Coal wall side crushing device of coal mining machine with large mining height

A technology of crushing device and shearer, which is applied in grain processing and other directions, can solve the problems of working face blockage, roof fall, and chipping, and achieve the effect of small occupied space, accurate crushing position, and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

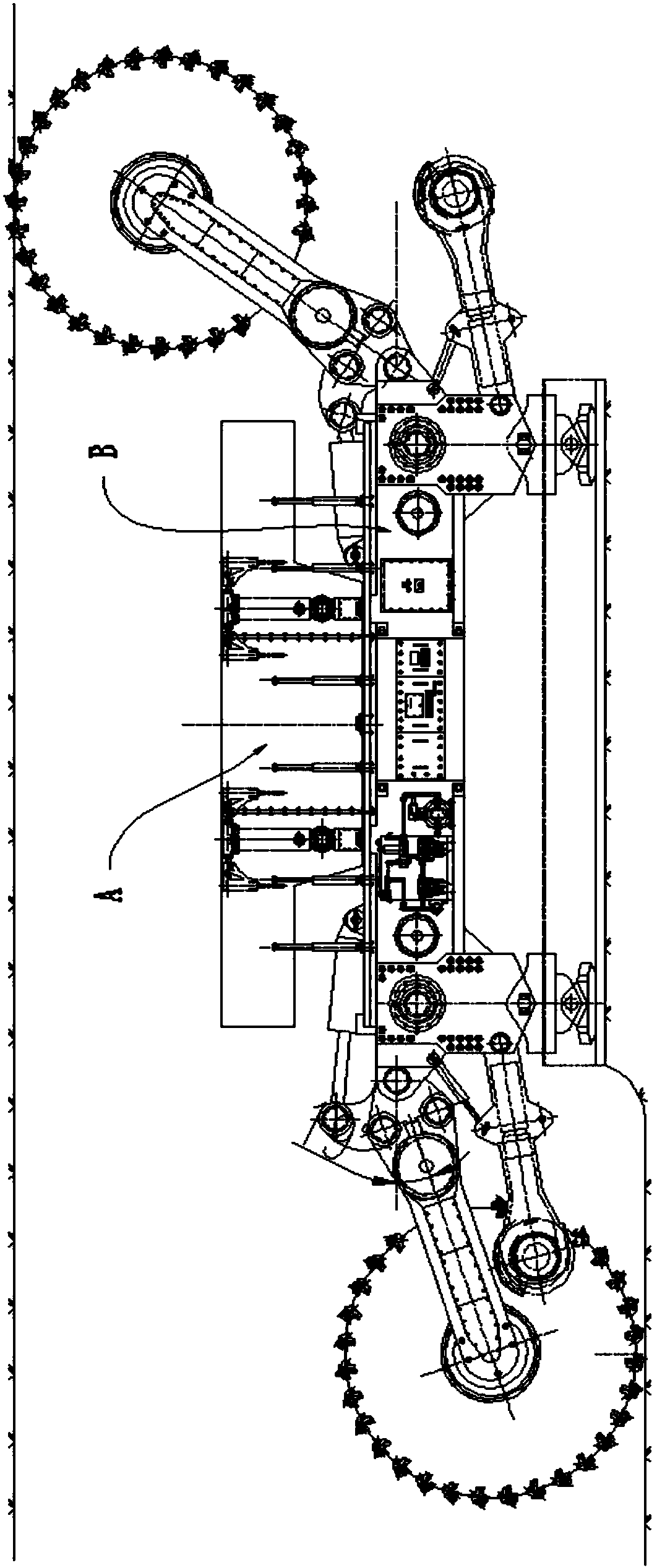

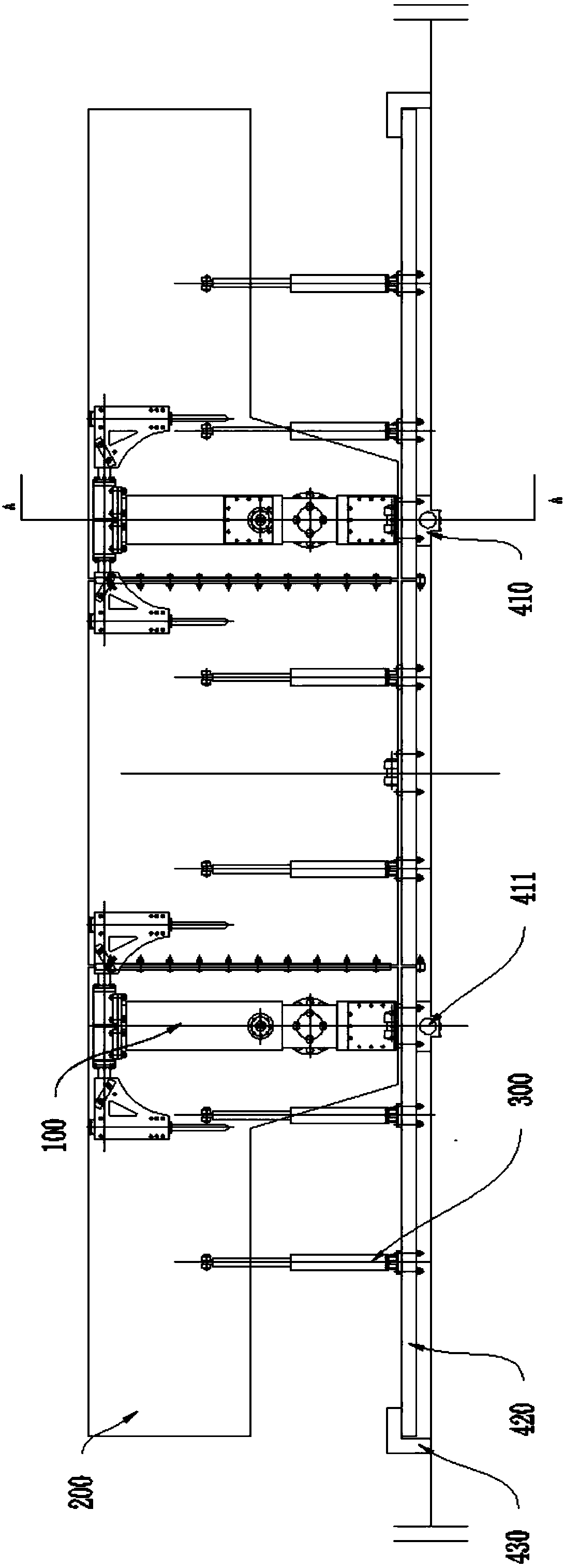

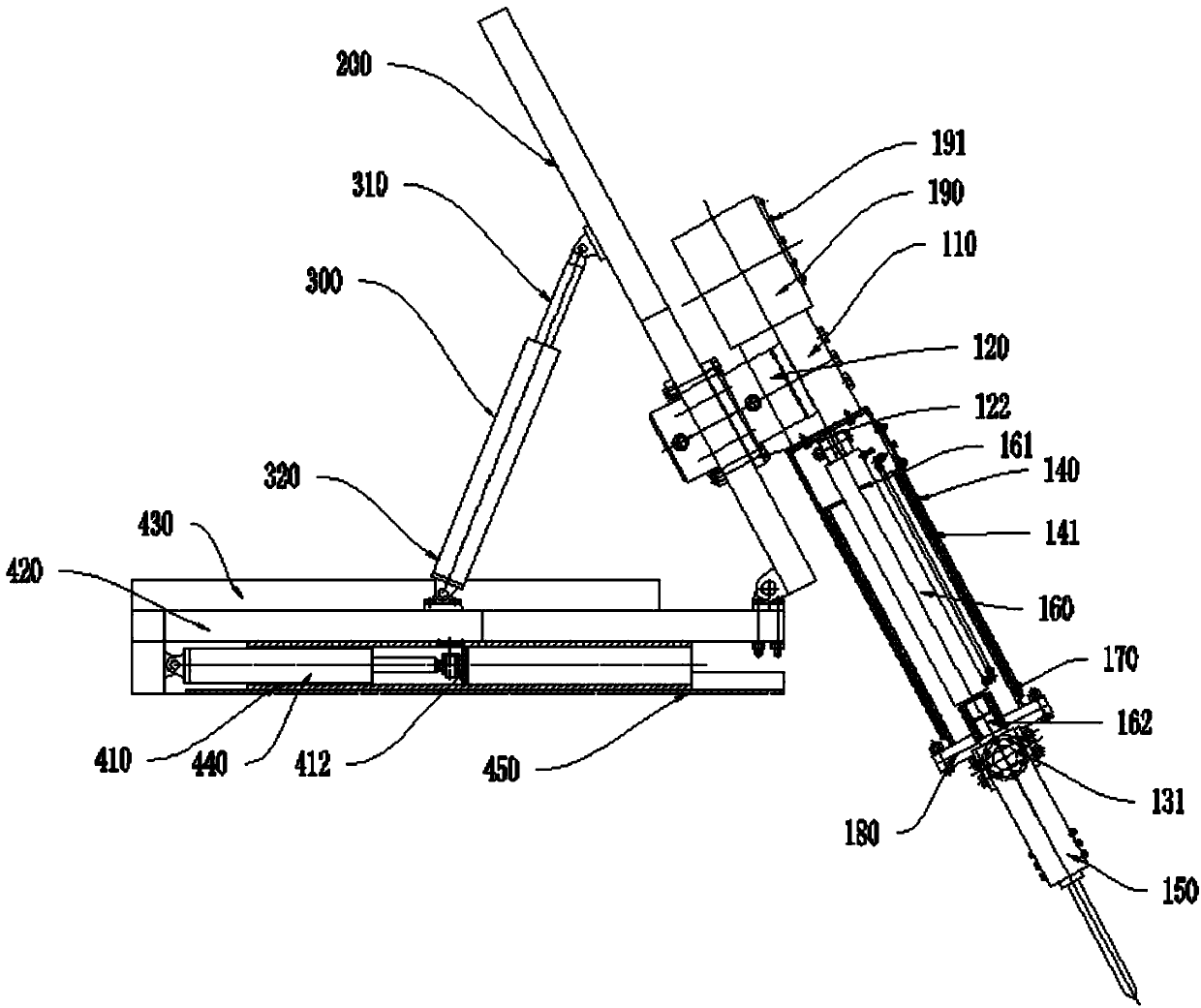

[0033] Such as Figures 1 to 5As shown, a large mining height shearer coal wall side crushing device, the large mining height coal wall side crushing device A is installed on the upper end of the shearer main frame B, wherein the crushing mechanism 100 includes the main frame 110, large swing oil cylinder 120, small swing oil cylinder 130, cantilever 140 and breaker 150, output flange I121 of large swing oil cylinder 120 is connected to the lower end of main frame 110, cantilever 140 is connected to the right end of main frame 110, small swing oil cylinder 130 Installed on the right side of the cantilever 140, the breaker 150 is connected to the output flange II131 of the small swing cylinder 130; it also includes a gangue blocking device 200 and a height adjustment cylinder 300, and the gangue blocking device 200 is connected to the large swing cylinder through the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com