Patents

Literature

632results about How to "For automatic discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

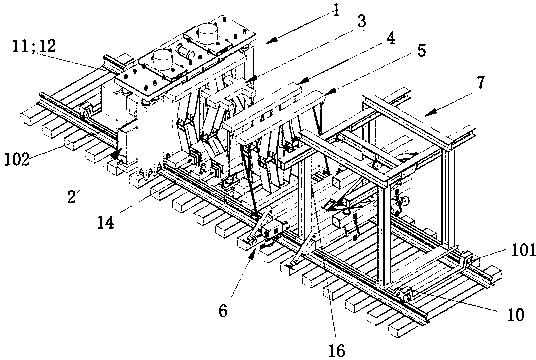

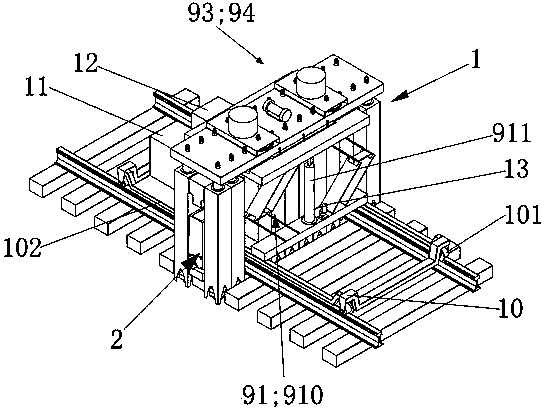

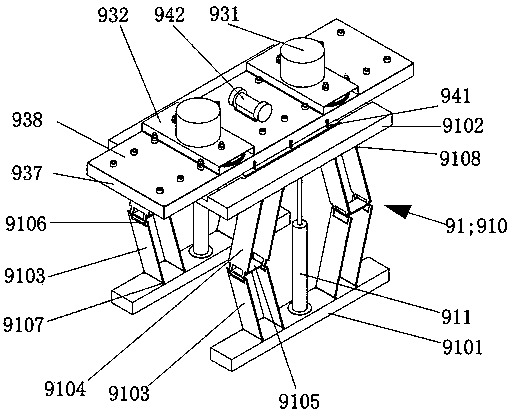

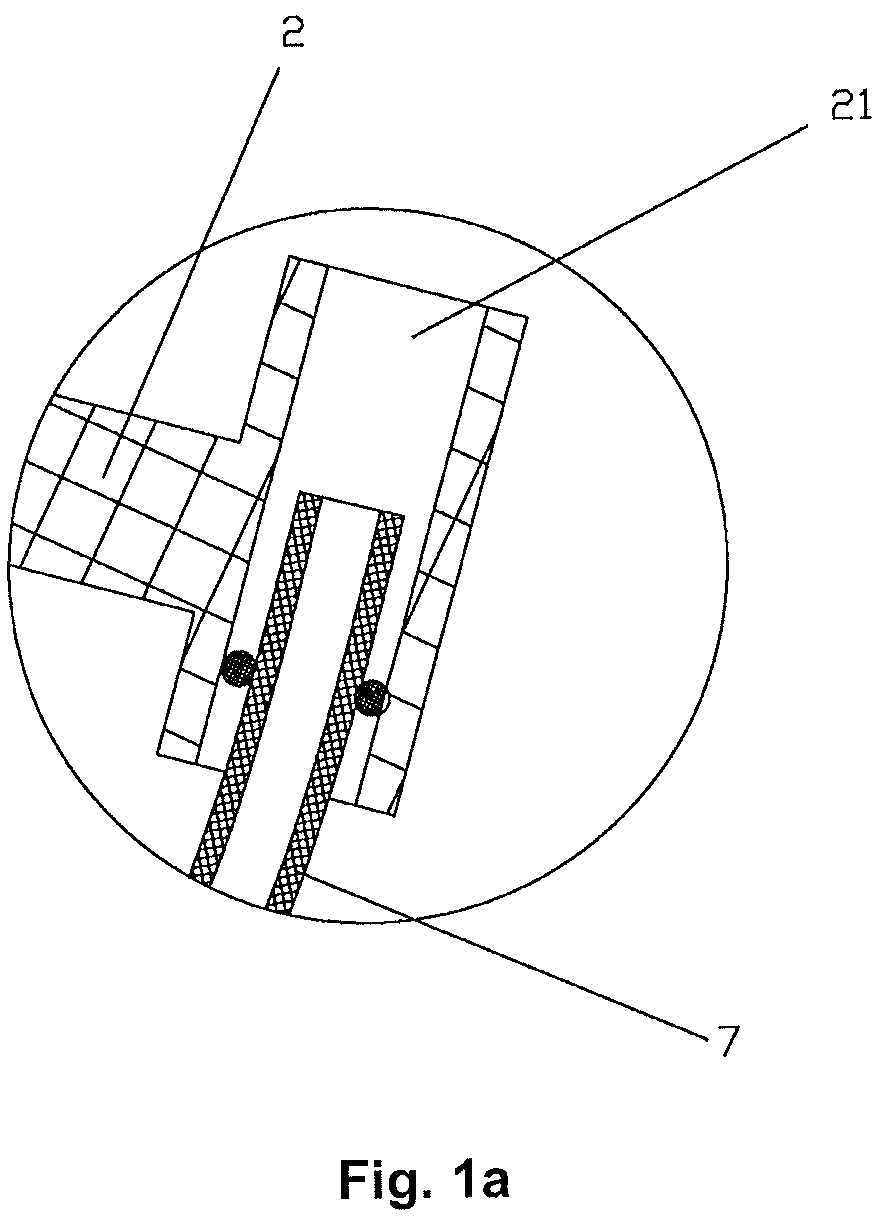

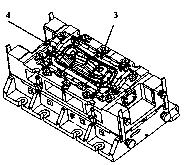

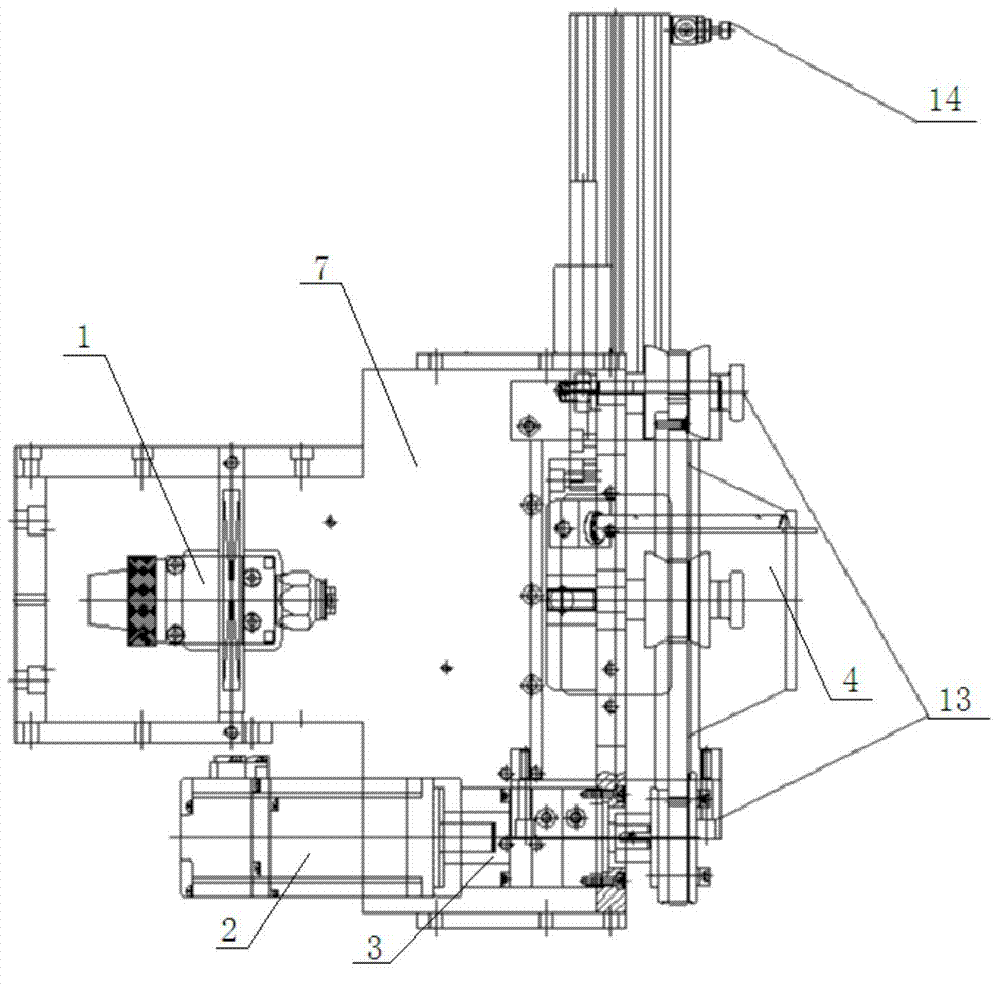

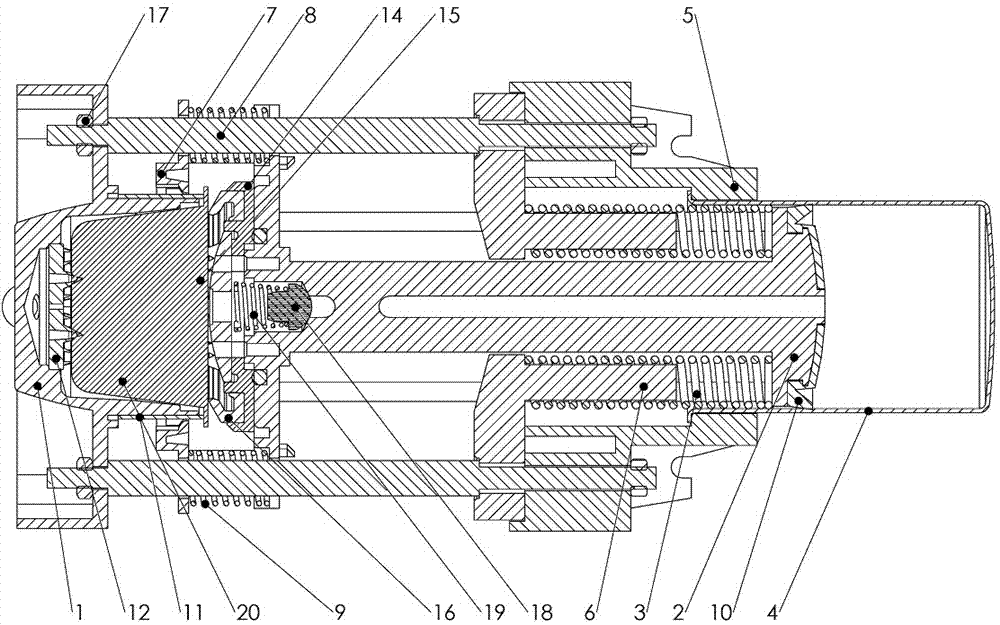

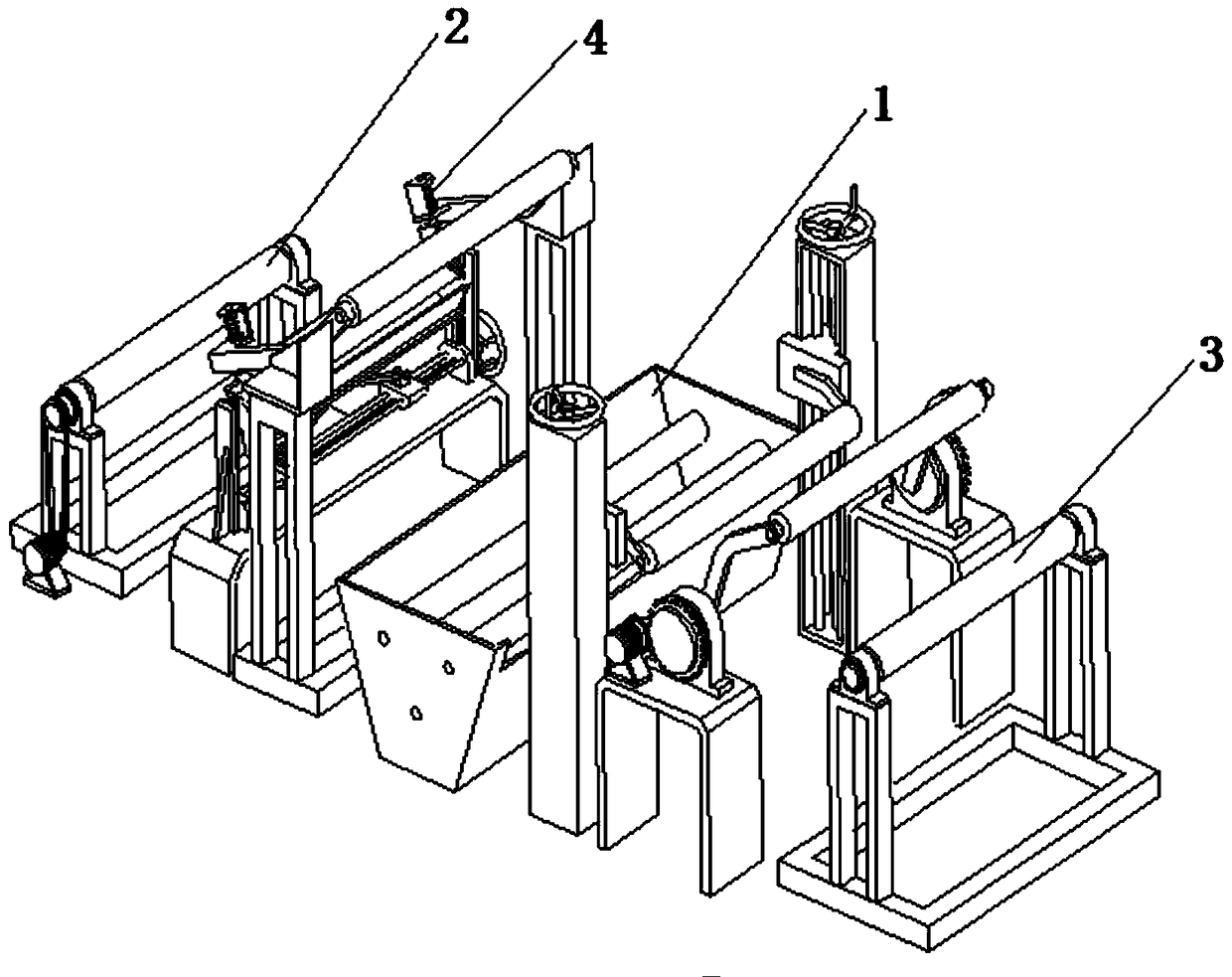

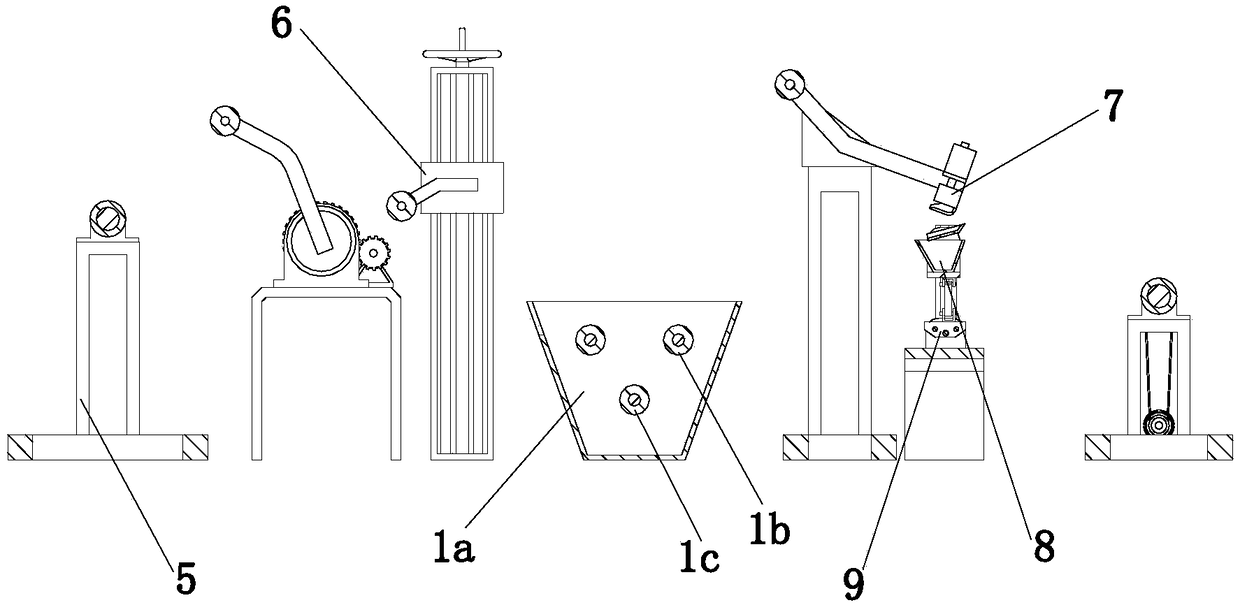

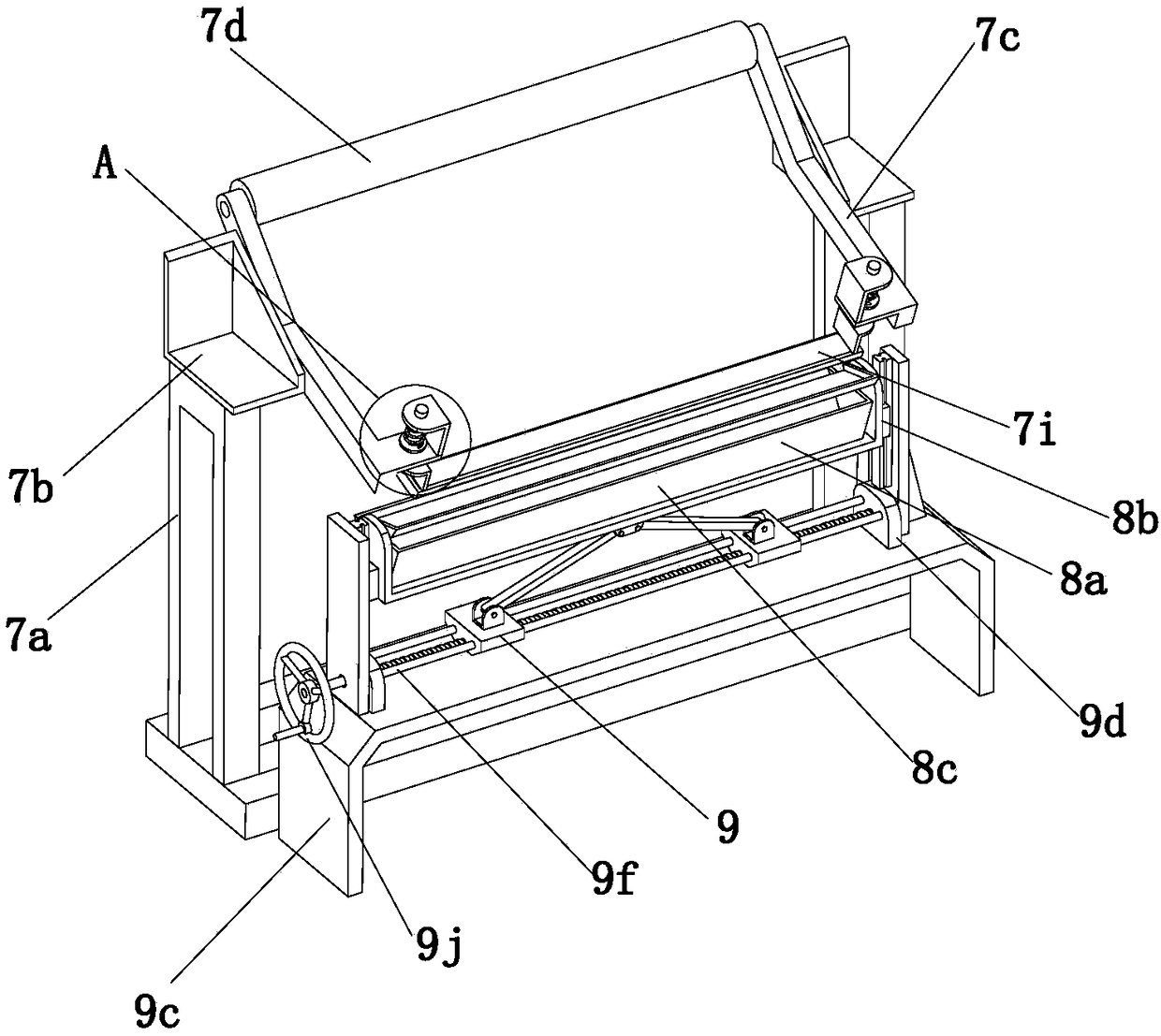

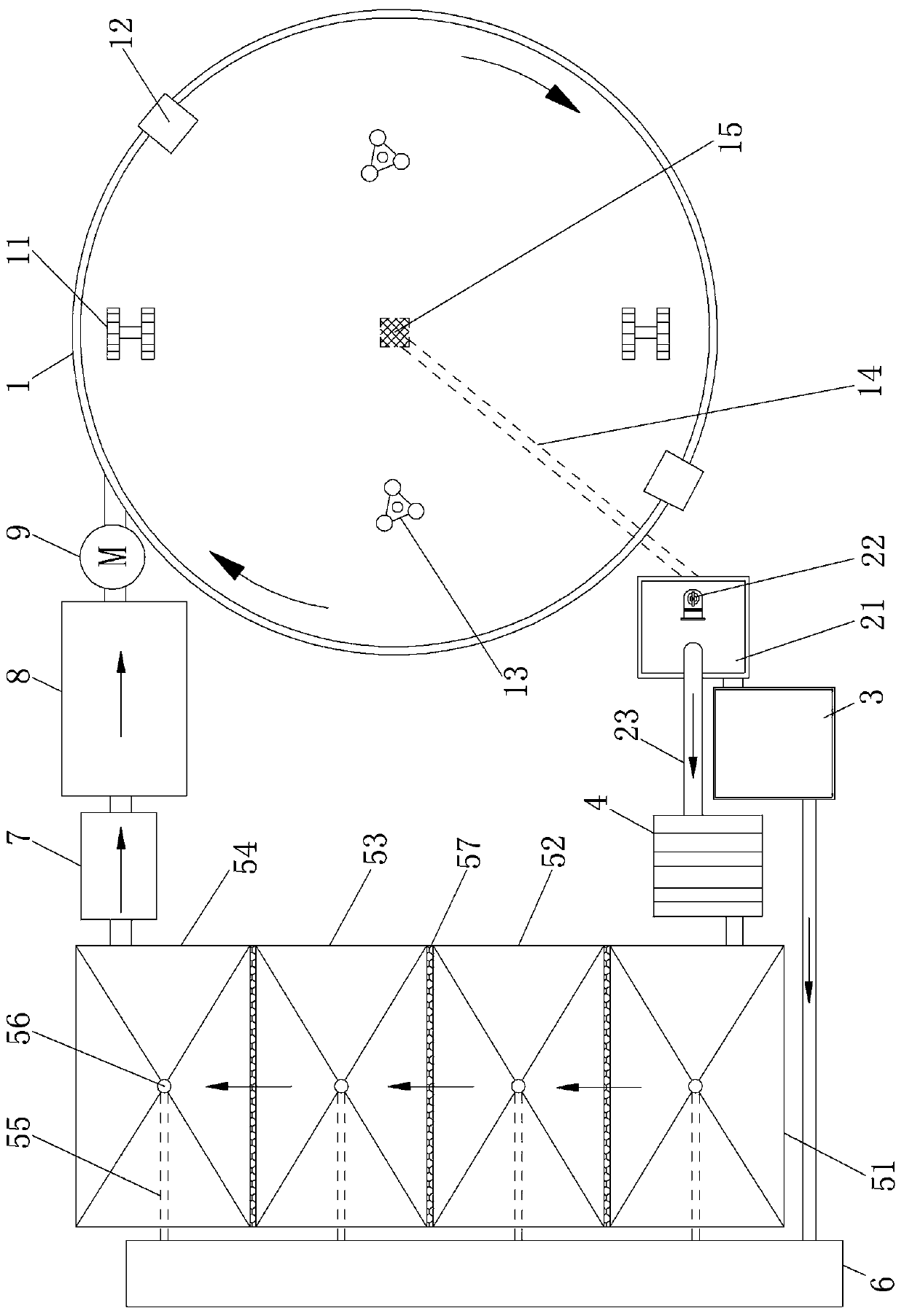

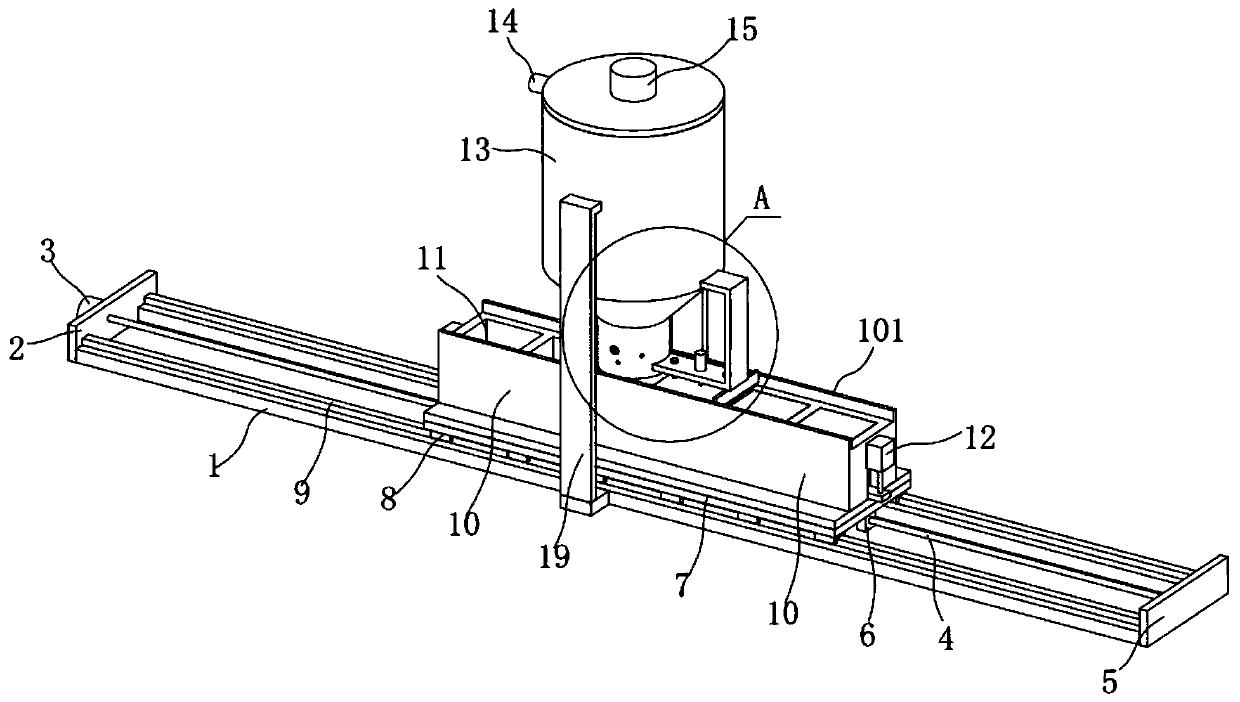

