Pipeline machine

A pipeline machine and reed switch technology, which is applied in the field of pipeline machines, can solve the problems of water bag water bag damage, trouble, manual discharge of water bags, etc., and achieve the effect of reducing manufacturing costs, reducing manufacturing costs, and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

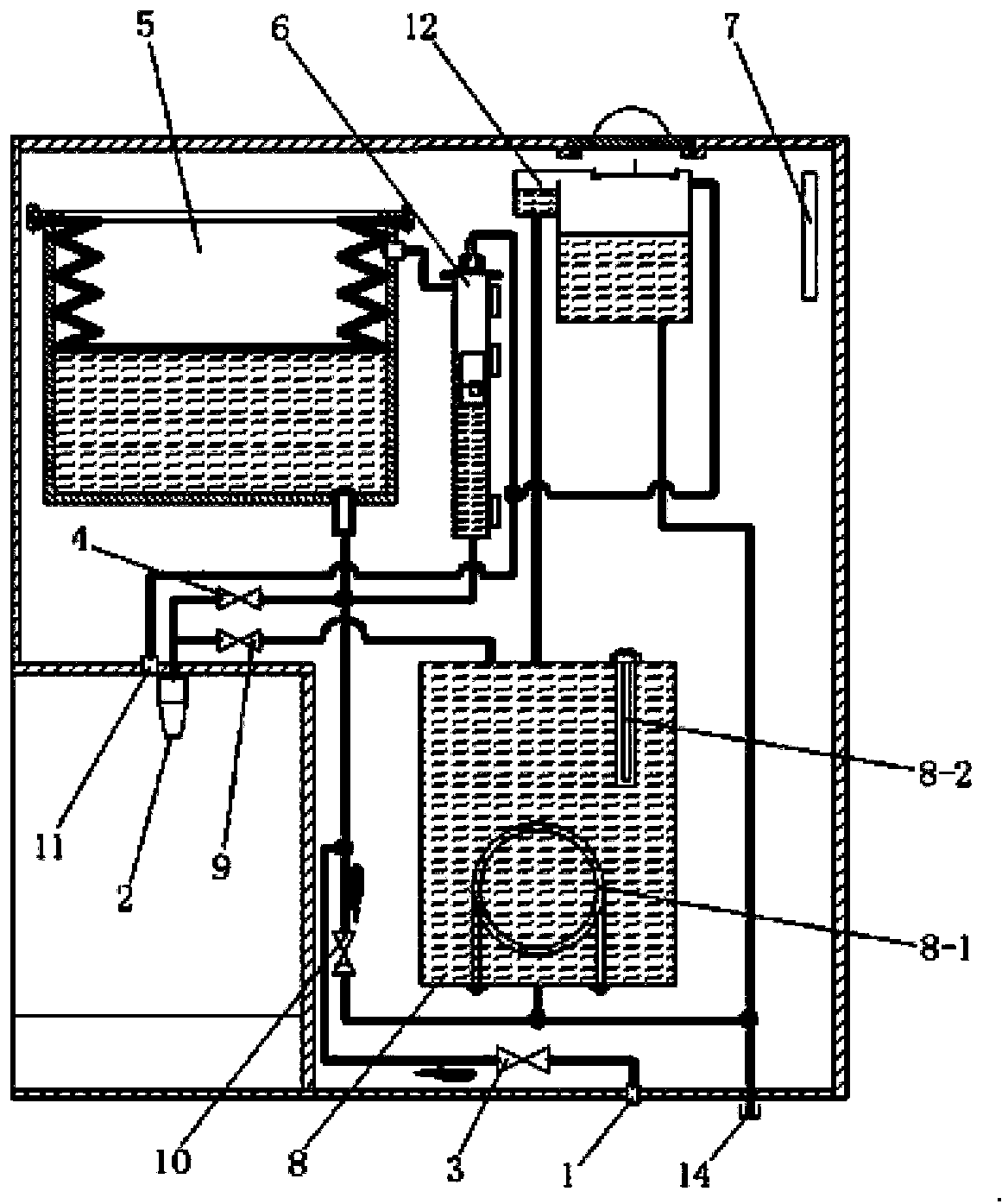

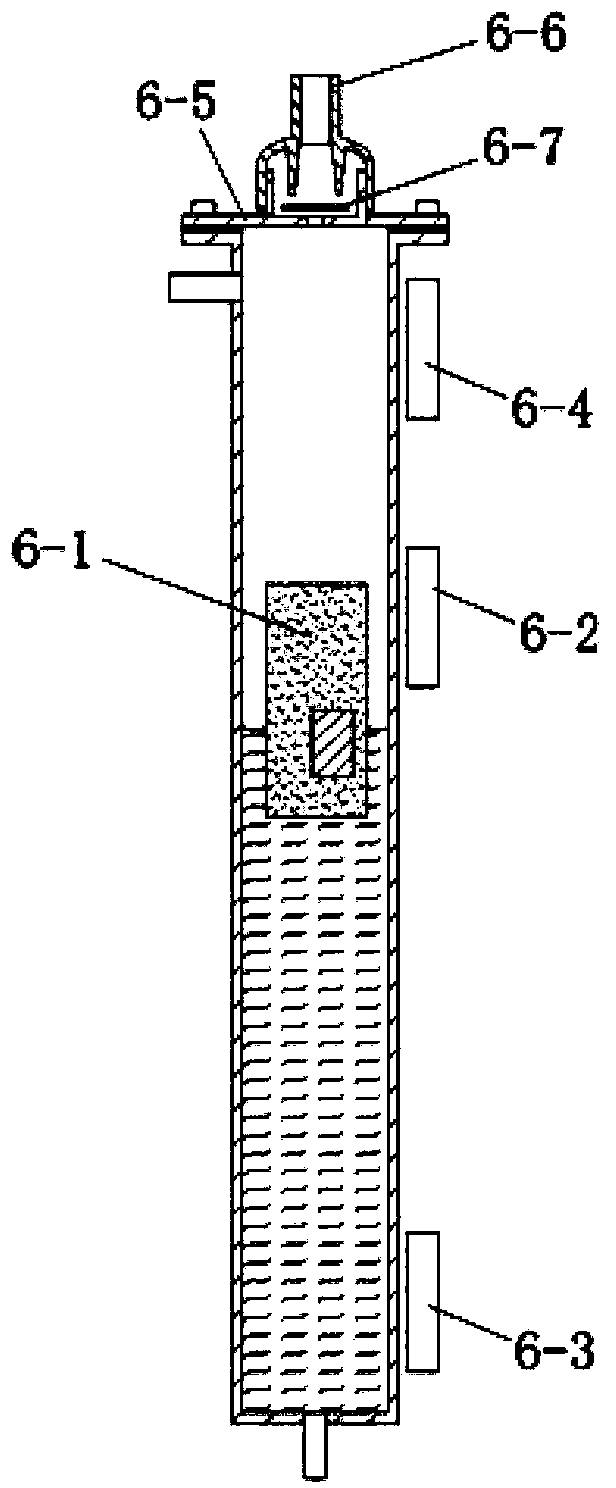

[0032] See Figure 1 to Figure 4 , the pipeline machine of this embodiment is characterized in that it includes a water inlet 1, a water outlet 2, a water inlet valve 3, a normal temperature water outlet valve 4, a diaphragm type water storage tank 5, a water level detector 6, an electrical control circuit board 7, a heat Tank 8, hot water outlet valve 9, hot tank water inlet check valve 10, exhaust port 11, expansion tank 12, sewage outlet 14 and water outlet electrical switch.

[0033] The water inlet 1 is connected to the inlet of the water inlet valve 3 , and the outlet of the water inlet valve 3 is connected to the diaphragm type water storage tank 5 . The inlet of the normal temperature water outlet valve 4 is connected to the bottom of the diaphragm type water storage tank 5 , and the outlet of the normal temperature water outlet valve 4 is connected to the water outlet 2 . The water level detector 6 is used to detect the water level in the diaphragm type water storage...

