Patents

Literature

63results about How to "Quick pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

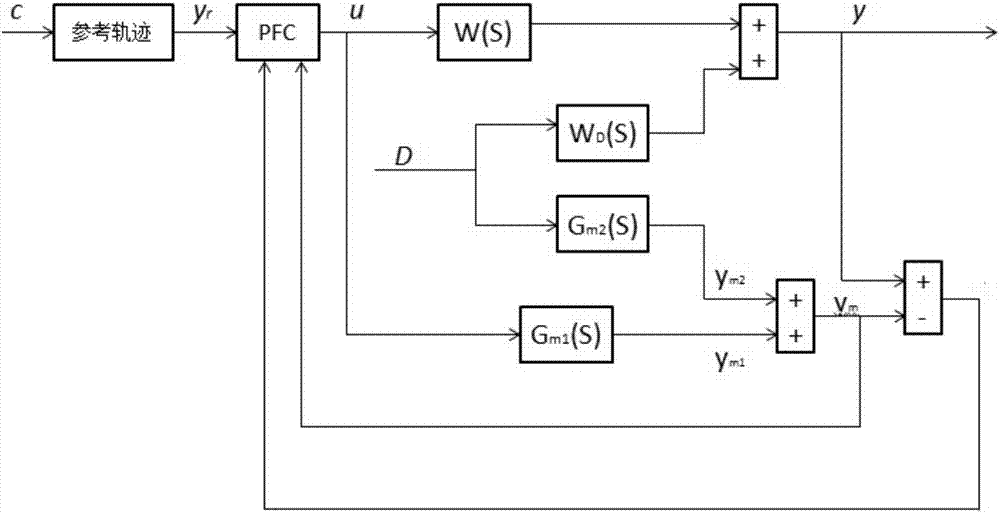

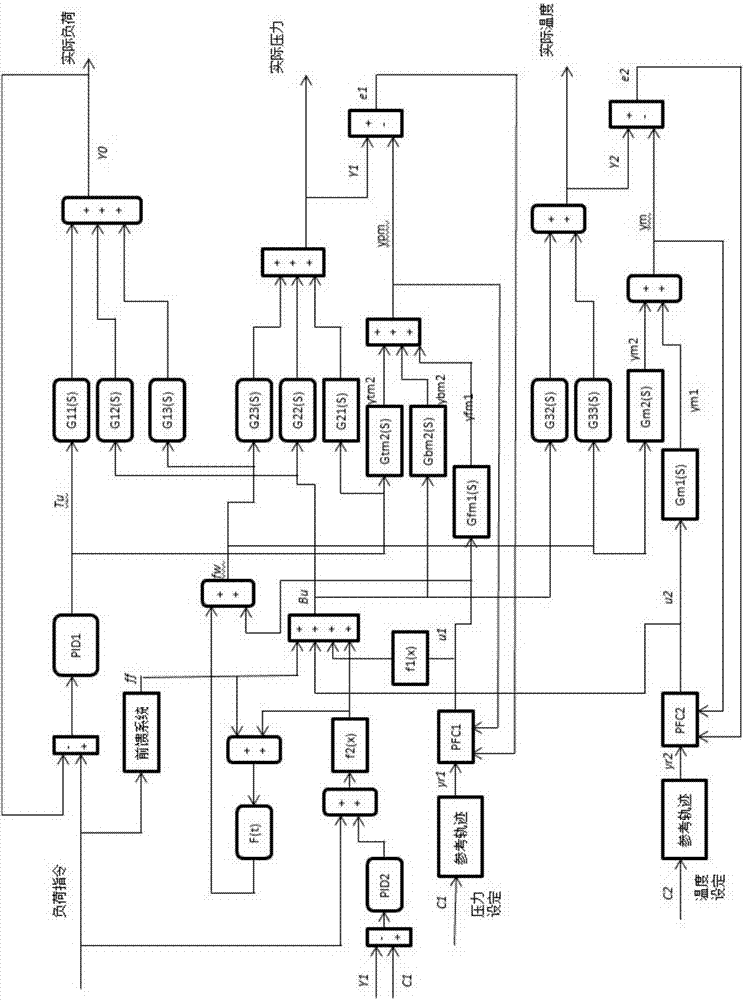

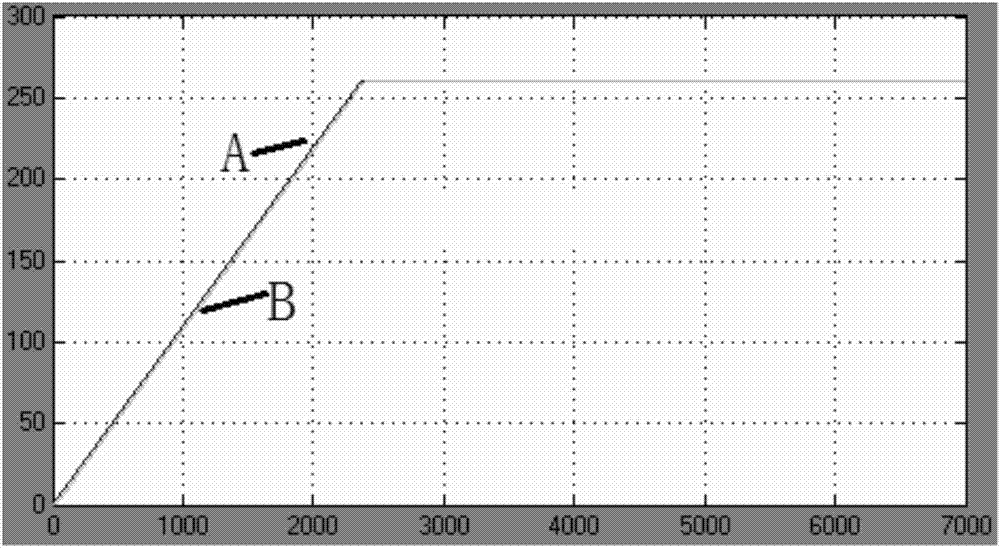

Supercritical unit coordinated predictive function control algorithm

ActiveCN107065518AProve excellent performanceSimple structureAdaptive controlSteam pressureClosed loop

The invention discloses a supercritical unit coordinated predictive function control algorithm. It is difficult for a conventional PID control system to consider the rapidity of load and stability of pressure and temperature at the same time, the quality of a coordinated control system needs to be improved. According to the supercritical unit coordinated predictive function control algorithm, predictive function control is applied to a pressure closed loop of a supercritical unit coordinated control system, a main steam pressure predictive function control system is formed. A control valve instruction and a coal quantity instruction are taken as a disturbance signal source of the whole pressure system. The predictive function control is applied to a temperature control loop of the supercritical unit coordinated control system, and an overhigh temperature prediction function control system is formed. A water supply instruction is taken as a disturbance signal source of a whole temperature system. According to the supercritical unit coordinated predictive function control algorithm, the control quality of the supercritical unit coordinated system is improved, and the rapidity of load and stability of pressure and temperature are considered at the same time.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

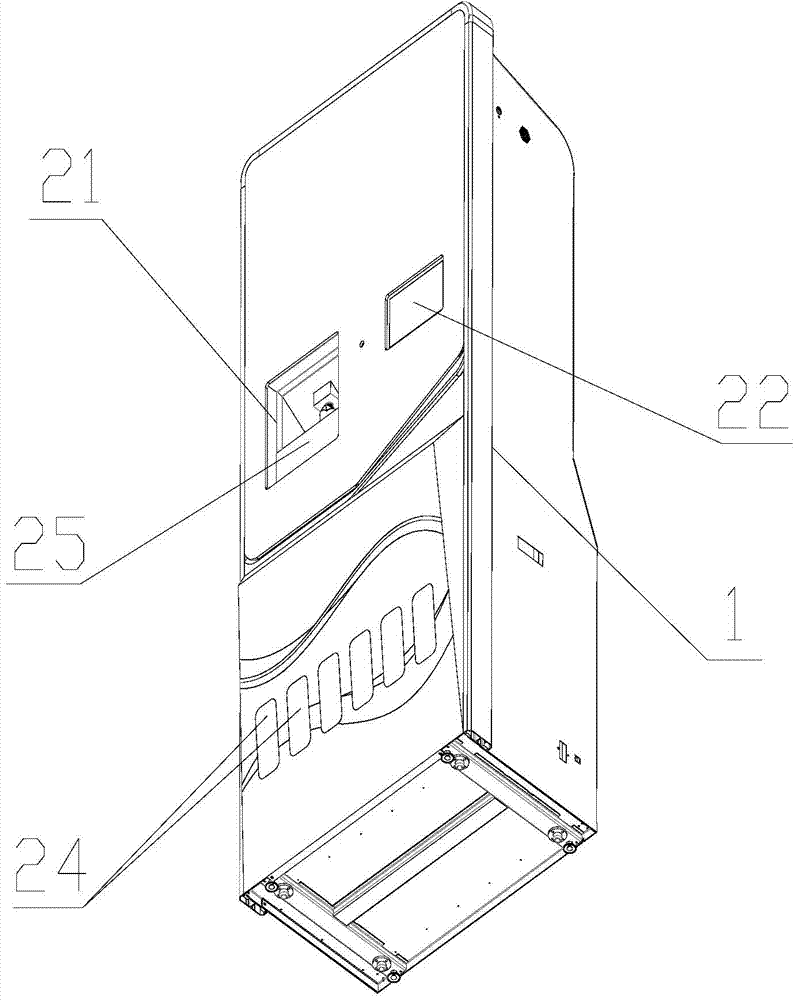

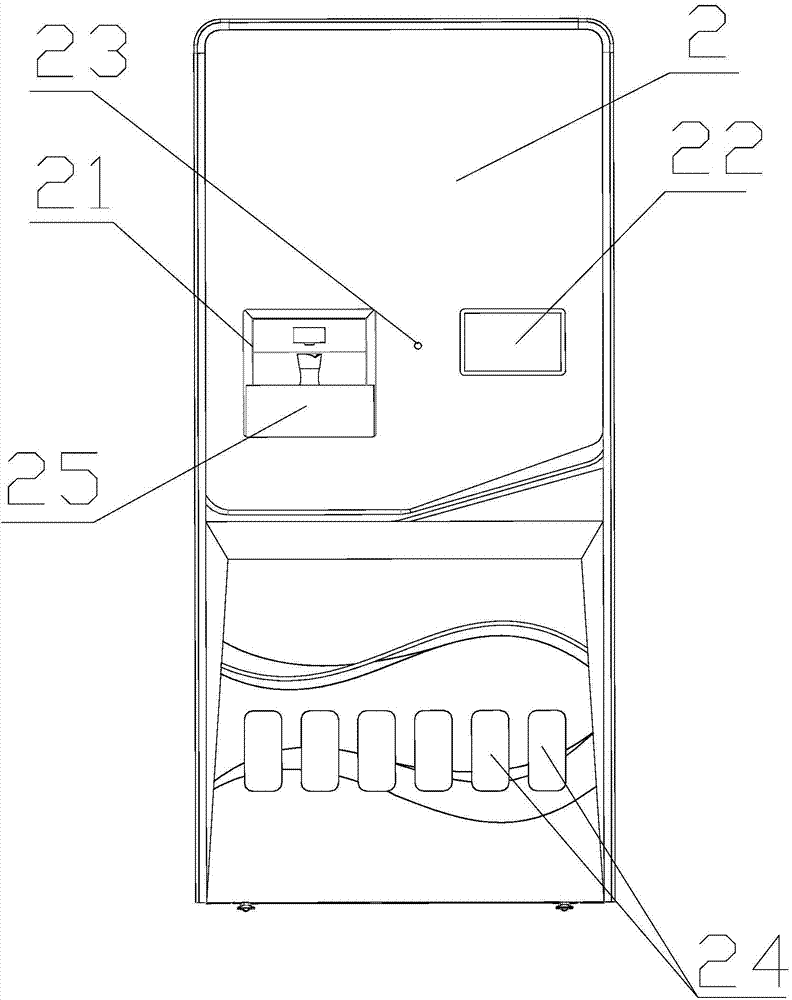

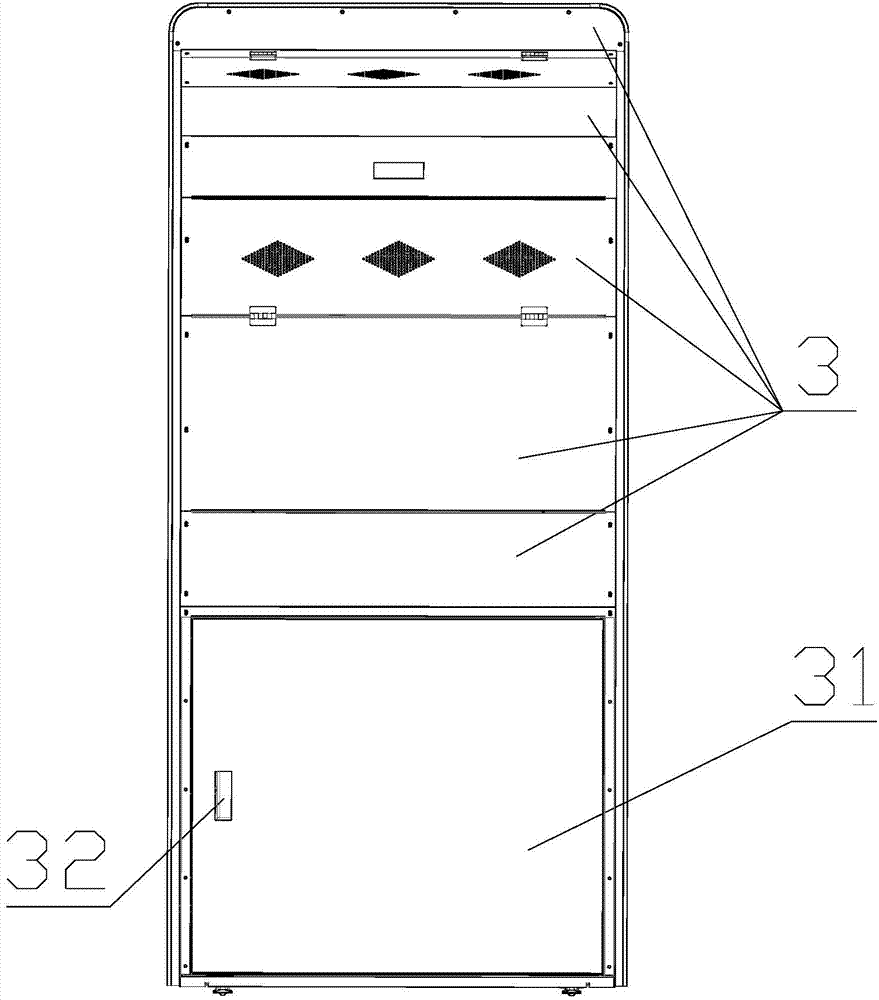

Alcohol sales machine

The invention discloses an alcohol sales machine, which comprises a shell, wherein the shell forms a box body by a front shell, a back shell and side shells; an alcohol receiving window, an operating screen and an alcohol discharging button are arranged on the upper end of the front shell; an alcohol barrel observing window is arranged on the lower end of the front shell; a glass lifting door is arranged on the window part of the alcohol receiving window; an alcohol barrel is arranged on the lower end in the shell; a puncturing and alcohol pumping system corresponding to the alcohol barrel is arranged in the shell; an alcohol discharging box body is arranged in the alcohol receiving window of the shell; an alcohol discharging pipe is arranged in the alcohol discharging box body; an alcohol pumping pipe communicated with the alcohol barrel and the alcohol discharging pipe is arranged in the puncturing and alcohol pumping system; a lifting door lifting system for driving the glass lifting door to lift up and down to open and close is arranged on the glass lifting door. Through the alcohol sales machine, an alcohol dealer can automatically sell retailed alcohol capacity, and an alcohol buyer can take alcohol by himself / herself according to the obtained alcohol capacity, so that convenience is brought to retailed alcohol capacity bargaining transaction.

Owner:SICHUAN DEMIN INVESTMENT CO LTD

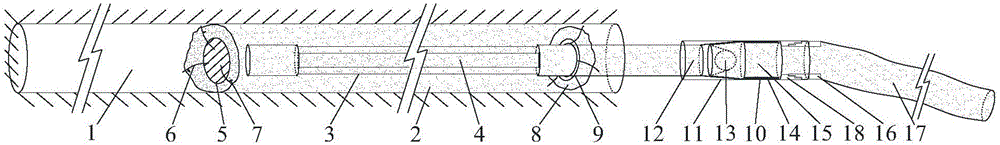

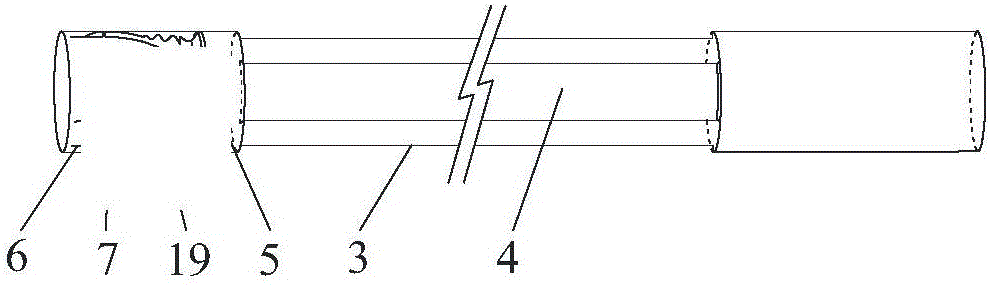

Flexible plastic quick grouting hole sealing device and method

ActiveCN106401522ARaise the initial pressureFlexibleDrilling rodsWell/borehole valve arrangementsSlurryMechanical engineering

The invention discloses a flexible plastic quick grouting hole sealing device and method. The device is mainly composed of an umbrella buckle type plugging device, a slotting flexible plastic grouting pipeline and a double-cone pipe connector device. The initial grout pressure in pipes is positively stored in a sealed mode through the differential flow of grout fed into and discharged out of the grouting pipes, and the processes of automatic pushing out, spreading and plugging of a convex angle umbrella buckle are completed. A flexible plastic pipe capable of being coiled is adopted to be inserted into a drill hole at a time, and the primary quick hole sealing operation requirement is met. According to the flexible plastic quick grouting hole sealing device and method, the process of traditional hole sealing operation is simplified, operation is convenient and quick, the cost is low, and the device and the method are novel hole sealing device and method which have wide application and popularization value.

Owner:CHINA UNIV OF MINING & TECH

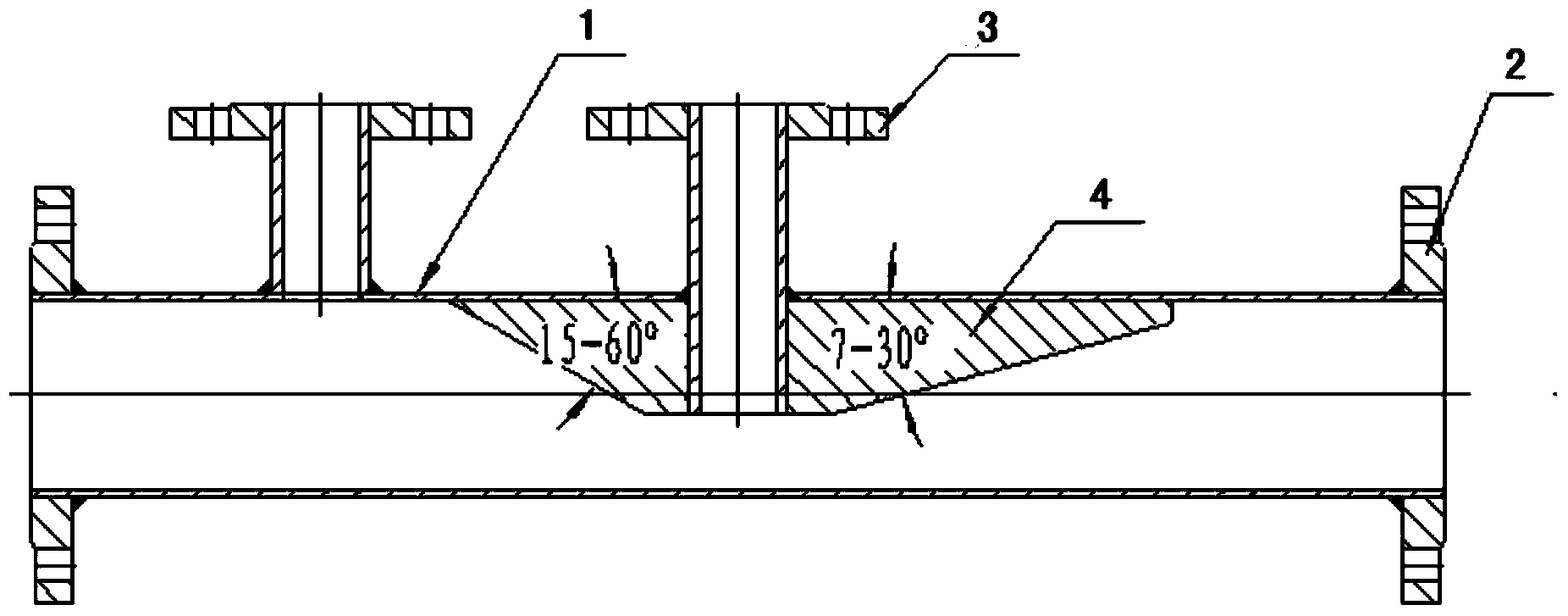

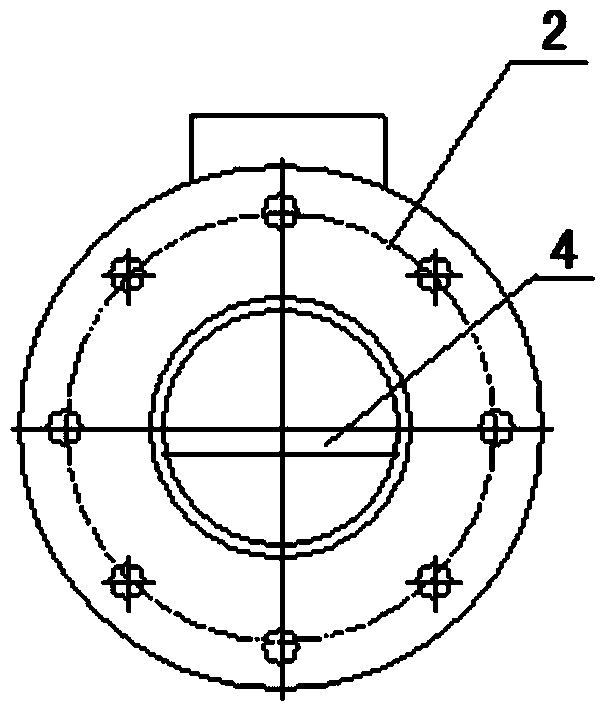

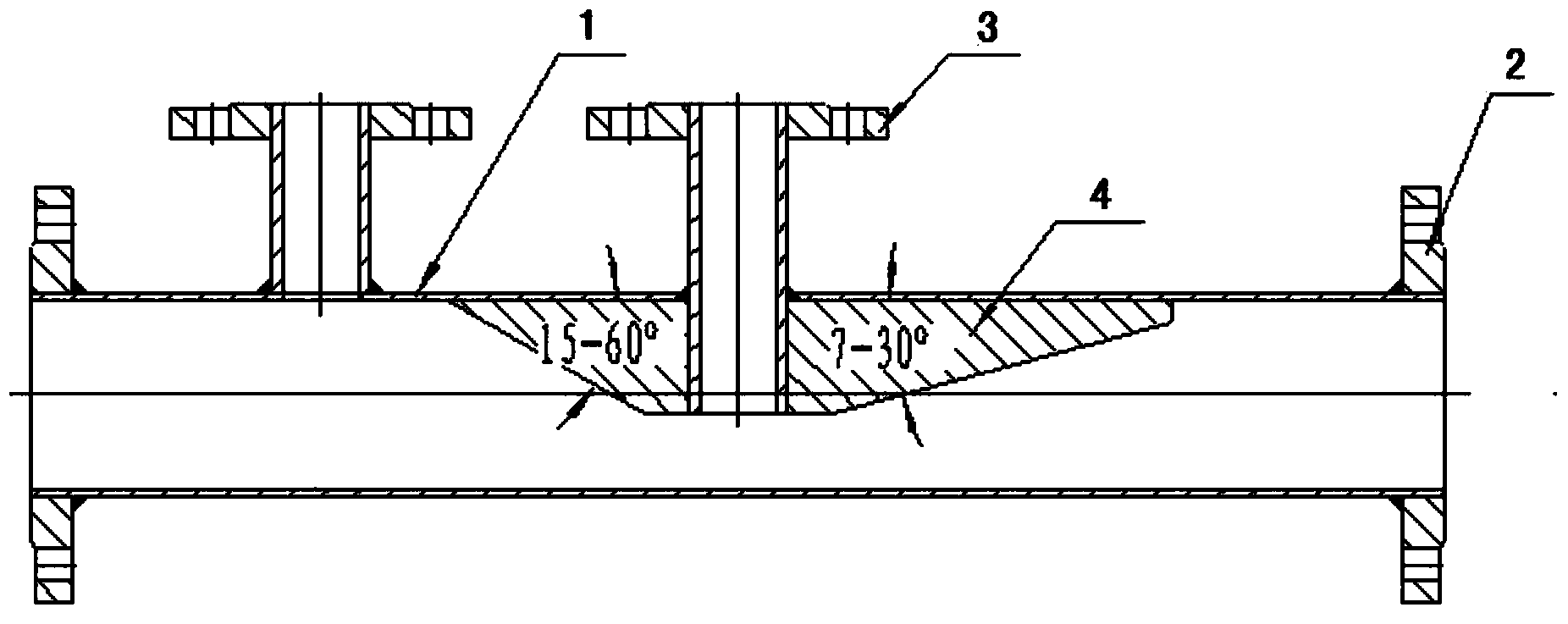

Diffusion tube type rectangular flow meter

InactiveCN104019853AUnique structureHigh precisionVolume/mass flow by differential pressureAcute angleEngineering

The invention relates to a flow meter, in particular to a diffusion tube type rectangular flow meter. The diffusion tube type rectangular flow meter comprises a measurement tube and body flanges welded to the two ends of the measurement tube, and a pair of pressure tapping flanges are welded to the measurement tube in the axial direction. The diffusion tube type rectangular flow meter is characterized in that a trapezoid throttling element is arranged at the position, below the pressure tapping flanges, in the measurement tube; the cross section of the trapezoid throttling element is in a circular notch shape, the front projection is in the inverted trapezoidal shape with the big upper portion and the small lower portion, two acute angles of the trapezoid are 15-60 degrees and 7-30 degrees respectively, and a negative pressure sampling hole is formed in the center of the throat. The diffusion tube type rectangular flow meter is unique in structure, high in accuracy, good in linearity, high in long-term working stability and reliability, long in service life, high in pressure recovery and small in perpetual pressure loss.

