Patents

Literature

61results about How to "Realize automatic glue application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

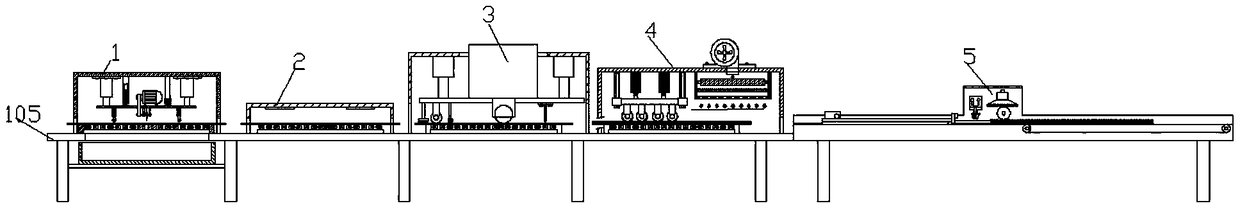

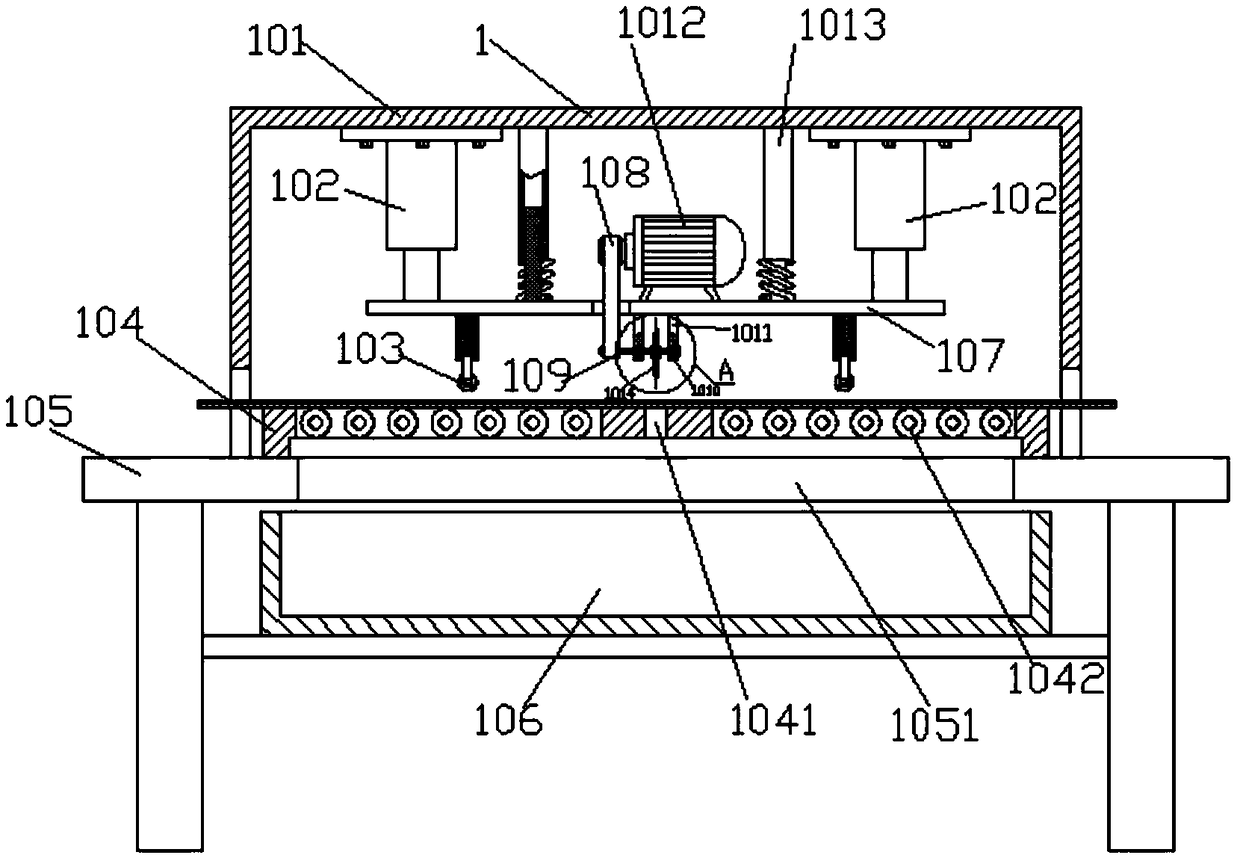

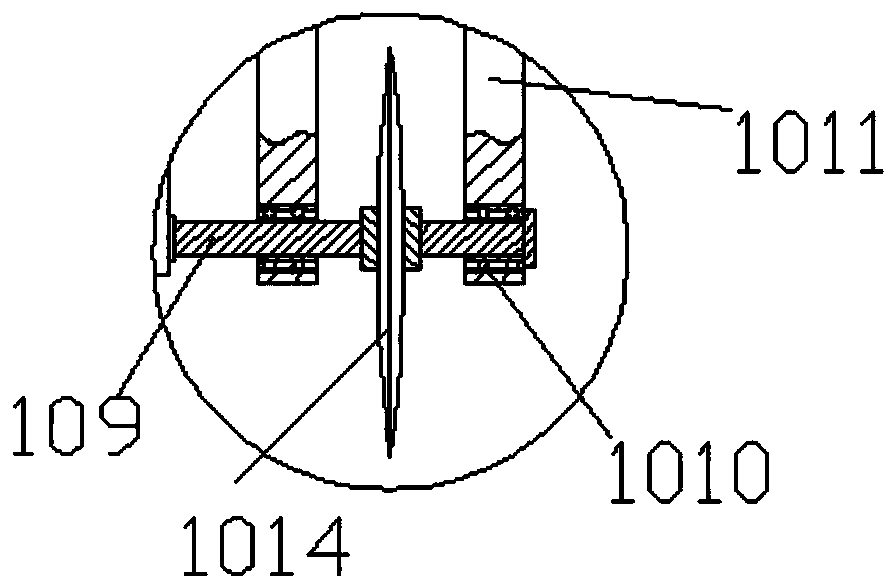

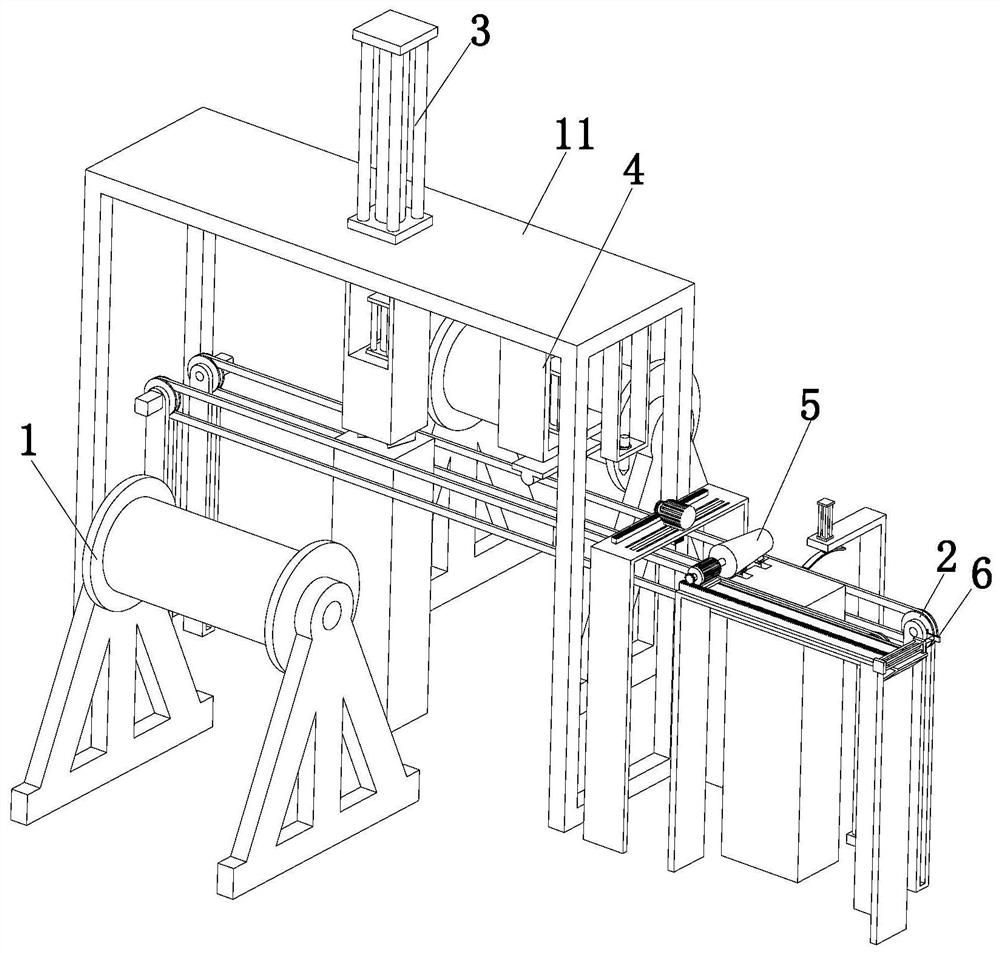

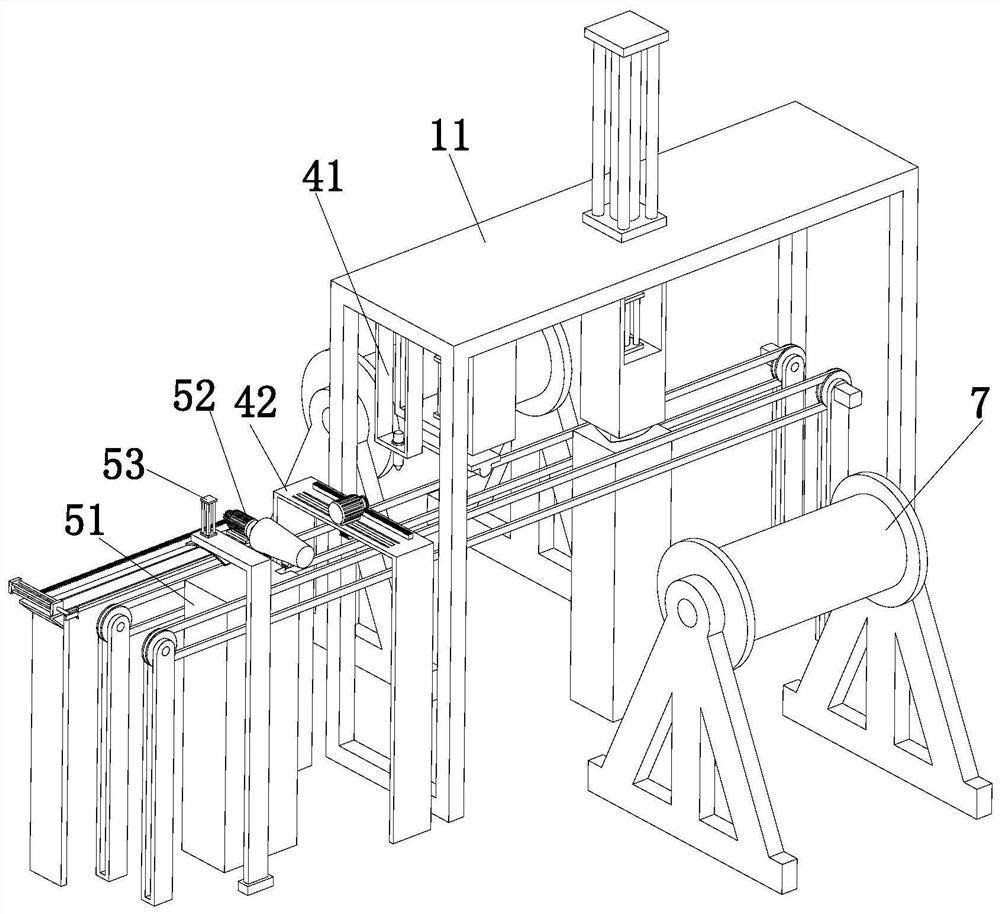

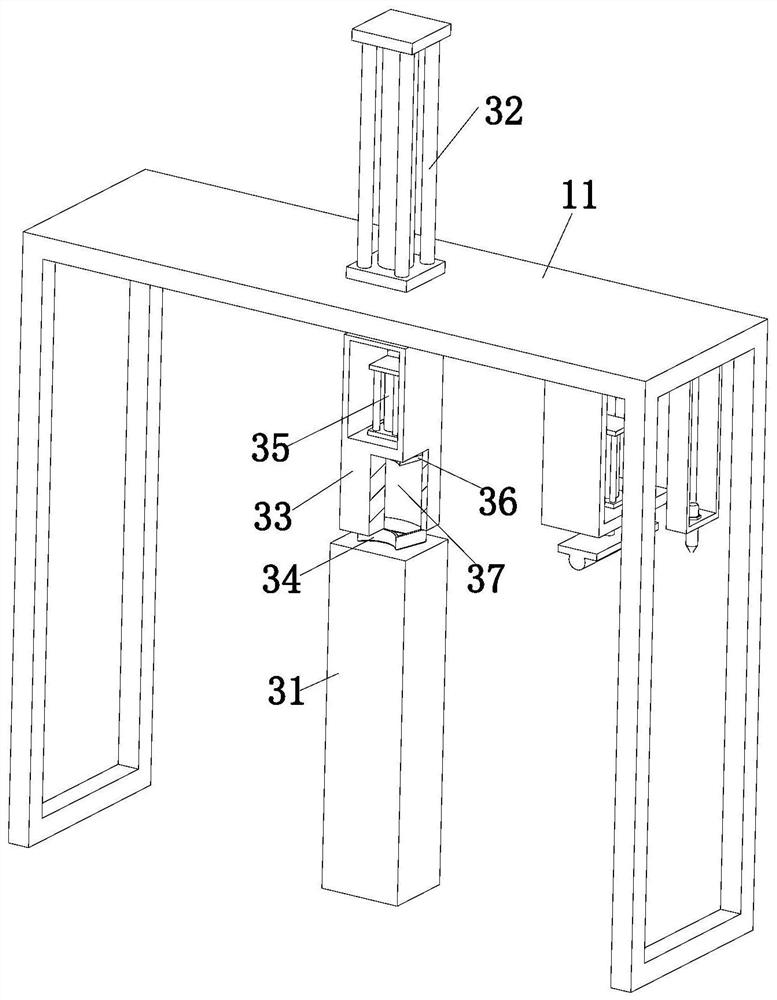

Production line used for wood board processing

The invention discloses a production line used for wood board processing. The production line comprises a sawing device, a drying device, a gumming device, a pressing device, a sanding device and a supporting frame. The production line used for wood board processing is complete in function, a stream-lined line production mode is adopted, and sawing, drying, automatic gumming, automatic pressing and automatic sanding of wood can be achieved.

