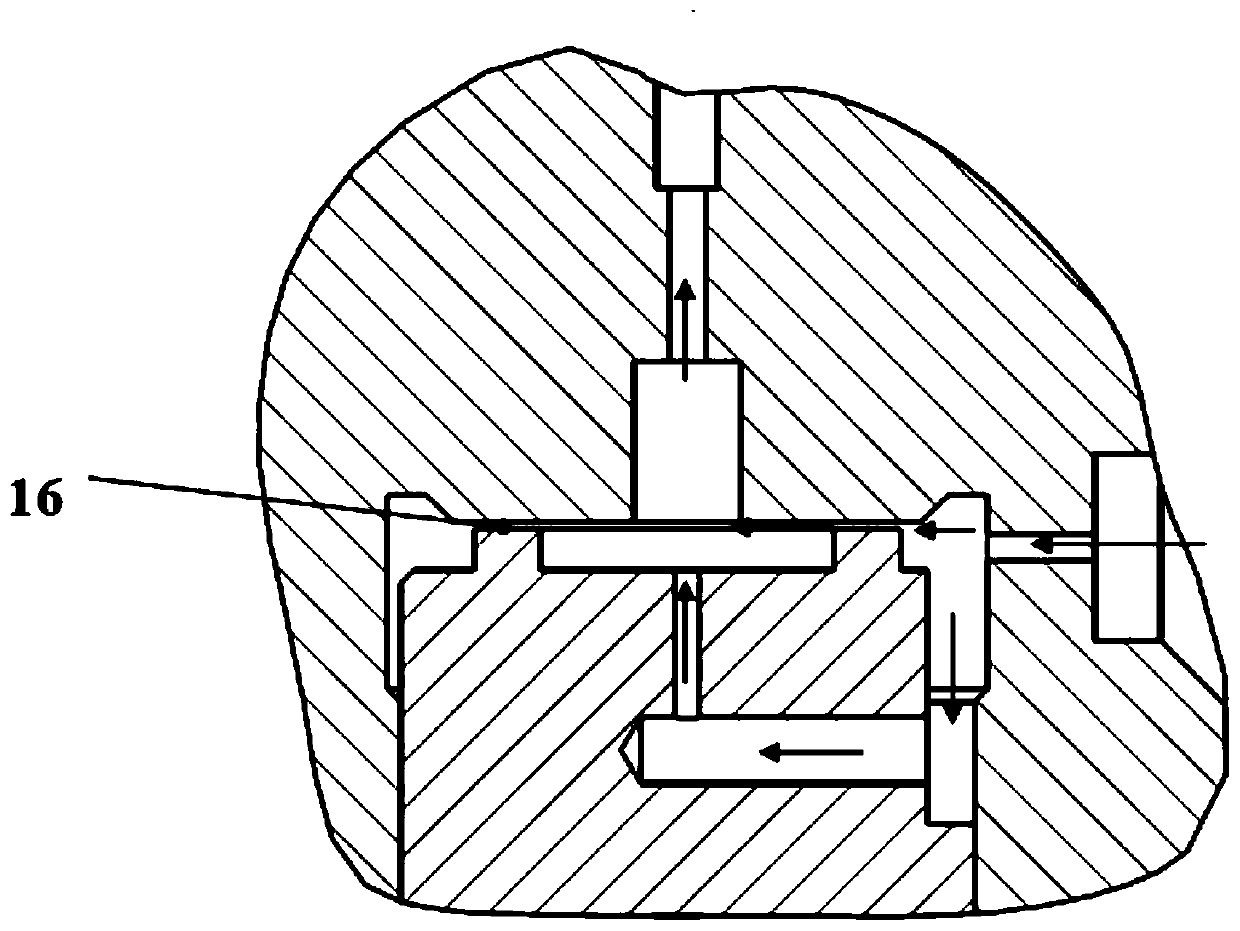

Common rail oil injector capable of reducing leakage

ActiveCN108397326AShort turn-off delayReduce leakageFuel injection apparatusMachines/enginesPistonElectromagnetic valve

The invention provides a common rail oil injector capable of reducing leakage. The common rail oil injector comprises an oil cavity A and an oil cavity B, wherein the oil cavity A and the oil cavity Bare formed by a control piston and a pore plate; when the control piston ascends and descends, a high-pressure oil passage communicates with a low-pressure oil passage through two oil passages of theoil cavity A and the oil cavity B. After the lift of the control piston reaches the maximum value, the communication between the oil cavity B and the low-pressure oil passage through a throttling ring belt is cut off, high-pressure oil only passes through a throttling hole and the oil cavity A to be leaked to the low-pressure oil passage through an oil outlet hole, so that the flowing resistanceis increased, and oil return during oil spraying, heating of the oil injector and oil supply pump power loss are reduced. Meanwhile, the flow ratio of the oil outlet hole to an oil inlet hole can be larger, so that the oil drainage time of a control cavity and the oil injection delay of the oil injector are reduced. After the communication of a passage, flowing through the throttling ring belt, between the oil cavity B and the low-pressure oil passage is cut off, and the oil cavity B only communicates with the low-pressure oil passage through the throttling hole and the oil cavity A, so that the flowing resistance of the low-pressure oil passage is increased, and the oil cavity B is kept higher in pressure, the pressure of the control cavity is restored faster after an electromagnetic valve is powered off, the oil spraying closing delay is shorter, and the oil spraying sensitivity of the oil injector is improved.

Owner:CHINA FIRST AUTOMOBILE

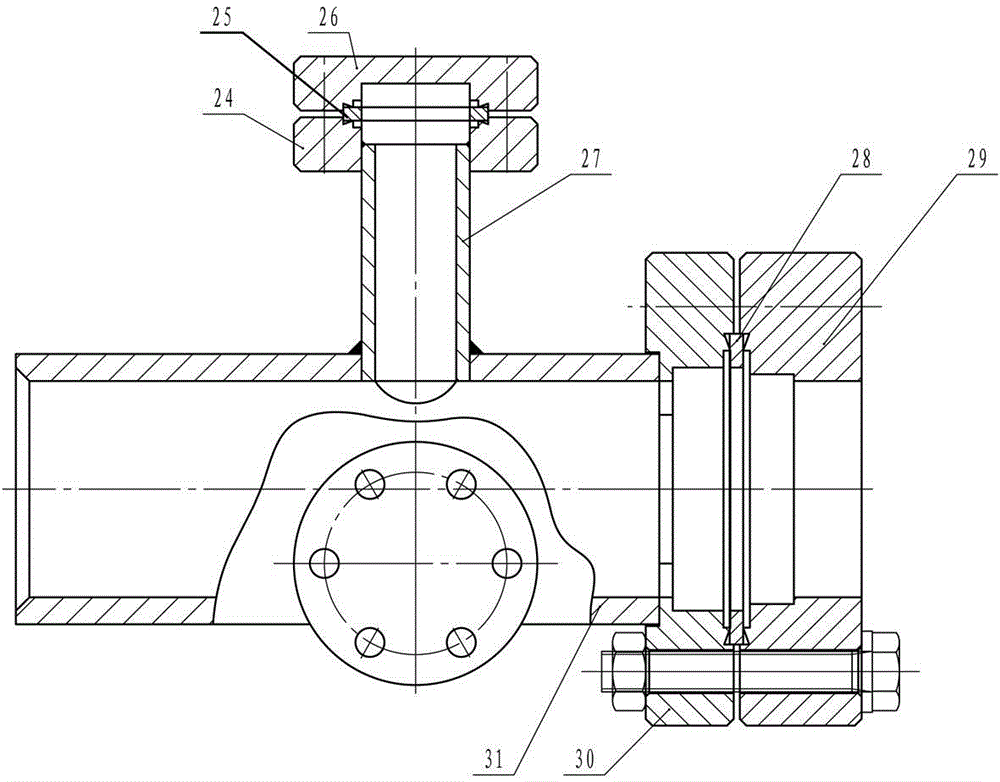

Control device for main steam valve of horizontal version oil control type steam turbine

ActiveCN105757328AReduce labor intensityPrevent accident hazardsOperating means/releasing devices for valvesPistonValve stem

The invention discloses a control device for a main steam valve of a horizontal version oil control type steam turbine. According to the control device, time and effort are saved, labor intensity of operators is greatly reduced, and the operators can rapidly close the main steam valve of a steam turbine to avoid the occurrence of accidents and dangers when the steam turbine has a failure. The control device comprises an oil cylinder, wherein an oil inlet is formed in the left end of the side wall of the oil cylinder; an oil return port is formed in the right end of the side wall of the oil cylinder; a piston is arranged in the oil cylinder; a control box with a shaft hole is arranged on the left end face of the piston; a compression spring I is connected between the control box and the inner wall at the left end of the oil cylinder; a control rod inserted in the shaft hole of the control box is mounted at the left end of the oil cylinder through threads; a sliding sleeve is arranged in the shaft hole of the control box; a compression spring II is connected between the control rod and the sliding sleeve; an axial penetrating oil through hole I is formed in a part, corresponding to the shaft hole, on the piston; an oil through hole II is formed in the side wall of the sliding sleeve; an oil through hole III is formed in the side wall of the control box; an air valve stem mounted on the right end face of the piston penetrates through the right end of the oil cylinder.