Owner:唐力南

Pneumatic pantograph lifting device for tram and pantograph lifting control method

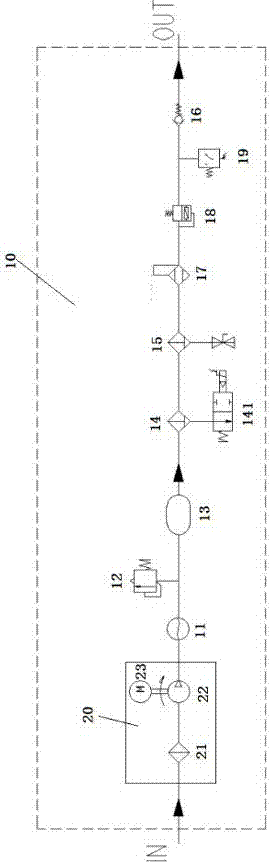

ActiveCN107415700AEffect of drying efficiencyReduce maintenance costsRailway vehiclesDispersed particle separationAir filterEngineering

The invention discloses a pneumatic pantograph lifting device for a tram and a pantograph lifting control method. The pneumatic pantograph lifting device comprises an oil-free air compressor, an air filter, a brushless direct current motor, an air cooler, an air-water separator, a pollution discharge electromagnetic valve, a heater, a one-way valve, an ATM dryer, an overflowing valve and a pressure switch. The air filter is arranged at the inlet end of the oil-free air compressor, and the brushless direct current motor supplies power to the oil-free air compressor. The outlet end of the oil-free air compressor is connected with an inlet of the air cooler, an outlet of the air cooler is connected with an inlet of the air-water separator, and the air-water separator is provided with the pollution discharge electromagnetic valve. The pollution discharge electromagnetic valve is provided with the heater, an outlet of the air-water separator is connected with an inlet of the ATM dryer through the one-way valve, and an outlet pipeline of the ATM dryer is connected with the overflowing valve and a pressure switch in sequence. The pressure switch and the brushless direct current motor are connected. According to the pneumatic pantograph lifting device for the tram and the pantograph lifting control method, the problems that pantograph lifting of the tram is frequent and the compresses air grade requirement is high can be effectively solved.

Owner:CRRC NANJING PUZHEN CO LTD

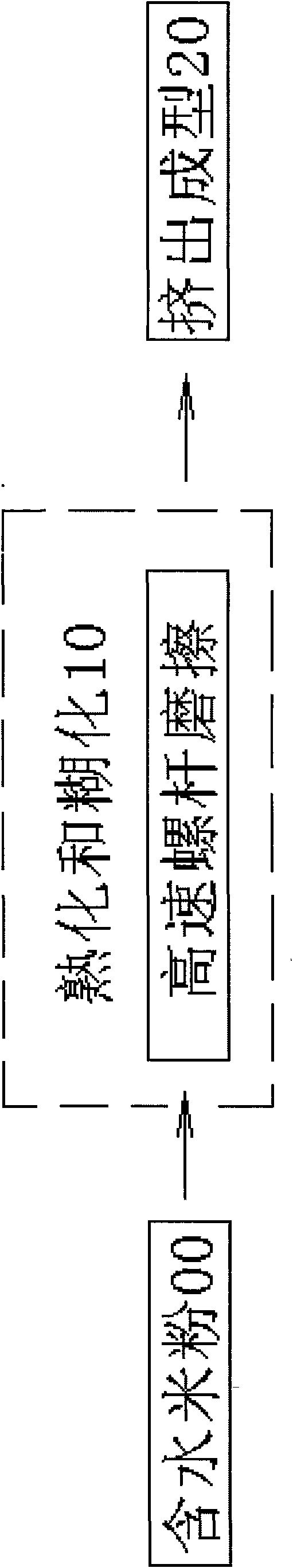

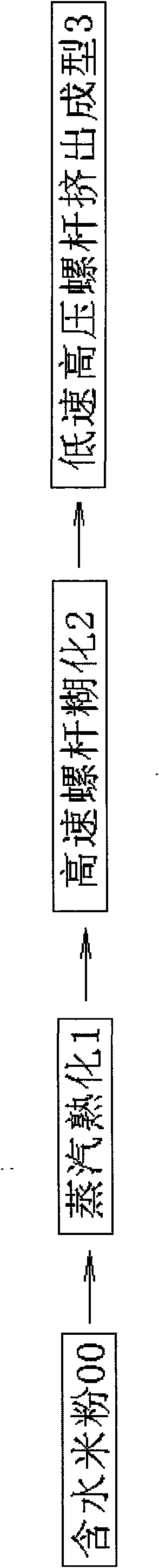

Cooking and extruding technology in instant rice noodle production

The invention relates to a cooking and extruding technology in instant rice noodle production, which belongs to the technical field of food processing. The invention aims to improve the cooking degree of rice noodles, optimize mouth feeling and save energy sources and sequentially comprises three working procedures of cooking, gelatinization and extrusion. The cooking and extruding technology is characterized in that cooking the rice noodles by a heating method; gelatinizing the cooked rice noodles by a high-speed screw rod; and finally extruding the rice noodles by a low-speed high-pressure extruder. Technical parameters of steam cooking (1) comprise the pressure of 3 kgf / cm-5 kgf / cm and the temperature of 120 DEG C-160 DEG C; parameters of high-speed screw rod gelatinization (2) comprise the rotating speed of 800 rpm-900 rpm and the time of 1 second or so; and parameters of low-speed high-pressure screw rod extrusion molding (3) comprise the rotating speed of 80 rpm-100 rpm and the pressure of 6 kgf / cm or so.

Owner:东莞市陈辉球米粉设备有限公司

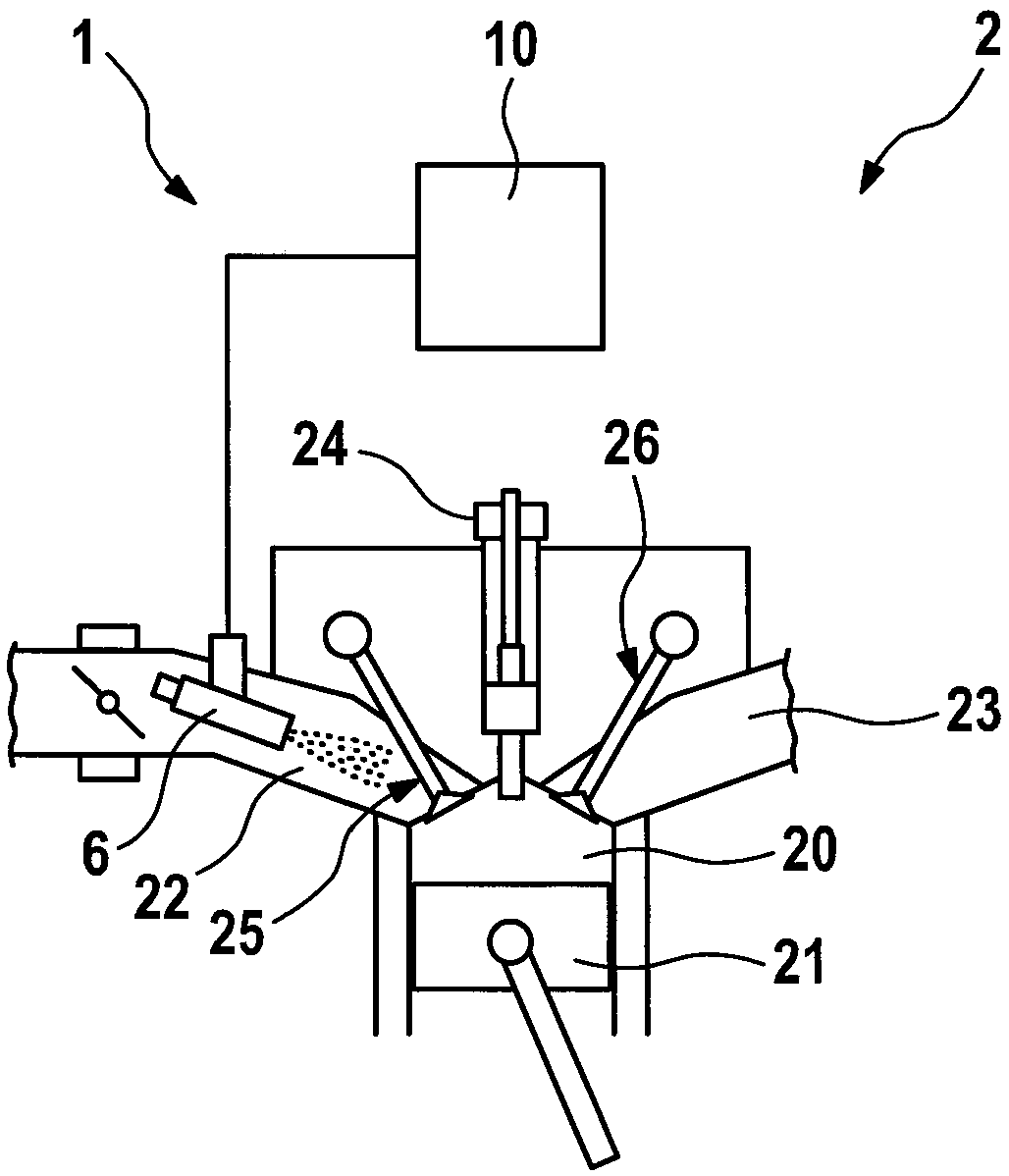

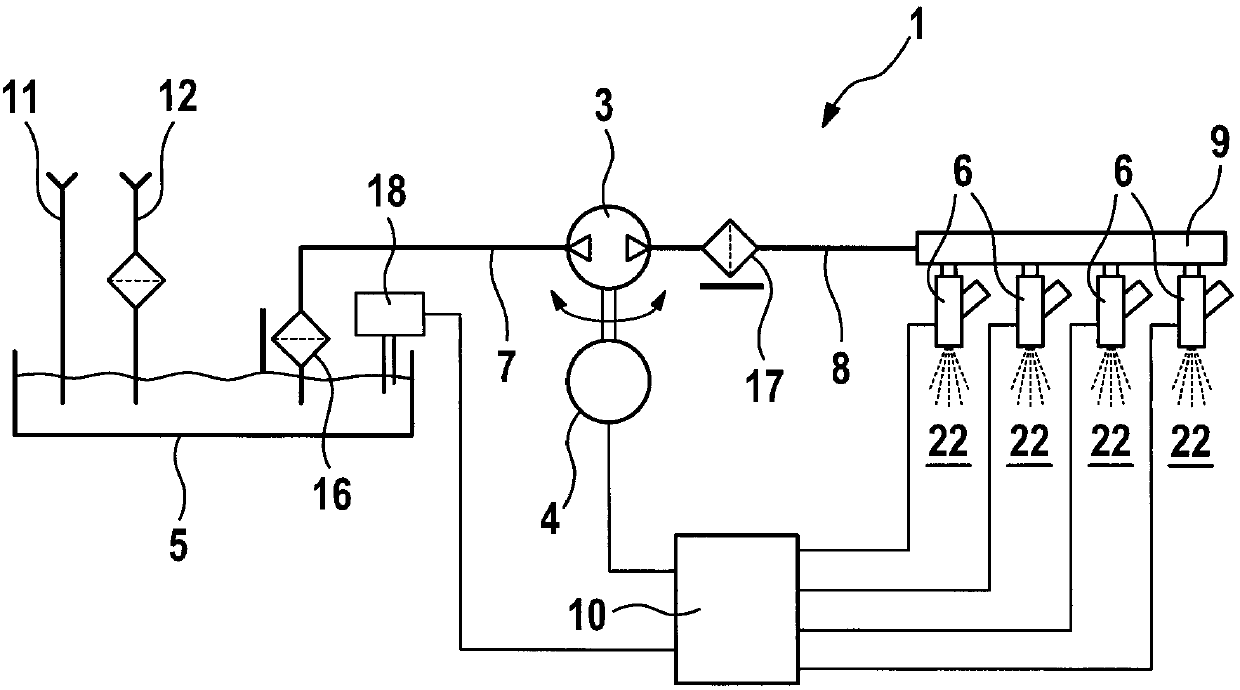

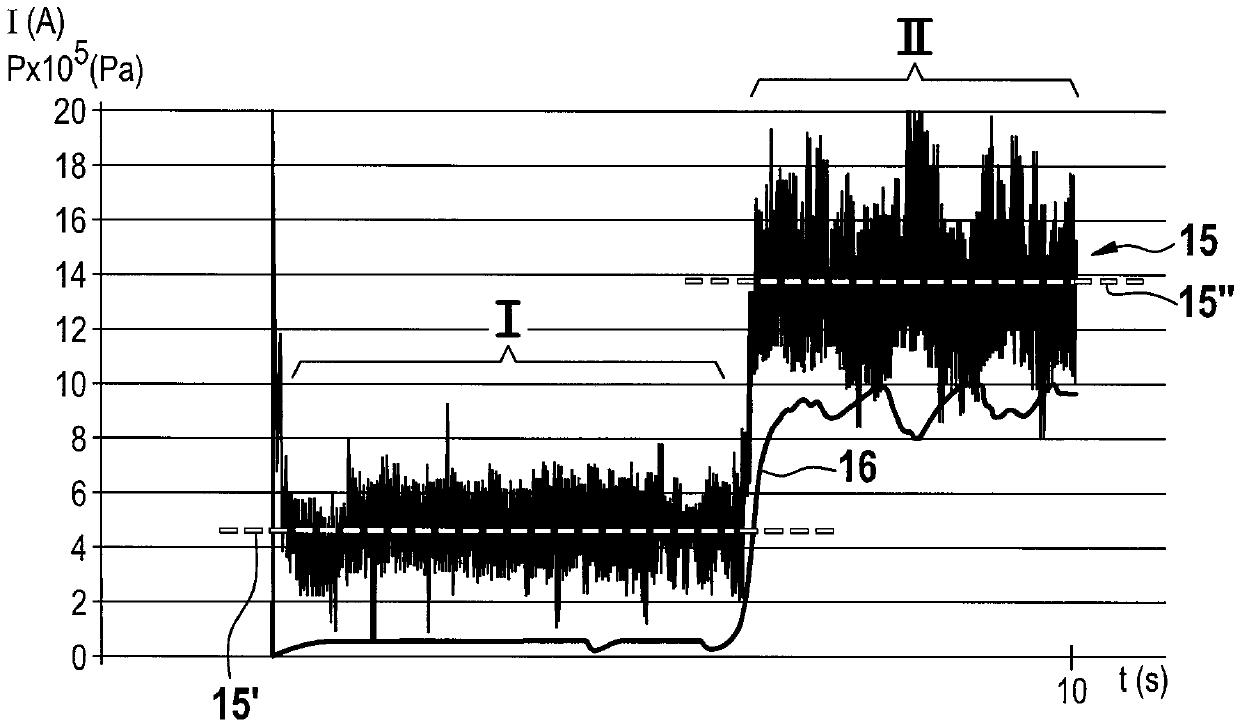

Device for injecting water of an internal combustion engine and method for operating a device of this type

ActiveCN107567539AAvoid generatingAvoid condensationElectrical controlNon-fuel substance addition to fuelSystem pressureEngineering

The present invention relates to a device for injecting water into an internal combustion engine (2), comprising: a water tank (5) for storing water; a conveying element (3) for conveying the water, wherein the conveying element (3) is connected to the water tank (5); at least one water injector (6) for injecting water, which is connected with the conveying element (5); a drive (4) for driving theconveyor element (3); and a control unit (10) which is configured to detect a power consumption of the drive (4) in order to determine a system pressure in a line region (8) between the conveying element (3) and the water injector (6). A further aspect of the present invention relates to an internal combustion engine (2) comprising a device (1) according to the invention. The invention further relates to a method for operating a device (1) according to the invention.

Owner:ROBERT BOSCH GMBH

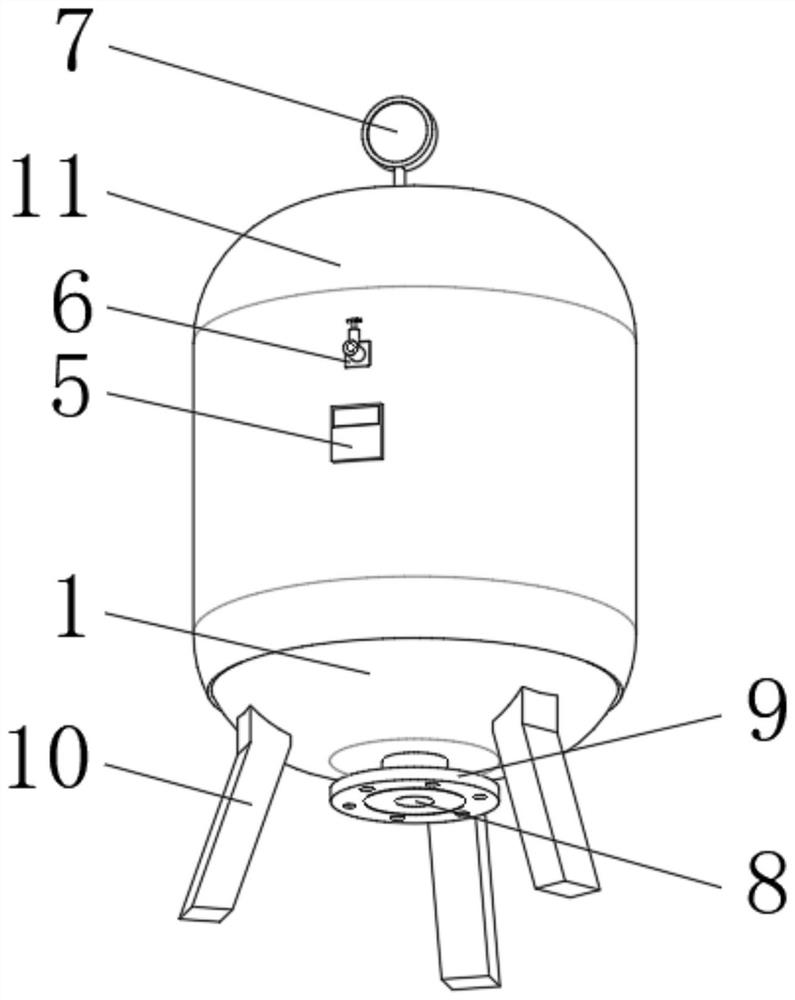

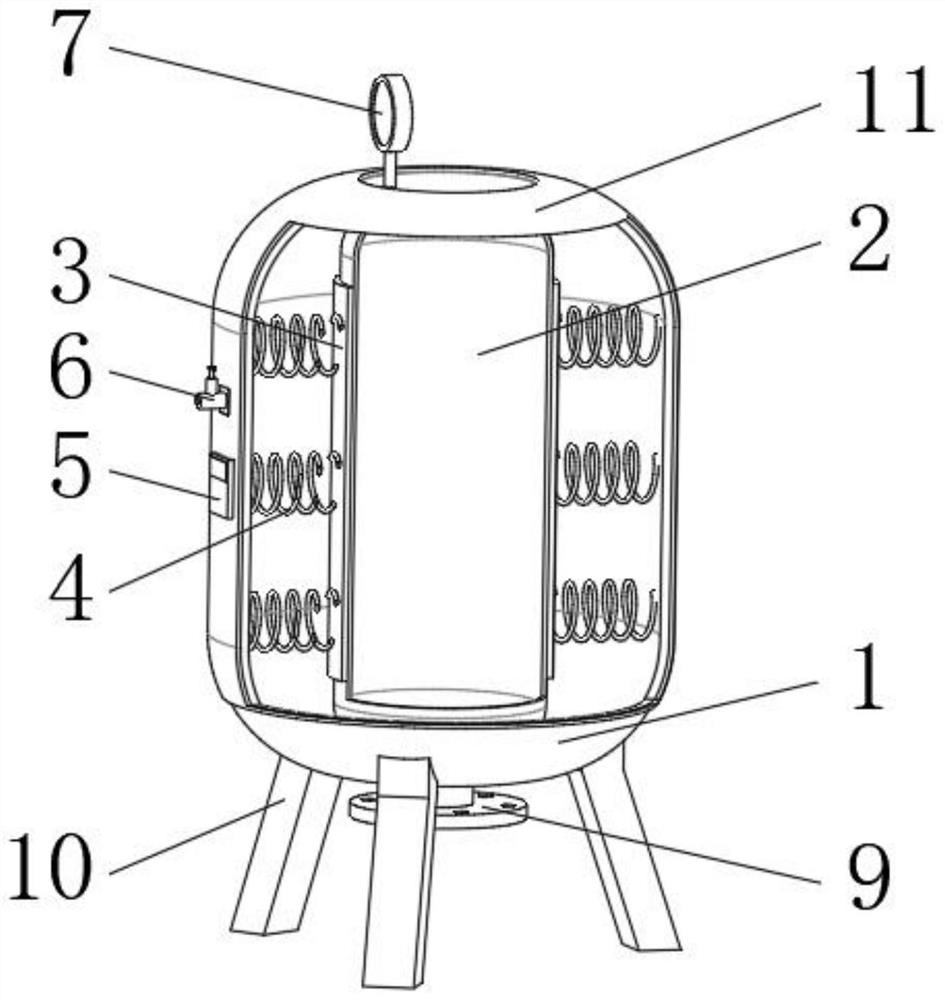

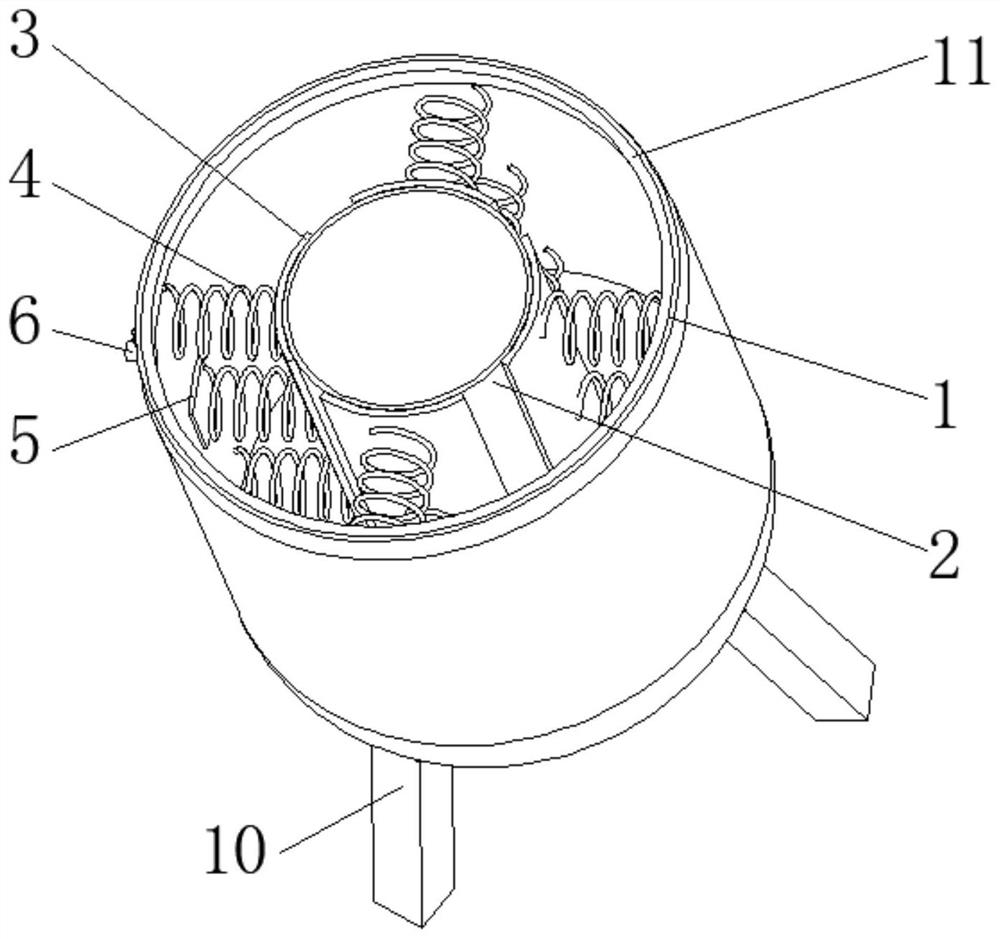

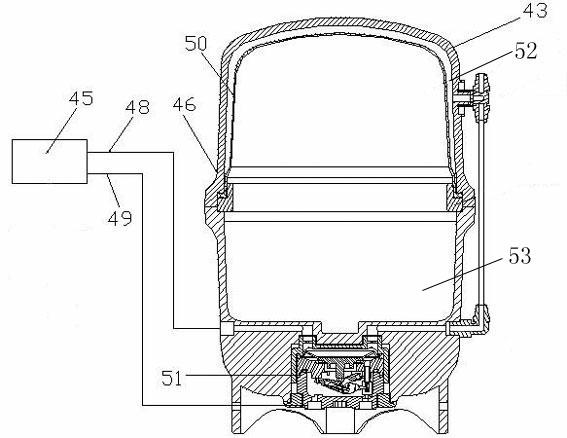

Diaphragm expansion tank for water network pressure compensation

ActiveCN112411683AQuick pressureEasy squeezeMeasurement of fluid loss/gain rateGeneral water supply conservationExpansion tankEngineering

The invention relates to the technical field of expansion tanks, in particular to a diaphragm expansion tank for water network pressure compensation. The diaphragm expansion tank comprises an expansion tank body, a gas bag is arranged in the expansion tank body, a support plate is fixedly connected to the exterior of the gas bag, and a support spring is fixedly connected to the exterior of the support plate; and a pressure sensor is arranged on the left side of the support spring, the left side of the expansion tank body is fixedly connected with a gas charging and discharging opening, and thetop of the expansion tank body is fixedly connected with a gas pressure meter. According to the diaphragm expansion tank for water network pressure compensation, the support spring is arranged outside the gas bag, the support spring is used for supporting the support plate to balance the pressure formed by expansion of the gas bag, the gas bag is extruded conveniently when the pressure of a waternetwork is reduced, water in the gas bag is conveyed into the water network, and the situation that the pressure in the water network is reduced too fast is avoided; and the problem that the water pressure cannot be compensated due to excessive gas leakage in a traditional expansion pipe is solved.