Owner:湖南九富家居材料有限公司

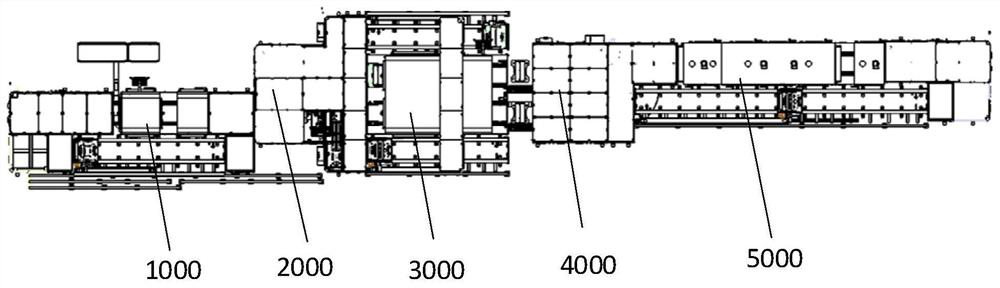

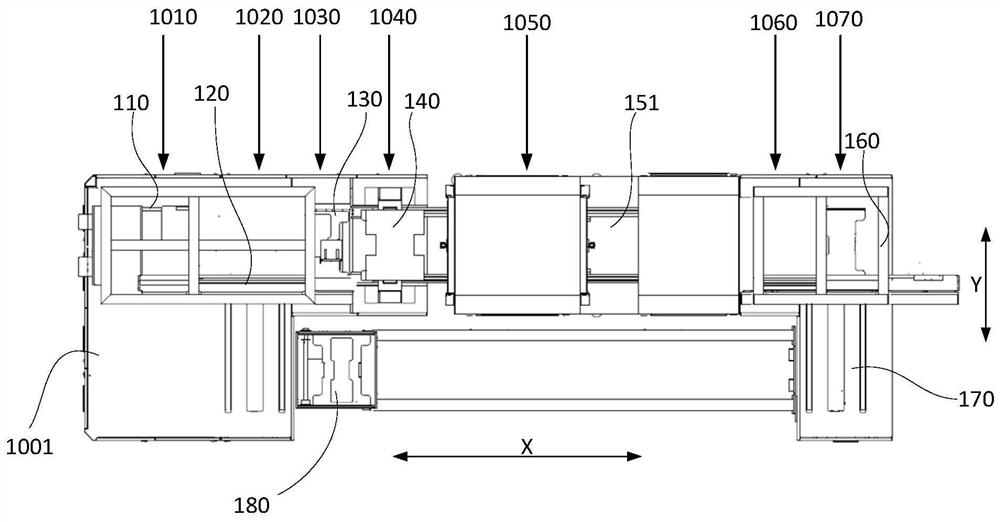

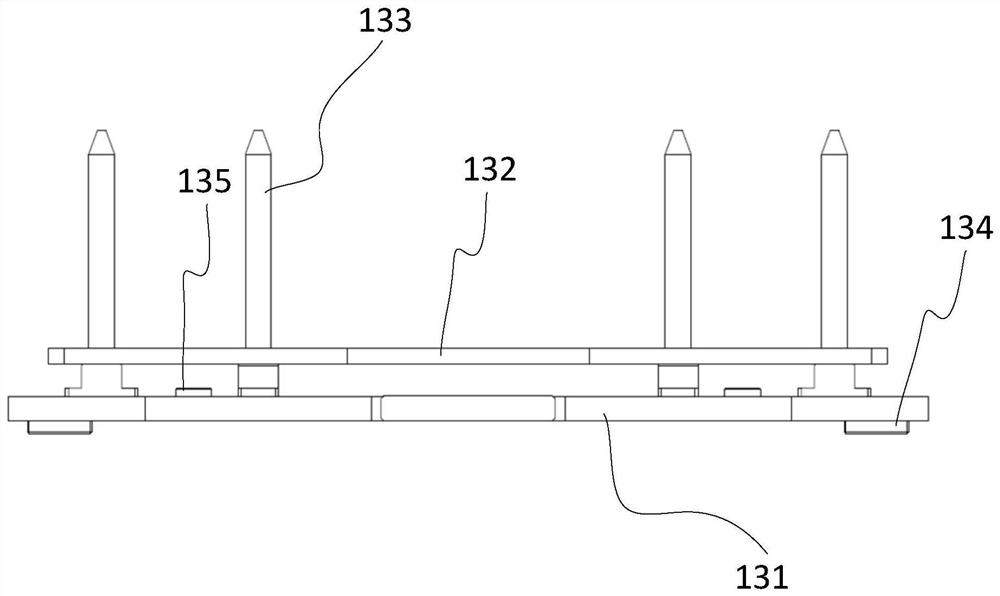

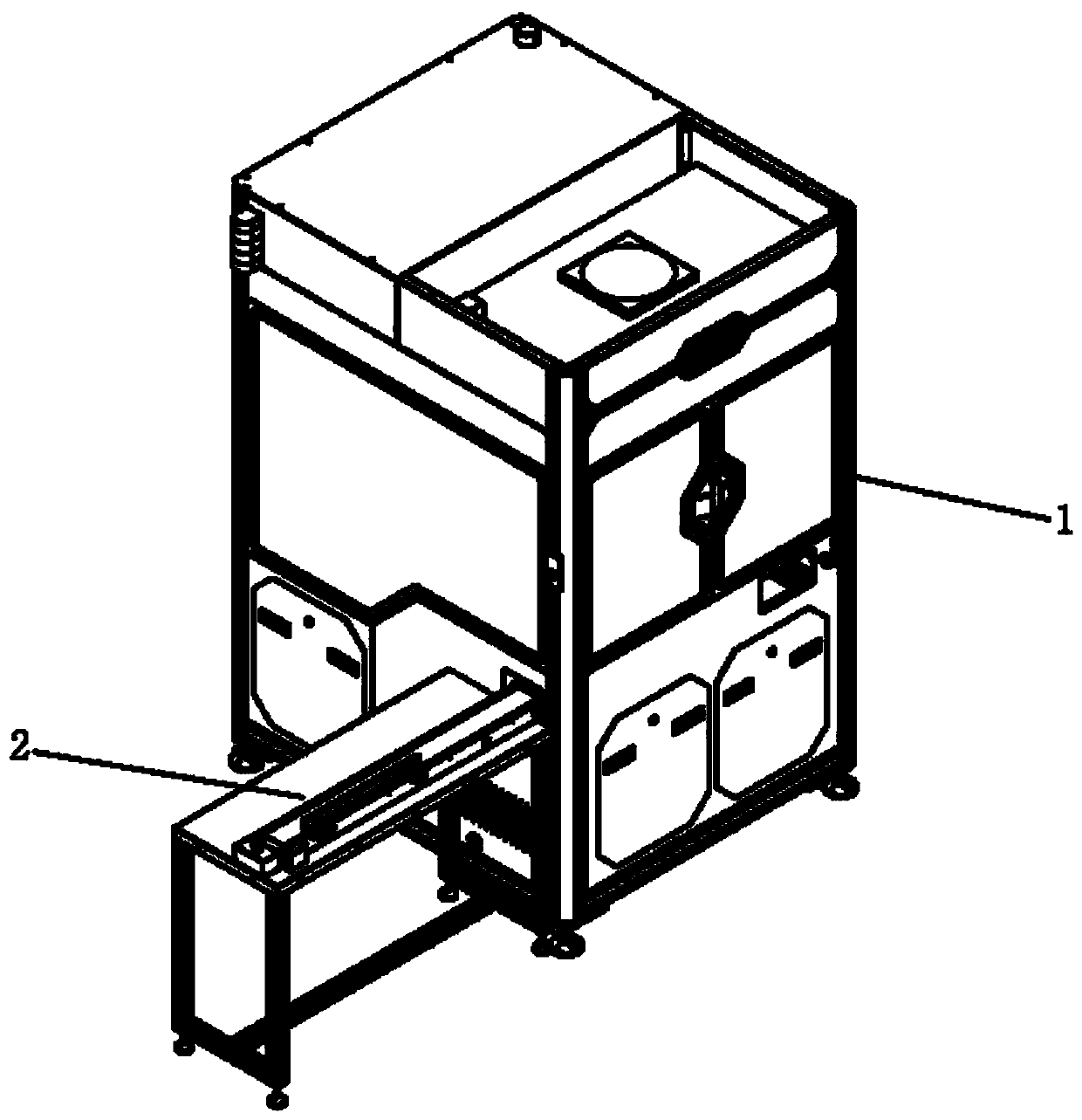

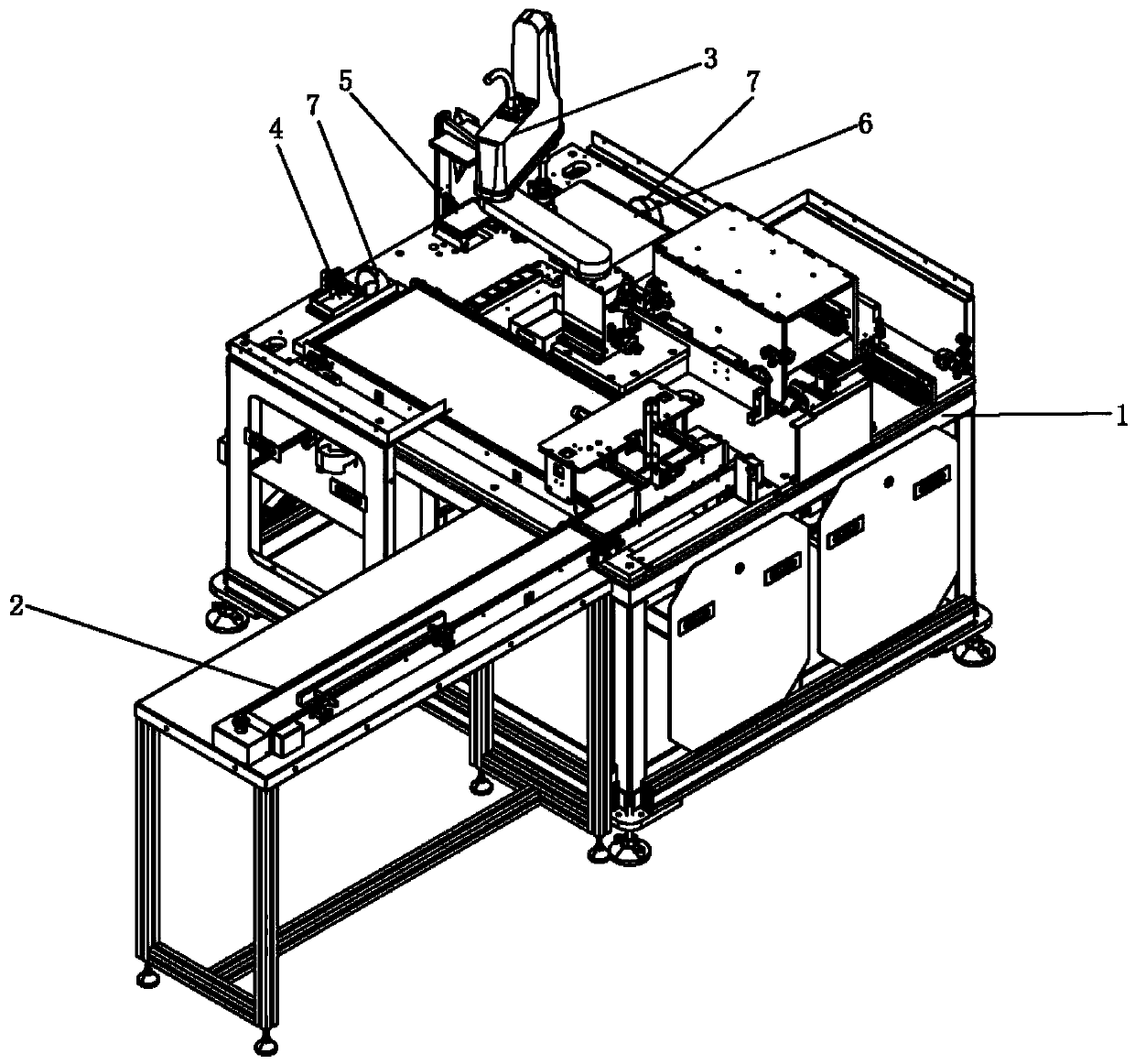

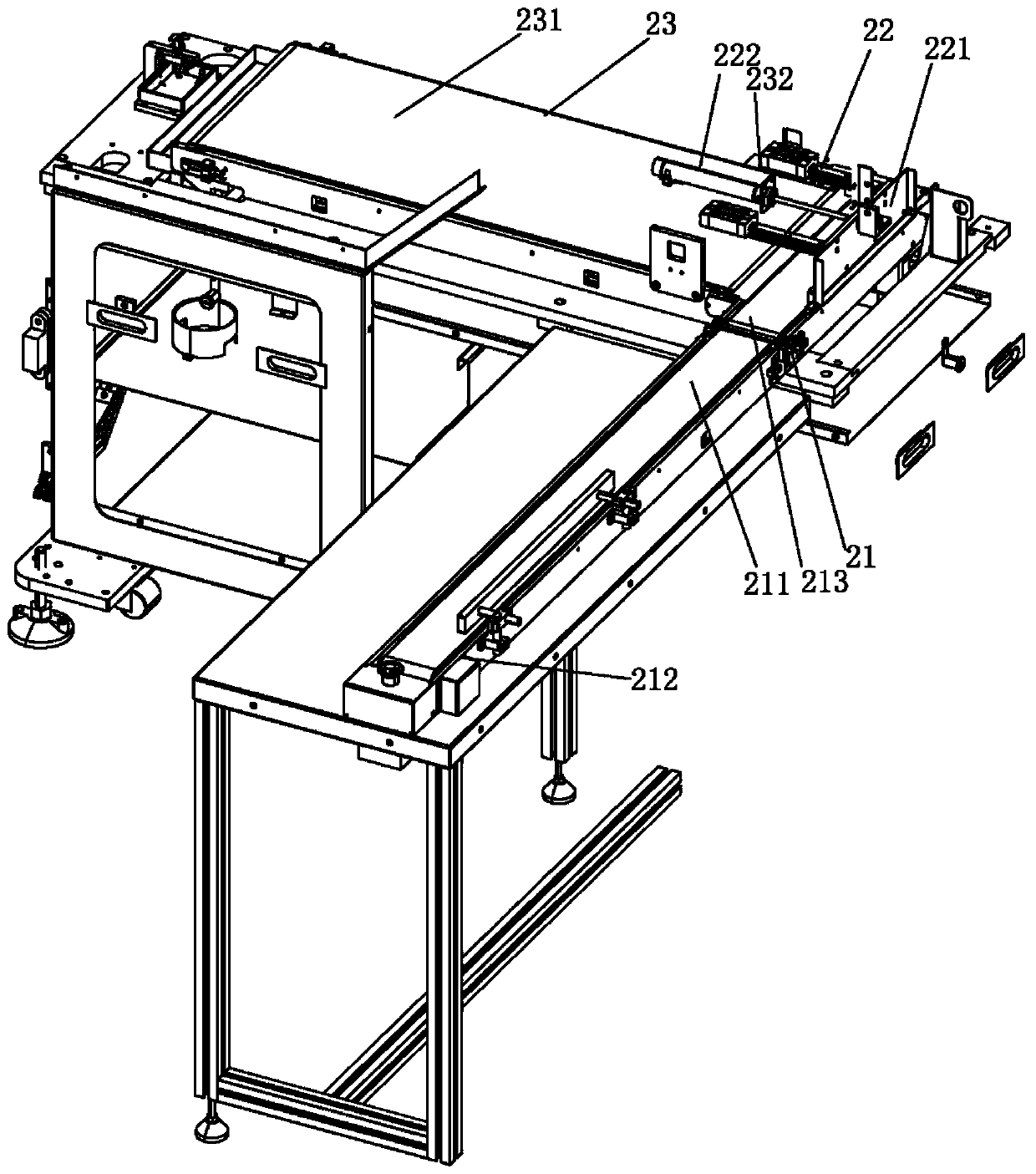

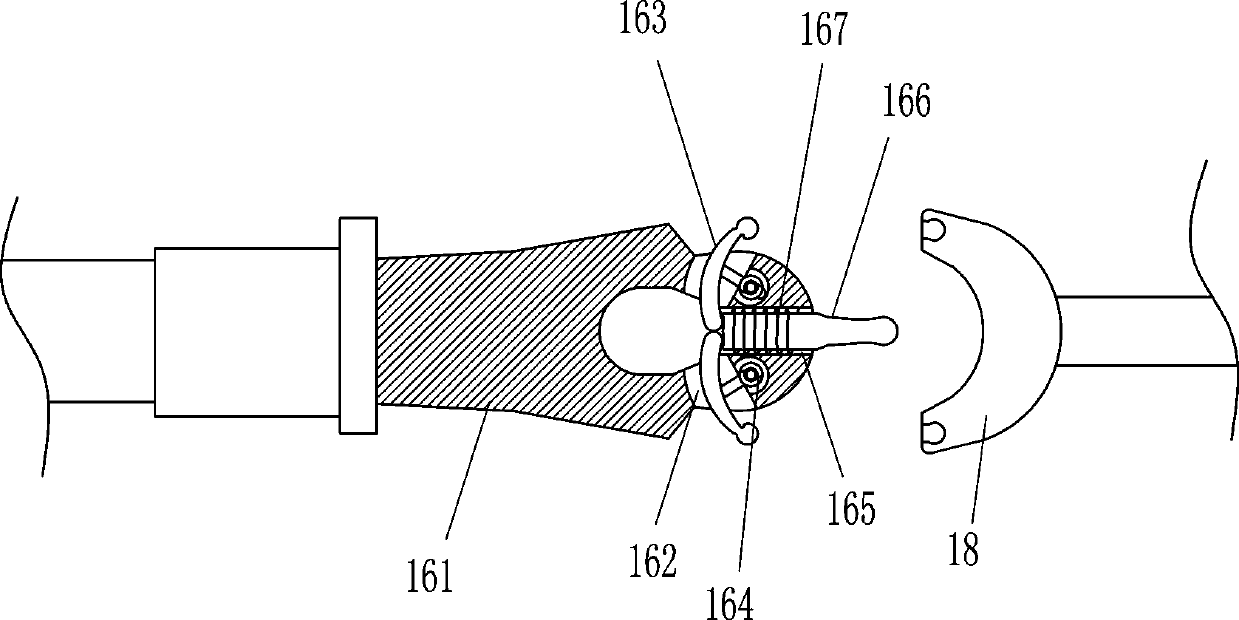

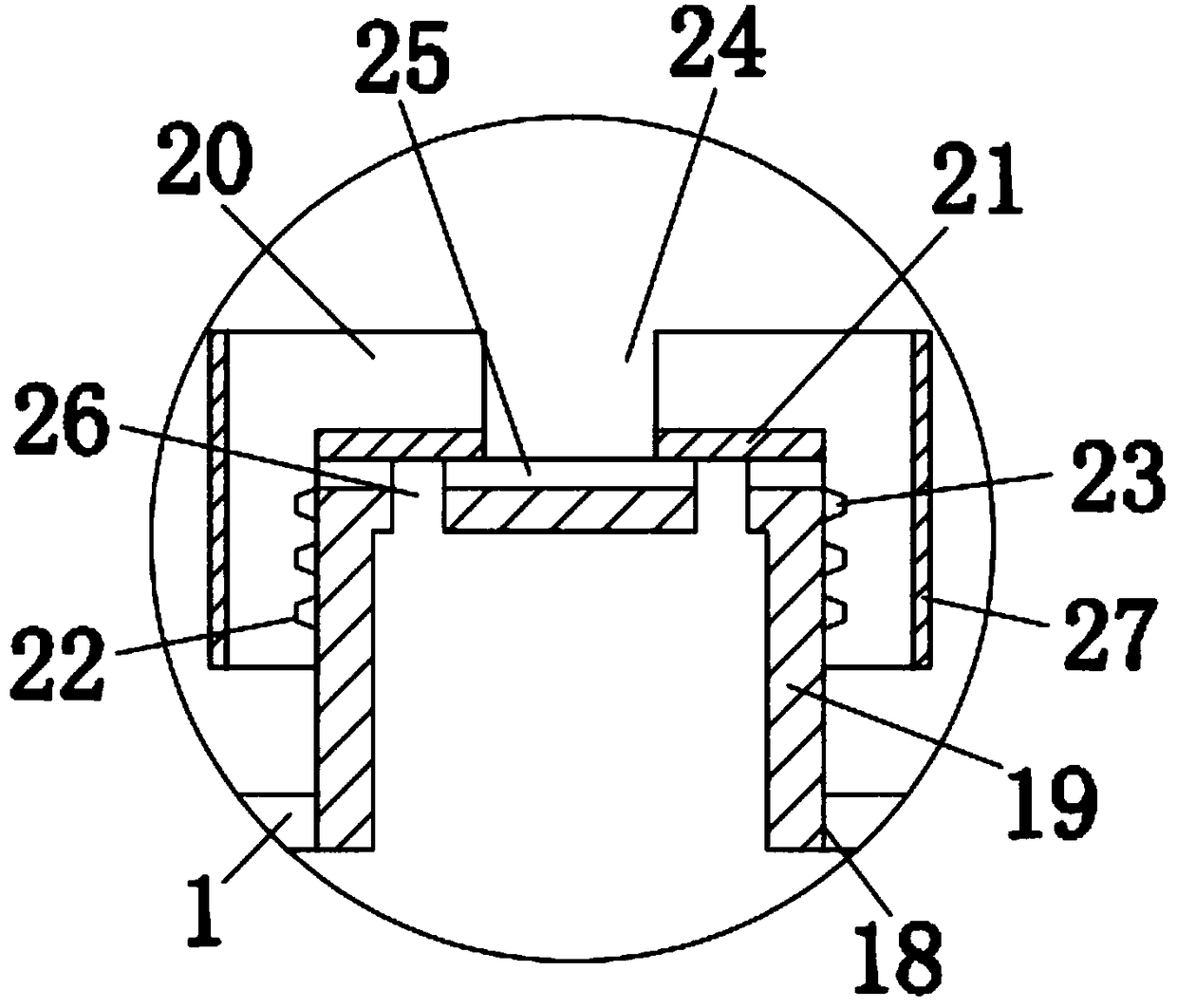

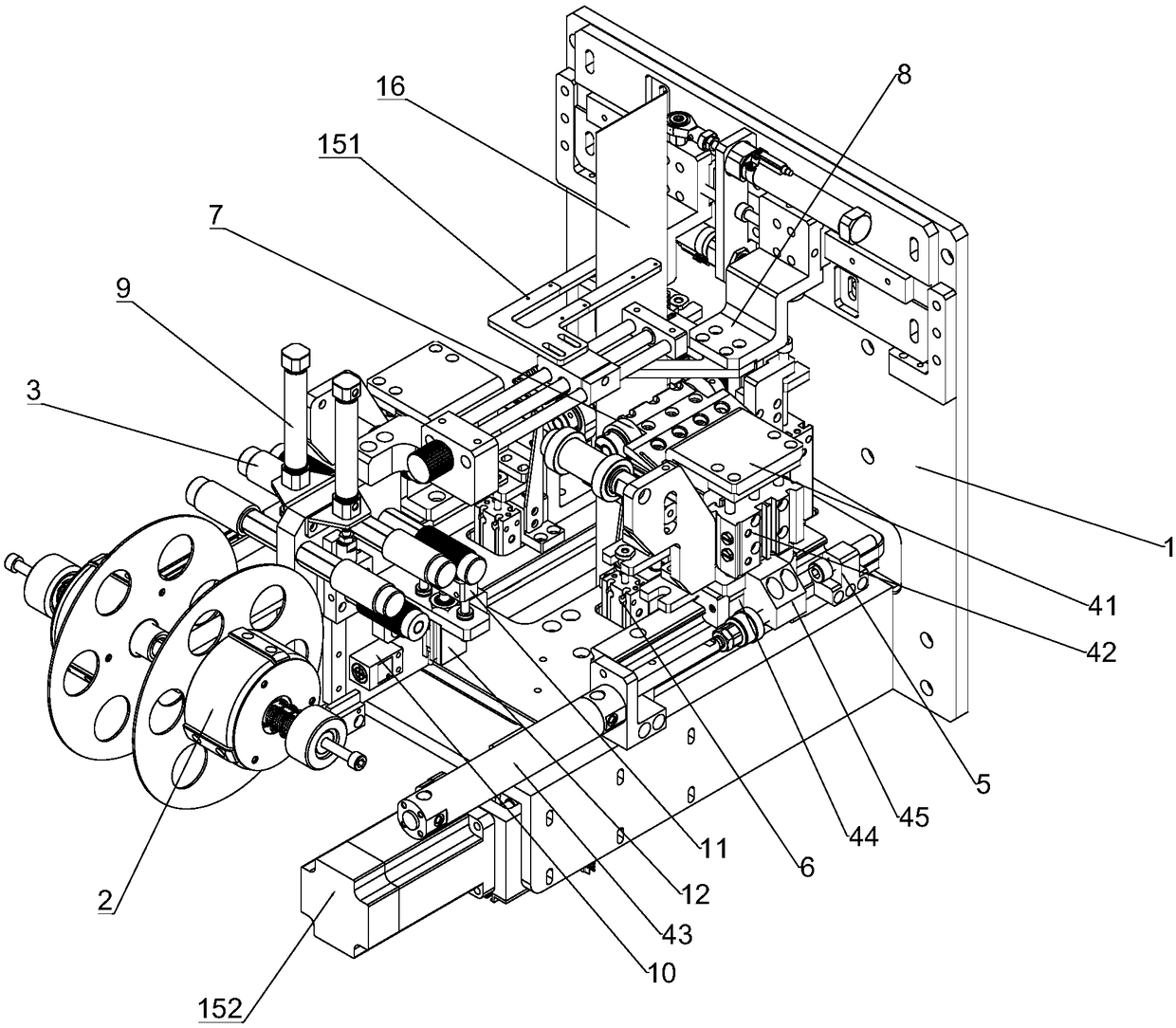

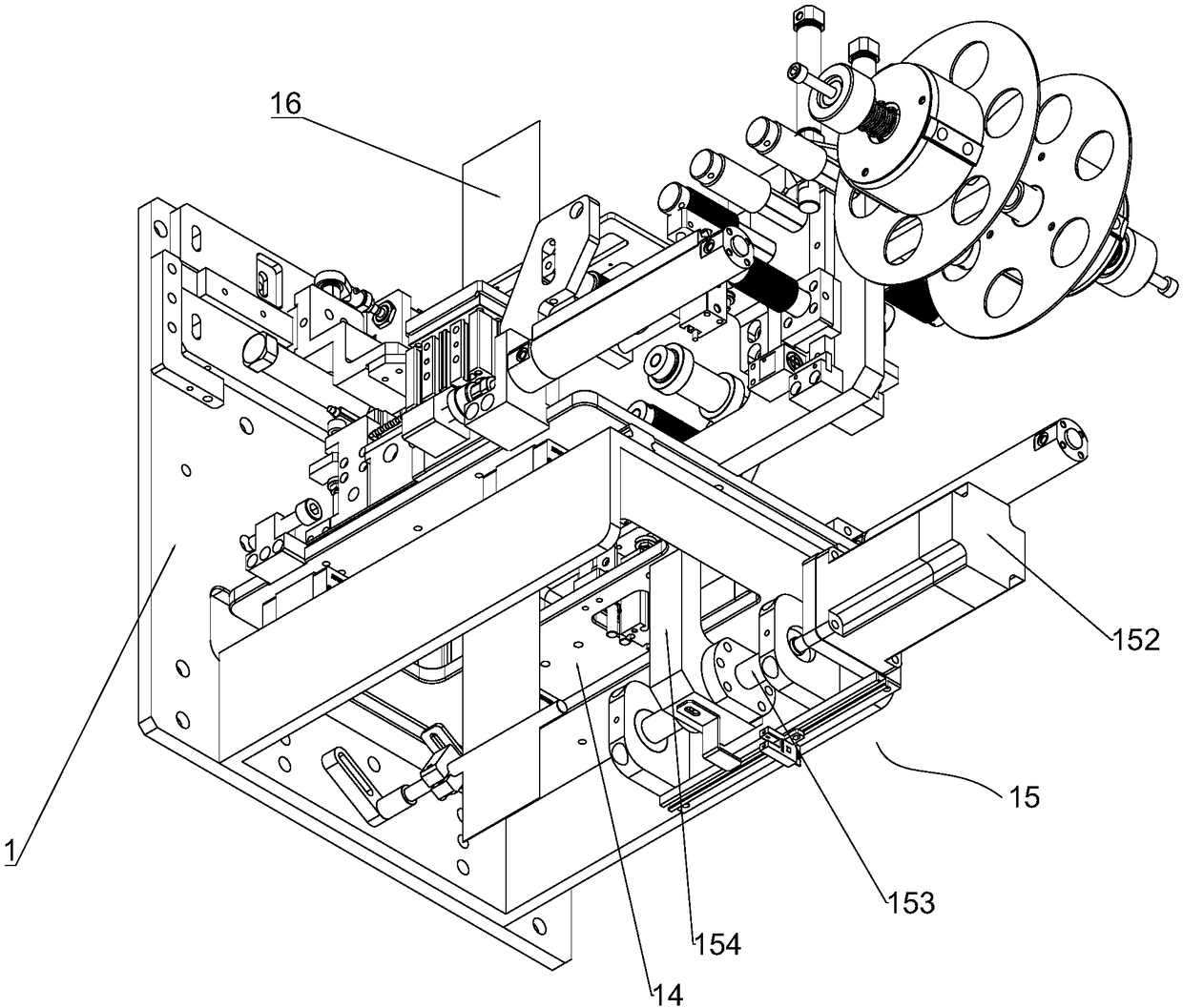

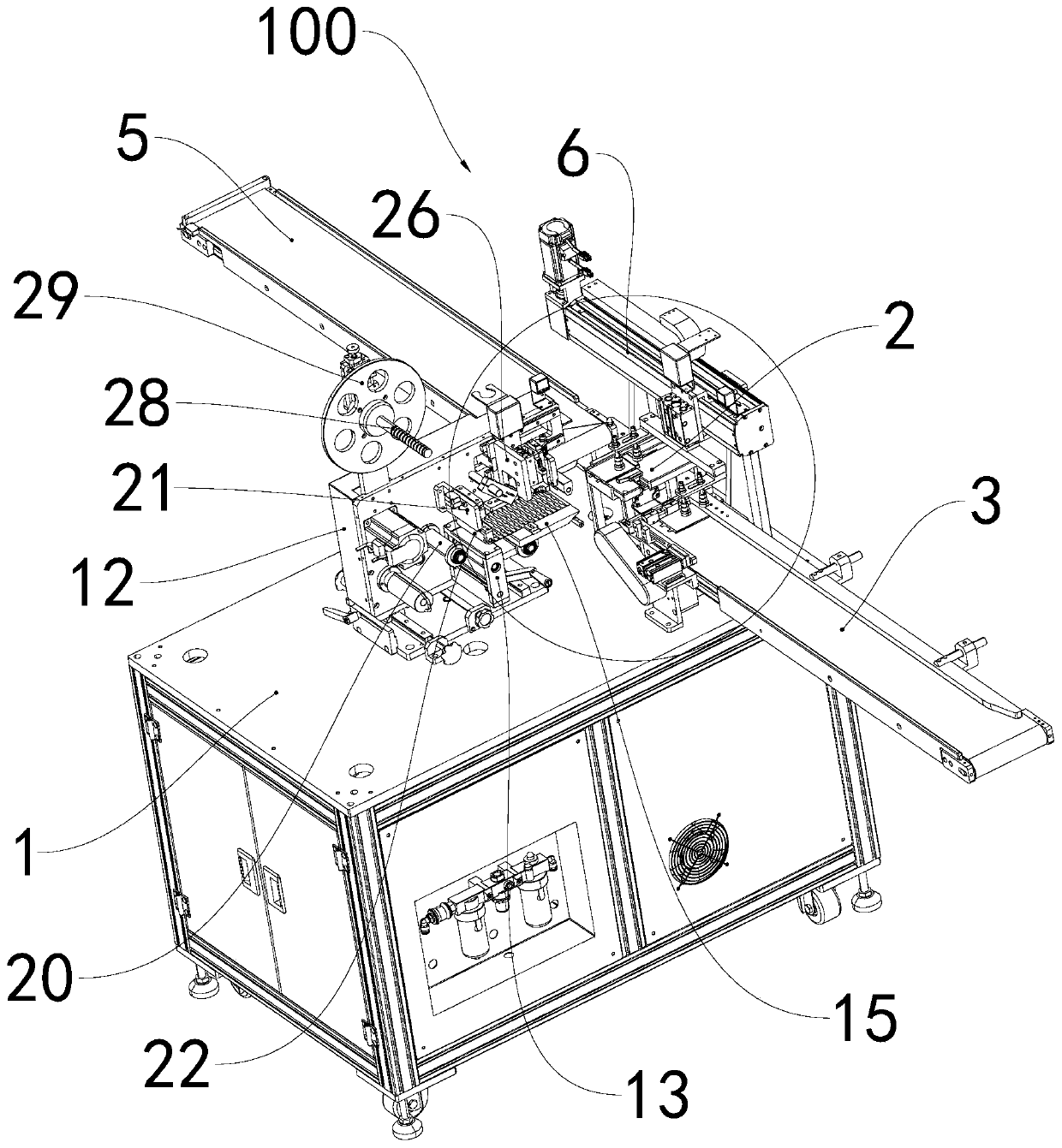

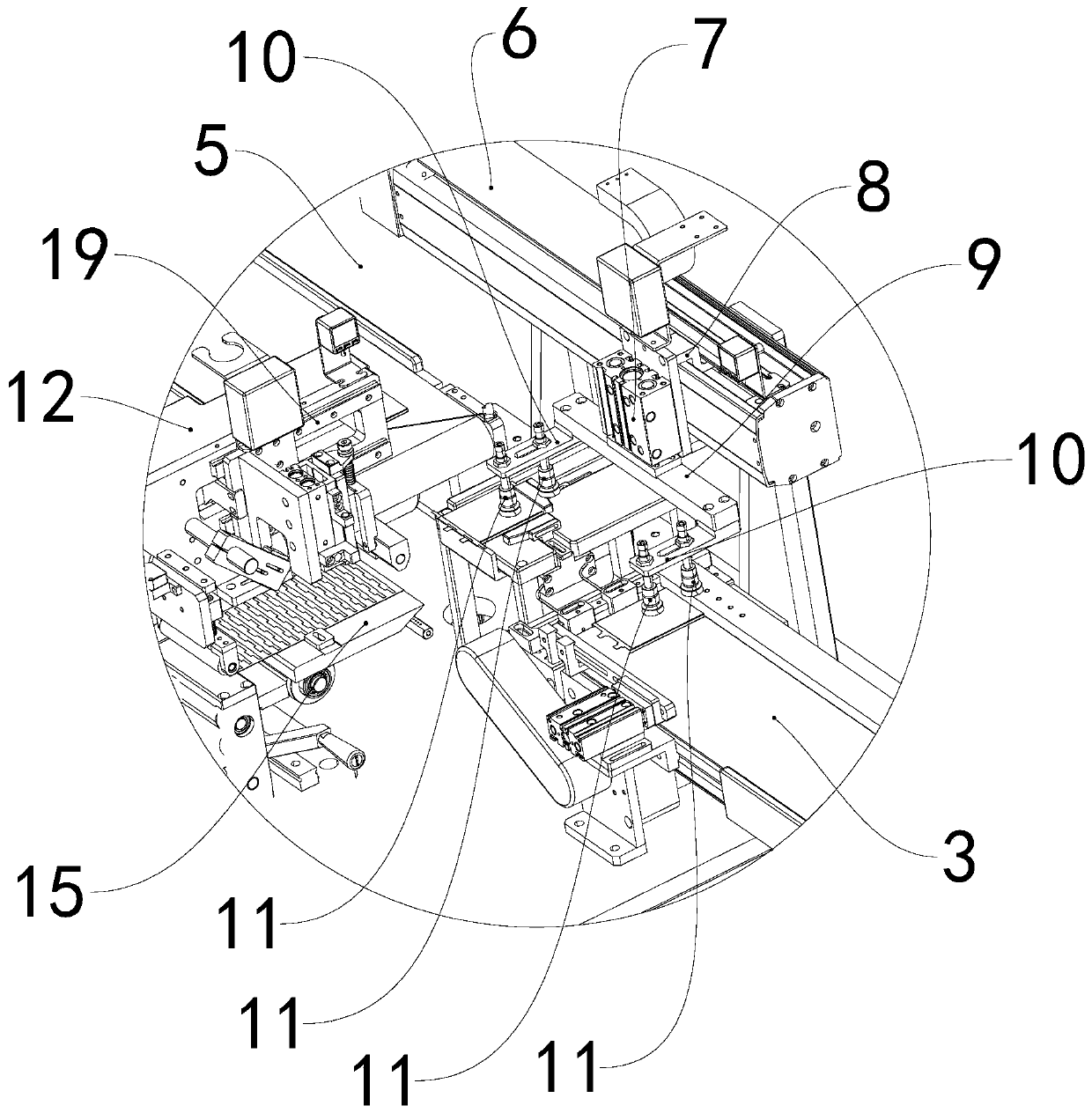

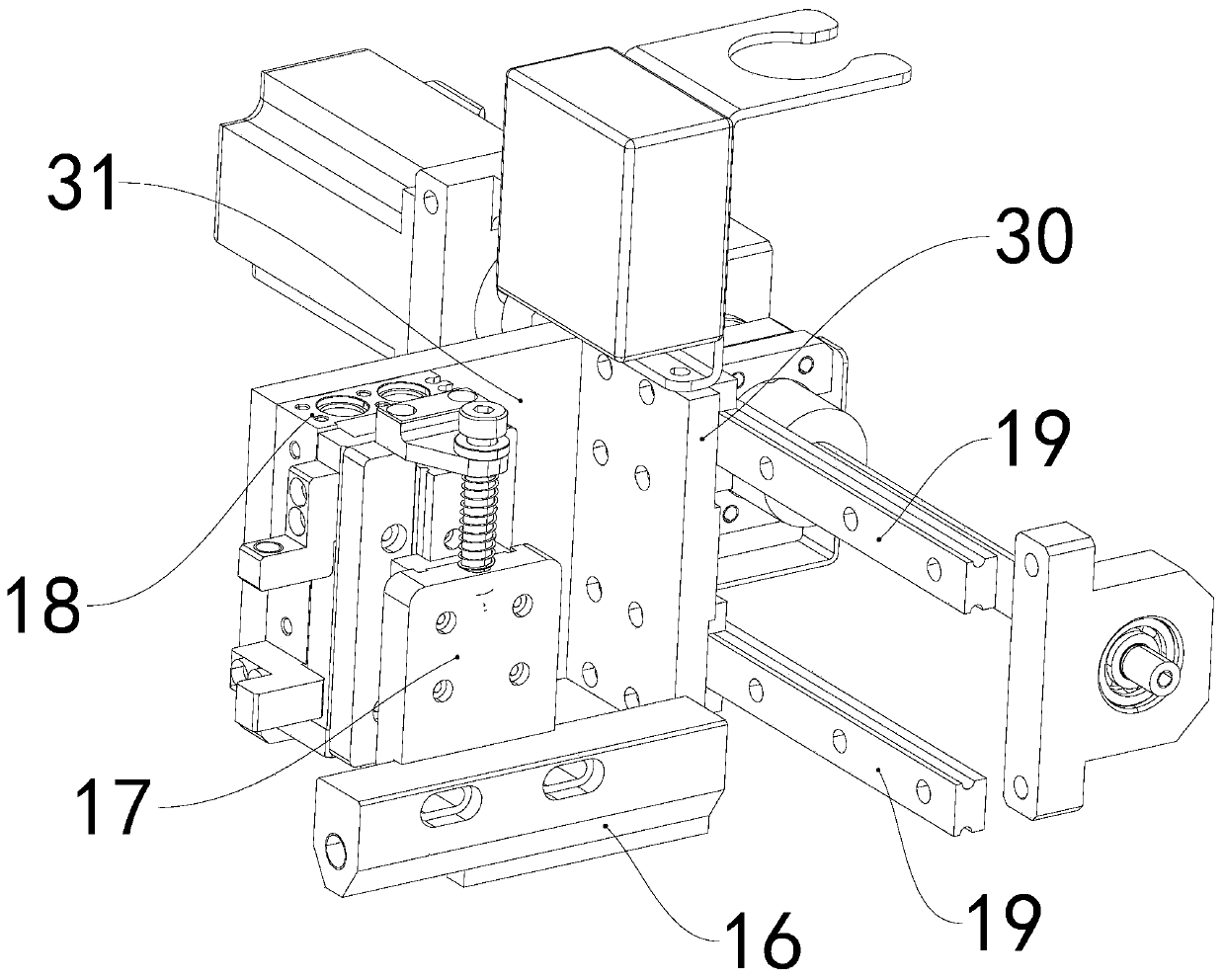

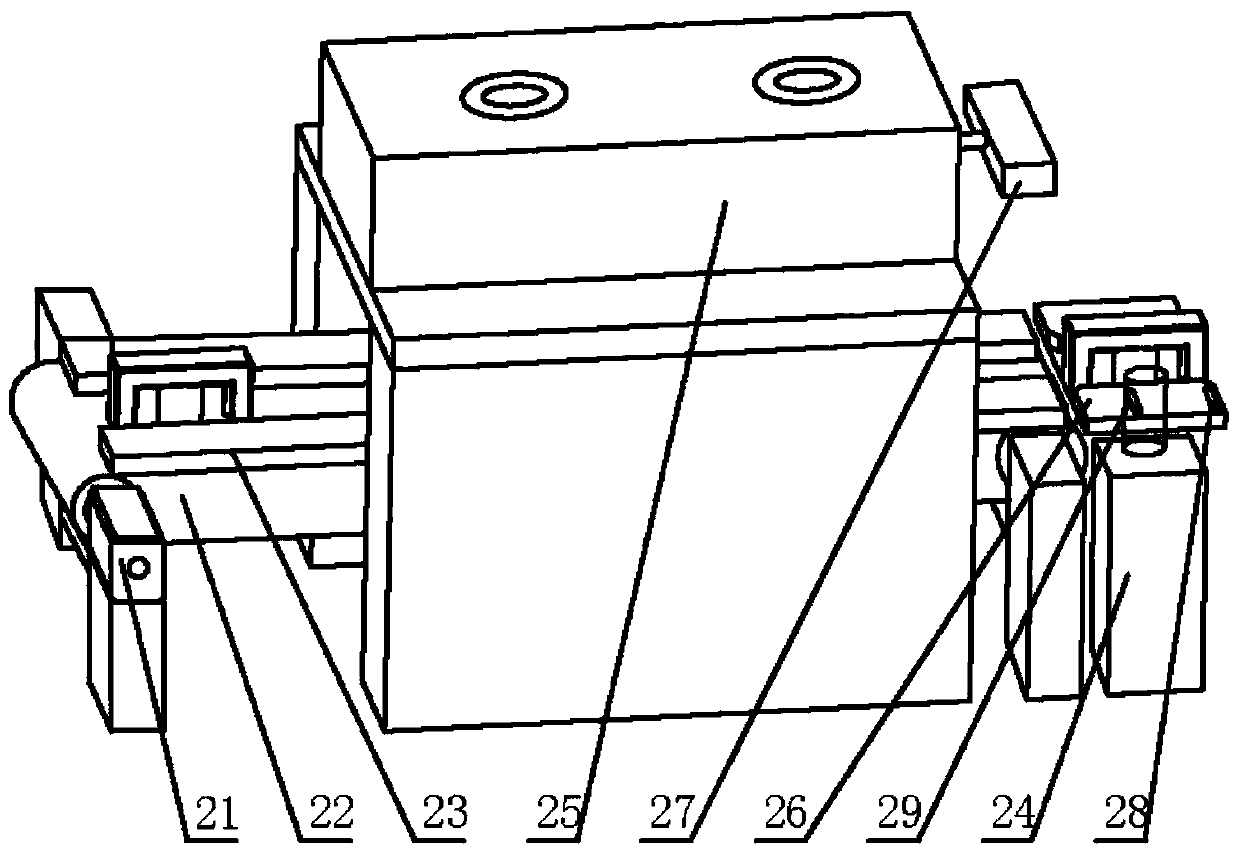

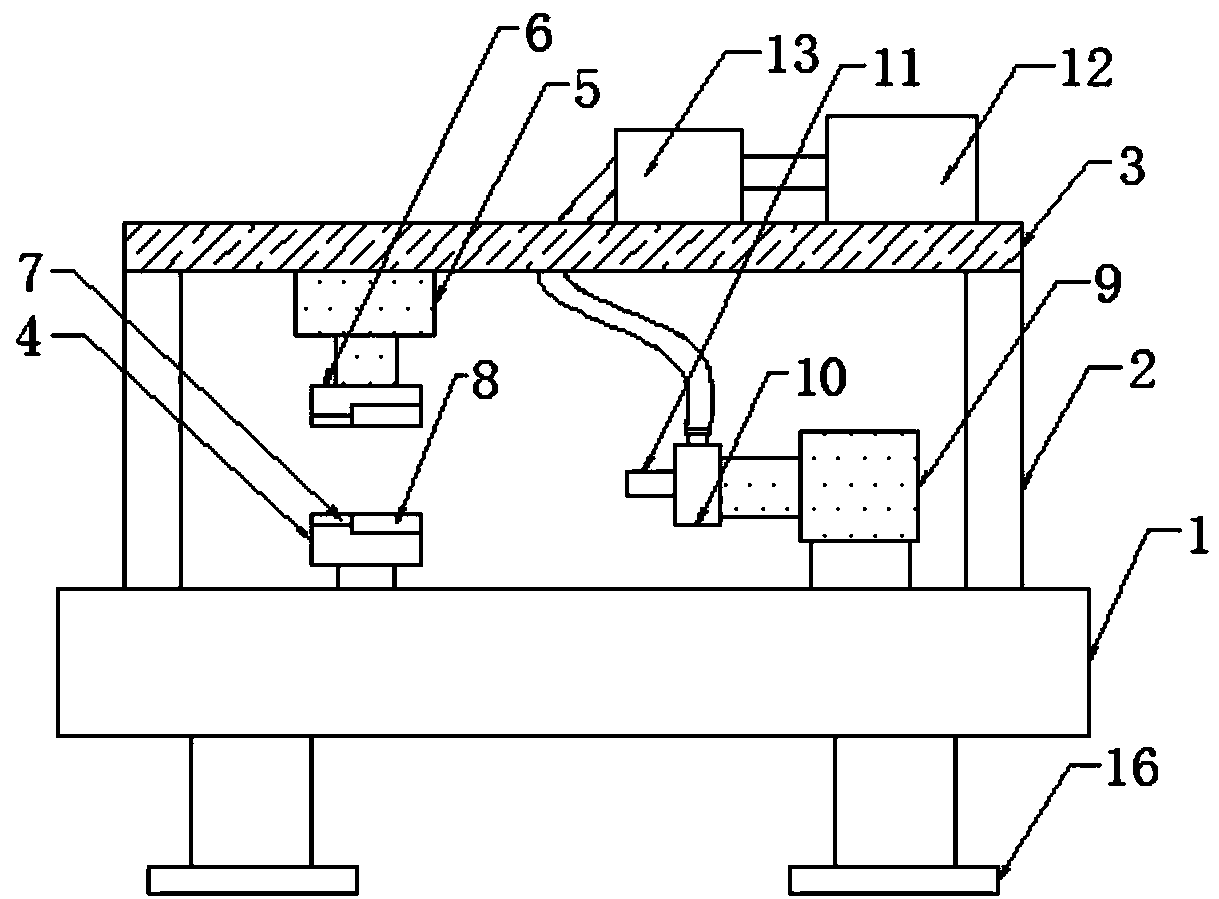

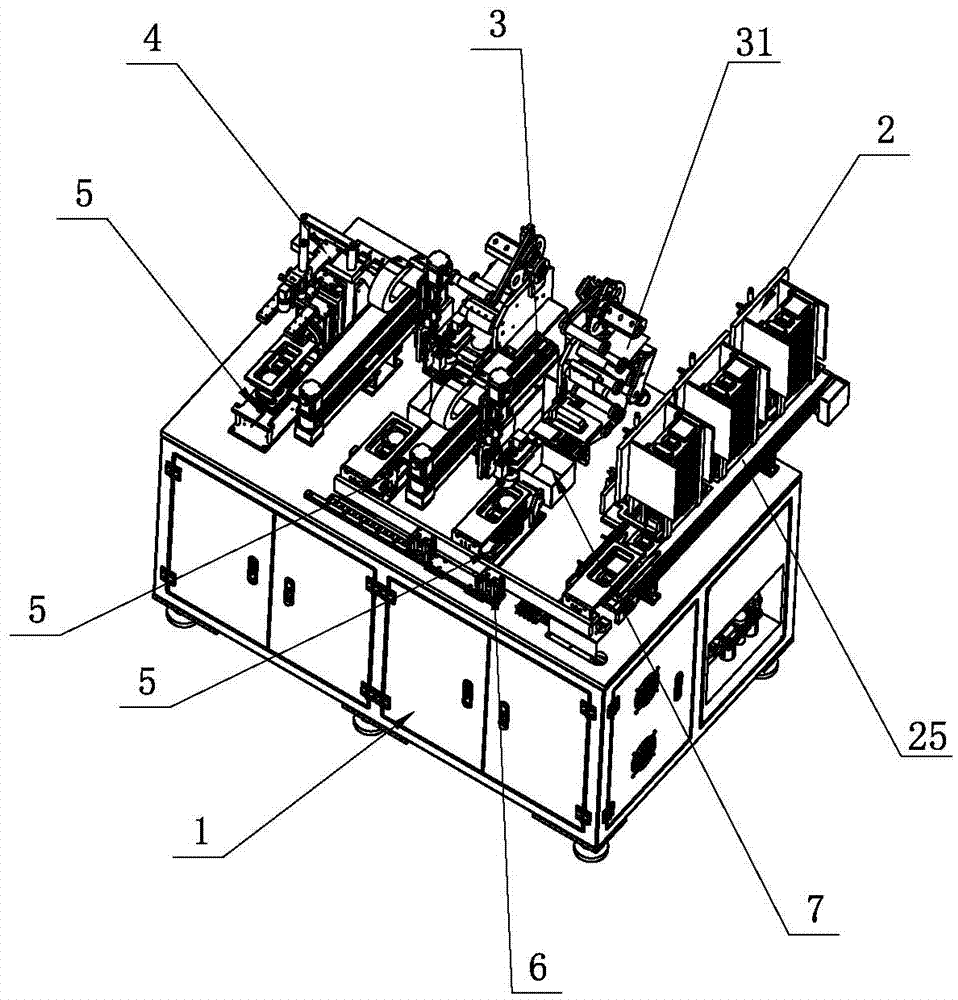

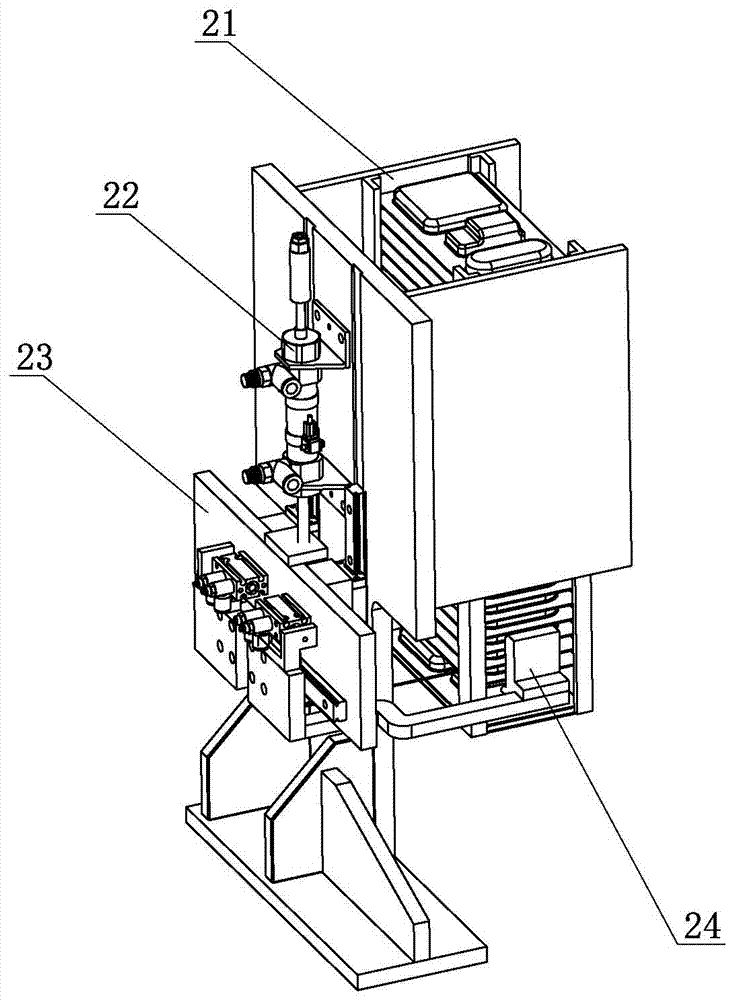

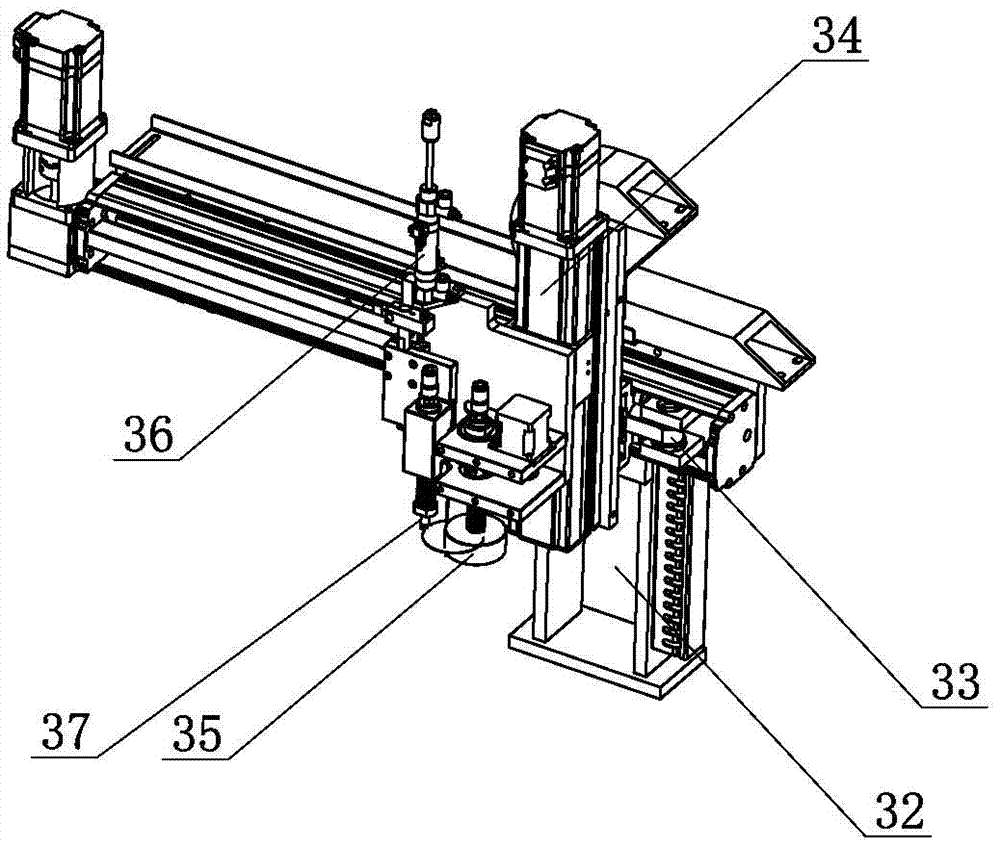

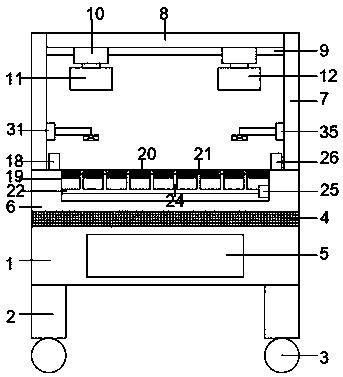

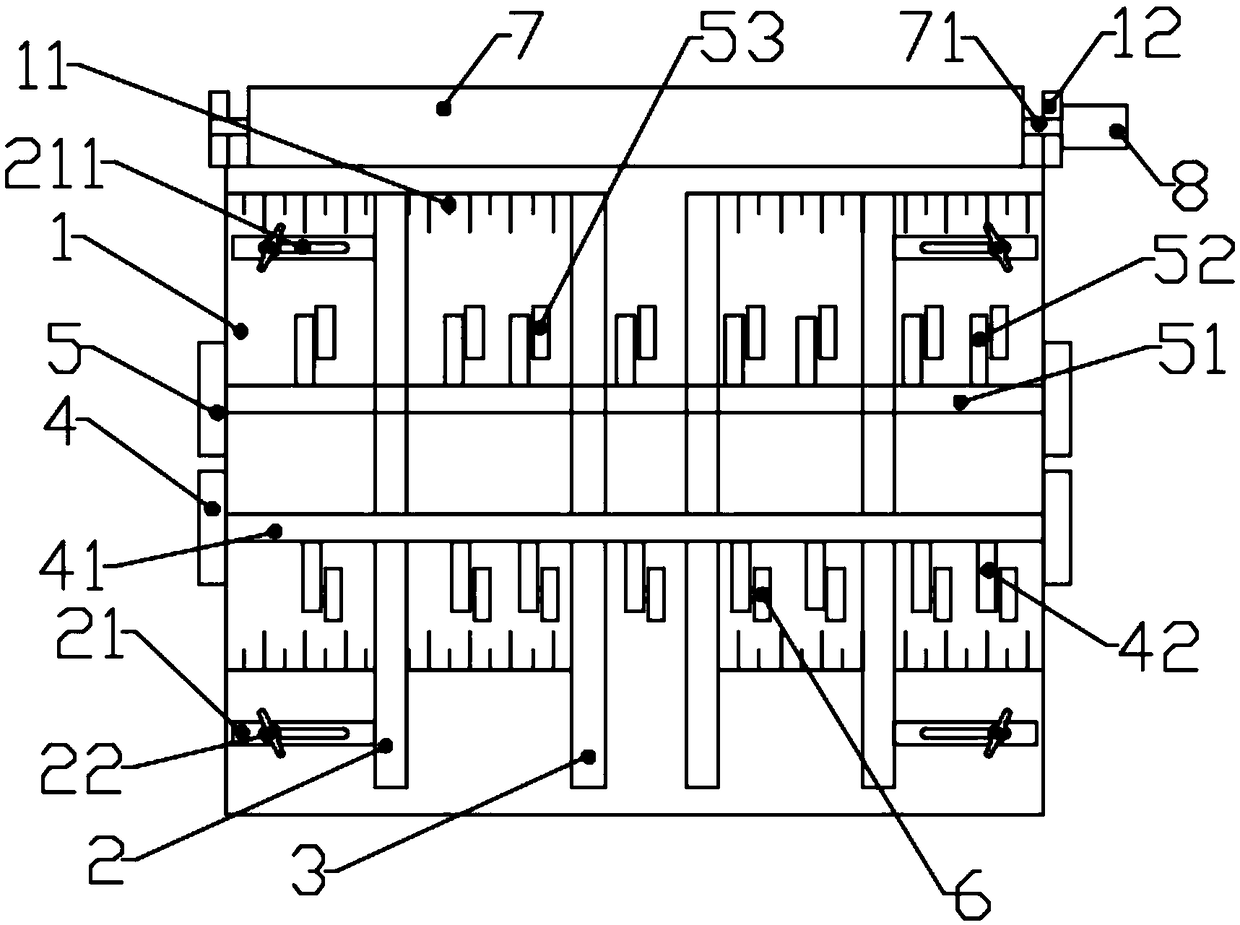

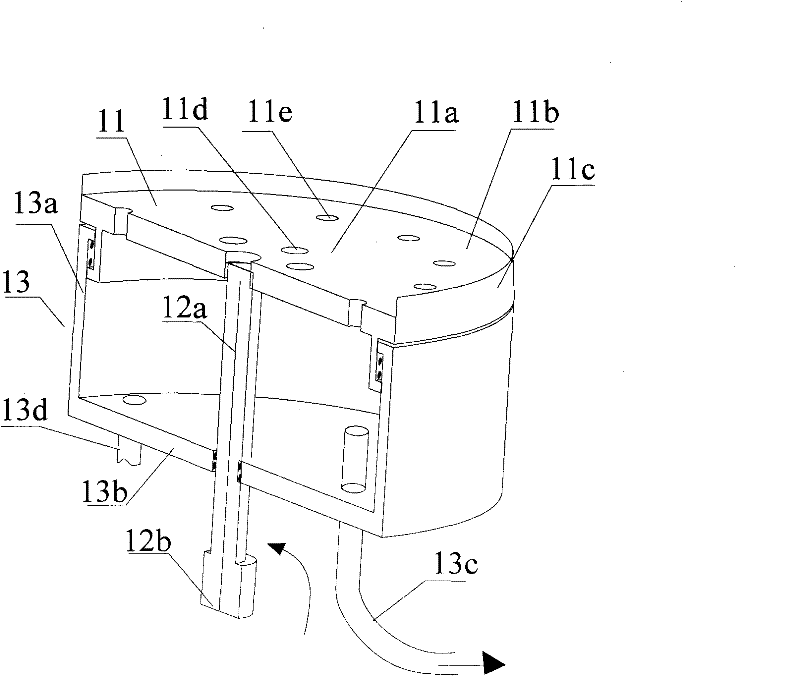

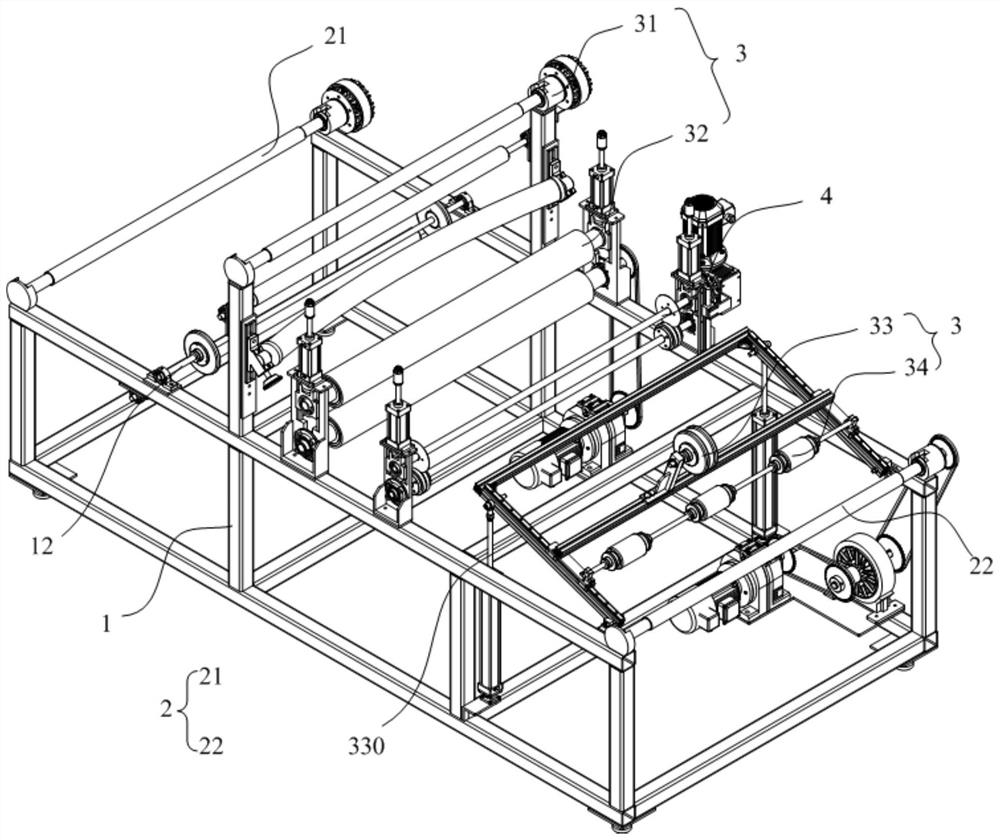

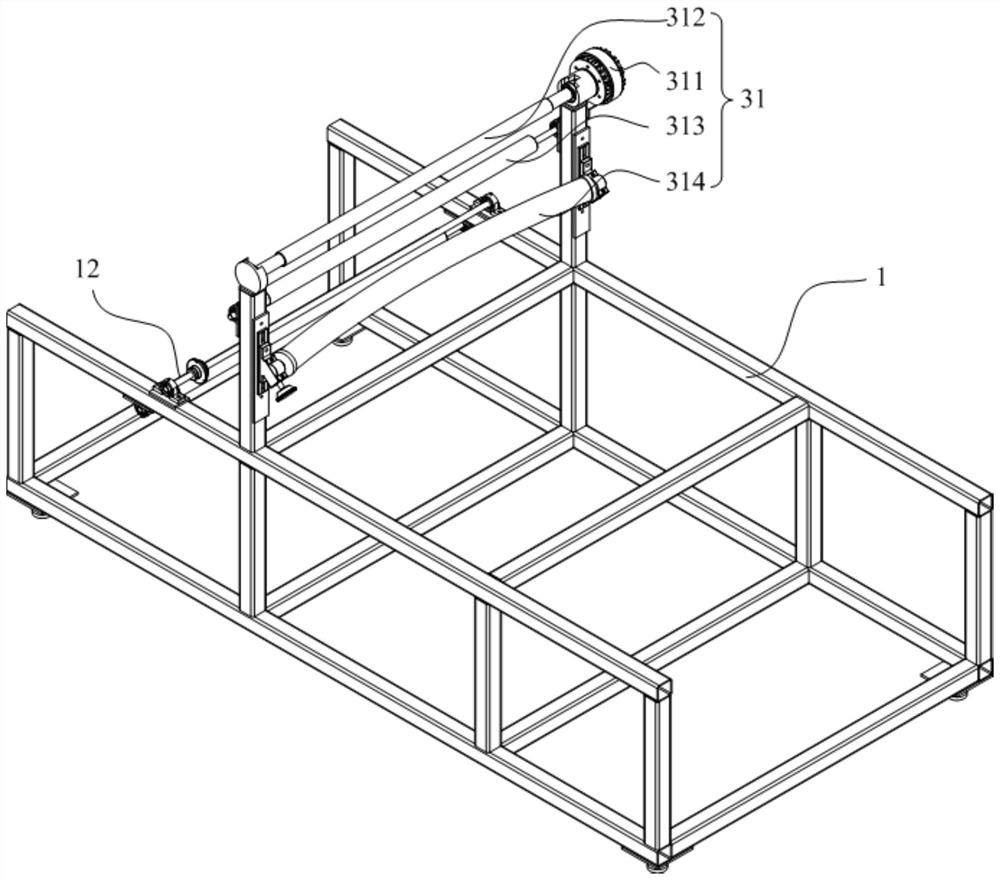

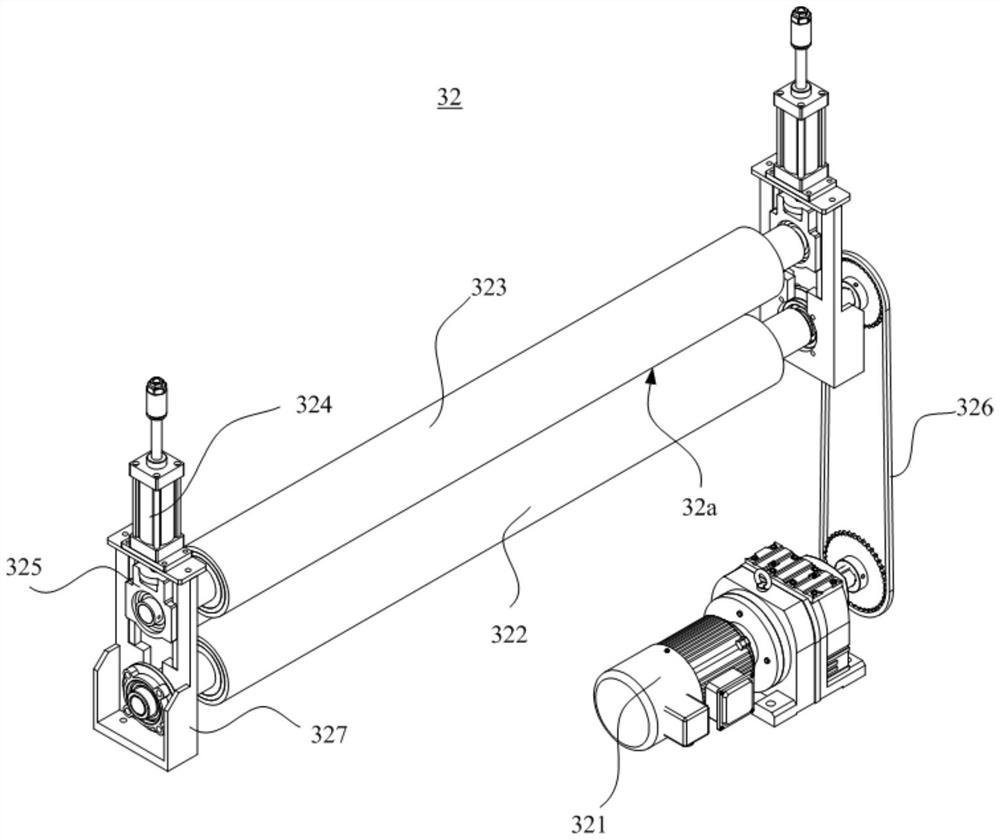

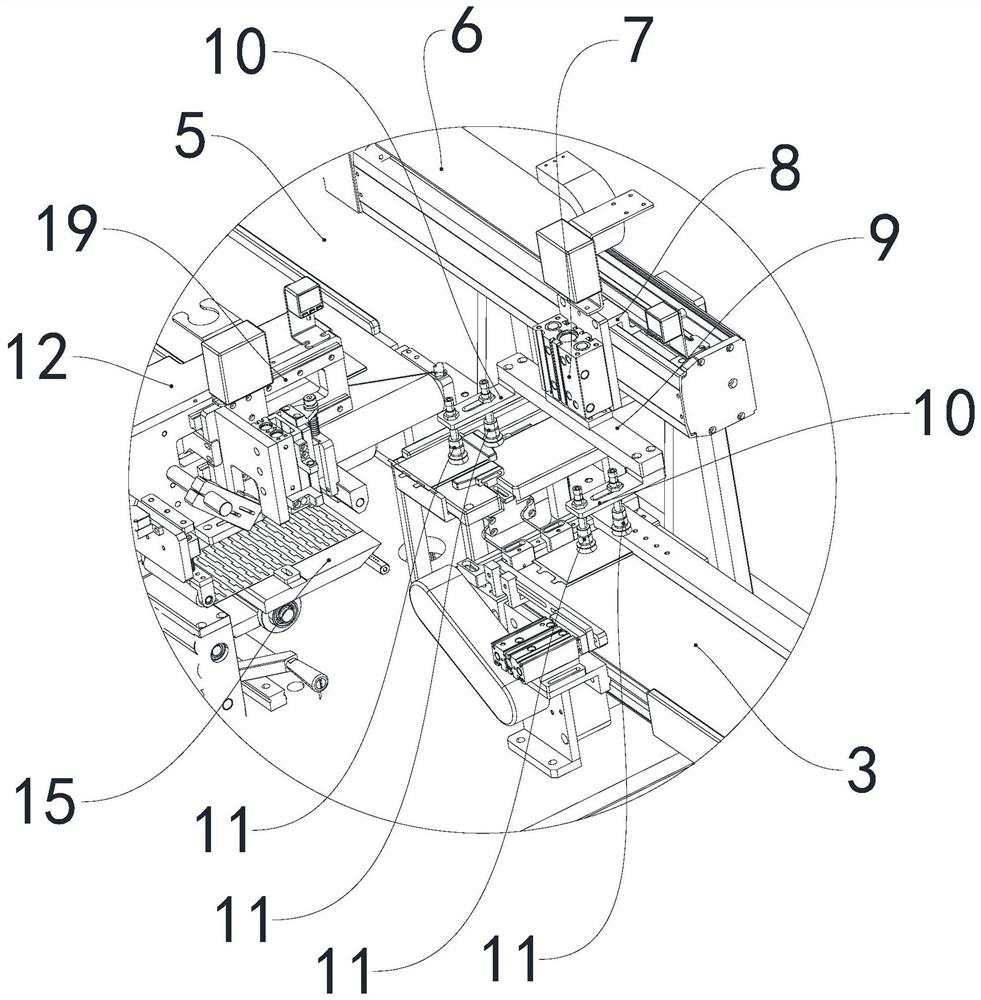

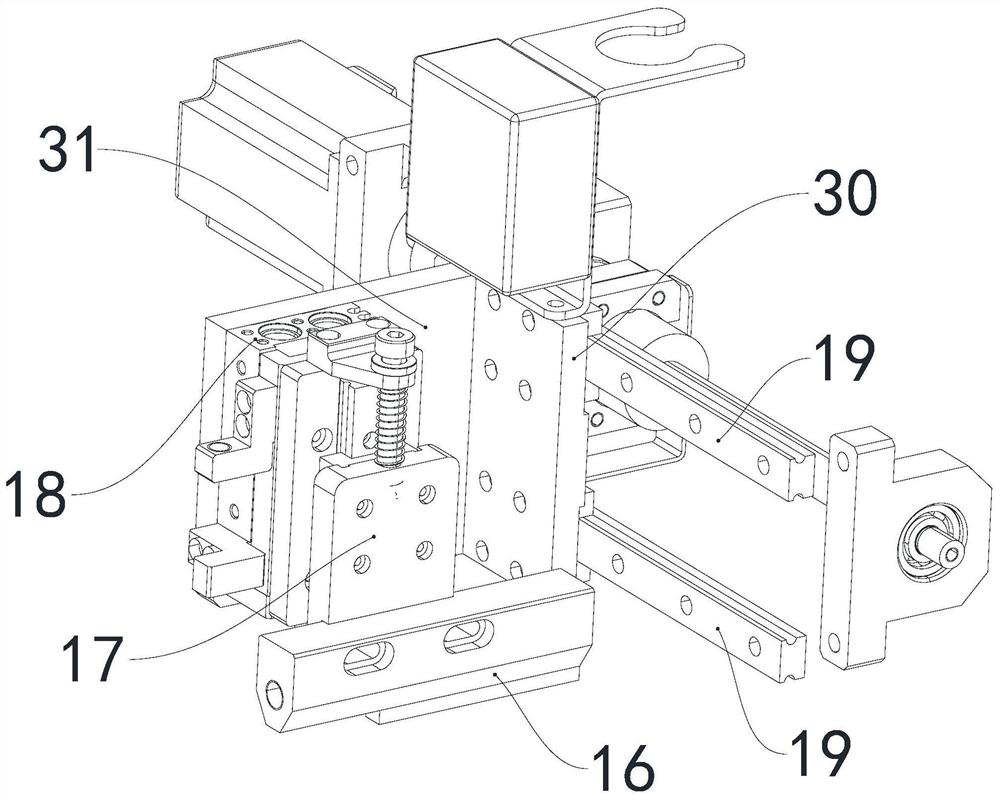

Fuel cell graphite bipolar plate production system

ActiveCN112366331AEfficient and stable productionRealize automatic glue applicationFinal product manufactureCollectors/separatorsFuel cellsGraphite

The invention discloses a fuel cell graphite bipolar plate production system. The system comprises a rack and also comprises automatic feeding, discharging and leveling equipment for a graphite polarplate, polar plate sealing ring dispensing and forming equipment, graphite polar plate sealing ring curing and forming equipment, graphite polar plate adhesive dispensing and forming equipment, bipolar plate bonding and curing equipment and a polar plate conveying mechanism which are arranged on the rack, wherein the automatic feeding, discharging and leveling equipment for the graphite polar plate is used for heating and leveling a cathode plate; the polar plate sealing ring dispensing forming equipment is used for carrying out sealing ring dispensing on an anode plate and the heated and leveled cathode plate; the graphite polar plate sealing ring curing and forming equipment is used for respectively drying and curing the anode plate and the cathode plate subjected to sealing ring dispensing; the graphite polar plate sealing ring curing and forming equipment is used for carrying out adhesive dispensing on the anode plate and the cathode plate after a sealing ring is cured and formed;and the bipolar plate bonding and curing equipment is used for bonding and curing the anode plate and the cathode plate subjected to adhesive dispensing to form a bipolar plate.