Owner:JINZHOU XINJINHUA MACHINERY MFG

Large diameter high vacuum oil diffusion pump

ActiveCN104989679BCompact structureShort heating timeMachines/enginesDiffusion pumpsElectricityCore component

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

In-cylinder direct-spray high-pressure pump

PendingCN110185565AImprove reliabilityReduced stiffness requirementsMachines/enginesFuel injecting pumpsSolenoid valveEngineering

The invention relates to an in-cylinder direct-spray high-pressure pump. The in-cylinder direct-spray high-pressure pump comprises a pump body, wherein an oil inlet and an oil outlet are formed in thepump body; a stable-pressure cavity, a low-pressure cavity, a high-pressure cavity, a first connecting oil path and a second connecting oil path are arranged in the pump body; the oil inlet communicates with the first connecting oil path through the stable-pressure cavity; the first connecting oil path communicates with the second connecting oil path through the low-pressure cavity and the high-pressure cavity in sequence; the second connecting oil path communicates with the oil outlet; a solenoid valve is arranged in the low-pressure cavity; a plunger piston device is arranged in the high-pressure cavity; the oil outlet is equipped with a pressure release valve; the pressure release cavity communicates with the low-pressure cavity or the high-pressure cavity; the pressure release valve comprises a sealing base with a through hole therein, a stud and a ball body arranged between the sealing base and the stud; the ball body and the sealing base can be connected in a sealing mode; the ball body is linked and matched with the stud; and a pressure release valve spring is arranged between the stud and the inner wall of the pressure release cavity. The pressure release valve structure is changed into spherical surface seal from plane seal, so that sealing effect is good, a sealing form is more stable, the closing effect is quicker, and oil supply efficiency of the high-pressure pumpis improved.

Owner:JIANGSU BATON TECH CO LTD

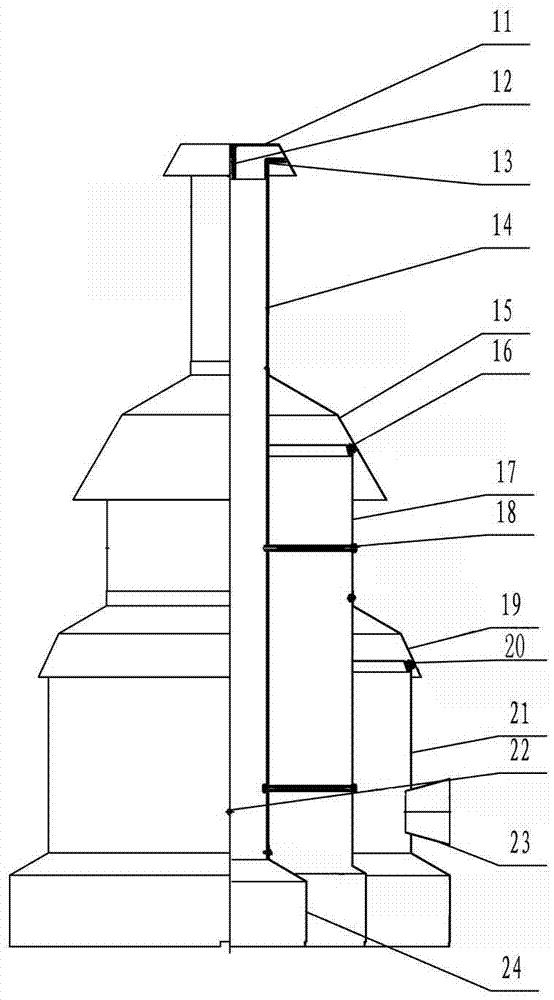

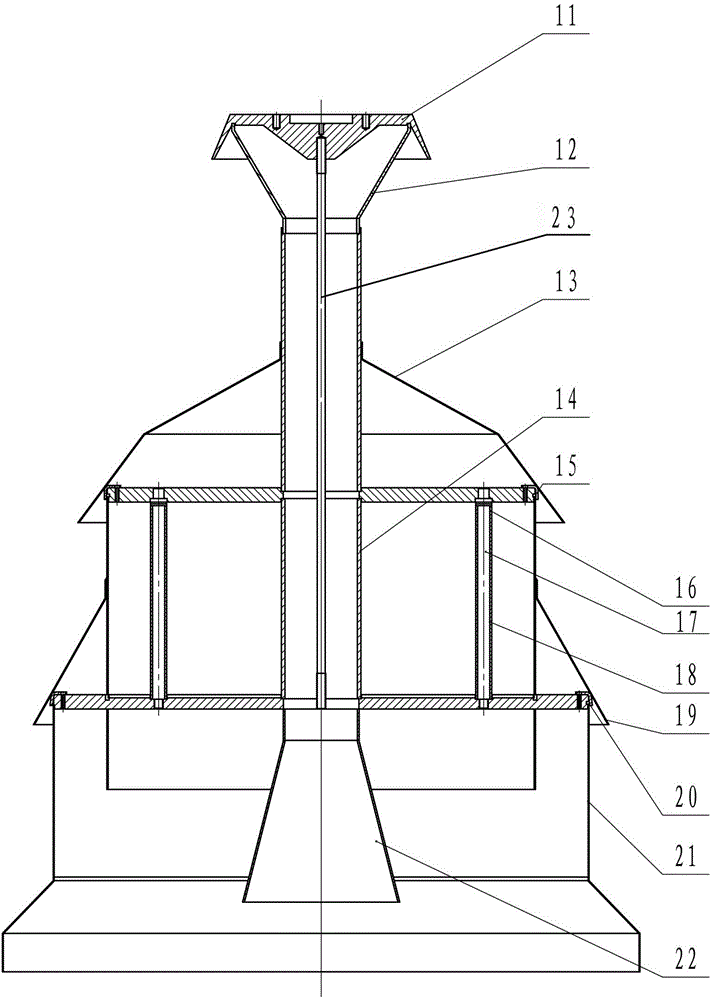

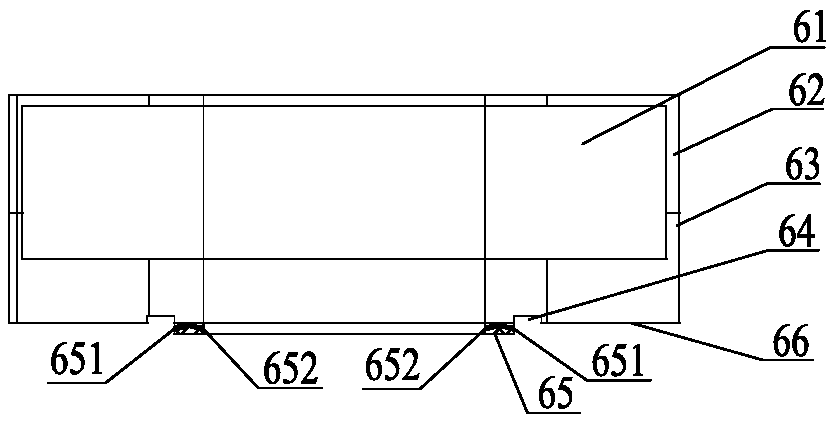

Quick precise injection platform

InactiveCN101380804AReduce oil returnSolve the problem of excessive noisePiston rodPetroleum engineering

The present invention discloses a fast precise injection table structure which comprises an injection table head plate component, a glue-injecting tail plate, two glue-injecting oil cylinder components and a glue-melting cylinder component. The glue-injecting oil cylinder components are arranged at two sides of the injection table head component. The glue-injecting tail plate is equipped with an oil motor. The glue-injecting oil cylinder component comprises a cylinder body, the inside of which is provided with a piston cavity which is equipped with a piston rod at the inside, the piston rod is fixedly equipped with a piston, and one end of the piston rod is fixed at the glue-injecting tail plate. The fast precise injection table structure is characterized in that the other side of the piston is equipped with a piston rod without a rod cavity, which extends outside the piston cavity. The additional piston rod of the fast precise injection table structure occupies a certain cubage of the piston cavity and reduces the hydraulic oil quantity of the piston cavity of the part correspondingly, and accordingly, the fast precise injection table structure can reduce the oil return quantity of the piston cavity of the part when glue is injected at a high speed, reduces the oil return speed and further solves the problem of too high noise caused by too high oil return pressure and speed when the original injection table injects the glue at a high speed.

Owner:广东力劲塑机智造股份有限公司

Electromagnetic heating high vacuum oil diffusion pump

ActiveCN105351258AShort heating timeImprove work efficiencyMachines/enginesDiffusion pumpsElectricityEngineering

The invention relates to a high vacuum oil diffusion pump, in particular to an electromagnetic heating high vacuum oil diffusion pump. According to the electromagnetic heating high vacuum oil diffusion pump, an electromagnetic heater is arranged on the bottom of a pump body; a water-cooling oil blocking device is arranged on the exhaust port of the pump body; a straight cavity structure is adopted by the pump body; a water channel type cooling jacket is arranged outside the pump body; a pump core assembly is vertically mounted at the center position inside the pump body; the pump core assembly structurally comprises an umbrella-shaped first-stage nozzle cap, an umbrella-shaped second-stage nozzle cap, a umbrella-shaped third-stage nozzle cap and a third-stage flow guide pipe from inside to outside in sequence to form a whole structure; flow guide pipes are respectively arranged on all umbrella-shaped nozzle caps; a first-stage diffusion flow guide pipe is vertically welded at the internal center position of the third-stage flow guide pipe; the first-stage flow guide pipe is higher than a second-stage flow guide pipe; and the second-stage flow guide pipe is higher than the third-stage flow guide pipe. The electromagnetic heating high vacuum oil diffusion pump has the characteristics that the heating speed is rapid; the cooling speed is rapid; the effect is good; the oil return rate is low; the ultimate vacuum is high; the exhausting rate is high; the electricity consumption is low; and the time to reach ultimate vacuum is short.