Embodiment 2)

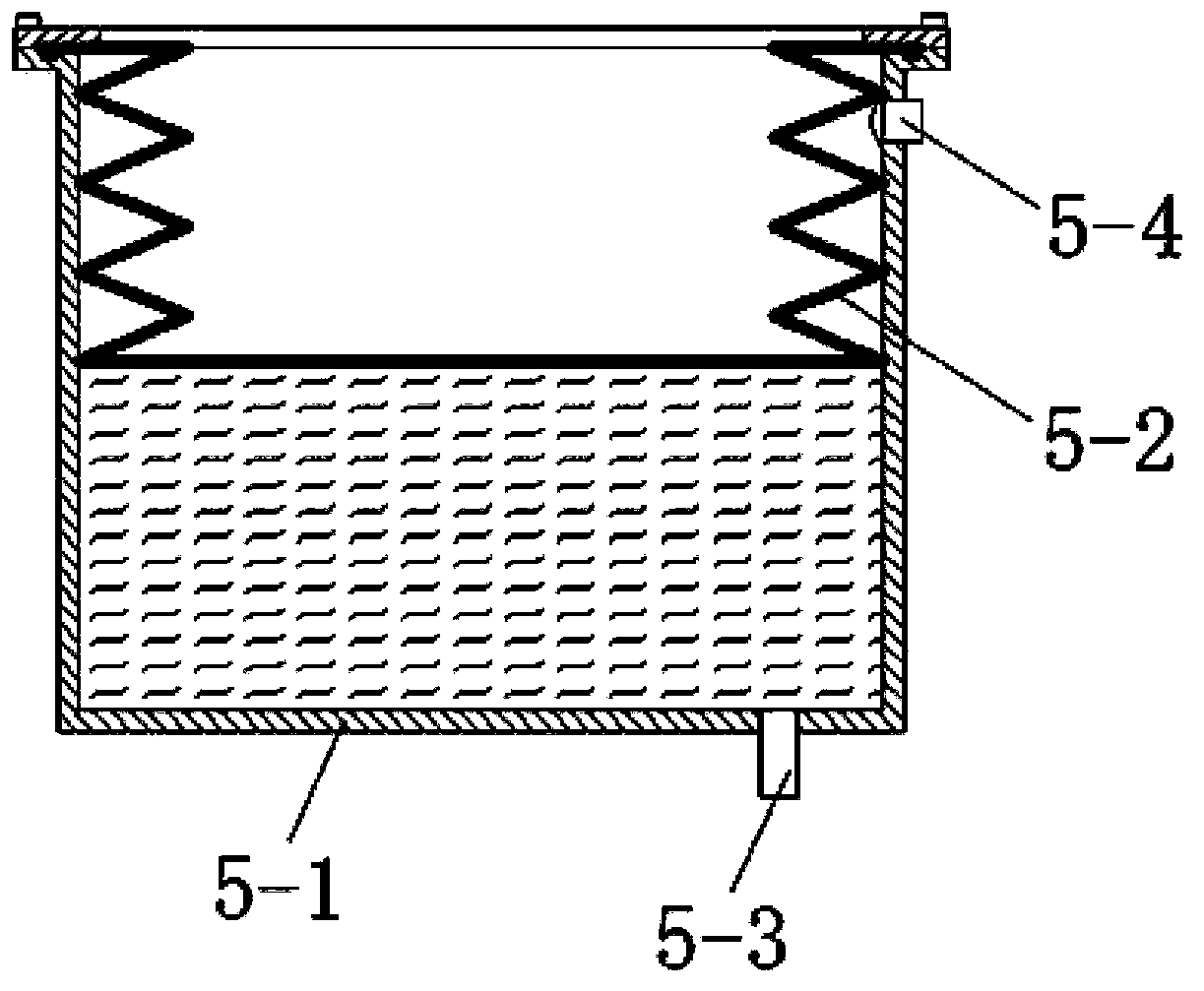

[0046] See Figure 5 , this embodiment is basically the same as Embodiment 1, except that: the water level detector 6 is arranged inside the water storage tank 5 .

[0047] The top of the diaphragm type water storage tank is provided with a water tank exhaust port 5-4, and the water tank exhaust port 5-4 communicates with the exhaust port 11 through a one-way valve 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com