Owner:宁夏水投云澜科技股份有限公司

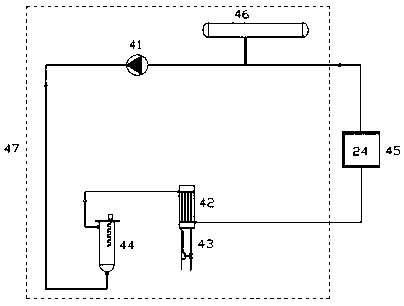

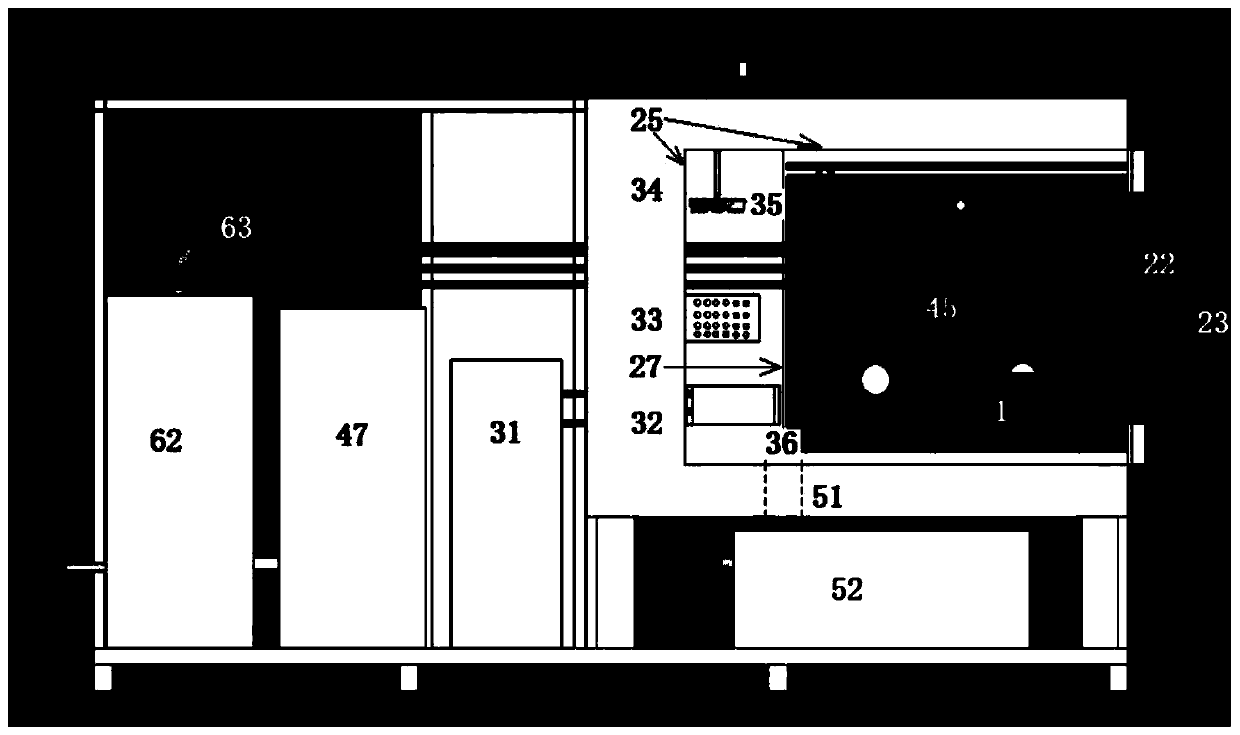

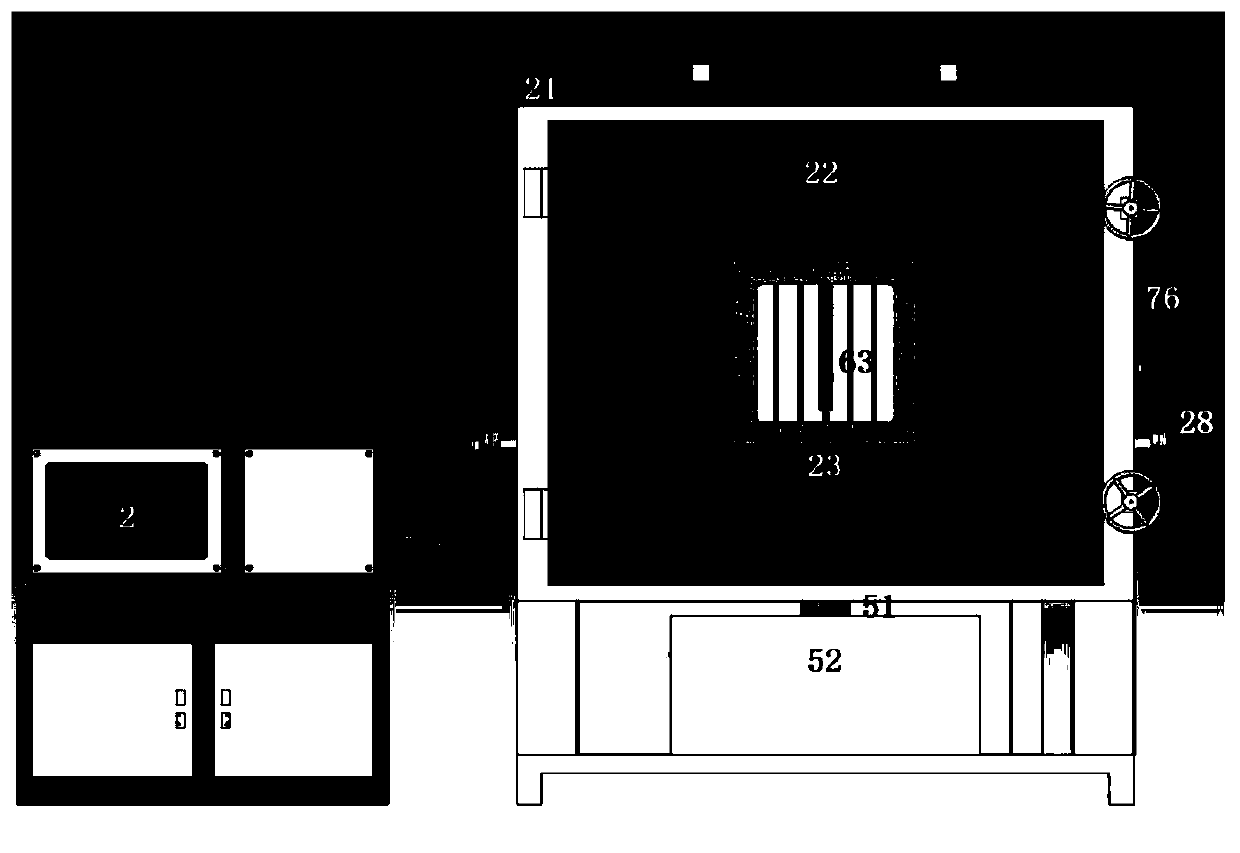

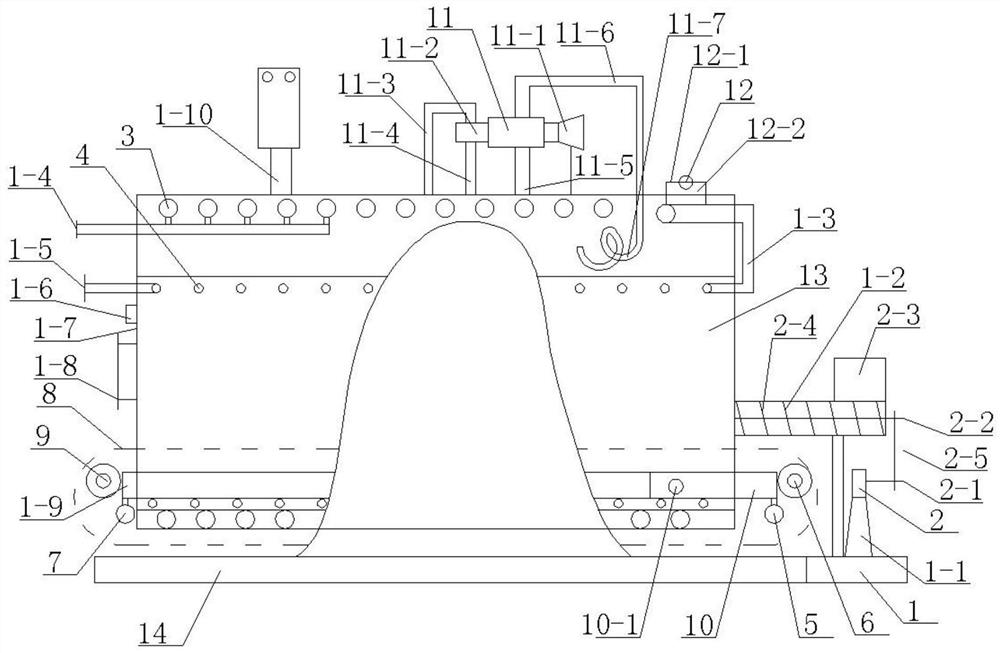

Temperature, pressure and air supply comprehensive testing device and method for aircraft electronic equipment

PendingCN110231843AQuick changeEasy to implementSimultaneous control of multiple variablesControl systemTransfer system

The invention discloses a temperature, pressure and air supply comprehensive testing device and method for aircraft electronic equipment. The device comprises: a box body, test space partition plates,a convection heat transfer system, a radiation heat transfer system, a vacuum system, an air supply system and a centralized control system, wherein the convection heat transfer system and the radiation heat transfer system cooperatively work to obtain the temperature required for the test; and when the pressure in the test space is low and the convection heat transfer system cannot exchange heatwell, the radiation heat transfer system can play the role of obtaining the required temperature. The device disclosed by the invention has the advantages that the realization is simple, the temperature of radiant panels can be rapidly changed and the temperature and the pressure can be simultaneously rapidly changed by cooperating with the convection heat transfer system and the vacuum system; and the sub-systems cooperatively work to ensure that the comprehensive testing requirements of temperature / pressure / air supply can be met and especially, the requirements for temperature changing andstabilizing can be met.

Owner:BEIJING REAL TEMP TECH CO LTD

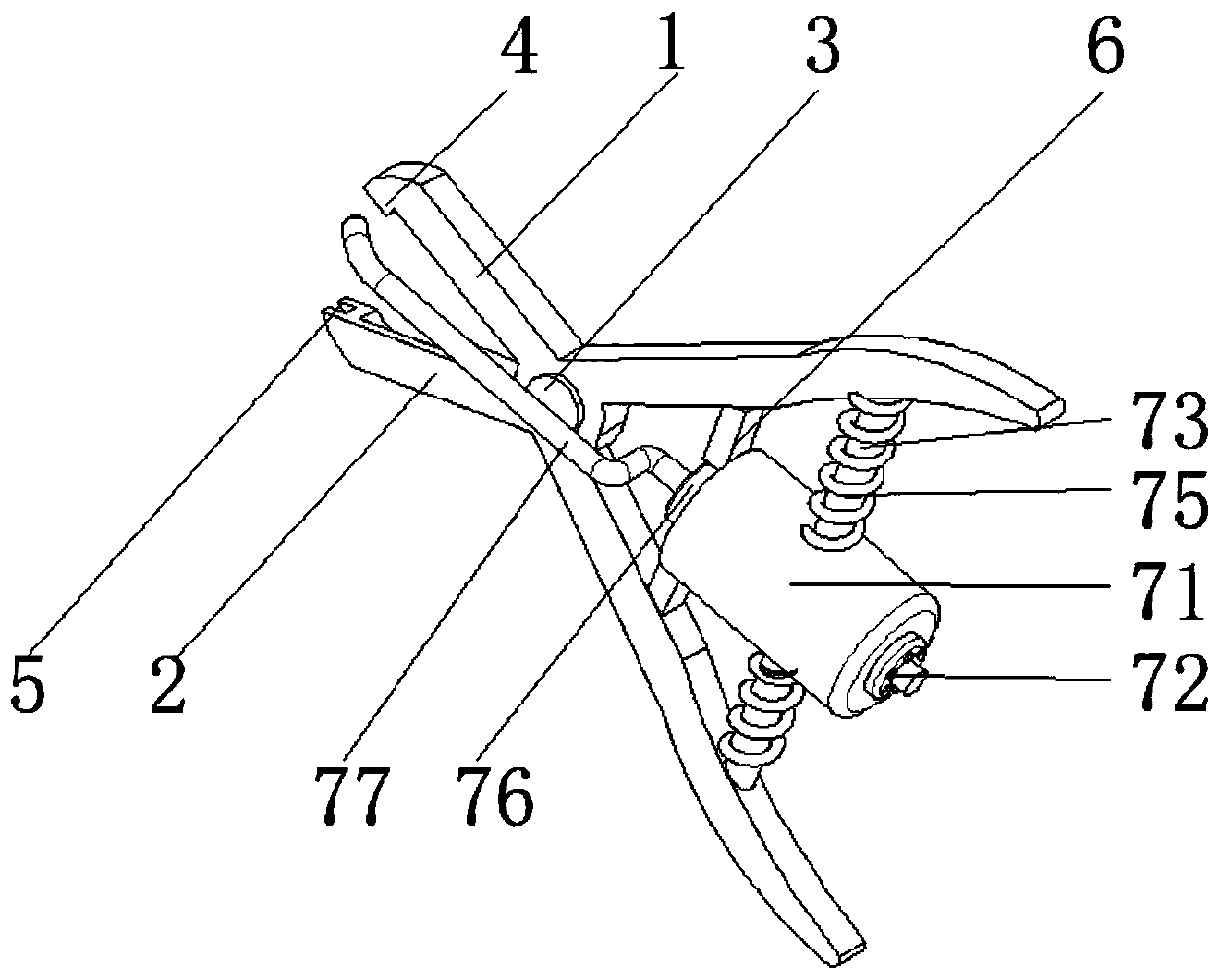

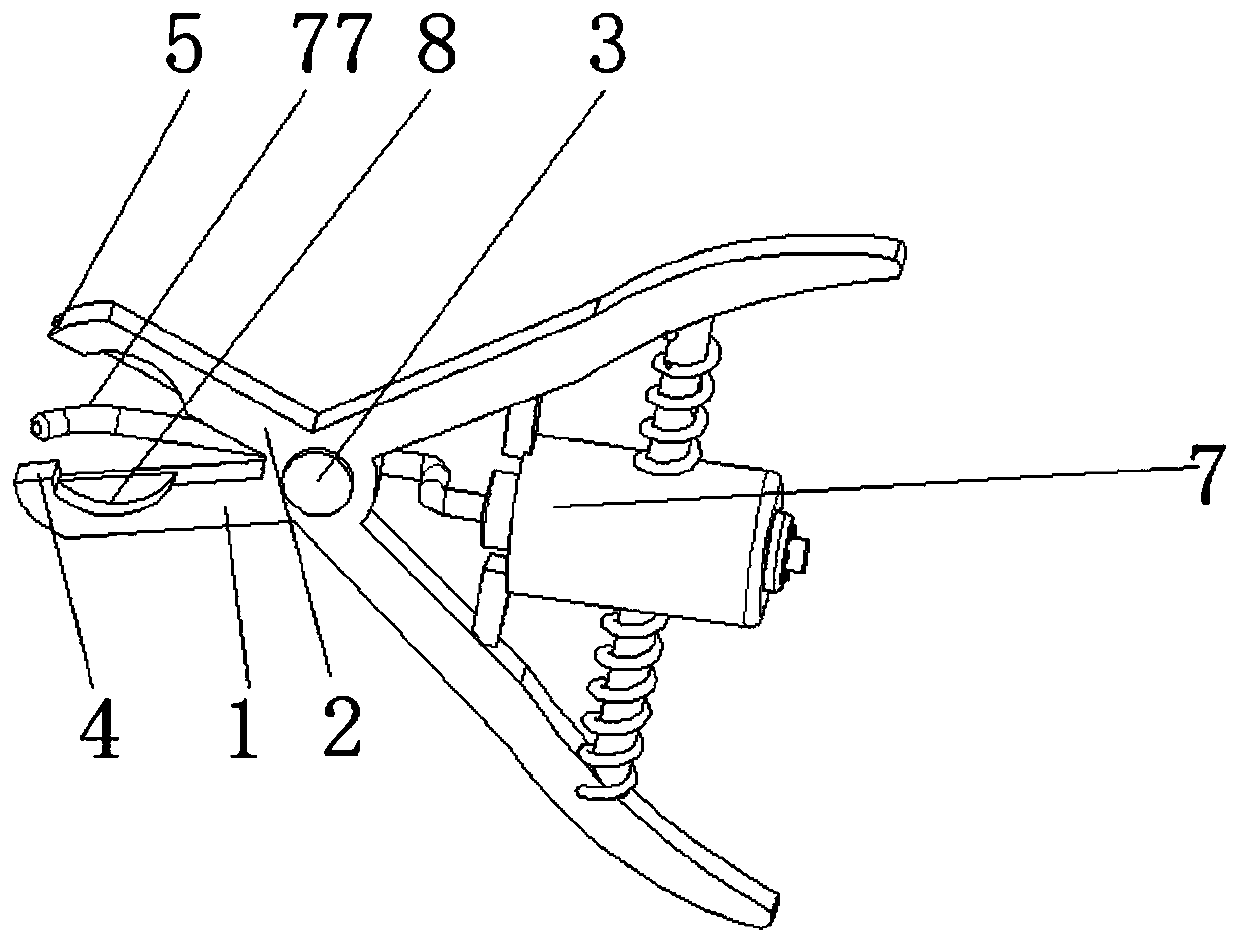

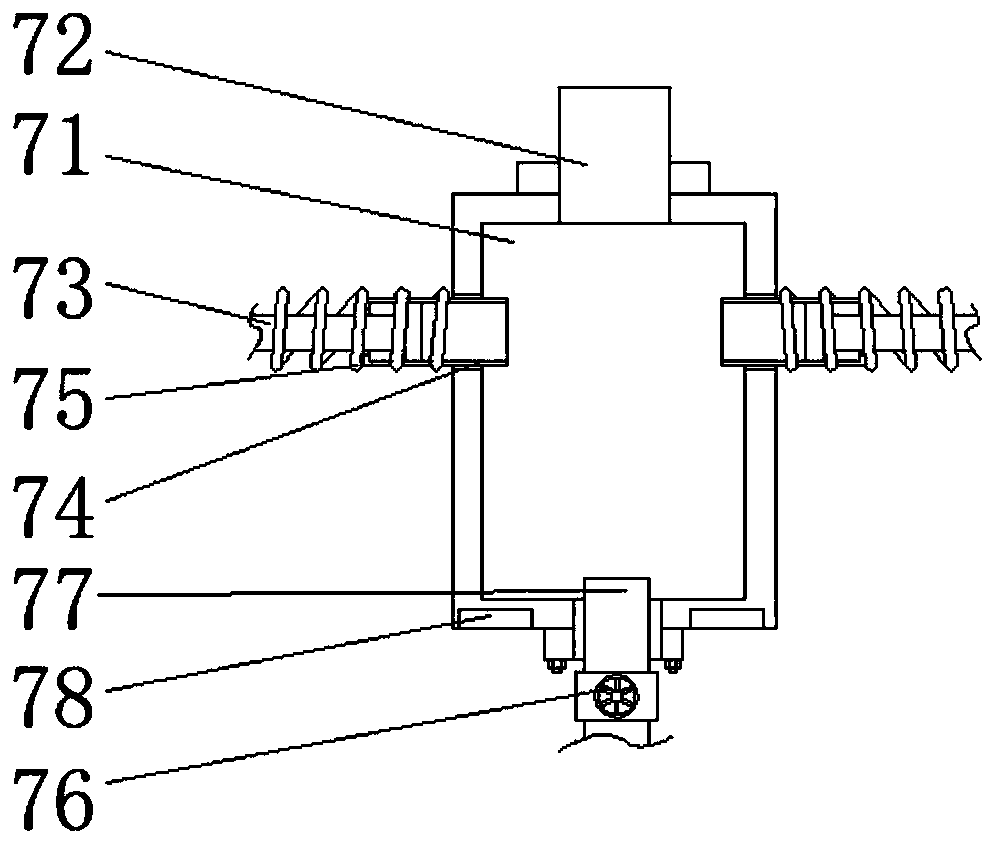

Non-invasive and quick removal forceps for tooth surface attachments

InactiveCN110916833AImprove practicalityReduce difficultyDental toolsTooth rinsingBleeding gumForceps

The invention provides a non-invasive and quick removal forceps for tooth surface attachments, and relates to the technical field of removal forceps. The removal forceps comprises a No.1 tailoring body and a No.2 tailoring body, wherein the No.1 tailoring body and the No.2 tailoring body are rotationally connected through a shaft rod, the outer surface of one end of the No.1 tailoring body is fixedly equipped with a buffer structure, the outer surface of one end of the No.2 tailoring body is provided with a notch edge, a sliding plate is fixedly installed between the opposite sides of the No.1tailoring body and the No.2 tailoring body, the top of the sliding plate is fixedly equipped with a hydraulic flushing structure, and the front surfaces of the No.1 tailoring body and the No.2 tailoring body are provided with auxiliary tailoring edges. The removal forceps achieves that the effects of rinsing while removing tartars can be met through performing operations with one hand, the difficulty of operations is reduced, one hand of a dentist is freed to be capable of coping with emergencies and some auxiliary operations, the practicability of the removal forceps is improved, rapid buffering can be performed, and the teeth are prevent from being compressed to cause bleeding gums.

Owner:张光中

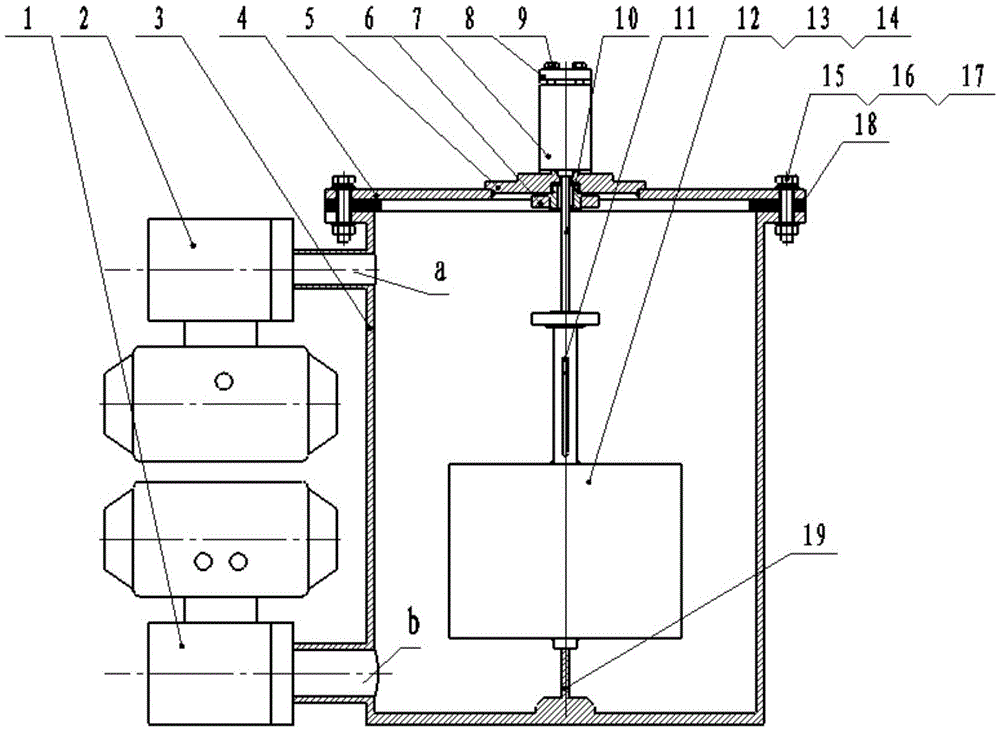

Two-phase pressure-less container combustion water gas steam engine

InactiveCN111649311ARapid temperatureEnergy savingSteam generation using pressureBoiler controlFlueSteam engine

The invention provides a two-phase pressure-less container combustion water gas steam engine, which comprises a base, wherein an oil cylinder body is installed on the base, a manhole is formed in oneside of the oil cylinder body, the manhole communicates with the oil cylinder body, a flue port is formed in one side of the oil cylinder body, the flue port communicates with the oil cylinder body, an oil-gas mixing box is installed on the oil cylinder body, the oil-gas mixing box communicates with the oil cylinder body, and a compression inlet pipe is installed at the top of the oil cylinder body; with a reasonable design, the two-phase pressure-less container combustion water gas steam engine can solve the problems of not controlling and regulating steam pressure and temperature for a longtime, not dry-firing a boiler, not relieving the boiler pressure quickly and low thermal efficiency, and the steam engine has low energy consumption, high thermal rate, less water consumption, quick gas production, controllable and regulating temperature and pressure, high intelligent control, safety and coal gasification integrated combustion steam, so the gap in national defense is filled.