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

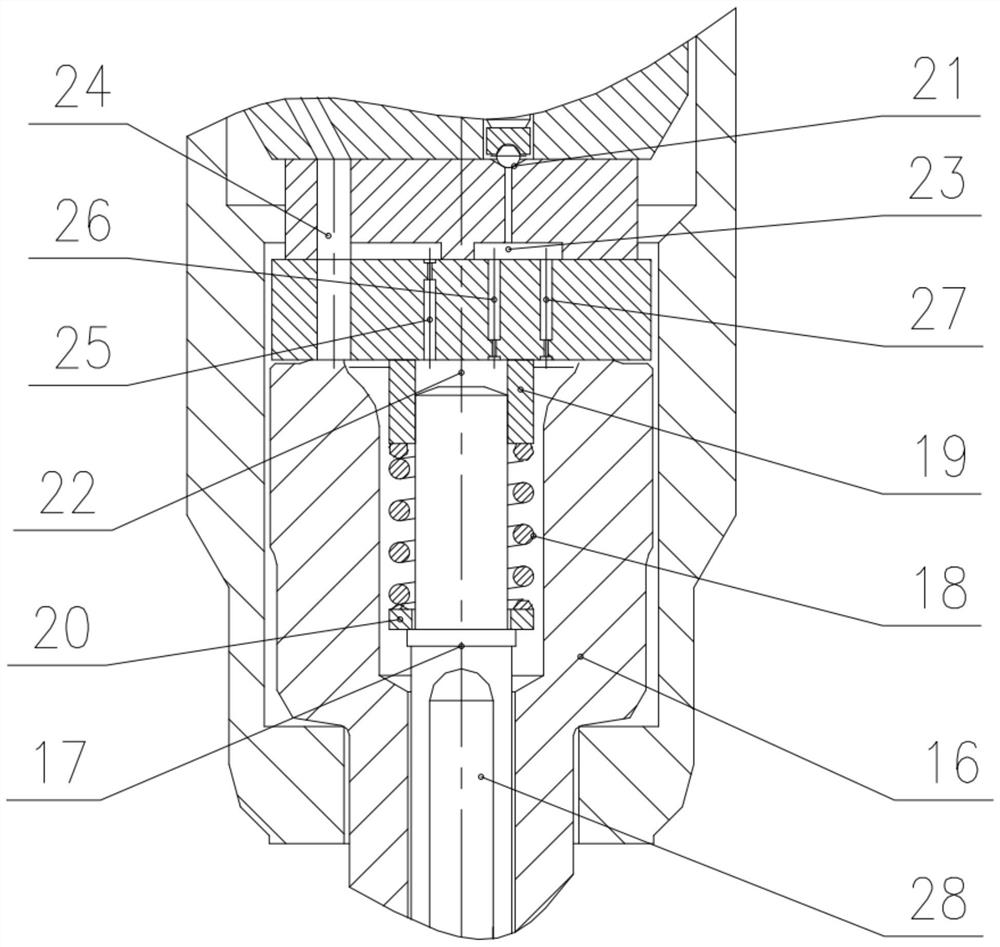

Pressure-accumulating dual-valve electronic fuel injector

InactiveCN109236526ASmall pressure fluctuationsFlexible and adjustableFuel injection apparatusMachines/enginesRail pressureSpray nozzle

It is an object of the present invention to provide a pressure-accumulating dual-valve electronic fuel injector. The pressure-accumulating dual-valve electronic fuel injector comprises a fuel injectorhead, a pressure-accumulating chamber wall, a pressurizing control valve, a pressurizing piston, a fuel injection control valve, a nozzle and a fuel injector body. The fuel injector body is providedtherein with a pressure accumulating chamber, which can reduce the pressure fluctuation in a fuel injection process, and is advantageous for the precise control of the fuel injection. The pressure-accumulating dual-valve electronic fuel injector can reduce the structural size of a common rail tube when used in a common rail fuel system, thereby reducing the material strength requirements of the common rail tube, prolonging the service life of the common rail tube and improving the space utilization ratio of the common rail tube. The pressure-accumulating dual-valve electronic fuel injector canwork in both non-pressurizing and pressurizing modes. In the non-pressurizing mode, the rail pressure injection is performed. In the pressurizing mode, the ultrahigh-pressure injection is performed,and the pressuring ratio can be flexibly adjusted, thereby achieving high reliability and a wide application range. The fuel injection control valve can stop the control chamber from replenishing thefuel during the fuel draining process, realizes micro dynamic oil return, improves the response speed of the needle valve, and improves the dynamic property and economical efficiency of a diesel engine.

Owner:HARBIN ENG UNIV

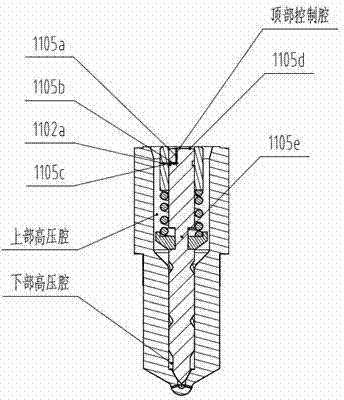

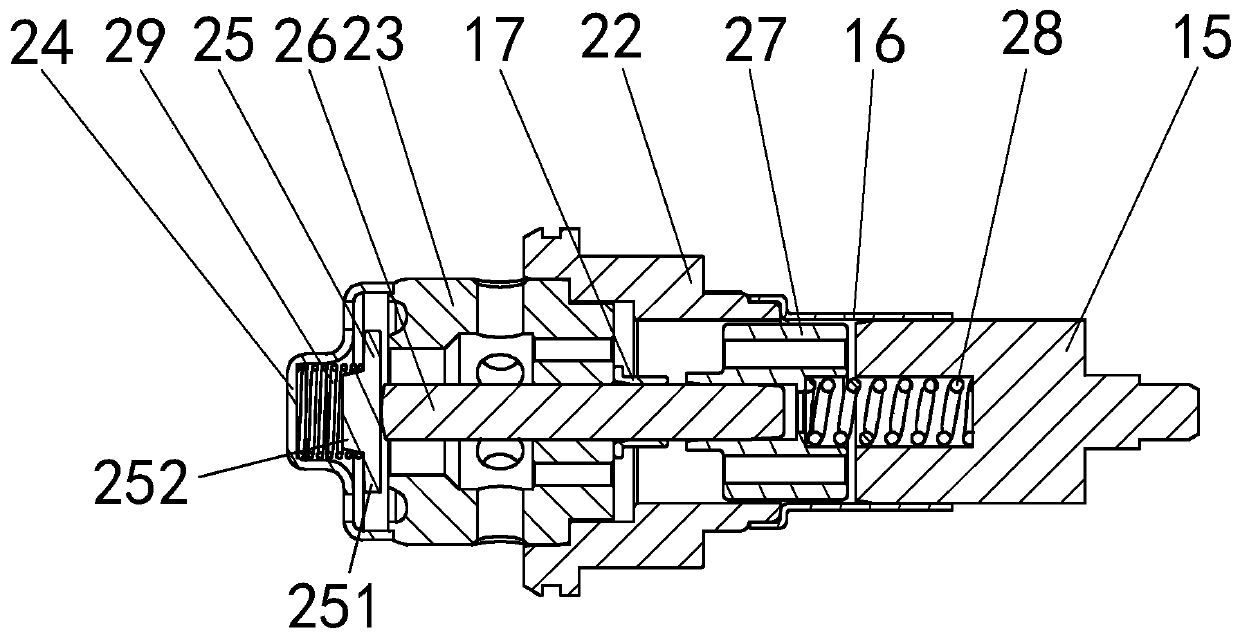

Micro-injection electronically-controlled fuel injector with pressure-maintaining structure

ActiveCN107524551AAccelerate the pressure build rateIncrease open rateFuel injection apparatusMachines/enginesInlet channelEngineering

The invention relates to a micro-injection electronically-controlled fuel injector with a pressure-maintaining structure. According to the micro-injection electronically-controlled fuel injector, an upper fuel cavity as well as a main fuel inlet channel, a main fuel return channel, a fuel inlet channel and a fuel return channel which communicate with the upper fuel cavity are formed in the upper body of the fuel injector; the lower body of the fuel injector is connected to the lower end of the upper body of the fuel injector through a fuel injector fastening nut, a lower fuel cavity is formed in the lower body of the fuel injector, and the lower fuel cavity communicates with the main fuel return channel; a nozzle member is connected to the lower end of the lower body of the fuel injector through a nozzle fastening nut and communicates with the lower fuel cavity, and further communicates with a main fuel channel penetrating through the lower body of the fuel injector; and an electromagnetic valve is connected to the left side of the upper part of the upper body of the fuel injector through an electromagnetic valve fastening nut, one end part of a control valve element of the electromagnetic valve stretches in the upper fuel cavity, and the other end part of the control valve element is abutted against an electromagnetic valve return spring arranged at the central part of an electromagnet. According to the micro-injection electronically-controlled fuel injector disclosed by the invention, a fuel inlet process and a fuel return process can be mutually independent, so that the influence of the mutual interference of fuel flowing in the fuel inlet process and the fuel return process on a fuel injection process is avoided; and the opening speed of a needle valve can be increased, so that the injection characteristic of a micro-injection fuel system is improved.

Owner:CHONGQING HONGJIANG MACHINERY

Dual valve electronically controlled fuel injector

ActiveCN109184989BQuick responseImprove hydraulic efficiencyFuel injection apparatusMachines/enginesRail pressureUltra high pressure

The invention aims to provide a double-valve electronic control fuel injector. The double-valve electronic control fuel injector comprises a fuel injector head, a boosting control valve, a boosting piston, a fuel injection control valve, a nozzle and a fuel injector body. Double solenoid valves are adopted to correspondingly control the boosting process and the fuel injection process to make the fuel injection process of the double-valve electronic control injector not restricted by the boosting process, so the double-valve electronic control injector can work in two modes of non-boosting andboosting; and rail pressure injection is carried out under the non-boosting mode, ultra-high pressure injection is carried out under the boosting mode, and the flexible adjustment of the pressure ratio can be achieved by changing the control strategy of the boosting control valve under the boosting mode, so that the double-valve electronic control fuel injector is higher in reliability and wider in application range. The fuel injection control valve can enable the double-valve electronic control injector to realize micro-dynamic fuel return, the fuel return amount is greatly reduced, the response speed of a needle valve is increased, and the power performance and economy of a diesel engine are effectively improved.