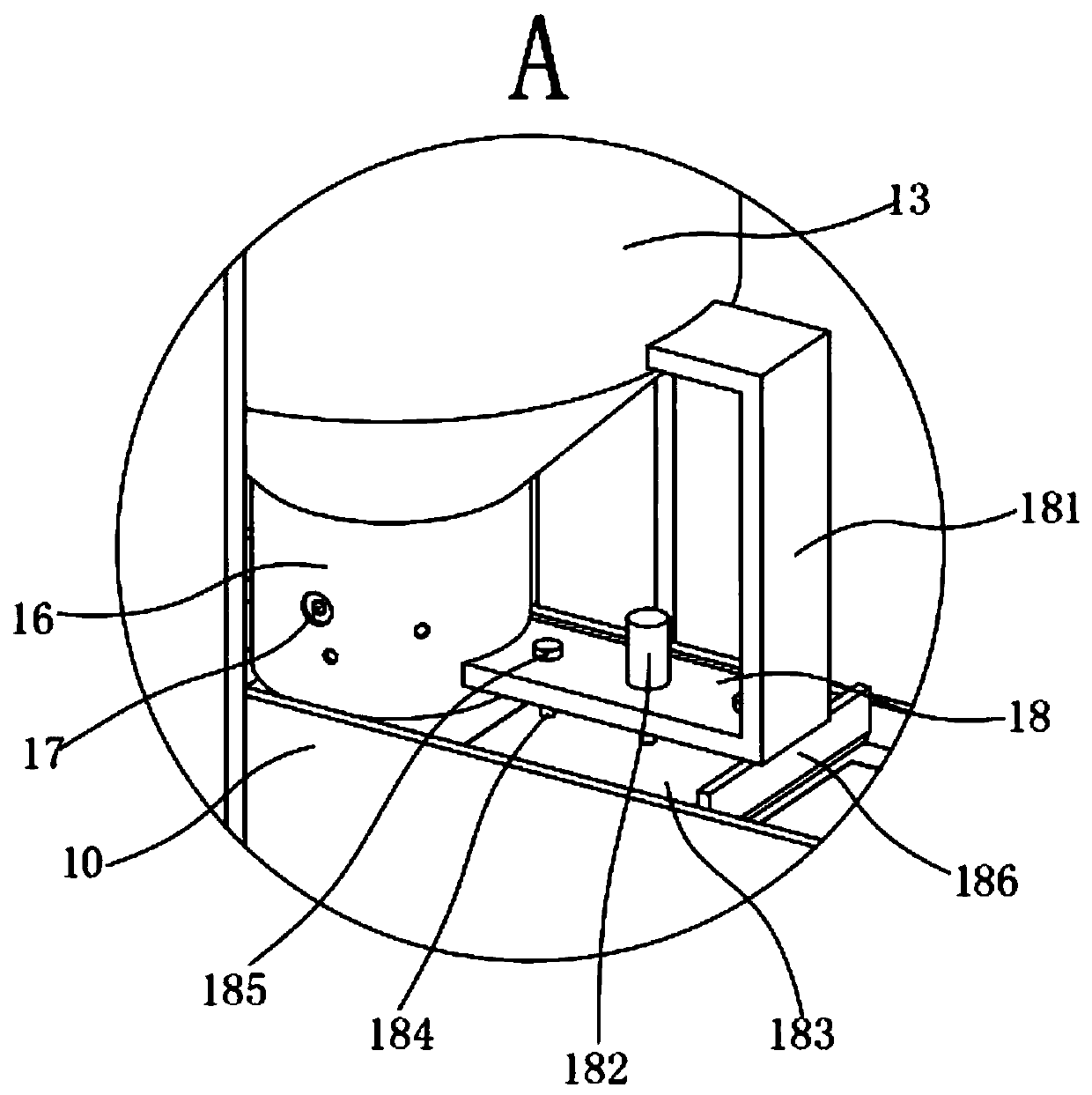

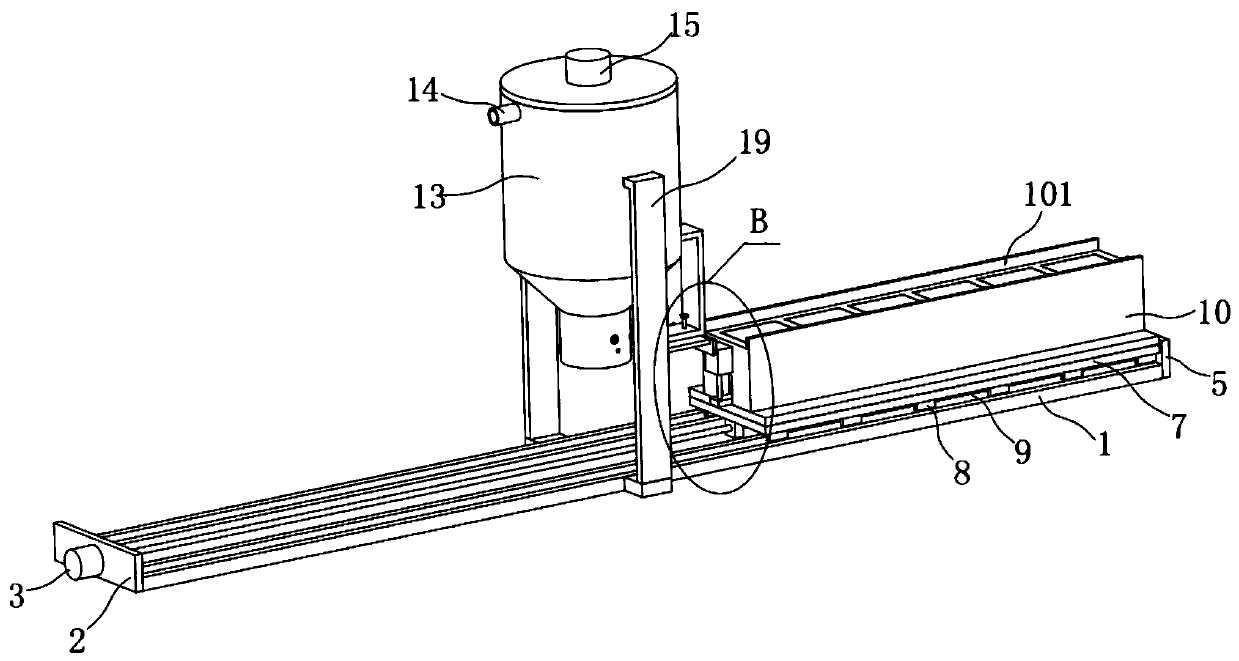

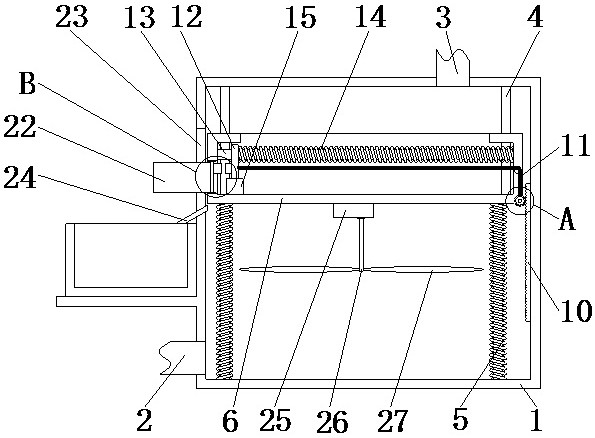

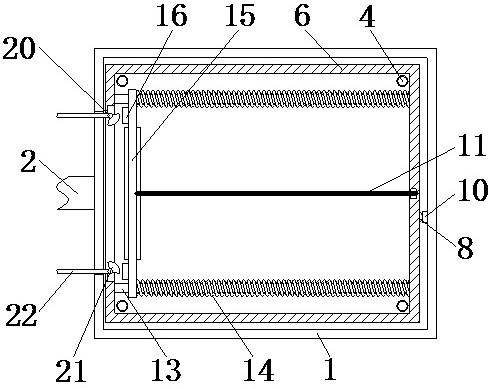

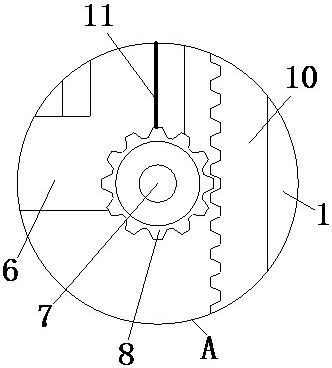

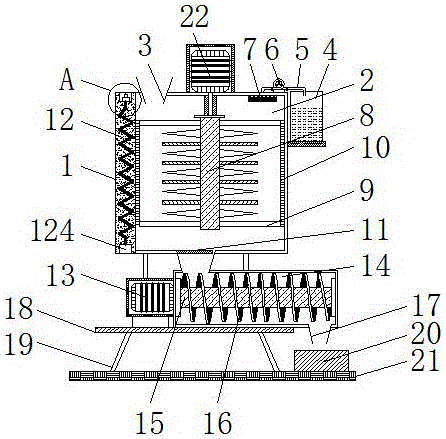

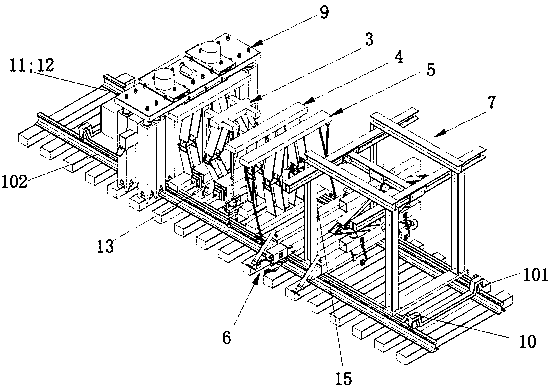

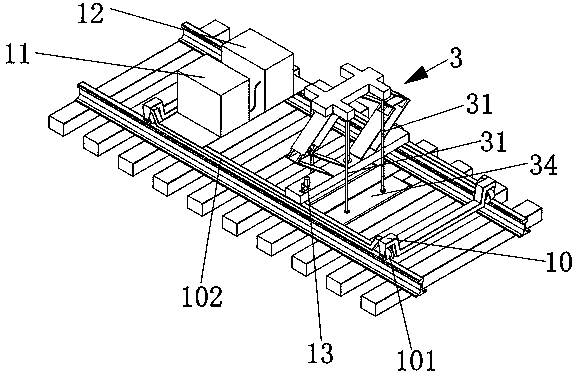

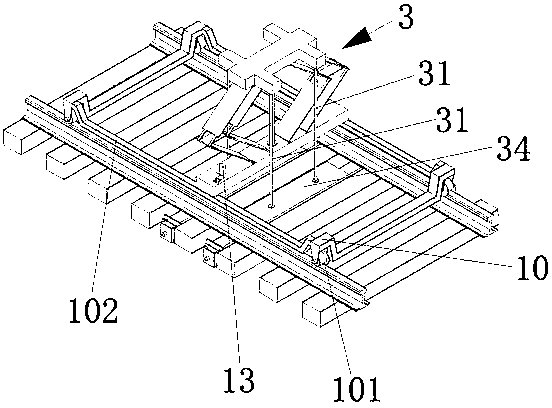

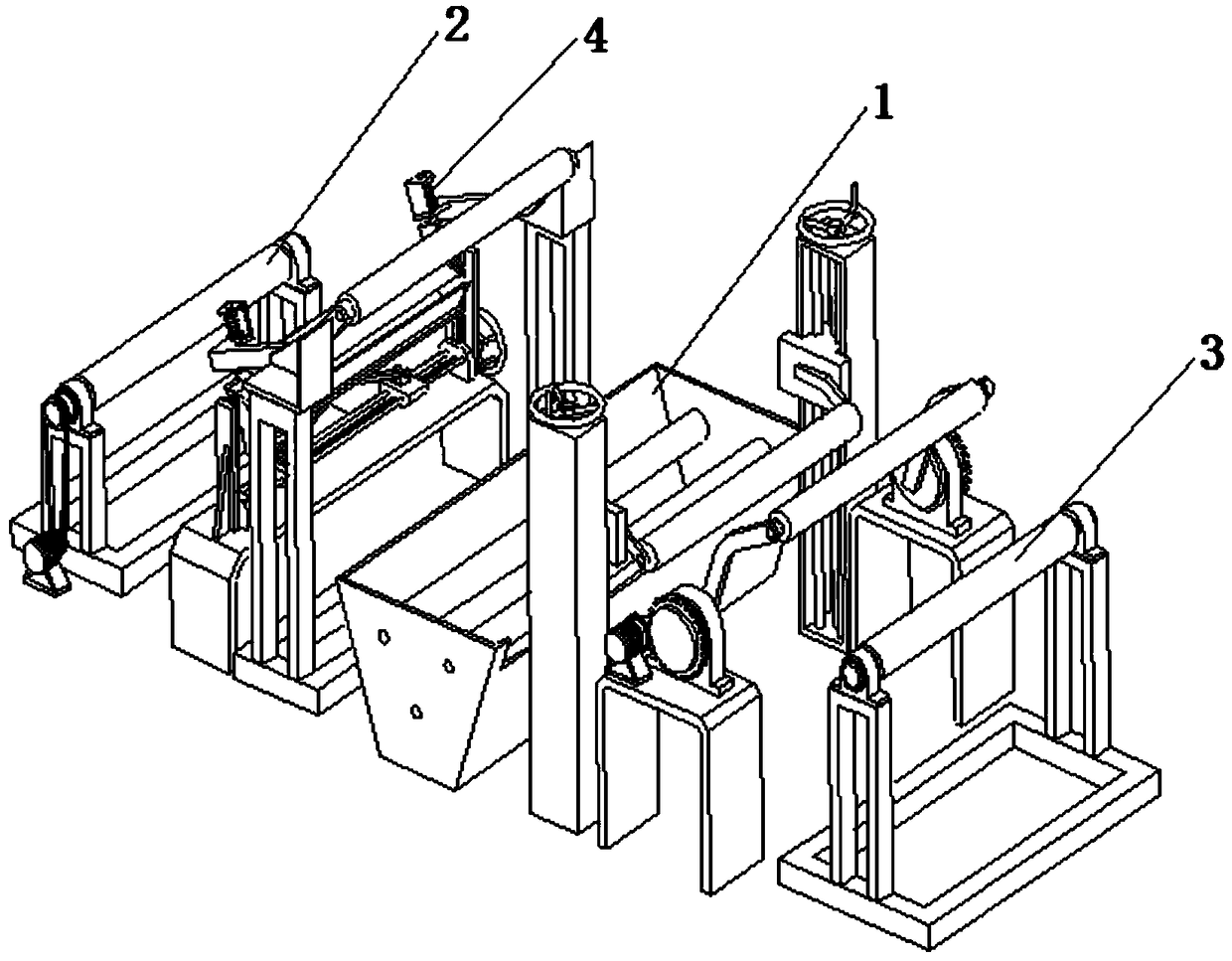

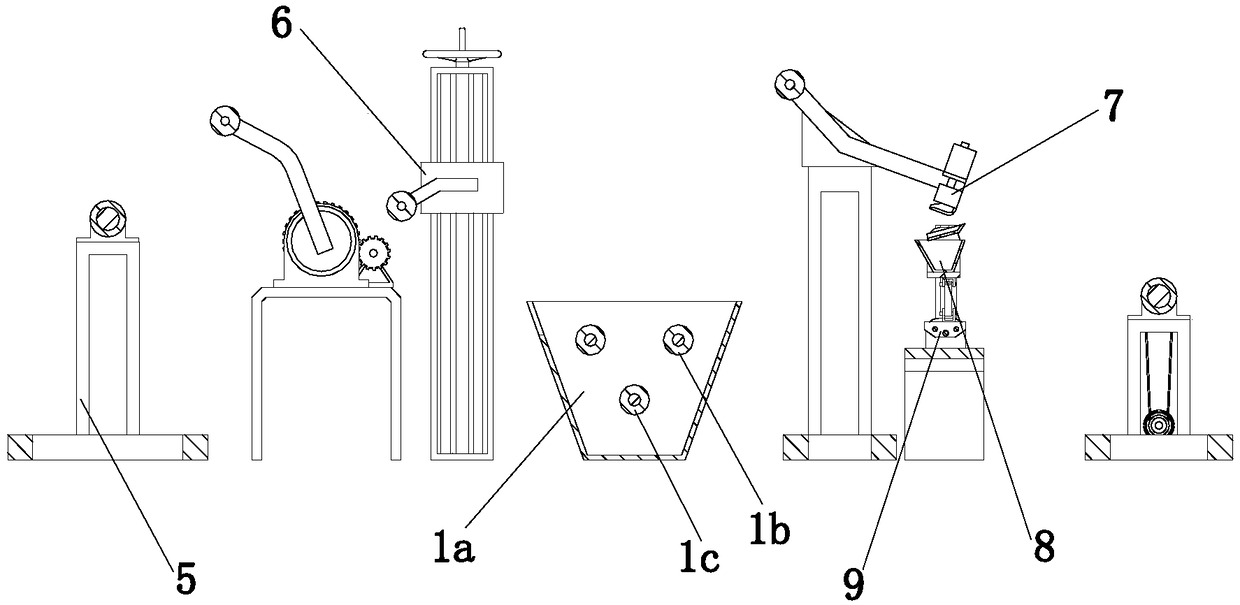

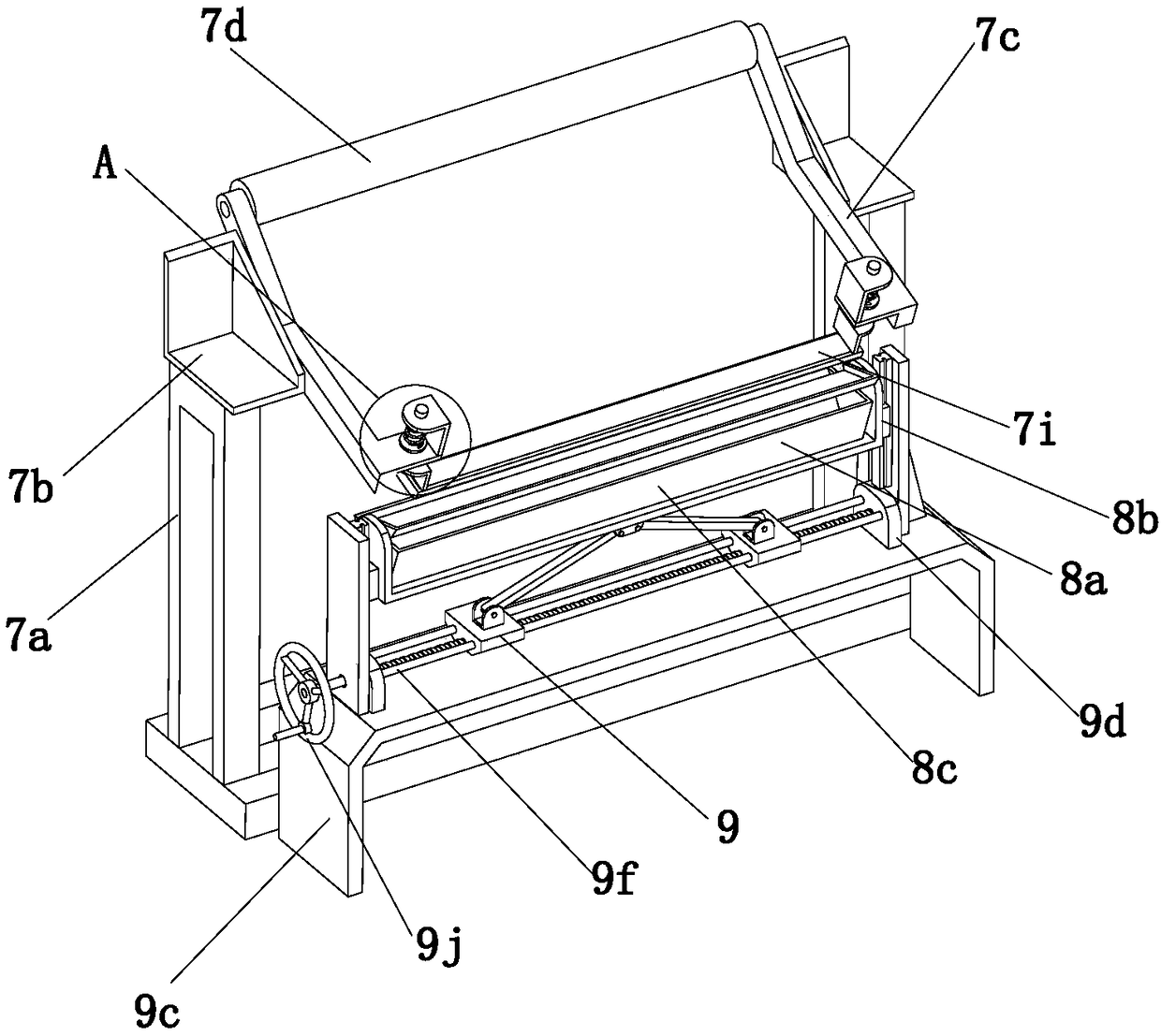

Full-mechanical rapid sleeper replacement machine

InactiveCN104195902AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullEngineering

