A common rail injector control valve

A common rail injector and control valve technology, which is applied to fuel injection devices, machines/engines, charging systems, etc., can solve the problems of difficulty in increasing injection pressure, slow reduction in fuel pressure, and reducing fuel system economy. The effect of reducing leakage and fuel injection delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

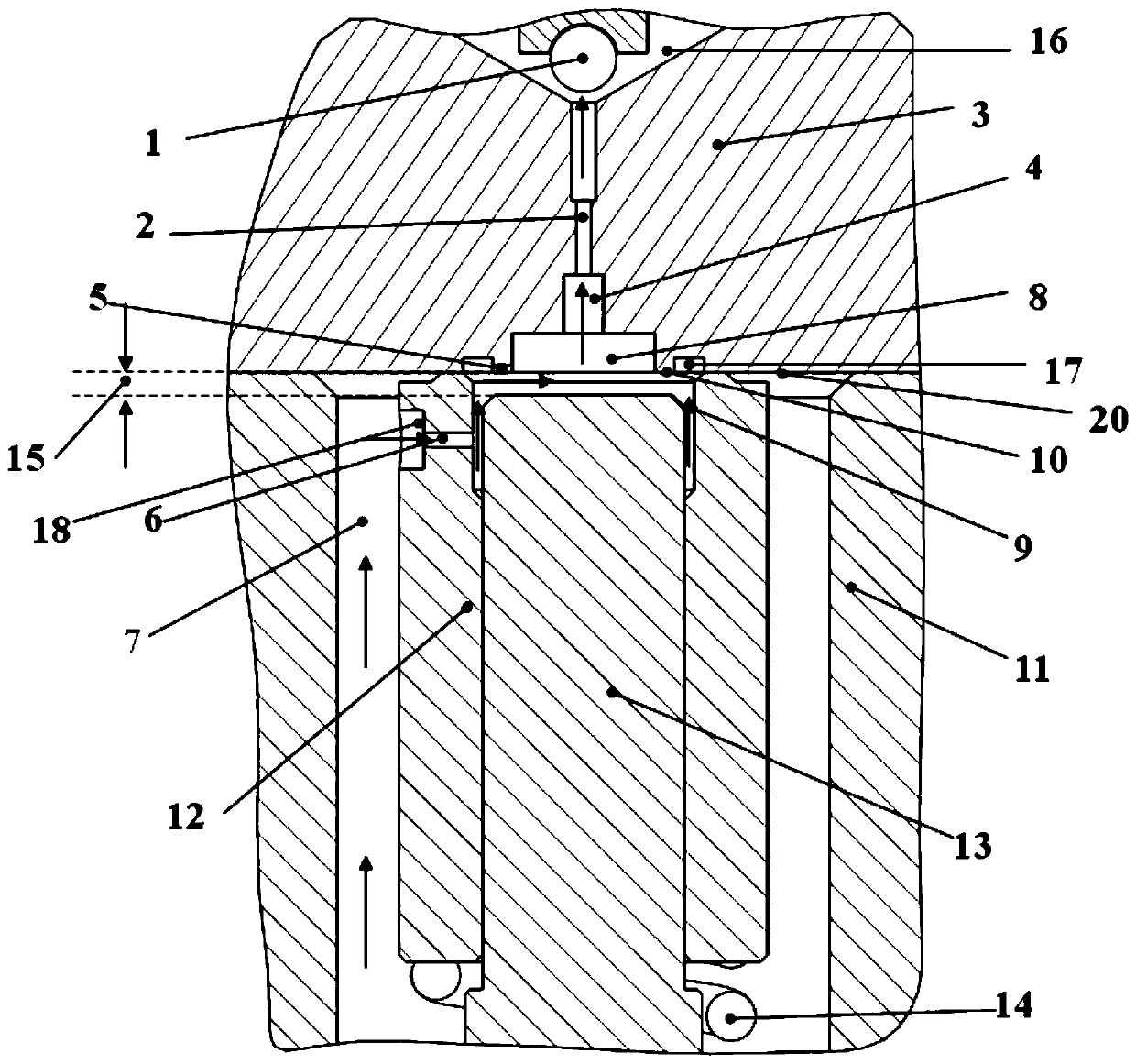

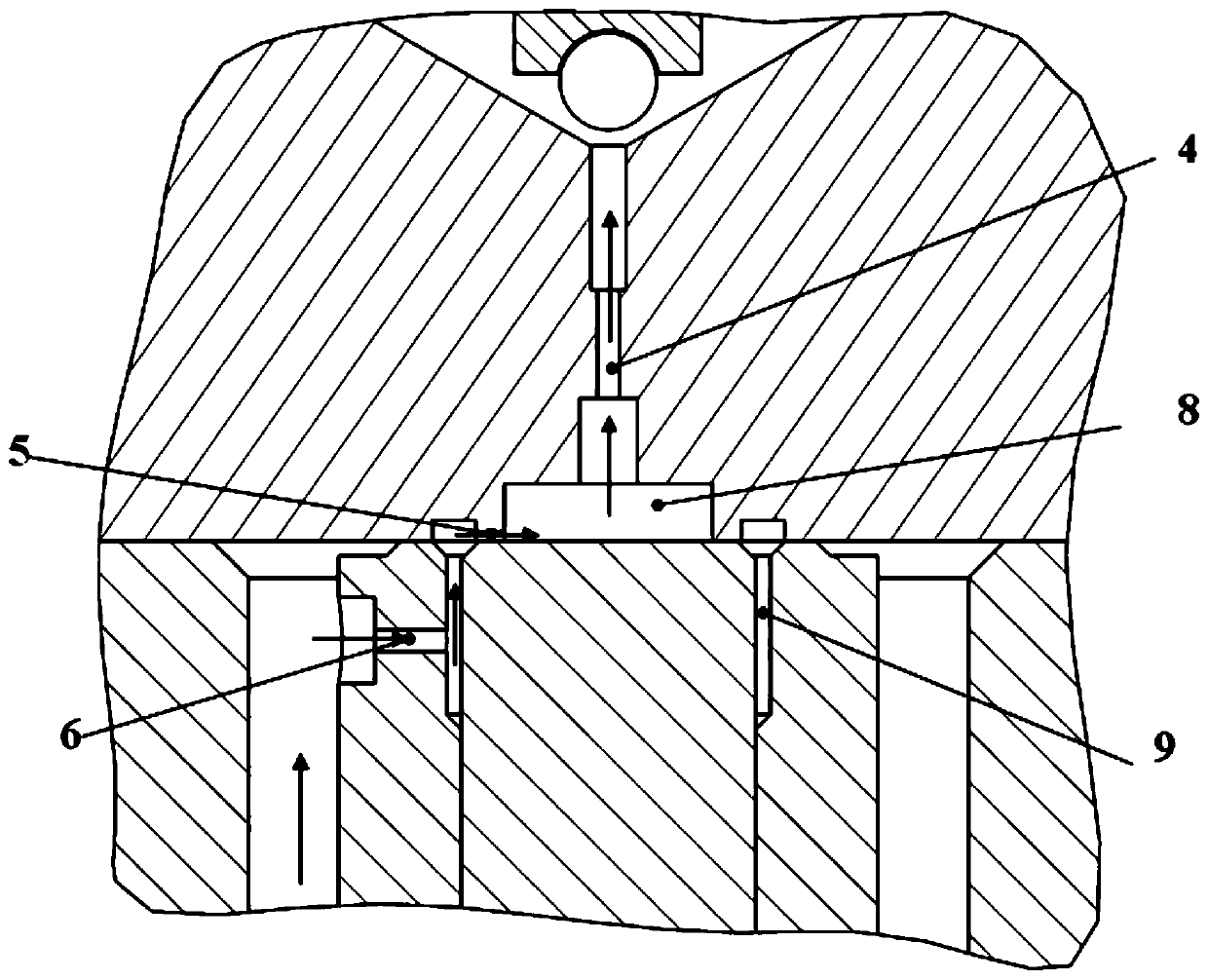