Owner:HARBIN ENG UNIV

An energy-saving high-pressure common rail electronically controlled fuel injector

ActiveCN104500297BSimple structureQuick responseFuel injection apparatusMachines/enginesCommon railFuel oil

The invention discloses an energy-saving high-pressure common-rail electronic-control oil injector. The energy-saving high-pressure common-rail electronic-control oil injector is characterized in that a high-speed electromagnetic valve is of a built-in structure and is compressed by a butterfly spring, and compressing force on the high-speed electromagnetic valve can be adjusted by the aid of an adjusting gasket; a hydraulic servo mechanism is positioned on the lower portion of the high-speed electromagnetic valve and is mounted inside an oil injector body; a control valve is provided with a positioning plane and a high-pressure sealing spherical surface, so that influence of accumulated machining errors on components can be reduced; a needle valve assembly comprises a needle valve body, a needle valve, a clip type spring seat, a spring and a sleeve. The energy-saving high-pressure common-rail electronic-control oil injector has the advantages that the needle valve body has an oil-passage-free character, and accordingly the production cost can be reduced; a large conical surface is arranged on the top of the needle valve, throttle holes and a circular groove are formed in the upper portion of the needle valve, a small cylinder is arranged in the middle of the needle valve, a spiral groove is formed in the lower portion of the needle valve, a throttle hole is formed in the sleeve, and the sleeve, the needle valve and the needle valve body are matched with one another, so that the electronic-control oil injector is quick in response, free of leakage and low in oil return, power consumption and fuel oil consumption of a high-pressure common-rail diesel engine can be reduced, emission of the diesel engine can be improved, and the energy-saving high-pressure common-rail electronic-control oil injector is particularly applicable to repeated injection common-rail diesel engines.

Owner:CHONGQING HONGJIANG MACHINERY CO LTD

Electromagnetic variable cam mechanism and small pulsation variable flow oil supply device

InactiveCN104791211BChange the oil supply capacityReduce oil returnPositive displacement pump componentsPiston pumpsInlet valveFuel tank

The invention discloses an electromagnetic variable cam mechanism and a small-fluctuation variable-flow oil supply device. The small-fluctuation variable-flow oil supply device comprises an oil tank and an oil pump, wherein the oil pump is composed of a cylinder body and a piston, an oil inlet of the cylinder body is communicated with the oil tank through an oil inlet valve and a filter, an oil outlet of the cylinder body is communicated with an oil inlet of an electric-control oil injector through an oil outlet valve and a pressure sensor, an oil return port of the electric-control oil injector is connected with an oil return port of the oil tank through an oil return control valve, the lower end of the piston makes contact with a single-action cam or a multi-action cam, and the pressure sensor, the electric-control oil injector, an electromagnetic coil and the oil return control valve are connected with a power source and a controller. According to the small-fluctuation variable-flow oil supply device, the single-action cam or the multi-action cam is selected to be used for changing the oil supply capacity of the oil pump in real time according to the rotating speed working condition and the load working condition of an engine, the amount of returned oil is controlled through the oil return control valve, the amount of returned oil of the oil pump is reduced, and fuel oil supplying efficiency is improved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Weak leakage anti-suckback fuel injection device

ActiveCN106704067BExtended service lifeImprove reliabilityMachines/enginesFuel injection with fuel accumulatorsEngineeringHigh pressure

The invention relates to a weak leakage oil return preventing fuel injection device. The weak leakage oil return preventing fuel injection device comprises an oil injector body, a throttle orifice plate, a control valve seat, an armature, a valve core, an adjusting gasket, an armature pre-tightening spring, an electromagnet tightening cap, an electromagnet assembly, a stroke adjusting ring, a control piston, a pre-tightening spring, a transition block, an oil nozzle matching part and an oil nozzle tightening cap. The weak leakage oil return preventing fuel injection device is characterized by further comprising a sealing pad, a control disc, a control disc pre-tightening spring and an armature guide sleeve; the sealing pad is arranged on the upper portion of the valve core in a sleeving mode and located below the adjusting gasket; an annular step is arranged on a circumferential ring at the head of the control piston; the control disc pre-tightening spring is arranged on the annular step at the head of the control piston in a sleeving mode; the control disc is arranged on the upper portion of the control disc pre-tightening spring; and the upper surface of the control disc is in contact fit with the throttle orifice plate. According to the weak leakage oil return preventing fuel injection device, the problem that the sealing leakage quantity is increased due to abrasion caused by movement of a control valve can be solved; the service life of an electronic control oil injector is prolonged; and meanwhile, the oil return quantity of the electronic control oil injector is decreased, the high-pressure energy consumption loss is reduced, and the mechanical efficiency is improved.

Owner:CHINA FIRST AUTOMOBILE

A common rail injector

ActiveCN105201716BVary the amount of fuel injected per cycleIdeal fuel injection timingFuel injection apparatusMachines/enginesSolenoid valveCommon rail

The invention discloses a common rail fuel injector, which comprises a fuel injector body part, a solenoid valve part and a fuel injector part. The present invention realizes the fuel injection control function by combining the two-position three-way electromagnetic control valve part and the fuel injection nozzle part with adjustable opening pressure, which makes the structure of the fuel injector simpler and can realize the flexible control of the fuel injection starting point and the fuel injection volume . The electromagnetic control valve core of the present invention is designed as a fuel pressure self-balancing structure, which can significantly improve the fuel injection opening response speed and reduce the driving current of the electromagnet, effectively improving the service life and reliability of the electromagnet. The present invention does not have the structure of the pressure control chamber, the oil outlet orifice control ball valve and the control piston pair of other traditional common rail injectors, so there is no need for precision parts with difficult processing technology, the processing difficulty is greatly reduced, and the process cost is also corresponding reduce.