Owner:武汉翊能科技有限公司 +2

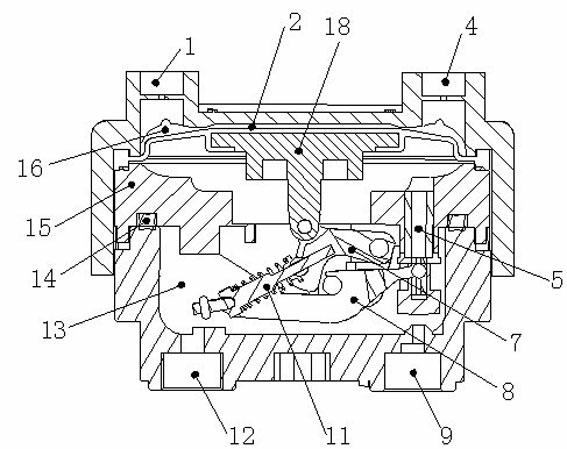

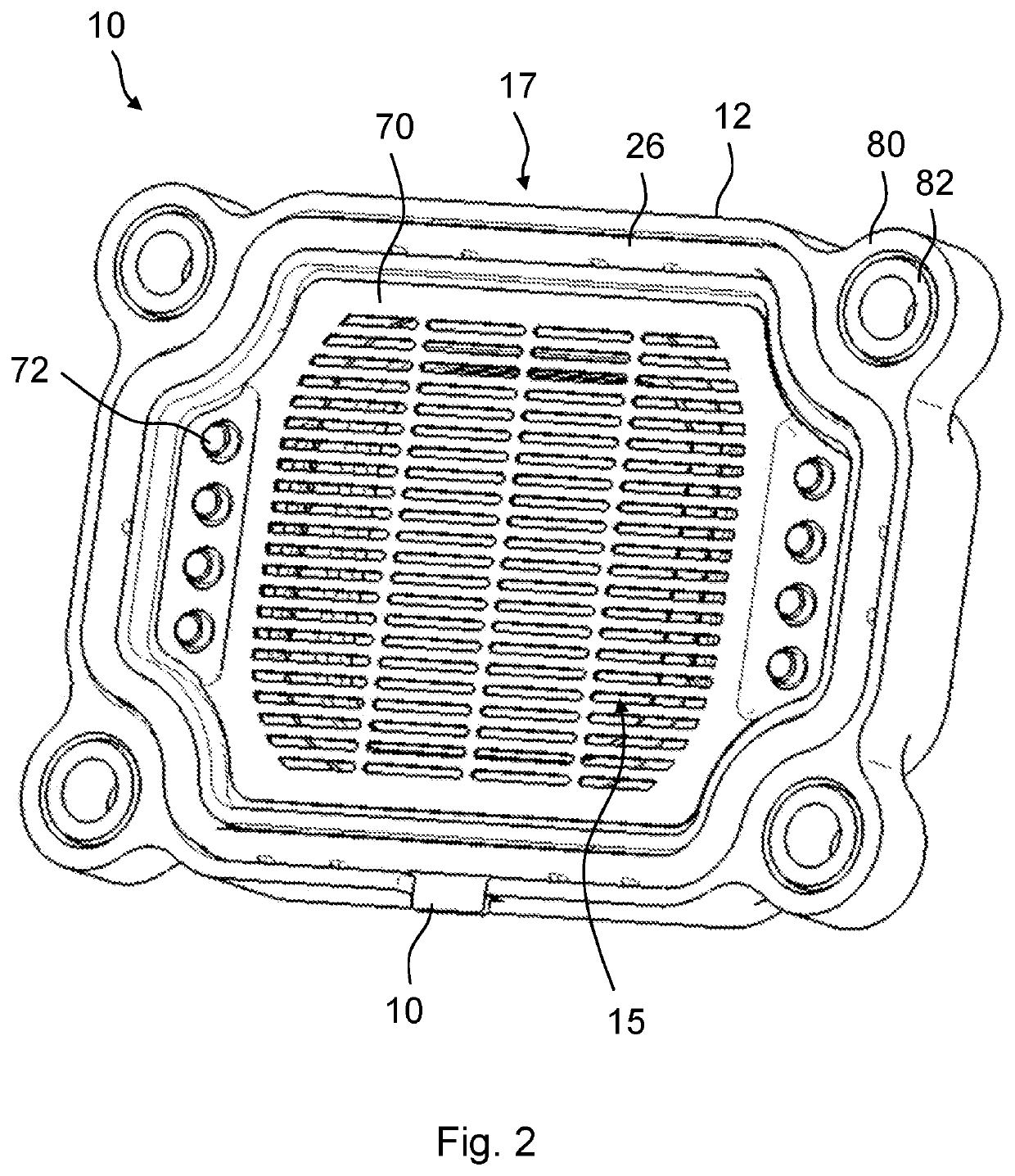

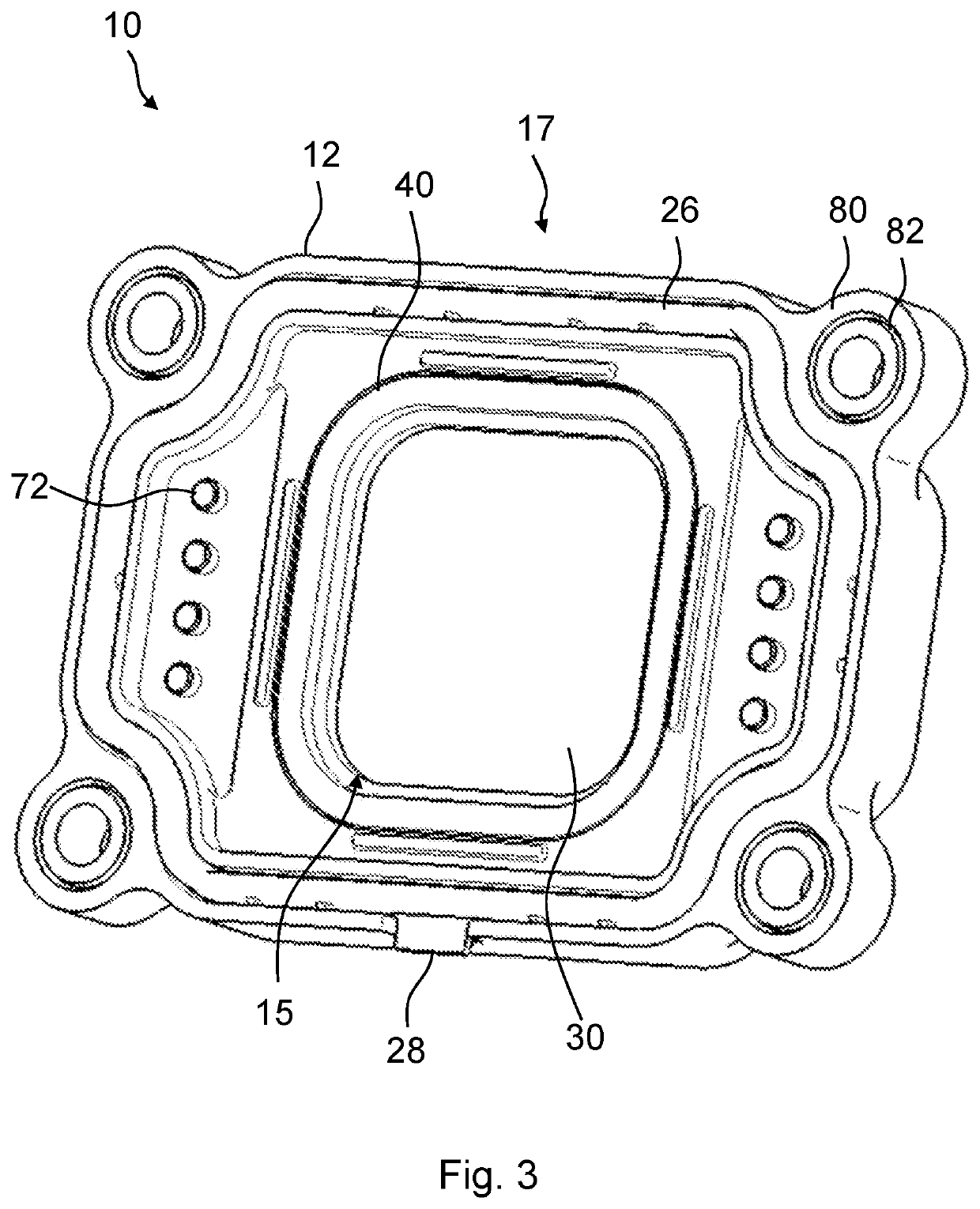

Stamp-pad ink sponge assembly as well as seal assembly and stamping machine applying stamp-pad ink sponge assembly

The invention discloses a stamp-pad ink sponge assembly as well as a seal assembly and a stamping machine applying the stamp-pad ink sponge assembly. The stamp-pad ink sponge assembly is used on the sealing machine and comprises a cavity, stamp-pad ink sponge, and a stamp-pad ink supplementary assembly for supplementing stamp-pad ink for the stamp-pad ink sponge in the cavity; the stamp-pad ink sponge is supported on the cavity; the stamp-pad ink supplementary assembly comprises a hose for conveying stamp-pad ink; the hose is provided with an output pipe section in the cavity; a stamp-pad inkchannel for conveying stamp-pad ink in the output pipe section has a critical pressure; at least one pore channel is arranged on the output pipe section, communicates with the stamp-pad ink channel, is in a closed state when the pressure in the stamp-pad ink channel is smaller than the critical pressure, and is in an opening state when the pressure in the stamp-pad ink channel is equal to or greater than the critical pressure to supplement stamp-pad ink for the stamp-pad ink sponge. The stamp-pad ink sponge assembly can uniformly add stamp-pad ink for the stamp-pad ink sponge to enable the stamping machine to stamp clearly and uniformly.

Owner:CHANGZHOU HANS & WILSON ELECTRONICS TECH

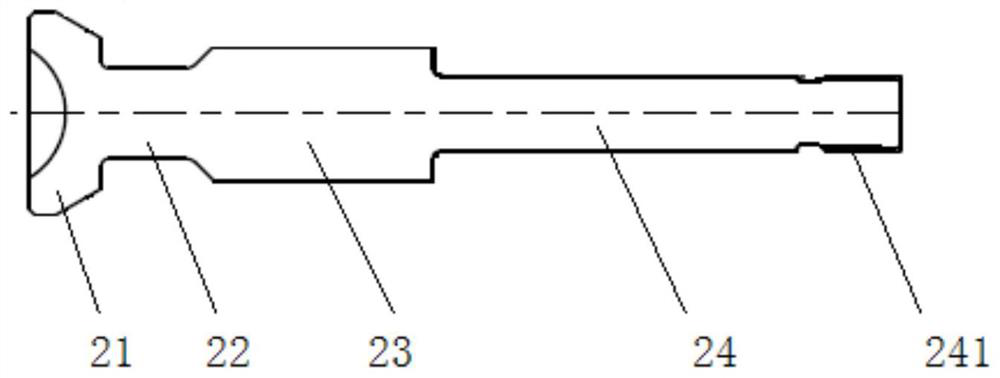

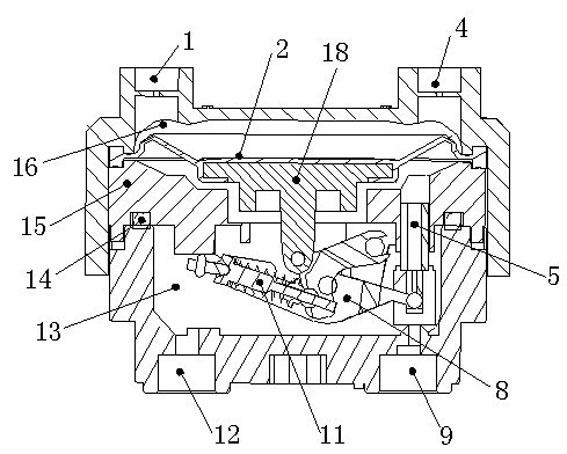

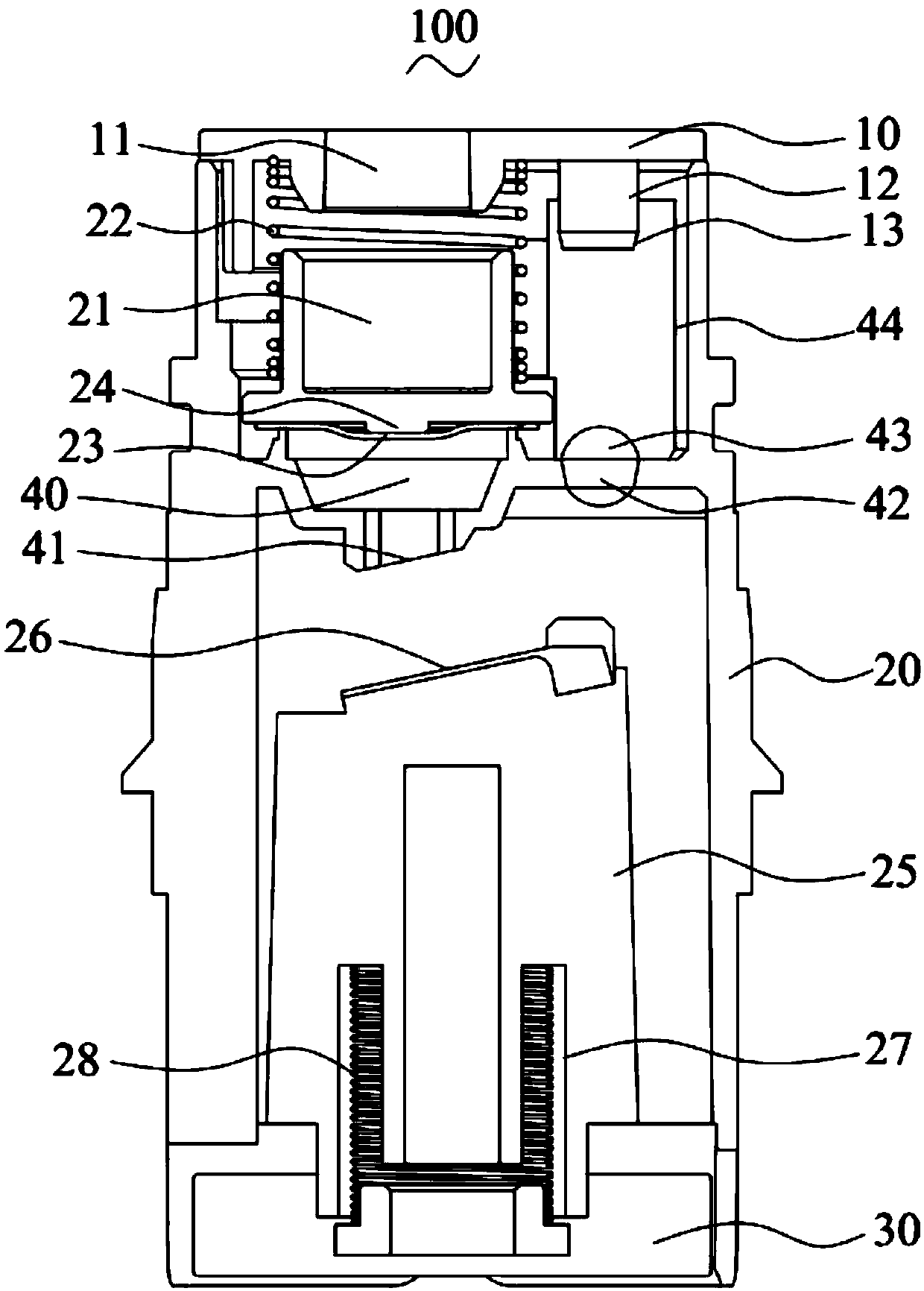

Small integrated high-pressure pneumatic control valve

ActiveCN112377650ASimple structureLight structureEqualizing valvesSafety valvesEngineeringControl valves

The invention provides a small integrated high-pressure pneumatic control valve, and solves the problems that an existing pneumatic control stop valve is relatively complex in structure and difficultto adapt to a large-vibration-force environment. The small integrated high-pressure pneumatic control valve comprises a shell, a valve element, a spring, a spring seat and a sealing assembly; an inletflow channel, a medium channel, a mounting cavity, a spring cavity and a control cavity which are sequentially communicated are formed in the shell; an outlet flow channel communicated with the medium channel is formed in the side wall of the shell; the valve core comprises a first blocking section, a second blocking section, a third blocking section and a fourth blocking section which are coaxially arranged in sequence; the first blocking section is located at the joint between the inlet flow channel and the medium channel; the second blocking section is arranged in the medium channel; the third blocking section is arranged in the mounting cavity, and a sealing assembly is arranged between the third blocking section and the mounting cavity; the fourth blocking section is arranged in thespring cavity, and an external thread is arranged at one end close to the control cavity; a small end of the spring seat is provided with a threaded hole connected with the fourth blocking section, and the outer circular surface of a large end is axially provided with a plurality of notches which are uniformly distributed along the circumference; an annular limiting boss is arranged on the springcavity; and the spring sleeves the fourth blocking section.

Owner:XIAN AEROSPACE PROPULSION INST

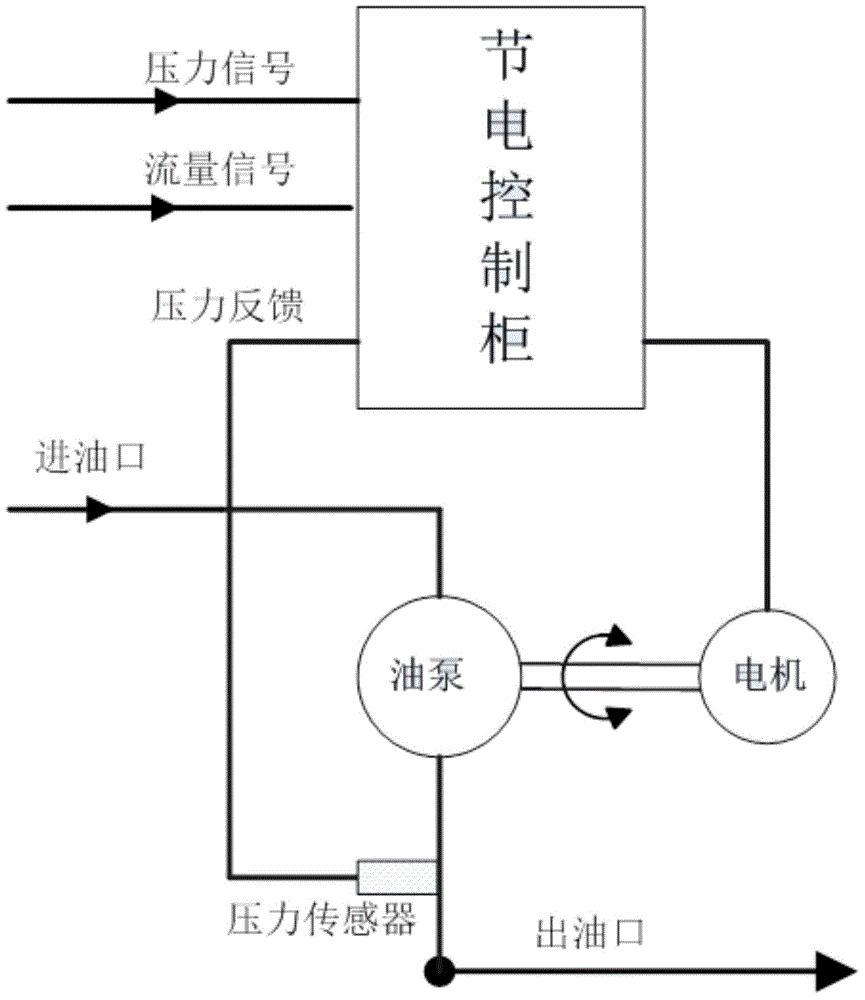

Energy-saving control system used for photovoltaic electric generator

The invention provides an energy-saving control system, used for a photovoltaic electric generator, capable of reducing energy consumption of a die-casting machine. The energy-saving control system comprises an electricity-saving control cabinet capable of collecting pressure and flow of the die-casting machine. The electricity-saving control cabinet is connected with a motor. The motor drives an oil pump. A pressure sensor is arranged at an oil outlet of the oil pump and connected with the electricity-saving control cabinet. According to the energy-saving control system used for the photovoltaic electric generator, the pressure and flow of a system is detected and fed back constantly, the rotational speed and torque of the synchronous motor are changed in time through an energy-saving controller, corresponding adjustment is made on the pressure and flow, finally, the pressure of the system is kept fast, accurate and stable, and set pressure and flow are reached. The overflow quantity of the die-casting machine is controlled to be minimum, so that the production needs of the die-casting machine is met, the energy-saving purpose is achieved, and the effect that how much is needed, how much is supplied is achieved.

Owner:HUANGSHI YIMU INFORMATION TECH

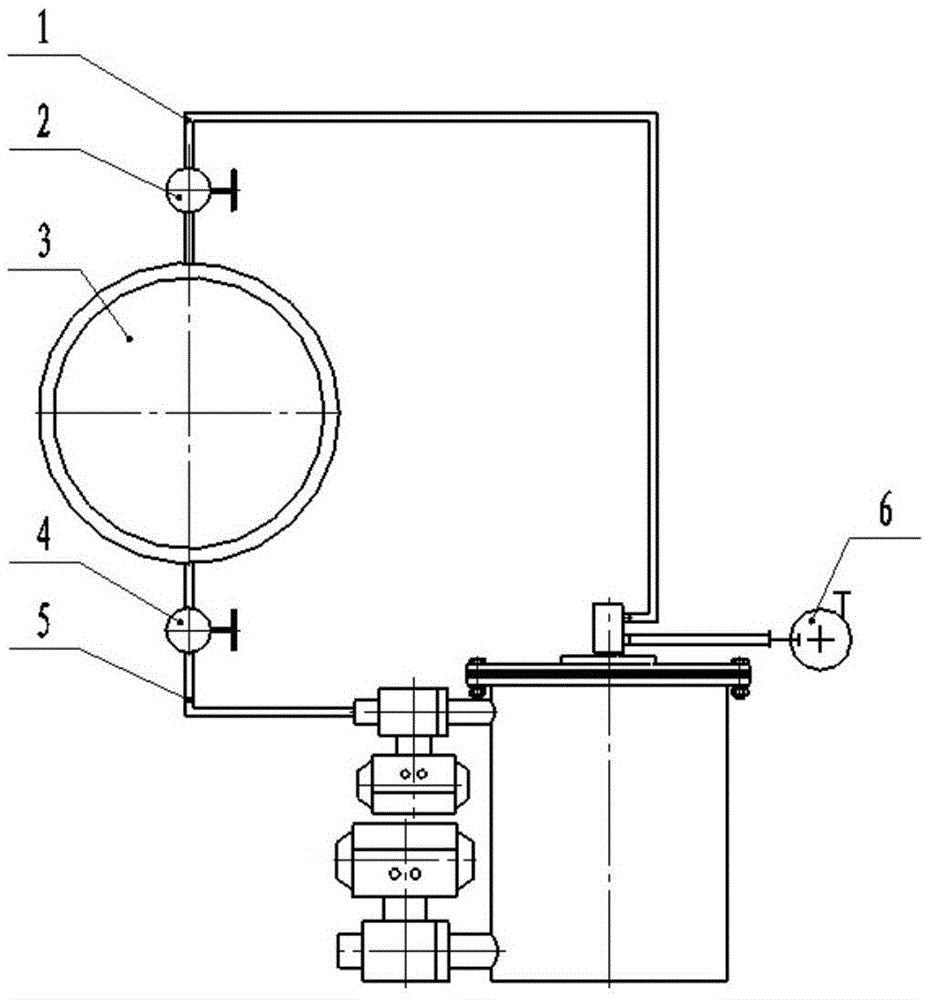

Reverse osmosis (RO) automatic pressurization device and RO automatic pressurization water storage tank

ActiveCN102616889ASmooth entryQuick pressureWater/sewage treatment bu osmosis/dialysisWater storageDifferential pressure

The invention relates to pressurization devices and water storage tanks, specifically to an RO automatic pressurization device and an RO automatic pressurization water storage tank. The RO automatic pressurization device is connected to the back of an RO permeator, and internally consists of a pure water chamber and a waste water chamber separated by an elastic diaphragm. The pure water chamber is equipped with an upper water inlet and an upper water outlet, while the waste water chamber is provided with a lower water inlet and a lower water outlet, and the inside of the waste water chamber is provided with a time-delay switch mechanism. The lower water outlet is equipped with a valve plug controlled by the time-delay switch mechanism. The lower surface of the elastic diaphragm is provided with a diaphragm handle, which drives the time-delay switch mechanism, and the elastic diaphragm moves under the pushing of differential pressure inside the waste water chamber and the pure water chamber. The RO automatic pressurization water storage tank is connected to the back of the RO automatic pressurization device, and is internally provided with an air bag, which divides the water storage tank into a water storage chamber and a pressure chamber precharged with a gas. The pure water in the RO permeator enters the water storage chamber after pressurization by the RO automatic pressurization device. The RO automatic pressurization device of the invention increases the feed water pressure of the RO automatic pressurization water storage tank, has a great water-making amount, and saves water resources.

