A Common Rail Injector with Reduced Leakage

A technology of common rail injectors and oil chambers, applied in fuel injection devices, machines/engines, charging systems, etc., which can solve problems such as power loss, efficiency decline, and fuel system economy reduction in common rail systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

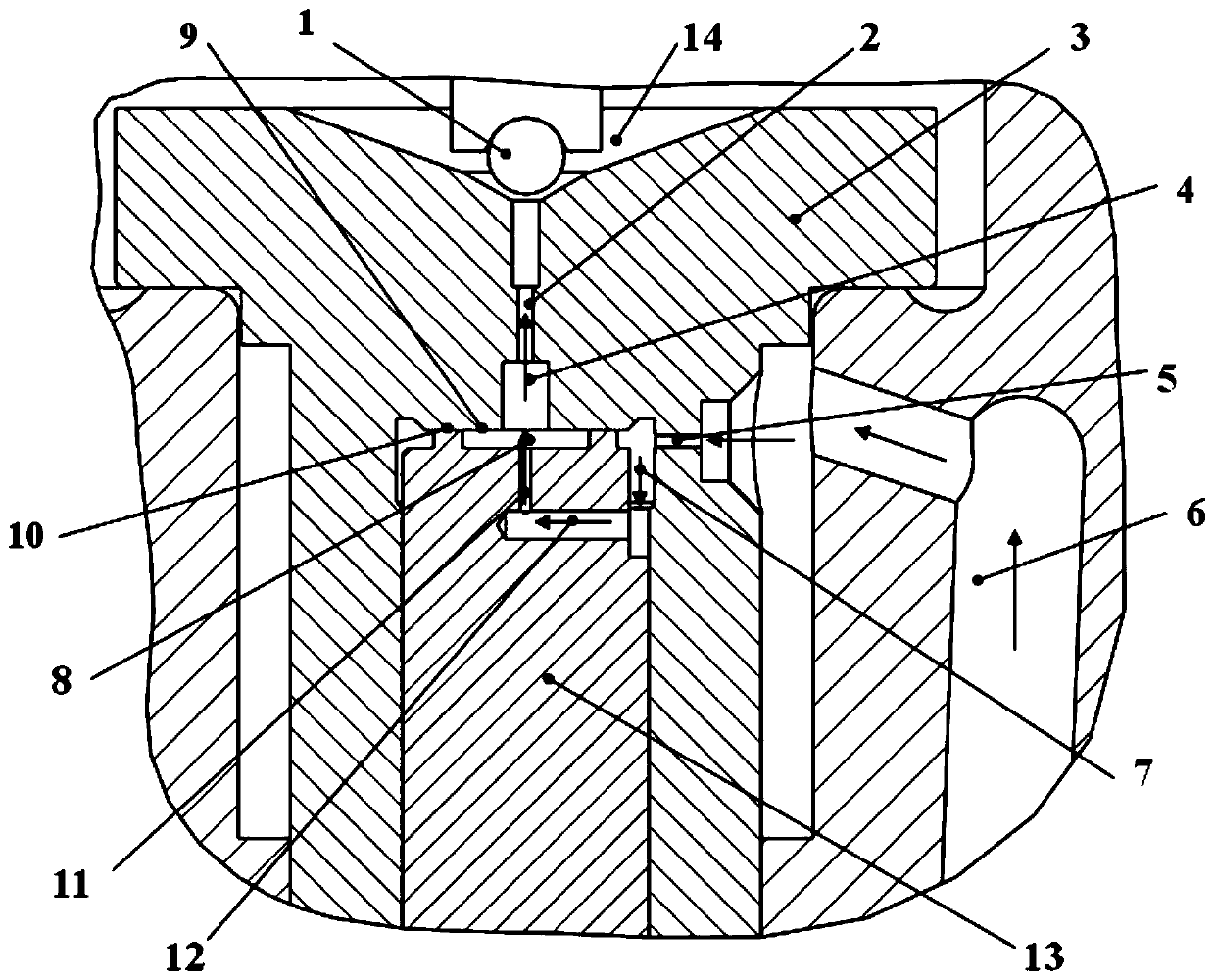

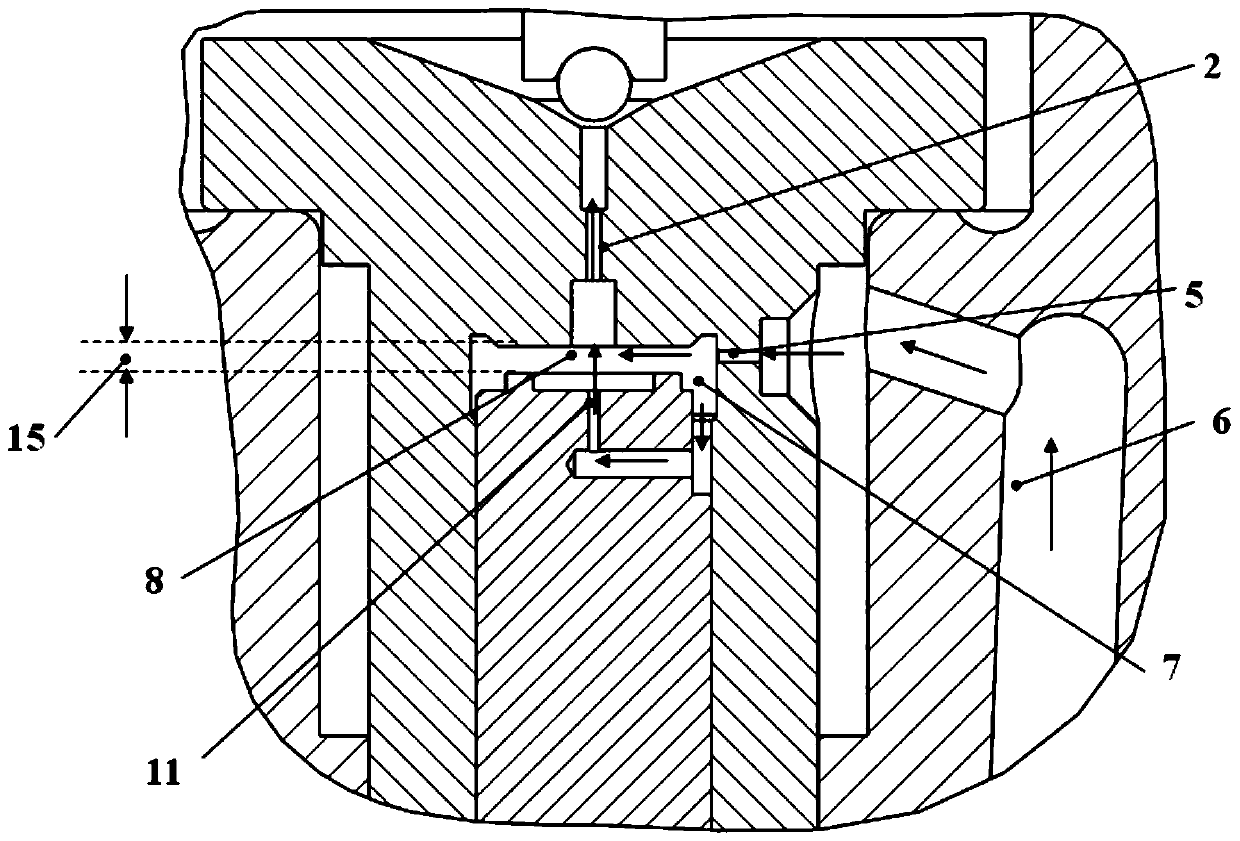

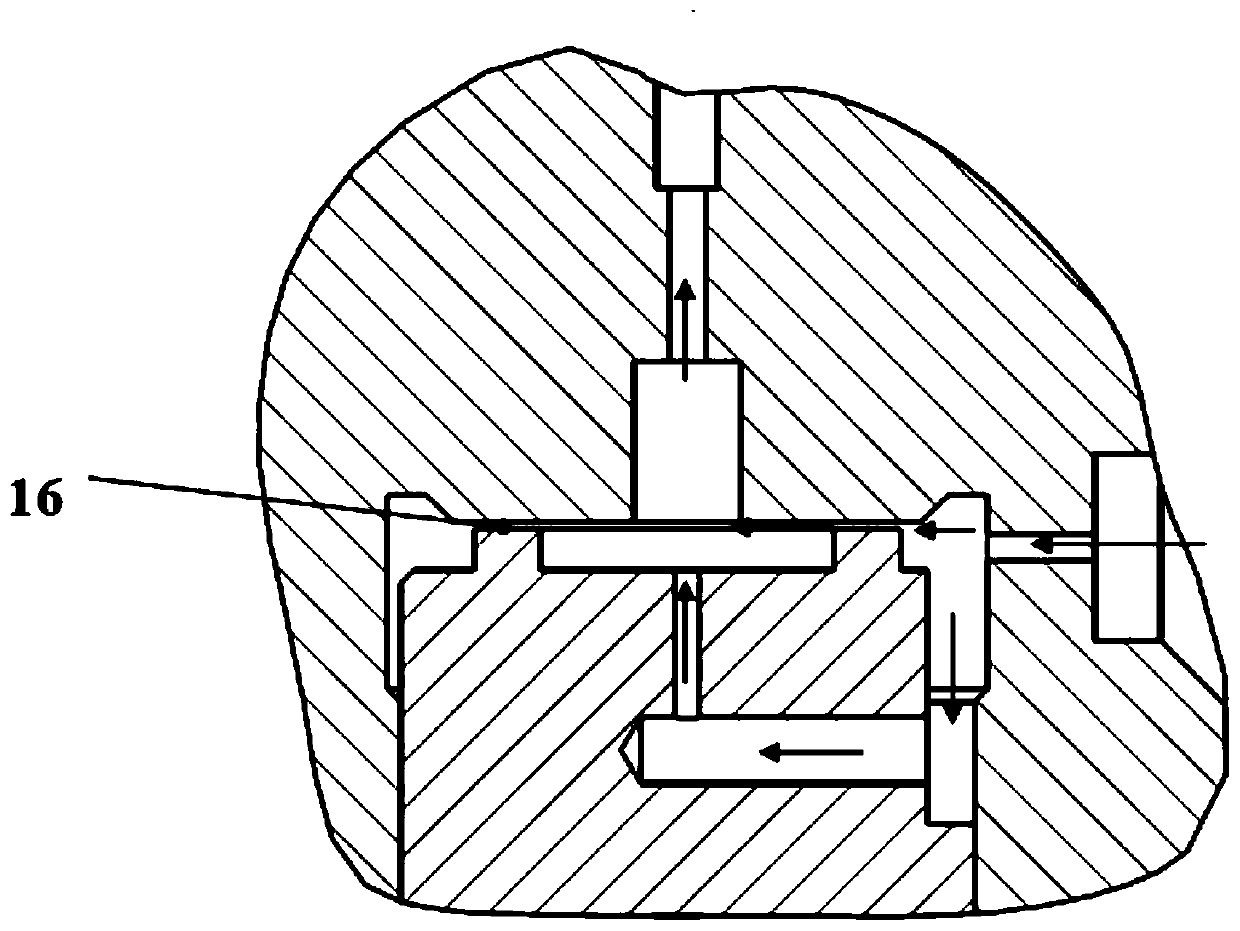

[0020] A common rail fuel injector that reduces leakage in the present invention can refer to the attached figure 1 , 2 , 3 descriptions.

[0021] A common rail fuel injector that reduces leakage, including a ball valve 1, an orifice 3, and a control piston 13. During fuel injection, after the control piston 13 rises, a seal is formed between the bottom of the orifice 3 and the control piston 13 Annulus 16, an oil chamber A8 and an oil chamber B7 are formed between the top of the control piston 13 and the bottom of the orifice plate 3, and the oil chamber A8 and oil chamber B7 are respectively located inside and outside of the throttle annulus 16 and located at the control On the top of the piston 13, two oil chambers form the injector control chamber; the oil chamber A8 is controlled by the ball valve 1 to communicate with the low-pressure oil passage 14 through the oil outlet hole 2 on the orifice plate 3; the oil chamber B7 passes through The oil inlet hole 5 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com