Owner:JIANGSU HYDROGEN GUIDE INTELLIGENT EQUIP CO LTD

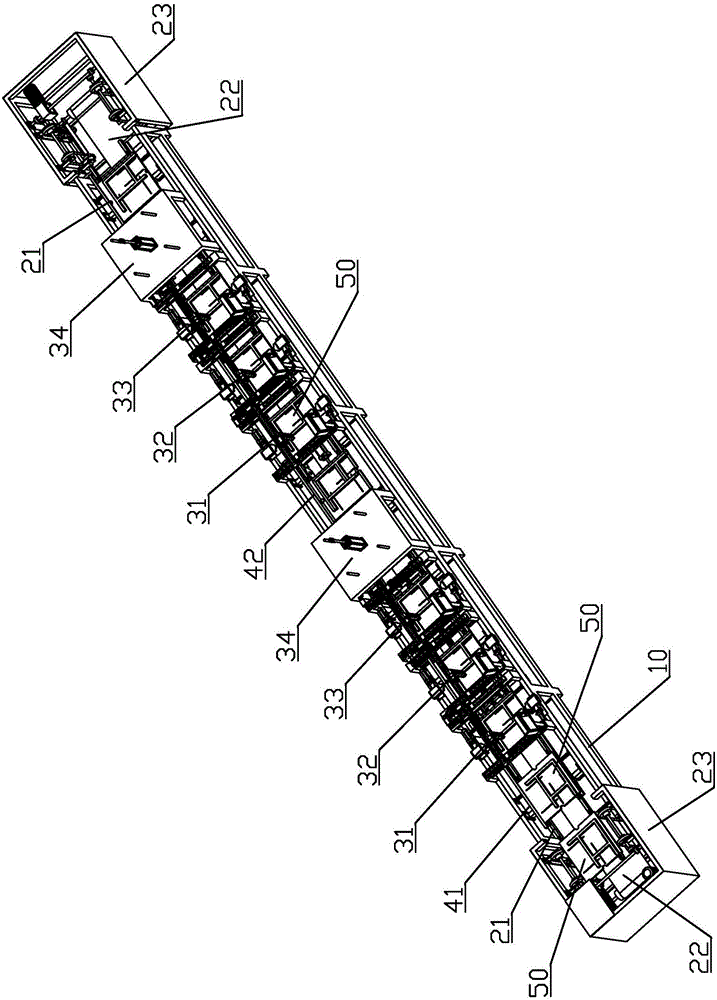

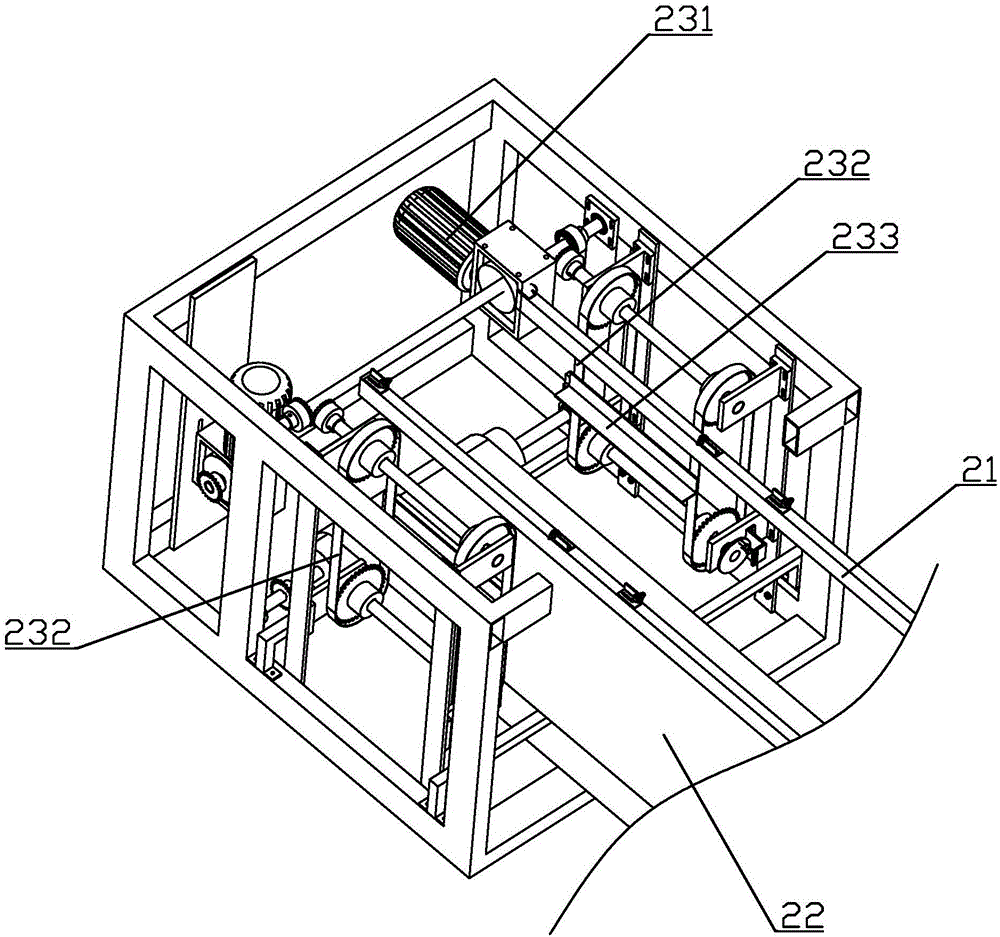

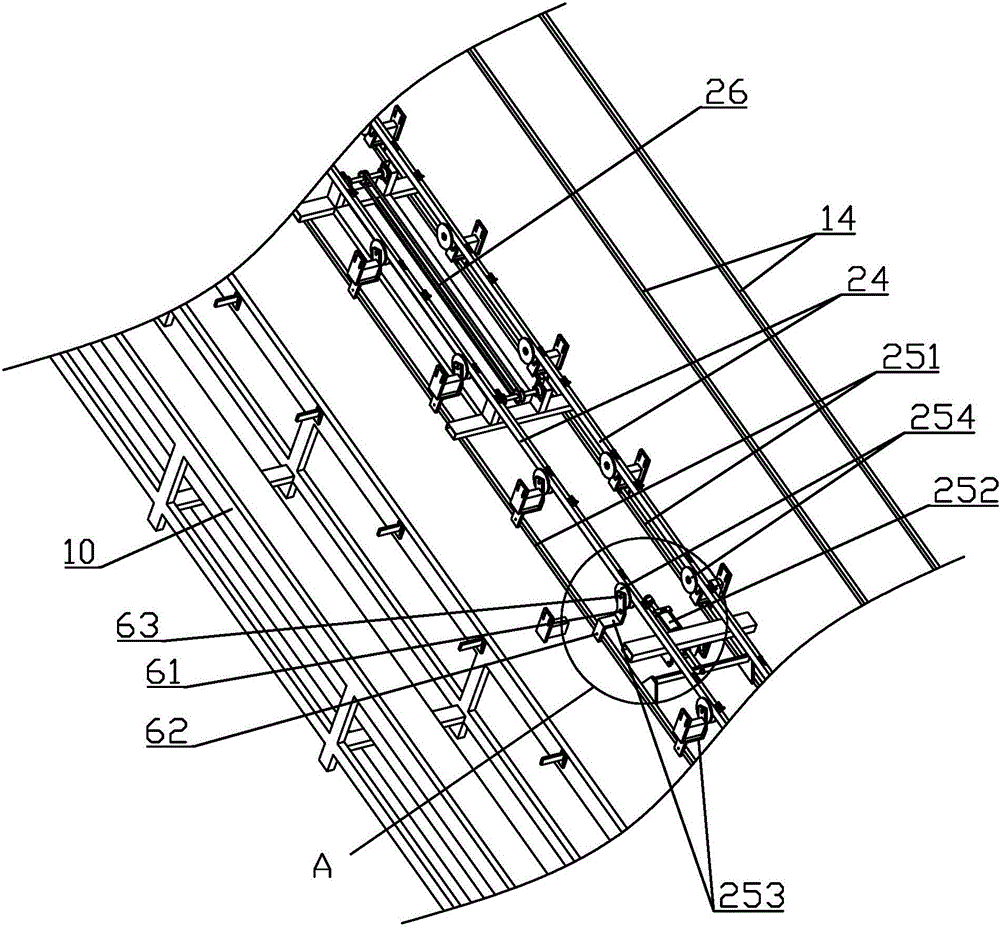

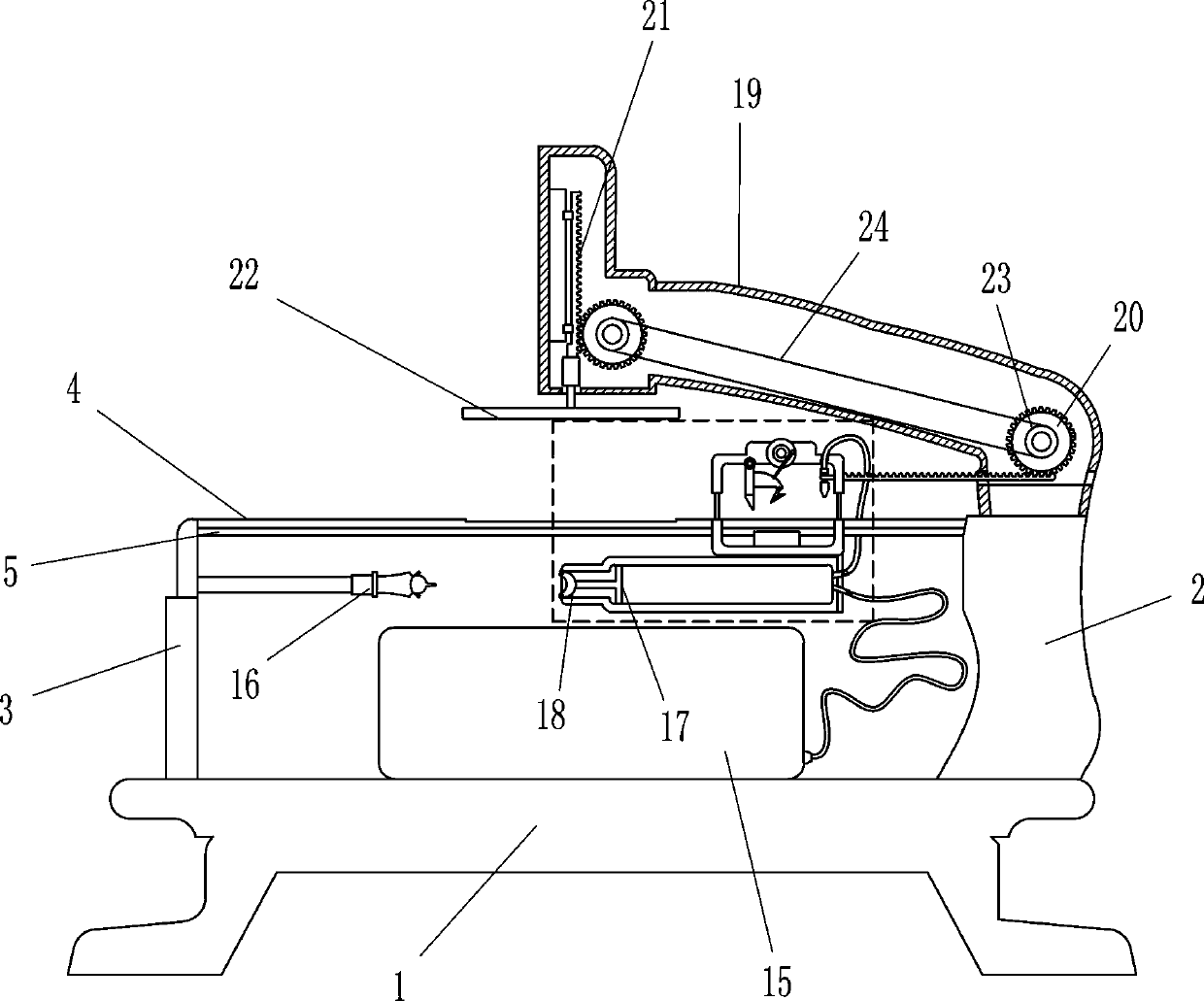

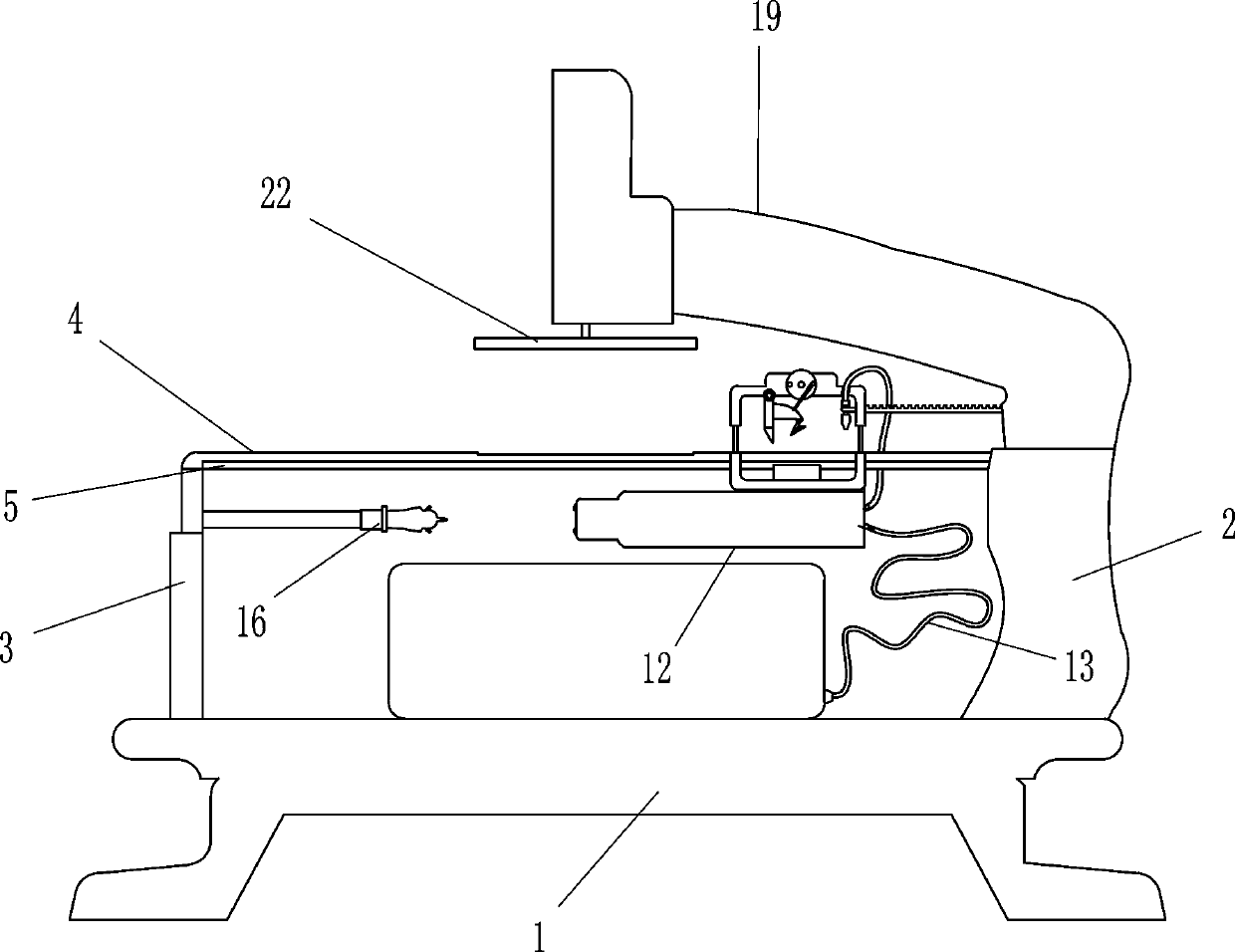

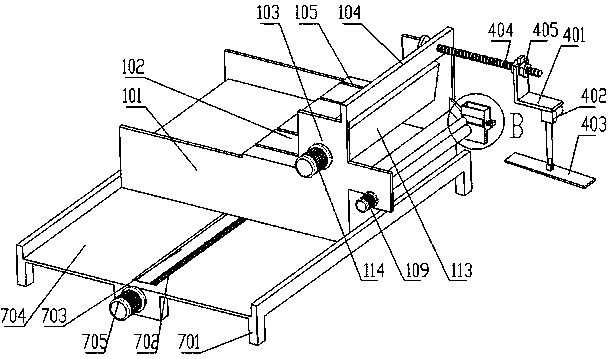

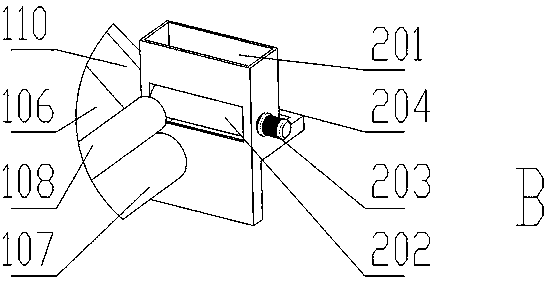

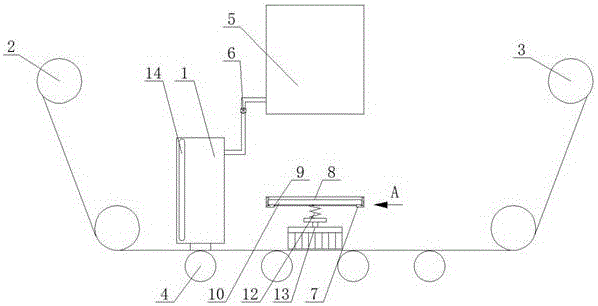

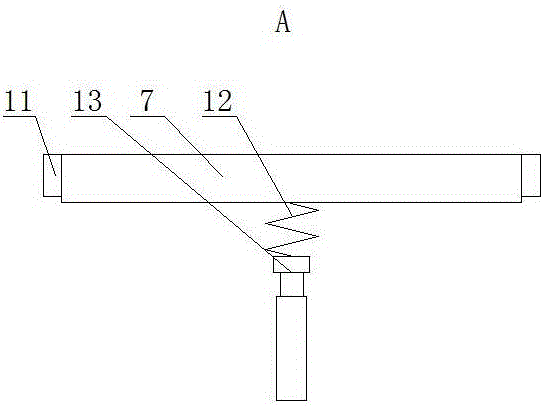

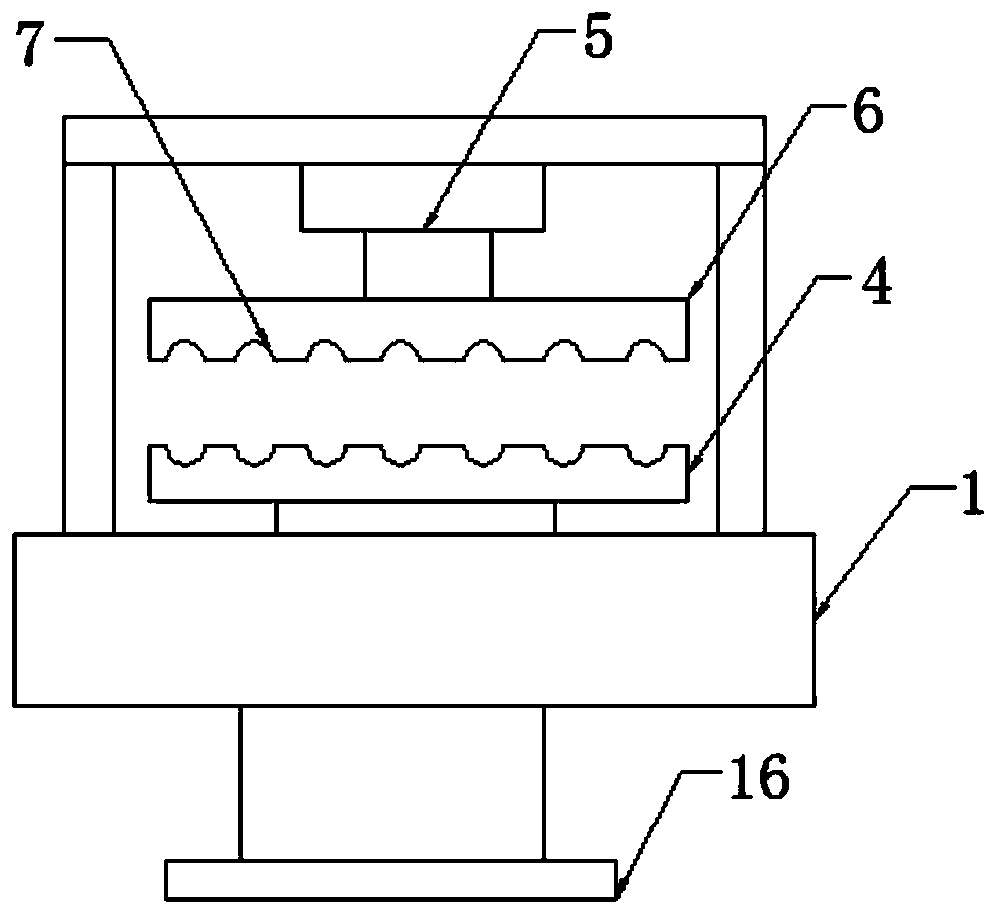

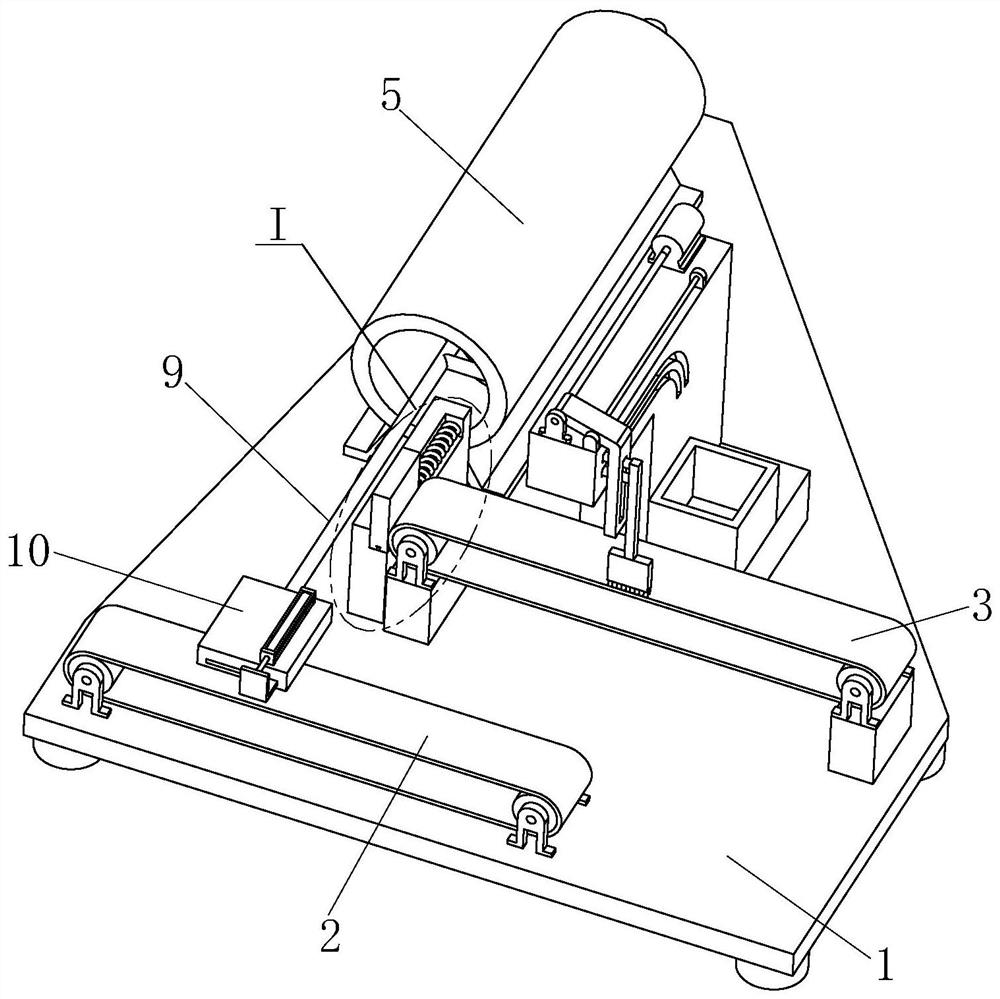

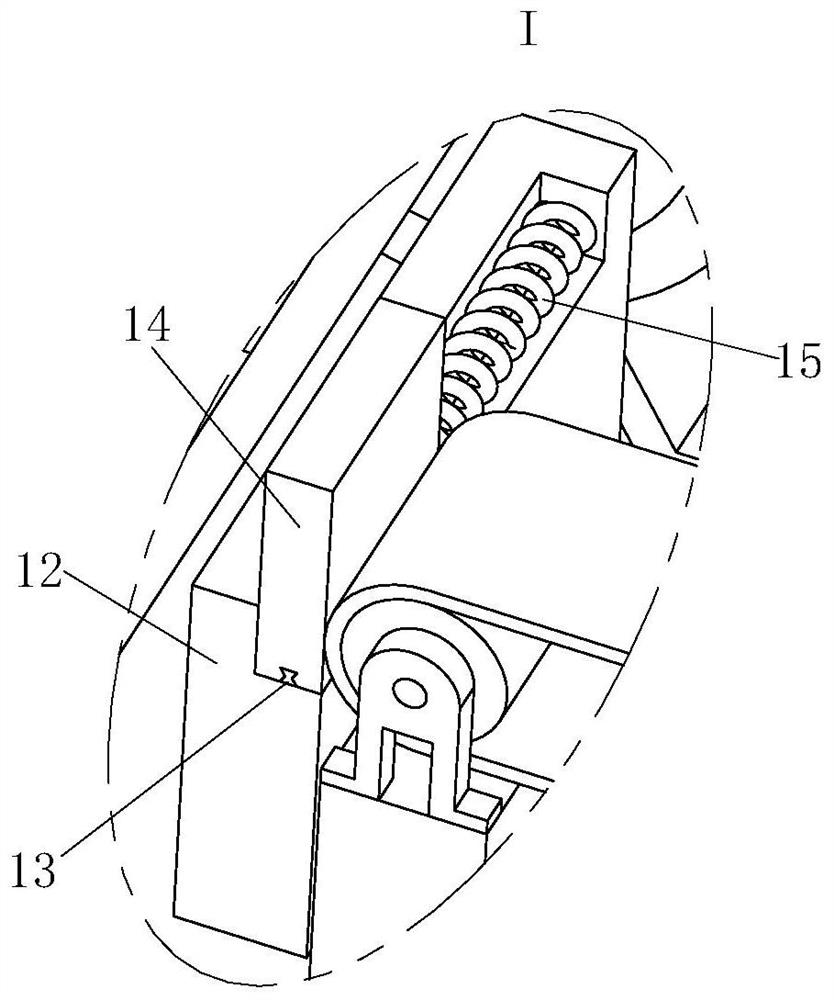

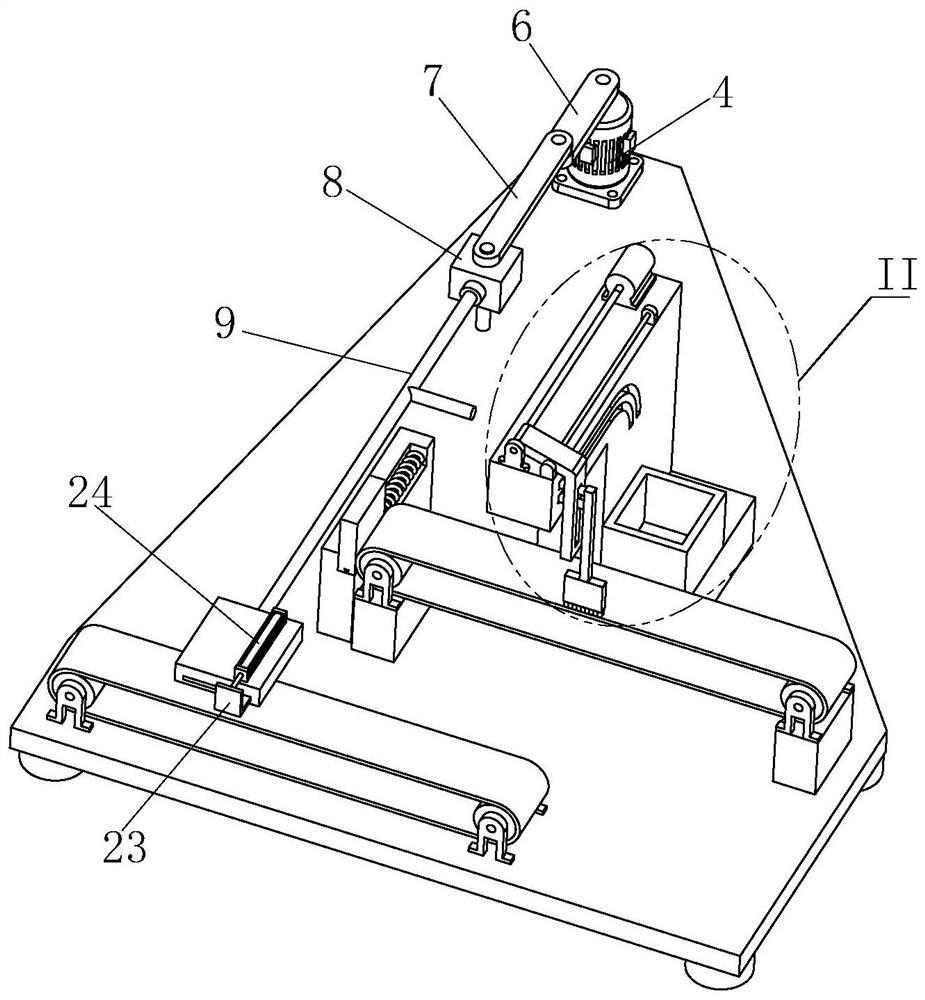

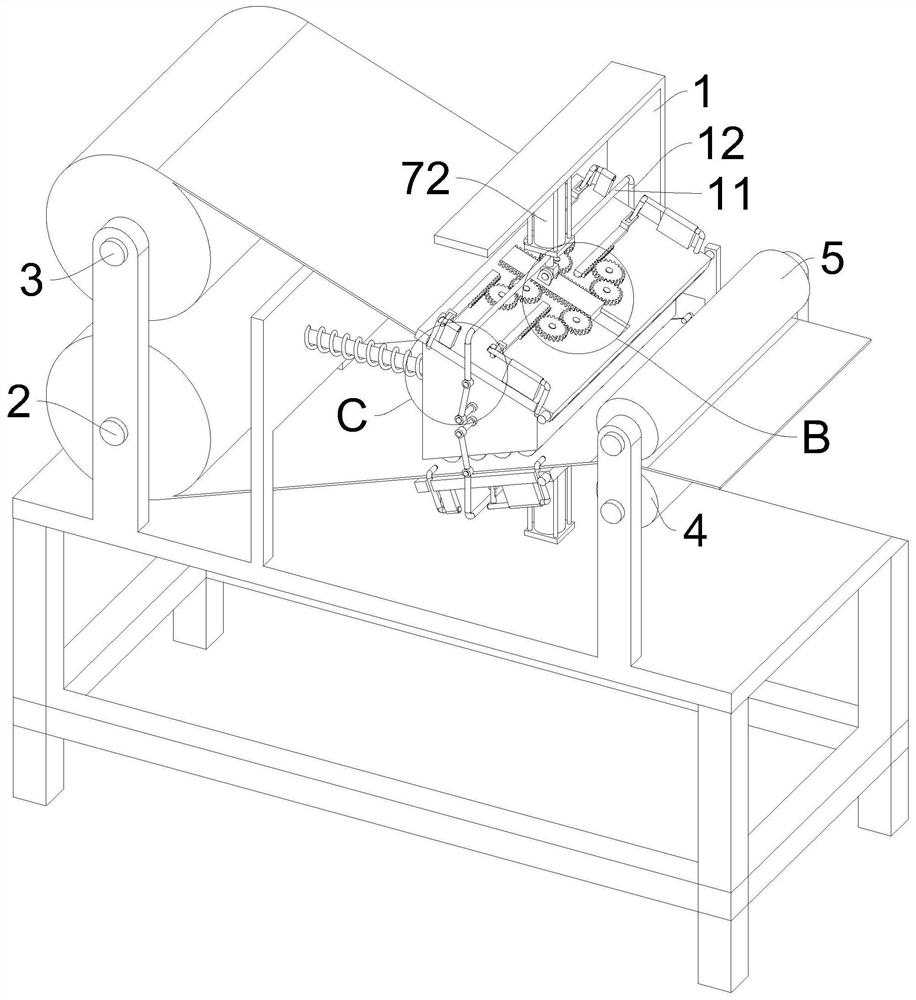

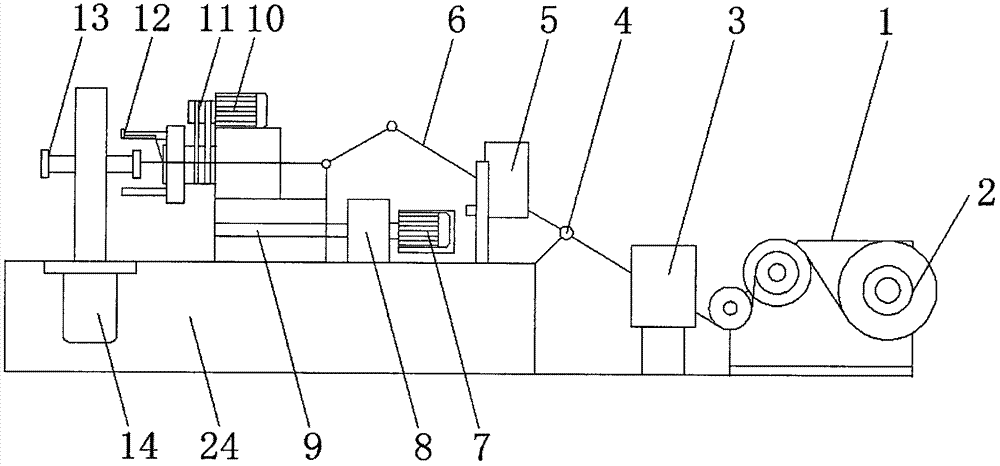

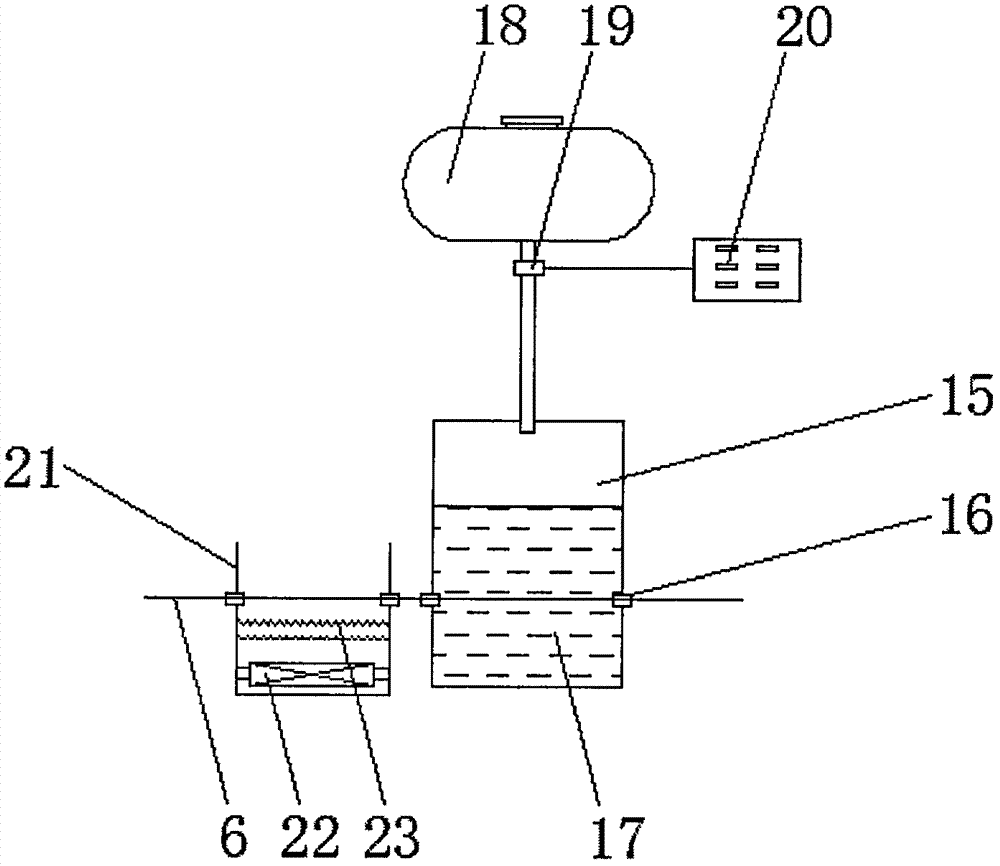

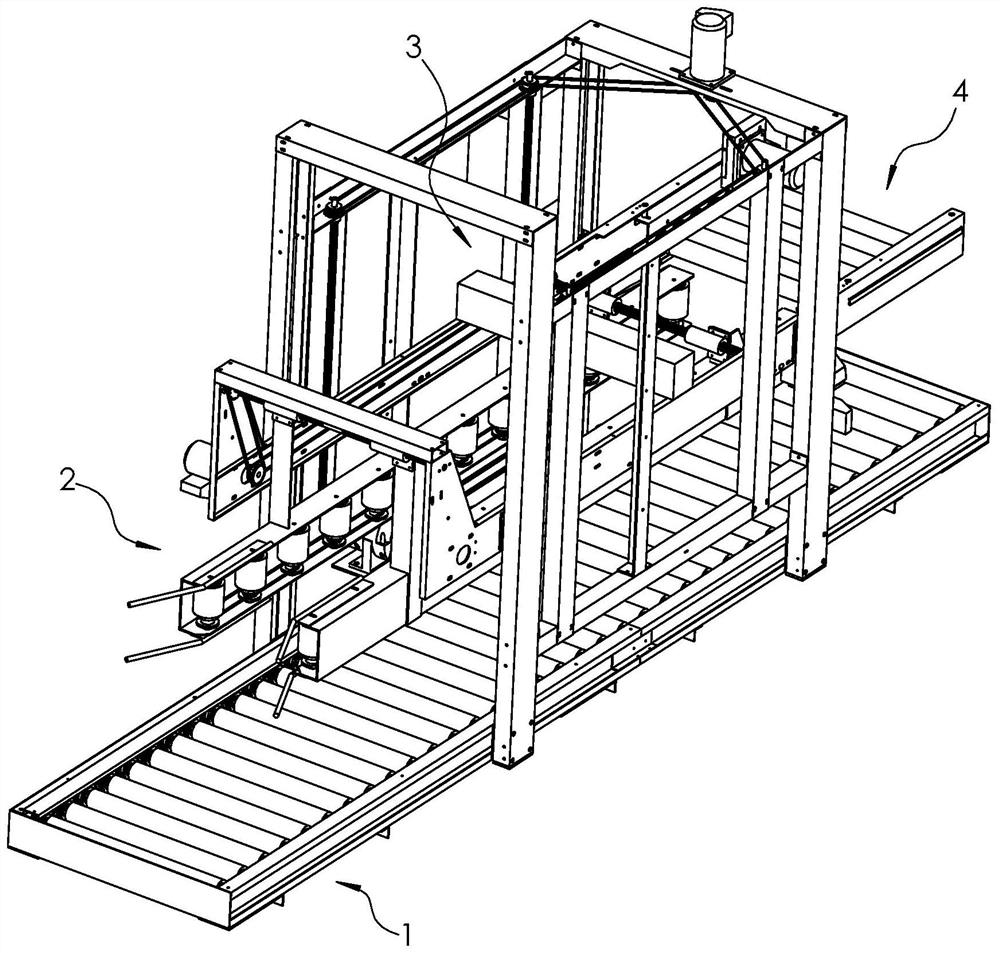

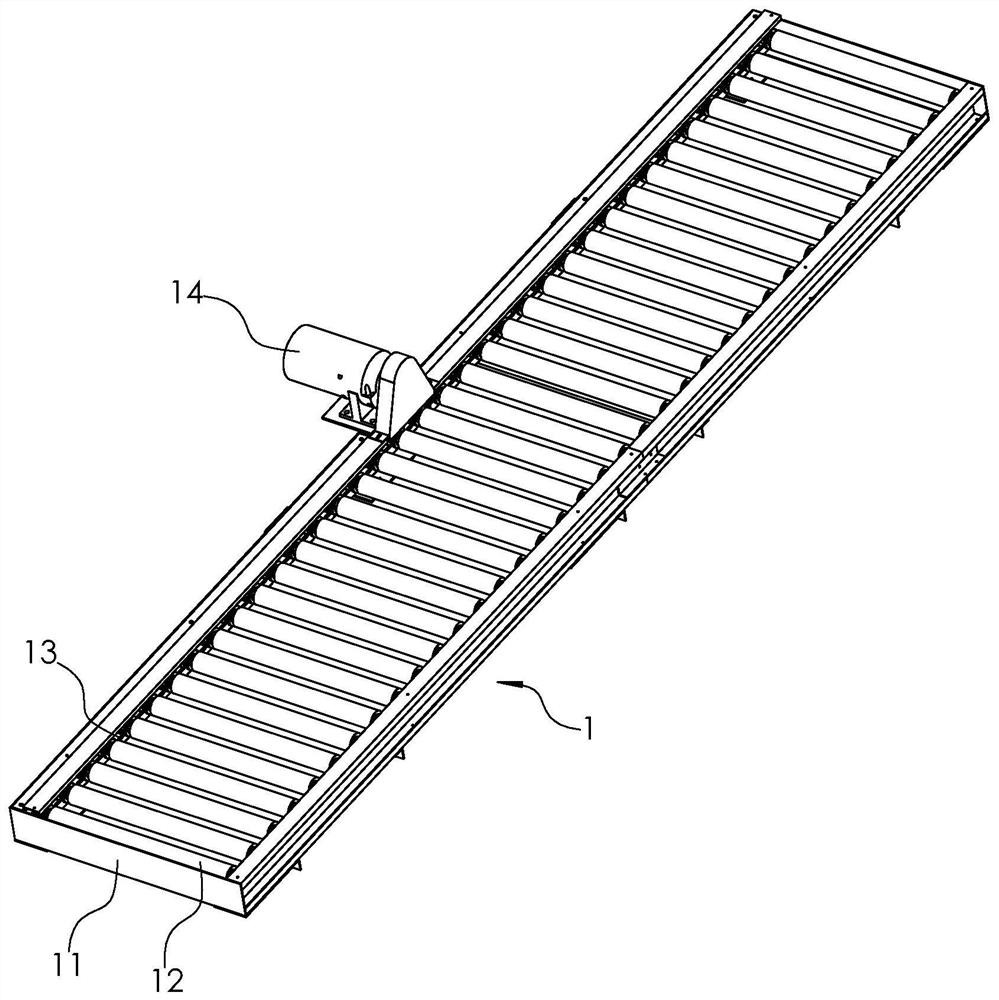

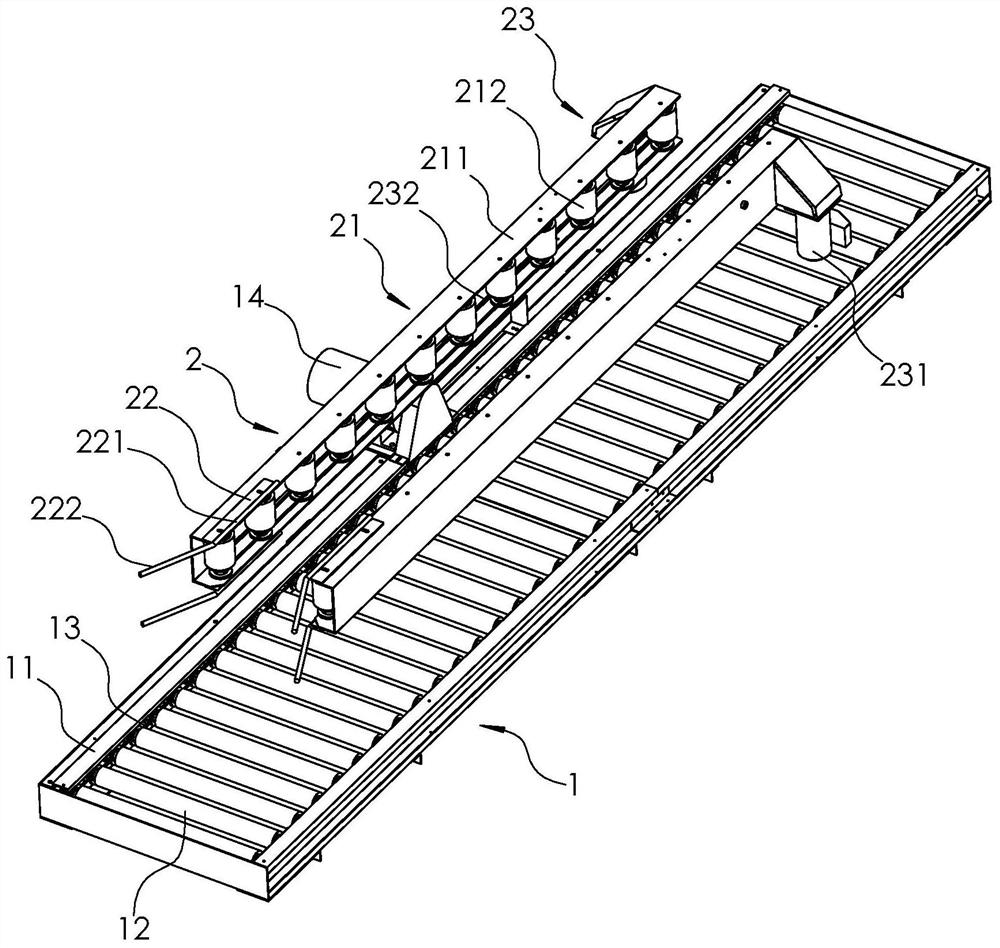

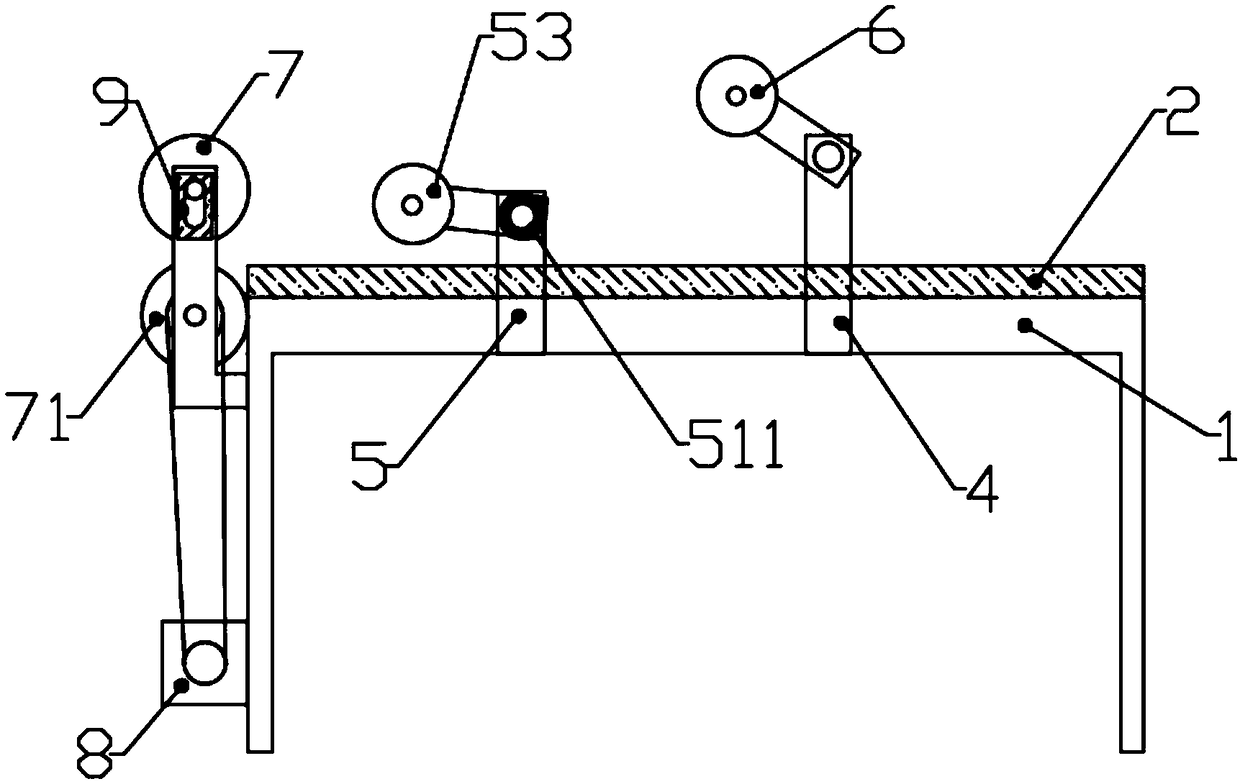

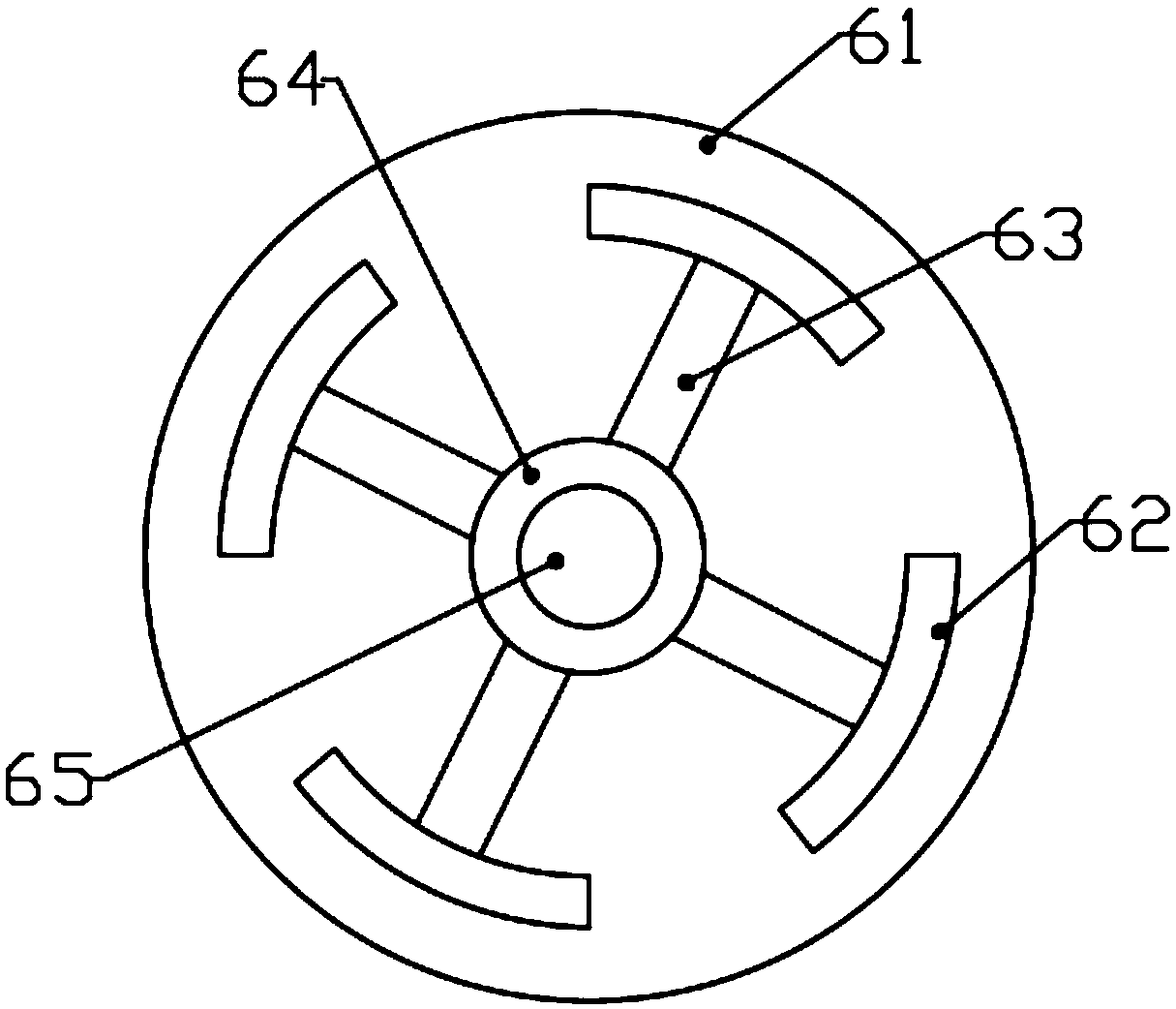

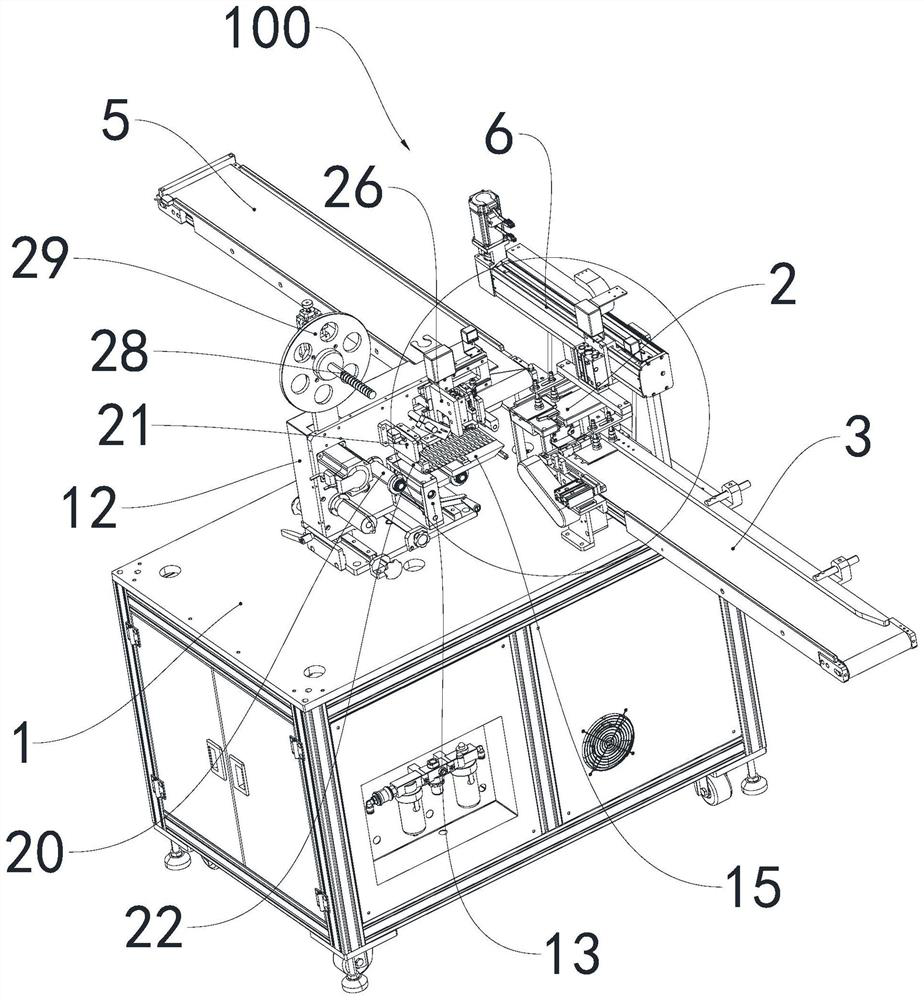

Automatic coating machine for filter screen

ActiveCN105834075AIncrease productivityReduce labor intensityLiquid surface applicatorsCoatingsMechanical engineeringCoating

The invention discloses an automatic coating machine for a filter screen. The automatic coating machine comprises a rack, wherein a conveying device and at least one coating processing line are arranged on the rack; the coating processing line comprises an overturning device, a coating device, a side pressing device and a pressurizing device which are successively arranged on the rack along the conveying device; the overturning device is used for overturning the covered edge of the filter screen outward; the coating device is used for smearing glue liquor inside the covered edge and / or in a position corresponding to the covered edge on the filter screen body; the side pressing device is used for overturning the covered edge of the filter screen inward to compress and adhere the covered edge to the filter screen body; the pressurizing device is used for continuously compressing the covered edge to the filter screen body. The automatic coating machine disclosed by the invention realizes automatic coating of the filter screen, so that the production efficiency is effectively improved, and the labor intensity of the worker is alleviated. Furthermore, the waste of the glue liquor can be reduced, and the phenomenon that the glue liquor drops to the working face of the filter screen body to affect the quality and performance of the filter screen can be avoided.