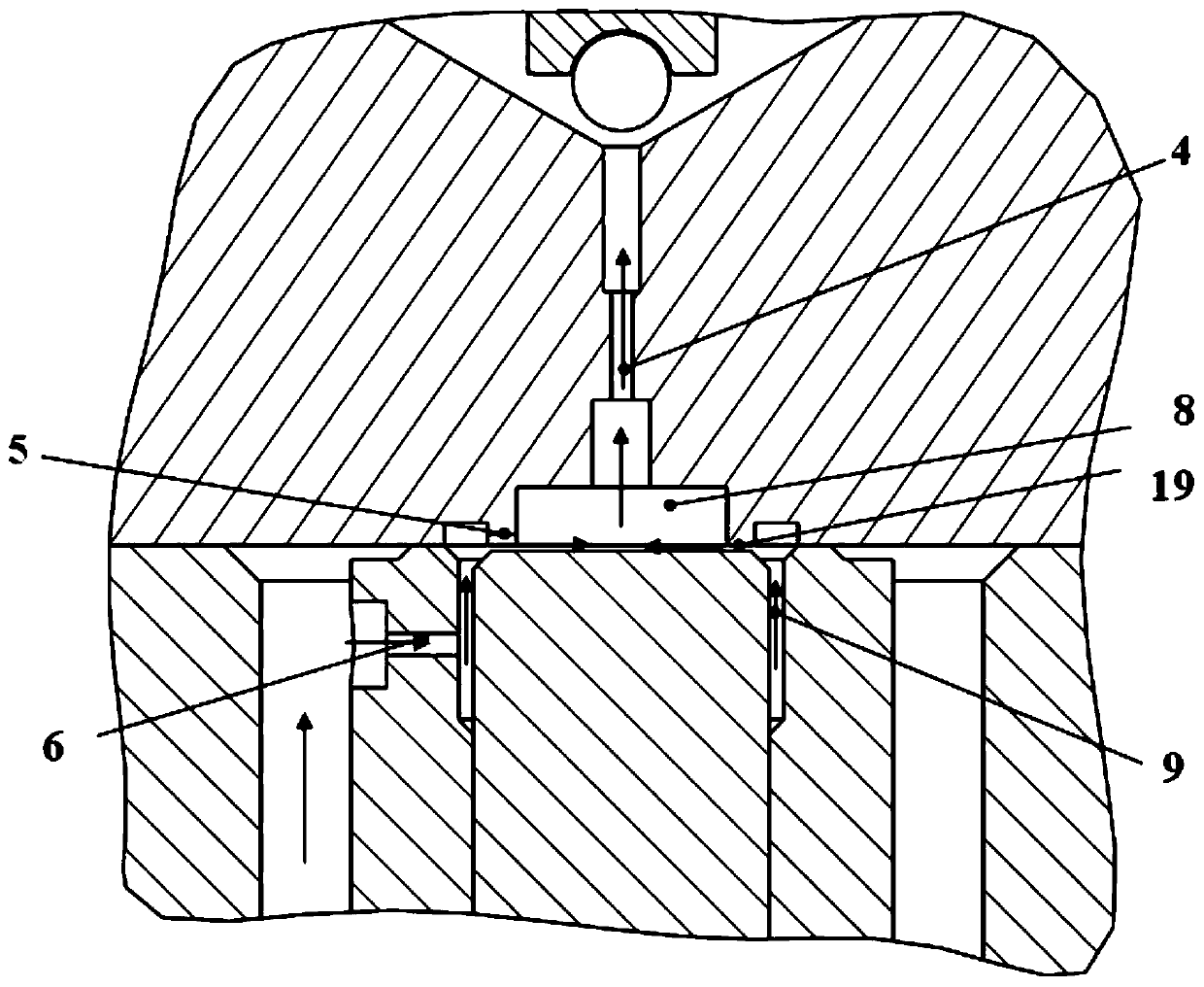

[0025] A kind of common rail fuel injector of the present invention can refer to attached figure 1 , 2 , 3, 4, and 5 descriptions.

[0026] A new type of common rail injector control valve, including injector body 11, orifice plate 3, control piston 13, floating sleeve 12 and preload spring 14; control piston 13, preload spring 14, floating sleeve 12 are located In the oil chamber 7. An oil return passage 16 is arranged inside the orifice plate 3 , and the connection between the oil return passage 16 and the low-pressure oil passage is opened or closed by the sealing surface and the ball valve 1 . The top of the control piston 13 is located in the inner cavity of the floating sleeve 12 . The inner cavity of the floating sleeve 12 has a stepped inner cylindrical surface, the top diameter of the inner cavity is larger than the bottom, and the bottom cylindrical surface matches the top cylinder of the control piston 13, and one end of the floating sleeve 12 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com