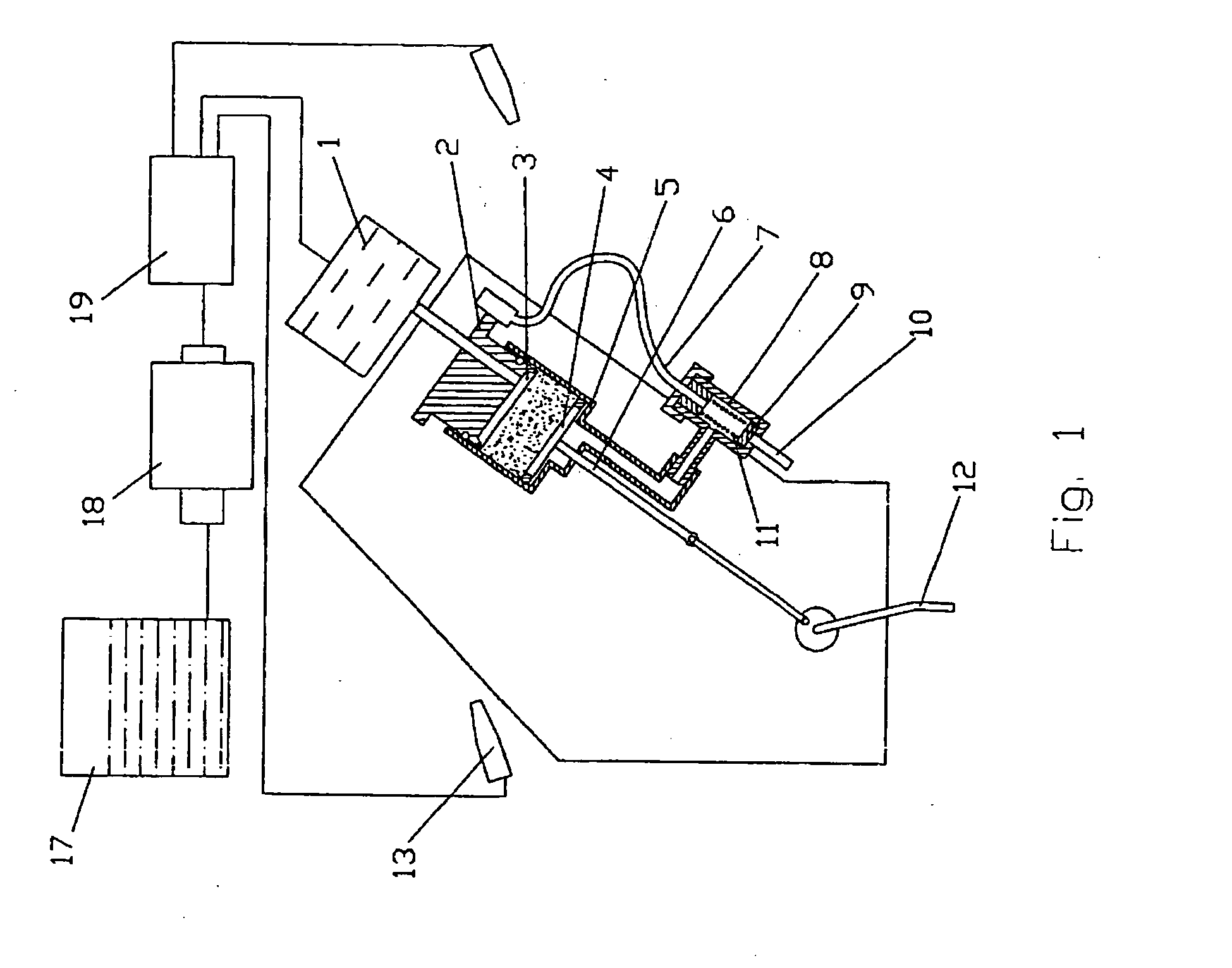

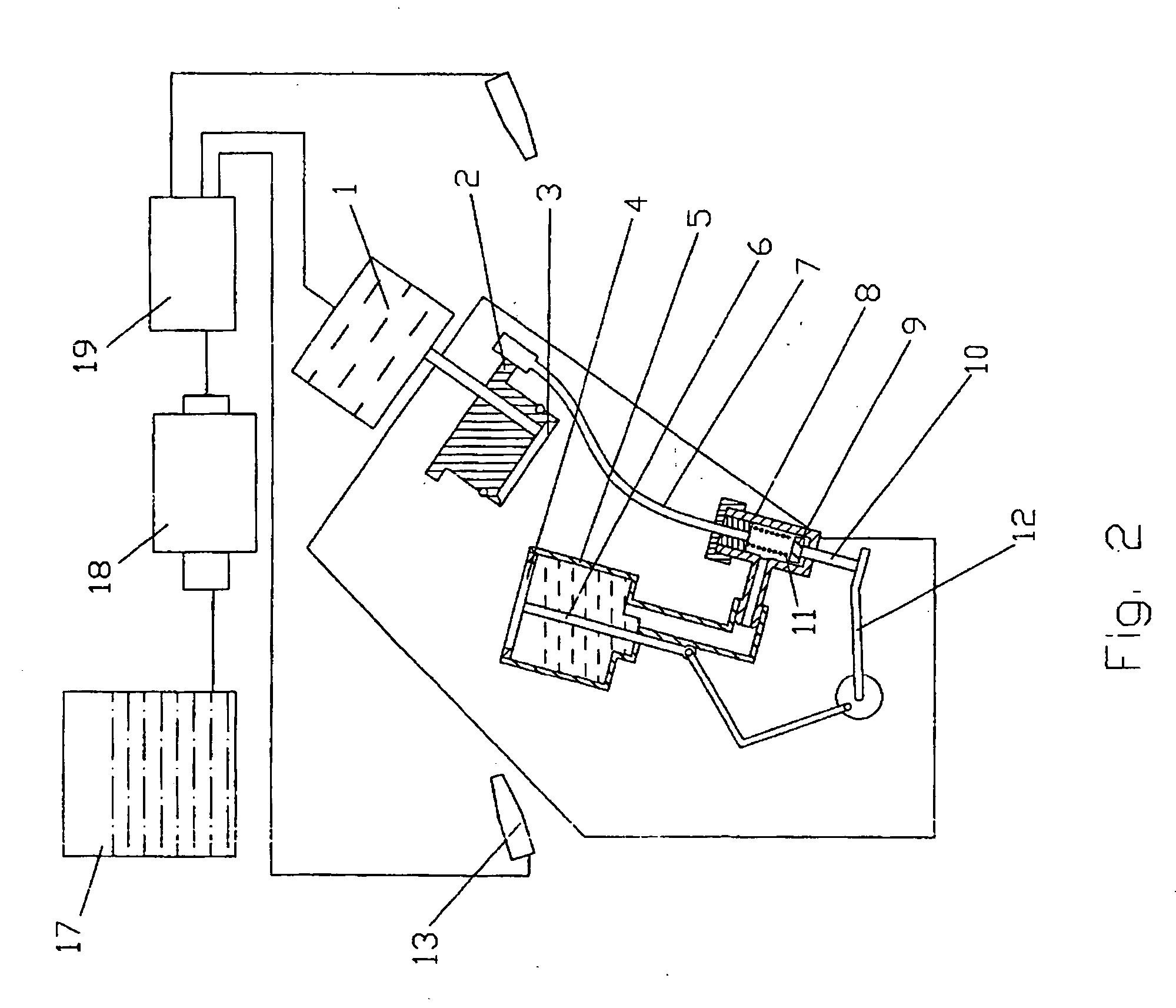

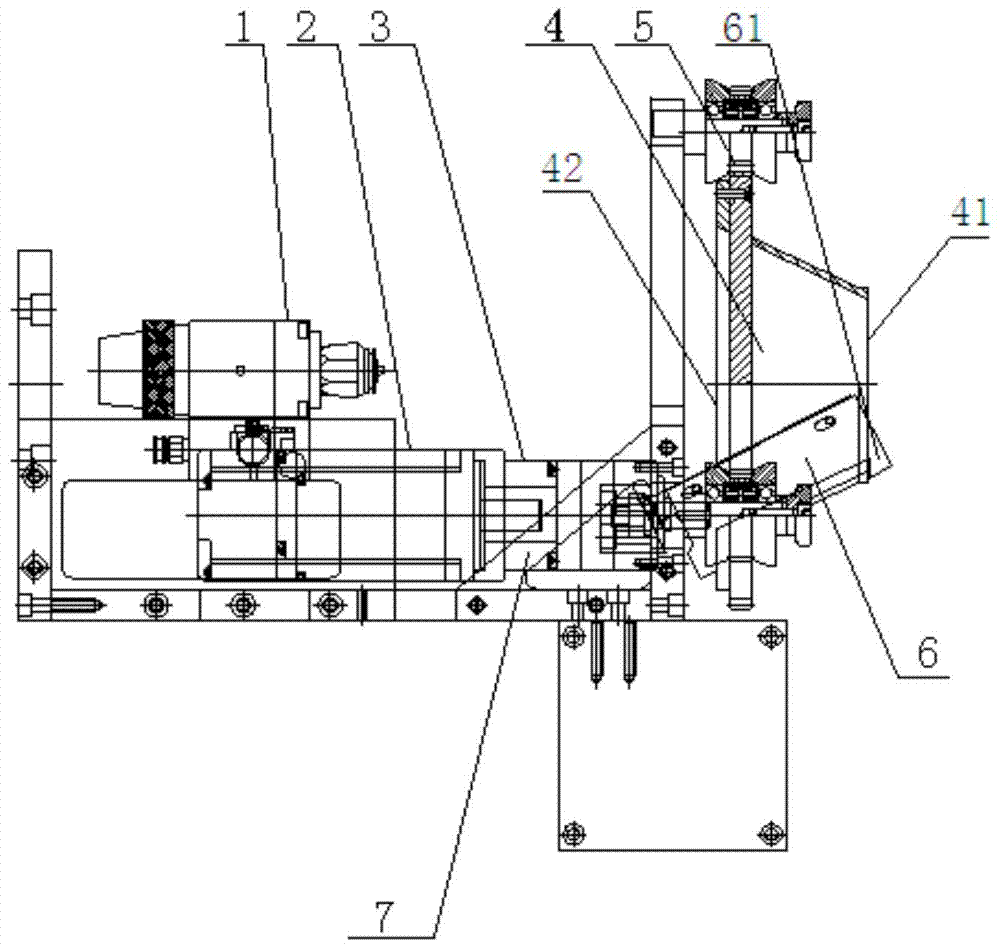

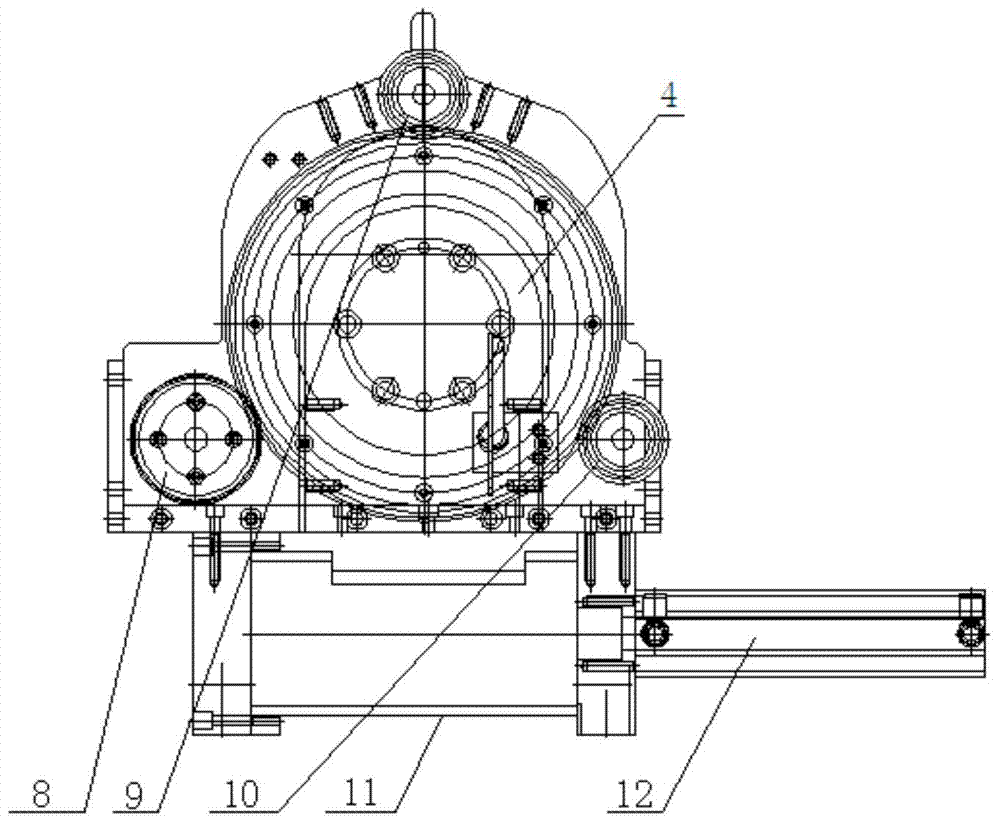

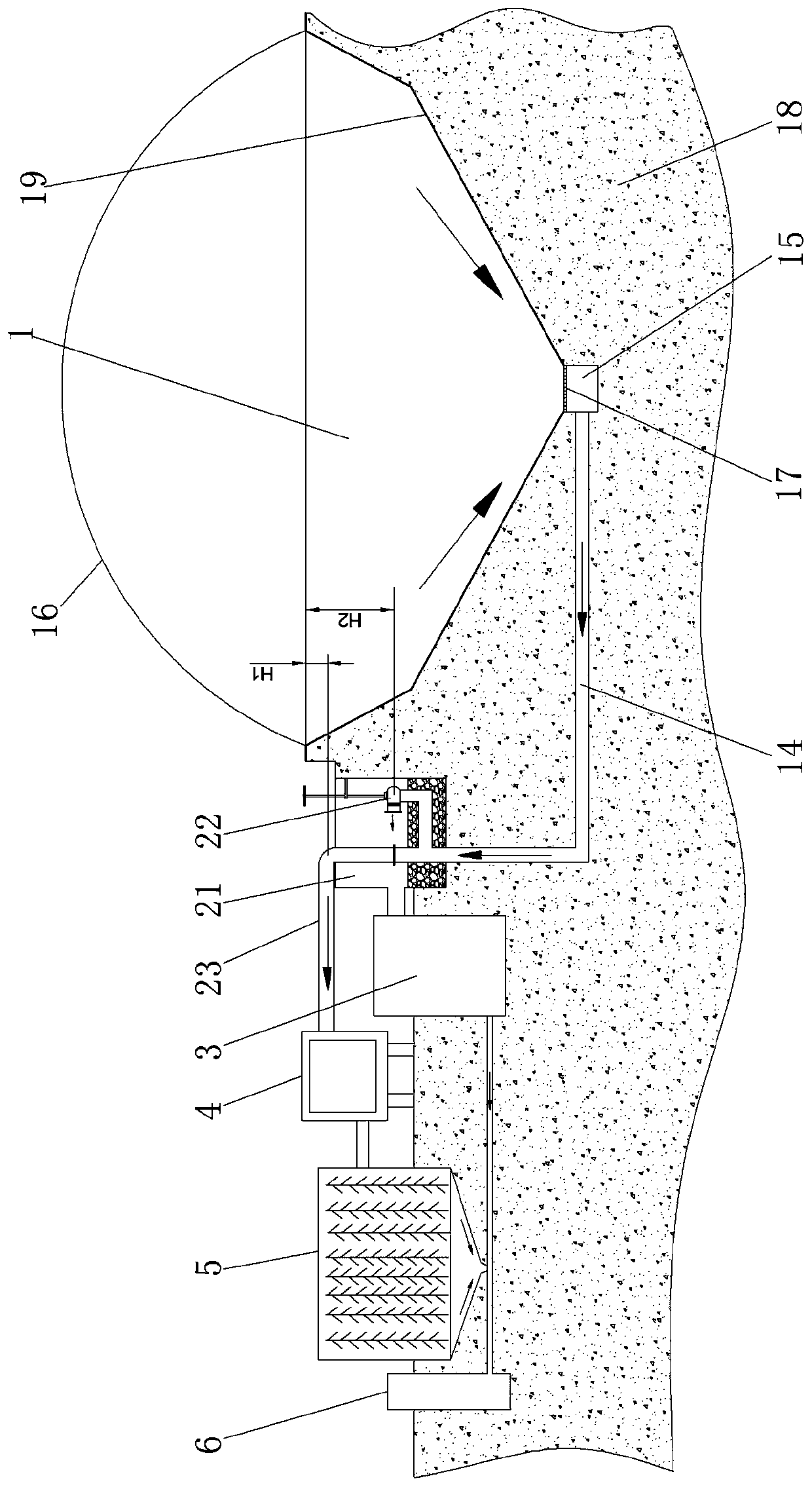

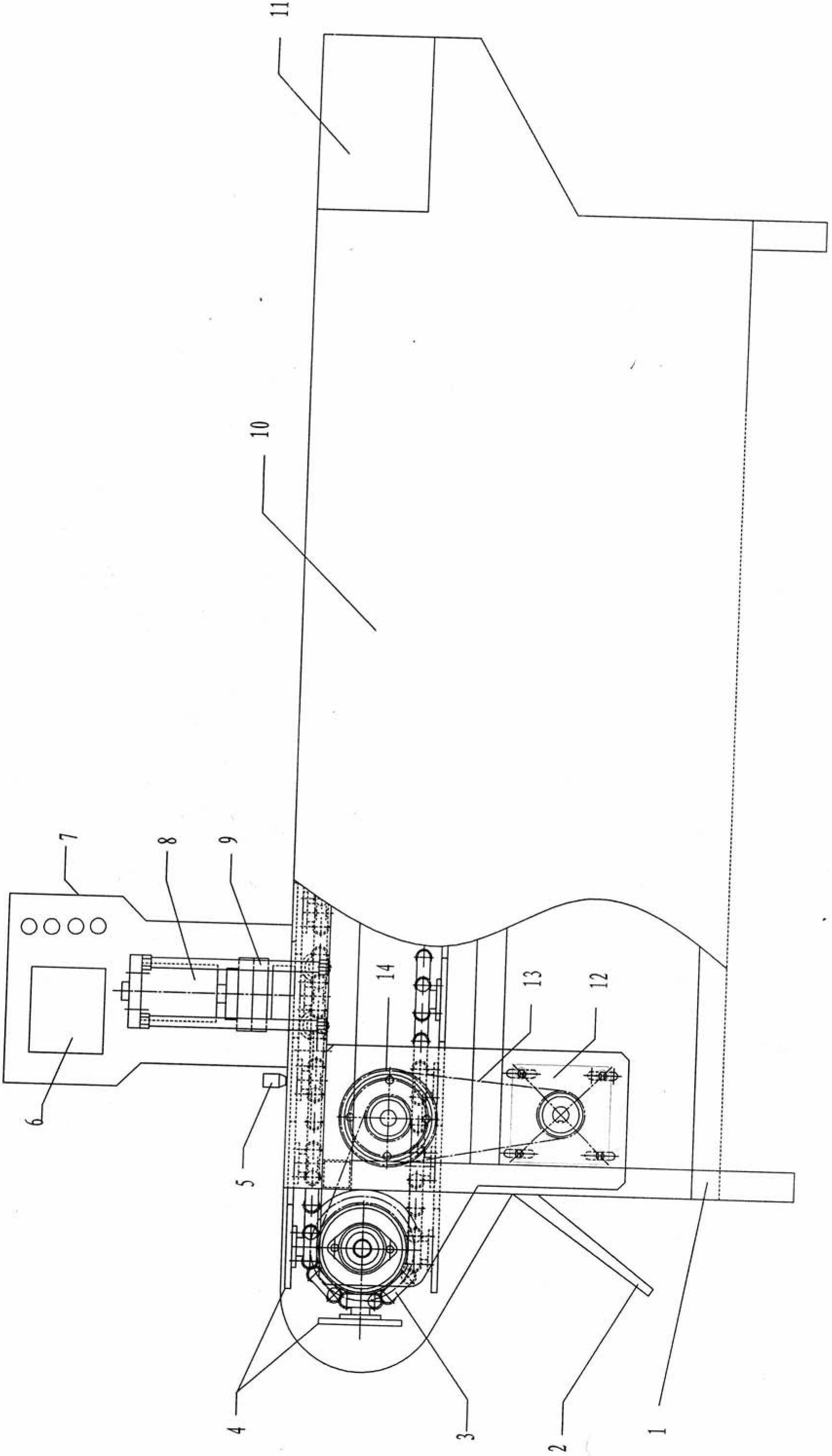

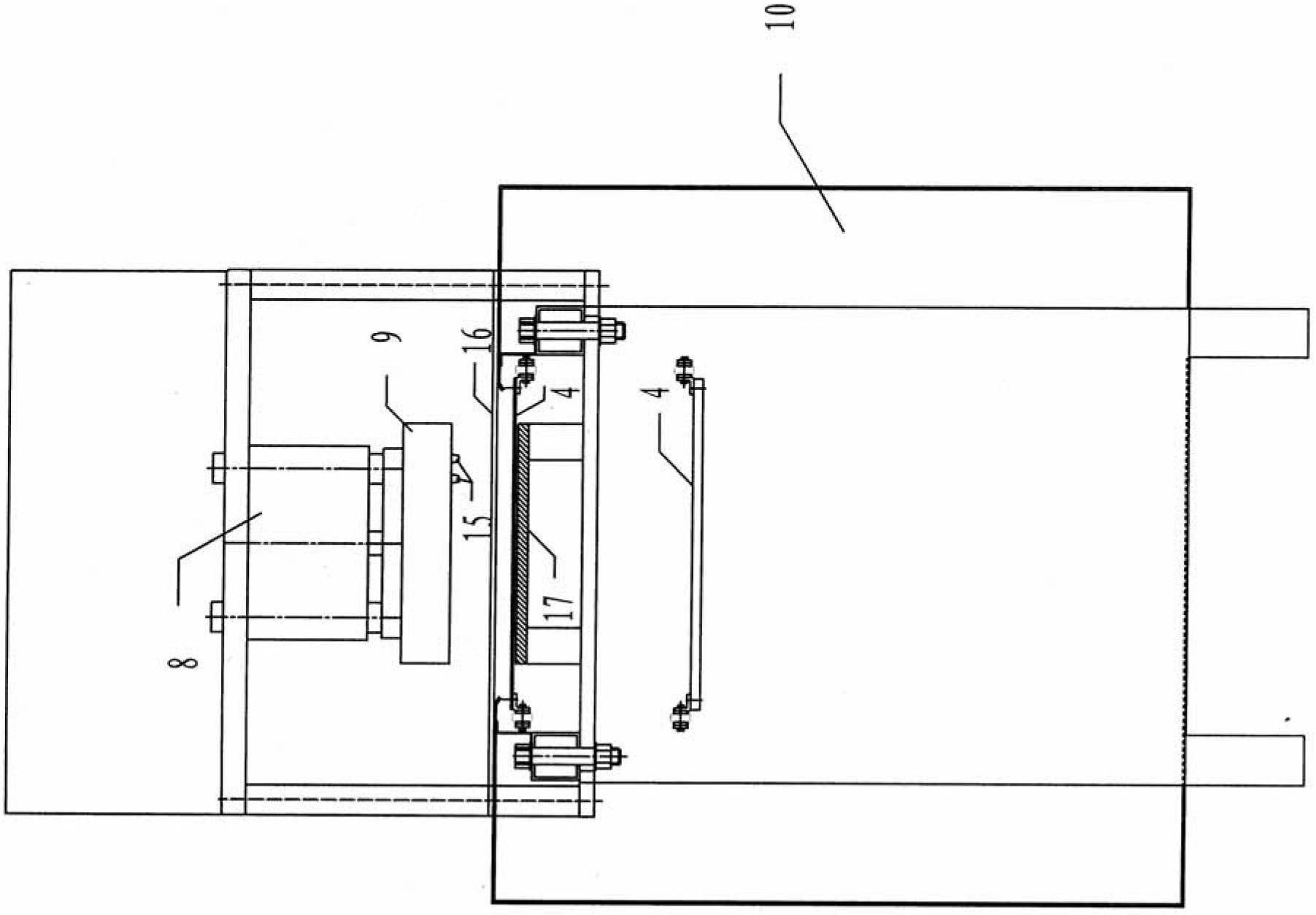

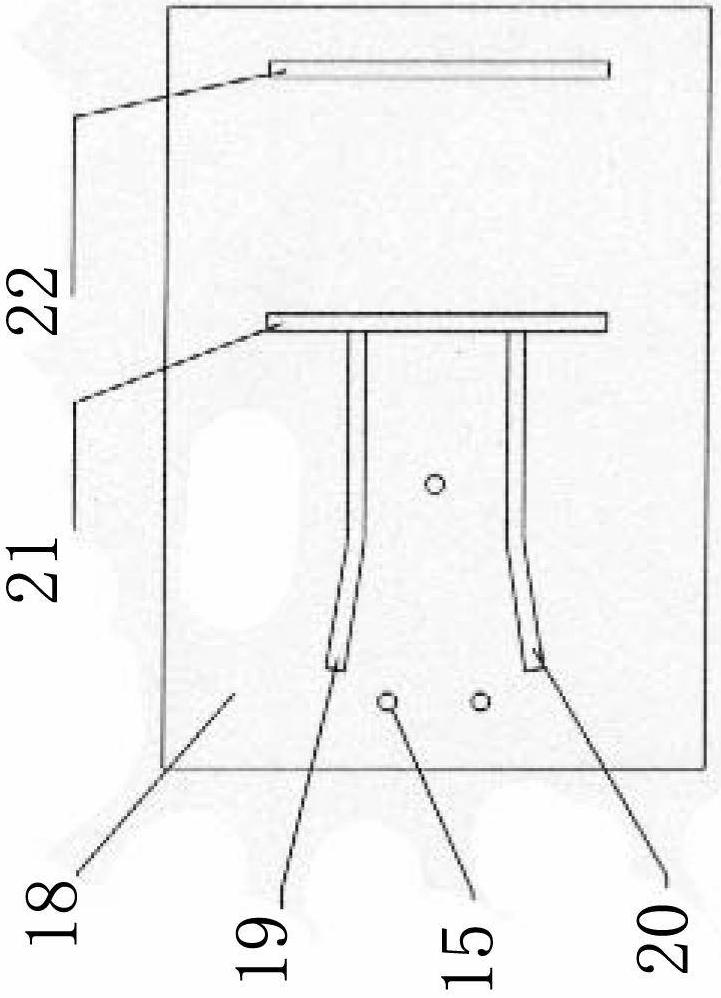

The invention discloses a full-mechanical rapid sleeper replacement machine which comprises a vibration rotary excavating and ballast removing device, a ballast collecting and discharging device, a vibration ballast pushing device, a four-nut synchronous assembly and disassembly device, a sleeper lifting and rotating device, a sleeper pushing and pulling device, a sleeper hoisting device, a rail car, a power generator, a hydraulic system box, a first camera assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a monitor. A plurality of casters and two longitudinal beams are arranged on the rail car, the vibration rotary excavating and ballast removing device, the ballast collecting and discharging device, the vibration ballast pushing device, the four-nut synchronous assembly and disassembly device, the sleeper lifting and rotating device, the sleeper pushing and pulling device, the sleeper hoisting device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tow tractor. The full-mechanical rapid sleeper replacement machine is suitable for rapid sleeper replacement on straight-line and curved rail rod segments, operating time in repairing skylight through limited line can be made full and reasonable use of, and full-mechanical sleeper replacement can be achieved.

