Water circulation cleaning treatment device of raw material straw for biogas production

A technology of clean treatment and water circulation, applied in the field of machinery, can solve the problems of slow response, low efficiency, waste of water, etc., and achieve the effects of improving crushing efficiency, reducing labor use, and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

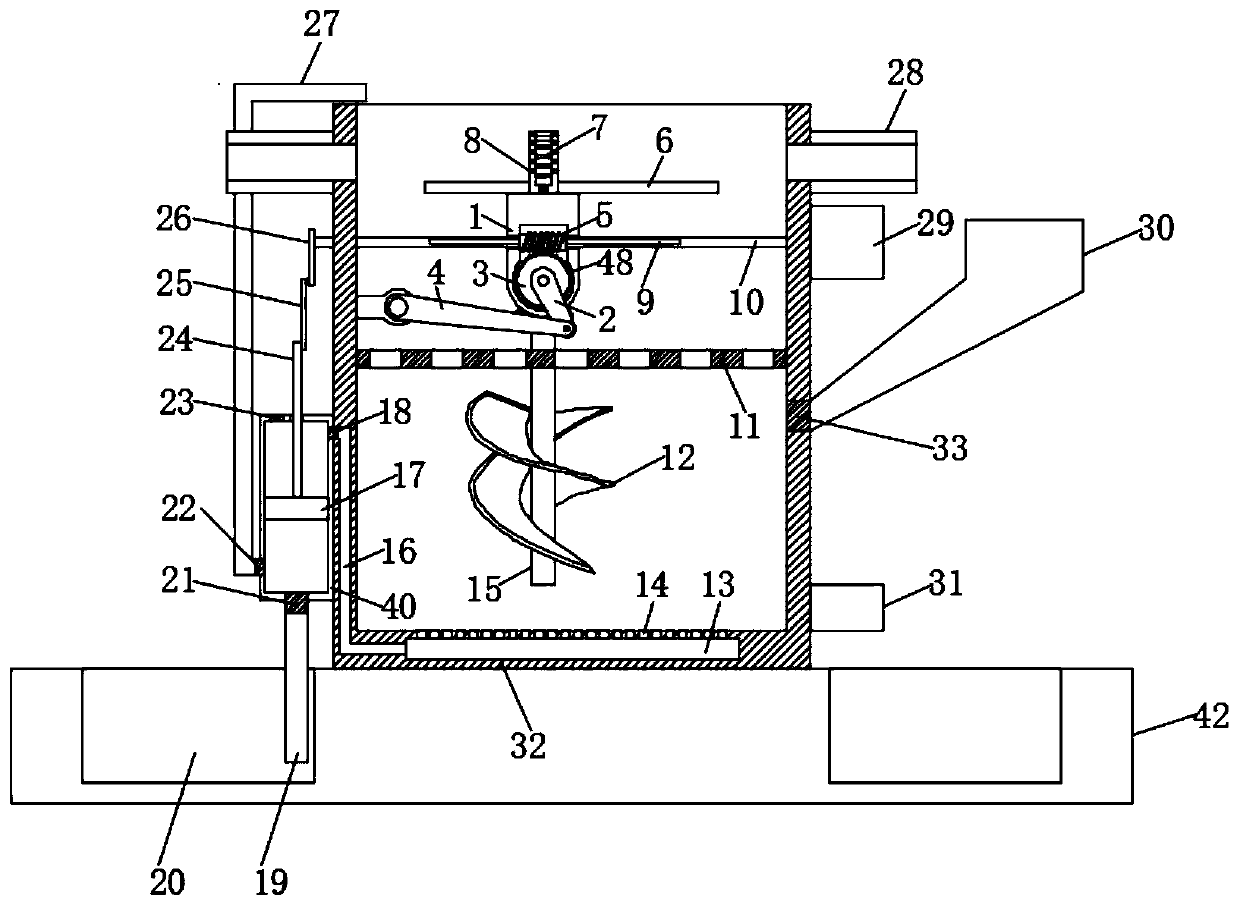

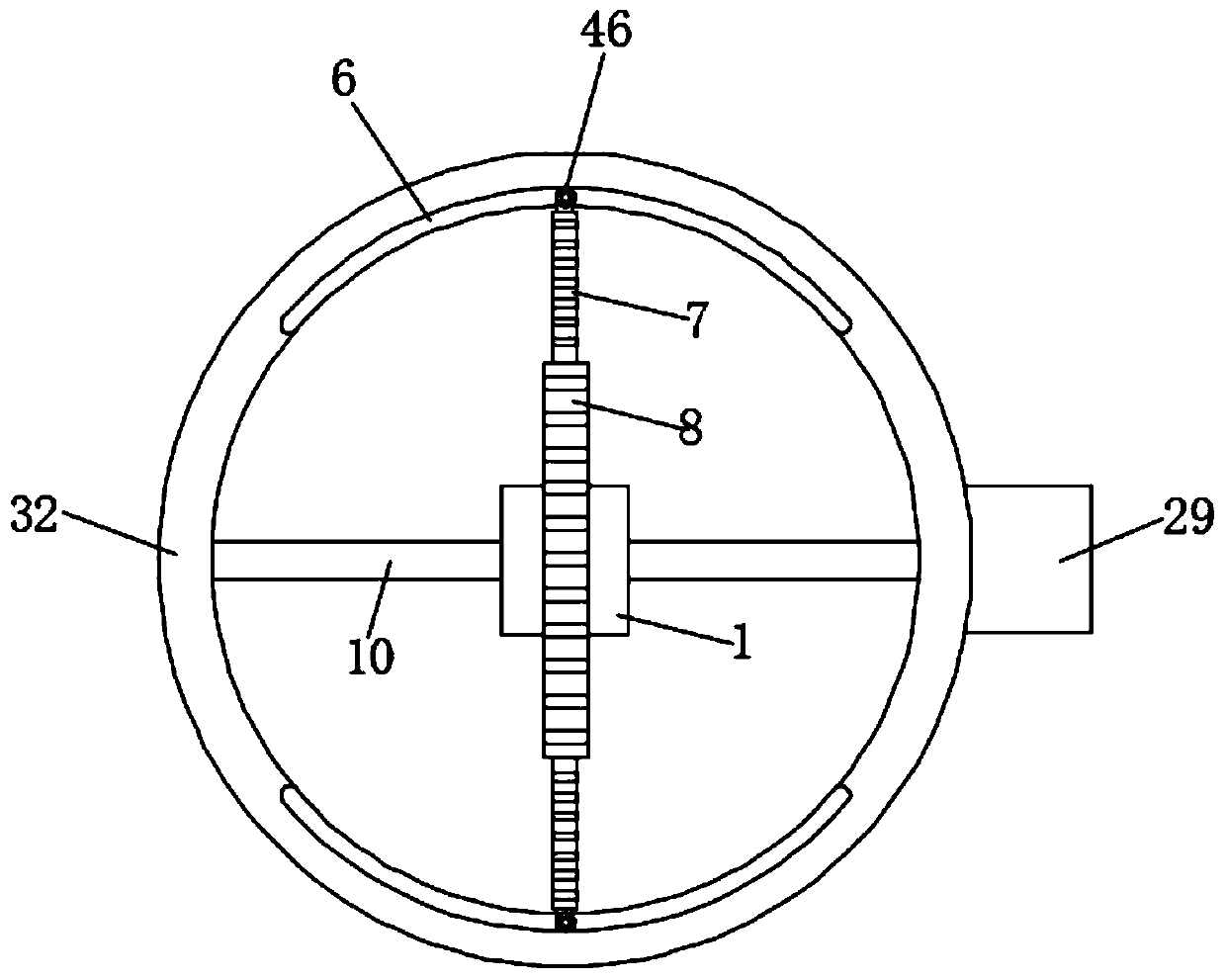

Method used

Image

Examples

Embodiment 2