Owner:聂九鹏

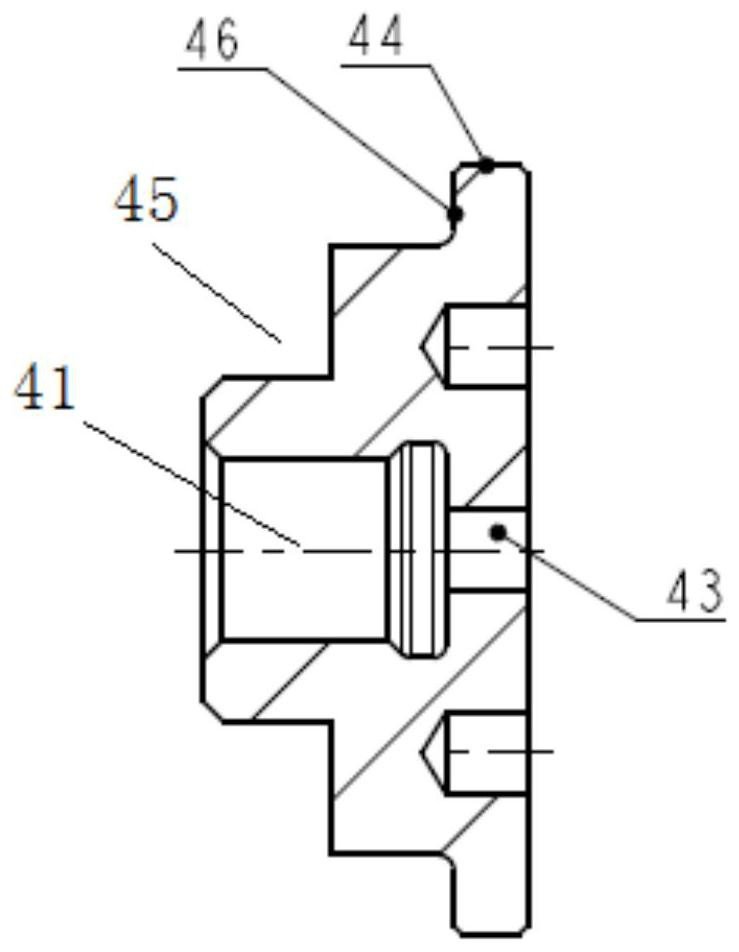

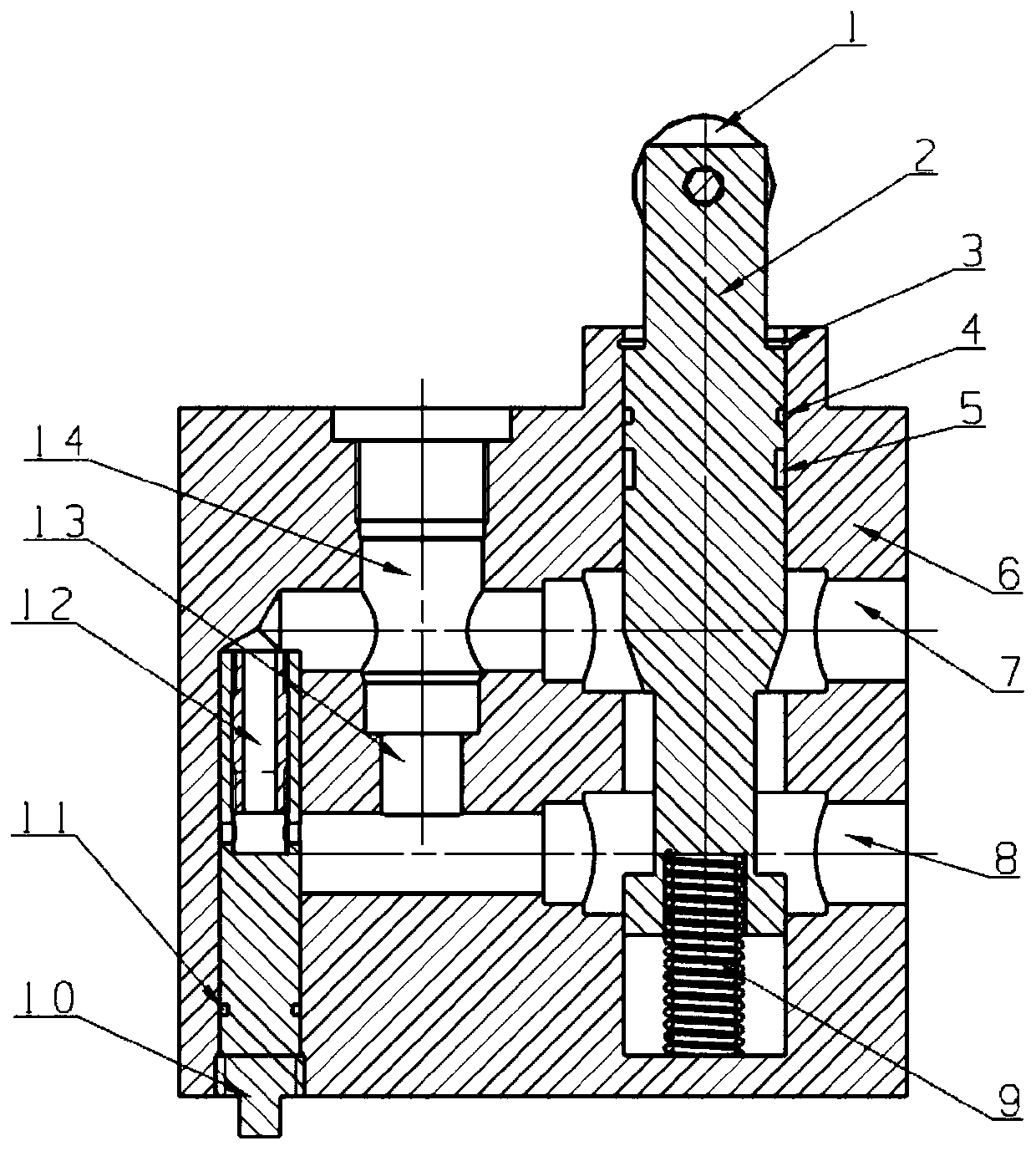

Mechanical throttling governing valve with adjustable damping hole

ActiveCN110821907ABuild up pressure quicklyAccurate pressureServomotor componentsHydraulic ramEngineering

The invention relates to a mechanical throttling governing valve with an adjustable damping hole and belongs to the technical field of hydraulic system control. The mechanical throttling governing valve with the adjustable damping hole is designed and can be used for throttling deceleration of the stroke tail end of a hydraulic executing element, pressure control is accurate, fast pressure establishment and fast deceleration of a hydraulic system are achieved, and the tail end speed of the hydraulic executing element can be accurately adjusted. The mechanical throttling governing valve can beused for throttling governing of hydraulic executing element such as a hydraulic oil cylinder. The mechanical throttling governing valve has the beneficial effects of being compact in structure, highin control precision, easy to achieve, high in operability, safe, stable and the like.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

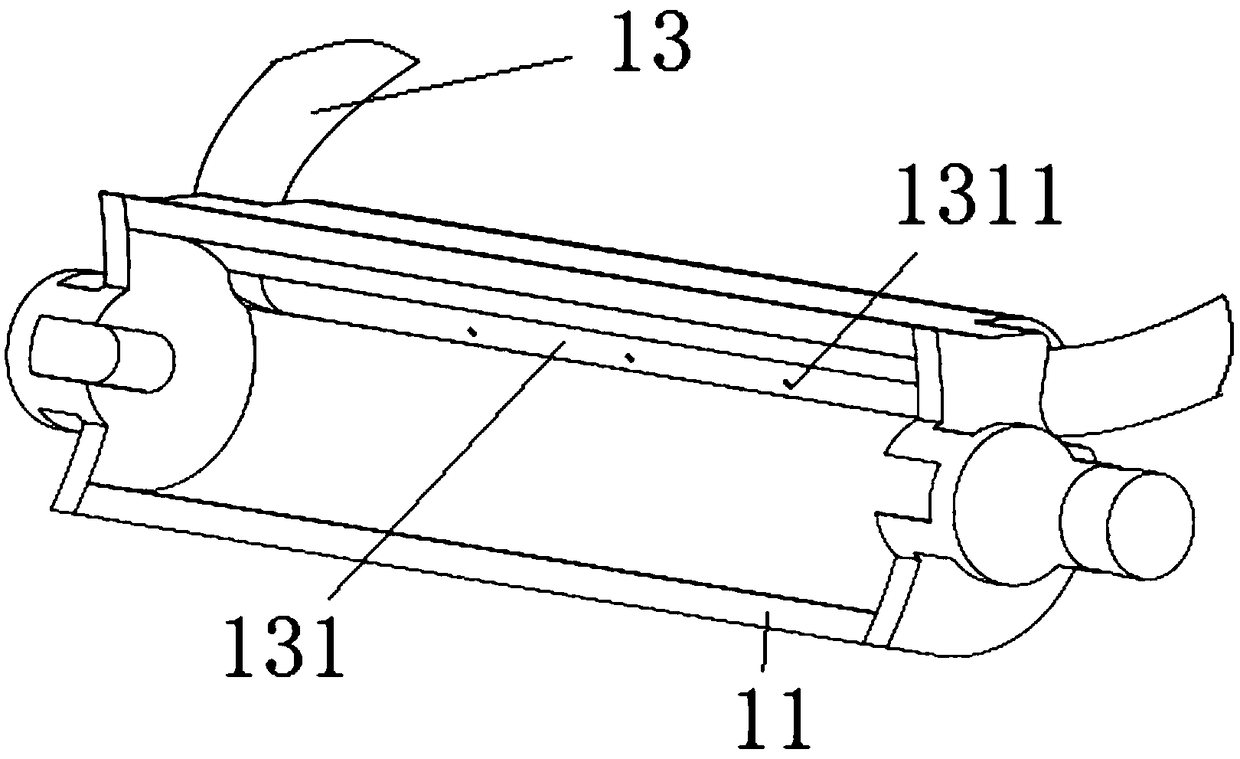

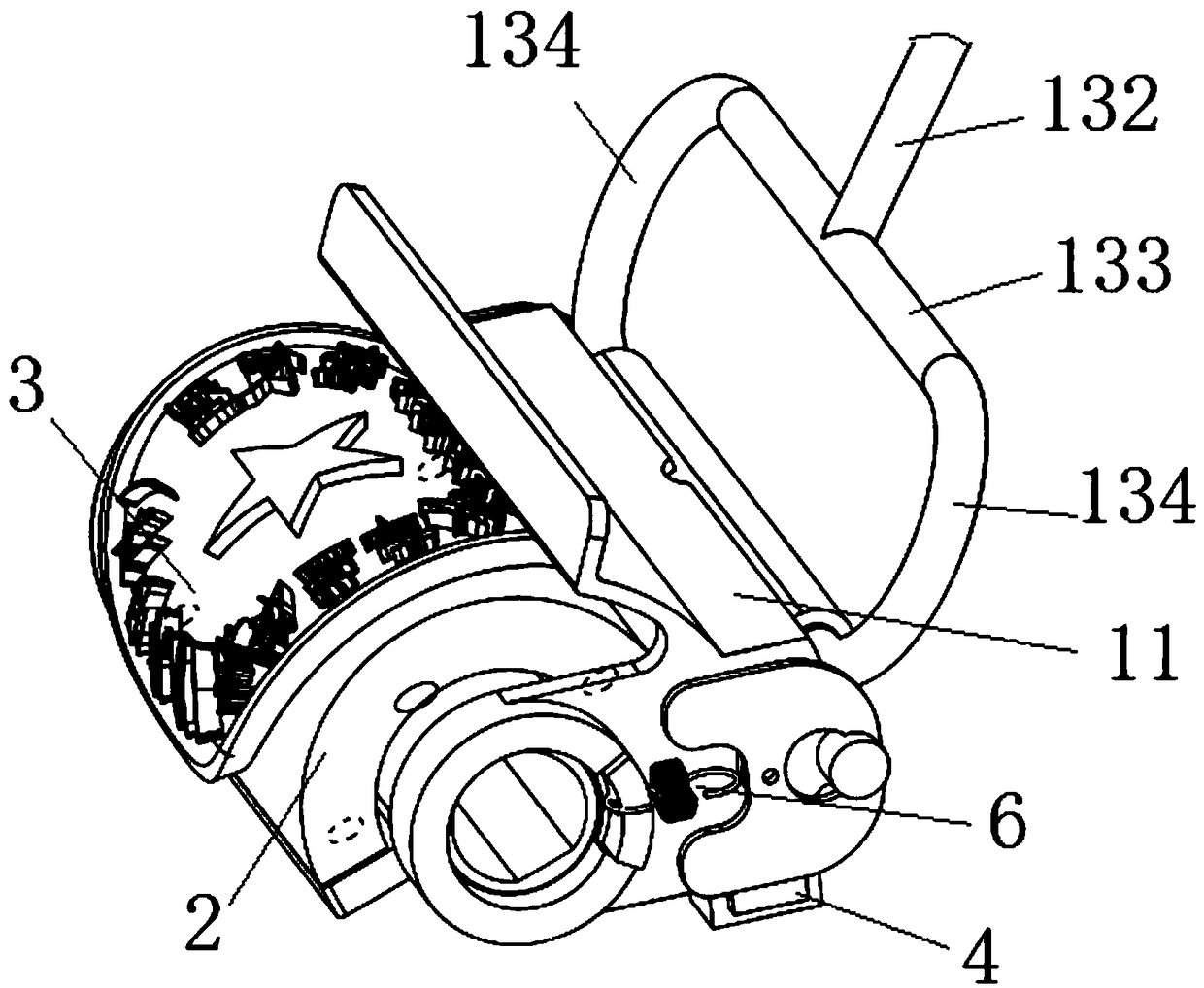

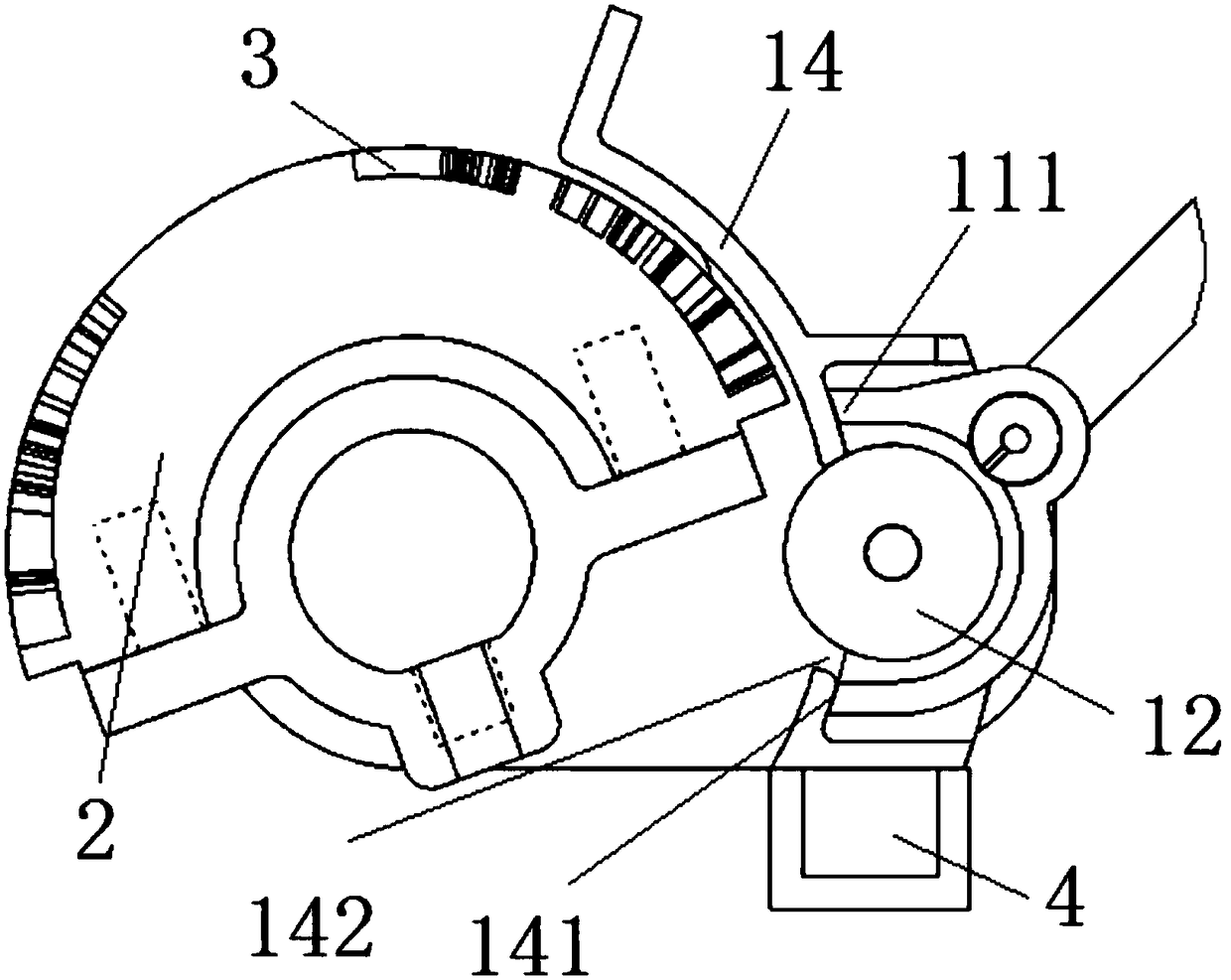

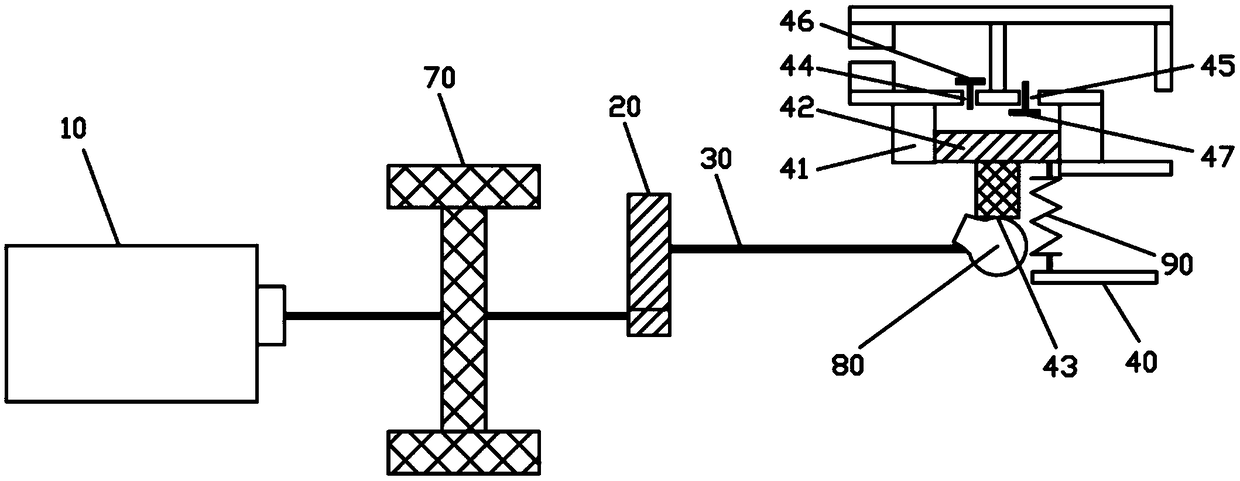

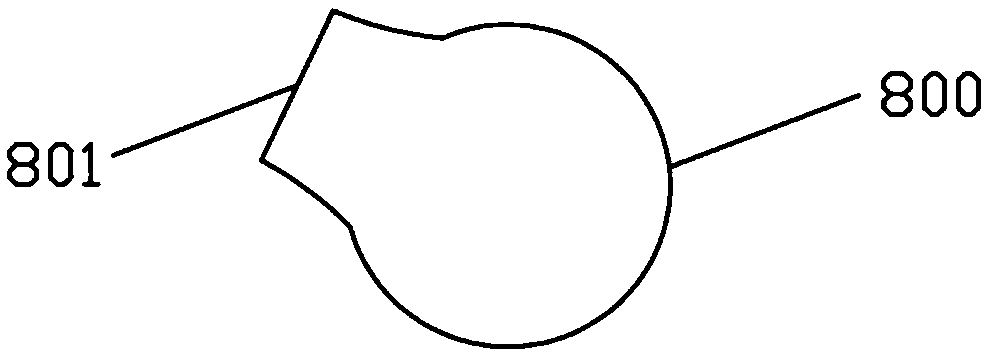

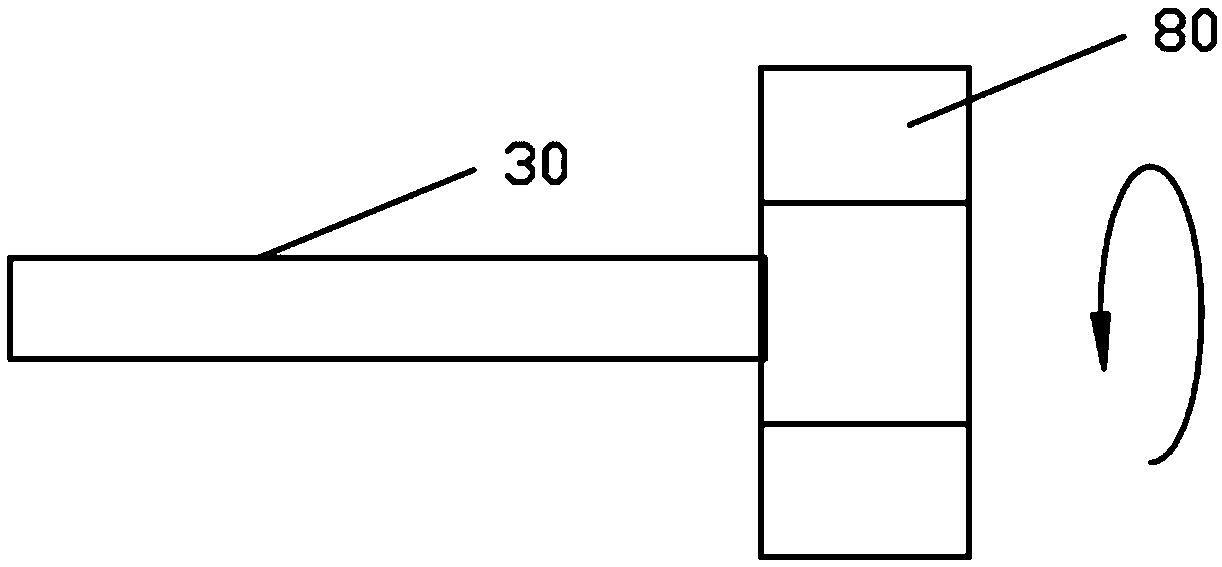

Electric water pump with improved transmission mechanism, and water gun structure

InactiveCN108869228AIncrease output water pressureHigh speed impactPositive displacement pump componentsPumpsEngineeringCam

The invention relates to the technical field of liquid pumps, in particular to an electric water pump with an improved transmission mechanism. The electric water pump comprises a motor, a gear set, atransmission mechanism and a piston mechanism; the output shaft of the motor is connected to the transmission mechanism through the gear set, and the transmission mechanism corresponds to the piston mechanism; the piston mechanism comprises a piston cylinder which is provided with a water outlet and a water inlet, and the water outlet and the water inlet are each provided with a valve; the pistoncylinder is internally provided with a piston body connected to a piston rod, and the transmission mechanism is used for driving the piston body to move upwards through the piston rod; the piston bodyis provided with a reset mechanism, and the transmission mechanism is provided with a peach-shaped cam corresponding to the bottom of the piston rod; and the peach-shaped cam is provided with a ringpart and a boss part, and driven by the transmission mechanism to rotate. According to the electric water pump, the transmission mechanism of the electric water pump is provided with the peach-shapedcam, and the ring part of the peach-shaped cam is driven by the transmission mechanism to rotate for energy storage, and the output water pressure of the electric water pump is increased.

Owner:佛山安豪科技服务有限公司

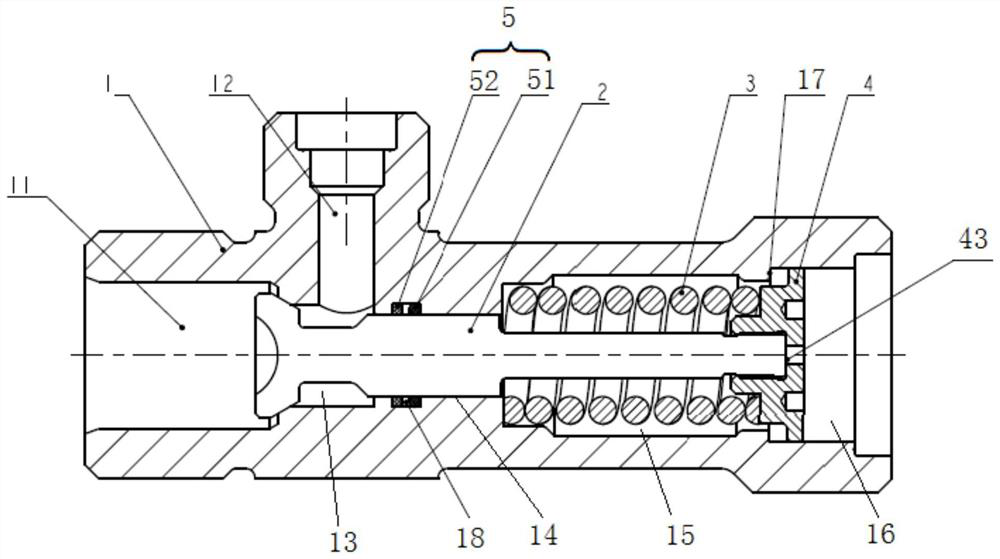

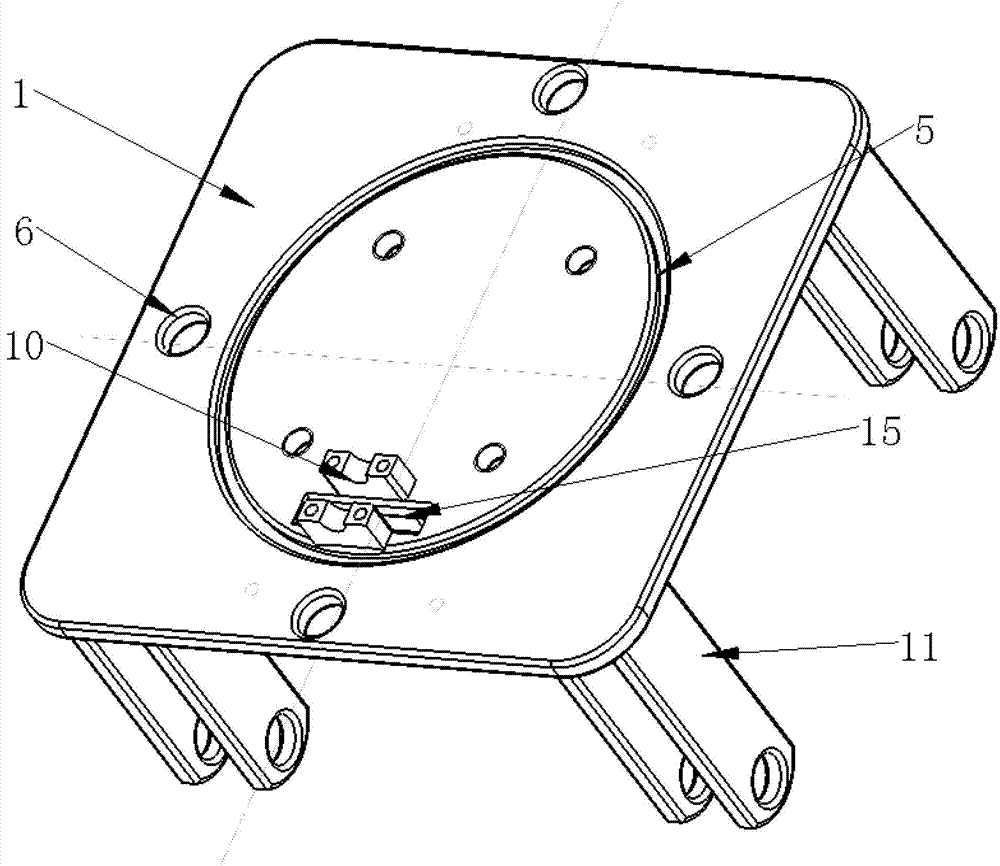

Pressurization electric lubricating grease injector

ActiveCN103398276AEasy to fillReduce the number of timesPressure lubricationOil and greaseDrive shaft

The invention relates to a pressurization electric lubricating grease injector which is mainly applied to maintenance devices with lubricating grease injection requirements. The pressurization electric lubricating grease injector is characterized in that a circular cylinder groove and cylinder fixing bolt holes are formed in the end surface of the top of a fixing bottom plate, a cylinder is arranged in the circular cylinder groove, a connecting boss and a cylinder lug are arranged on the cylinder, and driven shaft supports of the fixing bolt holes are respectively arranged on the circular cylinder groove; supporting wheel supports and driving shaft supports are arranged on the end surface of the bottom of the fixing bottom plate, motor fixing holes are formed in the end surface of the bottom of the fixing bottom plate, and the driving shaft supports correspond to the driven shaft supports. The pressurization electric lubricating grease injector has the advantages that lubricating grease can be injected to a plurality of devices after being injected into the cylinder at one step, waste of the grease in a filling procedure is reduced, and the lubricating grease filling frequency is reduced; air in a gun of the injector does not need to be exhausted owing to a pressurization effect, trouble of exhausting the air is reduced, accordingly, the cost is lowered, the labor intensity of maintenance staff is reduced, and the maintenance time is shortened by 0.5 hour approximately.