Owner:KUNMING UNIV

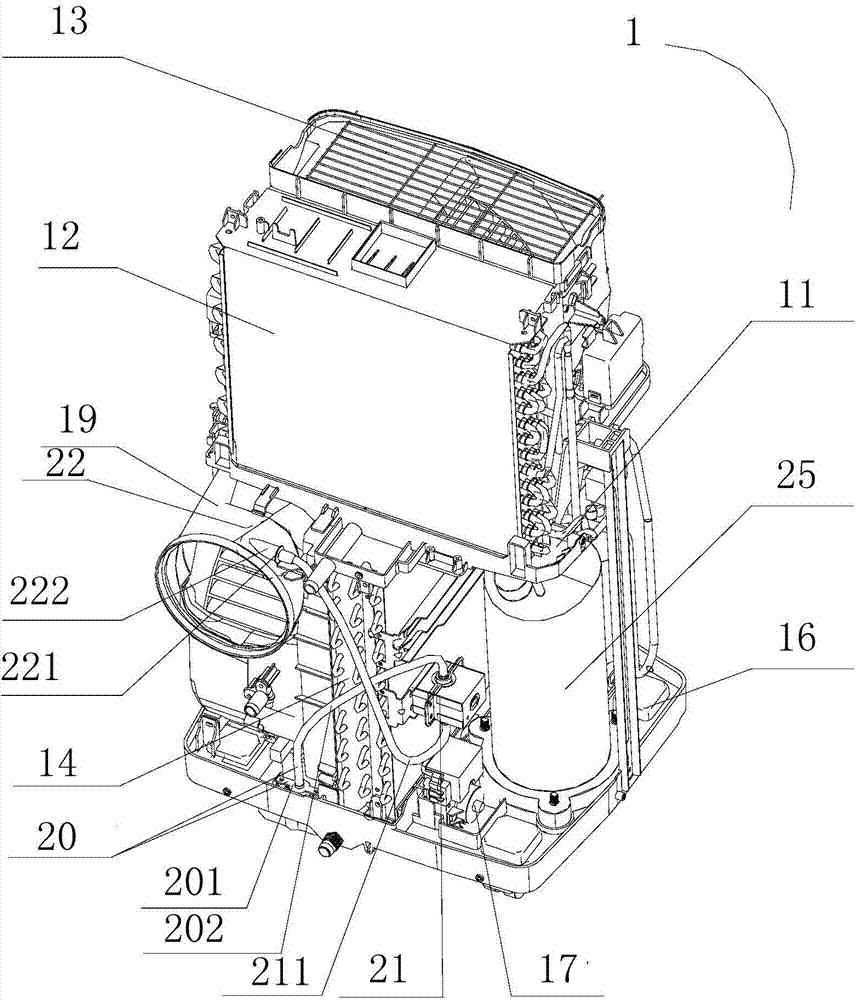

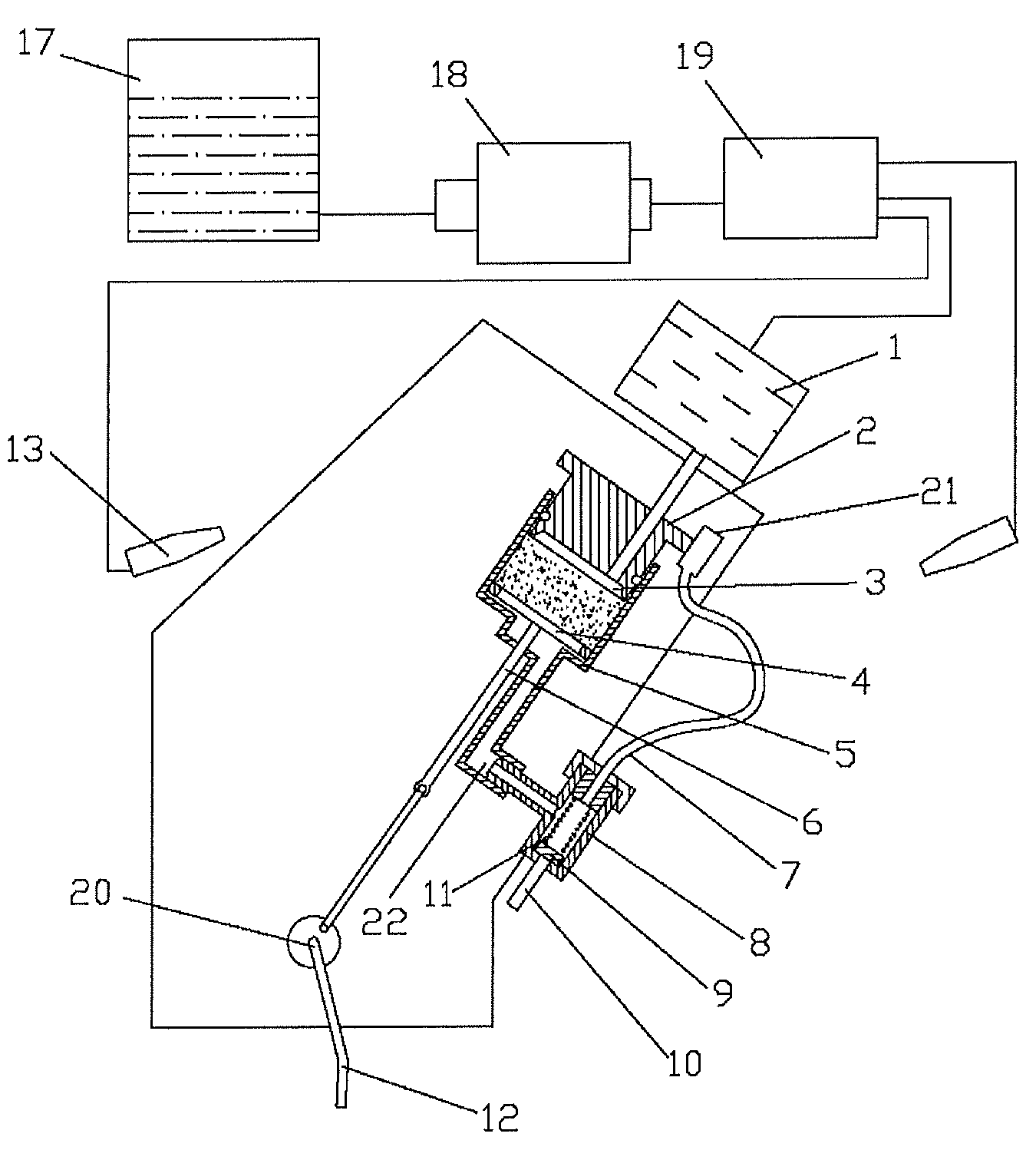

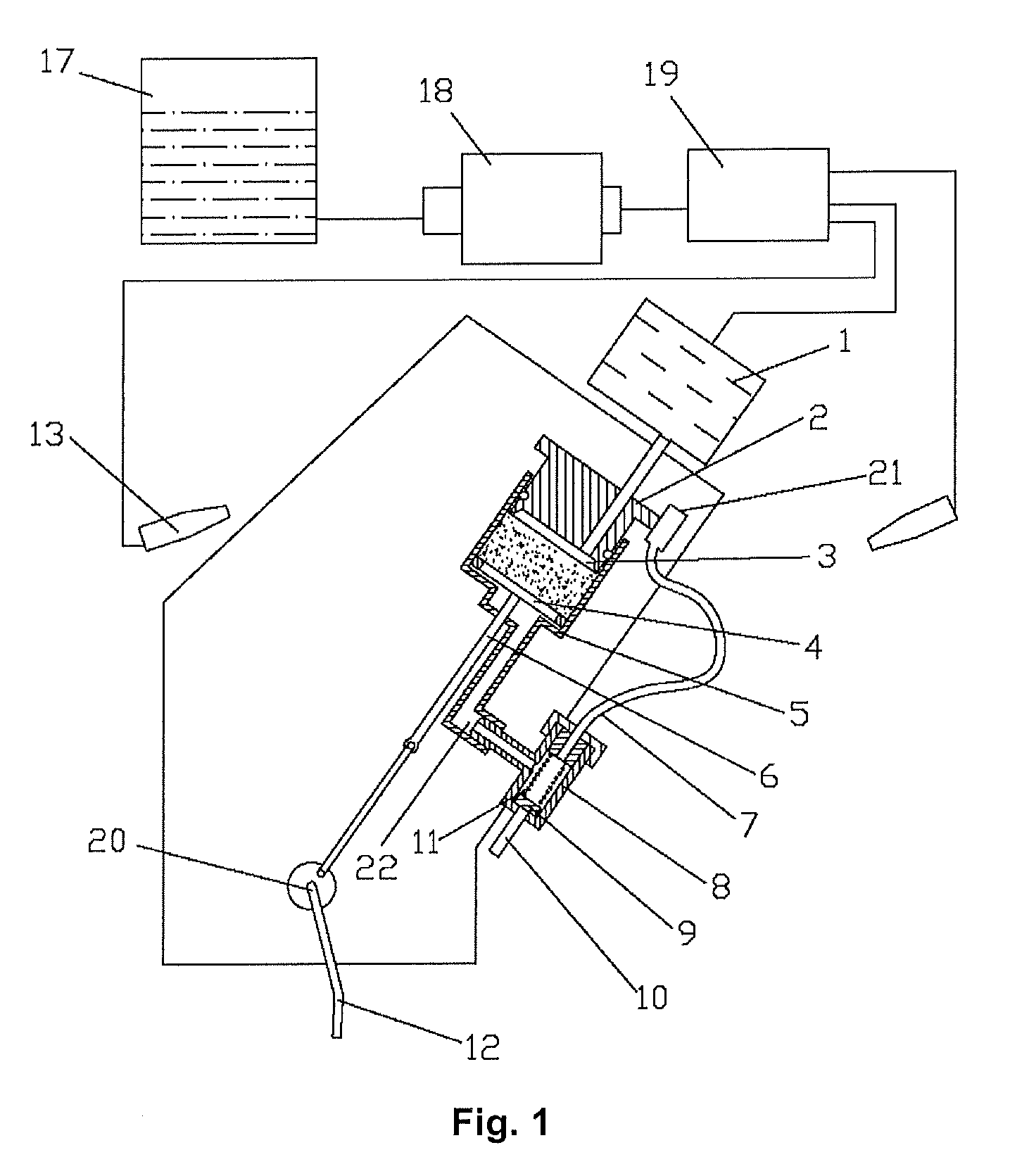

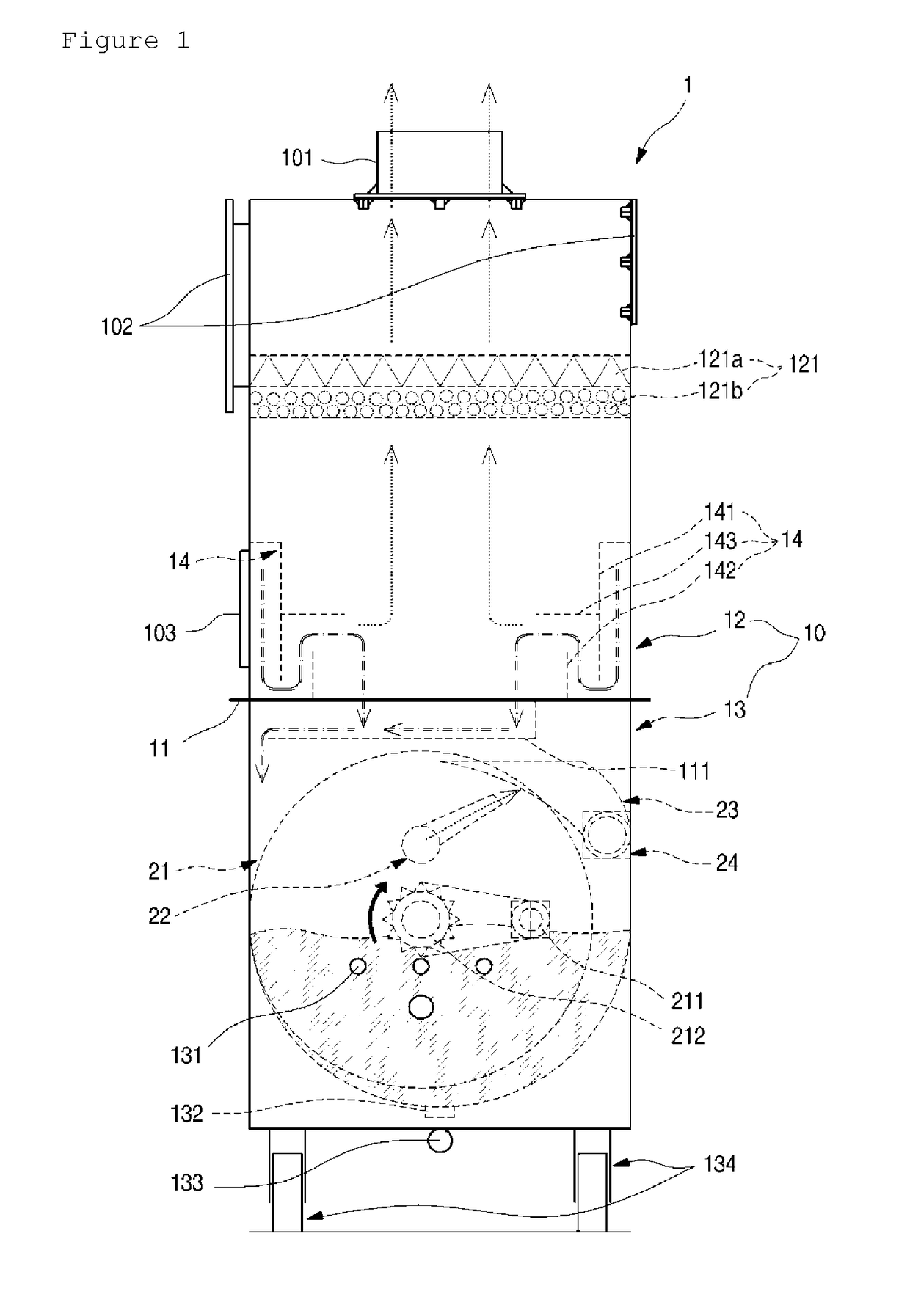

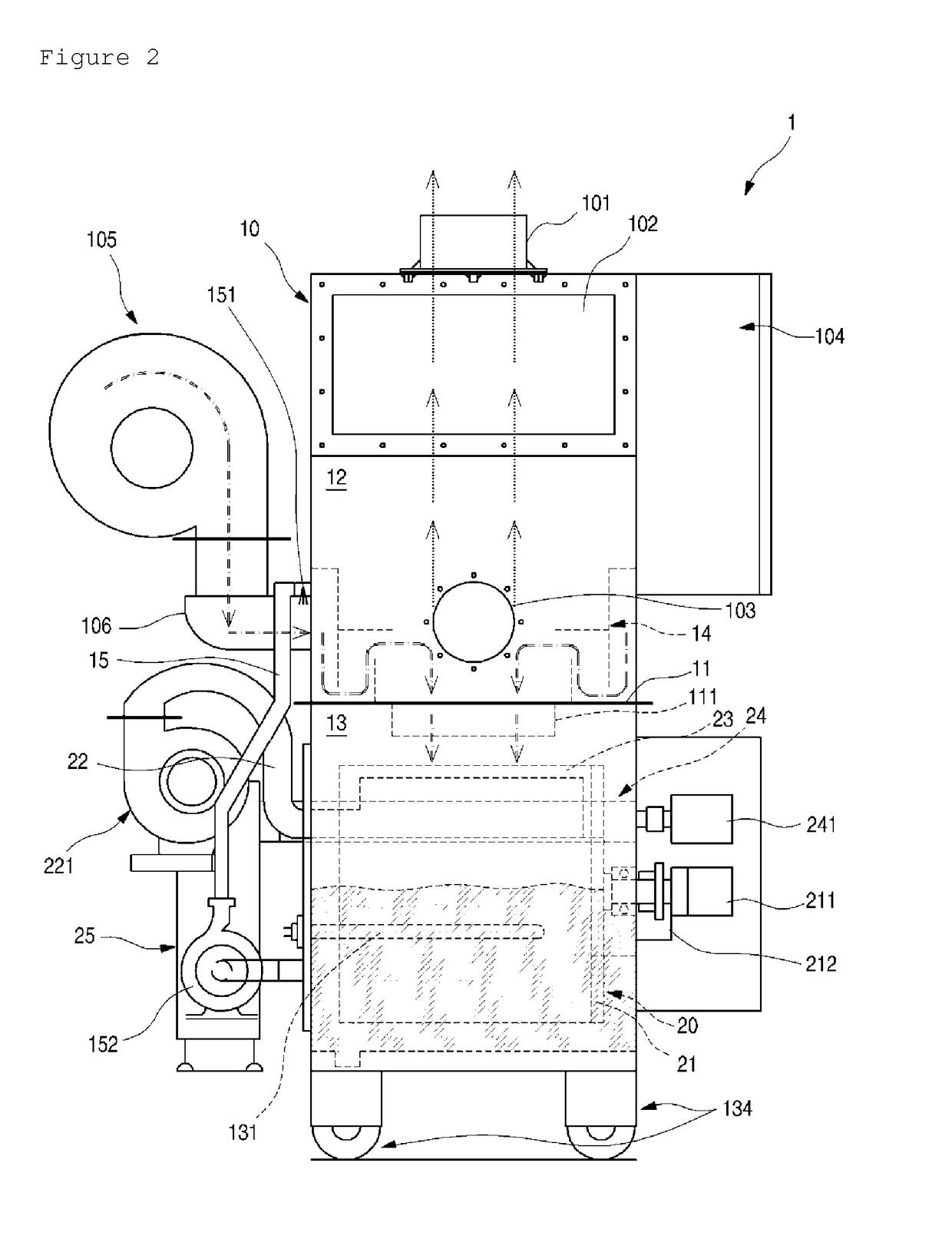

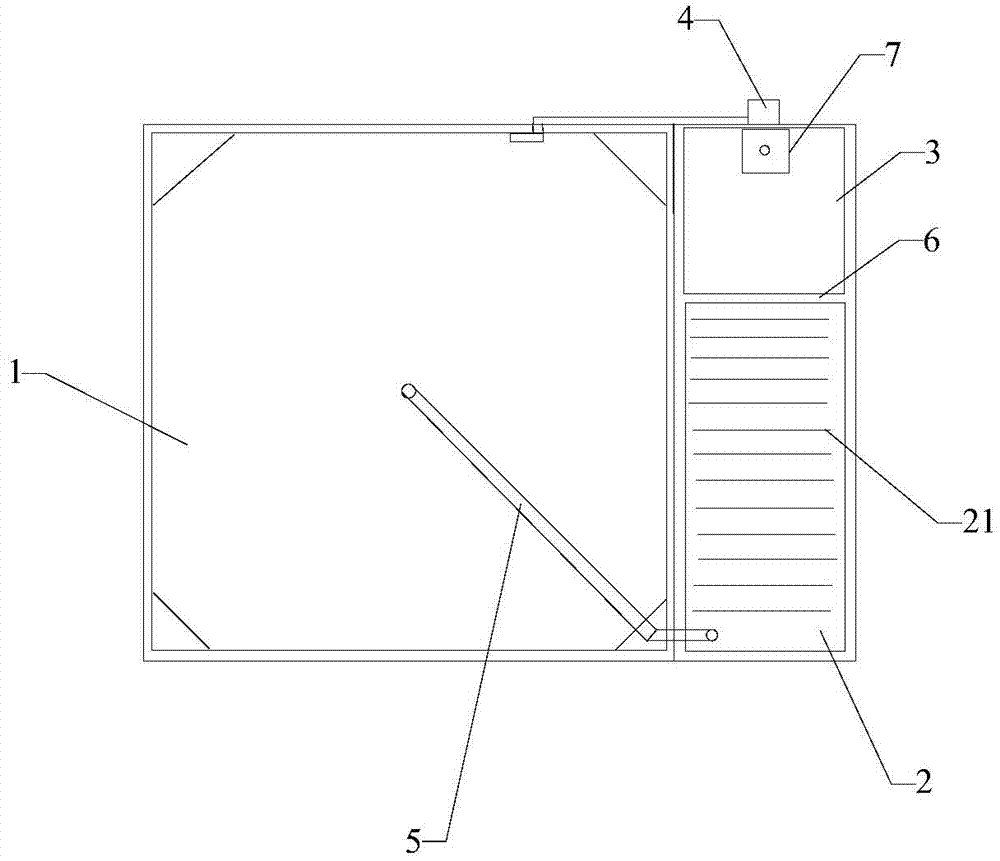

Integrated air conditioner and condensed water processing method for integrated air conditioner

ActiveCN104764095AImprove human needsFully recycleCondensate preventionLighting and heating apparatusEnvironmental engineeringWater processing

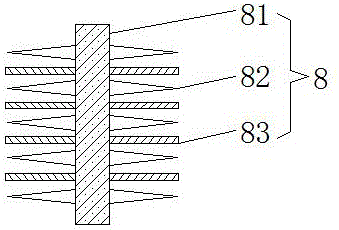

The invention discloses an integrated air conditioner and a condensed water processing method for the integrated air conditioner. The integrated air conditioner comprises an indoor water receiving plate, a drainage device connected with the indoor water receiving plate and used for leading the condensed water in the indoor water receiving plate to the outer side walls of multiple rows of condensers of the integrated air conditioner, the multiple rows of condensers used for heating condensed water on the outer side walls to at least vaporize part of the condensed water, a water tank arranged on a chassis of the integrated air conditioner and used for receiving non-vaporized condensed water on the outer side wall, and a water beating motor which comprises a plurality of water beating wheels and is used for beating the non-vaporized condensed water to the outer side walls of the condensers through the water beating wheels so as to enable the multiple rows of condensers to vaporize the non-vaporized condensed water again. By means of the technical scheme, the condensed water in the integrated air conditioner can be discharged automatically, and a user is protected from manually discharging the condensed water.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

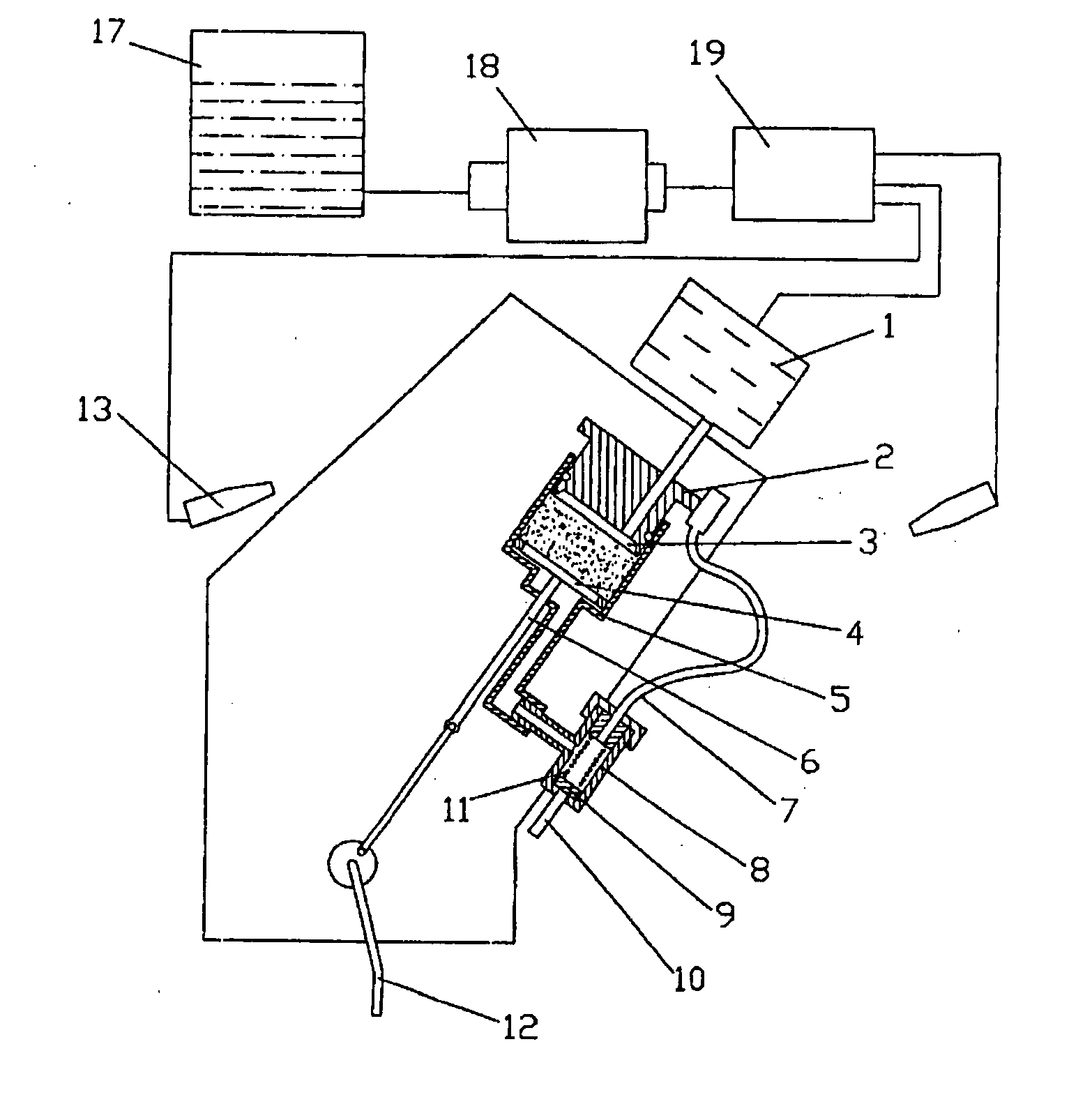

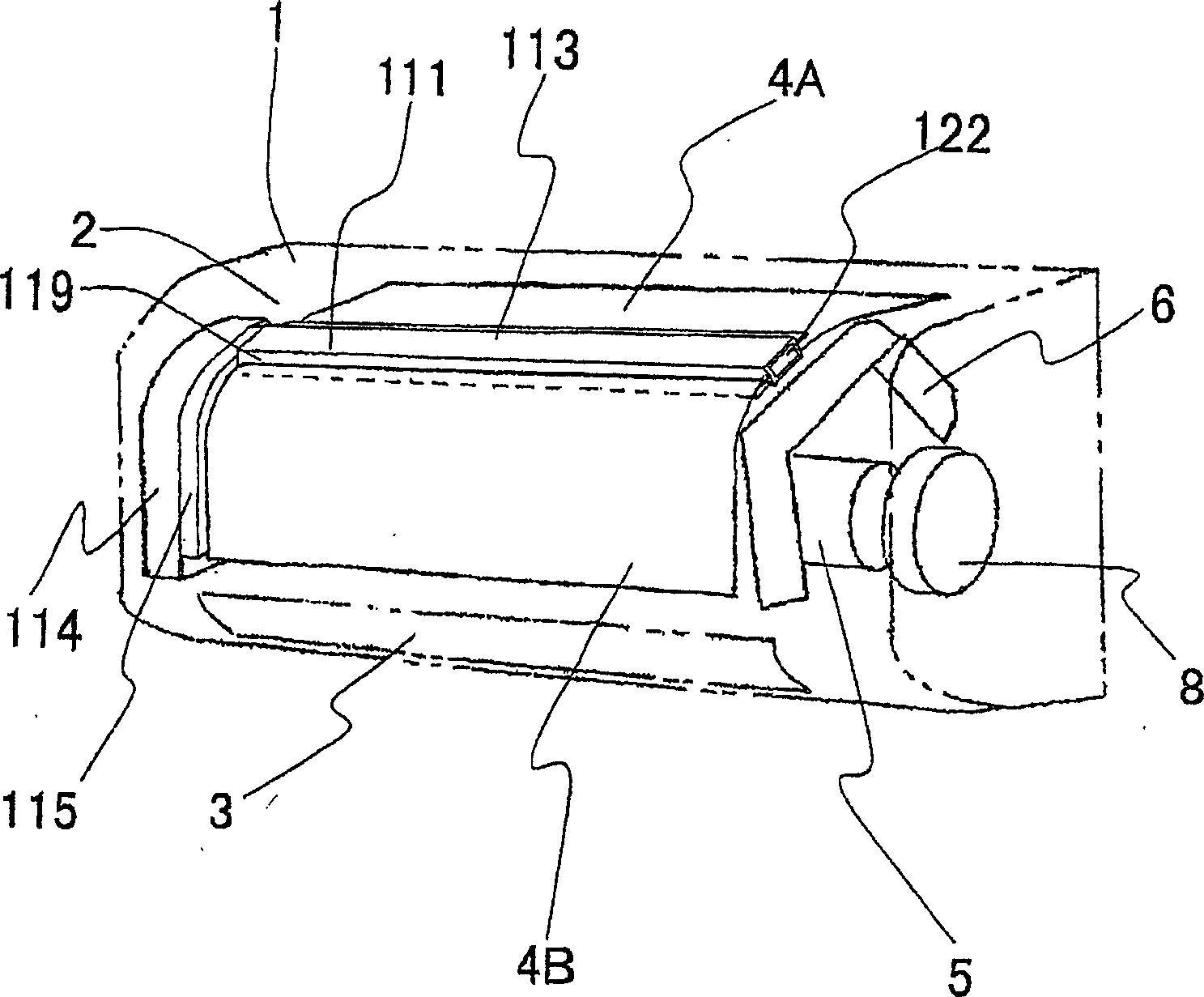

Automatic coffee brewing apparatus and control method

InactiveUS7571674B2Easy to clean automaticallyFor automatic dischargeBeverage vesselsWater dischargeWater flow

This invention provides for a coffee brewing apparatus and its control method, which comprises a control circuit and a water loop comprising a water reservoir, a pump, a control valve, a boiler, a brewing assembly, a three-way connector and a connecting hose. When coffee is to be brewed, hot water flows top-down through the brewing chamber cover, the upper filter, the coffee grounds, the lower filter, the brewing chamber, the first port of the three-way connector, the second port of the three-way connector and the connecting hose; the brewed coffee finally flows out from said connecting hose. This coffee brewing apparatus has additional functions of automatic residue discharge, automatic water discharge and automatic cleaning.

Owner:TOP TECH CO LTD

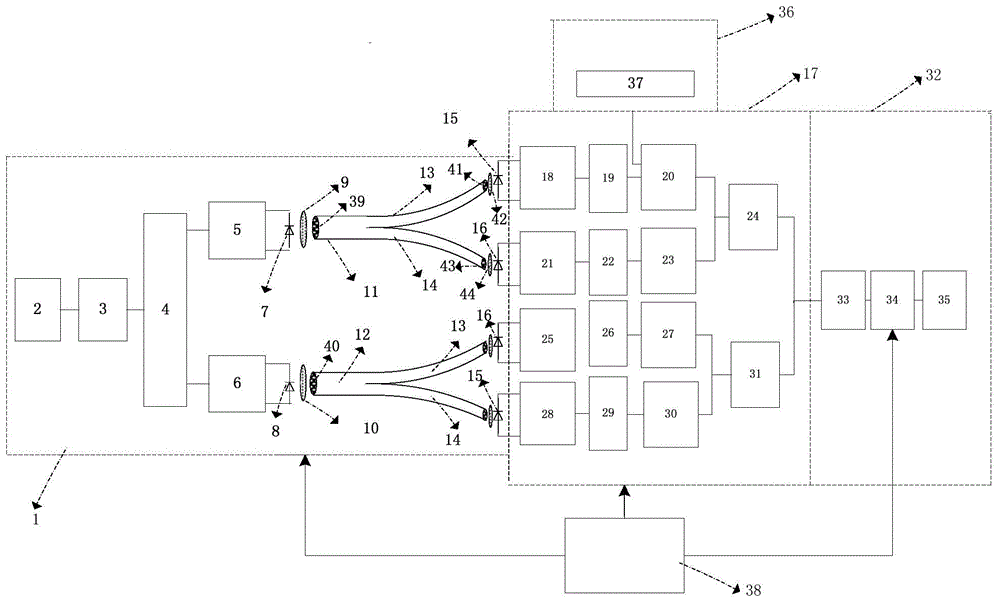

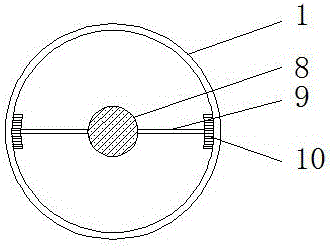

Two-channel optical fiber method and sensor for measuring turbidity

ActiveCN104596990AImprove accuracyImprove water resistanceScattering properties measurementsTransmissivity measurementsPhysicsScattered light

The invention discloses a two-channel optical fiber method and two-channel optical fiber sensor for measuring turbidity. The method is characterized in that a detection mode adopting double light sources, four laser beams and four photo-electricity is adopted, and the double different-wavelength light sources can be alternately lightened by an optical measuring module, so that 90-degree scattered lights and transmission lights can be alternately measured; a temperature measuring module is used for collecting temperature signals of water; a signal adjusting module is used for processing collected turbidity signals and temperature signals; a data processing module is used for calculation and treatment so that turbidity values and a temperature values are generated, and the in-site collecting data are transmitted to an upper computer. The different-wavelength light sources are simultaneously measured so that the stray light impact on turbidity measurement is eliminated; the external impact on the light signals is avoided through optical fiber transmission, thus the method has the high-temperature and high-pressure resisting performances and the anti-electromagnetic interference performance; temperature compensation is performed on the measured turbidity values so as to improve the measurement precision of turbidity. In-site online detection for the turbidity values is realized by the method, thus the method is high in sensitivity, excellent in linearity, low in cost and easy to carry and install, and the method is applied to narrow detection space and occasions where detected liquid is limited in capacity.

Owner:CHINA AGRI UNIV

Stamping method of multi-station efficient high-precision automobile covering part

The invention relates to a stamping method of a multi-station efficient high-precision automobile covering part, and belongs to the field of stamping. The stamping method includes the steps: feeding a plate into a draw die with a draw bead for drawing; transferring a drawn part onto a trimming and punching die for trimming and punching, removing five waste materials on the periphery of the part and simultaneously punching two positioning process holes; transferring the part onto a trimming die for trimming, and removing three waste materials remaining on an inclined surface in a previous working procedure; continuing transferring the part onto a secondary trimming and punching die, removing redundant waste materials at a split position and simultaneously punching four front holes; next, conveying the part onto a flanging and sizing die for flanging and sizing to determine the shape of the covering part; finally, transferring the part onto a side-punching and splitting die for side-punching and splitting. Based on consideration of the problems of part drawing breakage, rebound and positioning difficulty, the plate is drawn twice and trimmed for three times, and both the production efficiency and precision of the covering part are improved.

Owner:JIANGSU UNIV

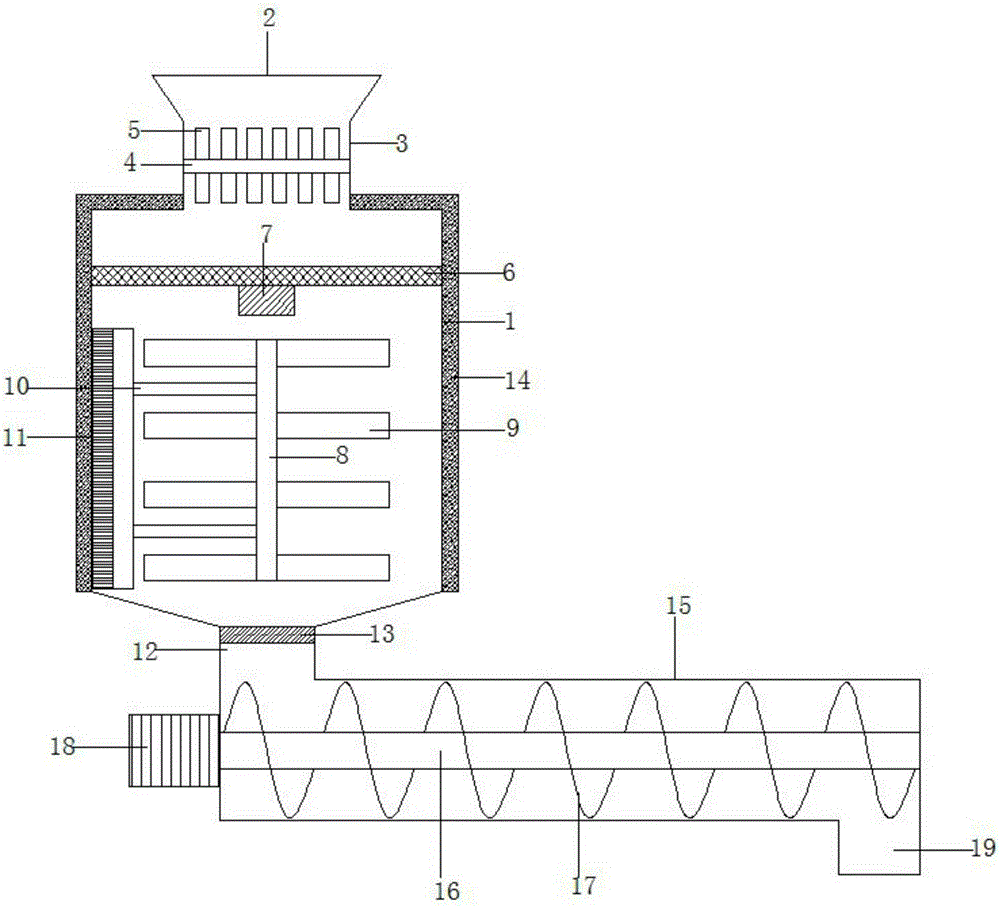

Efficient energy-saving feedstuff stirring machine

InactiveCN105169993AFalling smoothlyDrop savingsRotary stirring mixersMixer accessoriesBristleEngineering

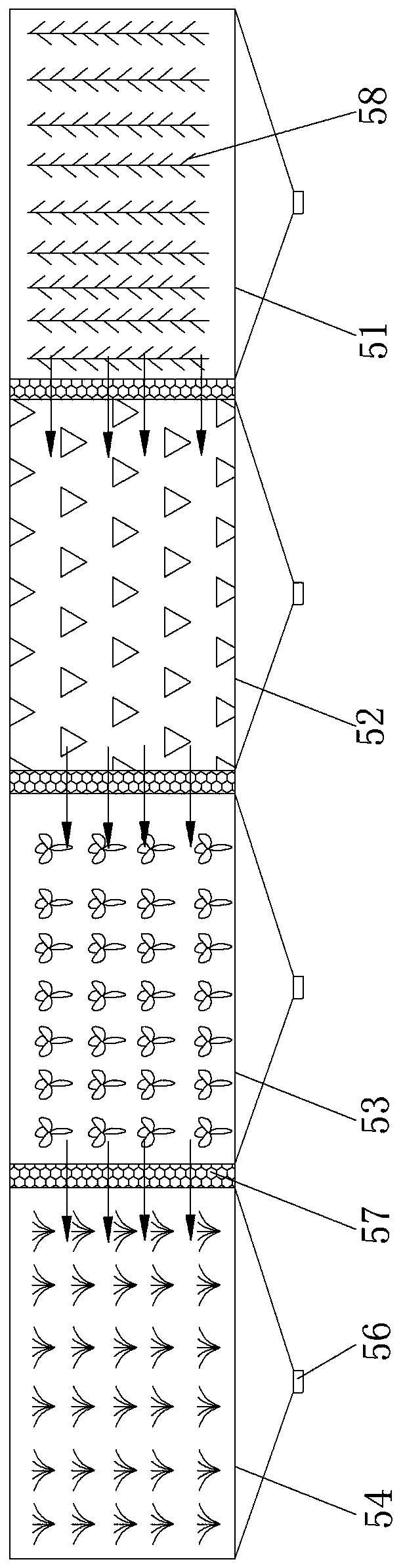

The invention discloses an efficient energy-saving feedstuff stirring machine. The efficient energy-saving feedstuff stirring machine comprises a stirring barrel, an iron removing cavity and a spiral conveying barrel. A feeding hopper is arranged on the upper side of the stirring barrel, the lower side of the feeding hopper is connected with the iron removing cavity, a rotating shaft is horizontally arranged inside the iron removing cavity, magnetic iron pieces are symmetrically arranged on the outer wall of the rotating shaft in the vertical direction, and the seven pairs of magnetic iron pieces are arranged in the left-right direction. The bottom end of the iron removing cavity is connected with a feeding port in the lower side of the stirring barrel, a sieve is horizontally arranged on the upper side inside the stirring barrel, and the periphery of the sieve is installed on the inner wall of the stirring barrel through bolts. The magnetic iron pieces are rotated to remove iron of feedstuff sufficiently, the vibration sieve can make the feedstuff evenly fall, and therefore the stirring effect and efficiency are improved; a scraping cleaning bristle brush can scrap off the feedstuff adhering to the inner wall, waste of the feedstuff is avoided, a solar cell panel converts solar energy into electric energy so that the electric energy can be used for the stirring machine, in this way, energy is saved, continuous and even automatic discharging can be achieved, and the working efficiency of the stirring machine is improved.

