Production line used for wood board processing

A production line and wood board technology, applied in the field of wood board processing, can solve the problems of inability to realize wood sawing, drying and automatic gluing, automatic pressing and automatic sanding, no unified production line, affecting workers' health, etc. Conducive to centralized processing, avoids flying around, and is conducive to the effect of replacement and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

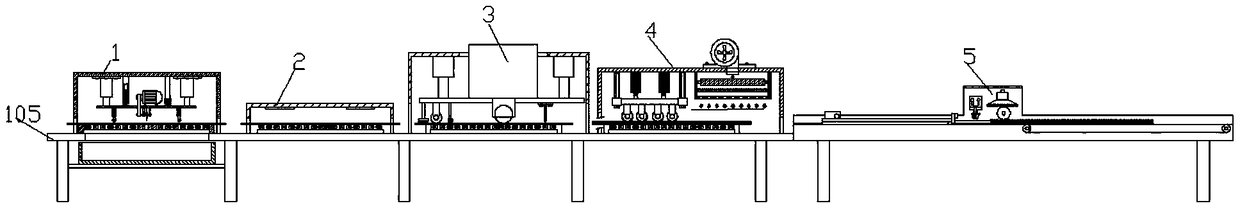

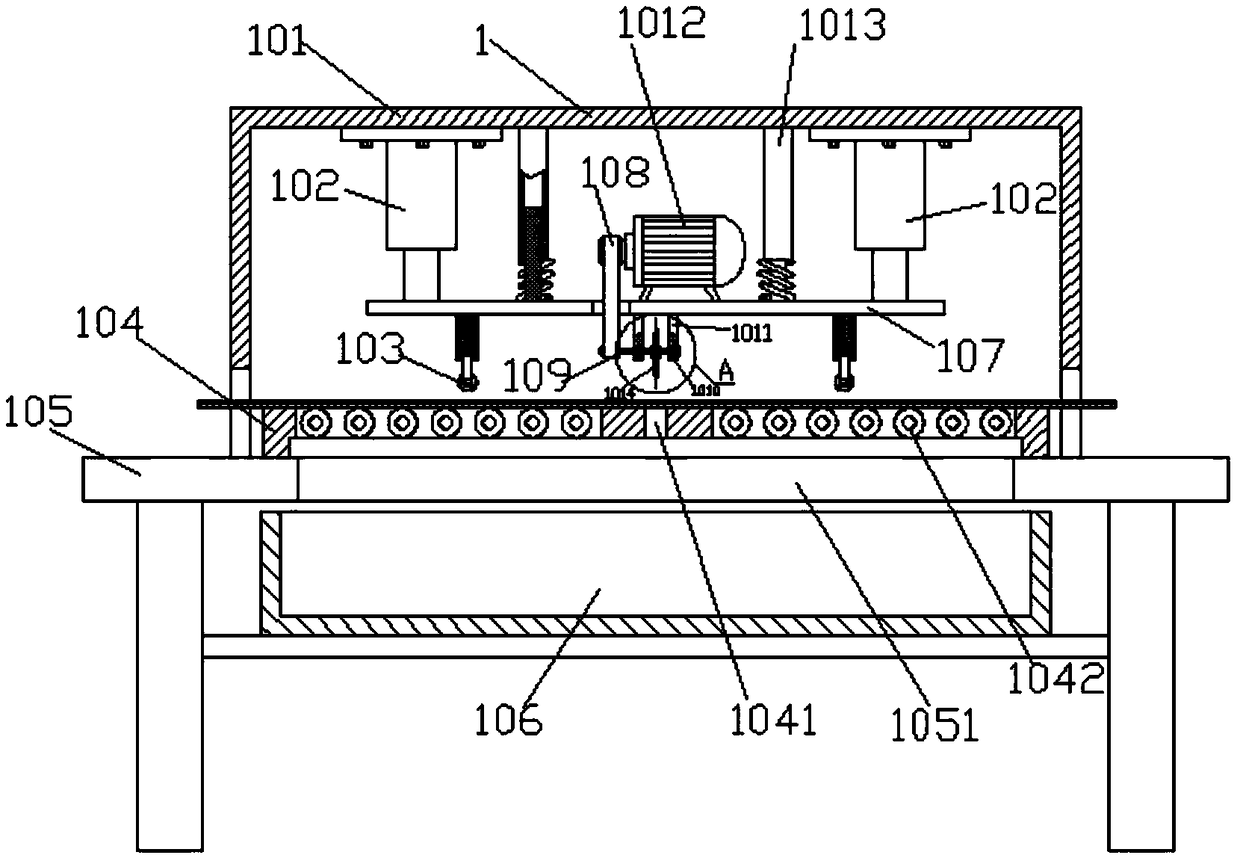

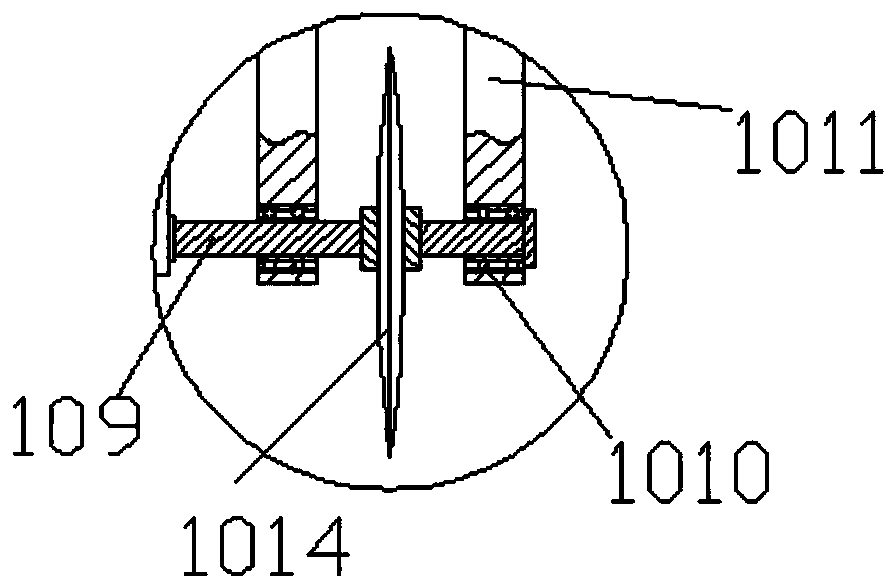

[0033] Such as Figure 1-Figure 8Shown, the specific structure of the present invention is: it comprises sawing device 1, drying device 2, gluing device 3, pressing device 4, sanding device 5 and support frame 105; The first housing 101 on the top, the support frame 105 is provided with a workbench 104, the left and right sides of the first housing 101 are respectively provided with a material inlet and a material outlet, and the distance between the two sides of the first housing 101 is provided with The first hydraulic cylinder 102, and the bottom of the piston rod of the first hydraulic cylinder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com