Owner:乌海包钢矿业有限责任公司

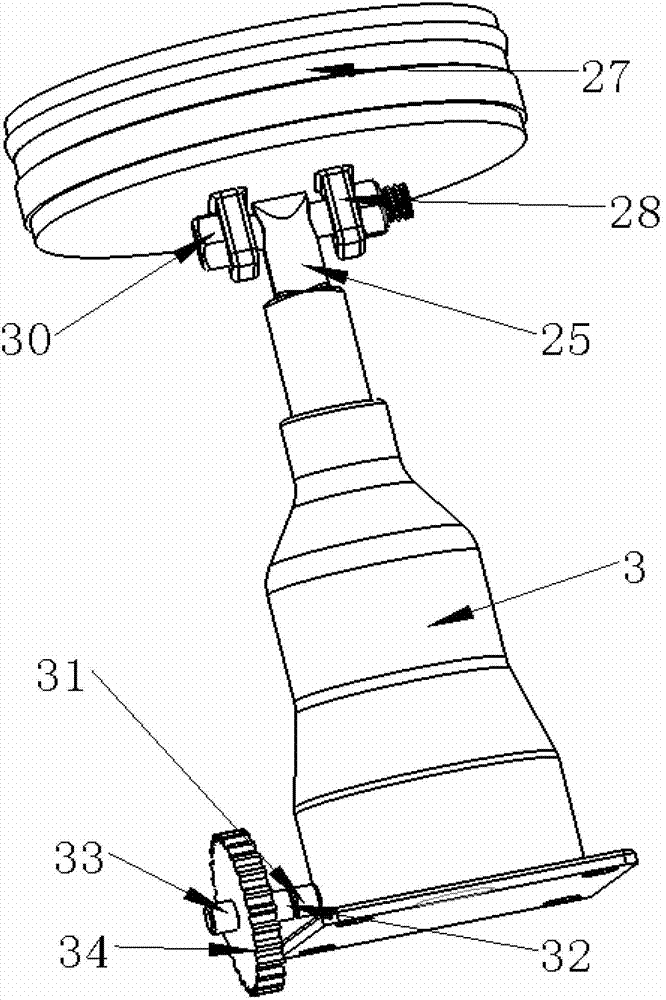

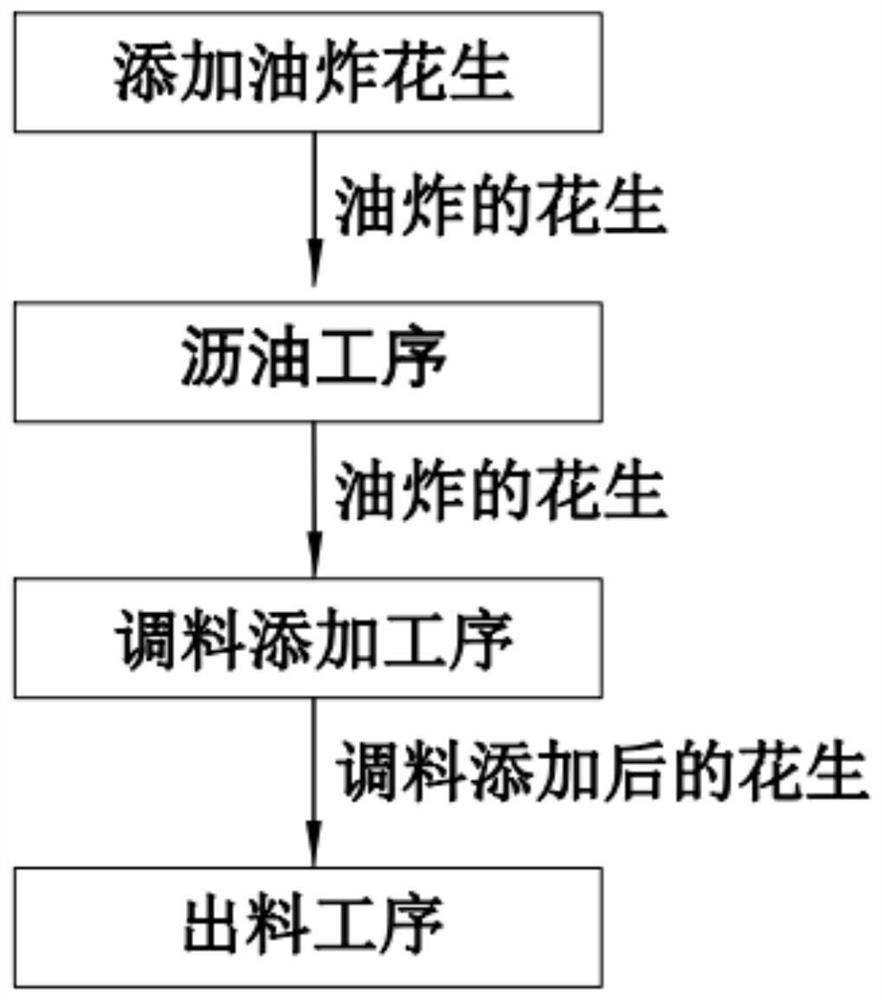

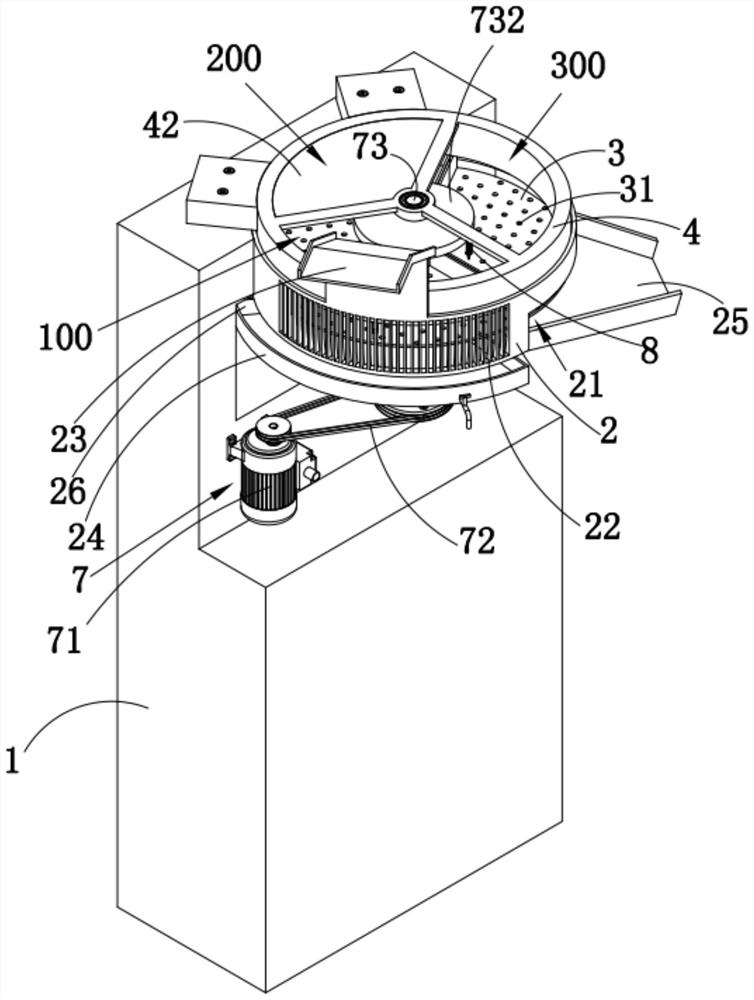

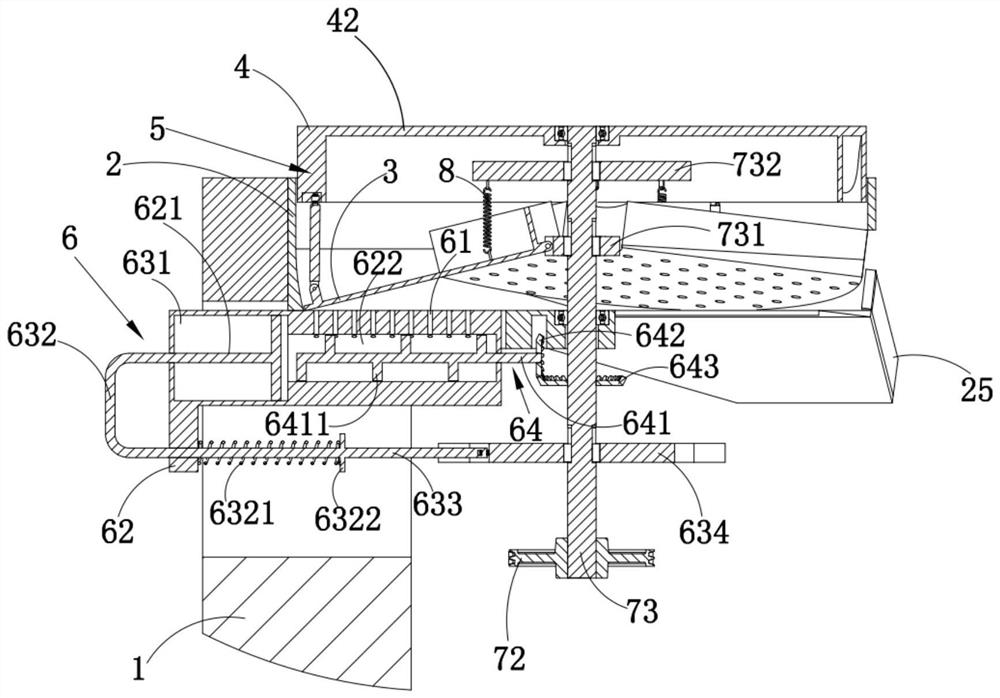

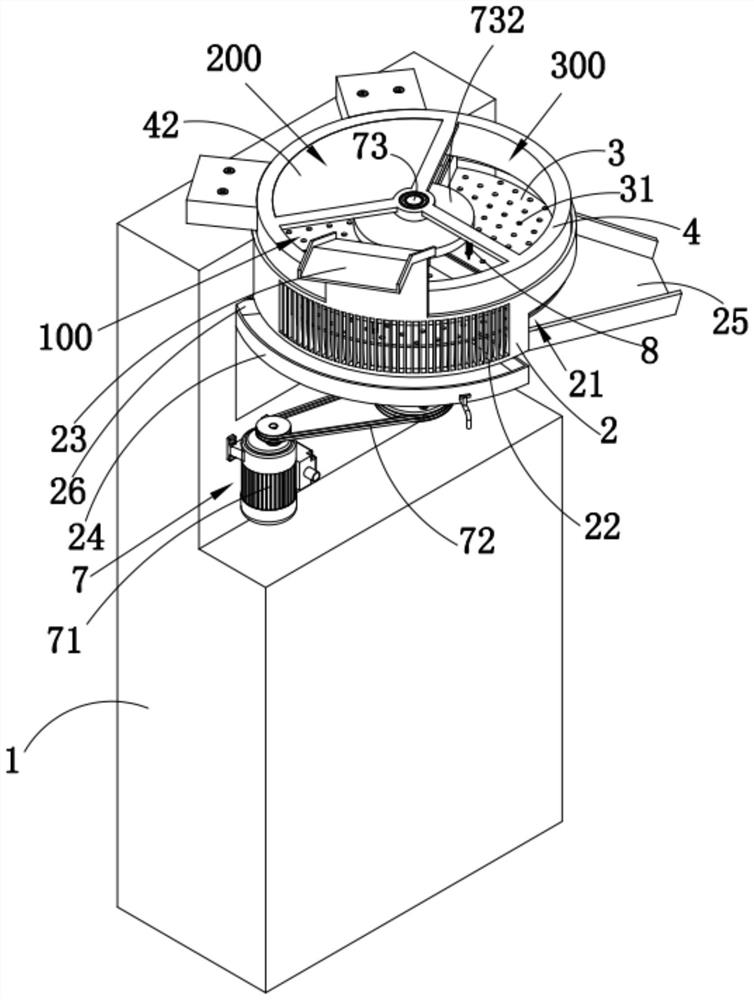

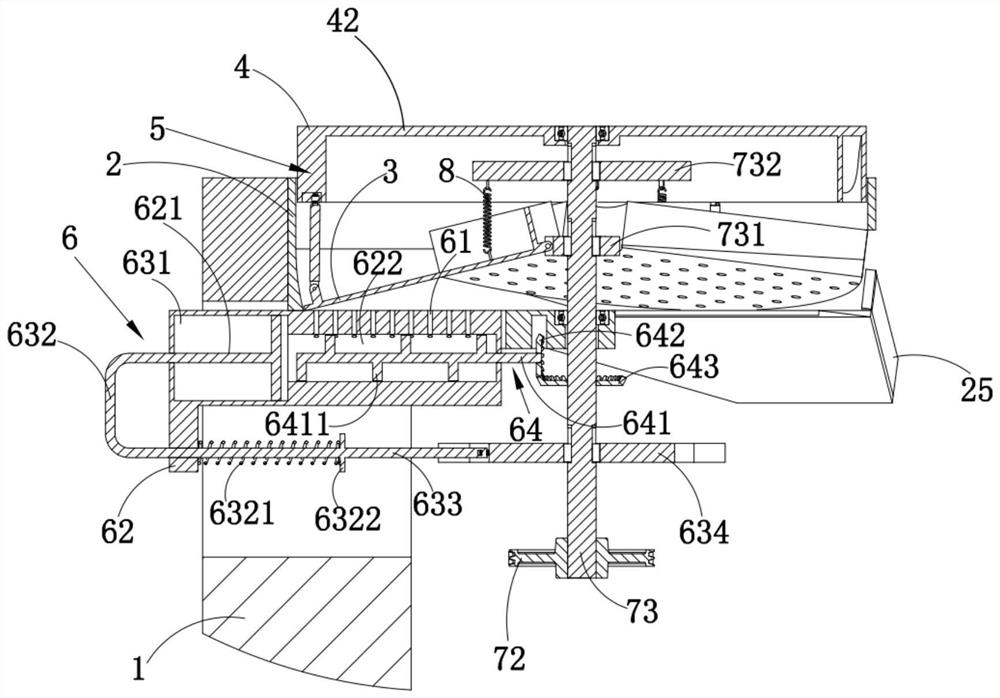

Method for draining oil and salting fried peanuts

ActiveCN112314650BAchieve up and down swingRealize manual up and downBaked articles handlingBaking ovenProcess engineeringSalting

Owner:日照金果粮油有限公司

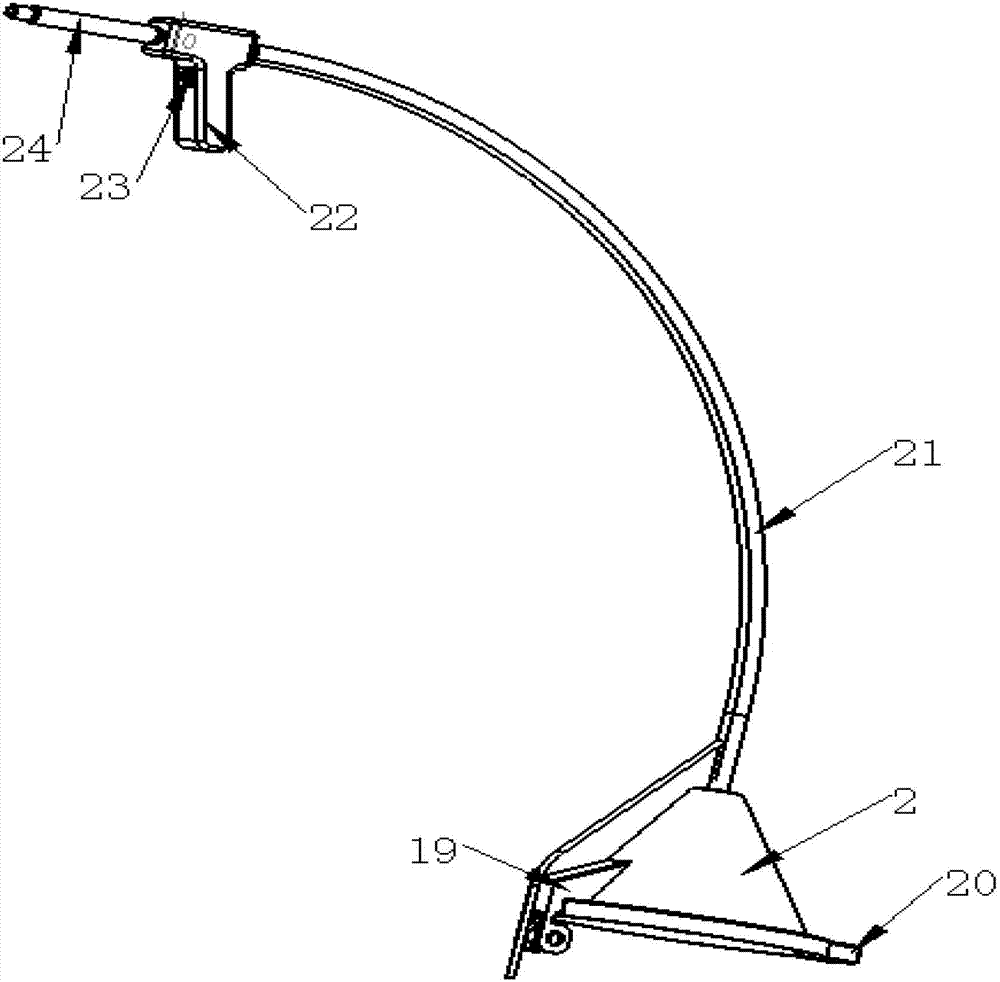

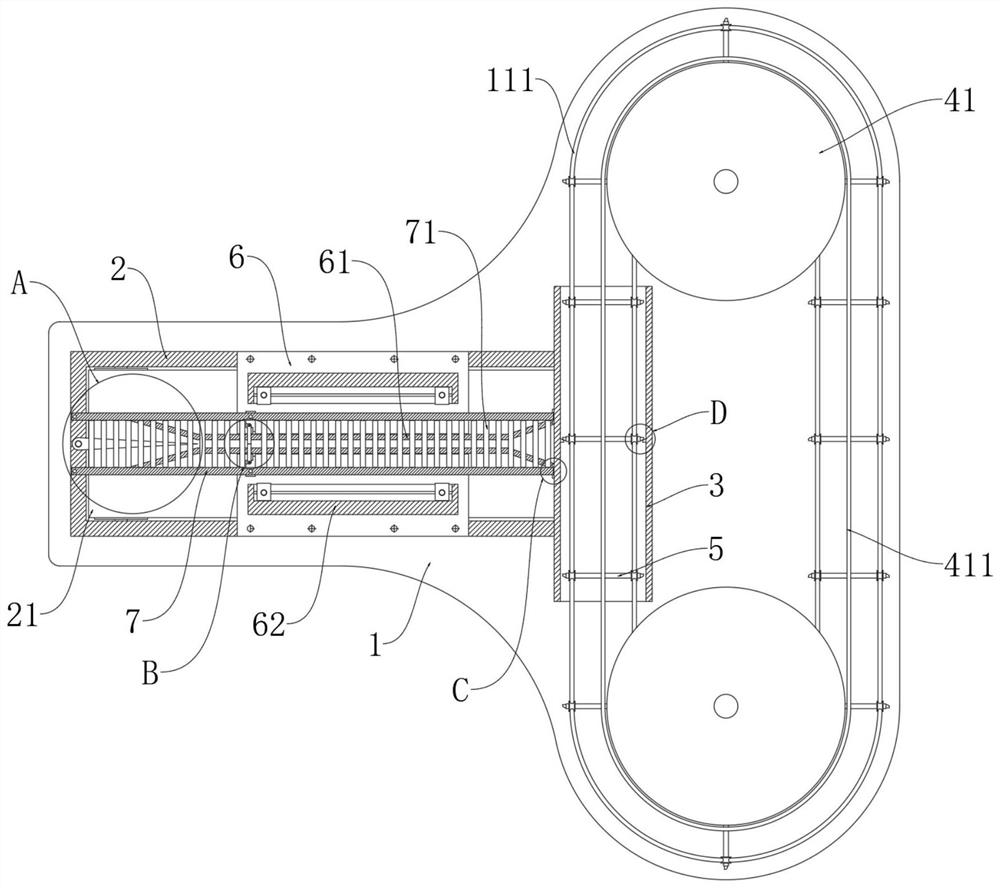

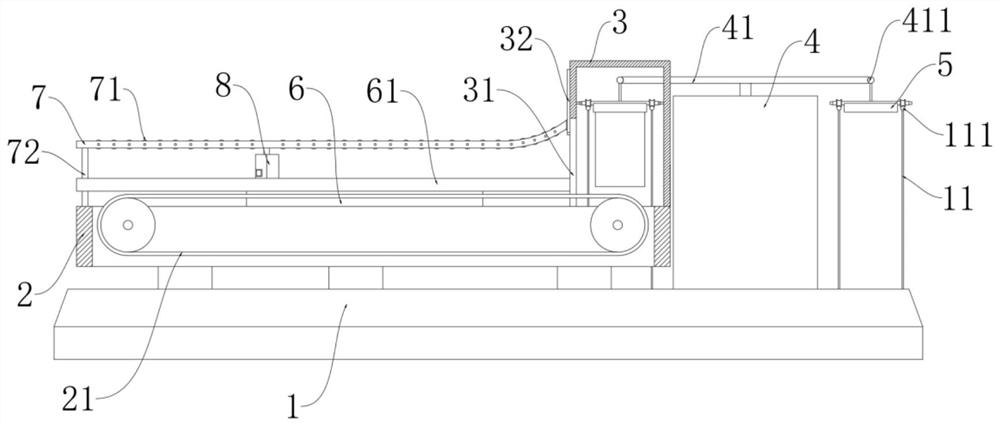

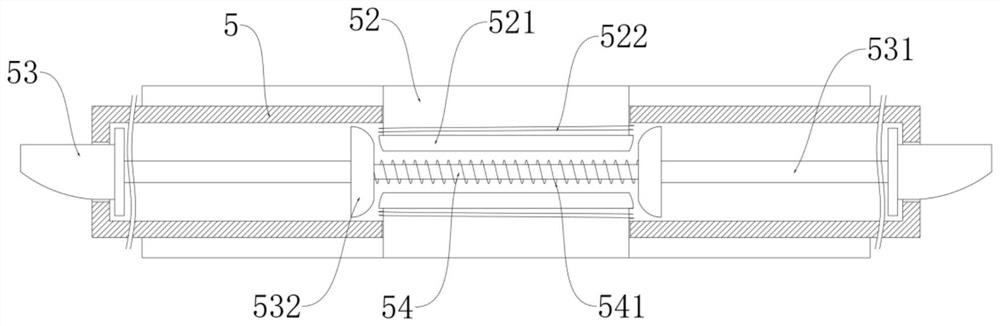

A flying probe testing machine and its flying probe module

ActiveCN113607984BFast loadingIncrease the feeding speedConveyorsElectrical testingStructural engineeringMachine

The invention discloses a flying probe testing machine, which includes a machine base, a plurality of support rods are equidistantly and symmetrically installed on one side of the support rod, and double surrounding rails are jointly installed on the upper ends of the plurality of support rods. A transport frame is installed on the base, and a belt conveyor is installed in the transport frame; the invention also discloses a flying probe module, which includes a driver installed on a screw rod, and a slide rail column is installed on one side of the driver , two square slide holes are symmetrically opened in the slide rail column. The present invention realizes the automatic cycle feeding through the cooperation of the double surrounding rails and the pinch pipe, the transmission disc and the transmission chain, realizes the functions of automatic straightening, automatic fixing and automatic positioning through the guide splint, the controllable baffle and the inner concave calibration roller, and through the separation Realize automatic sorting to the board, which is more efficient and reduces labor force. The half-split contact pin combined with conductive shrapnel and insulation realizes low-voltage and low-impact contact, reducing the possibility of damaging the circuit board.