Owner:林桂清

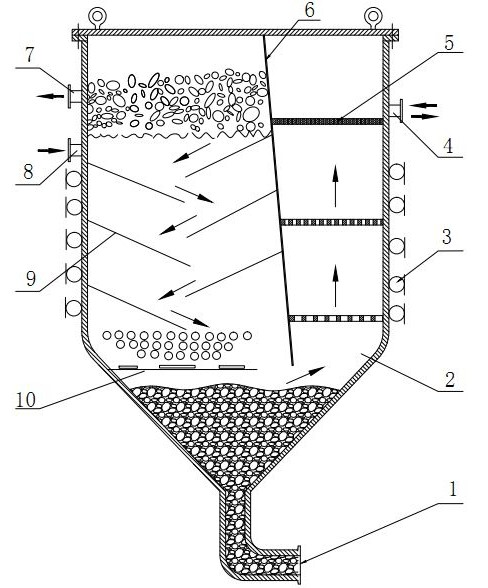

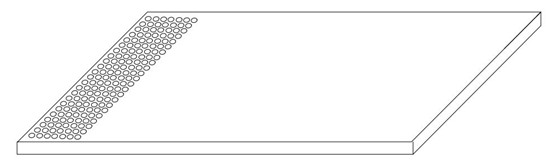

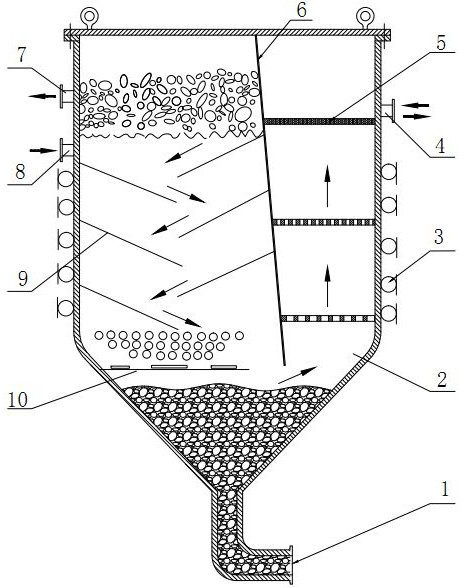

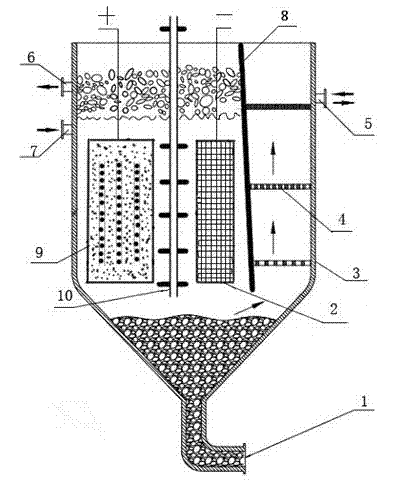

Method and device for continuously separating oil-water slag without dismantling and cleaning

InactiveCN102503008ABeneficial to emergeEasy dischargeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentStopped workSlag

The invention provides a method and a device for continuously separating oil-water slag with dismantling and cleaning. Due to the adoption of a technology of combining gravity separation, air floatation separation, ultrasonic separation and cleaning and the like, wastewater containing oil and slag is separated and treated. The device is a vertical tank type sealing container which is arranged vertically, wherein the upper part of the container is rectangular; the lower part of the container is of an inverted pyramidal shape; a rectangular casing is externally surrounded by an ultrasonic generator and is internally divided into two inner cavities with the different sizes by a partition board; an oil drain port, a wastewater inlet, rectangular inclined plates arranged in a staggered way andan air floatation coiled pipe are arranged in the bigger inner cavity; a clear water outlet, a rectangular dense hole filtering mesh plate, a rectangular mesoporous filtering mesh plate and a rectangular gross porous filtering mesh plate are respectively arranged in the smaller inner cavity; and a slag discharging opening is connected to the lower end of a groove body at the tank bottom of the inverted pyramidal shape. The device is advanced in separation method, simple in structure and high in treatment efficiency; and particularly, in the production, internal cleaning can be carried out without stopping work and dismantling a casing of the device, and thus the continuous high-efficiency operation of the equipment can be ensured.

Owner:HUBEI UNIV +1

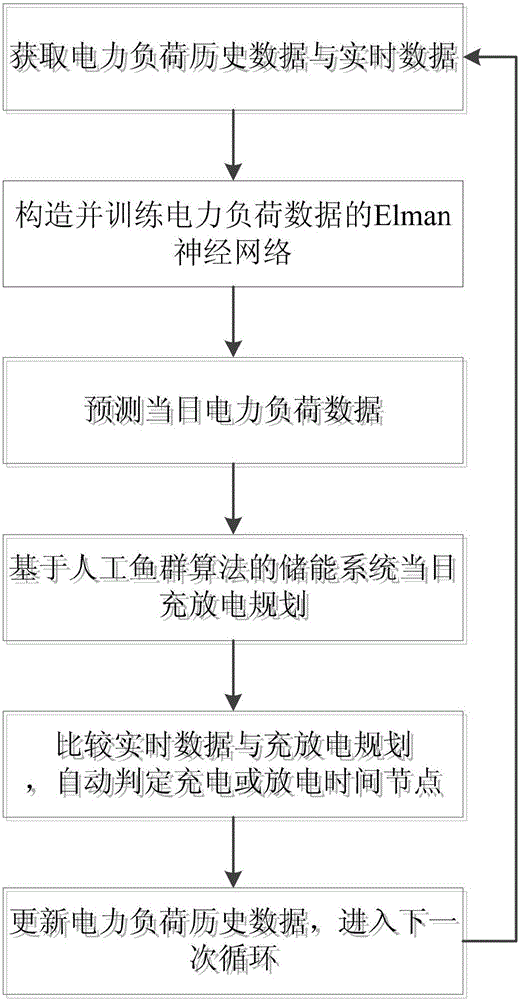

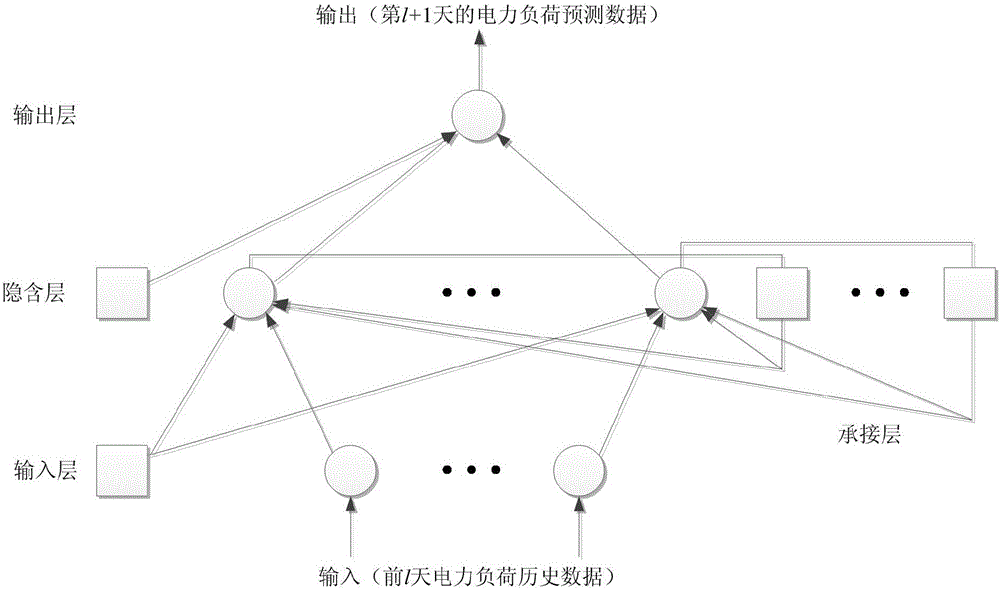

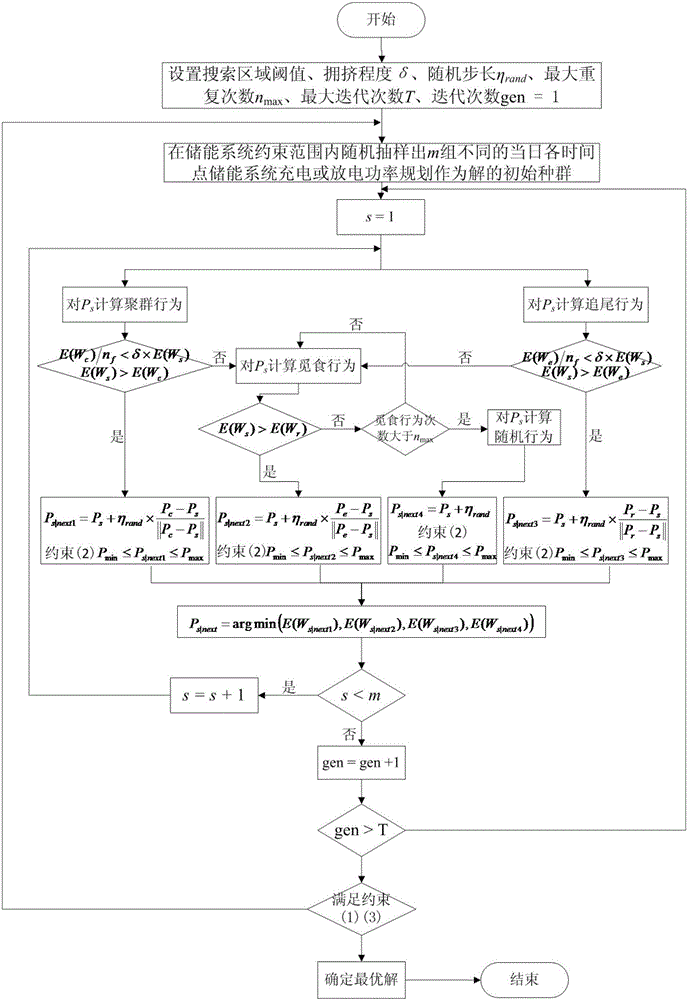

Intelligent energy storage system grid-connected real-time control method based on artificial fish swarm algorithm

ActiveCN105162151AImprove utilization efficiencyAutomatic charging and dischargingAc network load balancingNeural learning methodsReal-time dataCharge discharge

An intelligent energy storage system grid-connected real-time control method based on an artificial fish swarm algorithm adopts an Elman neural network to predict intraday power load real time data on the base of power load historical data, then utilizes the artificial fish swarm algorithm to plan the optimal charge-discharge time and the optimal power of intraday power load prediction data, and performs comparison with the electric power real time data through an intelligent electric meter, so as to determine the optimal charge-discharge time node. The invention achieves automatic grid-connected discharge in the peak of power utilization and achieves charge in the low ebb of power utilization, achieves peak load shifting on the user side, and improves the utilization efficiency of electric power resources.

Owner:STATE GRID CORP OF CHINA +2

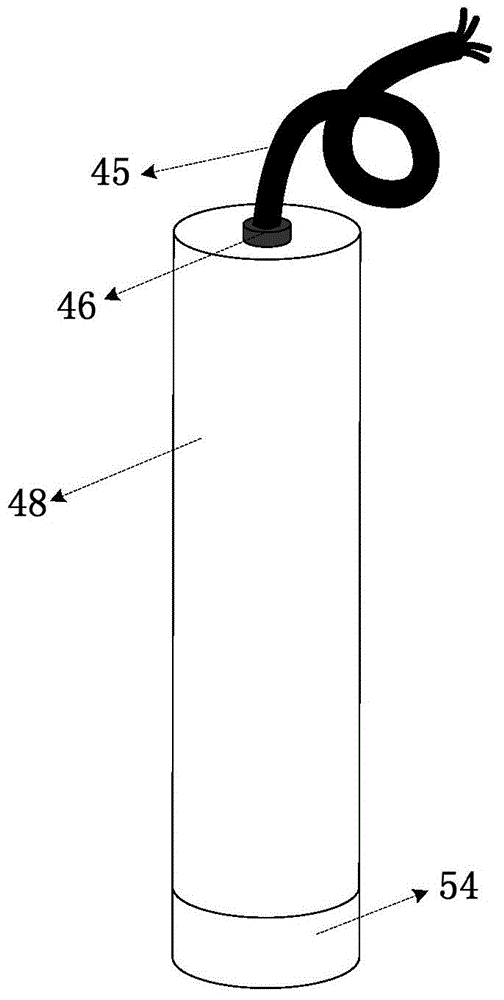

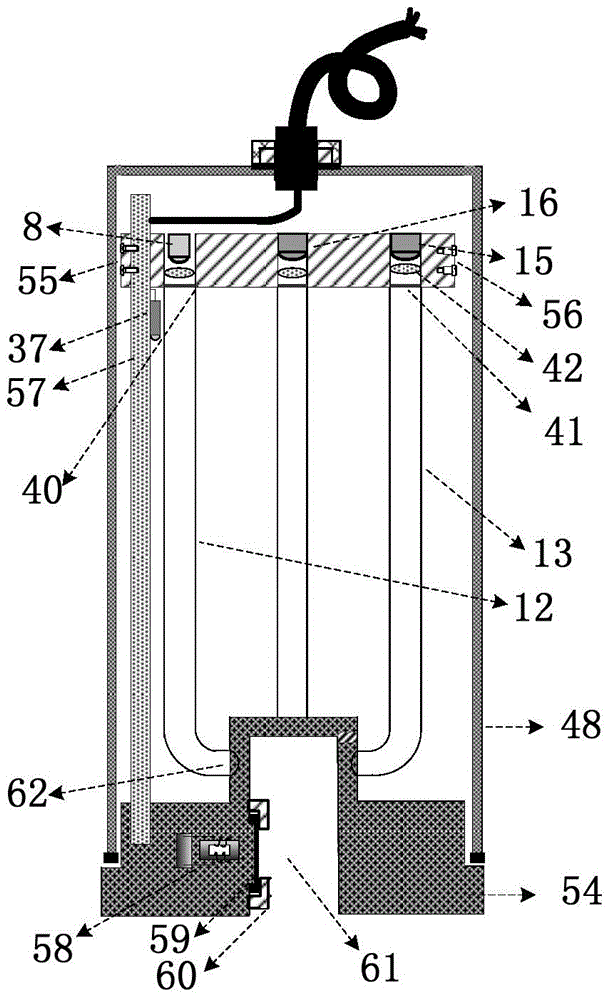

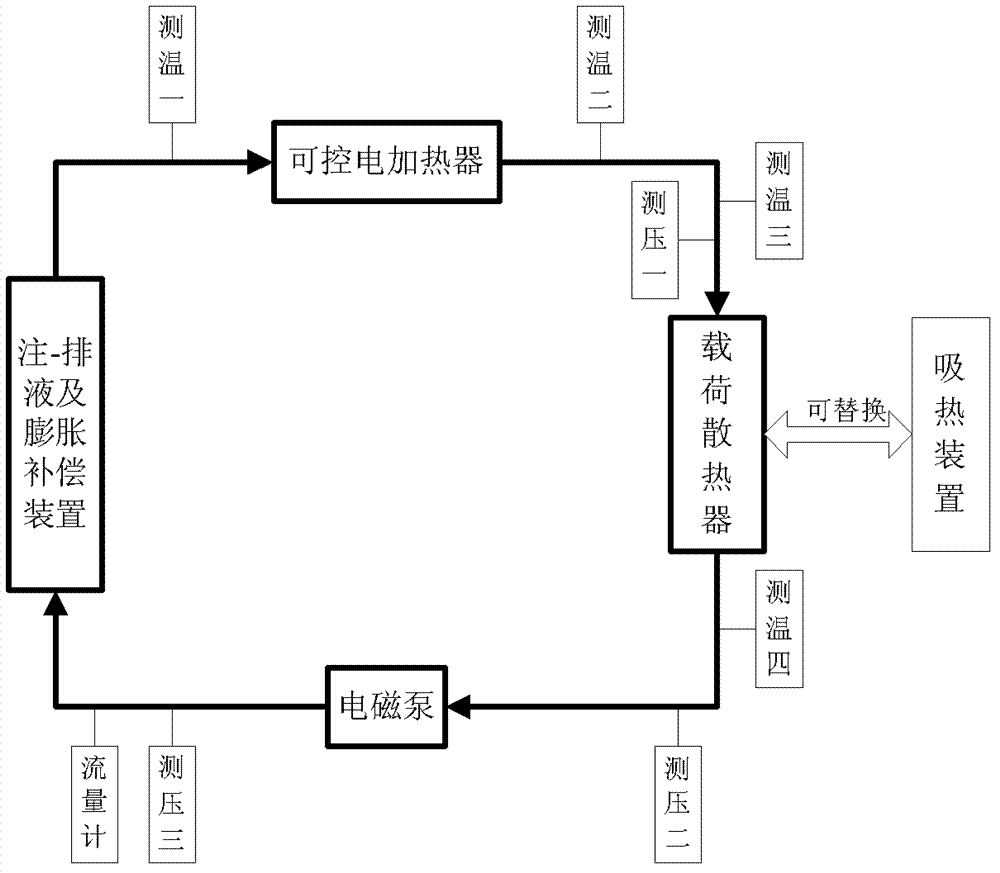

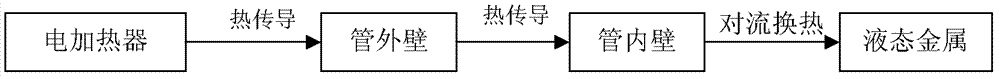

Electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus

ActiveCN103091355AAchieve cycleCircular heat transfer realizationMaterial heat developmentEngineeringThermal expansion

The invention belongs to a heat transfer performance measurement technology, and particularly relates to an electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus, wherein a purpose of the present invention is to verify and evaluate a heat transfer performance and a heat transfer control performance of the electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus. The electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus comprises: an electromagnetic pump, a controllable electric heater, a loading heat dissipator, a liquid injection-discharge device, an expansion compensation device, a measurement sensor and pipelines, wherein connection in series of various component is achieved with the pipelines, every component contains a hollow flow channel for liquid metal circulation, and a liquid metal flowing sequence is that: a liquid metal is injected into the whole testing apparatus through the liquid injection-discharge device and the expansion compensation device, then flows to the controllable electric heater through the pipeline, then flows to the loading heat dissipator after heating by the controllable electric heater, and returns to the liquid injection-discharge device through the electromagnetic pump. The electromagnetic pump driven liquid metal circulation heat transfer performance testing apparatus has the following advantages that: heating, circulation, and temperature and pressure detection of the liquid metal can be achieved, thermal expansion and contraction of the liquid metal can be compensated, gas in the liquid metal can be automatically discharged, and the problem of electromagnetic pump driven liquid metal circulation heat transfer performance testing is solved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

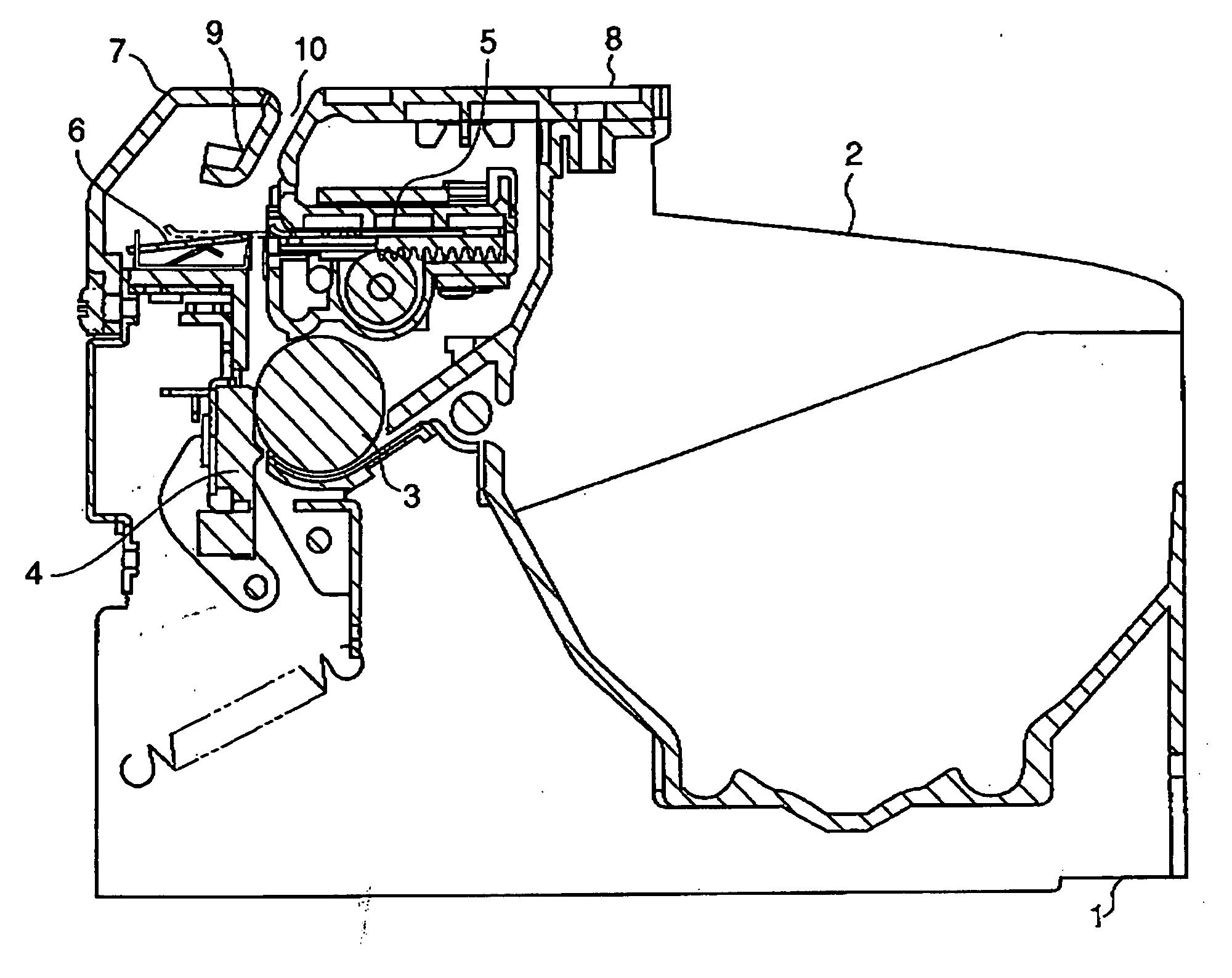

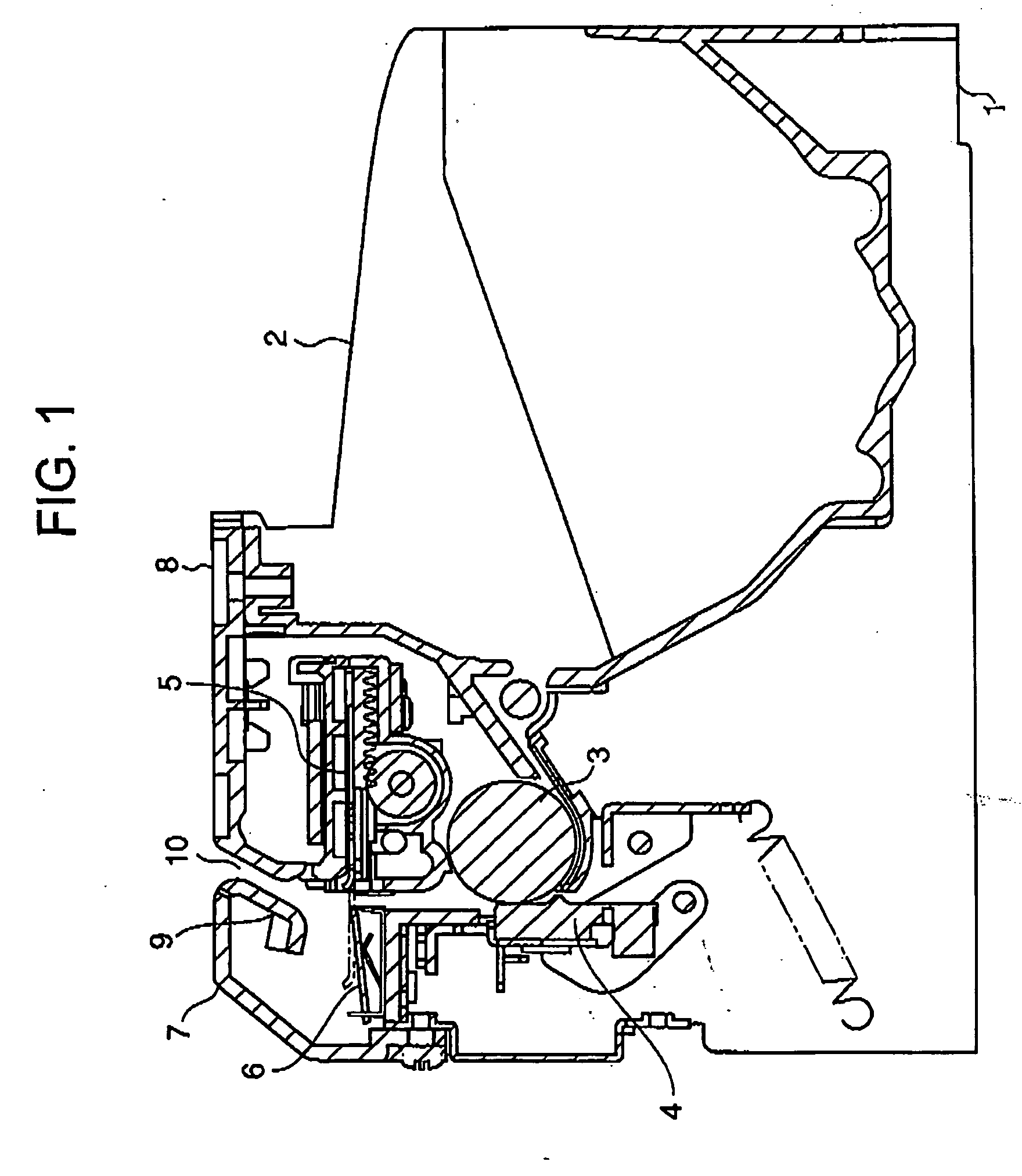

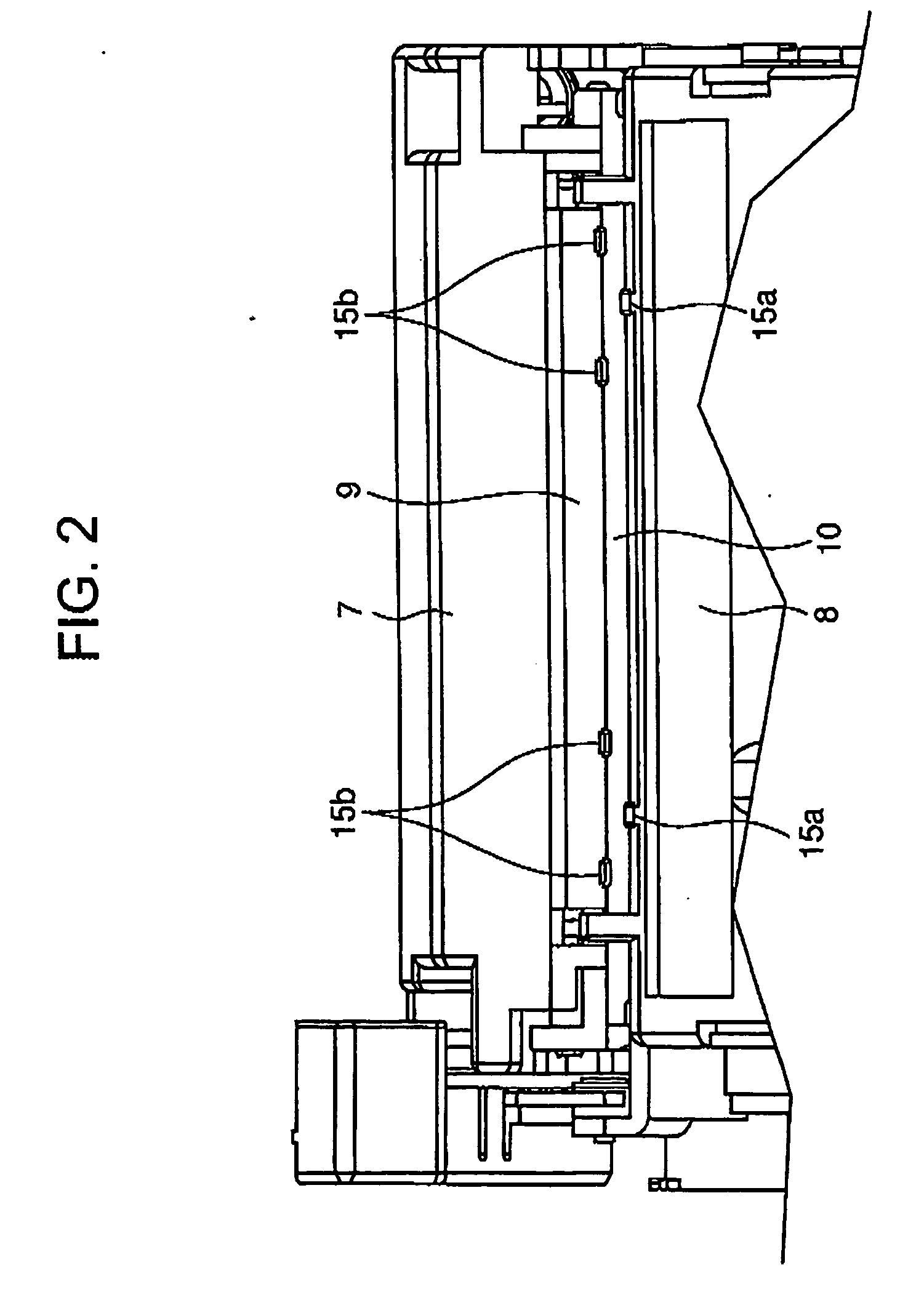

Printer, cut paper discharge mechanism used for printer, and paper jam prevention method

InactiveUS20070065217A1High degree of curlEasy to curlOther printing apparatusArticle deliveryRolling paperPulp and paper industry

A plurality of ribs are provided on a cut paper discharge guide and an upper cover which define a discharge port for discharging a cut paper. The ribs hold a cut paper in width direction. Even if a cut paper having a high degree of curl is supplied when a roll diameter of a roll paper is reduced, it is possible to prevent a paper jam such as falling or clogging of the cut paper. It is desirable that the ribs provided on the cut paper discharge guide and the upper cover are disposed in an alternate pattern along the width direction of the discharge port. This arrangement is particularly effective in a printer having an inclined paper passage.