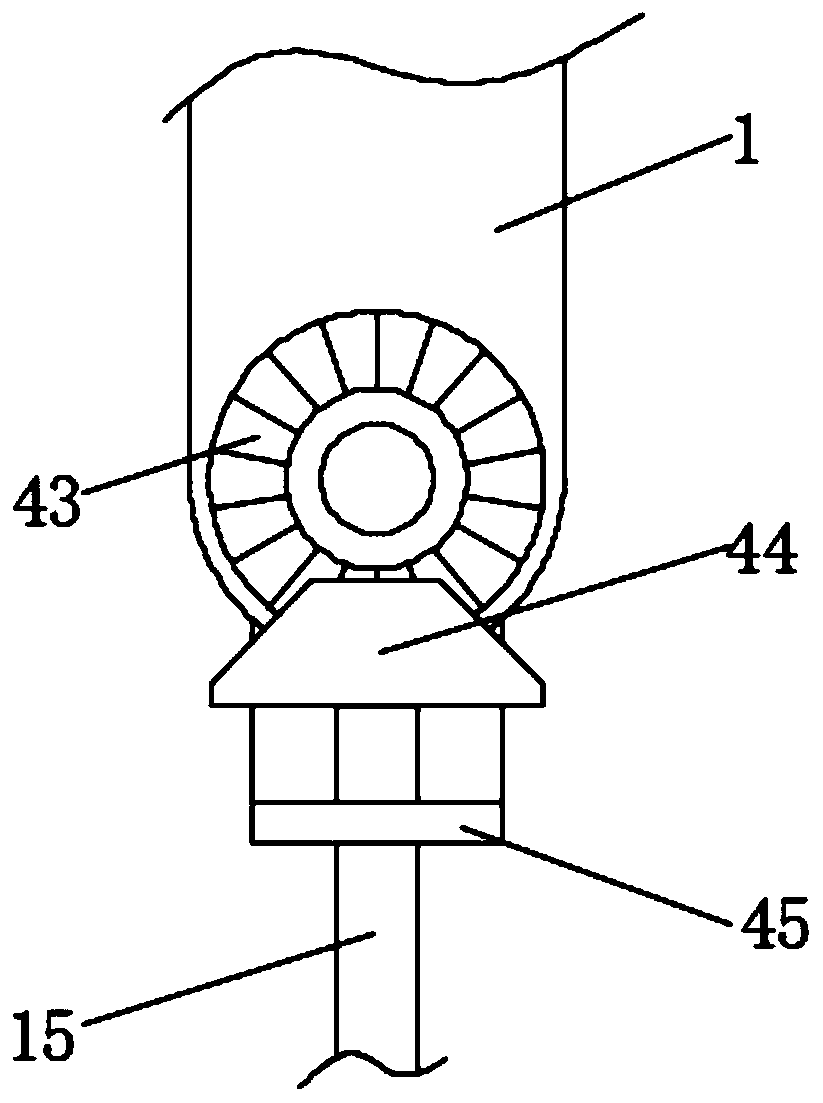

[0034] refer to Figure 4-7 , different from Embodiment 1, the slider 47 is slidably connected in the bar-shaped groove 37, the transmission shaft 15 runs through the slider 47, the two sides of the slider 47 are fixedly connected with racks, and the lower end of the screen 11 is located in the bar-shaped Both sides of the groove 37 are rotationally connected with a plurality of first gears 38 matched with the rack at equal intervals, the lower end of the first gear 38 is fixedly connected with the third bevel gear 41 coaxially, and the lower end of the screen 11 is fixedly connected with a plurality of gears. The vertical plate 34 and the third bevel gear 41 of the vertical plate 34 are correspondingly arranged. The side wall of each vertical plate 34 is provided with a third rotating shaft 36. The fourth bevel gear 39 is fixedly connected with the stirring blade 35 on the third rotating shaft 36 .

[0035] In the present invention, when the mounting plate 1 reciprocates, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com