Owner:昆山兢美电子科技有限公司

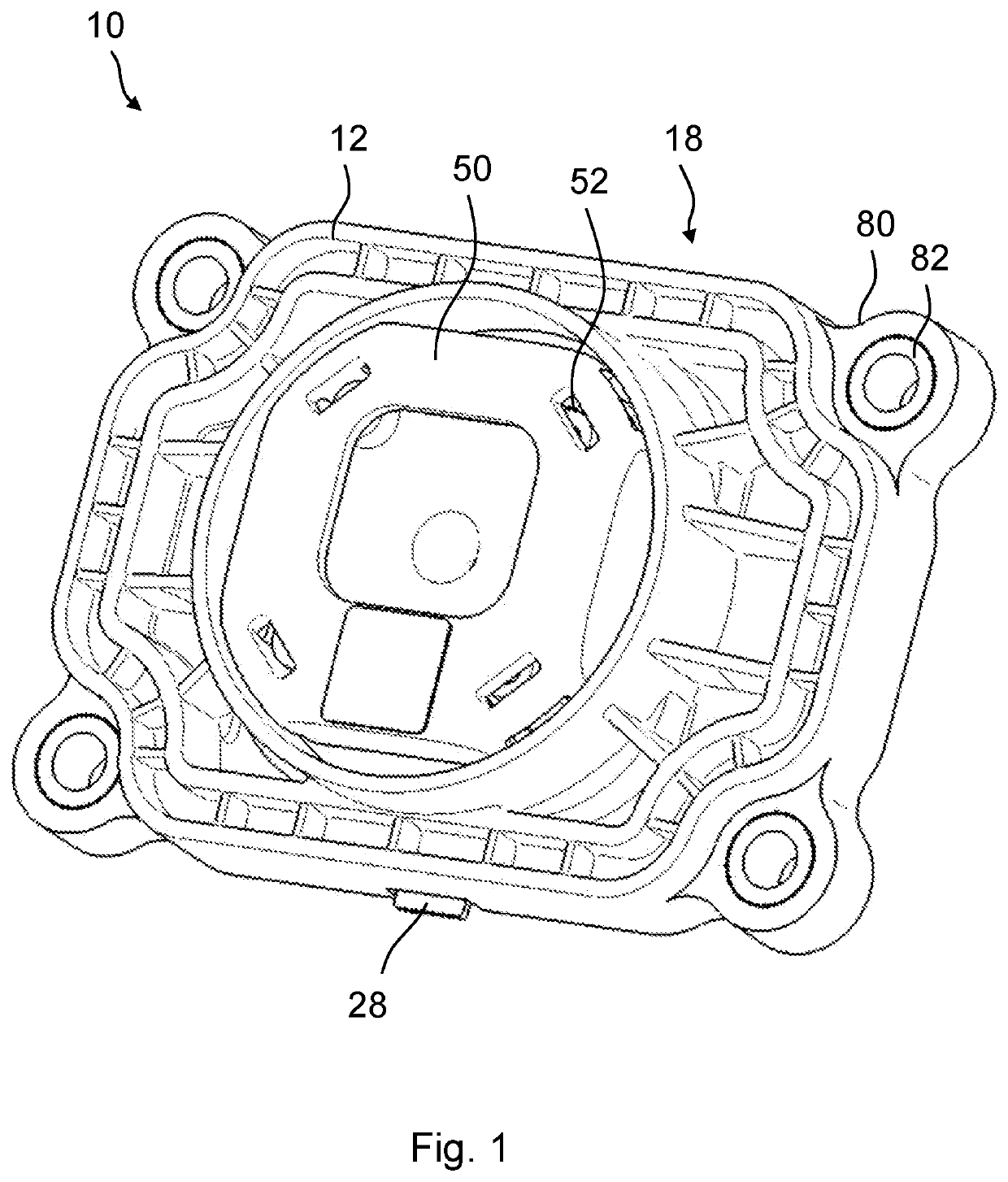

Venting Unit and Housing, in Particular Battery Housing

Owner:MANN HUMMEL GMBH

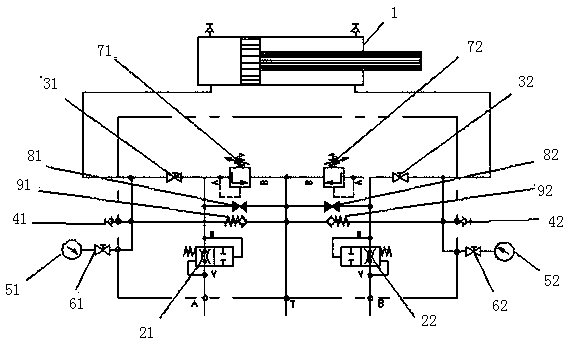

Combined oil cylinder anti-explosion valve assembly

InactiveCN109595210AGood pressure holding effectStable pressure balanceFluid-pressure actuator safetyServomotor componentsInternal pressurePressure difference

The invention discloses a combined oil cylinder anti-explosion valve assembly. The combined oil cylinder anti-explosion valve assembly comprises two oil paths; and each oil path comprises an oil cylinder, an explosion-proof valve, a plate-type ball valve, a pressure measuring joint, a pressure gauge, a pressure gauge switch, an overflow valve, a ball valve, a one-way valve, an explosion-proof valve, a plate ball valve, a pressure measuring joint, a pressure gauge, a pressure gauge switch, an overflow valve, a ball valve and a one-way valve, wherein the anti-explosion valve set is arranged on the cylinder side valve block. Under the normal condition, oil can quickly pass through the explosion-proof valve bank, and meanwhile, the pressure gauge of the cylinder side valve block monitors the oil way pressure in real time, so that a good preventive effect can be achieved for the emergency situation; the internal pressure can be adjusted in the maintenance process, so that the internal pressure and the pressure difference of the system under the normal working state are achieved; and meanwhile, when an oil cylinder breaks down, the ball valve and the one-way valve can provide safety guarantee for overhauling, the overflow valve in the assembly can also play a good pressure maintaining effect, the oil cylinder can run stably, and the service life of the oil cylinder is guaranteed.

Owner:HOHAI UNIV CHANGZHOU

Integrated control valve and oil tank using integrated control valve

PendingCN107806523APrevent oil leakageAvoid damageEqualizing valvesSafety valvesFloat chamberEngineering

The invention provides an integrated control valve and an oil tank using the integrated control valve. The integrated control valve comprises an upper cover, a cover body and a lower cover; a first ventilation hole is formed in the upper cover; the lower cover is provided with multiple second ventilation holes; a separation plate is arranged in the cover body; the separation plate is provided witha third ventilation hole and a fourth ventilation hole; the upper cover is provided with a support column; the support column penetrates through the top of the cover body, and extends into an upper cavity; the support column is provided with an air transmission hole; an exhaust base is arranged in the upper cavity; a first spring sleeves the exhaust base; the top end of the first spring is connected with the inner wall of the cover body; multiple fifth ventilation holes are formed in the exhaust base, and a diaphragm is arranged on the side, towards the separation plate, of the exhaust base;a limiting groove is formed in the upper cavity; a steel ball is arranged in the limiting groove; and a floater is arranged in the lower cavity. When the oil tank rolls over, the leakage of oil can beeffectively prevented, so that the safety is improved, and accidents are prevented; and when the pressure in the oil tank is acutely increased, the pressure in the oil tank can be effectively and quickly released, so that the damage of the oil tank is prevented.

Owner:JIANGXI CHANGHE AUTO

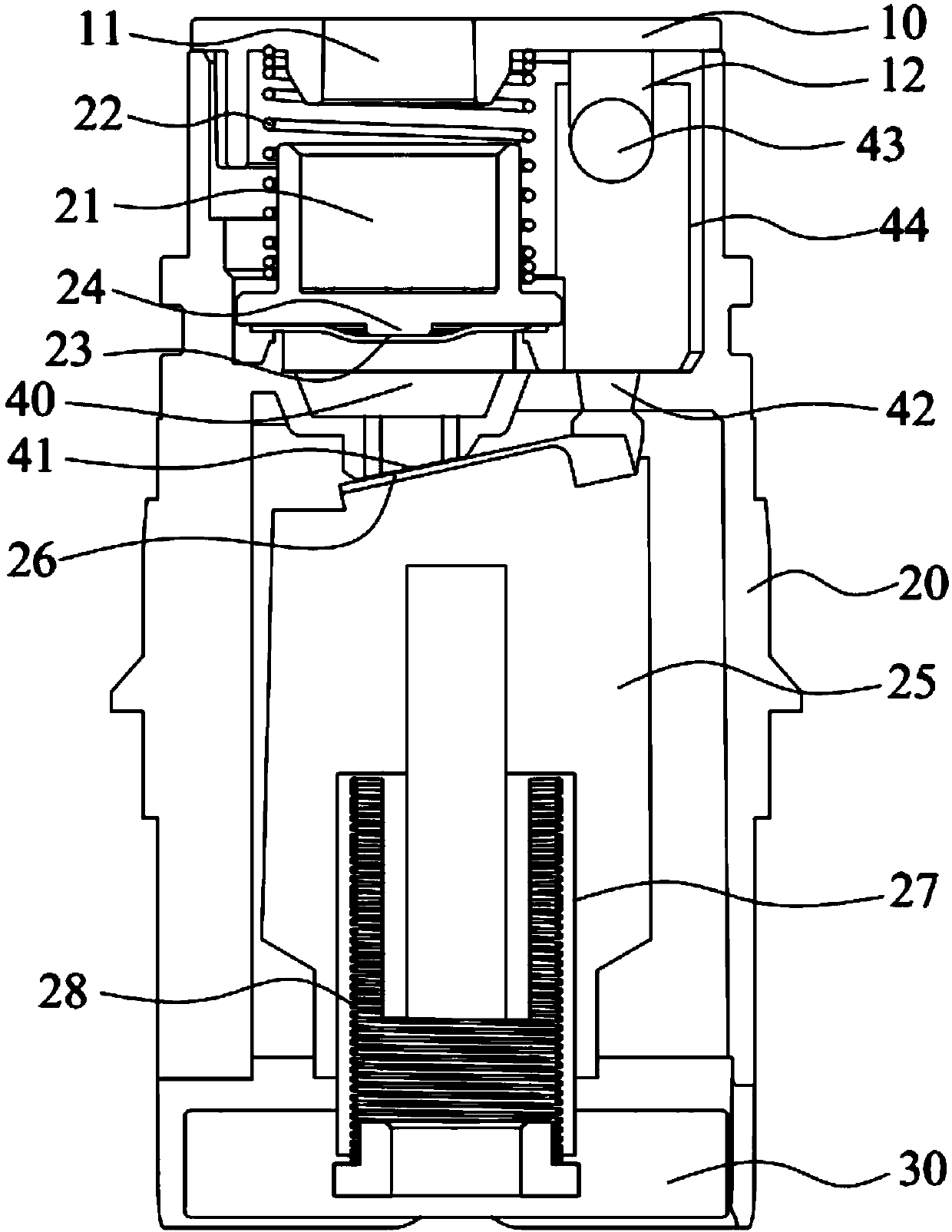

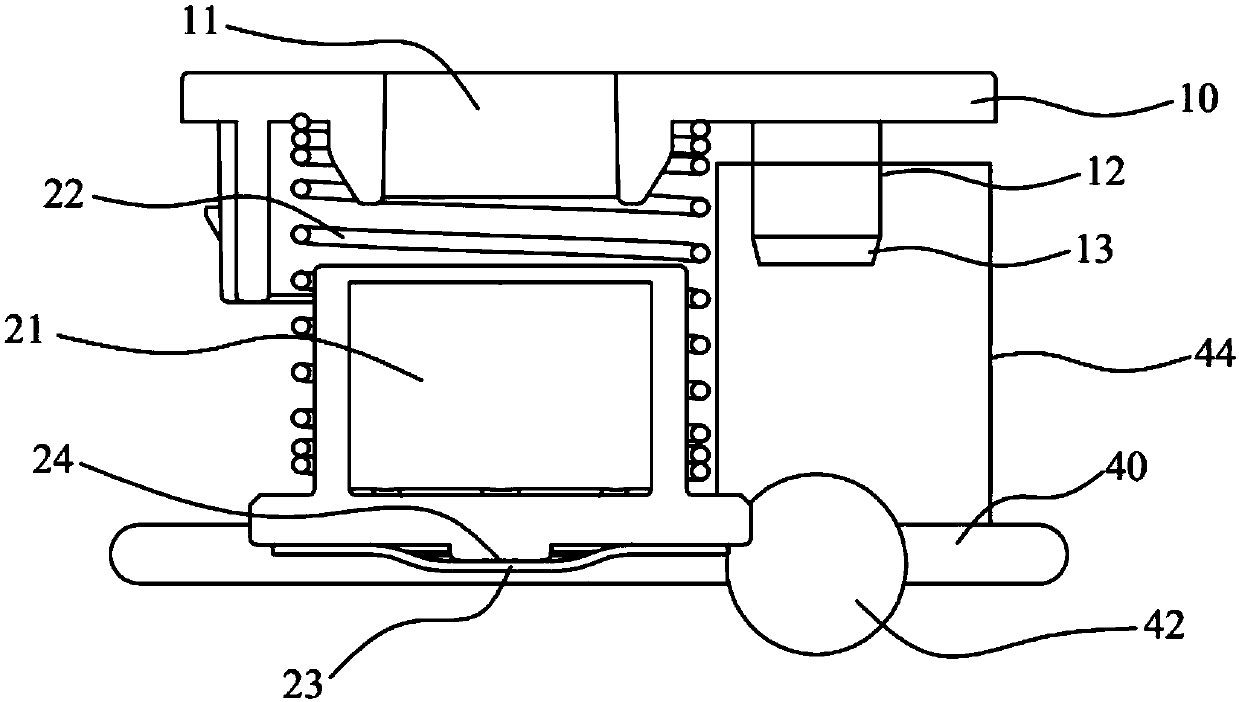

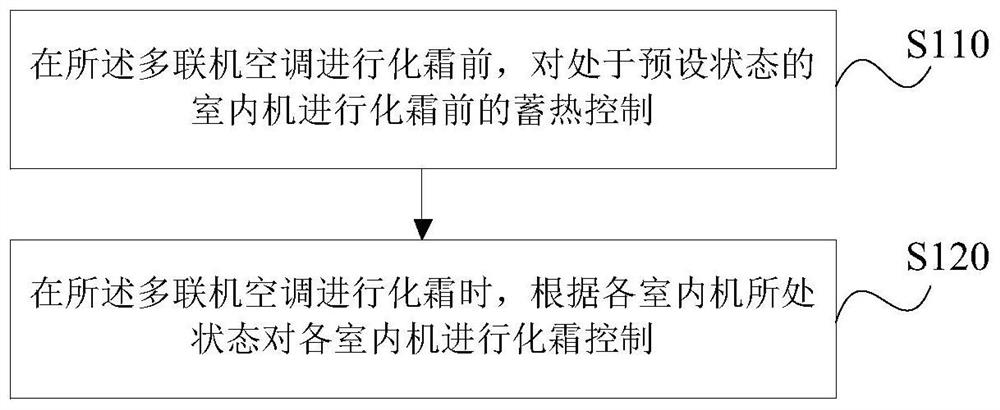

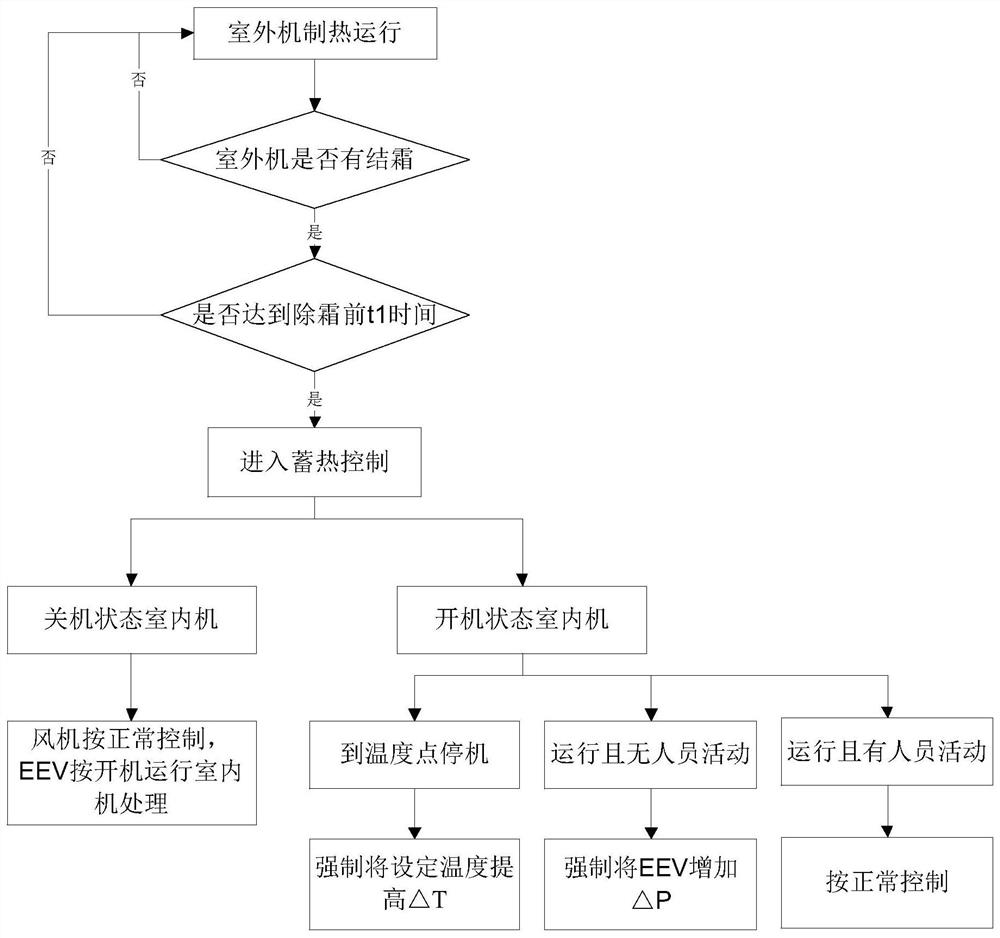

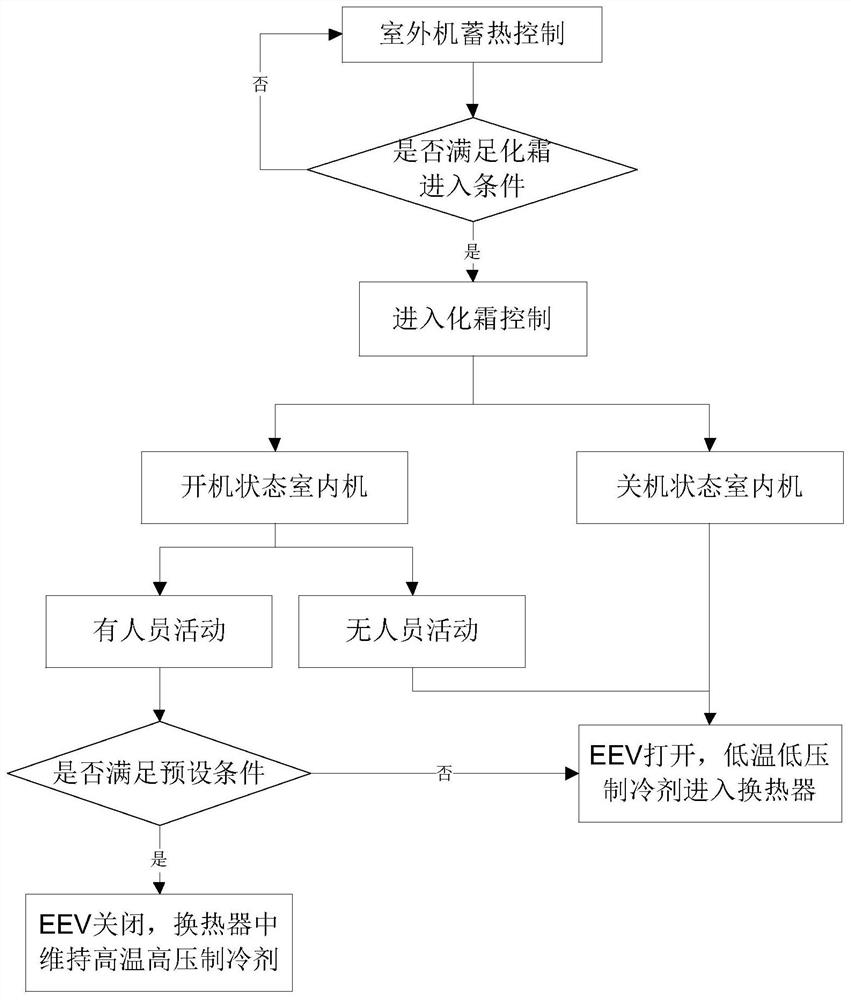

A multi-connected air conditioner and its defrosting control method, device and storage medium

ActiveCN111765595BReduce the amount of solutionIncrease temperatureMechanical apparatusSpace heating and ventilation safety systemsChemical controlControl engineering

The present invention provides a multi-connected air conditioner and its defrosting control method, device, and storage medium. The method includes: before the multi-connected air conditioner defrosts, the indoor unit in a preset state is stored before defrosting. Thermal control; when the multi-connected air conditioner is defrosting, defrosting control is performed on each indoor unit according to the state of each indoor unit; the preset state includes: shutdown state, power-on and shutdown state when it reaches the temperature point, and / or Or power on and there is no one in the room. The solution provided by the invention can accelerate the defrosting process and reduce the defrosting time.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

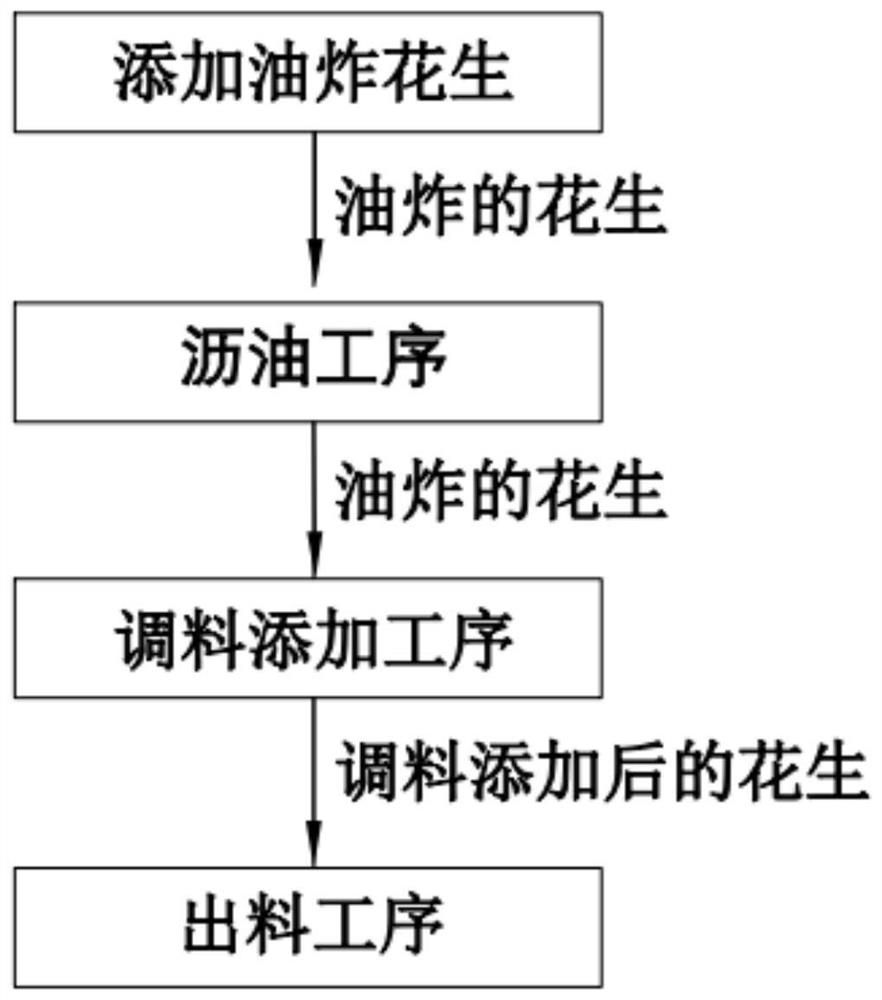

Oil draining and salt sprinkling method for fried peanuts

ActiveCN112314650AAchieve up and down swingRealize manual up and downBaked articles handlingBaking ovenProcess engineeringMechanical engineering

The invention provides an oil draining and salt sprinkling method for fried peanuts. The method comprises the following steps of a fried peanut adding process that the fried peanuts are added to a fan-shaped tray; an oil draining process that a transmission shaft drives the fan-shaped tray to rotate, the fan-shaped tray swings up and down while rotating under the combined action of an annular track groove and a guide connecting rod assembly, and up-down shaking of the peanuts is achieved to complete oil draining; a seasoning adding process that intermittent seasoning spraying is achieved through cooperation of a piston assembly arranged in a seasoning box and a stirring unit; and a discharging process that a discharging opening formed in the side face of an annular support is used for being matched with vertical swinging of the fan-shaped tray to achieve discharging through vertical swinging when the fan-shaped tray rotates to the position of the discharging opening. The mixing of seasonings and the peanuts is more uniform, and the taste of the fried peanuts is ensured, so that the problem of residual oil on the surfaces of the peanuts, the problem in adding the seasonings simultaneously and the problem of equipment investment are solved.

Owner:日照金果粮油有限公司

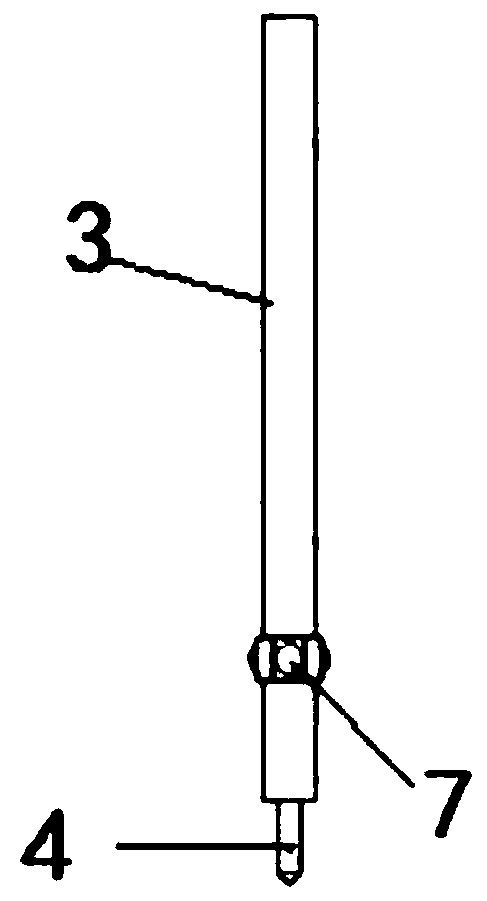

A high-efficiency automatic water release device for coal mine gas drainage pipeline

InactiveCN103967520BEmission safetyEfficient emissionsDrainageGas removalWater dischargeEnvironmental engineering

The invention discloses an automatic high-efficiency water discharging device for a coal-mine gas extraction pipe and belongs to the field of coal mine automation. The automatic high-efficiency water discharging device is used for automatically discharging water accumulated in the gas extraction pipe. The automatic high-efficiency water discharging device comprises a water discharging device cylinder assembly, an upper cover assembly and a flat floating ball assembly. The water discharging device cylinder assembly comprises a dual-acting pneumatic ball valve, a single-acting pneumatic ball valve, a cylinder and a static guide rod, and the flat floating ball assembly comprises a flat floating ball, a flat floating ball guide rod and a flat floating ball magnet. The automatic high-efficiency water discharging device has the advantages of being high in water discharging efficiency, simple in structure, stable in operation and capable of automatically being switched off when decompression happens, and can discharge water accumulated in the gas extraction pipe efficiently, safely, stably and automatically.