Owner:NEC PLATFORMS LTD

Pipeline machine

ActiveCN103417121AReduced strength requirementsAvoid breakingBeverage vesselsWater storage tankInlet valve

The invention discloses a pipeline machine which comprises a water inlet, a water outlet, a water inlet valve, a normal temperature water outlet valve, a membrane-type water storage tank, a water level detector and an electrical control circuit board; the water inlet is communicated with an inlet of the water inlet valve, and an outlet of the water inlet valve is communicated with the membrane-type water storage tank; an inlet of the normal temperature water outlet valve is communicated with the bottom of the membrane-type water storage tank, and an outlet of the normal temperature water outlet valve is communicated with the water outlet; the water level detector is used for detecting the water level in the membrane-type water storage tank; a magnetic floater capable of lifting along with the rising and falling of the water level is arranged in the water level detector, and a reed pipe is arranged outside the water level detector; the electrical control circuit board is electrically linked with the reed pipe. According to the pipeline machine, the membrane-type water storage tank is adopted, secondary pollution to drinking water can be prevented effectively, meanwhile, due to the fact that a membrane of the membrane-type water storage tank does not contain water, requirements for intensity of the membrane are reduced, the membrane is not damaged easily, and even though the membrane is damaged, leakage of the pipeline machine does not occur.

Owner:江苏正本净化节水科技实业有限公司

Automatic coffee brewing apparatus and control method

InactiveUS20060156928A1Easy to clean automaticallyFor automatic dischargeBeverage vesselsWater dischargeWater flow

This invention provides for a coffee brewing apparatus and its control method, which comprises a control circuit and a water loop comprising a water reservoir, a pump, a control valve, a boiler, a brewing assembly, a three-way connector and a connecting hose. When coffee is to be brewed, hot water flows top-down through the brewing chamber cover, the upper filter, the coffee grounds, the lower filter, the brewing chamber, the first port of the three-way connector, the second port of the three-way connector and the connecting hose; the brewed coffee finally flows out from said connecting hose. This coffee brewing apparatus has additional functions of automatic residue discharge, automatic water discharge and automatic cleaning.

Owner:TOP TECH CO LTD

Vehicle body glue spraying shielding device and vehicle body glue sprayer

The invention provides a vehicle body glue spraying shielding device, comprising a bearing rack, a hollow truncated conical shielding disc, a driving device, a driving gear, and a spray gun, an idler gear, a glue scraper and a glue collecting drum which are arranged on the bearing rack; the shielding disc is provided with outer teeth meshed with the idler gear; the driving gear is meshed with the outer teeth and is driven by the driving device; the large end of the shielding disc is closer to the spray gun than the small end of the shielding disc; the glue scraper clings to the internal surface of the shielding disc; the glue collecting drum is positioned below the glue scraper and is used for collecting the residual glue scraped by the glue scraper. The invention also provides a vehicle body glue sprayer with the shielding device. The vehicle body glue spraying shielding device and the vehicle body glue sprayer have the advantages of being high in production efficiency, good in consistency, more environment-friendly, more cost-saving and the like.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Electrochemical wastewater treatment method and device capable of continuously separating oil, water and residue

ActiveCN103043753ALow water solubilityWith flocculationFatty/oily/floating substances removal devicesLiquid separationHigh concentrationChemical oxygen demand

The invention discloses an electrochemical wastewater treatment method and device capable of continuously separating oil, water and residue. The device adopts proposals such as physical absorption, electrochemical catalytic oxidization, flocculent precipitate, adopting a central partition, bottom sediment, three-layer mesh and the like, so as to realize a technology of combining dynamic water treatment and automatic oil, water and residue separation, reduce COD (Chemical Oxygen Demand), ammonia nitrogen and chrominance in coking wastewater (or other organic wastewater) furthest, and the device has a low power consumption and a good degradation effect, while the device is simple, and has a high treatment efficiency, a low preparation and operation cost and a good separation effect. While a plurality of identical devices can be connected together through pipelines (or grooves) to carry out multi-stage treatment to the wastewater, so that organic wastewater of high concentration or high difficulty can be easily degraded to meet the standard. Compared with biochemical treatment, the treatment method occupies a small area, has less investment and lower cost, and can work continuously and efficiently.

Owner:王麒钧 +1

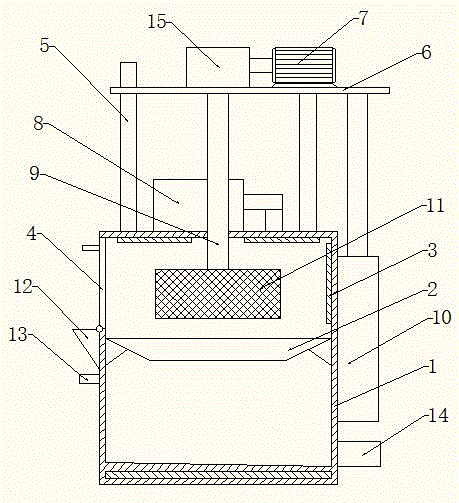

Chinese herbal medicine desulfurizer

ActiveCN105583188AEasy to cleanFor automatic dischargeDrying using combination processesDrying machines with non-progressive movementsDrive shaftMedicine

The invention discloses a Chinese herbal medicine desulfurizer in the field of Chinese herbal medicine processing. The Chinese herbal medicine desulfurizer comprises a box, a drying device and a drive device. The box is provided with a guiding column. The guiding column is provided with a supporting plate. A partition plate is arranged in the box. The box is divided into a drying chamber and a desulfuration chamber through the partition plate. The desulfuration chamber is connected with a water outlet pipe and a water inlet pipe. The drying chamber is provided with a feeding port. The box is provided with a cover plate for closing the feeding port. The drive device comprises an air cylinder, a motor and a rotating shaft. The output end of the air cylinder and the supporting plate are fixed. The motor is located on the supporting plate. A transmission shaft is located in the box and connected with the motor, and a net box is arranged at the bottom end of the transmission shaft. The drying device comprises an exhaust fan communicating with the drying chamber and electric heat plates fixed to the bottom of the desulfuration chamber and the side wall of the drying chamber. According to the scheme, desulfuration and drying operation of Chinese herbal medicines can be finished on the same device, the net box contains the Chinese herbal medicines, tuber type or leaf type or grass type Chinese herbal medicines can be immersed in water in the desulfuration chamber together with the net box, and multiple kinds of Chinese herbal medicines can be subjected to desulfuration and drying more conveniently.

Owner:CHONGQING KANGZE SCI & TECH DEV CO LTD

Air purifying apparatus

InactiveUS20180111080A1For automatic dischargeImprove convenienceCombination devicesSludge treatment by de-watering/drying/thickeningPhotocatalytic reactionSludge

The present invention provides an air purifying apparatus that can continuously discharge sludge separated from suctioned contaminated air from a dust collecting apparatus to the outside, thereby improving convenience of use and air purifying performance, and can mix contaminated air with water, eliminate the sludge and contaminants in the air, and allow the eliminated sludge and contaminants to pass through a photocatalytic purifying unit and purify air using a photocatalytic reaction, thereby improving air purifying performance.

Owner:LEE SEONG HUN

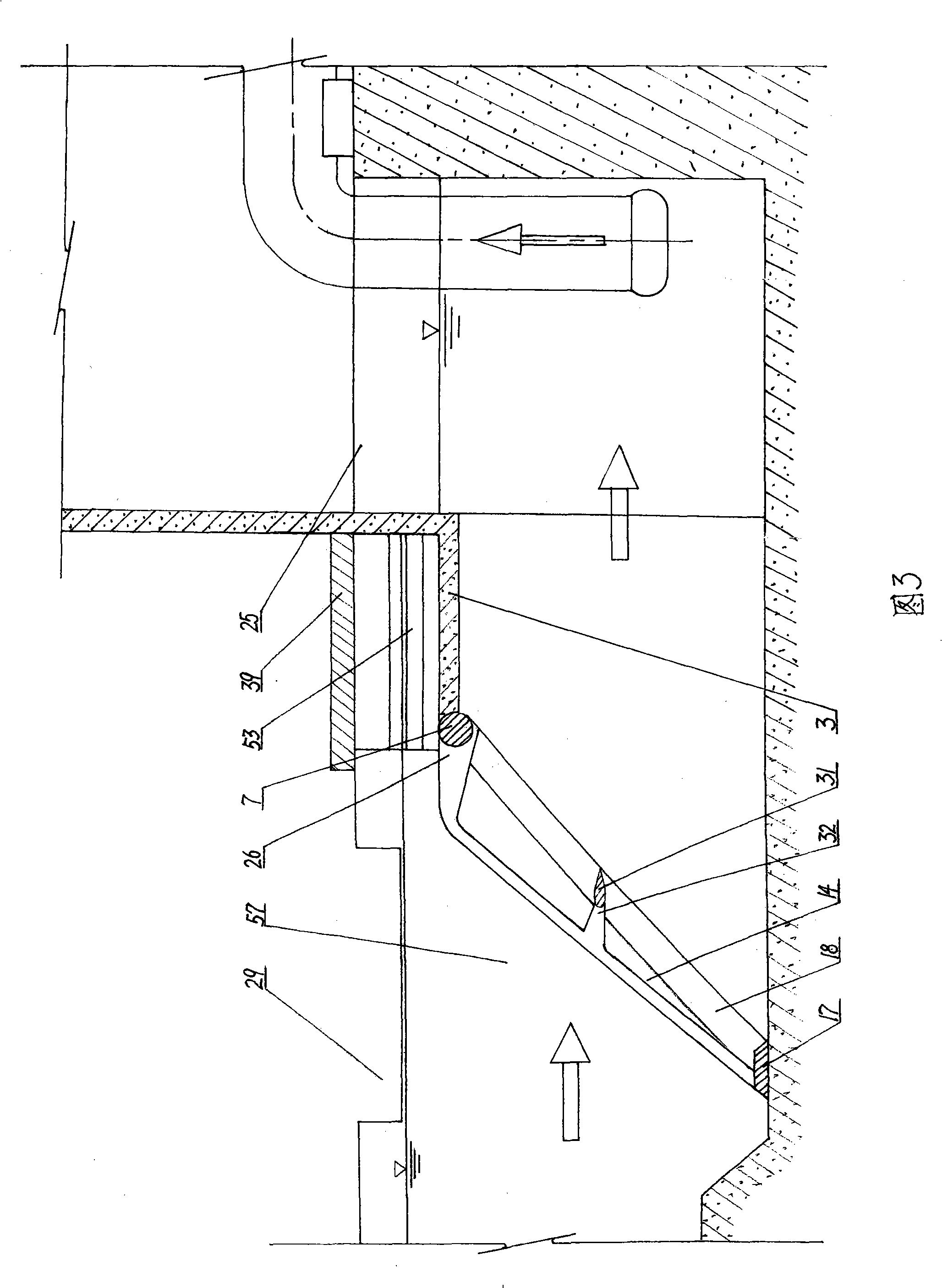

Full automatic pollution removing ice discharge apparatus

InactiveCN101353887AEffects and Significant ImprovementsFor automatic dischargeWater cleaningArtificial water canalsCantileverSewage

The invention discloses a full-automatic sewage cleaning and ice removing device which relates to a full-automatic mechanical device that automatically and promptly clean and automatically discharge sundries and ice slush brought by water current in a water passage or a pressure fore bay of a diversion type hydropower station. The device comprises a dump tank at the top part of a flow passage or the pressure fore bay, and a sewage disposal door or a sewage sump thereof and a sewage funnel thereof, a cantilever type folded surface trash rack which is arranged on a water cross section between the dump tank or the sewage sump and the bottom part of the flow passage or the pressure fore bay, a mobile type sewage disposal rake arranged on the downstream face of the cantilever type folded surface trash rack, a pressure sensor, an electric circuit, a power plant, and the like. The device not only can automatically clean sundries and ice slush brought by water current by means of the own structure, but also can automatically discharge the sundries and the ice slush.

Owner:黄国宏

Capsule type coffee maker

The invention relates to a capsule type coffee maker which comprises a coffee box, a pump, a control valve, a boiler, a water tank, a piston push rod, a return spring, a cylinder, a cylinder fixing seat, a spring seat, a capsule bracket, a guide rod, a bracket spring, a coffee box protection sleeve, a piston rod sealing ring, water outlet silica gel and a water outlet spring. During use, the pump is used for pumping water, the control valve is turned on, and high-pressure water enters a driving water inlet port to press the piston push rod to forwards move so as to jack a capsule into the coffee box until the bottom to ensure that the piston push rod cannot be forwards moved any more; then the pump is used for continuatively pumping water to ensure that the pressure of the whole system is risen to exceed the pressure of a one-way pressure valve formed by the water outlet silica gel and the water outlet spring; the water outlet silica gel is opened, water in the pump flows into a hot water inlet port after being heated by the boiler, and then coffee begins to be extracted; and after the coffee is finished being extracted, the pump is stopped pumping water, the control valve is turned off, and water in the cylinder flows back to the water tank through the control valve under the action of the return spring.

Owner:王荐品

Yarn sizing device for textile

ActiveCN109267267AAutomatic sizingAutomatic dischargeTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingYarnEngineering

The invention discloses a yarn sizing device for textile, and belongs to the technical field of textile equipment. The device comprises a sizing mechanism, a receiving mechanism, a discharging mechanism and a scraping mechanism, wherein the discharging mechanism comprises a discharging assembly and a yarn limiting assembly, the yarn limiting assembly is arranged at the right end of the dischargingassembly, the scraping mechanism comprises a top-surface scraping assembly and a bottom-surface scraping assembly, the top-surface scraping assembly is arranged above the bottom-surface scraping assembly, the bottom-surface scraping assembly comprises a scraping assembly and a lifting assembly used for driving the scraping assembly to rise and fall, and the scraping assembly is arranged at the top of the lifting assembly. The yarn sizing device for textile has the advantages that scraping can be automatically performed on yarn through the scraping mechanism, thereby ensuring the surface thickness of warp yarn; the tension of the yarn can be automatically adjusted through the yarn limiting assembly, thereby avoiding the phenomena of breakage, abrasion and the like of the yarn during transport.

Owner:江苏富尔达电子科技有限公司

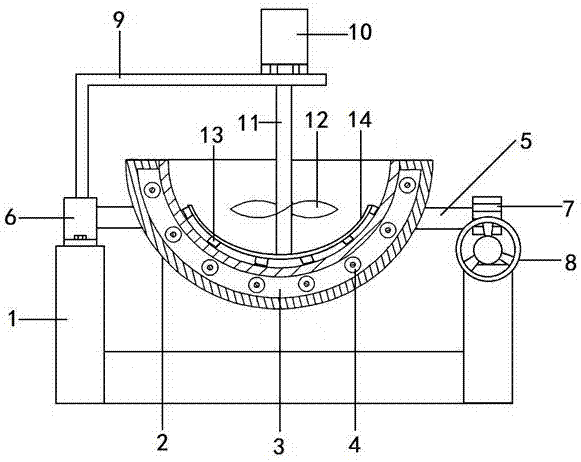

Herbal medicine roasting device

InactiveCN107411963AEvenly heatedStir wellPharmaceutical product form changeDomestic articlesElectric heatingTurbine

The invention discloses a herbal medicine roasting device which comprises a frame, a herbal medicine roasting pot and a stirring device. Two sides of the herbal medicine roasting pot are rotatably mounted on the frame through horizontally fixed rotating shafts, the stirring device is arranged above the center of the herbal medicine roasting pot, stirring blades are arranged in the middle of a stirring shaft of the stirring device, an arc-shaped stirring rod is arranged at one end of the stirring shaft, a scraper is arranged between the arc-shaped stirring rod and the herbal medicine roasting pot, the herbal medicine roasting pot is provided with an interlayer, an electric heating tube is arranged in the interlayer in a surrounding manner, a turbine fixedly sleeves one end of the rotating shaft, a worm in meshing transmission with the turbine is arranged on the frame, and a turntable is arranged at the end of the worm. By the aid of the interlayer and the electric heating tube in the interlayer, the whole herbal medicine roasting pot is uniformly heated and matched with the stirring device with the arc-shaped stirring rod and the stirring blades, so that medicinal materials can be all-dimensionally stirred and uniformly heated, and roasting quality is improved. After roasting, the herbal medicine roasting pot can be automatically inclined to realize discharging only by turning the turntable, and the herbal medicine roasting device is efficient and convenient.

Owner:赵爱

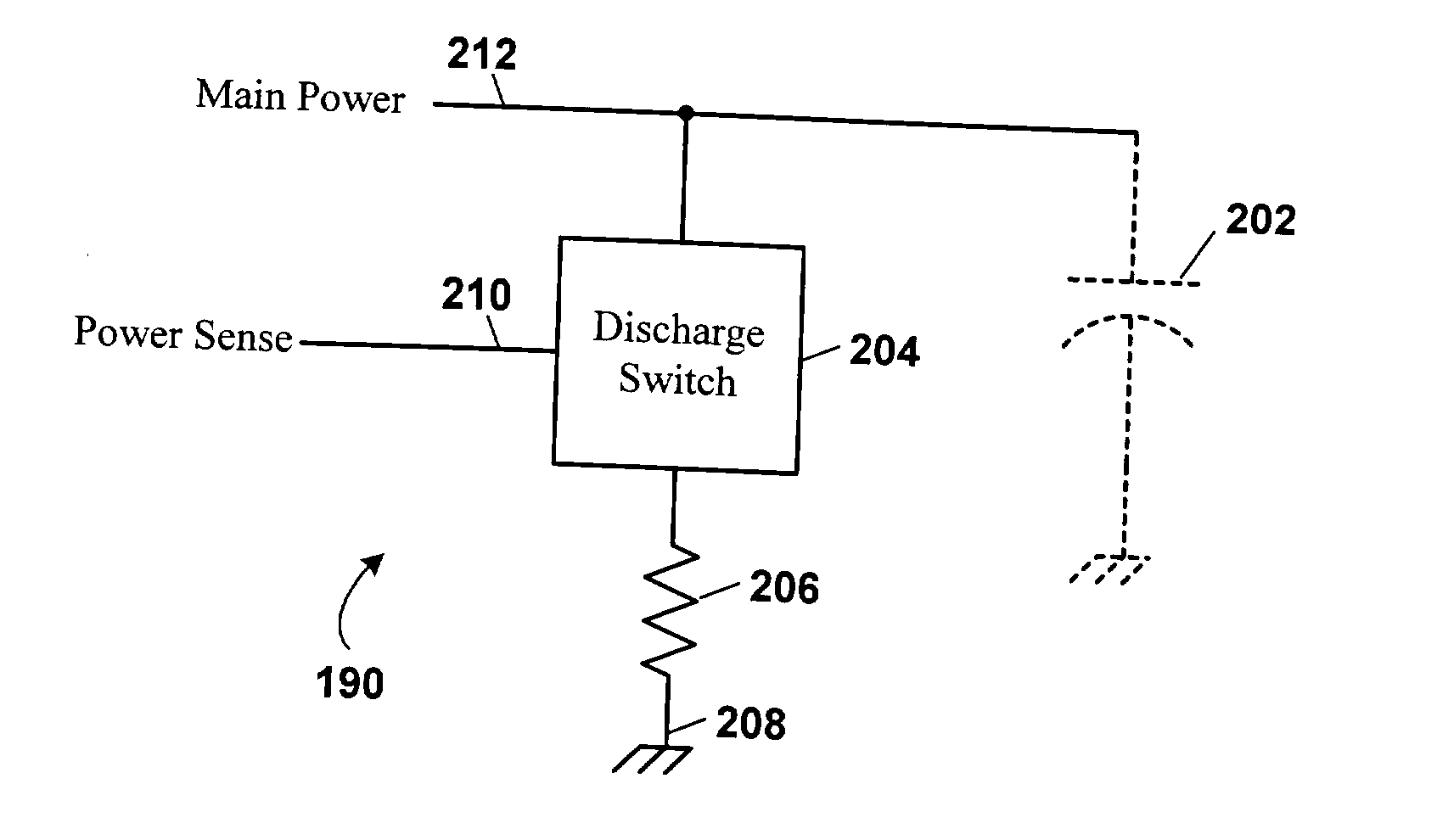

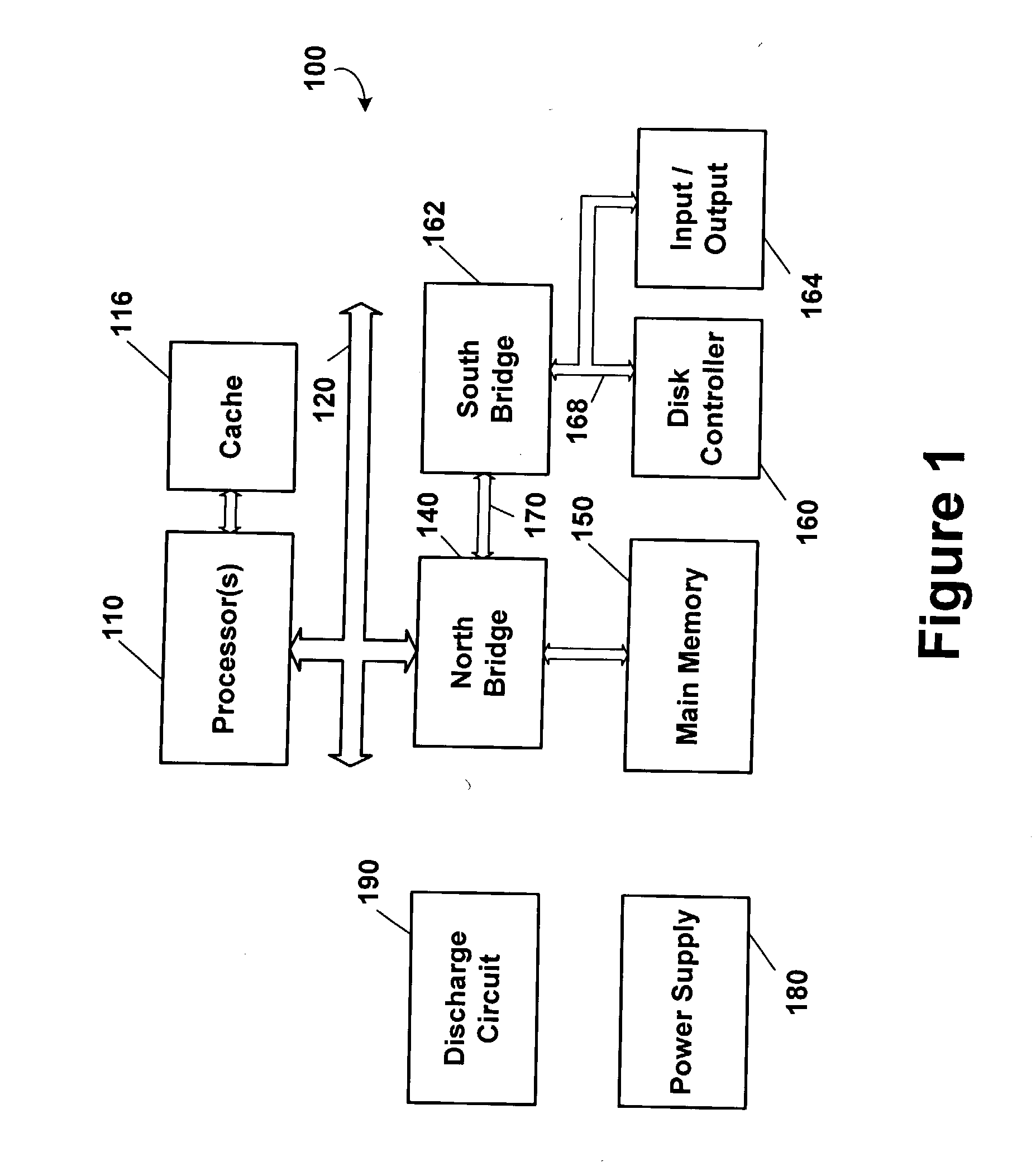

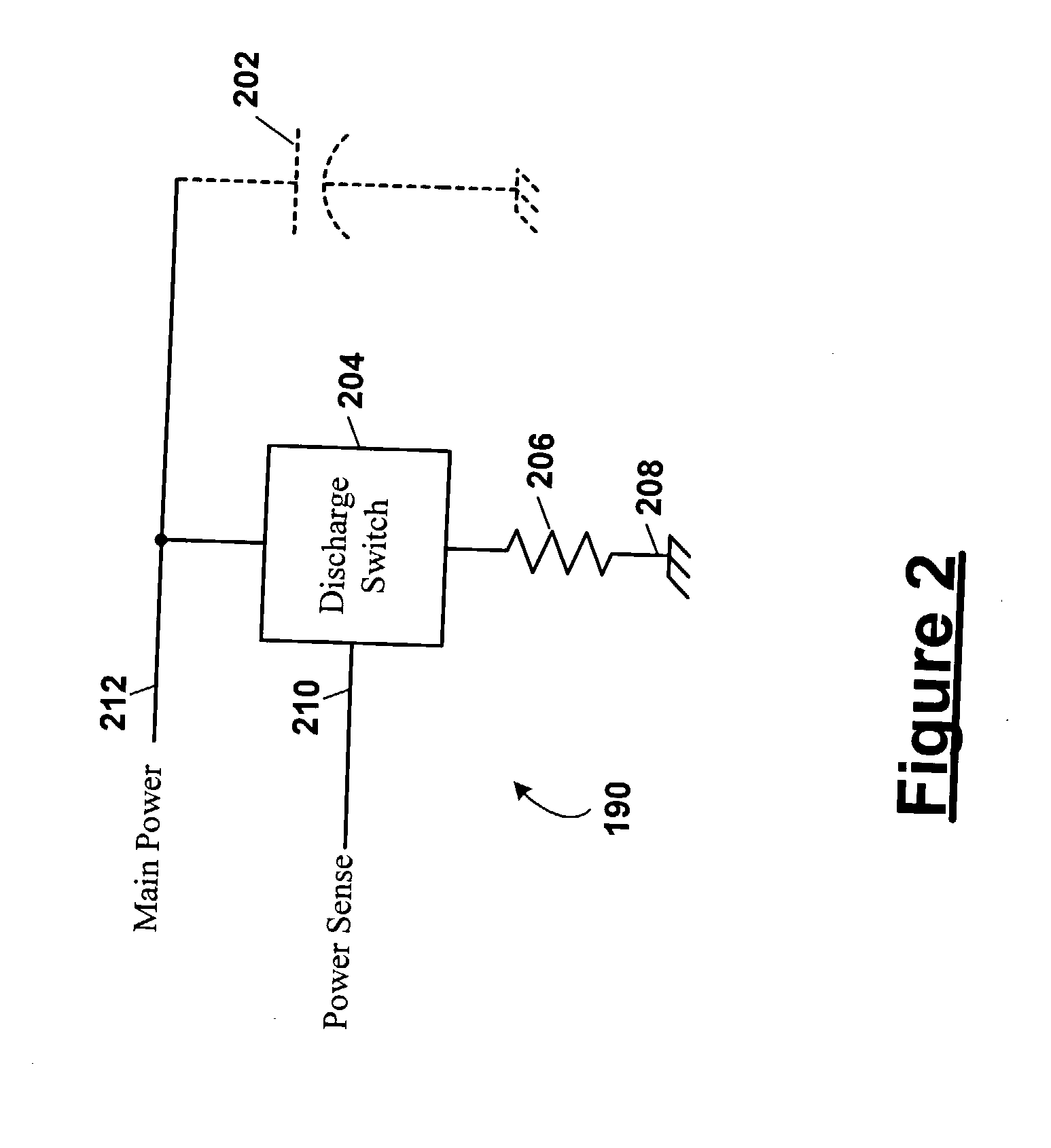

Draining residual power from a voltage plane

ActiveUS20040205363A1Reduce power consumptionEasy dischargePulse automatic controlVolume/mass flow measurementCapacitanceElectrical resistance and conductance

An energy discharge resistance is isolated from storage capacitance containing a voltage charge until power is removed from the storage capacitance. Then the discharge resistance may be coupled to the storage capacitance to drain residual charge therefrom. The discharge resistance is coupled to the storage capacitance when external power is removed and is un-coupled from the storage capacitance when external power is applied to the storage capacitance. In this way, unnecessary power draw during operation or standby of an electronic system is substantially eliminated.