Owner:NANYUE FUEL INJECTION SYST CO LTD

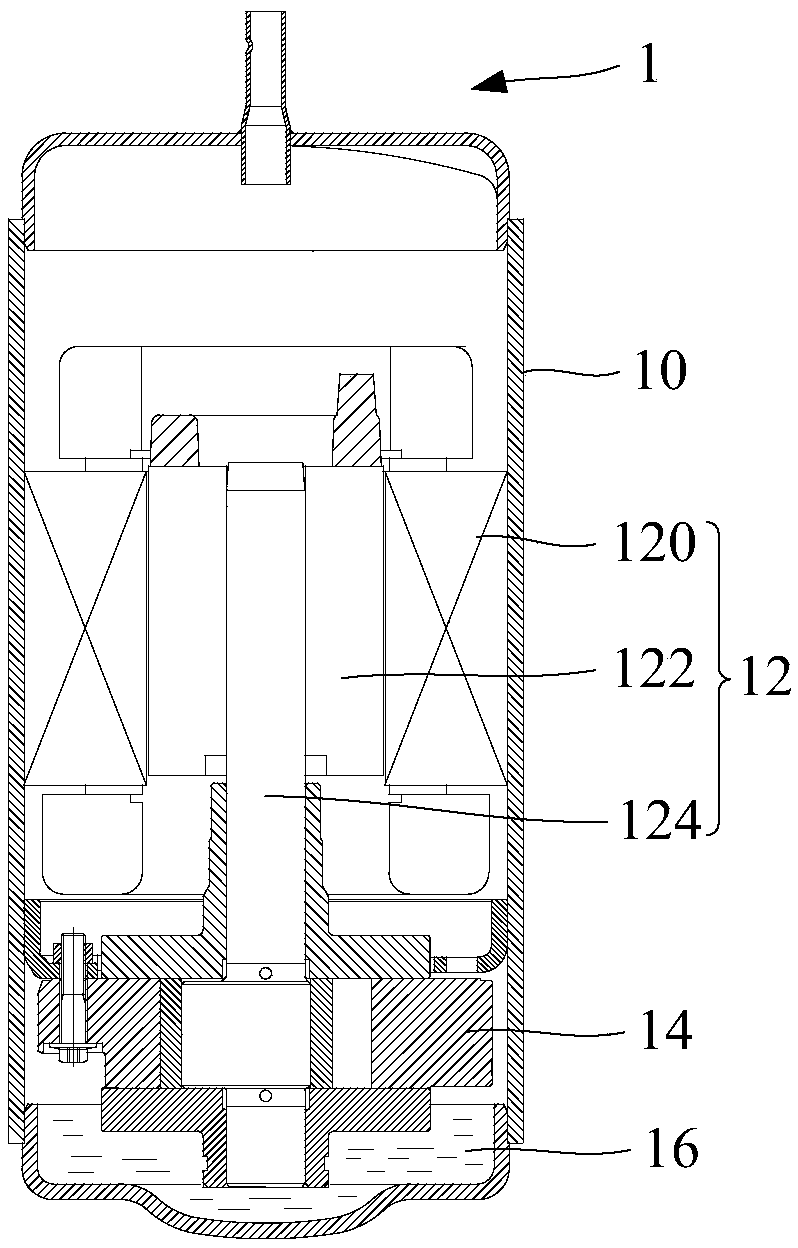

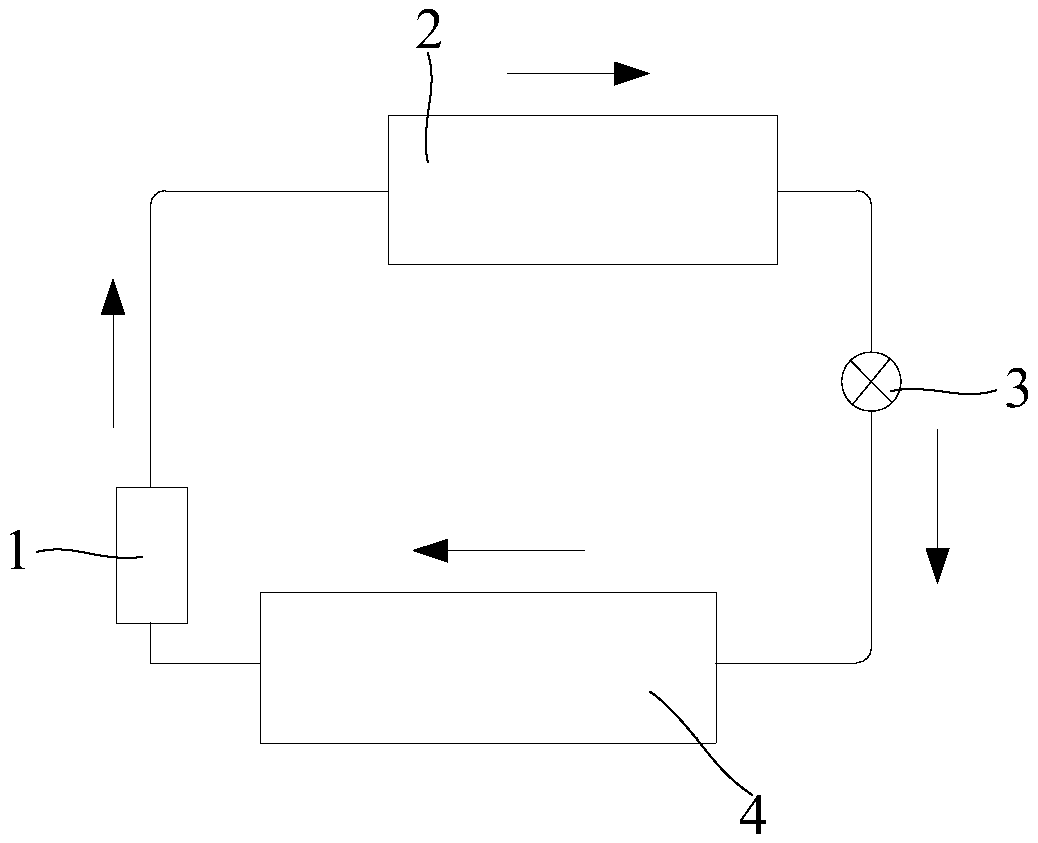

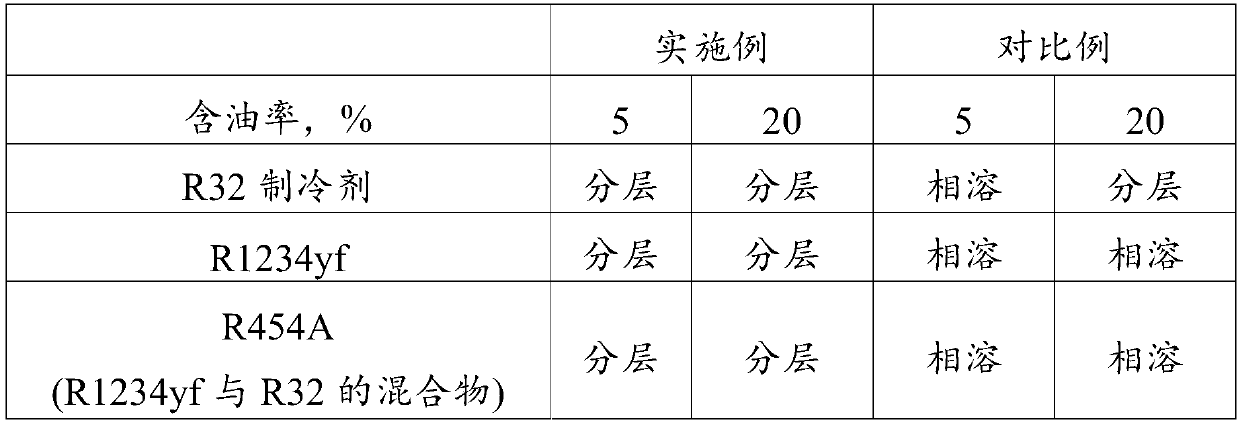

Compressor and refrigerating device

InactiveCN111237166ALow pour pointGuaranteed SolubilityPositive displacement pump componentsHeat-exchange elementsPolyolElectric machinery

The invention provides a compressor and a refrigerating device. The compressor comprises a shell, a motor and a compression structure, wherein the motor is arranged in the shell; the compression structure is located in the shell and is connected to the motor; the compression structure is internally provided with a refrigerant which comprises a hydrofluoroolefin refrigerant and / or a hydrofluorocarbon refrigerant; engine oil is contained in the shell, the compression structure is partially immersed in the engine oil, and the engine oil comprises base oil and polyalcohol ester, and the polyalcohol ester is formed by compounding polyalcohol and at least one organic acid, the carbon number of which is smaller than or equal to 10. According to the compressor, the refrigerant comprises the hydrofluoroolefin refrigerant and / or the hydrofluorocarbon refrigerant. The engine oil comprises the base oil and the polyalcohol ester, and the polyalcohol ester is formed by compounding polyalcohol and atleast one organic acid, the carbon number of which is smaller than or equal to 10. The engine oil is compatible with the hydrofluoroolefin refrigerant and the hydrofluorocarbon refrigerant simultaneously, so that the universality of the compressor is improved.

Owner:ANHUI MEIZHI PRECISION MFG

Pressure-accumulating piezoelectric-electromagnetic dual-valve electronic fuel injector

ActiveCN109236528ASmall pressure fluctuationsQuick responseFuel injection apparatusMachines/enginesElectricityRail pressure

It is an object of the present invention to provide a pressure-accumulating piezoelectric-electromagnetic dual-valve electronic fuel injector which comprises a pressurizing control valve, a pressurizing piston, a fuel injection control valve, a nozzle and a fuel injector body. The fuel injector body is provided therein with a pressure-accumulating chamber, which can reduce the pressure fluctuationin a fuel injection process, and is advantageous for the precise control of the fuel injection. A piezoelectric stack and the electromagnetic valves can be configured to independently control the pressurization process and the fuel injection process such that the pressure-accumulating piezoelectric-electromagnetic dual-valve electronic fuel injector can work in both non-pressurizing and pressurizing modes. In the non-pressurizing mode, the rail pressure injection is performed. In the pressurizing mode, the ultrahigh-pressure injection is performed, and the pressuring ratio can be flexibly adjusted, thereby achieving high reliability and a wide application range. The fuel injection control valve can stop the control chamber from replenishing the fuel during the fuel draining process, realizes micro dynamic oil return, improves the response speed of the needle valve, and improves the dynamic property and economical efficiency of a diesel engine.

