Capsule type coffee maker

A technology of coffee machines and capsules, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of small sealing force, poor reliability, and large manpower, and achieve the effect of large sealing force, simple structure, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

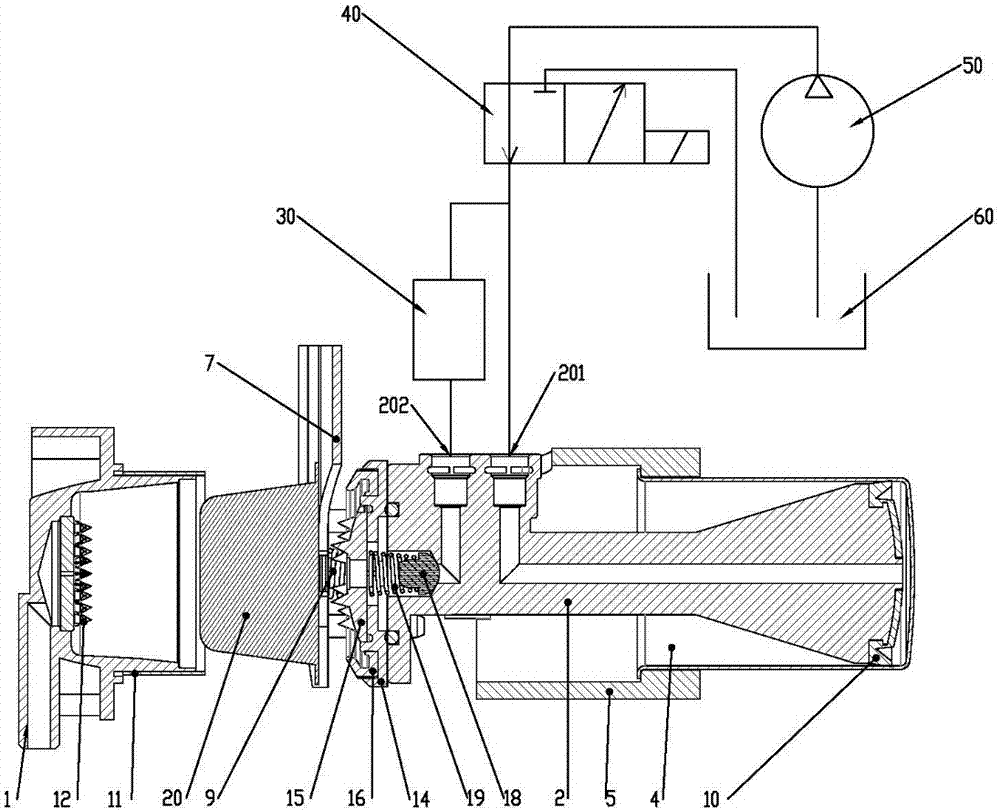

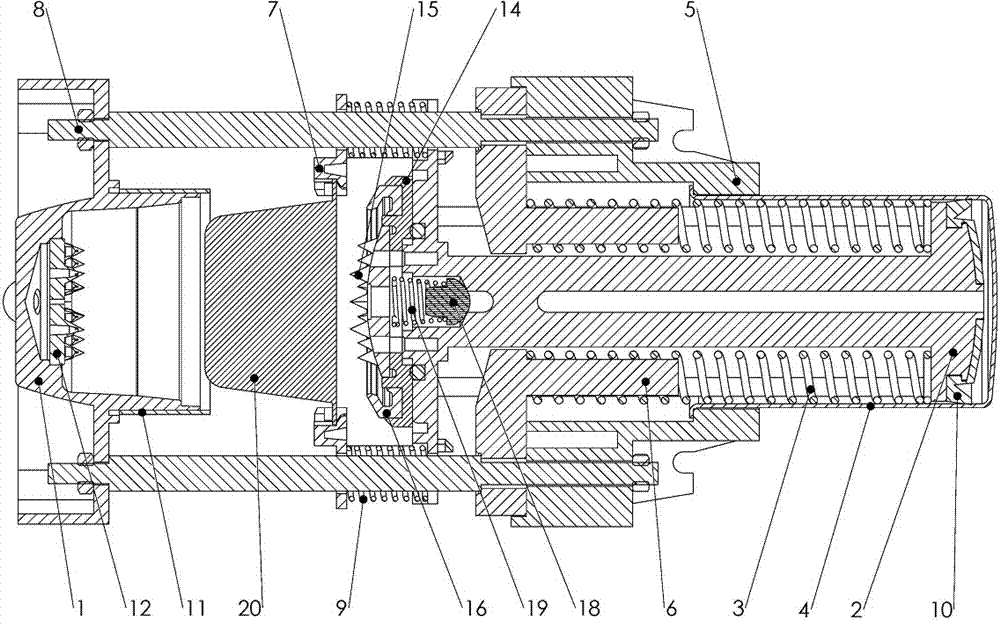

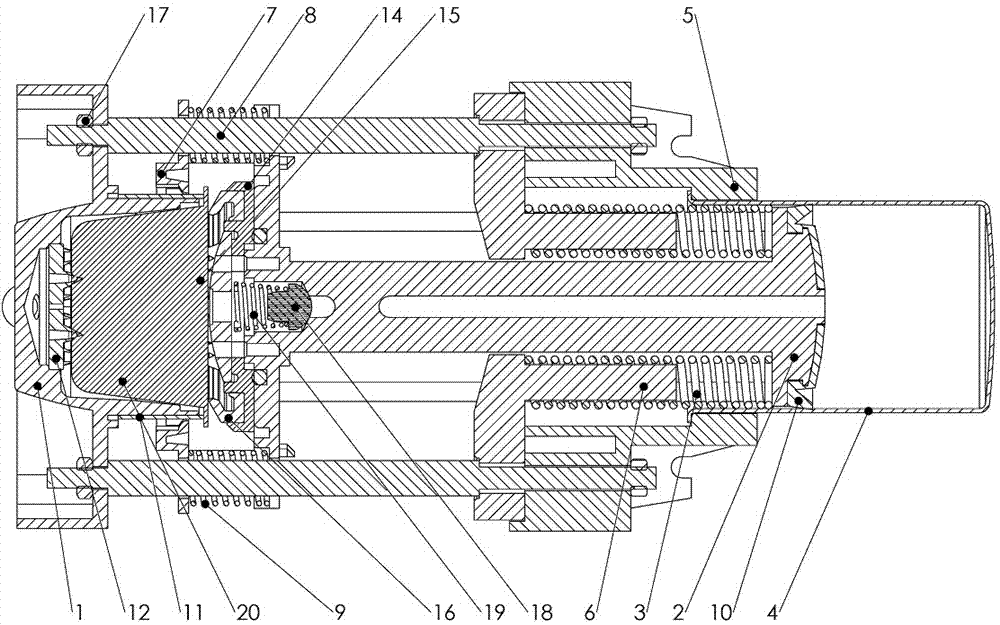

[0017] The technical solutions of the present invention will be further described below through embodiments and in conjunction with the drawings.

[0018] A capsule coffee machine, comprising a coffee box 1, a pump 50, a control valve 40, a boiler 30, a water tank 60, a piston push rod 2, a return spring 3, a cylinder 4, a cylinder fixing seat 5, a spring seat 6, and a capsule Bracket 7, guide rod 8, bracket spring 9, coffee box protective sleeve 11, piston rod seal 10, outlet silicone rubber 18, outlet spring 19, upper dial 15, lower dial 12, upper dial holder 14 and needles Disk seal 16 etc., in the capsule coffee machine, the cylinder 4 and the cylinder fixing seat 5 are combined and fixed together, the piston push rod 2 is installed in the cylinder 4, and the piston push rod is driven by the pump 50 to pump water 2 Moving outwards, the spring seat 6 is fixed between the guide rod 8 and the cylinder fixing seat 5, and the return spring 3 is installed in the piston push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com