Owner:DELL PROD LP

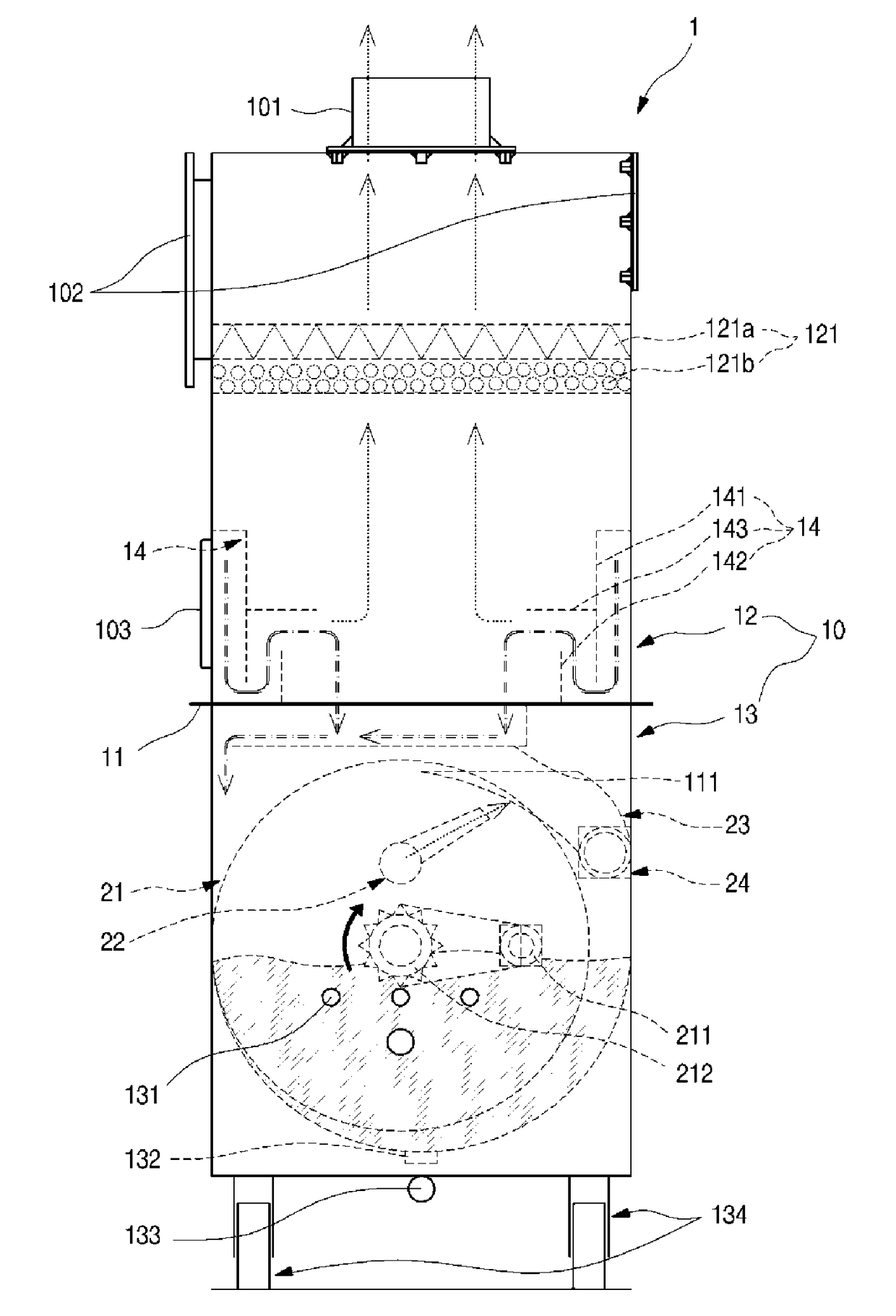

Novel ecological wetland circulating water comprehensive cultivation system

PendingCN109906994ALow costReduce investmentAgricultural buildingsClimate change adaptationDiseaseThermal insulation

The invention relates to a novel ecological wetland circulating water comprehensive cultivation system. The system includes a funnel-shaped fish pond, a sewage drainage well, a sewage collection tank,a sieve filter, an ecological wetland and a thermal insulation greenhouse. The funnel-shaped fish pond is formed in a soil matrix, a PE anti-permeation film is laid on the soil matrix of the slope ofthe fish pond, geotechnical cloth is laid on the portion, near the upper edge of fish pond, of the PE anti-permeation film, the conical bottom of the fish pond is provided with a fish-pond sewage discharge hole connected with the PE anti-permeation film hermetically, the fish-pond sewage discharge hole is communicated with the sewage drainage well through an underground sewage discharge pipe, twowater outlets, in the sewage drainage well, of the sewage discharge pipe are communicated with a sewage discharge valve and an overflow pipe respectively, the peak water levels of the sewage discharge valve and the overflow pipe are lower than the upper edge of the fish pond, the sewage drainage well is communicated with the sewage collection tank, the ecological wetland is communicated with thesieve filter, the other end of the ecological wetland is communicated with a sterilization pond and an oxygen aeration pond in sequence, the oxygen aeration pond is communicated with the fish pond through the circulating pump, and a hemispherical heat preservation greenhouse is built above the fish pond. The system has less land occupation and less investment, the water environment of the fish pond is excellent, there are fewer fish diseases, fish grows fast, and energy conservation, ecological protection and high efficiency are achieved.

Owner:郑州市水产技术推广站

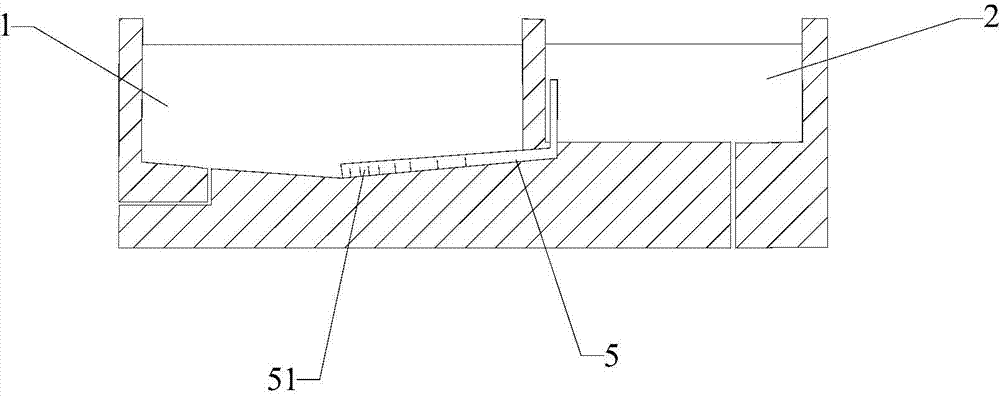

Aquatic animal breeding system

ActiveCN104705238ARealize the effect of clean and dirty separationResidue reductionPisciculture and aquariaAquatic animalMaterial resources

The invention relates to the field of aquatic animal breeding, and provides an aquatic animal breeding system. The aquatic animal breeding system comprises a breeding pond, a settling pond, a filter pond and a water pump. The bottom of the breeding pond is inclined from the periphery to the center. The breeding pond and the settling pond are connected through a pollution collecting pipe. The end, connected with the breeding pond, of the pollution collecting pipe is located in the center of the bottom of the breeding pond. The end, connected with the settling pond, of the pollution collecting pipe is vertically arranged. One or more pollution absorption grooves are formed in the end, connected with the breeding pond, of the pollution collecting pipe. A partition plate is arranged between the settling pond and the filter pond. The aquatic animal breeding system has the advantages that water pressure is utilized, the effect of pollution removal and separation of the breeding pond can be achieved by opening the water pump, the purpose of cleaning the bottom of the pond even in the breeding cycle can be achieved, breeding pollutant residues in the pond are reduced, the water changing frequency is reduced, and manpower and material resources are saved.

Owner:福州市海洋与渔业技术中心

Iron furnace slag and coal cinder ash autoclaved brick production device

ActiveCN111216217APrevent solidificationUnobstructed feedingDischarging arrangementFeeding arrangmentsBrickSlag

The invention discloses an iron furnace slag and coal cinder ash autoclaved brick production device. The iron furnace slag and coal cinder ash autoclaved brick production device comprises a mounting seat, wherein a first mounting plate is fixed at one end of the mounting seat; a first servo motor is fixed on the first mounting plate; a screw rod is fixed on an output shaft of the first servo motor; the screw rod is in threaded connection with a movable block; a movable seat is welded to the movable block; a forming die is mounted on the movable seat; a plurality of forming cavities are formedin the forming die; a material ejection mechanism is arranged in each forming cavity; a material storage barrel is arranged in the middle of the mounting seat; the material storage barrel is welded tothe mounting seat through a supporting frame; the upper end of the material storage barrel communicates with a feeding pipe; a stirring mechanism is arranged in the material storage barrel; the bottom end of the material storage barrel communicates with a discharging pipe; a discharging switch mechanism is arranged in the discharging pipe; a material pressing mechanism is arranged on one side ofthe lower end of the discharging pipe; and the forming die is located below the discharging pipe and the material pressing mechanism. By adopting the iron furnace slag and coal cinder ash autoclaved brick production device, raw materials are stirred and the flowability is improved; and automatic discharging, material pressing, material scraping and material ejection are realized, and the working efficiency is high.

Owner:淮北市恒兴新型建材科技有限公司

Cooling liquid circulation scrap removing device for machining

ActiveCN112454000AEasy to reuseReduce consumptionMaintainance and safety accessoriesProcess engineeringCooling fluid

The invention discloses a cooling liquid circulation scrap removing device for machining. The cooling liquid circulation scrap removing device comprises a cooling box shell, a return spring and a filter box, a water outlet is formed in one end of the cooling box shell, a water inlet is formed in the top surface of the cooling box shell, and a vertical supporting rod is arranged in the cooling boxshell; and the lower end of the vertical supporting rod is sleeved with a reset spring, the upper end of the vertical supporting rod is movably sleeved with a filter box, and a connecting shaft is arranged in one end of the filter box. According to the cooling liquid circulation scrap removing device for machining, when the whole device operates, the filter box is driven to descend through impactforce generated when cooling liquid flows back, the filter box is driven to reset and slide upwards through elasticity of the reset spring in the follow-up process, and power in cooling liquid circulation can be repeatedly utilized, so that energy-free driving is achieved, energy consumption is reduced, environmental pollution caused by energy consumption is avoided, and then the overall environmental protection effect is improved.

Owner:南京钱仓机械铸造有限公司

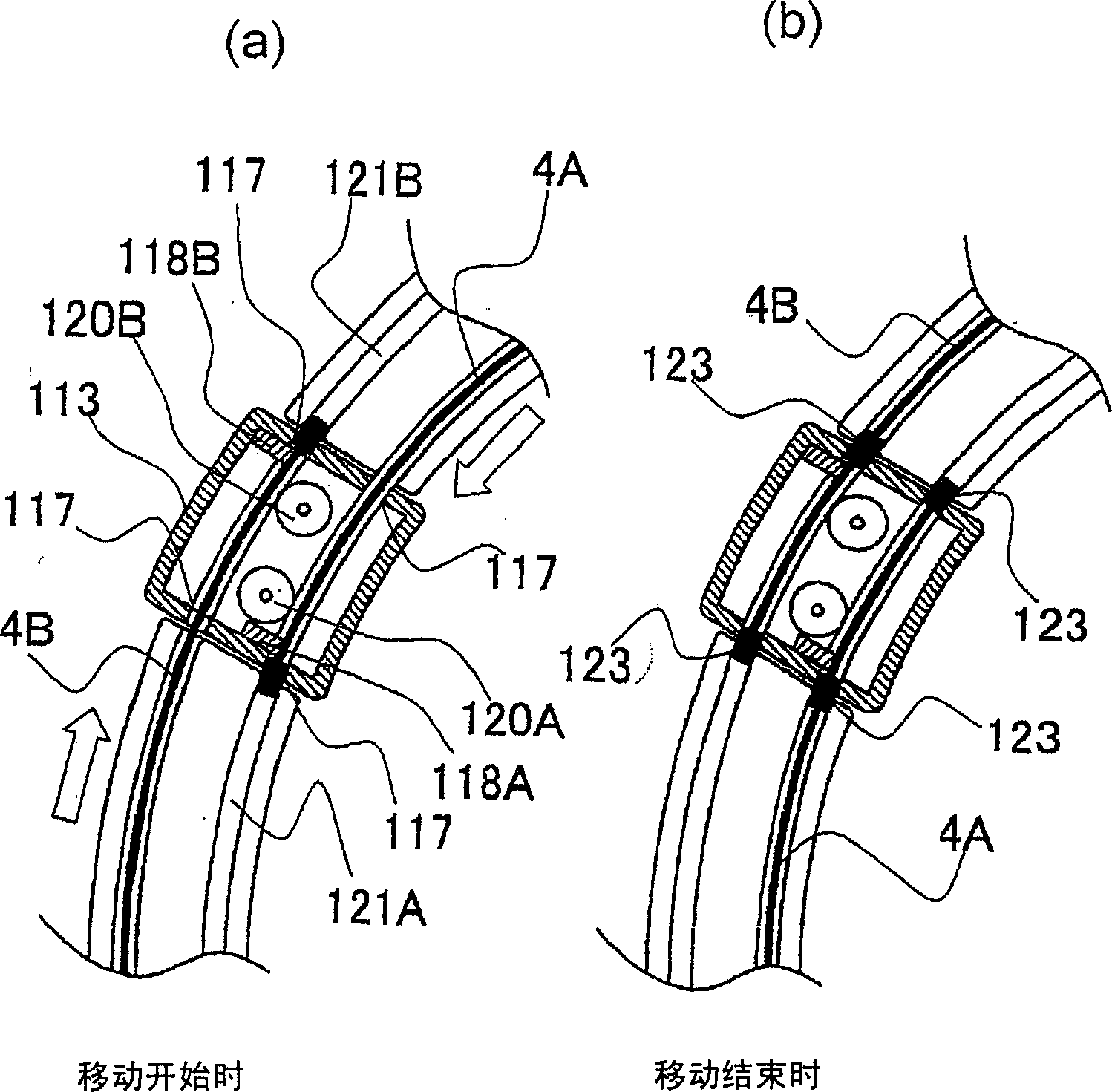

Air conditioner having indoor unit with automatic air filter cleaning function

ActiveCN1906449AWon't hitGood lookingMechanical apparatusDispersed particle filtrationAir filterDust particles

The present invention relates to an air conditioner. The indoor unit of the air conditioner is equipped with a heat exchanger and a fan blowing the air exchanged by the heat exchanger into the room in the main unit. In the air channel of the air port, a filter, a heat exchanger, and a blower fan are respectively installed, and at the same time, a dust collection part for removing and collecting dust on the filter is installed on the main unit. Also, the filter is divided into a plurality of parts in the moving direction, and each filter can reciprocate to pass through the dust collection part.

Owner:PANASONIC CORP

Good stirring effect reaction kettle for chemical raw materials

InactiveCN106552575AAvoid blockingPlay the role of automatic dischargeHollow article cleaningChemical/physical/physico-chemical stationary reactorsMotor driveEngineering

The invention discloses a good stirring effect reaction kettle for chemical raw materials. The reaction kettle comprises a stirring kettle body, the stirring kettle body is internally provided with a stirring cavity, one side at the top of the stirring kettle body is provided with a material inlet, the middle part at the top of the stirring kettle body is equipped with a stirring motor, an output shaft of the stirring motor runs through and extends into the stirring kettle body and is fixedly connected to a stirrer, two ends outside the stirrer are both fixedly connected to a connecting rod, wall scraping brushes are fixedly connected between the connecting rods, and one side outside the stirring kettle body is fixedly connected to a reaction liquid box, the top of the reaction liquid box is fixedly connected to a liquid pipe, and one end of the liquid pipe is fixedly connected to a liquid pump outlet. According to the invention, the reaction kettle is equipped with a discharging helical disc, a discharging motor drives the discharging helical disc to rotate, chemical raw materials rotate to a discharging port through the discharging helical disc to reach an automatic discharging function, thus achieving automatic, continuous and uniform discharging effects, and preventing blocking of chemical raw materials in the discharging port.

Owner:WUXI RISHENG CHEM CO LTD

Chicken-foot partitioning machine

InactiveCN102657255AGood segmentation shape consistencyWith computer locationPoultry processingEngineeringWork productivity

The invention discloses a chicken-foot partitioning machine, mainly composed of a rack, chicken-foot carrying plates, a body housing and a box. The chicken-foot partitioning machine is characterized in that a convey chain is installed on the upper part of the rack; a partitioning cushion plate is arranged on the lower part of the convey chain; the mutually independent chicken-foot carrying plates are fixed on the convey chain; a retreating plate is arranged on the upper part of the convey chain; a shaping-partitioning knife is arranged on the upper part of the retreating plate; the shaping-partitioning knife is connected with a special cylinder; and toe-separating nozzles are arranged on the bottom of shaping-partitioning knife. The chicken-foot partitioning machine disclosed by the invention has the advantages of being novel in structure, high in working efficiency, good in the consistency of partitioning shape, greatly improved in the labour conditions of workers, reduced in potential safety hazard, and guaranteed in food sanitation; and the chicken-foot partitioning machine is the optimized ideal equipment for chicken-foot processing enterprises.