Owner:DALIAN UNIV OF TECH

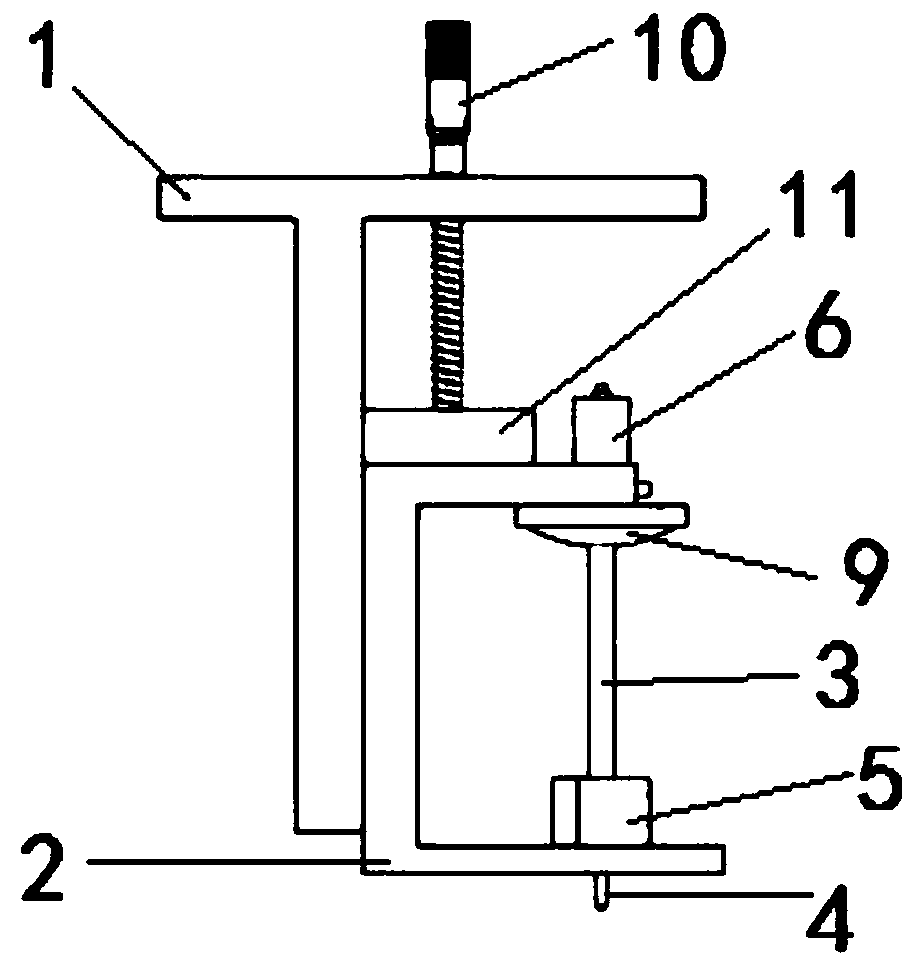

Vertical surface roughness measuring head and surface roughness instrument

PendingCN111366108AHigh measurement accuracyFast measurementUsing optical meansFixed frameSurface roughness

The invention discloses a vertical surface roughness measuring head and a surface roughness instrument. The vertical surface roughness measuring head comprises a fixed frame, a movable frame, a displacement measuring module, a probe rod, a contact probe and a guide device, wherein the movable frame is vertically connected to the fixed frame in a sliding manner, the probe rod is arranged on the movable frame, the guide device is arranged on a bottom plate of the movable frame, the guide device can be used for vertically guiding the probe rod to prevent the probe rod from swinging, the contact probe is fixedly arranged at the bottom end of the probe rod, the probe rod penetrates through the guide device, the contact probe penetrates through the bottom plate of the movable frame, and the displacement measuring module is used for measuring the moving distance of the probe rod in the vertical direction. The surface roughness instrument comprises a frame body, a moving device and the vertical surface roughness measuring head. According to the invention, the contact probe and the probe rod are always perpendicular to the surface of a workpiece in the measurement process under the action of the guide device, the operation is simple and convenient, and the measurement accuracy is high.

Owner:NAT INST OF METROLOGY CHINA

Automatic high-efficiency water discharging device for coal-mine gas extraction pipe

The invention discloses an automatic high-efficiency water discharging device for a coal-mine gas extraction pipe and belongs to the field of coal mine automation. The automatic high-efficiency water discharging device is used for automatically discharging water accumulated in the gas extraction pipe. The automatic high-efficiency water discharging device comprises a water discharging device cylinder assembly, an upper cover assembly and a flat floating ball assembly. The water discharging device cylinder assembly comprises a dual-acting pneumatic ball valve, a single-acting pneumatic ball valve, a cylinder and a static guide rod, and the flat floating ball assembly comprises a flat floating ball, a flat floating ball guide rod and a flat floating ball magnet. The automatic high-efficiency water discharging device has the advantages of being high in water discharging efficiency, simple in structure, stable in operation and capable of automatically being switched off when decompression happens, and can discharge water accumulated in the gas extraction pipe efficiently, safely, stably and automatically.

Owner:DALIAN UNIV OF TECH

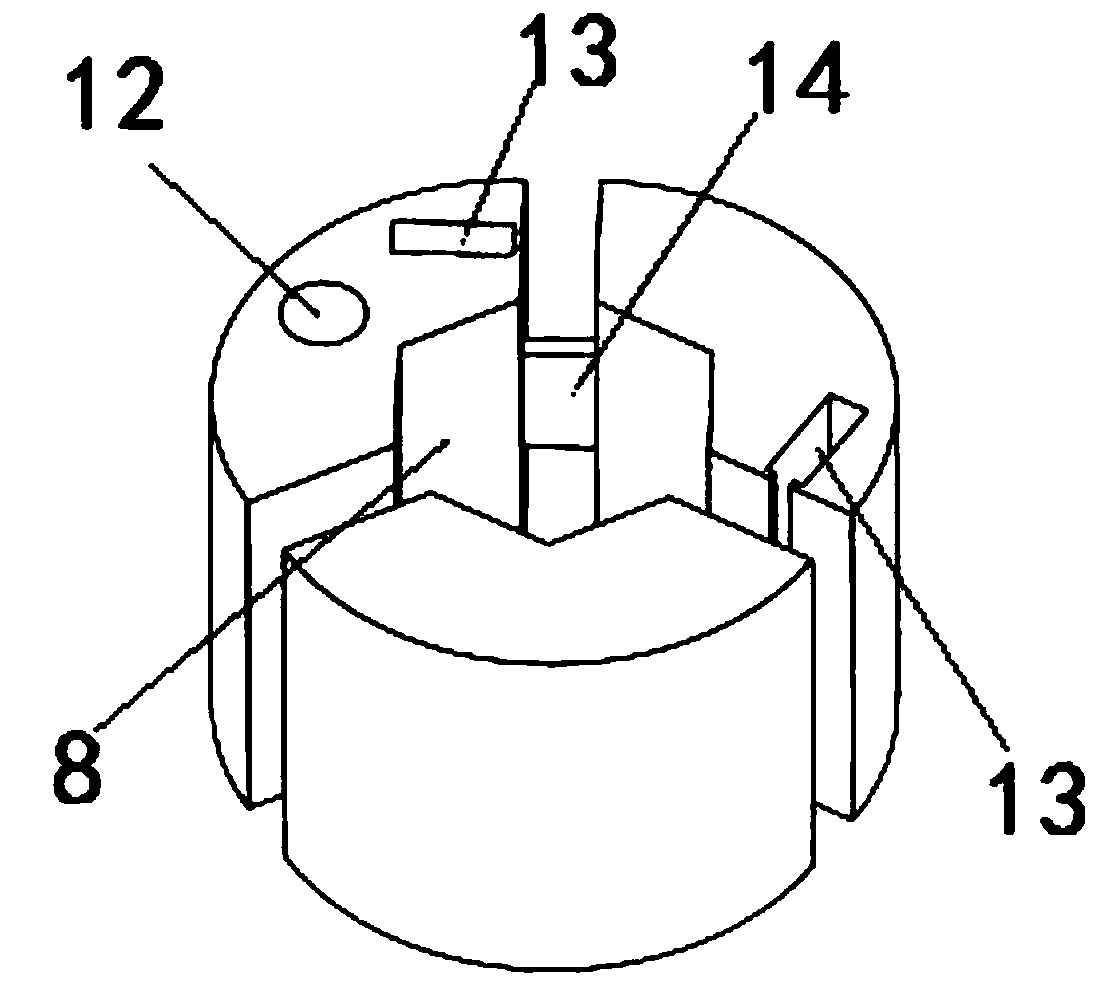

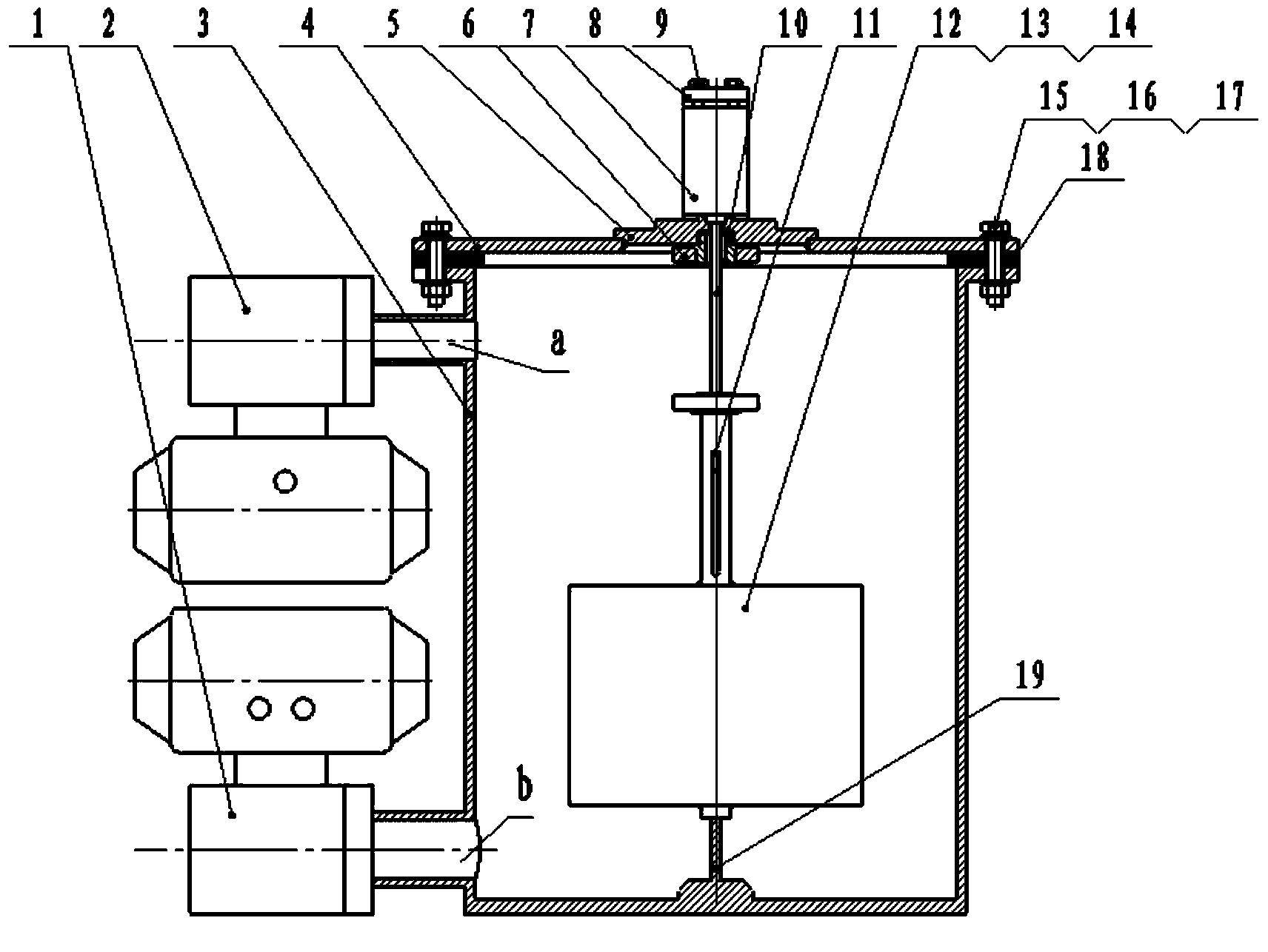

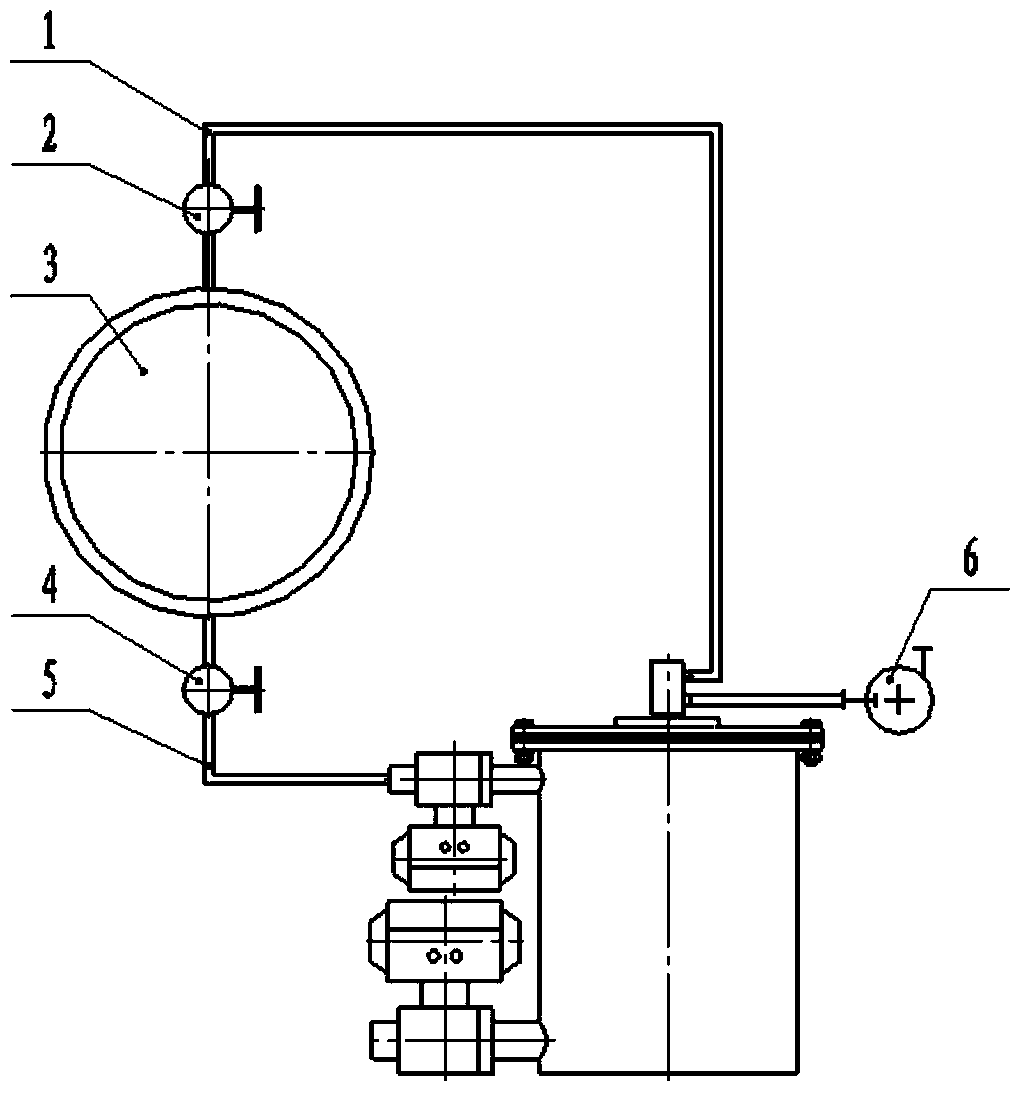

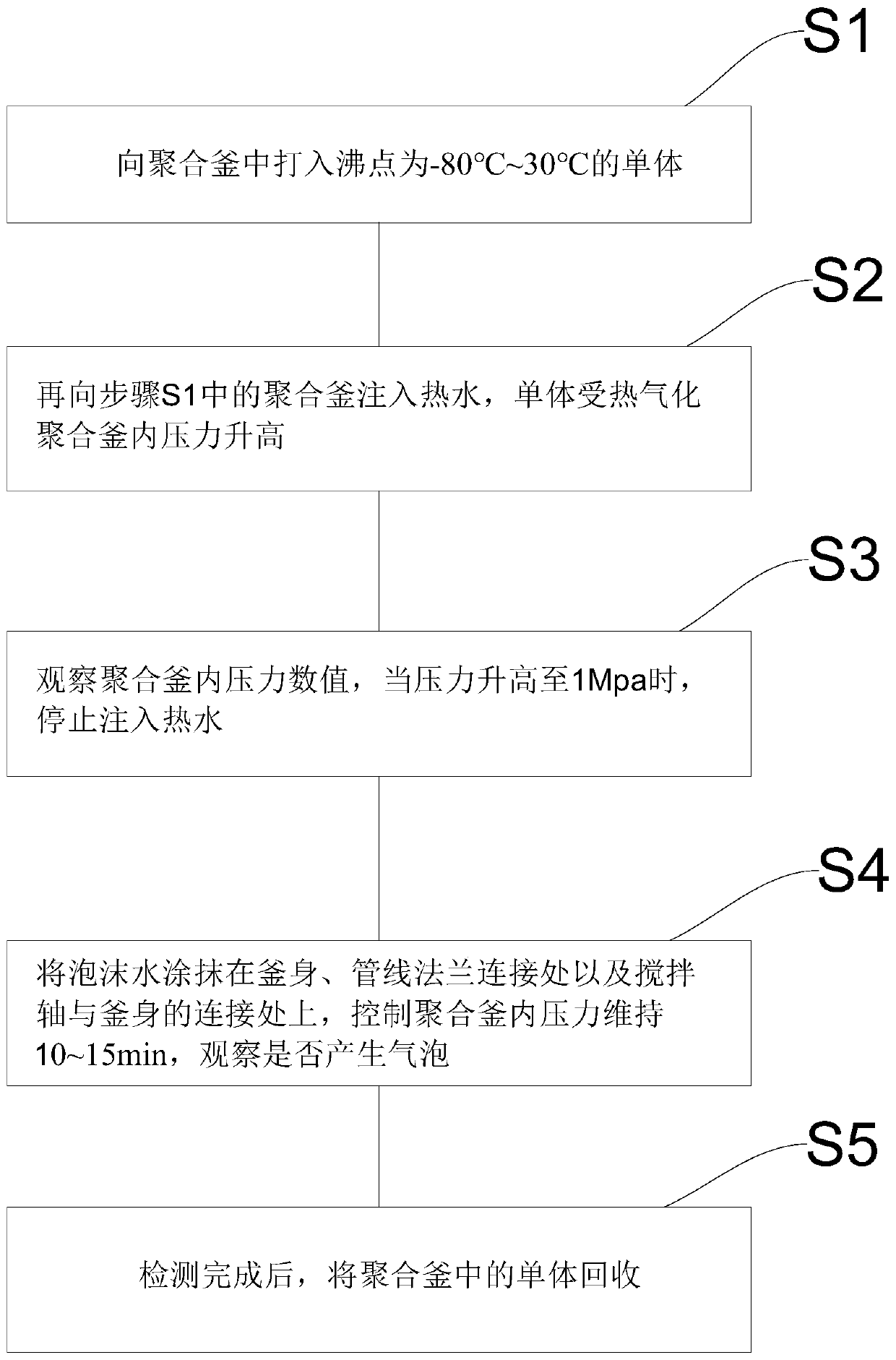

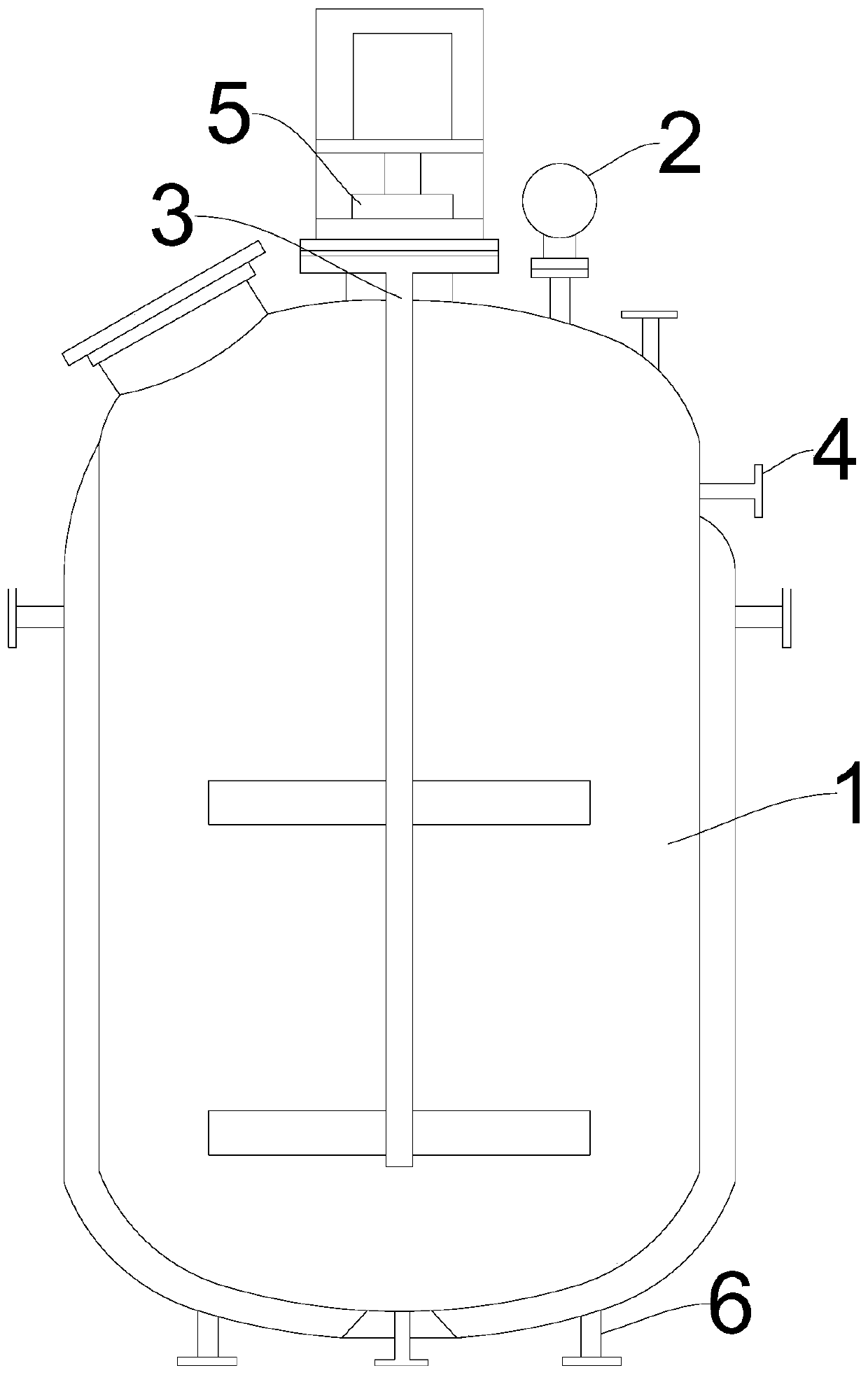

Leakage test method of polymerization kettle

InactiveCN110440995AQuick to useImprove efficiencyDetection of fluid at leakage pointPolymer scienceBoiling point

The invention relates to a leakage test method of a polymerization kettle, and belongs to the technical field of chemical production. The leakage test method comprises the following steps ofS1, addinga monomer with the boiling point being -80 DEG C to 30 DEG C into the polymerization kettle; S2, injecting hot water into the polymerization kettle in the step S1, so that the monomer is heated to begasified, and the pressure in the polymerization kettle is increased; S3, observing a pressure value in the polymerization kettle, and stopping injecting the hot water when the pressure is increasedto 1 Mpa; S4, coating the joint of a kettle body and a pipeline flange and the joint of a stirring shaft and the kettle body with foam water, controlling the pressure in the polymerization kettle to be maintained for 10-15 minutes, and observing whether bubbles are generated or not; and S5, recovering the monomer in the polymerization kettle after detection is finished. The method has the beneficial effects that the detection time for leakage of the polymerization kettle can be greatly shortened, so that the utilization rate of the polymerization kettle is improved, and meanwhile, the production benefit of an enterprise is improved.

Owner:XINJIANG HUATAI HEAVY CHEM CO LTD +1

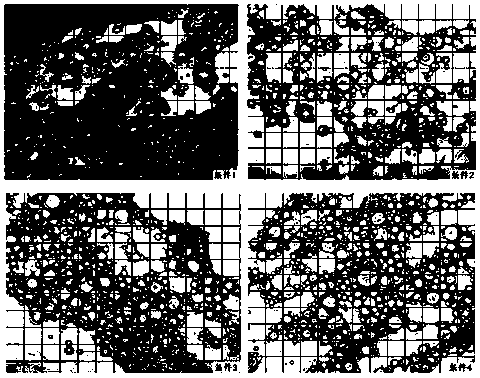

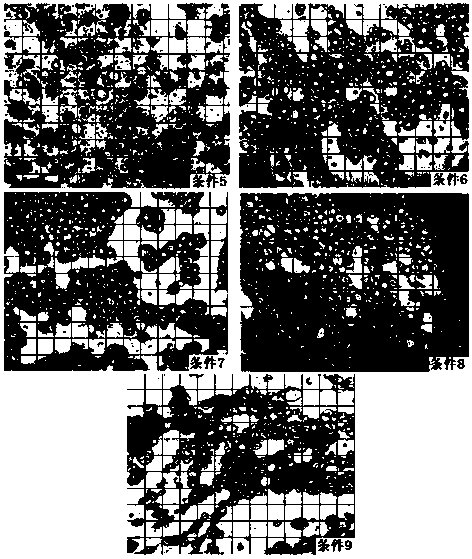

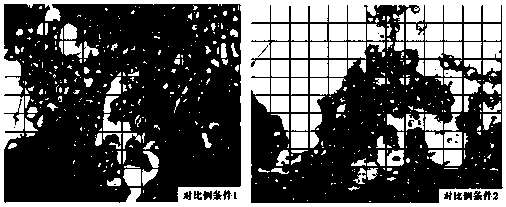

Reaction kettle type foaming device of thermally expandable microspheres and foaming method

PendingCN110900938APrecise monitoring of foamingReduce Shrinkage ProblemsMicrospherePhysical chemistry

The invention discloses a reaction kettle type foaming device of thermally expandable microspheres and a foaming method. The foaming device comprises a kettle type foaming tank body, a kettle type foaming tank cover and a steam engine, wherein the kettle type foaming tank body is detachably connected with the kettle type foaming tank cover in a sealed mode, the kettle type foaming tank cover tankcover communicates with the steam engine through a pipeline, the kettle type foaming tank body is of a sandwich structure, and a pressure gauge and a temperature measuring device are arranged on the kettle type foaming tank cover. According to the foaming device and the foaming method, by utilizing a transparent glass foaming kettle with the sandwich structure, the pressure, the temperature and the foaming condition of the microspheres in the kettle can be accurately monitored through the pressure gauge and the temperature measuring device of the kettle type foaming tank cover; cooling water can be rapidly added into the device, so that the shrinkage and sticking conditions of the foamed microspheres are reduced, and dust generated by the foamed microspheres is eliminated; safety foaming of the microspheres at different temperatures or even high-temperature can be carried out by utilizing the characteristics of the temperature resistance and pressure resistance of glass; and the inputvolume of steam can be controlled so as to control the degree of foaming of the microspheres.

Owner:CRERAX SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com