Owner:HARBIN ENG UNIV

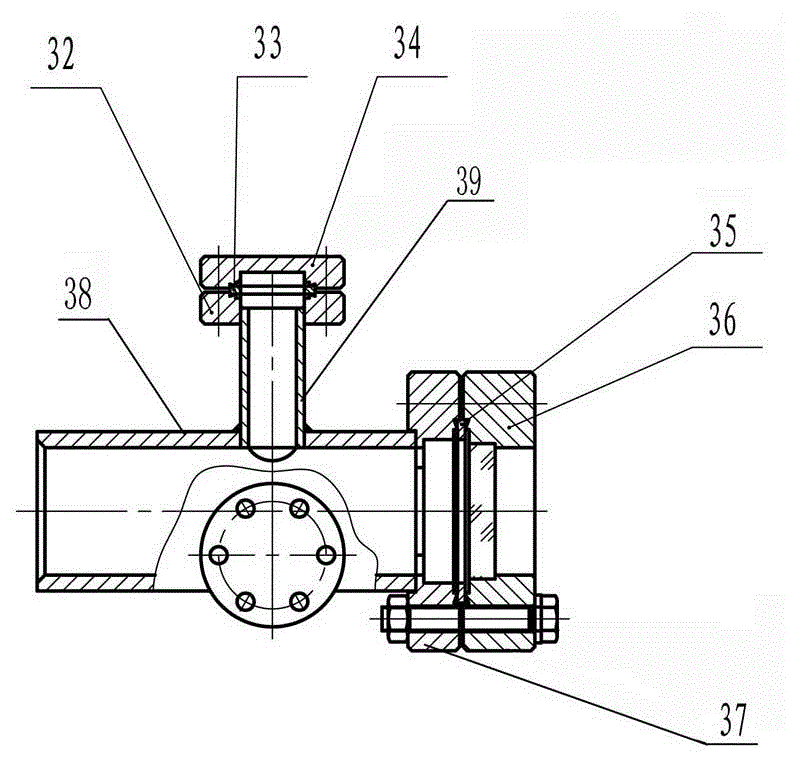

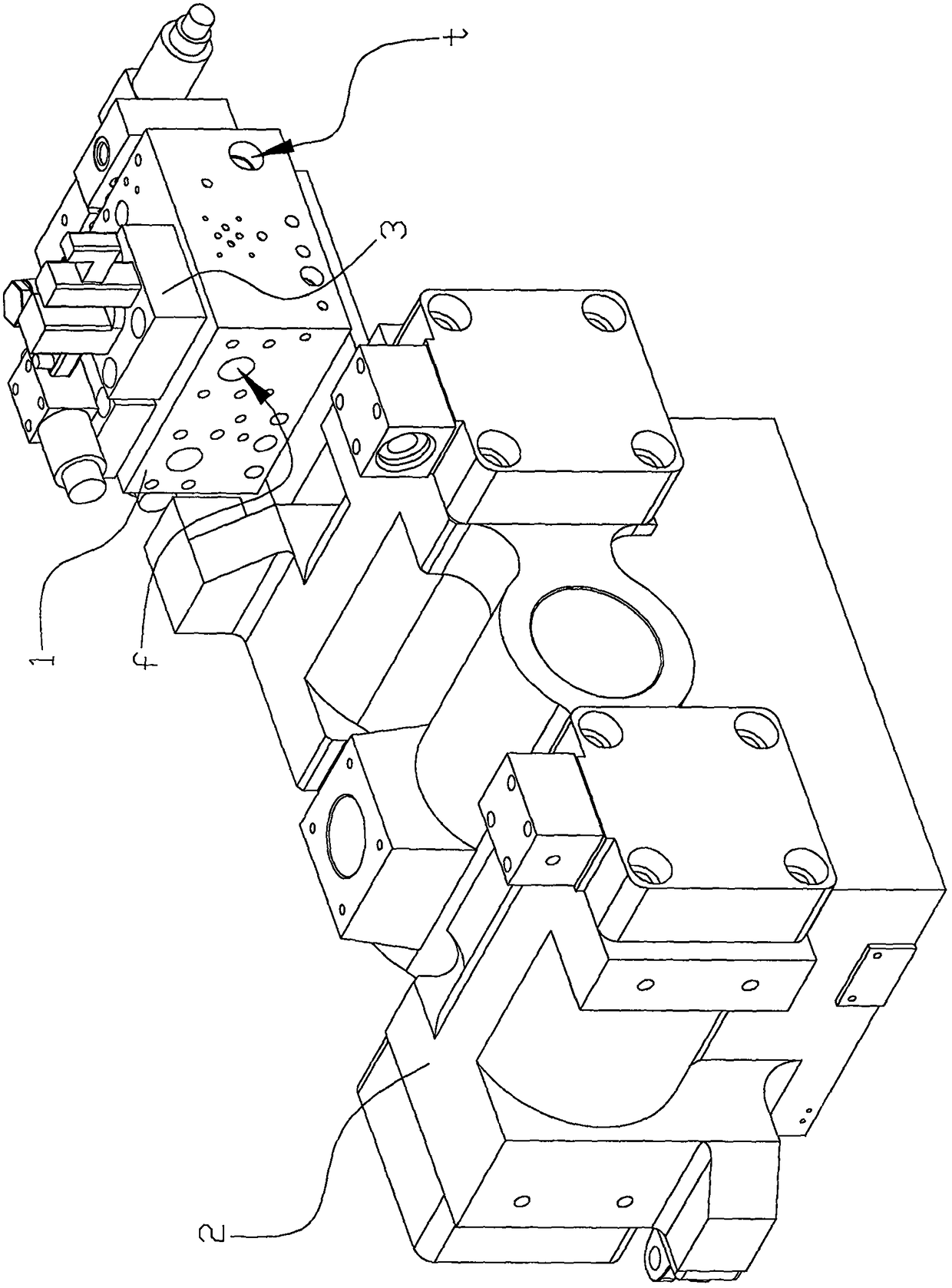

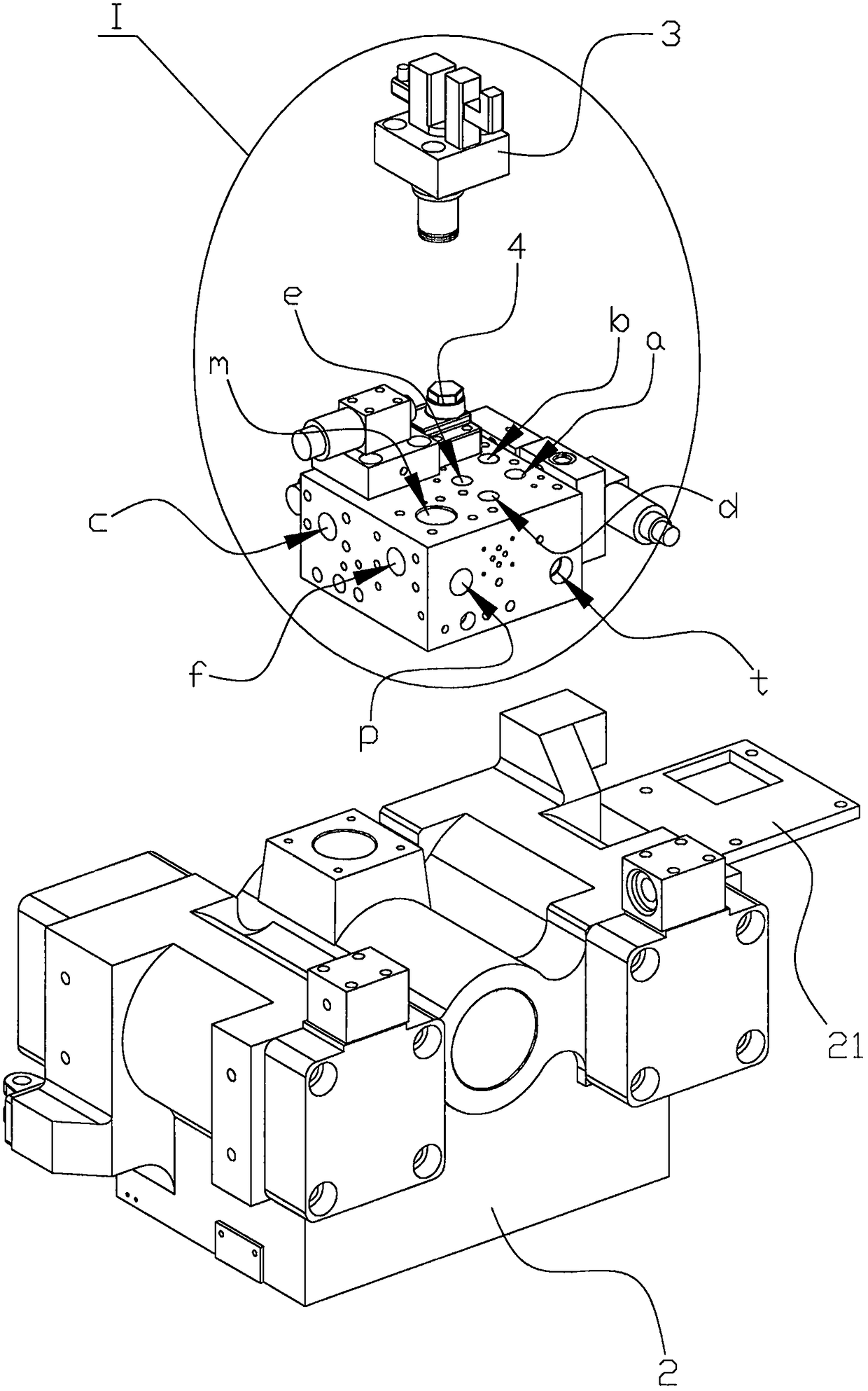

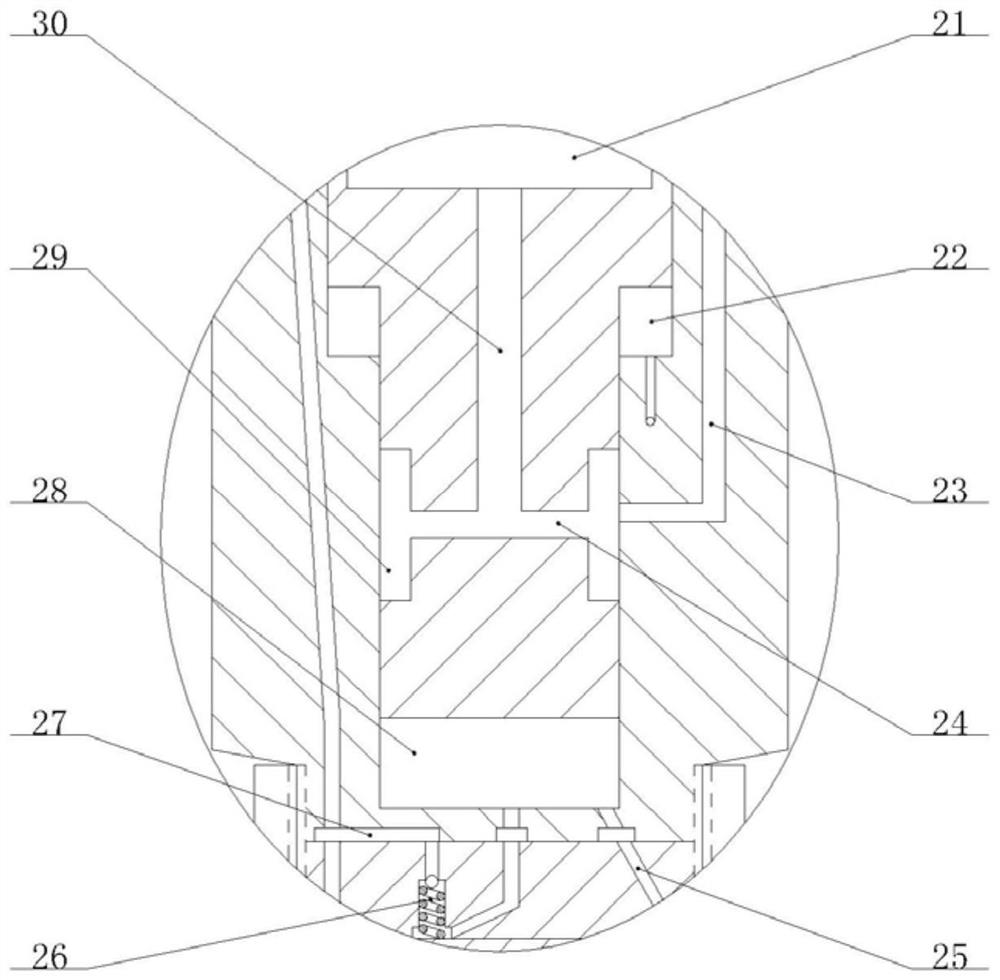

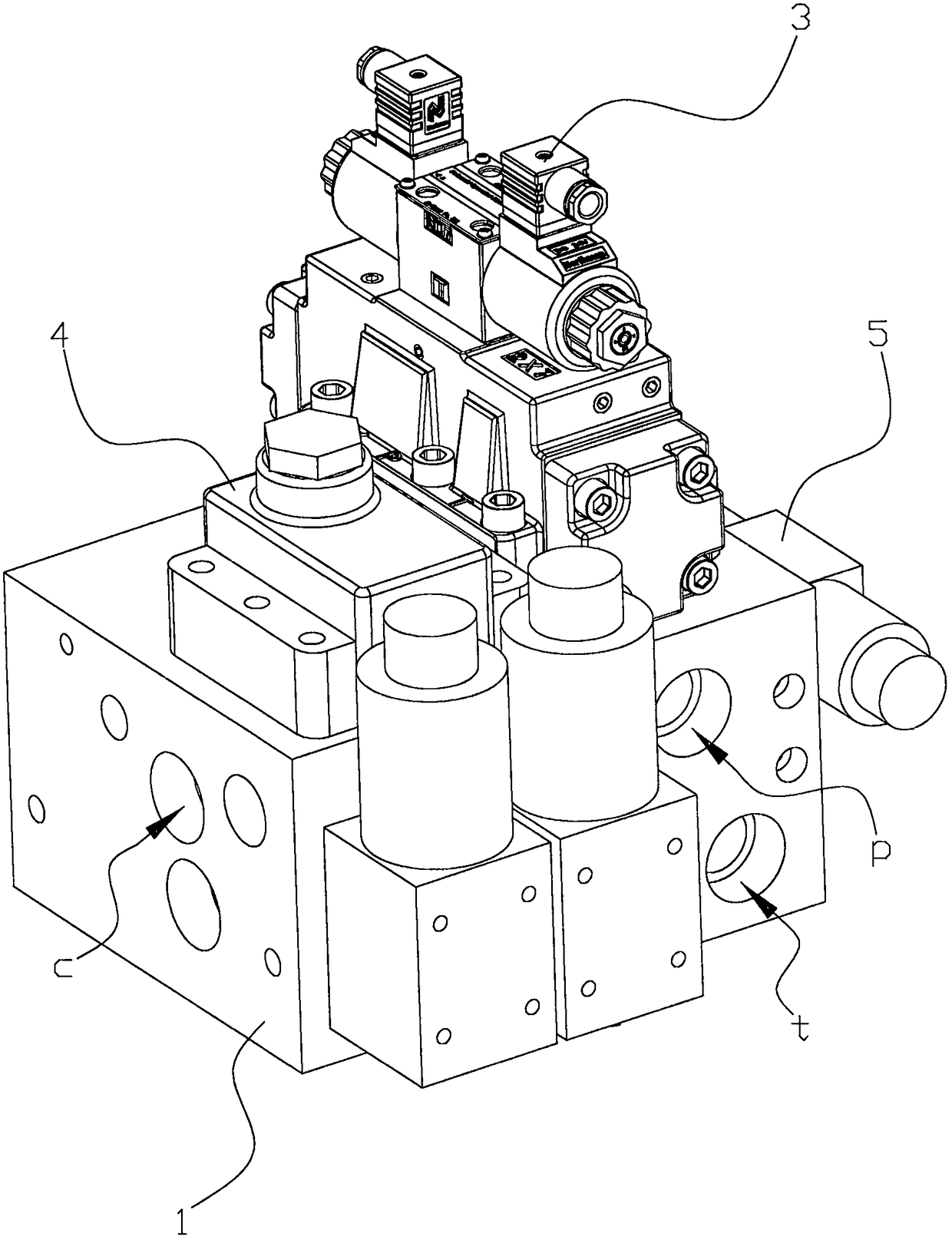

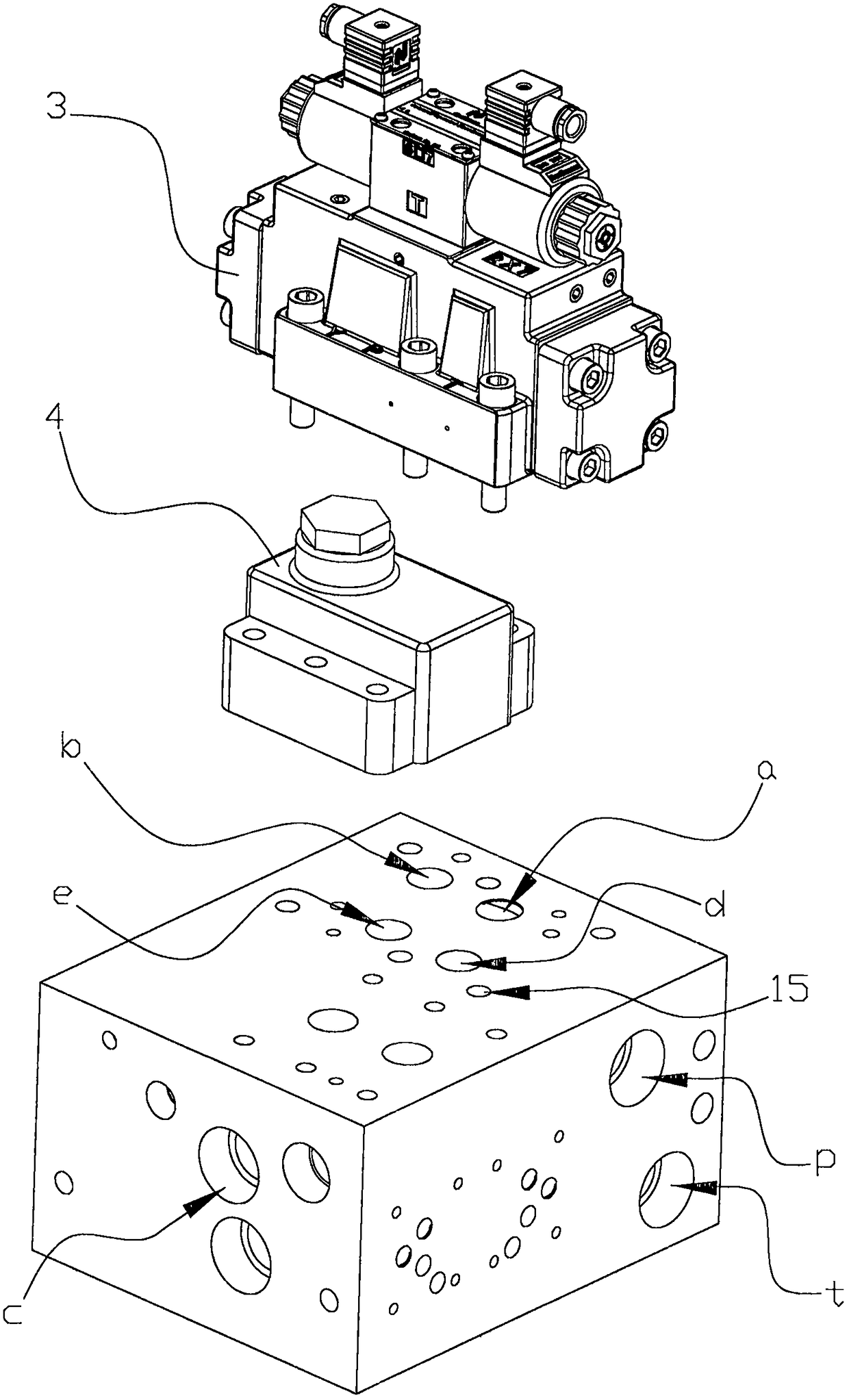

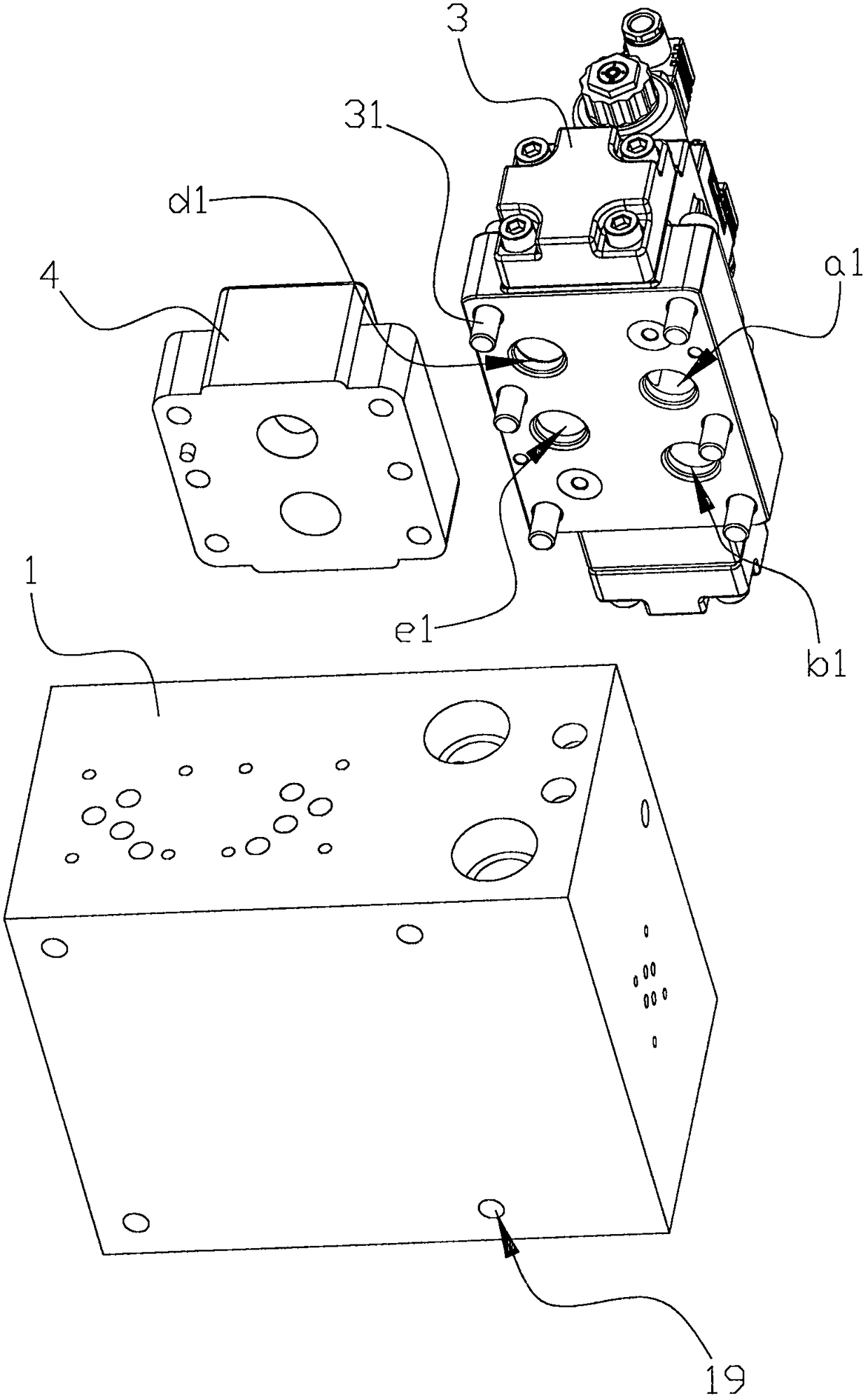

Differential injection modules for injection molding machines

ActiveCN106122156BHigh movement accuracyEasy to unlockServomotor componentsInjection molding machineControl valves

A differential injection module used on an injection molding machine comprises a mold body. The mold body is provided with an oil inlet, an oil outlet, an oil entering opening, an oil backflow opening, an injection control valve, a one-way valve and a flow control valve, wherein the oil inlet and the oil outlet communicate with an oil tank, the oil entering opening communicates with a push cavity of an injection oil cylinder, and the oil backflow opening communicates with a loosening cavity of the injection oil cylinder. The injection control valve, the one-way valve and the flow control valve are connected with a control circuit through wires correspondingly. The oil inlet, the oil outlet, the oil entering opening and the oil backflow opening communicate with the injection control valve through pipelines correspondingly. The one-way valve is arranged on the pipeline enabling the oil backflow opening to communicate with the injection control valve. The flow control valve is arranged on the pipeline enabling the oil inlet to communicate with the injection control valve. A valve element capable of moving left and right is arranged in the injection control valve. After the valve element moves leftwards / rightwards, the oil inlet communicates with the oil entering opening; and after the valve element moves rightwards / leftwards, the oil inlet communicates with the oil backflow opening. The differential injection module has the beneficial effects that the oil way flow is adjusted conveniently, and the injection oil cylinder is stable in pushing and high in push efficiency.

