Vertical shaft multistage board hammer sand making machine

A vertical shaft, sand making machine technology, applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to hit, small crushing range, etc., achieve fast crushing speed, improve crushing efficiency, and avoid impact Environmental and worker health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

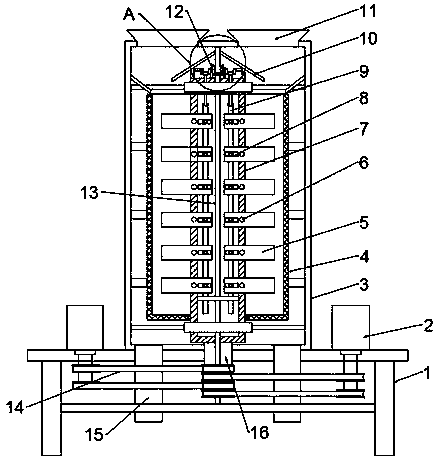

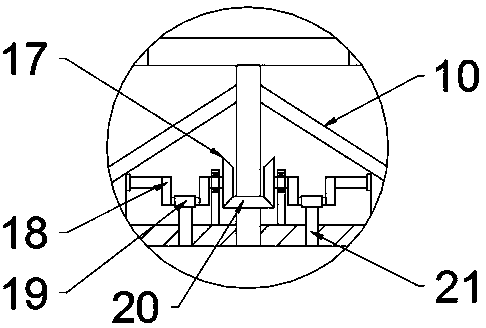

[0020] see Figure 1~2 , in an embodiment of the present invention, a vertical shaft multi-stage blow bar sand making machine includes a frame 1, a casing 3, a metal screen cylinder 4, a driving motor 2, a blow bar rotor 7 and a blow bar 5, and the frame 1 is installed with an organic casing 3 through screws, and a metal screen cylinder 4 is concentrically fixed in the casing 3 through a support rod. The top of the metal screen cylinder 4 is open, and the metal screen cylinder 4 is equipped with a blow bar rotor 7, and the bottom of the blow bar rotor 7 is concentric. The hollow shaft 16 is welded and fixed, and the hollow shaft 16 extends to the bottom of the frame 1. On the frame 1, the drive motor 2 is installed on both sides of the casing 3 through bolts. The output shaft of the drive motor 2 is connected to the hollow shaft through the belt transmission member 14. 16 connection, both sides of the top of the casing 3 are provided with feed hoppers 11, both sides of the bot...

Embodiment 2

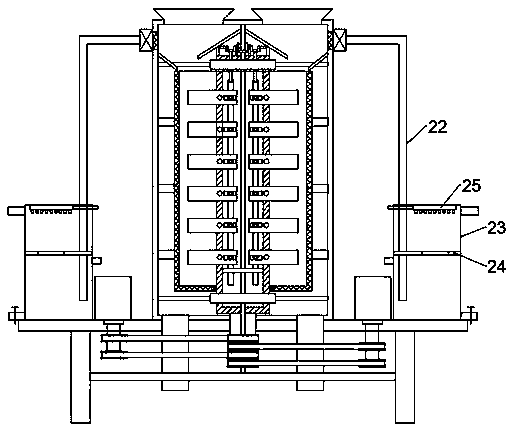

[0022] see image 3 The difference between this embodiment and Embodiment 1 is that it also includes a dust suction device, which includes a suction fan, a dust removal box 23 and a spray pipe 25, and both sides of the top of the casing 3 are equipped with suction The air pipe 22 is connected to the air outlet of the exhaust fan, and the other end of the air pipe 22 runs through the top of the dust removal box 23 and extends to the bottom of the inner cavity of the dust removal box 23. A partition 24 is fixed in the middle of the inner cavity of the dust removal box 23. Below 24 is a water storage chamber, and air holes are provided on the partition 24. A spray pipe 25 is installed on the top of the dust removal box 23, and a plurality of nozzles are integrated at the bottom of the spray pipe 25, and a water supply pipe is connected to the spray pipe 25. , the exhaust fan extracts the air with a large amount of dust and then passes it into the dust removal box 23 through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com