Method and device for continuously separating oil-water slag without dismantling and cleaning

A technology for separating oil and water without dismantling and washing, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, flotation water/sewage treatment, etc. Slow speed and other issues, to achieve the effect of low processing cost, high processing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

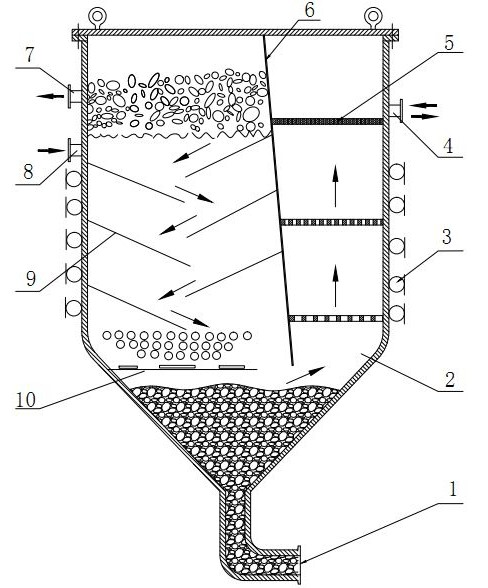

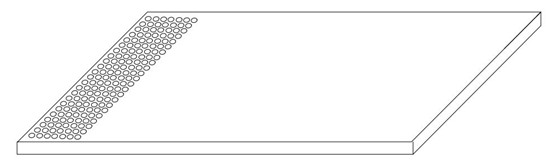

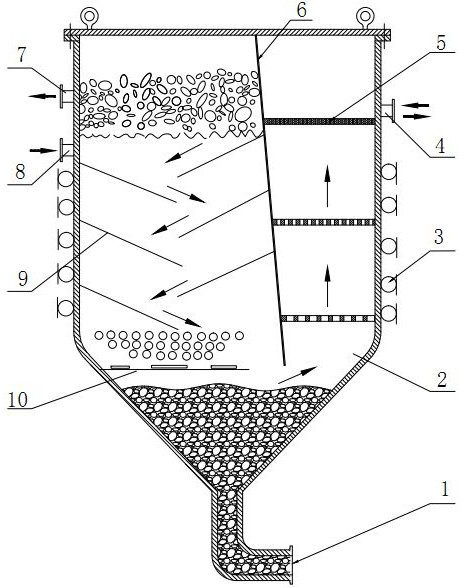

[0017] Embodiment one: as attached figure 1 The non-removable and washable continuous separation of oil and water slag shown in the device is a vertically placed vertical pot-shaped sealed container with a rectangular upper part and an inverted cone-shaped lower part. Ultrasonic generators 3 are evenly distributed on the four sides of the rectangular housing. Outside; the rectangular partition 6 divides the rectangular shell into two inner cavities with different volumes, the volume of the larger inner cavity is twice the volume of the smaller inner cavity; the lower end of the partition 6 is 5 degrees to the left; the oil discharge port 7. The waste water inlet 8 is located in the upper part of the larger inner cavity, and the six rectangular inclined plates 9 arranged alternately on the left and right sides are also located in the larger cavity. The inclined plates 9 (see attached figure 2 ) has a round hole at one end, and the round hole is located at the top of the slanti...

Embodiment 2

[0019] Embodiment 2: The waste water inlet 8 and the clean water outlet 4 are installed at the same level, but lower than the oil discharge port 7, and other parts of the structure are the same as in Embodiment 1.

[0020] The oil-water slag separation method of the non-removable and washable continuous oil-water slag separation device of the present invention is as follows:

[0021]After the waste water is pumped into the device from the waste water inlet, it hits the central partition 6 and the upper inclined plate 9, and then flows downward, most of the oil layer floats on the upper part, and the coarse slag sinks. After the water flows through the second and third layers of sloping plates 9 and turns back and forth, the coarse slag basically gathers on the top of the sloping plates 9, and after gathering to a certain amount, it automatically falls into the bottom of the device tank bottom tank 2 from the bottom end. The fine oil droplets are separated and enriched to the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com