Owner:ZHONGSHAN JANDD ACTIVATED CARBON FILTER CO LTD

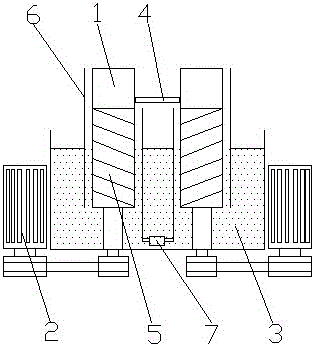

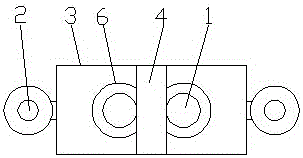

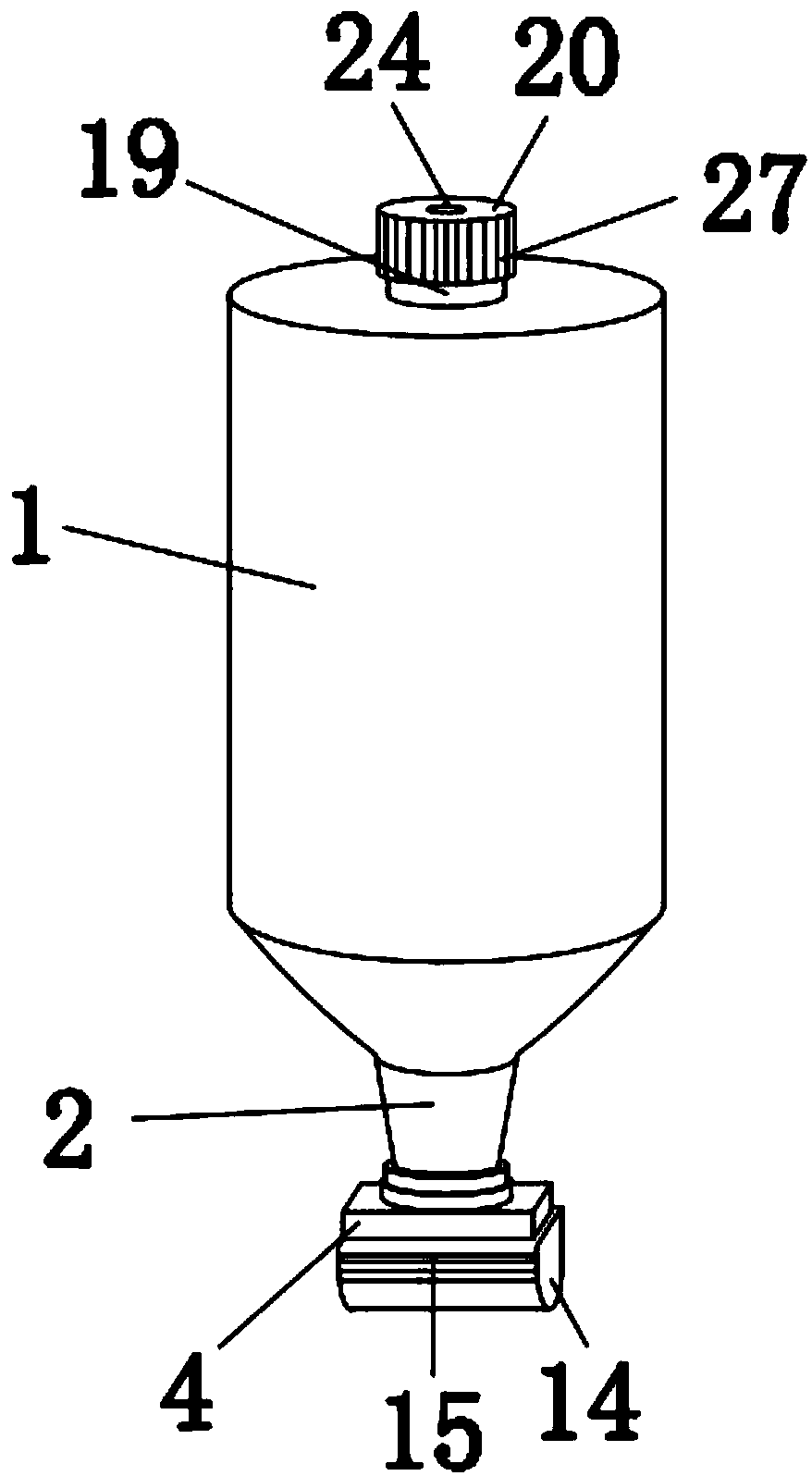

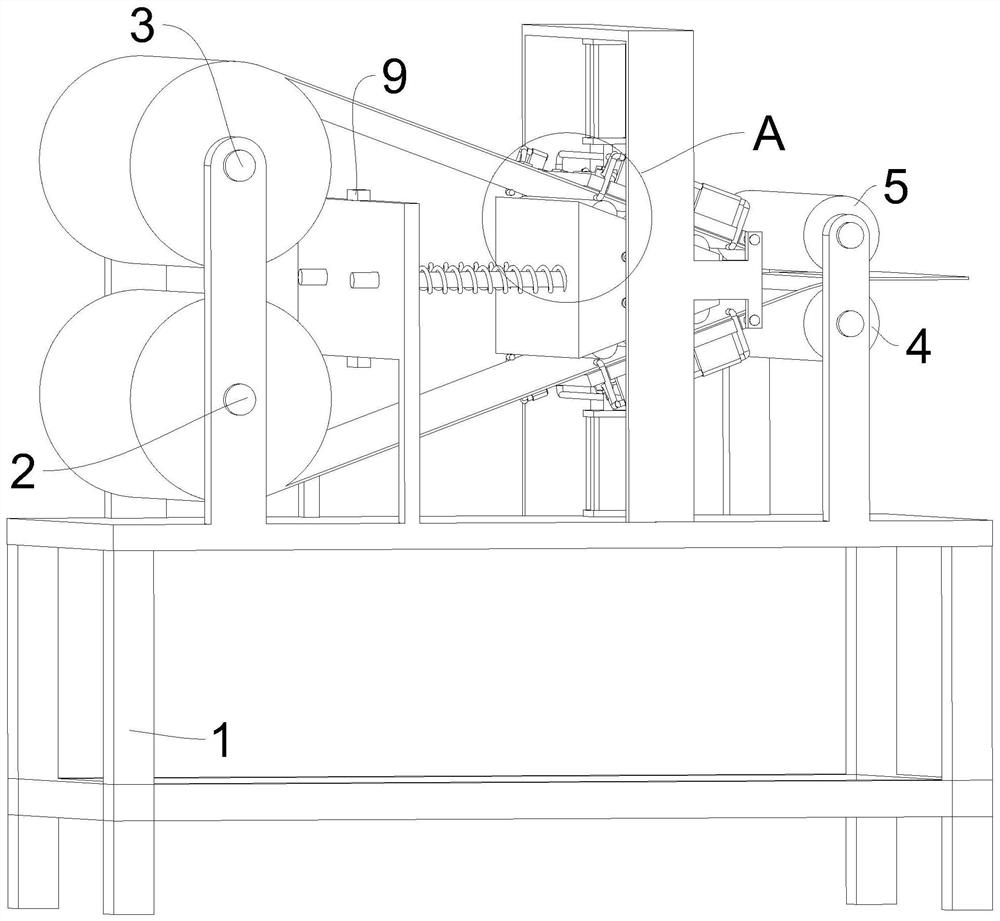

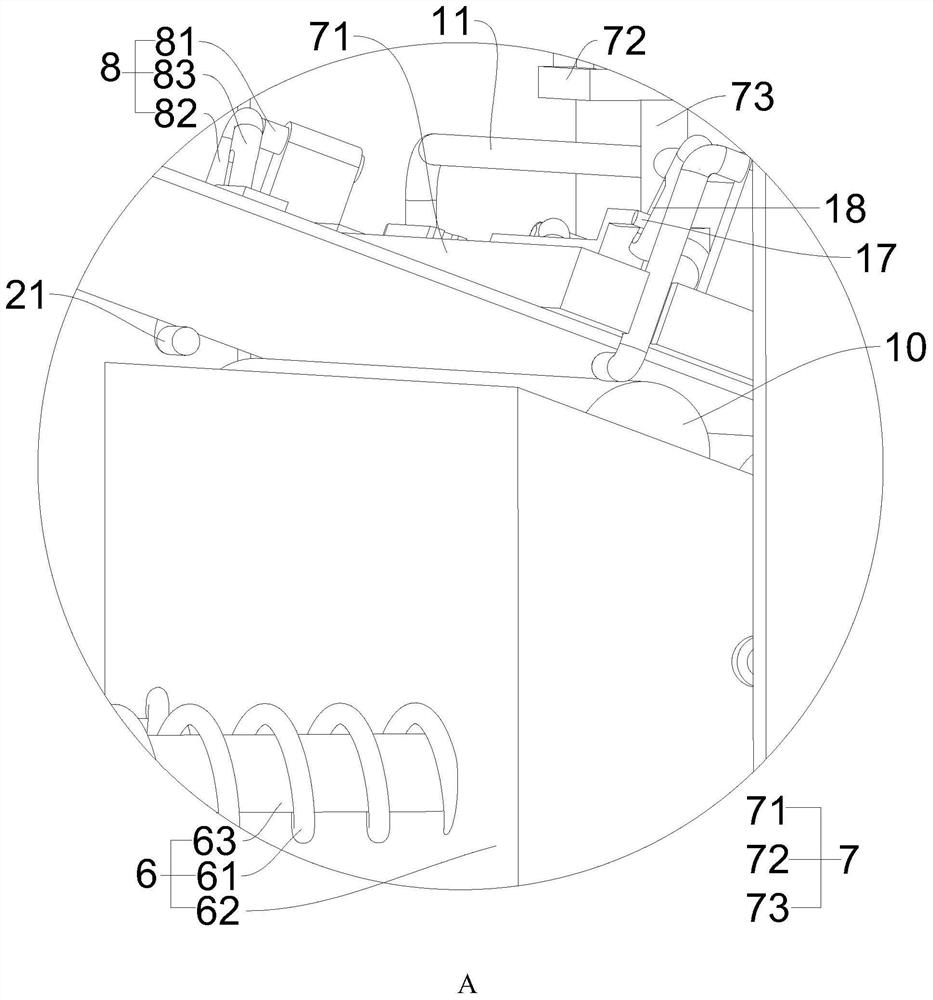

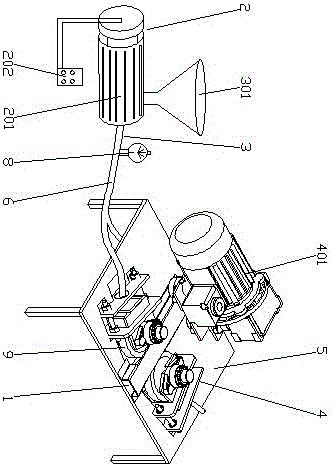

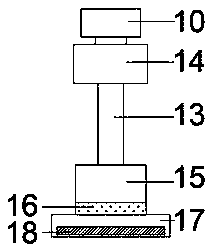

Spiral feeding-type automatic gluing apparatus

ActiveCN106000757AUniform rotation speedNot too muchLiquid surface applicatorsCoatingsPulp and paper industry

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

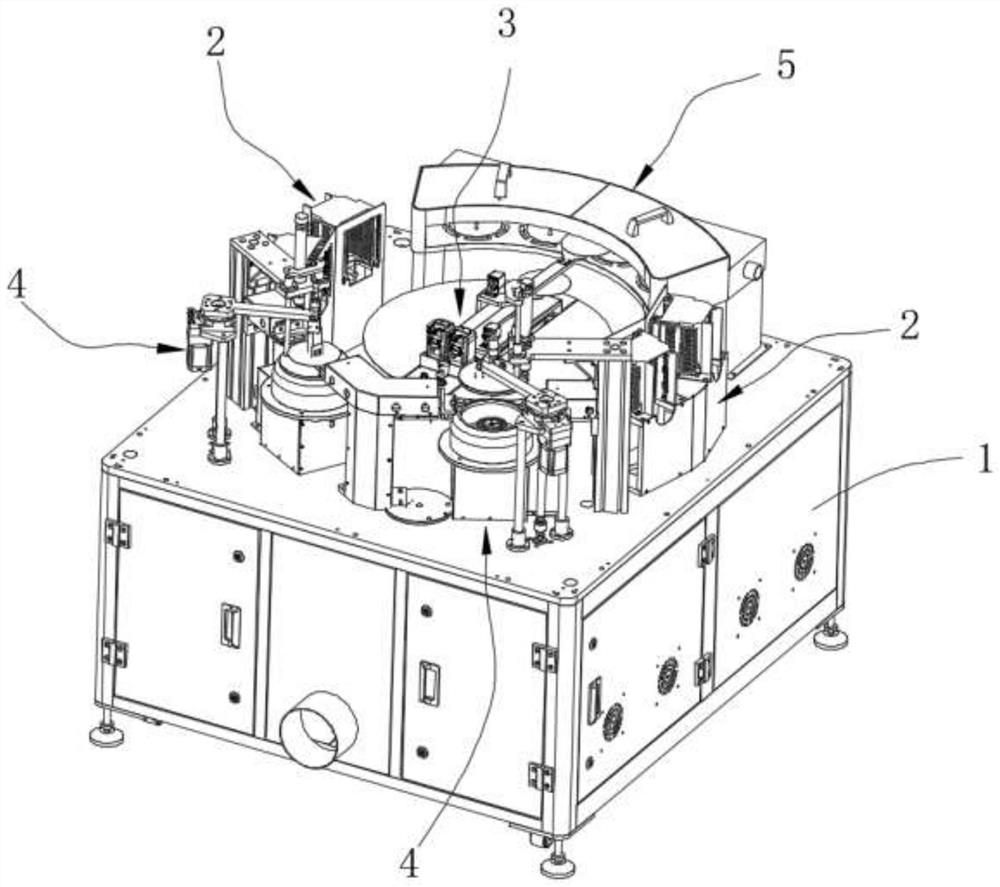

Intelligent magnet gumming machine

ActiveCN111558501AEasy to operateLow costLiquid surface applicatorsMeasurement devicesMagnetRobot hand

The invention discloses an intelligent magnet gumming machine which comprises a rack. A feeding device, a mechanical arm device, a gumming device, a detecting device and a discharging device are arranged on the rack. The mechanical arm device is used for grabbing magnets on the feeding device and sequentially moving the magnets to the gumming device to achieve gumming work, to the detecting deviceto achieve detecting work and to the discharging device to achieve discharging. After the feeding device achieves feeding, the mechanical arm device grabs the magnets on the feeding device, the magnets are sequentially moved to the gumming device to achieve gumming work, to the detecting device to achieve detecting work and to the discharging device to achieve discharging, automatic feeding, automatic gumming, automatic detecting and automatic discharging can be achieved, operation is convenient, the cost is low, and the rate of finished products of the magnets is high.

Owner:厦门诺博视科技有限公司

Leather adhesion assistant gluing equipment

ActiveCN110509655ARealize SupplementApply evenlyLamination ancillary operationsLaminationEngineeringExtrusion

The invention belongs to the technical field of leather processing, in particular relates to leather adhesion assistant gluing equipment and aims to solve the technical problem of providing the leather adhesion assistant gluing equipment which is capable of implementing rapid gluing and has an extrusion function. According to the technical scheme, the leather adhesion assistant gluing equipment comprises a base, a fixing rack, a connecting rack, and the like, wherein the fixing rack and the connecting rack are arranged on the base. The equipment is capable of implementing rapid gluing and hasthe effect of an extrusion function; according to the equipment, by pushing a mounting rack to move leftwards, the surface of leather can be scraped by a scraper till a rough state, and meanwhile, automatic gluing can be achieved; and according to the equipment, by pushing the mounting rack to move rightwards, a glue can be uniformly smeared, the glue in a cylinder can be replenished, a pressing plate can be also driven to move downwards, and two pieces of leather to be bonded can be extruded and bonded tightly.

Owner:广州市创坤金葱粉皮革有限公司

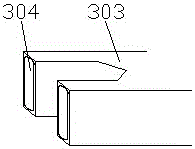

Glue coating machine applicable to bamboo wood product

InactiveCN108296135ARealize automatic glue applicationAvoid inconvenienceLiquid surface applicatorsCoatingsTransverse planeEngineering

The invention discloses a glue coating machine applicable to a bamboo wood product. The glue coating machine comprises a first cylinder, wherein a guide pipe is fixedly connected with the bottom of the first cylinder; a first screw thread is arranged at the lower part of the outer wall of the guide pipe; a transverse plate is arranged under the guide pipe; a first through holes is formed in the top of the transverse plate; a second screw thread is arranged at the upper part of the inner wall of the first through hole; the outer wall of a semicircular column fits the inner wall of the first through hole; and the semicircular column is in clearance fit with the first through hole, and connected with the transverse plate in clamping manner through the first through hole. The glue coating machine applicable to the bamboo wood product has the beneficial effects that the bonding strength insufficiency caused by the insufficient amount of glue coating can be avoided; the higher glue coating efficiency and speed can be achieved; when a plurality of bamboo wood plates are bonded, more convenience can be brought; and consequently, the glue coating machine applicable to the bamboo wood product can completely meet the current demand of people for a bamboo wood product glue coating machine which can be applied to various bamboo wood plates, can be used in accord with the actual demand, andis high in working efficiency.

