A high-efficiency automatic water release device for coal mine gas drainage pipeline

An automatic water release device and coal mine gas technology, which is applied in the direction of gas discharge, drainage, mining equipment, etc., can solve the problems of low water discharge efficiency, poor safety, and water discharge device failure, and achieve high water discharge efficiency, stable operation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

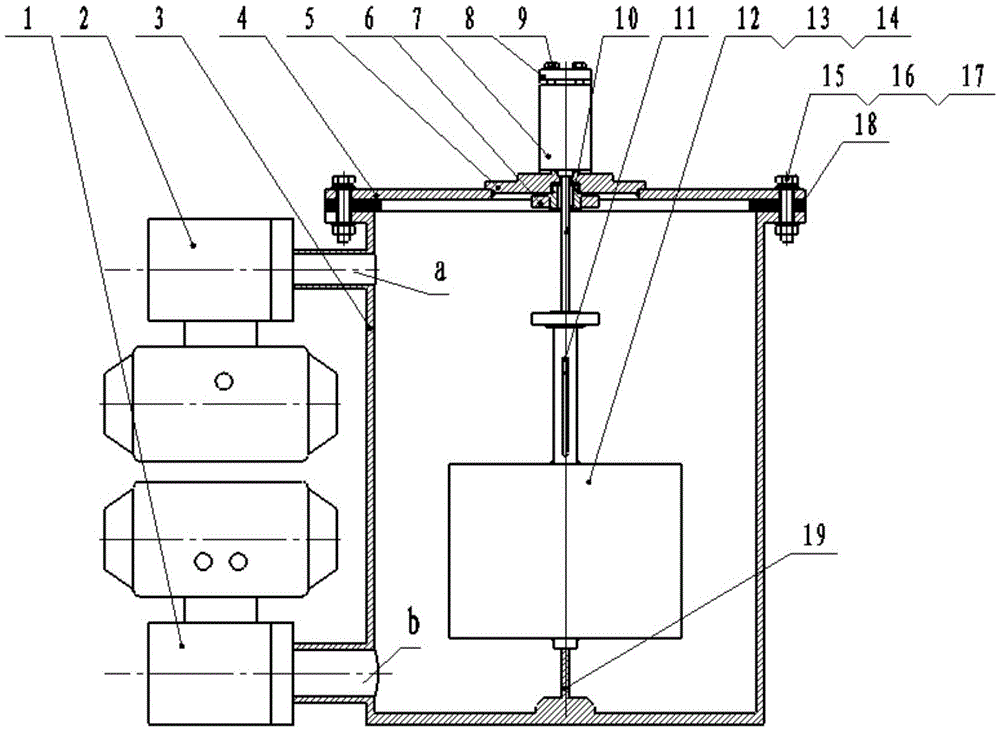

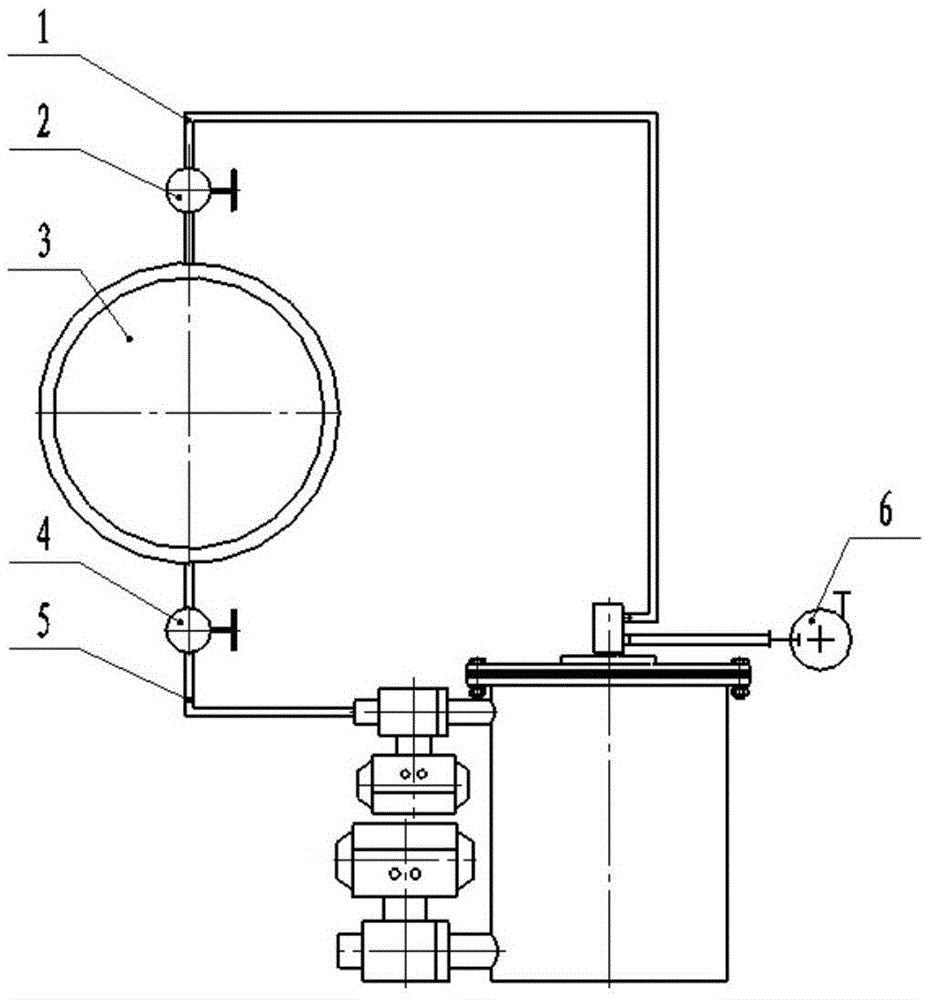

[0012] The specific implementation of the patent of the present invention is described in detail below in conjunction with technical scheme and accompanying drawing. attached figure 2 It is a schematic diagram of the installation of the present invention in the gas drainage pipeline. The upper end of the drainer is connected to the gas source 6. The drainer is connected to the gas pipeline 3 through the balance pressure pipeline 1 and the balance pressure valve 2, and the accumulated water in the pipeline passes through the water inlet pipe. Road valve 4 and water inlet pipeline 5 enter the drainer.

[0013] as attached figure 1 As shown, in the initial state of the water dispenser, there is no water in the cylinder body 3 and no external air source, the self-weight of the flat float assembly III is greater than the suction force between the upper cover magnet 6 and the flat float magnet 14, and the moving guide rod 10 is pulled down. , and itself is at a low position, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com