Owner:李树国

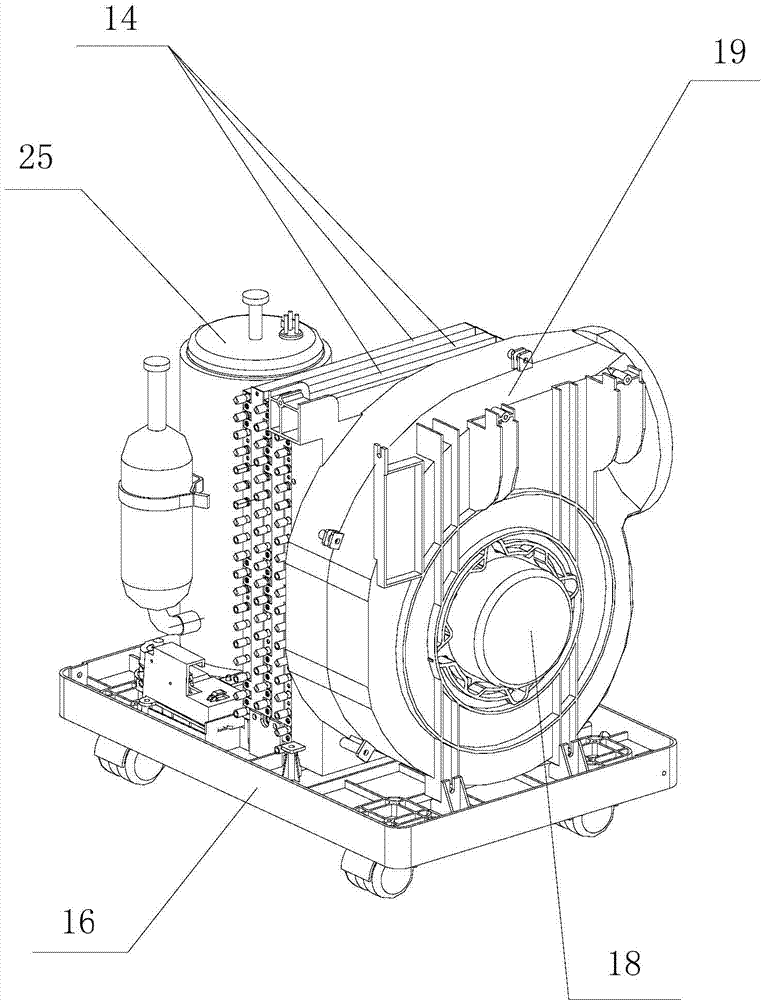

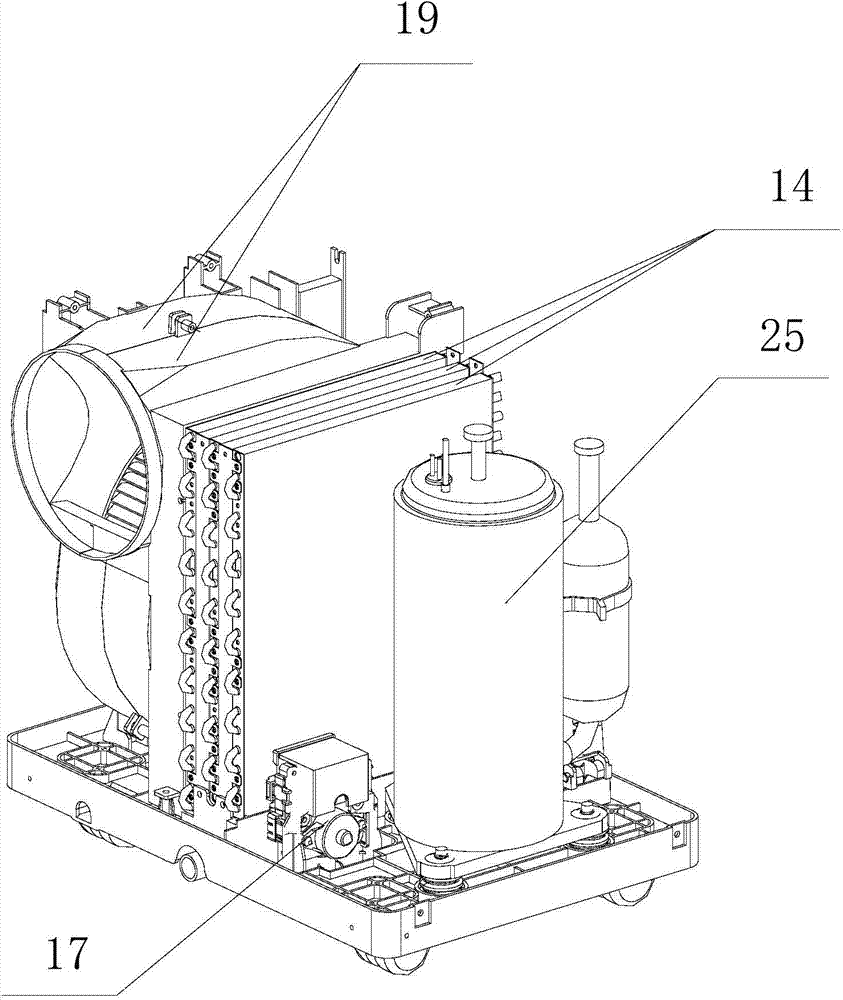

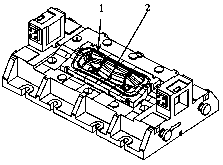

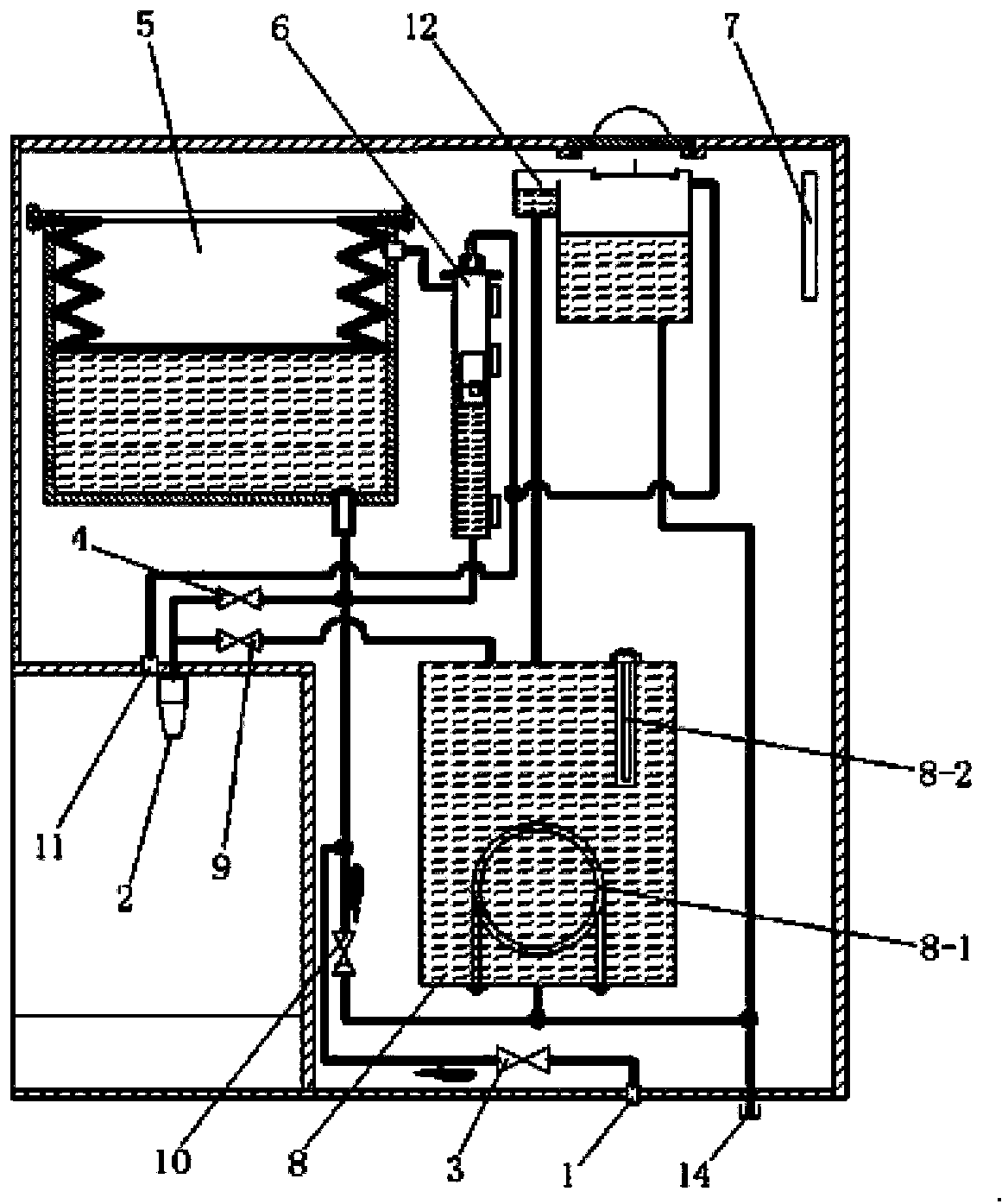

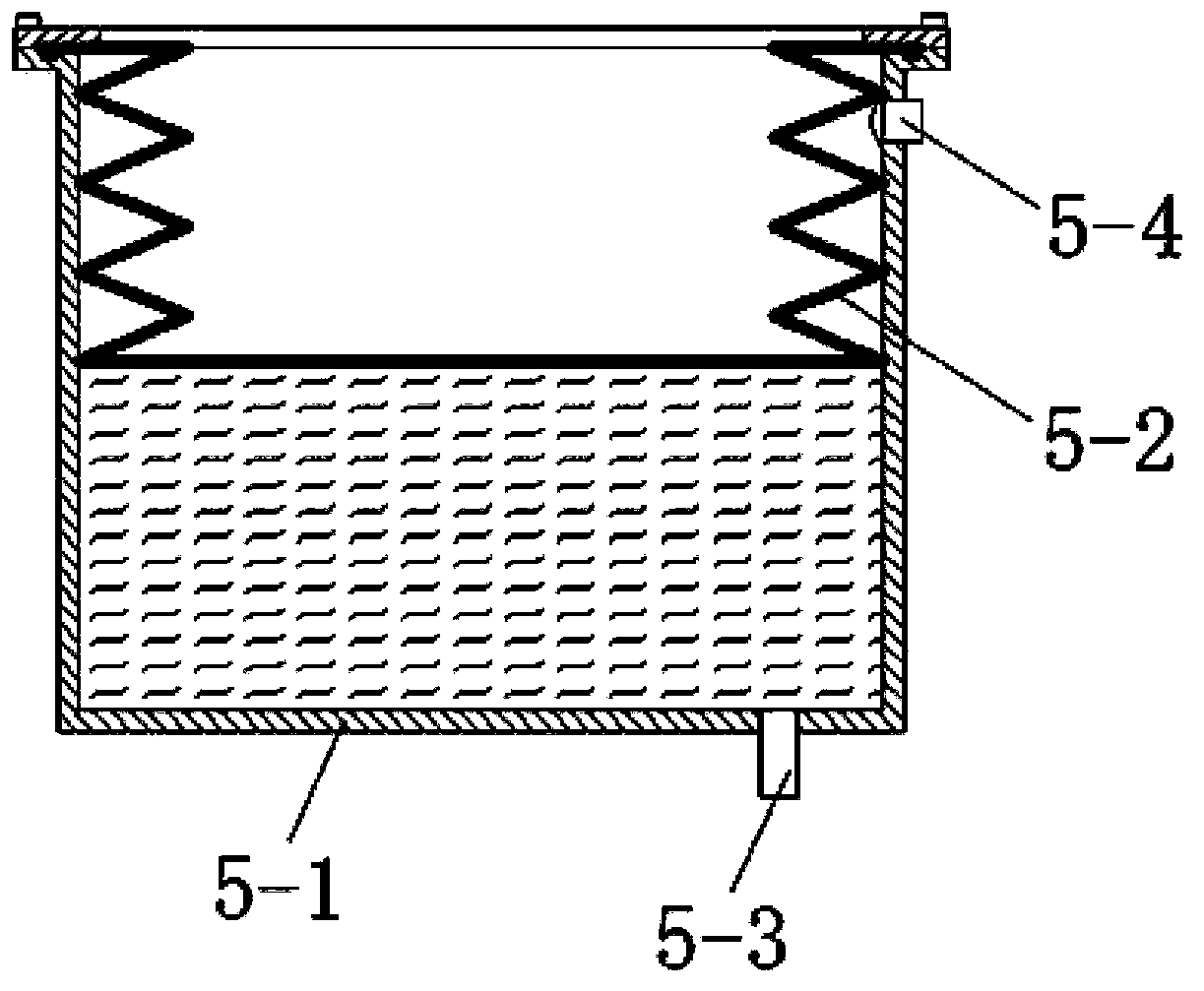

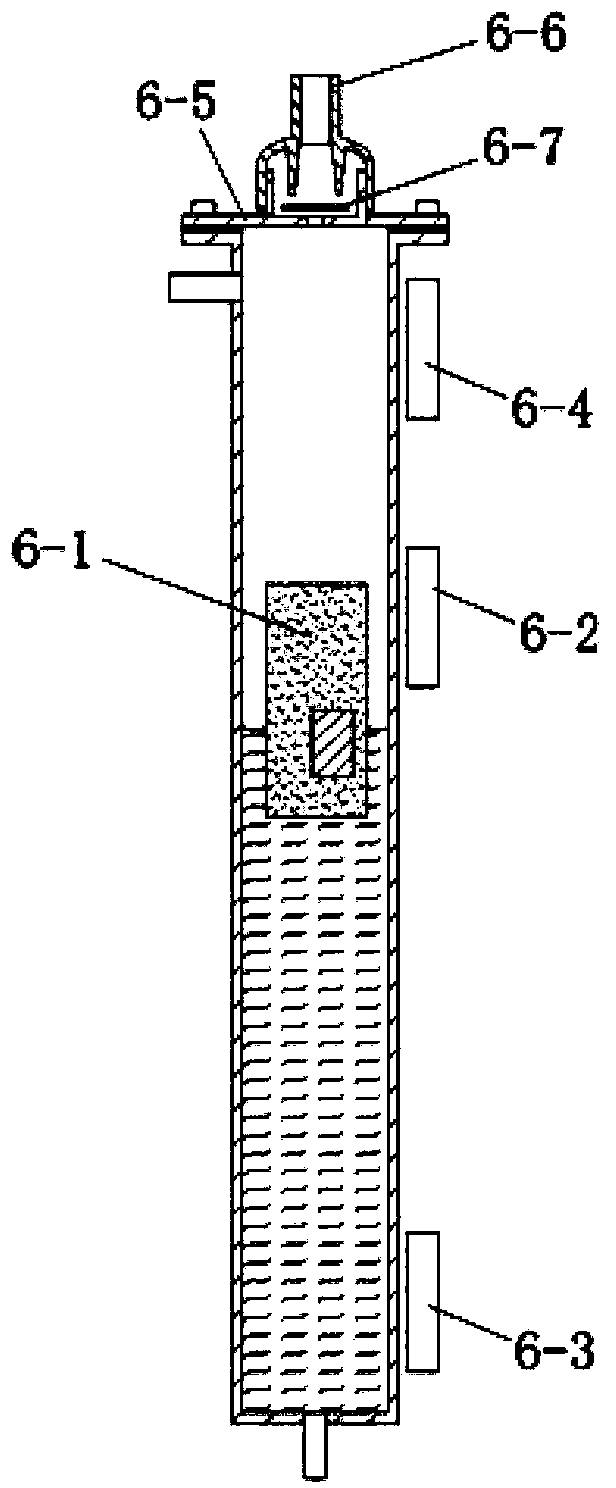

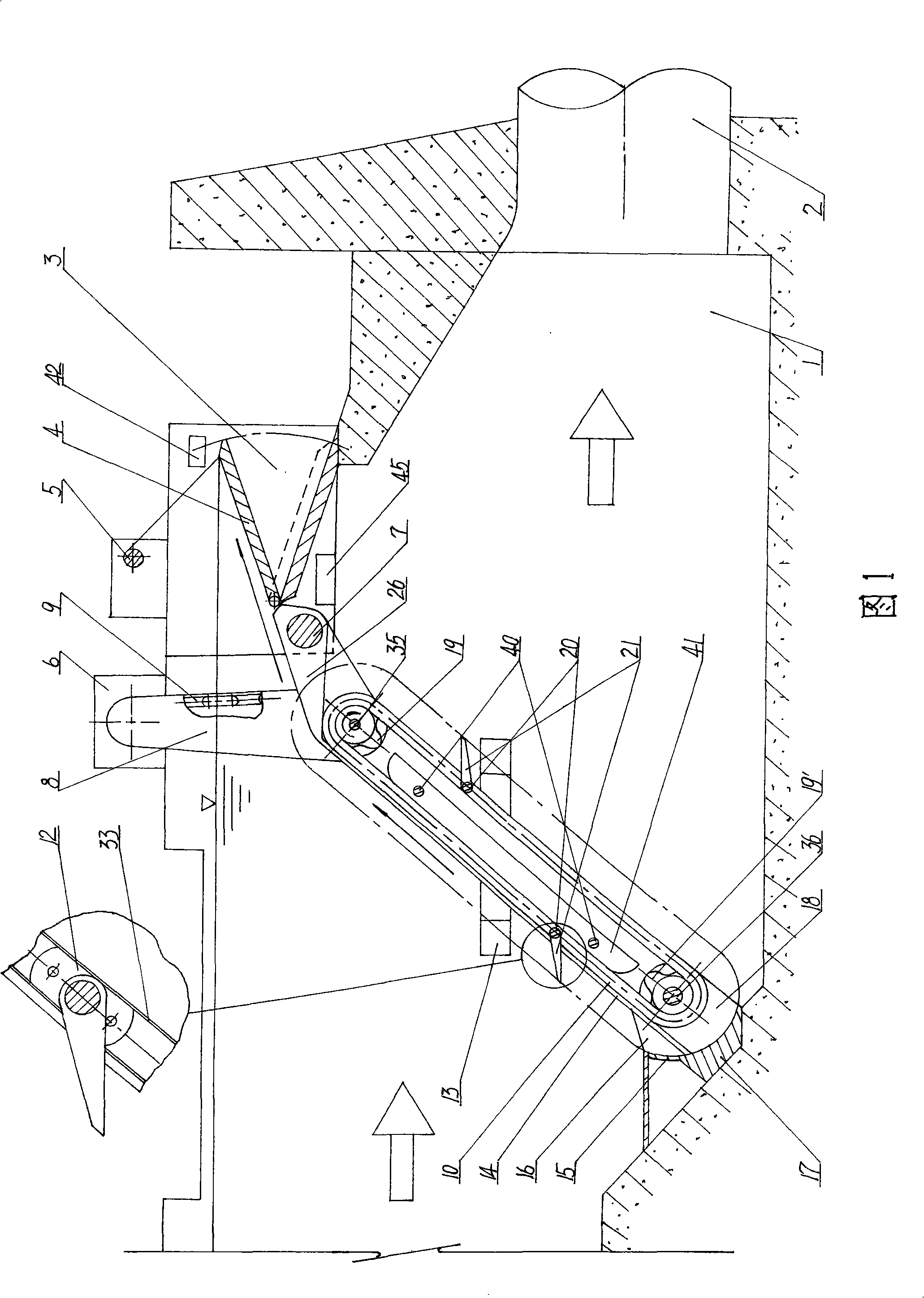

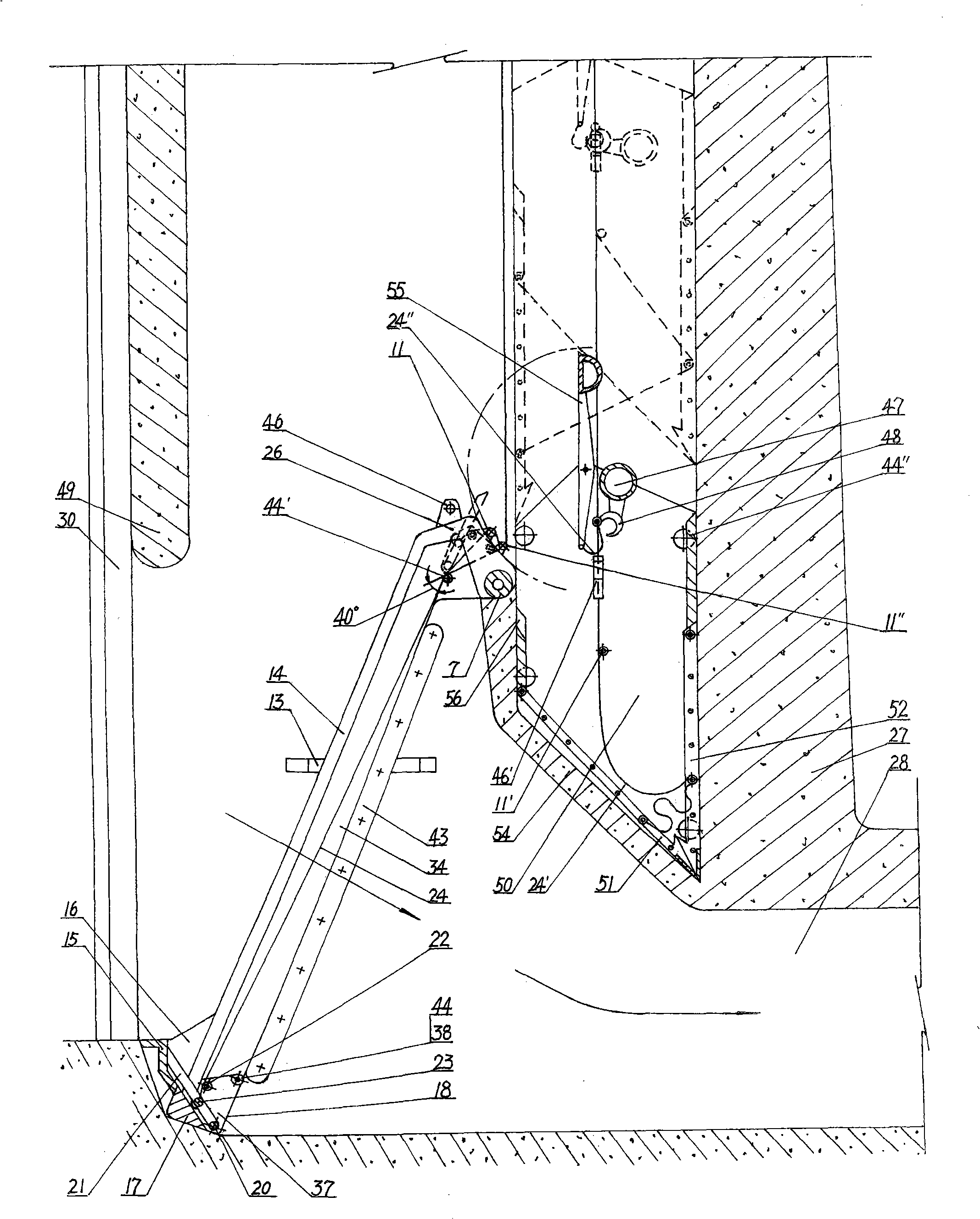

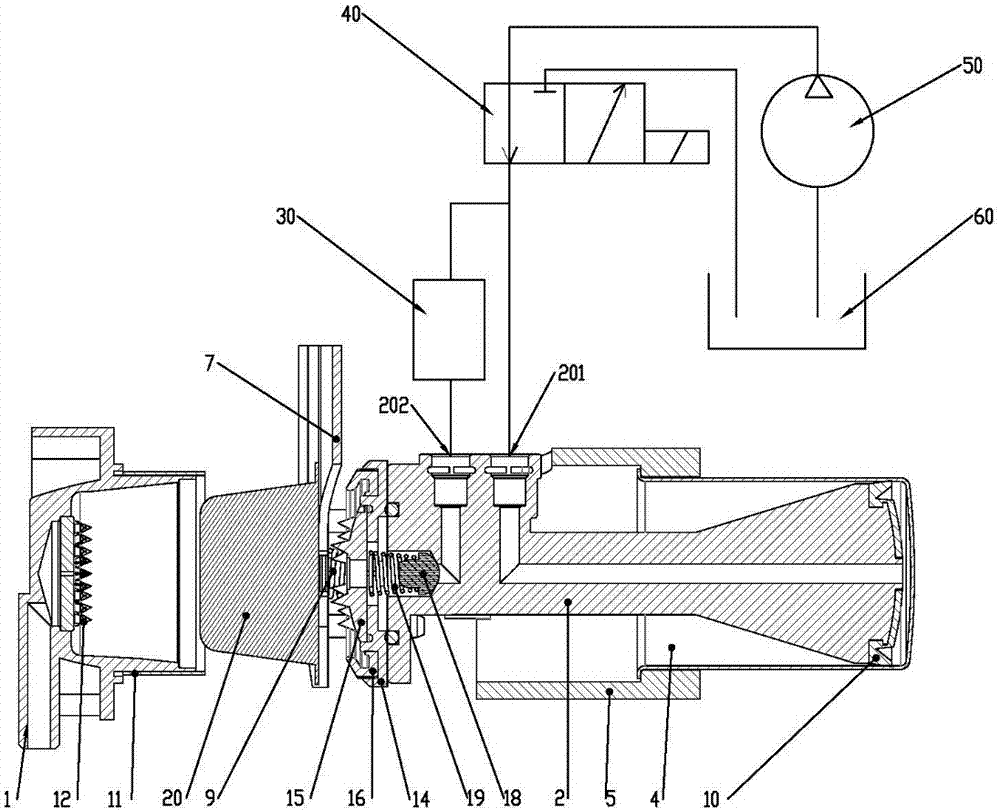

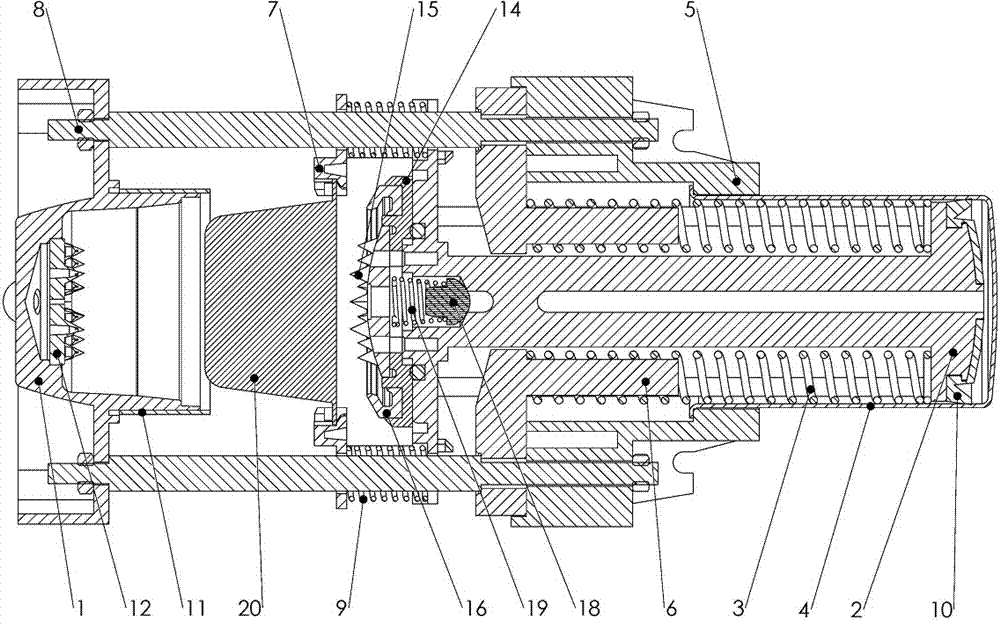

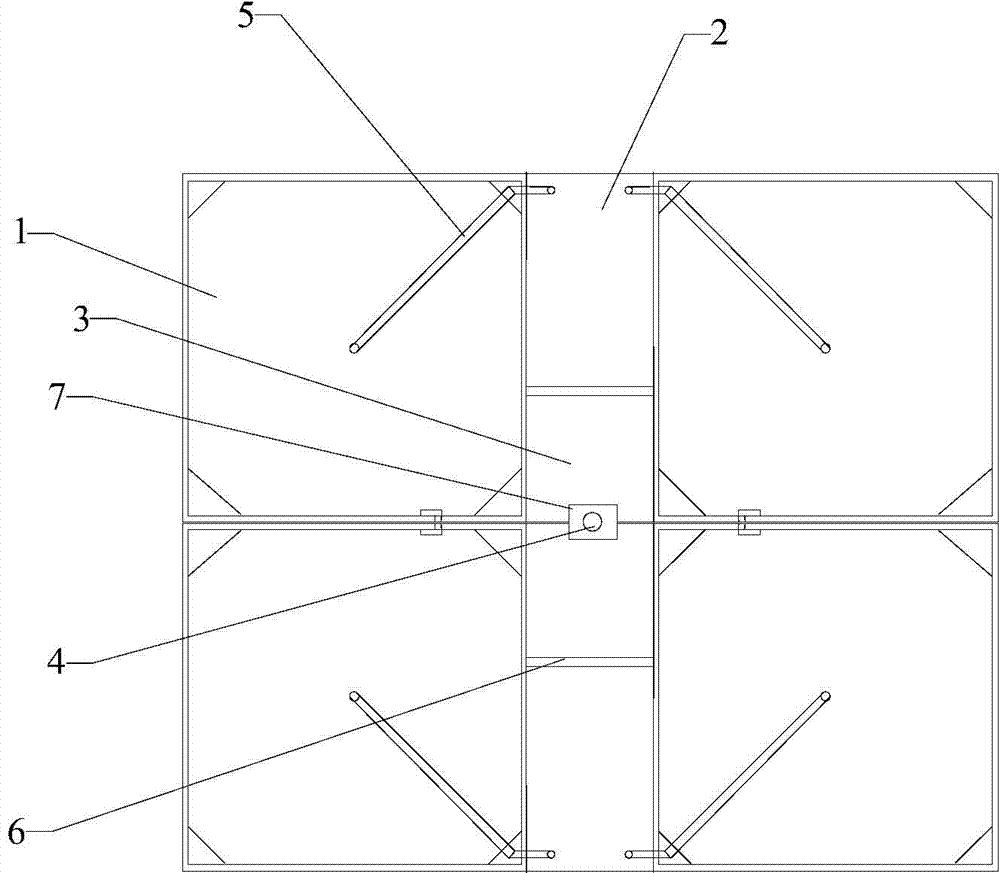

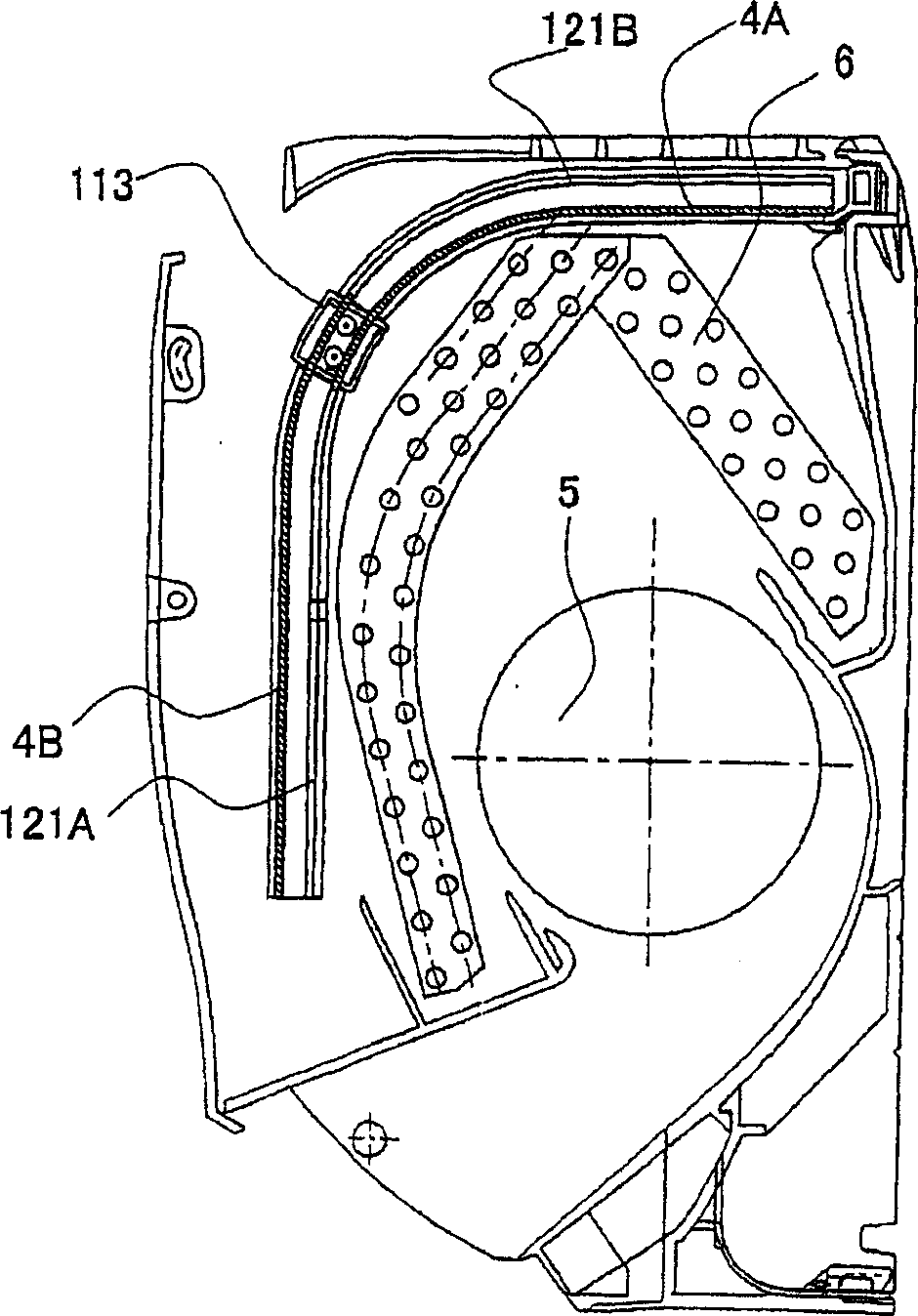

Mechanical sleeper replacing machine

InactiveCN104195904AAutomatic separation and dischargeFor automatic dischargeBallastwayRailway track constructionAutomatic controlPush and pull

The invention discloses a mechanical sleeper replacing machine. The mechanical sleeper replacing machine is composed of a vibration stone pushing device, a four nut synchronous mounting and dismounting device, a rail lifting and sleeper rotating device, a sleeper pushing and pulling device, a sleeper hoisting device, a vibration rotary excavating type stone removing device, a rail car, a power generator, a hydraulic system box, a first camera shooting component, a second camera shooting component, a third camera shooting component, a fourth camera shooting component, a fifth camera shooting component, a sixth camera shooting component and a monitor, wherein the rail car is provided with multiple trundles and two longitudinal beams, the vibration stone pushing device, the four nut synchronous mounting and dismounting device, the rail lifting and sleeper rotating device, the sleeper pushing and pulling device, the sleeper hoisting device, the vibration rotary excavating type stone removing device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a tractor cab. According to the mechanical sleeper replacing machine, a working device can be aligned with a working position quickly, requirements for quick sleeper replacement on linear and curve rail sections can be met, automatic program control can be achieved easily, and limited train passing gaps for track maintenance can be fully and reasonably utilized to achieve sleeper replacement.

Owner:KUNMING UNIV

Working method of yarn sizing device for textiles

ActiveCN109338625AAutomatic sizingAutomatic dischargeTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingYarnPulp and paper industry

The invention discloses a yarn sizing device for textiles and belongs to the technical field of textile equipment. The yarn sizing device comprises a sizing mechanism, a material receiving mechanism,a material discharging mechanism and a material scraping mechanism; the material discharging mechanism comprises a material discharging assembly and a yarn limiting assembly, the yarn limiting assembly is disposed at the right end of the material discharging assembly, the material scraping mechanism includes a top face pulp scraping assembly and a bottom face pulp scraping assembly, and the top face pulp scraping assembly is disposed above the bottom face pulp scraping assembly; the bottom face pulp scraping assembly includes a pulp scraping component and a lifting assembly used for driving the pulp scraping component to ascend and descend, and the pulp scraping component is disposed on the top of the lifting assembly. Through the material scraping mechanism, automatic pulp scraping work can be conducted on yarn, so that the surface thickness of the warp yarn is ensured; moreover, through the yarn limiting assembly, the tension of the yarn can be automatically adjusted, so that the phenomena of breakage, wearing and the like of the yarn during transport are avoided.

Owner:江苏富尔达电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com