Owner:安吉县杰安竹木制品工艺厂

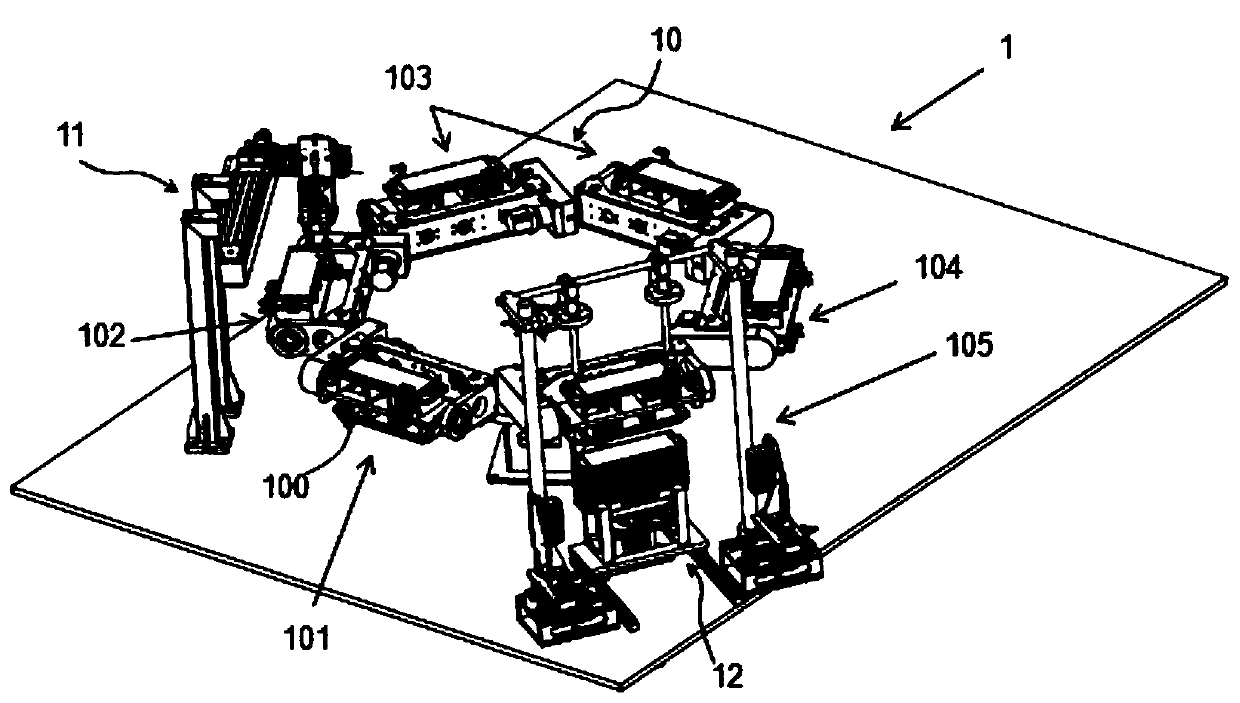

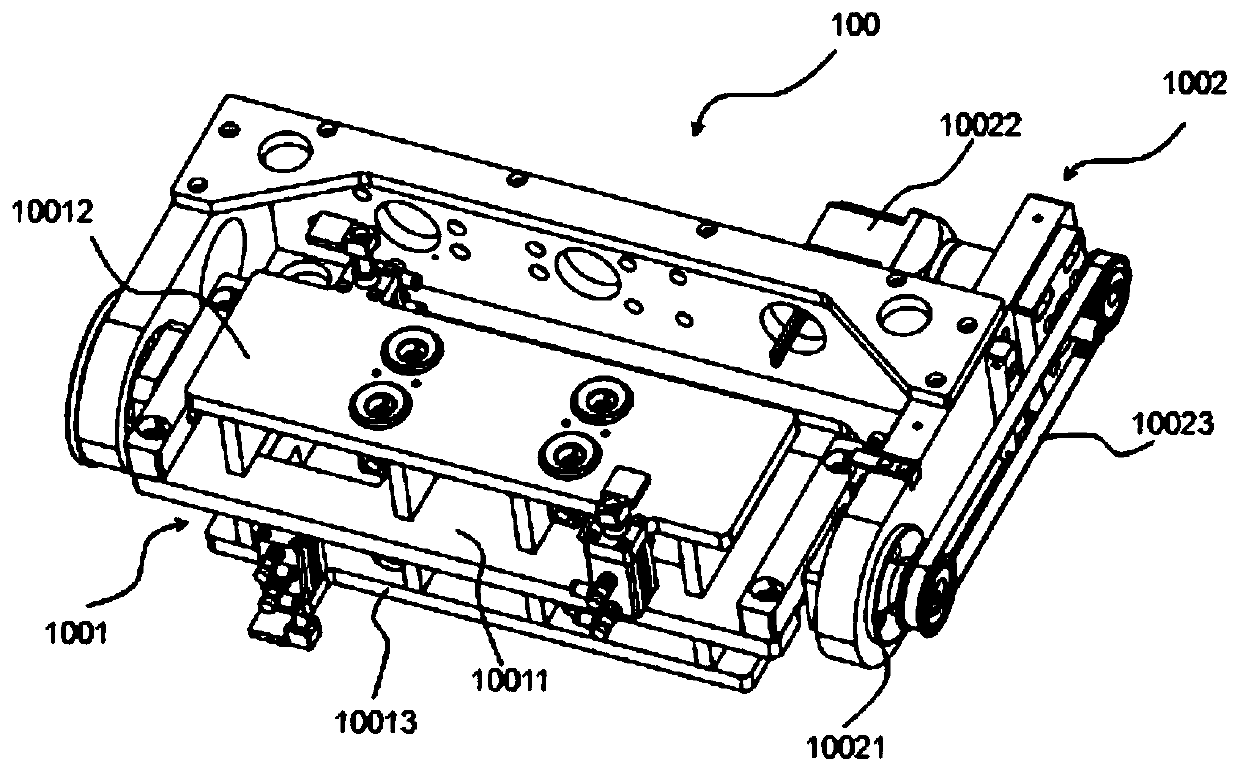

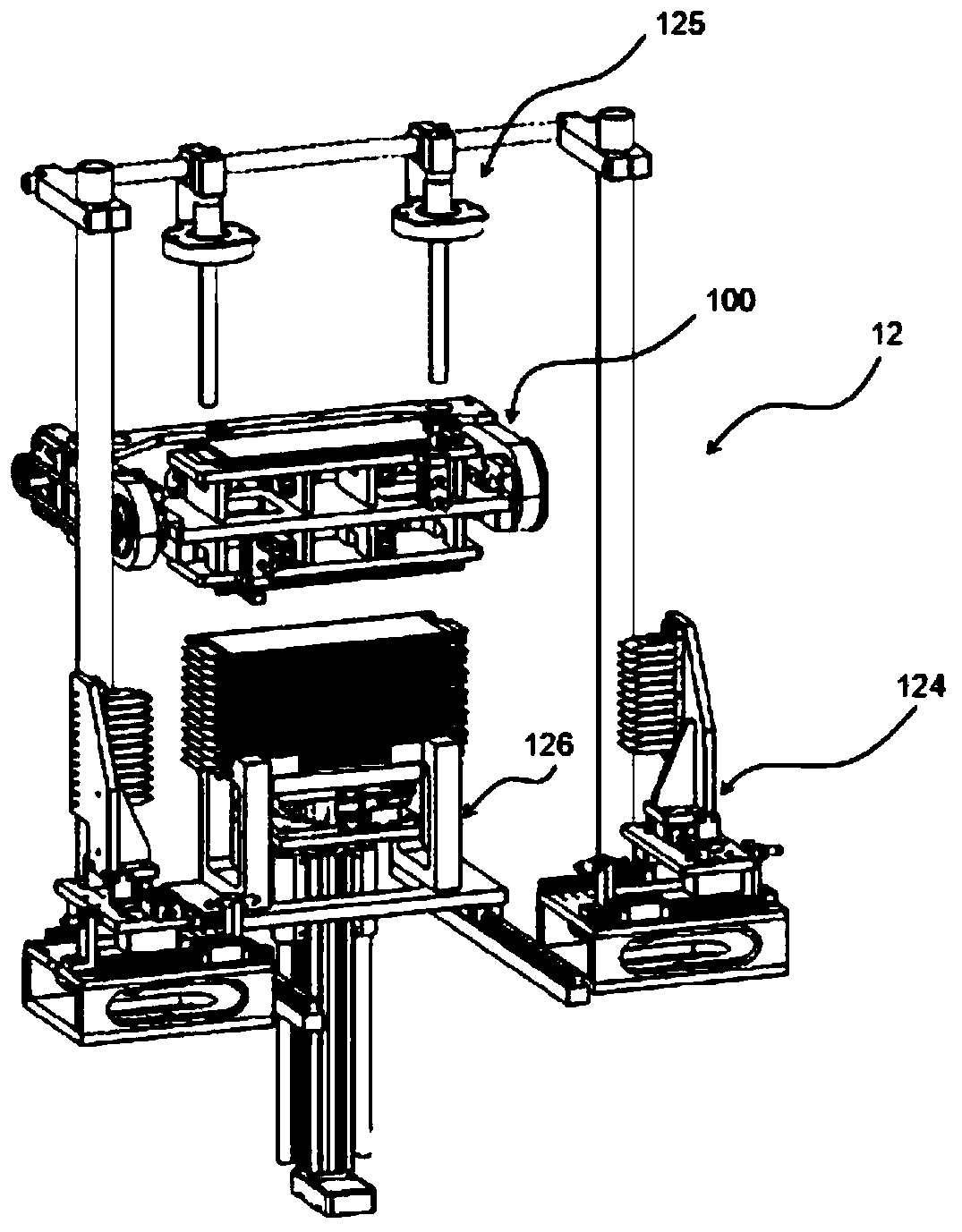

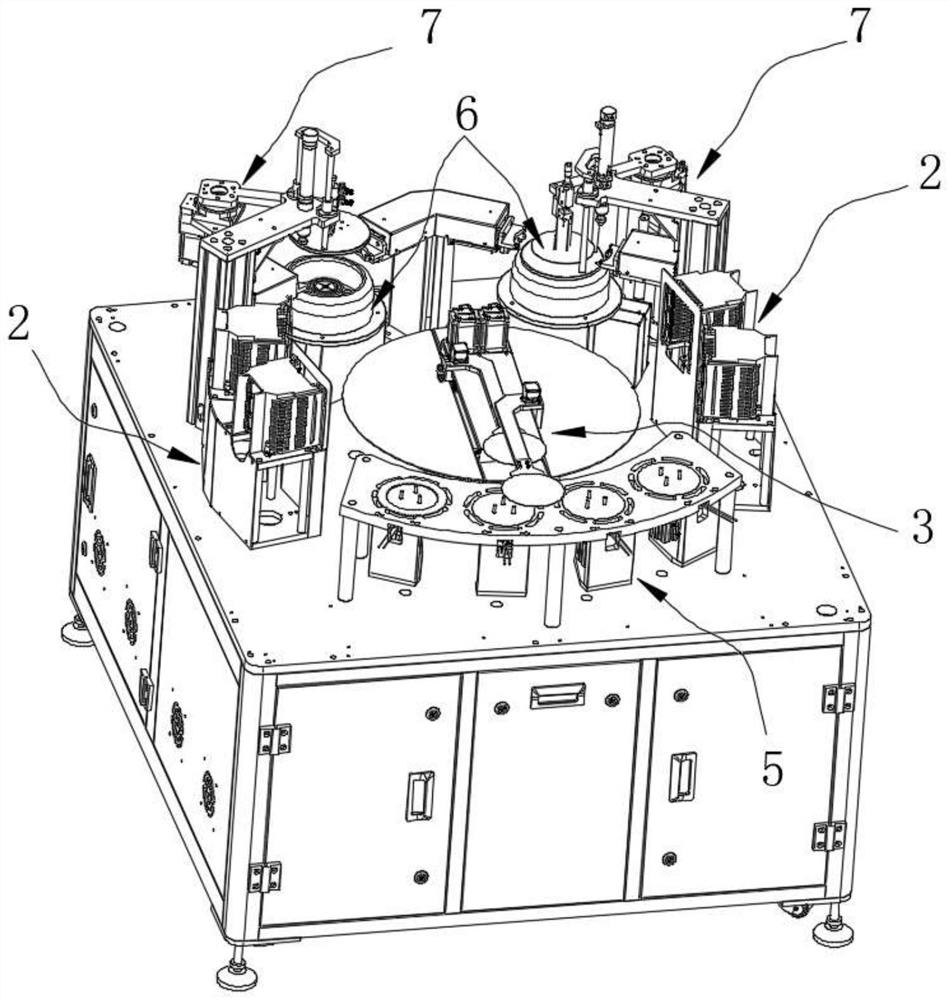

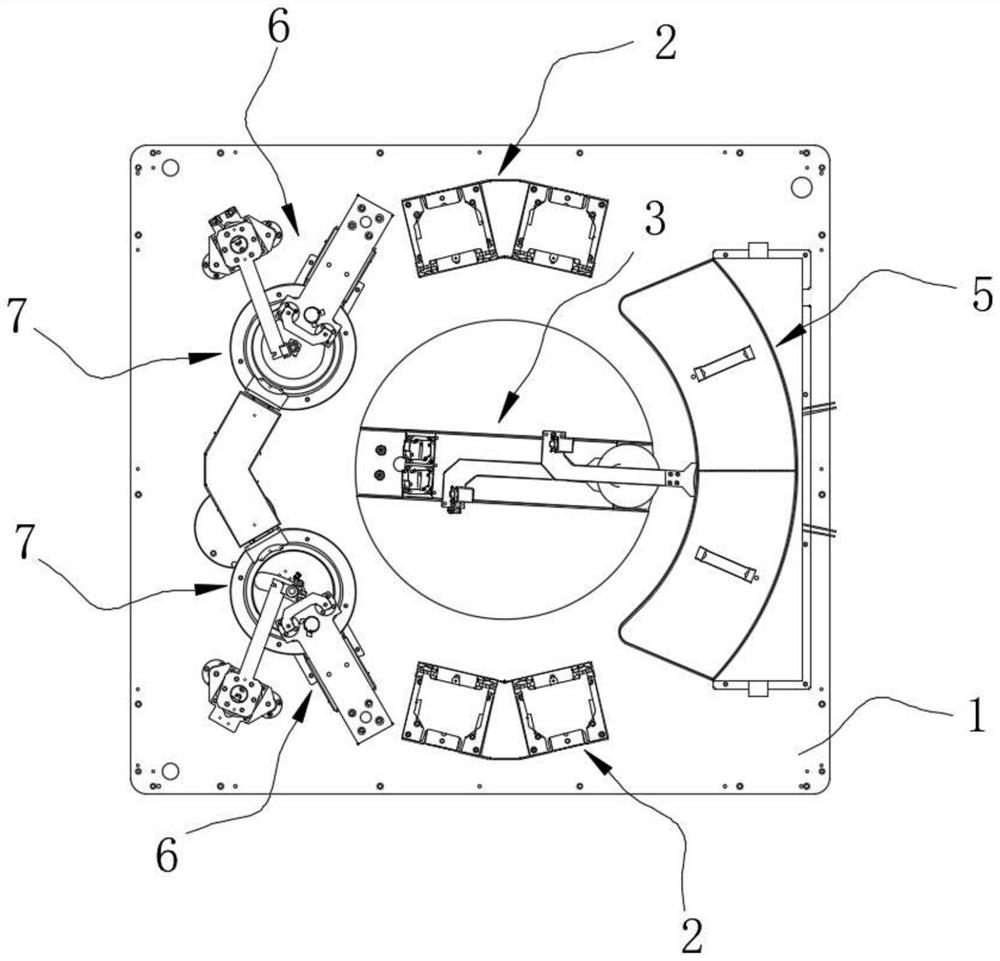

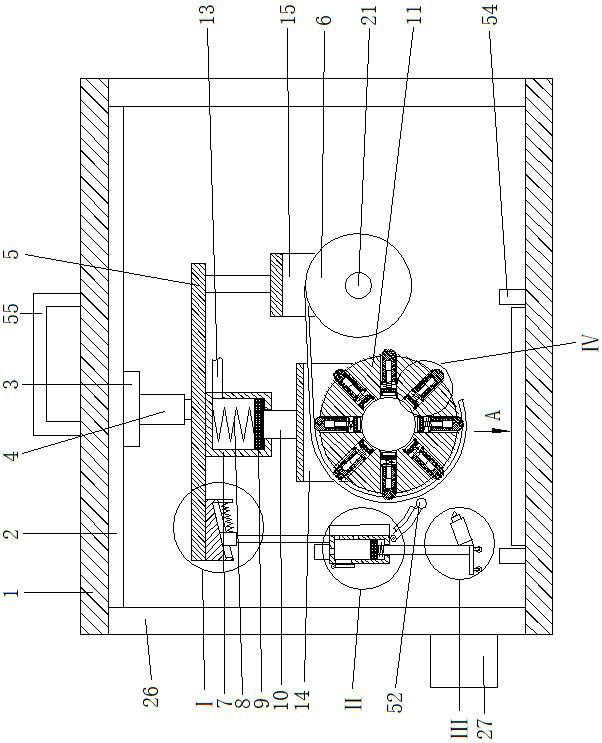

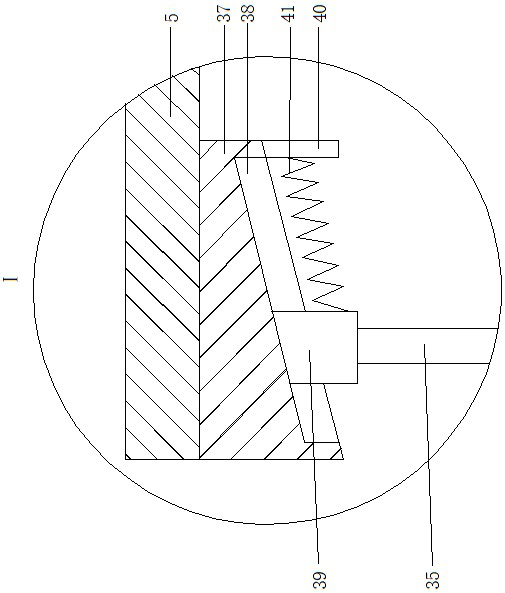

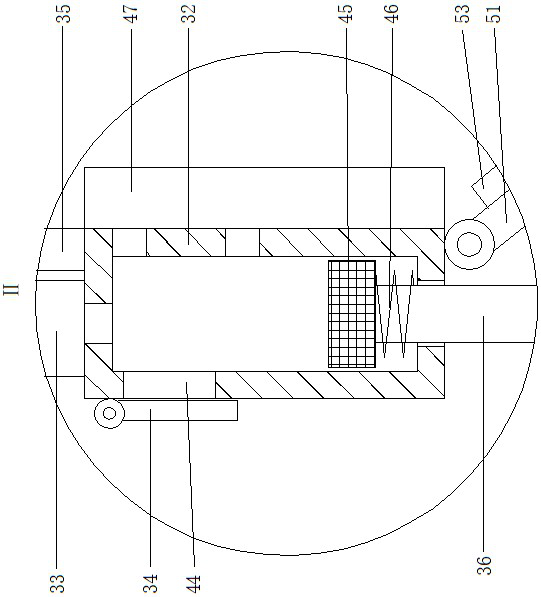

Cell stacking device

PendingCN109980296ARealize the stacking functionRealize automatic glue applicationFinal product manufactureSecondary cellsEngineering

The invention provides a cell stacking device. The cell stacking device comprises a cell rotating working part, a cell gluing mechanism and a cell stacking mechanism, wherein at least one cell feedingmechanism is arranged on the cell rotating working part; a rotating path of the cell feeding mechanism is at least provided with a cell gluing station and a cell stacking station; the cell feeding mechanism drives born cells to rotate to the cell gluing station and then rotate to the cell stacking station; the cell gluing mechanism is used for gluing the cells which rotate to the cell gluing station; and the cell stacking mechanism is configured to stack the cells which rotate to the cell stacking station into a cell stack. The device disclosed by the invention has the advantages that a cellstacking function and automatic gluing of the cells can be realized, so that the cell stacking efficiency is improved.

Owner:WUXI AOTEWEI INTELLIGENT EQUIP CO LTD

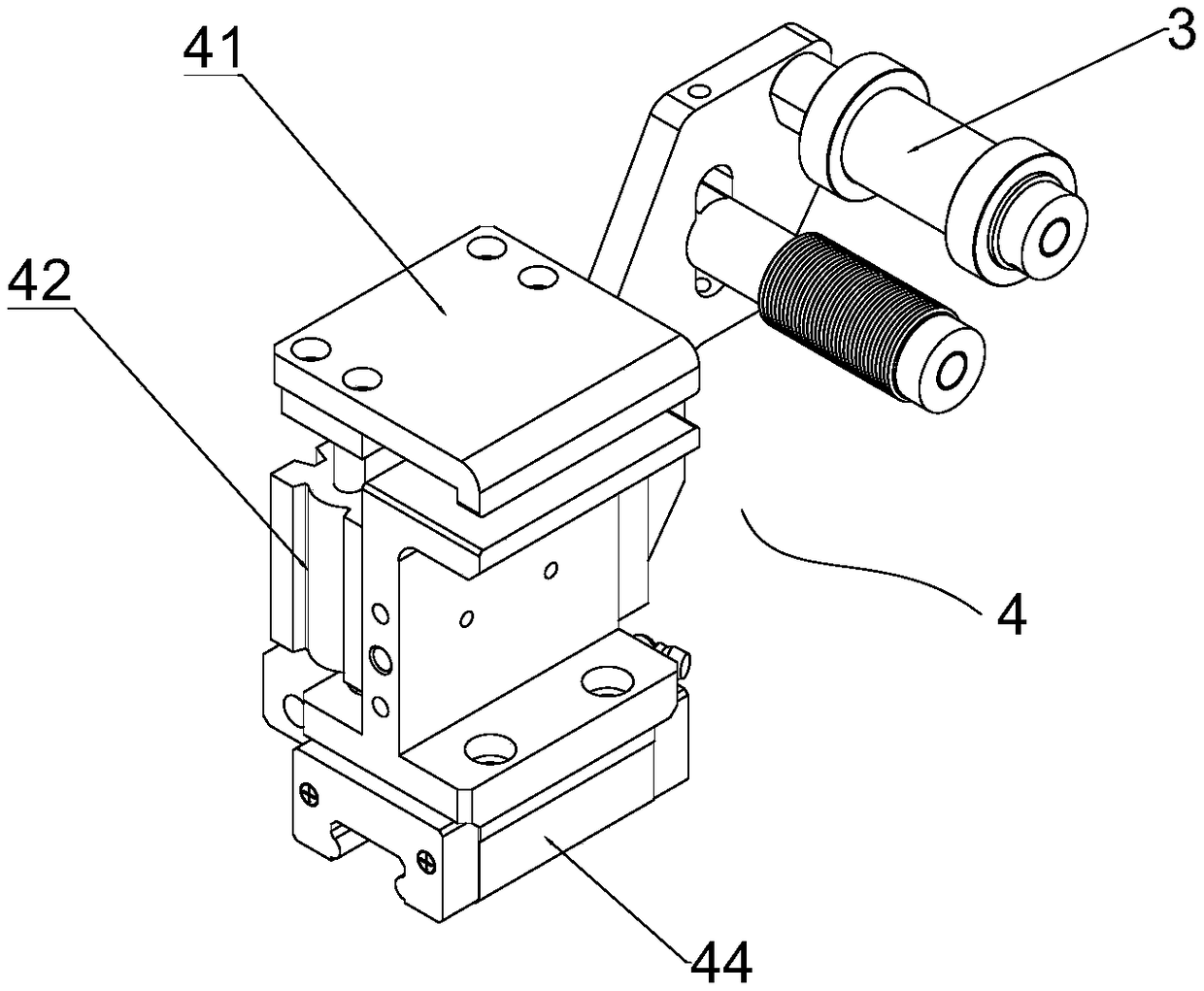

Tape applicator

PendingCN108807841AAdapt to continuous needsRealize automatic glue applicationElectrode manufacturing processesEngineeringMechanical engineering

The invention discloses a tape applicator, comprising a total fixed plate, and a tape unreeling disc, a coating wheel, a tape pinching mechanism, a tape cutting mechanism, a rotating applying plate and two patting plates on the total fixed plate, wherein a tape unreeled through the tape unreeling disc is transferred from the coating wheel to the tape pinching mechanism and then is transferred ontoa support table through the tape pinching mechanism, a pinching driving mechanism is connected with the rotating applying plate, and the rotating applying plate is located above the support table androtates to the tape and sticks to the half side of the tape, the tape cutting mechanism cuts off the tape, an object to be glued passes between the two patting plates, the tape stuck on the rotatingapplying plate is rotated to the object to be glued, the two patting plates stick to each other oppositely to press the other half of the tape stuck on the rotating applying plate to the object to beglued, and the rotating applying plate rotates to be separated from the stuck half of the tape. The tape applicator can be used for applying tapes very fast, and can adapt to tapes of different lengths and accurately and firmly attach tapes onto lugs to ensure the quality of products.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Invoice pasting device

The invention provides an invoice pasting device. The invoice pasting device comprises an invoice discharge mechanism; a gluing mechanism is arranged on any side of a discharge place of the invoice discharge mechanism; and a paper placing platform is arranged in the position, opposite to a discharge port, of the outer side of the gluing mechanism. The invoice pasting device further comprises a pressing mechanism arranged on the paper placing platform. The invoice pasting device has the beneficial effects of replacing financial staff to paste invoices, saving the time of the financial staff andimproving the working efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

Automatic glue pasting method for battery

ActiveCN110212207AImprove glue application efficiencyRealize automatic glue applicationPrimary cell manufactureFinal product manufactureEngineeringPush out

The invention relates to an automatic glue pasting method for a battery and provides automatic glue pasting equipment for the battery; the automatic glue pasting equipment comprises a base station, abearing table, a feeding belt and a discharging belt, further comprises a material taking guide rail, a material taking air cylinder, a sliding part, a cross frame and a vertical frame, and further comprises a fixed table, a first glue conveying table, a second glue conveying table, a glue pasting piece, a glue pasting connecting piece, a glue pasting air cylinder and a glue pasting guide rail; the method comprises the steps that the glue pasting air cylinder pushes out the glue pasting piece, and the glue pasting piece drives a special-shaped glue strip to move; a suction nozzle sucks a cellof the feeding belt to a clamp of the bearing table, and the glue pasting piece is used for attaching the special-shaped glue to the cell; and the suction nozzle moves a battery positioned on the bearing table to the discharging belt. The suction nozzle moves the cell of the feeding belt to the bearing table, the glue pasting piece moves to the position above the cell along the glue pasting guiderail, and the glue pasting air cylinder pushes the glue pasting piece, and the glue pasting part moves downwards to automatically attach the special-shaped glue to the tail part of the cell, so that automatic glue pasting is completed, and the glue pasting efficiency is improved.

Owner:珠海市嘉德电能科技有限公司

Wafer uniform glue baking machine

PendingCN114100970ARealize automatic glue applicationHigh degree of automationConveyorsPretreated surfacesWaferMechanical engineering

A wafer uniform glue baking machine disclosed by the present invention comprises a rack, the upper surface of the rack is provided with a material receiving and supplying rack, a manipulator, a uniform glue module and a baking table, the material receiving and supplying rack is used for placing a wafer, the uniform glue module comprises a gluing mechanism and a uniform glue spin-drying mechanism, the gluing mechanism is used for gluing the wafer, the uniform glue spin-drying mechanism is used for uniformly smearing glue on the wafer, and the baking table is used for baking the wafer. The baking table is used for drying the glued wafer; according to the invention, after the wafer is taken out from the material receiving and supplying frame through the manipulator, the wafer is placed on the glue uniformizing module for glue coating and uniform smearing, the wafer is transferred to the baking table after glue coating is completed, and finally the dried wafer is placed in the material receiving and supplying frame, so that automatic glue coating, glue uniformizing and baking of the wafer are realized, the automation degree of the equipment is improved, and the production efficiency is improved. According to the photoresist coating device, the coating uniformity is guaranteed, meanwhile, the thickness of the photoresist on the surface meets the requirement, then the photoresist is dried through the baking table, the baking quality is guaranteed, and the photoresist coating uniformity is further improved.

Owner:苏州康沃斯智能装备有限公司

Automatic gluing device for sanitary towel

InactiveCN106513254AShorten the timeImprove work efficiencyLiquid surface applicatorsCoatingsEngineeringElectromagnetic valve

The invention relates to an automatic gluing device for a sanitary towel. The device comprises a glue storage box with a plurality of small holes in the bottom. Hairbrush heads are arranged in the small holes of the glue storage box, a heating rod is arranged in the glue storage box, a material discharging roll and a material receiving roll are arranged on the left and right sides of the glue storage box, respectively, a plurality of conveyor rolls are arranged below the glue storage box, a paper slip can successively pass through the material discharging roll, the conveyor roll and the material receiving roll, a reserve glue barrel is arranged above the glue storage box, the glue storage box is connected to the reserve glue barrel through a pipeline, an electromagnetic valve is arranged on the pipeline between the glue storage box and the reserve glue barrel, a slide rail is fixedly mounted on the paper slip, a horizontal through groove is formed in the slide rail, a strip-like hole which is formed in the lower part of the slide rail communicates with the through groove, an iron slide block is arranged in the through groove, the slide block is wider than the strip-like hole, electromagnets are arranged at two ends of the through groove, the lower part of the slide block is connected to one end of a spring, and the other end of the spring is connected to a strike-off brush. The device provided by the invention can automatically glue the paper slip, so that the time is effectively shortened, and the work efficiency is improved.

Owner:天津信氏佳科技发展有限公司

Automatic core glue attaching equipment

ActiveCN109148141AEasy for subsequent glue applicationEasy to operateMagnetic core manufactureEngineeringDrive motor

The invention provides an automatic magnetic core glue sticking device, which comprises a magnetic core conveying mechanism, a frame, an adhesive tape releasing mechanism, a magnetic core clamping mechanism, a glue cutting mechanism, an air compressor, a controller and a power supply. The machine frame is provided with a feeding position, a glue sticking position and a material discharging position; A tape release mechanism, a magnetic core clam mechanism, a glue cutting mechanism, an air compressor, a control and a power supply are arranged on that rack. At that same time of clamping the magnetic core, the magnetic core separator automatically separates the magnetic core and maintain equal spacing, so as to facilitate the subsequent glue pasting and glue cutting operation; A lead screw drive motor drives a bi-directional cylinder, a first clamp plate and a second clamp plate clam that magnetic core and moving, at the same time, glue sticking operation can be carried out, and the magnetic core drives a pressing wheel to rotate in the moving process, so as to realize automatic glue sticking; After the glue application process is completed, the front and rear pressure cylinders respectively press the magnetic cores of the tape to be cut to ensure that the position of the magnetic cores is not affected when the glue is cut.

Owner:郴州成瑞电子有限公司

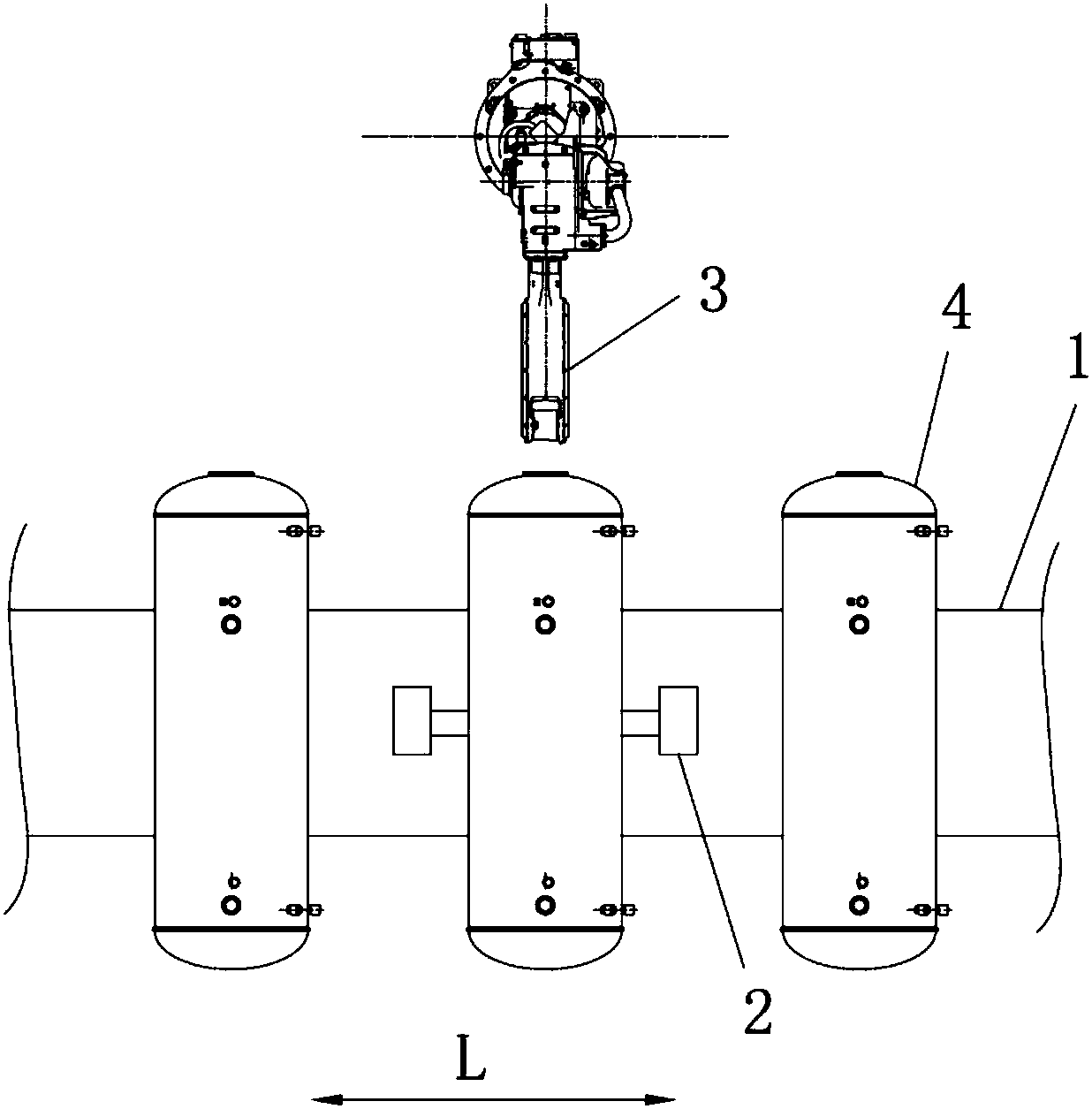

Automatic gluing equipment and method for inner containers

InactiveCN108126865AImprove gluing efficiencyGuaranteed accuracyLiquid surface applicatorsCoatingsManipulatorWater heater

The invention discloses automatic gluing equipment for inner containers. The automatic gluing equipment comprises a belt conveying assembly, clamping assemblies, a manipulator and a control assembly,wherein a to-be-glued inner container is conveyed to a gluing area, and a glued inner container is transported to be away from the gluing area; the clamping assemblies are arranged at two ends of theto-be-glued inner container in the gluing area and clamp the to-be-glued inner container; the manipulator is connected with a gluing gun and drives the gluing gun to glue the gluing position of the to-be-glued inner container; the belt conveying assembly, the clamping assemblies and the manipulator are connected to the control assembly, and the control assembly controls the manipulator to search and determine the gluing position of the to-be-glued inner container. With the adoption of the gluing equipment and the gluing method, the inner container of a water heater can be glued automatically,traditional operation of manually determining the gluing position, performing manual gluing by the gluing gun and manually clamping and loosening the to-be-glued inner container is replaced, gluing efficiency is improved, and accuracy of the gluing position is guaranteed.

Owner:QINGDAO HAIER NEW ENERGY ELECTRIC APPLIANCE +1

Data line interface gluing device

PendingCN108940746AApply glue evenlyRealize automatic glue applicationLiquid surface applicatorsCoatingsHydraulic cylinderSoftware engineering

The invention discloses a data line interface gluing device. The data line interface gluing device comprises an operating table, wherein four corners of the top end of the operating table are fixedlyconnected with supporting rods; the top ends of the four supporting rods are fixedly connected with the bottom end of a top plate; one side of the top end of the operating table is fixedly equipped with a lower pressure plate through a fixed block; and the position, above the lower pressure plate, of one side of the lower end of the top plate is fixedly connected with a first hydraulic cylinder; and the bottom end of the first hydraulic cylinder is fixedly connected with an upper pressure plate. According to the data line interface gluing device disclosed by the invention, automatic gluing ofa data line interface can be realized through the first hydraulic cylinder, a second hydraulic cylinder, a glue spraying pump and a glue outlet box, so that time and labor consumption of manual gluingis saved, and gluing efficiency of the data line interface is improved; and gluing of the data line interface can be more uniform through the upper pressure plate, the lower pressure plate, a gluingtube, a ring-shaped glue outlet slot and a circular glue outlet, so that waste of glue is prevented, and therefore, the gluing effect is improved.

Owner:吴江市凯宝电器有限公司

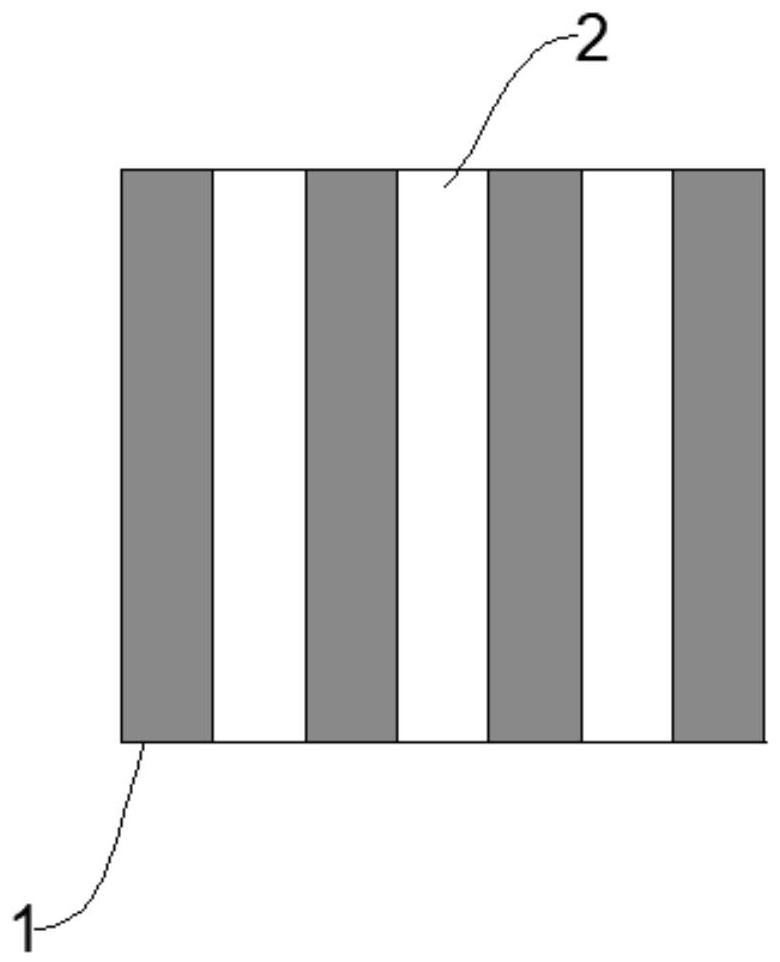

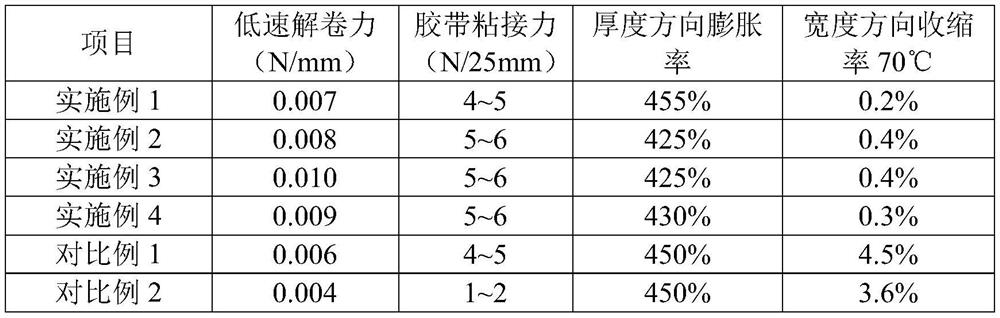

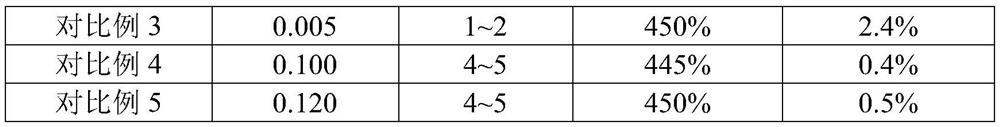

Easily-recognized and easily-unwound composite expansion adhesive tape and preparation method thereof

PendingCN114316829ANot easy to degummingReduce process timeNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive glueSilicone tape

The invention provides a composite expansion adhesive tape easy to identify and unroll. The composite expansion adhesive tape comprises an expansion film, a first adhesive layer, a base film and a second adhesive layer which are sequentially compounded, the second adhesive layer comprises a gluing area and a blank area which are arranged at an interval in the width direction of the composite expansion adhesive tape; the gluing area contains a color developing material, so that color contrast is formed between the gluing area and the blank area; glue for forming the first adhesive layer is transparent polyacrylate glue, and the transparent polyacrylate glue comprises 45%-55% of polyacrylate, 0.04%-0.07% of a curing agent, 0.1%-0.3% of amino resin and p-toluenesulfonic acid. The adhesive tape provided by the invention has the advantages of being capable of realizing automatic rubberizing, easy to unroll and capable of reducing the difficulty of industrial production.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Label paper gluing pasting equipment applied onto packaging line

InactiveCN111776395ARealize automatic glue applicationHigh degree of automationLabelling machinesElectric machineryConveyor belt

The invention relates to label paper gluing pasting equipment applied onto a packaging line. The label paper gluing pasting equipment comprises a base, wherein an original conveyor belt and a processing conveyor belt are separately mounted on the base; the rear side of the processing conveyor belt is separately provided with a coating assembly and a turnover assembly; the turnover assembly comprises a motor I and a cylindrical frame which are mounted on the base; the motor I is connected to a turnover transfer assembly which is adaptive to the cylindrical frame; and the left side of the processing conveyor belt is provided with a limiting assembly which is adaptive to the turnover transfer assembly. The label paper gluing pasting equipment is high in degree of automation, controls a brushhandle to slide along a track, controls a spade box to turn over in a front-rear sliding process on the basis of controlling label paper and a product packaging box to convey by the conveyor belts, can realize automatically gluing on the label paper and pasting the label paper onto the product packaging box, and has the advantages of being convenient in use and capable of saving a great deal of labor power.