Owner:浙江台意德塑机制造有限公司

Accumulated piezoelectric-solenoid double-valve electronically controlled fuel injector

ActiveCN109236528BSmall pressure fluctuationsQuick responseFuel injection apparatusMachines/enginesRail pressureDieseling

It is an object of the present invention to provide a pressure-accumulating piezoelectric-electromagnetic dual-valve electronic fuel injector which comprises a pressurizing control valve, a pressurizing piston, a fuel injection control valve, a nozzle and a fuel injector body. The fuel injector body is provided therein with a pressure-accumulating chamber, which can reduce the pressure fluctuationin a fuel injection process, and is advantageous for the precise control of the fuel injection. A piezoelectric stack and the electromagnetic valves can be configured to independently control the pressurization process and the fuel injection process such that the pressure-accumulating piezoelectric-electromagnetic dual-valve electronic fuel injector can work in both non-pressurizing and pressurizing modes. In the non-pressurizing mode, the rail pressure injection is performed. In the pressurizing mode, the ultrahigh-pressure injection is performed, and the pressuring ratio can be flexibly adjusted, thereby achieving high reliability and a wide application range. The fuel injection control valve can stop the control chamber from replenishing the fuel during the fuel draining process, realizes micro dynamic oil return, improves the response speed of the needle valve, and improves the dynamic property and economical efficiency of a diesel engine.

Owner:HARBIN ENG UNIV

A Common Rail Injector with Reduced Leakage

ActiveCN108397326BShort turn-off delayReduce leakageFuel injection apparatusMachines/enginesCommon railElectromagnetic valve

The invention provides a common rail oil injector capable of reducing leakage. The common rail oil injector comprises an oil cavity A and an oil cavity B, wherein the oil cavity A and the oil cavity Bare formed by a control piston and a pore plate; when the control piston ascends and descends, a high-pressure oil passage communicates with a low-pressure oil passage through two oil passages of theoil cavity A and the oil cavity B. After the lift of the control piston reaches the maximum value, the communication between the oil cavity B and the low-pressure oil passage through a throttling ring belt is cut off, high-pressure oil only passes through a throttling hole and the oil cavity A to be leaked to the low-pressure oil passage through an oil outlet hole, so that the flowing resistanceis increased, and oil return during oil spraying, heating of the oil injector and oil supply pump power loss are reduced. Meanwhile, the flow ratio of the oil outlet hole to an oil inlet hole can be larger, so that the oil drainage time of a control cavity and the oil injection delay of the oil injector are reduced. After the communication of a passage, flowing through the throttling ring belt, between the oil cavity B and the low-pressure oil passage is cut off, and the oil cavity B only communicates with the low-pressure oil passage through the throttling hole and the oil cavity A, so that the flowing resistance of the low-pressure oil passage is increased, and the oil cavity B is kept higher in pressure, the pressure of the control cavity is restored faster after an electromagnetic valve is powered off, the oil spraying closing delay is shorter, and the oil spraying sensitivity of the oil injector is improved.

Owner:CHINA FIRST AUTOMOBILE

Piezoelectric-Solenoid Double Valve Electronically Controlled Injector

ActiveCN109252999BQuick responseImprove hydraulic efficiencyFuel injection apparatusMachines/enginesMarine engineeringDieseling

Owner:HARBIN ENG UNIV

Oil circuit locking device

ActiveCN106351916BRealize closed mold movementEasy to unlockFluid-pressure actuatorsMotor controlControl circuit

Provided is an oil way locking device which comprises a locking device body. The locking device body is provided with an oil inlet, an oil outlet, an oil entrance, an oil returning hole communicated with the back cavity of the oil cylinder, a directional valve and a check valve, both of which are connected with the control circuit by control cables. The oil inlet, oil outlet, oil entrance and the oil returning hole are all communicated with the directional valve. The check valve is provided at the pipe section from the oil returning valve to the directional valve. The directional valve inside is provided with a valve element moving leftward and rightward. The oil inlet and the oil returning hole are communicated. The advantages of the present device is the attainment of the opening and closing operation of the oil tank membrane, excellent locking effects, easy unlocking procedure, high efficiency; the motor control of the directional valve and the check valve with high reaction sensitivity, fast start up; solid locking device body, pipe cavities installed on the solid body communicating with various openings, simple structure and easy processing.

Owner:浙江台意德塑机制造有限公司

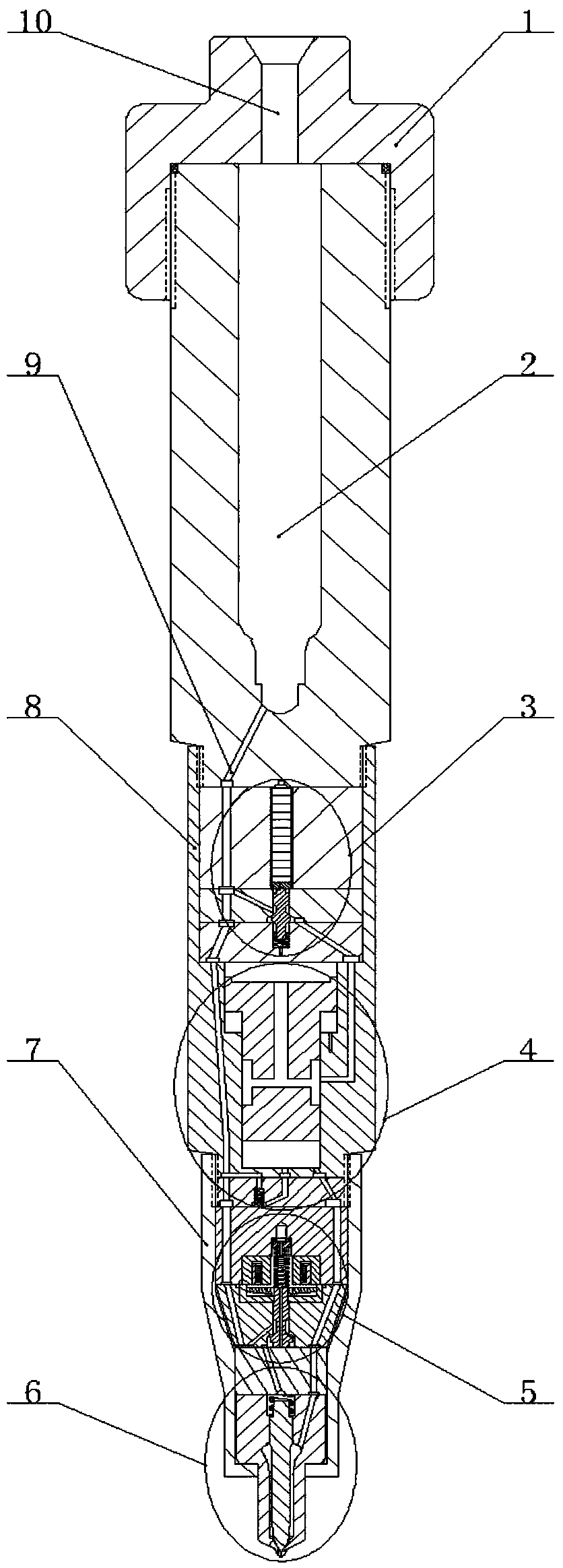

Electronically controlled diesel injector

ActiveCN108547717BReduce distanceQuick responseMachines/enginesSpecial fuel injection apparatusDiesel injectorNeedle valve

The invention discloses an electronically controlled diesel injector which comprises an oil injector body, a locking nut, an electromagnet part, a seal ball, a ball seat, an upper transition block, alower transition block and an oil nozzle part. A needle valve is matched with an upper spring seat; the upper spring seat is matched with the lower transition block; a lower spring seat is connected with the needle valve; a needle valve spring is matched with the upper spring seat and the lower spring seat; the oil injector body, the upper transition block, the lower transition block and a needlevalve body are sequentially connected; the ball seat is matched with an inner wall of the oil injector body in a sealing way, and is connected with the electromagnet part; the lower transition block,the upper spring seat and the needle valve form a control cavity; the upper transition block, the lower transition block and an upper conical surface form a pressure cavity; an oil inlet channel is arranged in the oil injector body, the upper transition block and the lower transition block, and communicates with an inner cavity of the needle valve body; the lower transition block is provided witha left oil channel, a middle oil channel and a right oil channel; the oil inlet channel communicates with the control cavity; the control cavity communicates with the pressure cavity; the pressure cavity communicates with the oil inlet channel; the upper end of the needle valve spring is matched with the upper spring seat; and the lower end of the needle valve spring is matched with the lower spring seat.

Owner:龙口龙泵柴油喷射高科有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com