Owner:焦磊

Double-sided adhesive tape applicator for cartons

PendingCN107139531ARealize automatic glue applicationLow costBox making operationsPaper-makingCartonEngineering

The invention relates to the technical field of tape applicators, in particular to a double-sided adhesive tape applicator for cartons. The double-sided adhesive tape applicator comprises a rack. A carbon discharging mechanism, double-sided adhesive tape application mechanisms and a carbon overturning mechanism are sequentially arranged on the rack. The front end of each double-sided adhesive tape application mechanism and the front end of the carton overturning mechanism are each provided with a carbon positioning mechanism. The rack is further provided with carbon conveying manipulators for conveying the cartons of the carton discharging mechanism to the carton positioning mechanisms. The cartons to be subjected to adhesive tape application are discharged one by one through the carbon discharging mechanism. The carbon conveying manipulators suck the carbons and put the cartons into the carbon positioning mechanisms. The carbons are fixed through the carbon positioning mechanisms. The carbons are subjected to double-sided adhesive tape application through the double-sided adhesive tape application mechanisms. The carbon conveying manipulators suck the cartons and put the cartons on the carton positioning mechanisms. The carbons are turned over by 180 degrees through the carbon overturning mechanism. The external manipulators suck the cartons and make an application action. By the adoption of the double-sided adhesive tape applicator for the cartons, the automatic adhesive tape application of the double-sided adhesive tape is achieved, the adhesive tape application quality is good, the work efficiency is high, and the manpower cost of enterprises is lowered.

Owner:DONGGUAN RONGXU AUTOMATION TECH

Body base lap joint device

ActiveCN113561506ARealize automatic glue applicationIncrease productivityPlastic recyclingLap jointMechanical engineering

The invention relates to the field of waterproof coiled materials, and discloses a body base lap joint device. The device comprises a rack, a first body base frame rotationally arranged at one side of the rack, a second body base frame rotationally arranged on the rack, a first conveying roller rotationally arranged at the other side of the rack and a second conveying roller rotationally arranged on the rack. The second body base frame is located over the first body base frame, the bottom end of the second conveying roller is tangent to the top end of the first conveying roller, a gluing mechanism is arranged on the rack in the horizontal direction, and pushing mechanisms capable of pushing the gluing mechanism to conduct gluing on body bases at the upper side and the lower side are symmetrically arranged on the rack. A plurality of limiting mechanisms for limiting the body bases are symmetrically arranged on the pushing mechanisms; and by arranging the gluing mechanism, the pushing mechanisms, the first conveying roller and the like, automatic gluing lap joint of the tail and the head of a body base roll on the first body base frame and the second body base frame is achieved, manual gluing is not needed, and the production efficiency is improved.

Owner:荆州市中宇防水材料有限公司

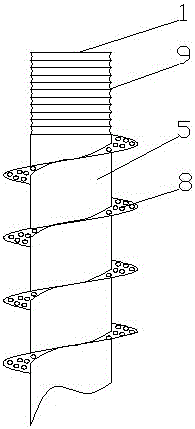

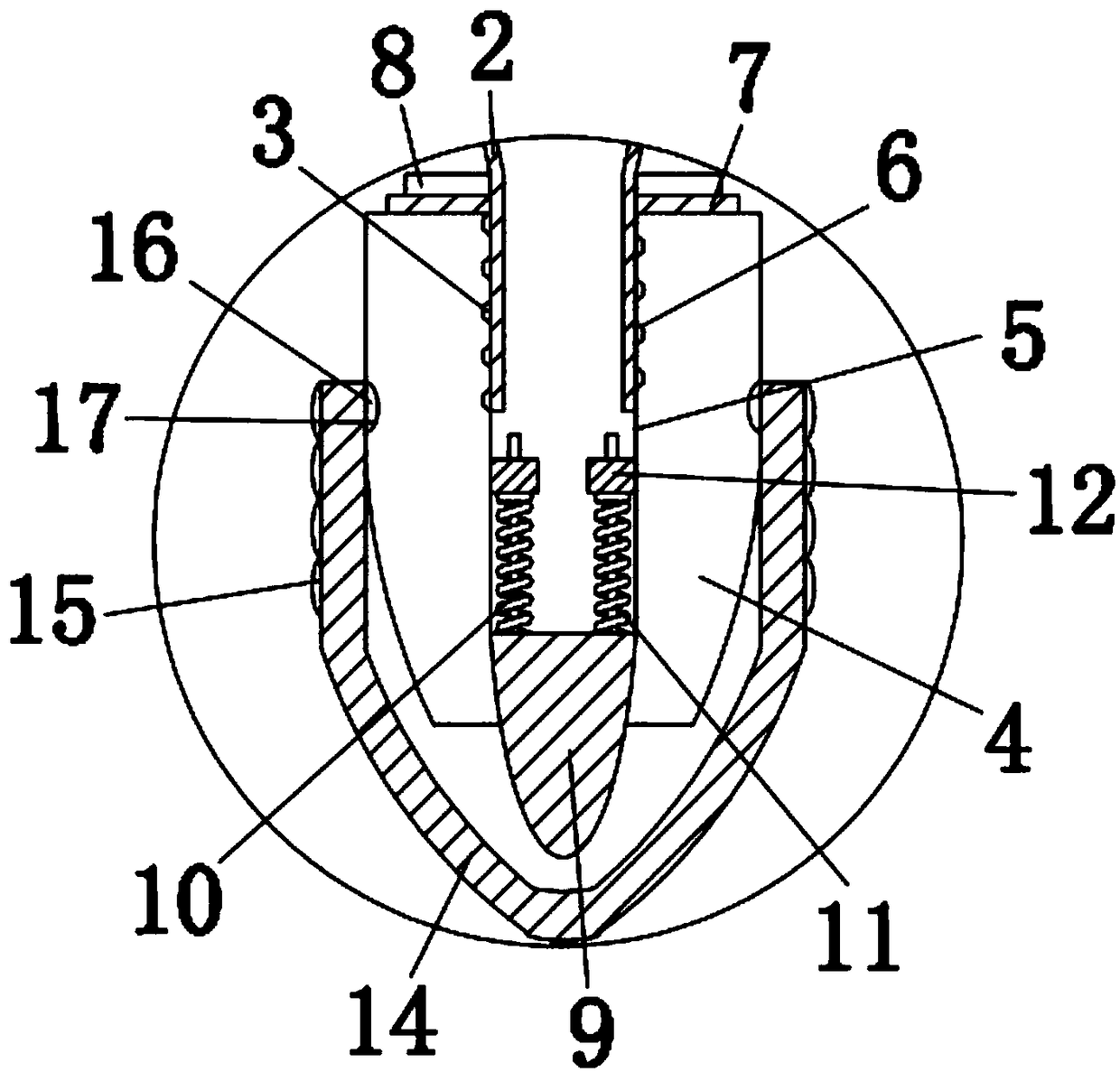

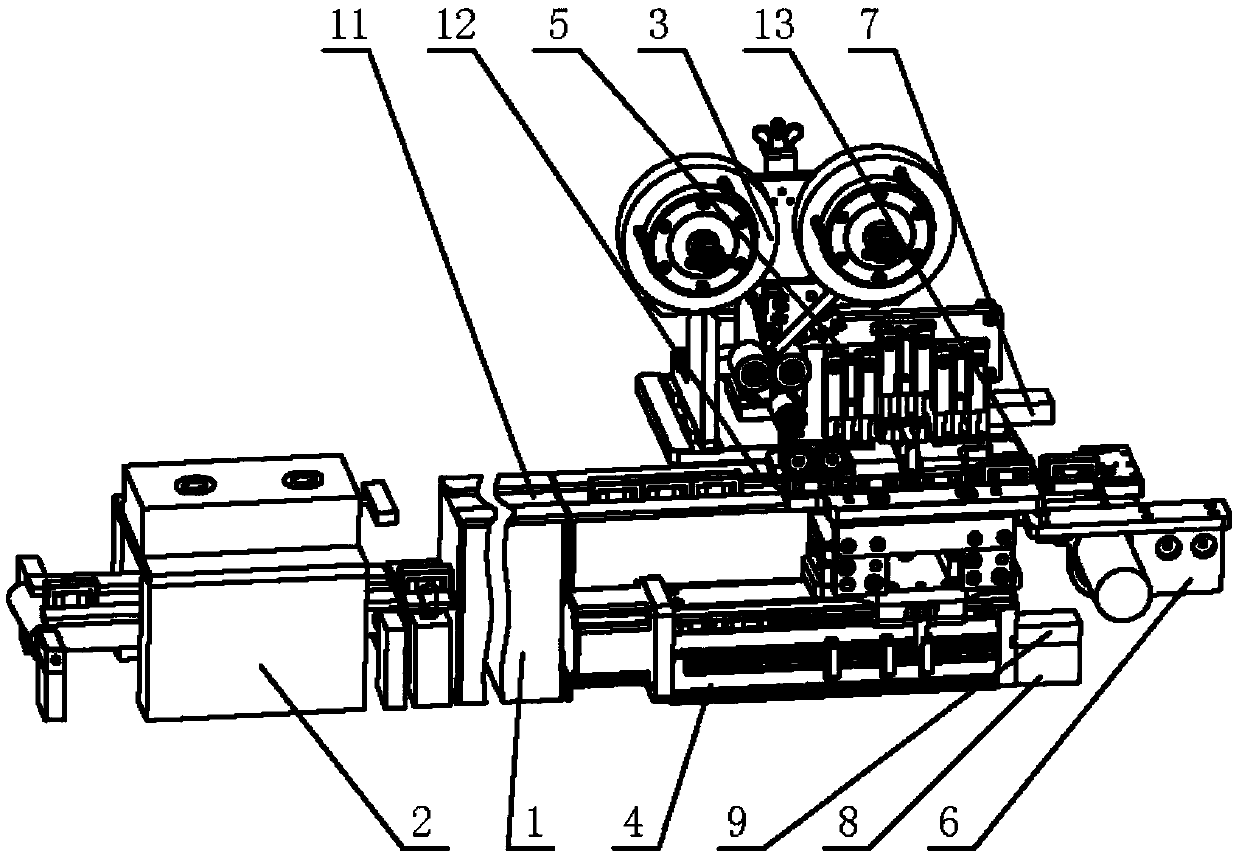

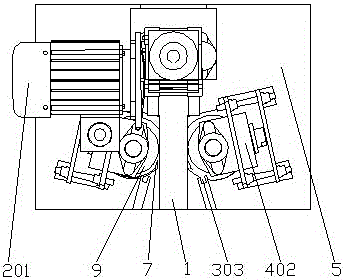

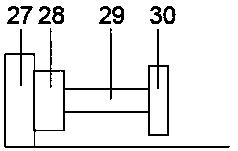

Pumping type automatic gluing apparatus

ActiveCN106040521AReasonable structureEasy to controlLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a pumping type automatic gluing apparatus, comprising a conveyer belt, a power mechanism, a feeding mechanism, a gluing mechanism and a workbench, wherein the feeding mechanism utilizes power provided by the power mechanism to convey glue to the gluing mechanism via a conduit for gluing, the power mechanism comprises an electric pump and a control panel controlling working of the electric pump, the gluing mechanism comprises one gluing motor and two gluing platforms, the centers of the two gluing platforms are respectively provided with gluing rollers horizontally rotating around the center shaft under the driving of the gluing motor, and the gluing rollers are respectively located at two sides of the conveyer belt. The pumping type automatic gluing apparatus is reasonable in structure, uniform in gluing and free of glue waste in usage, adjusts glue feeding amount according to product needs, and overcomes the technical problems that conventional gluing machines are unreasonable in structure and nonuniform in gluing, greatly waste glue in usage, cannot adjust glue feeding amounts according to product needs, etc.; compared with the prior art, the pumping type automatic gluing apparatus is a great technological innovation and has good market prospect and development space.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

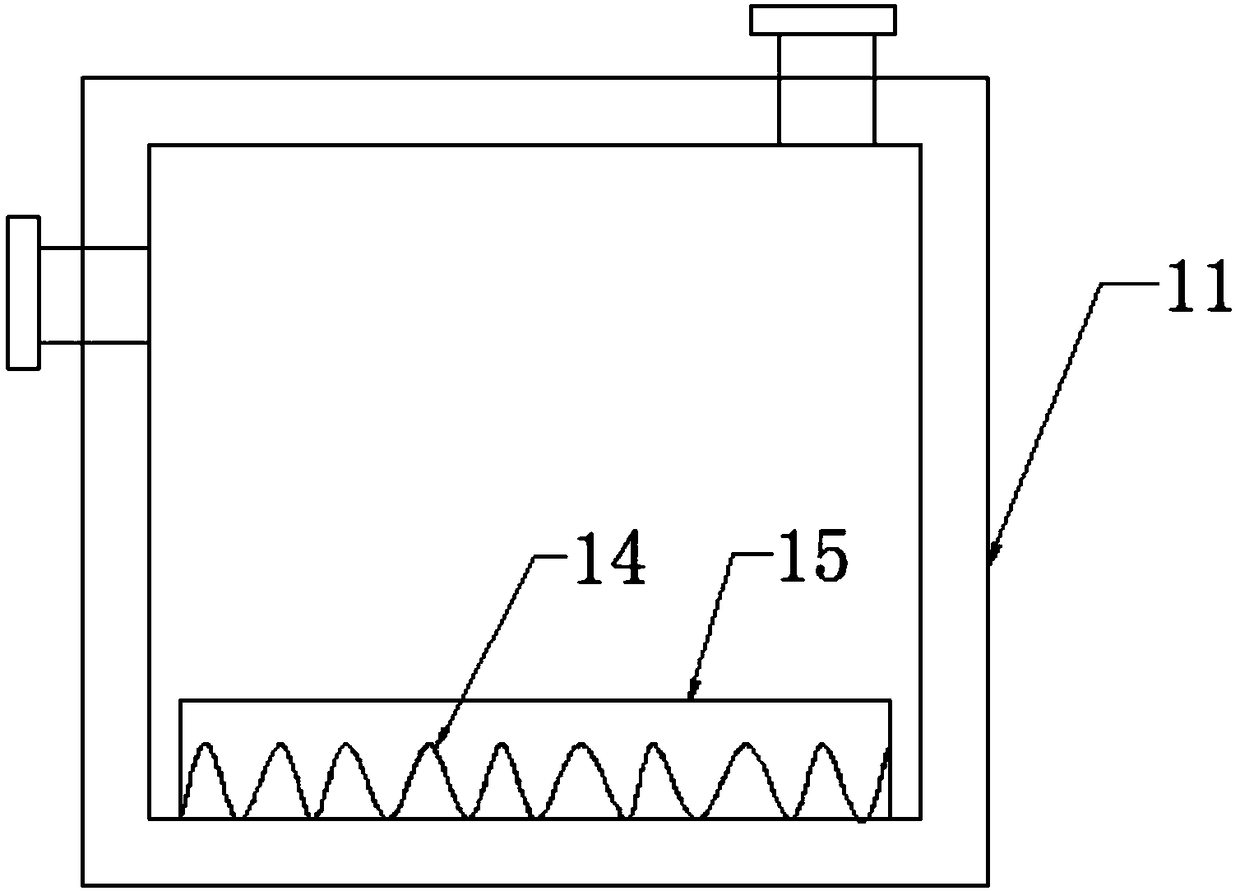

Automatic forming equipment for expandable polyethylene heat insulation cup sleeve

InactiveCN112971498ARealize automatic cutting operationRealize automatic glue applicationLiquid surface applicatorsCoatingsAutomatic processingMoulding device

The invention discloses automatic forming equipment for an expandable polyethylene heat insulation cup sleeve, and belongs to the technical field of automatic cup sleeve machining. The equipment comprises an expandable polyethylene unwinding frame, a mounting frame, an arc-shaped cotton moving device, an arc-shaped cutting device, an ironing and glue dispensing device, an automatic forming device and a forming and discharging device, wherein the expandable polyethylene unwinding frame is located at one end of the mounting frame, the arc-shaped cotton moving device is located below the mounting frame, the arc-shaped cutting device is arranged on the mounting frame, the ironing and glue dispensing device comprises an ironing and glue dispensing part and a glue dispensing and uniform smearing part, the ironing and glue dispensing part is arranged on the mounting frame, and the automatic forming device is arranged on the side of the arc-shaped cotton moving device. The automatic forming device comprises a supporting table, a coiling piece and a flattening piece, the coiling piece is located beside the arc-shaped cotton moving device, the flattening piece is located above the supporting table, and the forming and discharging device is located beside the automatic forming device. According to the invention, automatic processing and forming operation of the cup sleeve is realized, and the working efficiency is improved.

Owner:黄波

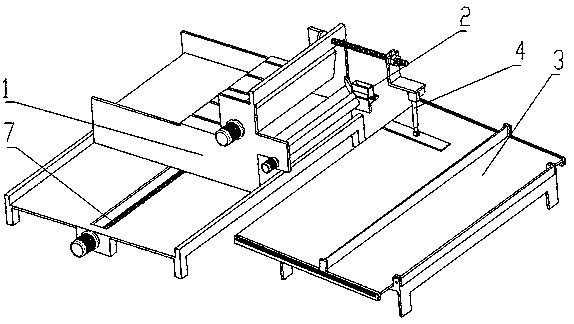

Plate splicing device

InactiveCN110253693ARealize automatic glue applicationImprove work efficiencyOther plywood/veneer working apparatusWood veneer joiningComputer engineering

The invention relates to a plate splicing device. The plate splicing device comprises a machine frame, wherein supporting legs are arranged on two sides of the bottom of the machine frame, fixable rolling wheels are fixedly installed on the supporting legs on the two sides, a control keyboard is arranged on one side of the machine frame, a working platform is arranged on the machine frame, a left supporting rod and a right supporting rod are arranged at the two ends of the working platform correspondingly, the tops of the left supporting rod and the right supporting rod are connected through a connecting rod, a sliding rail is arranged on the connecting rod, two sliding blocks are arranged on the sliding rail, a first plate splicing device and a second plate splicing device are fixedly installed under the two sliding blocks correspondingly, a groove is formed in the working platform, a plurality of partition plates are uniformly arranged on the groove, a glue pipe is arranged in the groove, a glue branch pipe is arranged on the glue pipe, a plurality of spray holes are uniformly formed in the glue branch pipe, glue brushes are arranged in gaps between the multiple partition plates, the glue pipe is connected to a glue box, the glue box is installed on one side of the machine frame, and a first fixing device and a second fixing device are arranged on the left side and the right side of the working platform respectively.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

High copper space factor double-fly-fork rotor winding machine

InactiveCN106899152ARealize automatic glue applicationAvoid the uninformedManufacturing dynamo-electric machinesWinding machineSolenoid valve

The invention discloses a winding machine for a double-flying-fork rotor with a high slot full rate, which comprises a glue application box, a threading hole, glue, a glue storage tank, a solenoid valve, a time controller, a drying tank, a blower, a heating wire and a frame. The copper wire is connected to the glue box through a threading hole, the glue box is connected to the glue storage tank through a pipeline, the servo motor is arranged on the top of the ball screw feeding platform, and the servo motor passes through The synchronous pulley is connected with the fly fork, and the rotor is arranged on the working shaft of the fixture motor. The double-flying-fork rotor winding machine with high slot full rate is equipped with a gluing device, which can realize automatic gluing of copper wires. The wire can reach a semi-dried state, so that the copper wire can be dried in the shortest time after being wound on the rotor, shortening the subsequent drying time, thereby improving production efficiency.

Owner:赵洁

Automatic carton sealing machine

ActiveCN112938035ARealize transportationImprove sealing efficiencyWrapper twisting/gatheringCartonStructural engineering

The invention relates to the technical field of packaging equipment, in particular to an automatic carton sealing machine. The automatic carton sealing machine comprises a conveying mechanism used for conveying a carton, and a material guiding mechanism, a gluing mechanism and a material pressing mechanism which are sequentially arranged in the movement direction of the carton; the material guiding mechanism comprises two abutting assemblies abutting against the two opposite sides of the carton correspondingly, and each abutting assembly is provided with two limiting rods sequentially arranged from top to bottom; the limiting rods located on the upper sides abut against the upper surface of the bent flange, and the limiting rods located on the lower sides abut against the outer wall of the carton; inclined rods are arranged on the sides, away from the output end of the conveying mechanism, of the limiting rods, and the distance between every two inclined rods oppositely arranged on the vertical face is gradually reduced in the moving direction of the carton; and the material pressing mechanism abuts against the upper surface of the bent flange. According to the automatic carton sealing machine, the carton sealing efficiency can be improved.

Owner:杭州彬特智能设备有限公司

Double-sided adhesive tape pasting device

PendingCN108612720AMeet the needs of useOvercoming the technical problem of low efficiency of manual glue applicationMaterial gluingAdhesiveMechanical engineering

The invention discloses a double-sided adhesive tape pasting device. A baffle plate comprises a movable baffle plate and a static baffle plate arranged on a tabletop; the movable baffle plate is provided with a fixed bar and a pressing screw; a long groove is formed in the fixed bar; the pressing screw penetrates through the long groove for fixing the movable baffle plate on the tabletop; a double-sided adhesive placing device comprises a rubber roller bracket, a rubber roller cross beam, a rubber roller vertical beam, and a rubber roller main body for fixing double-sided adhesive; the lower end of the rubber roller bracket is connected to two sides of the tabletop, and the upper end is connected with the rubber roller cross beam; the rubber roller cross beam is connected with the rubber roller main body through the rubber roller vertical beam; a double-sided adhesive pressure pasting device comprises an adhesive pressing roller bracket, an adhesive pressing roller cross beam, an adhesive pressing roller plate and an adhesive pressing roller main body; the lower end of the adhesive pressing roller bracket is connected to two sides of the tabletop, and the upper end is connected with the adhesive pressing roller cross beam; the adhesive pressing roller cross beam is connected with the adhesive pressing roller main body through the adhesive pressing roller plate; two extrusion rollers are provided; the extrusion rollers are connected with extrusion roller fixed plates through extrusion roller shafts; and the extrusion roller fixed plates are connected to the tabletop. The double-sided adhesive tape pasting device overcomes the technical problem of lower manual adhesive pasting efficiency in the prior art.

Owner:镇江立达纤维工业有限责任公司

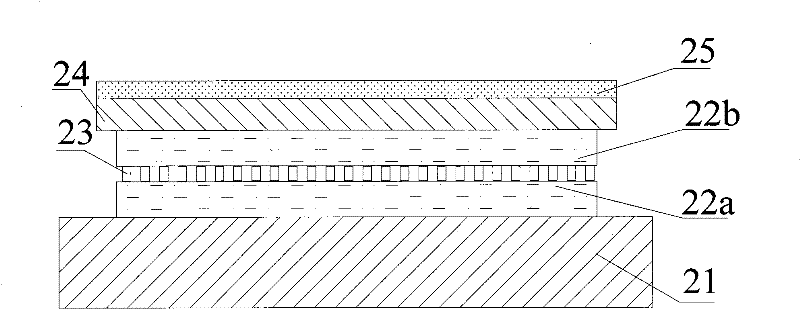

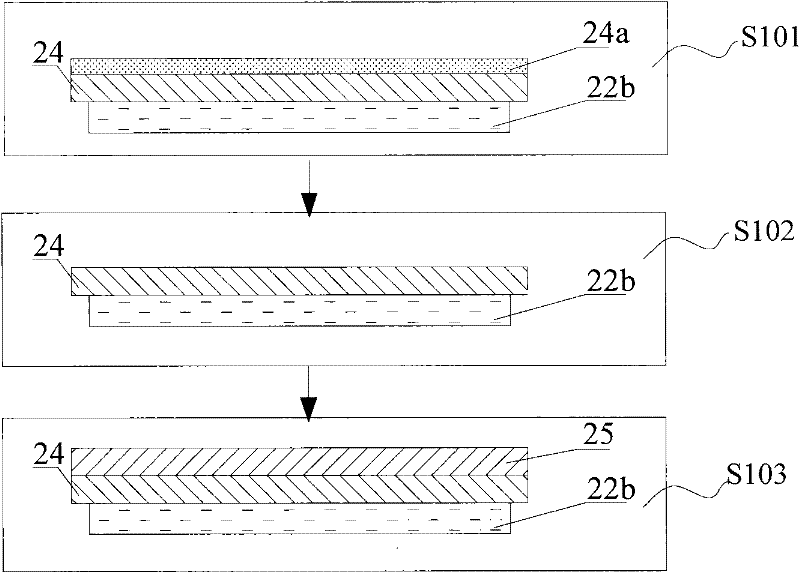

Coating device and coating method for optical cement

InactiveCN101884971BRealize automatic glue applicationContinuous and stable productionPretreated surfacesCoatingsBiochemical engineeringCoating

The invention provides a coating device for optical cement, which comprises a tray for bearing a conductive layer, a driving device arranged below the tray and used for driving the tray to rotate, and a vacuum tank arranged below the tray and used for forming negative pressure to adsorb the conductive layer on the tray, wherein the tray comprises a circular bearing part for bearing the conductivelayer and an edge part connected on the periphery of the circular bearing part, and the circular bearing part is provided with a vacuum passage; the vacuum tank comprises a circular shell and a bottom wall connected at the bottom of the circular shell; and a rotating shaft of the driving device passes through the bottom wall and is connected with the tray, the top end of the circular shell is rotationally and hermetically connected with the tray, and the vacuum passage is communicated with the vacuum tank. The coating device provided by the invention can realize automatic coating of the conductive layer, is favorable for realizing continuous and stable production of the coating process, and improves the production efficiency. Moreover, the liquid optical cement can avoid bubbles during rotary coating, and is favorable for improving the yield of a product.

Owner:徐天龙

Glue pasting mechanism for foam

PendingCN112850317ARealize glueRealize automatic glue applicationArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses glue pasting mechanism for foam. The glue pasting mechanism for the foam comprises a machine frame, a feeding device and a glue pasting device, the feeding device comprises an unwinding assembly and a winding assembly which are arranged on the machine frame, the unwinding assembly and the winding assembly are arranged in a spaced mode, the two ends of foam are folded in the unwinding assembly and the winding assembly respectively so that the foam can be conveyed, the glue pasting device comprises a glue pasting assembly and a glue pressing assembly which are arranged on the machine frame, the glue pressing assembly is located between the glue pasting assembly and the winding assembly, the glue pasting assembly is used for mounting a glue pasting piece, and the glue pressing assembly presses a part, away from the glue pasting assembly, of the glue pasting piece to the foam so as to be tightly attached. According to the glue pasting mechanism for the foam, automatic glue pasting of the foam is achieved through a mechanical structure, the production efficiency is improved, and the consistency of the foam after glue pasting can be improved.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD +1

A test paper sealing device that can realize automatic gluing

ActiveCN113043774BRealize automatic glue applicationEasy to useEnvelope closersAdhesive glueIndustrial engineering

Owner:HUNAN INSTITUTE OF ENGINEERING

A kind of battery automatic pasting glue method

ActiveCN110212207BRealize automatic glue applicationPrimary cell manufactureFinal product manufactureAdhesiveMechanical engineering

The invention relates to a method for automatic battery gluing, which includes providing an automatic battery gluing device, which includes a base platform, a bearing platform, a feeding belt and a feeding belt, and the automatic battery gluing equipment also includes a feeding guide rail, a feeding Cylinders, sliding parts, horizontal frames and vertical frames, battery automatic adhesive equipment also includes fixed table, first adhesive feeding table, second adhesive feeding table, adhesive parts, adhesive connecting parts, adhesive cylinder and adhesive guide rail; The method includes: the gluing cylinder pushes out the gluing parts, and the gluing parts drive the special-shaped rubber strips to move; The special-shaped glue is attached to the battery core; the suction nozzle moves the battery on the loading platform to the unloading belt. The suction nozzle moves the battery cells on the feeding belt to the loading table, and the glue stick moves to the top of the battery cells along the glue guide rail, and the glue stick cylinder pushes the glue stick, and the glue stick moves down to automatically attach the special-shaped glue to the battery cells Tail, so as to complete the automatic glue application and improve the glue application efficiency.

Owner:JIADE ENERGY TECH (ZHUHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com