Leather adhesion assistant gluing equipment

A technology of gluing and equipment, applied in lamination auxiliary operations, clothing, lamination devices, etc., can solve the problems of heavy workload and low work efficiency, and achieve the effect of fast gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

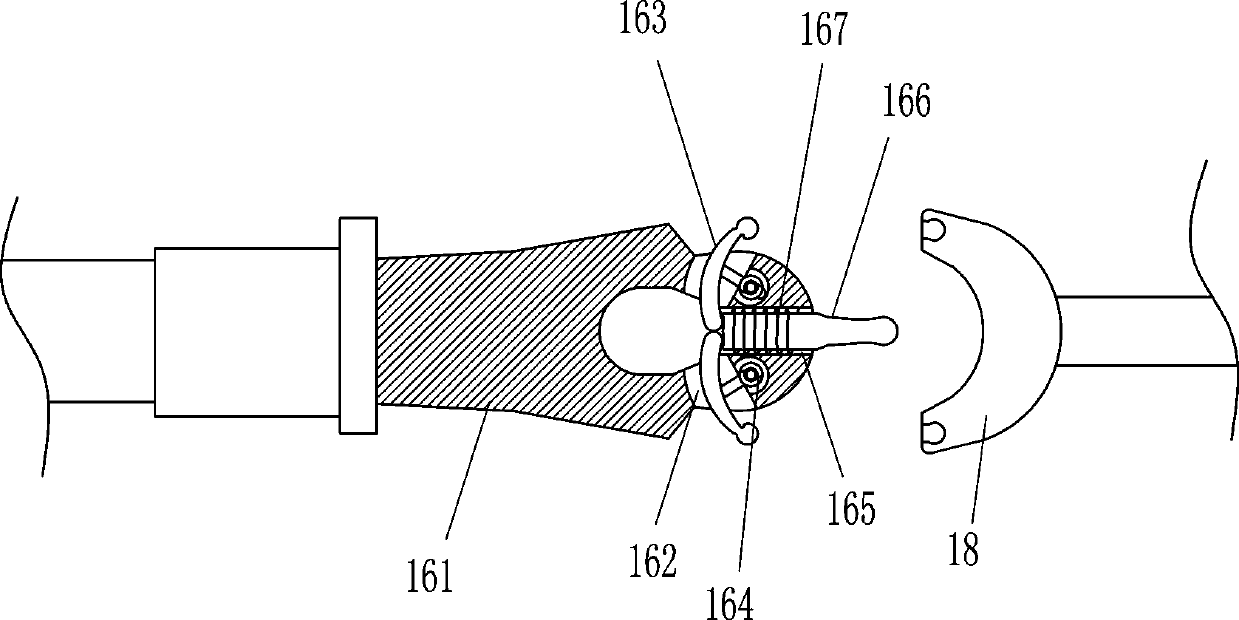

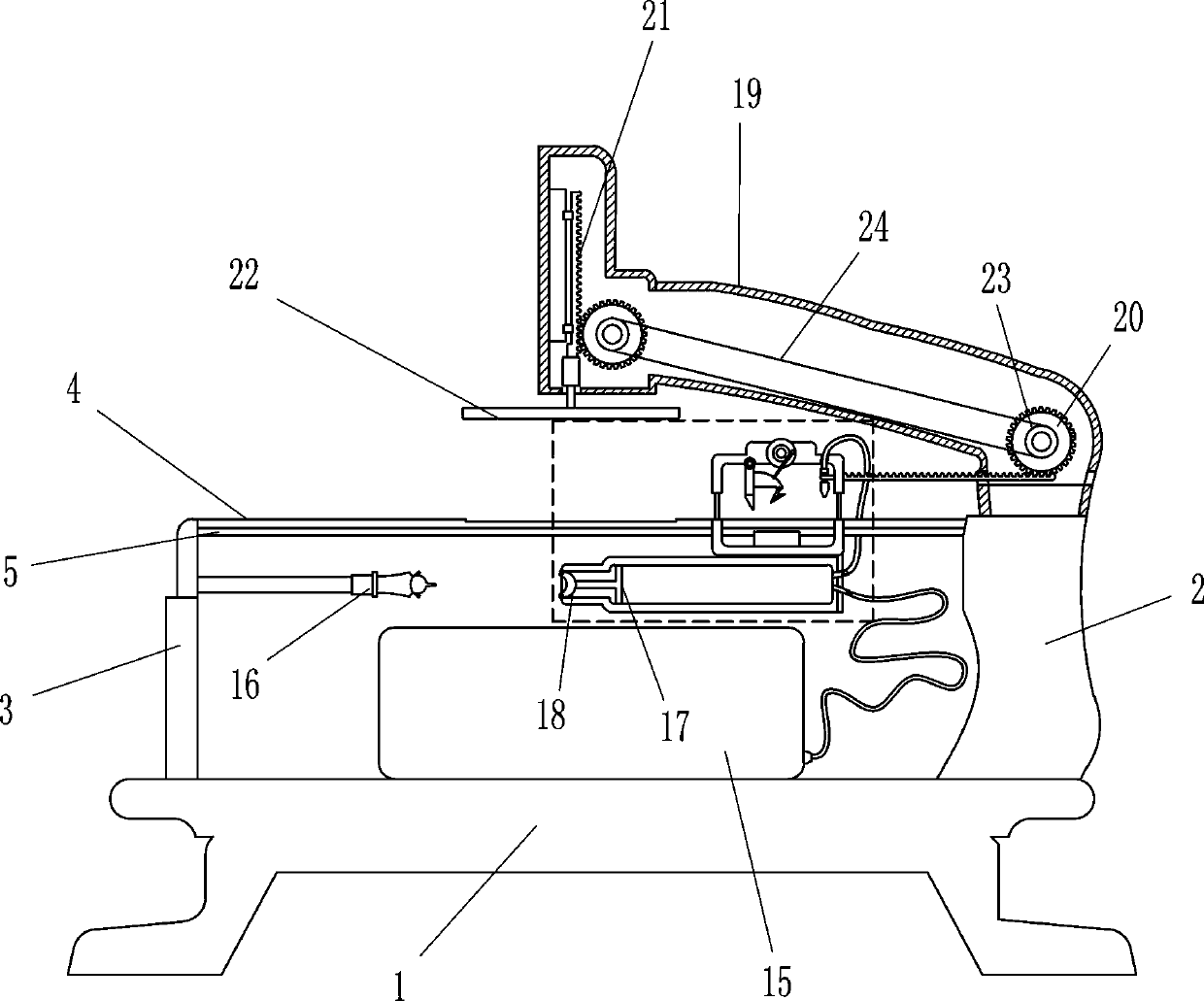

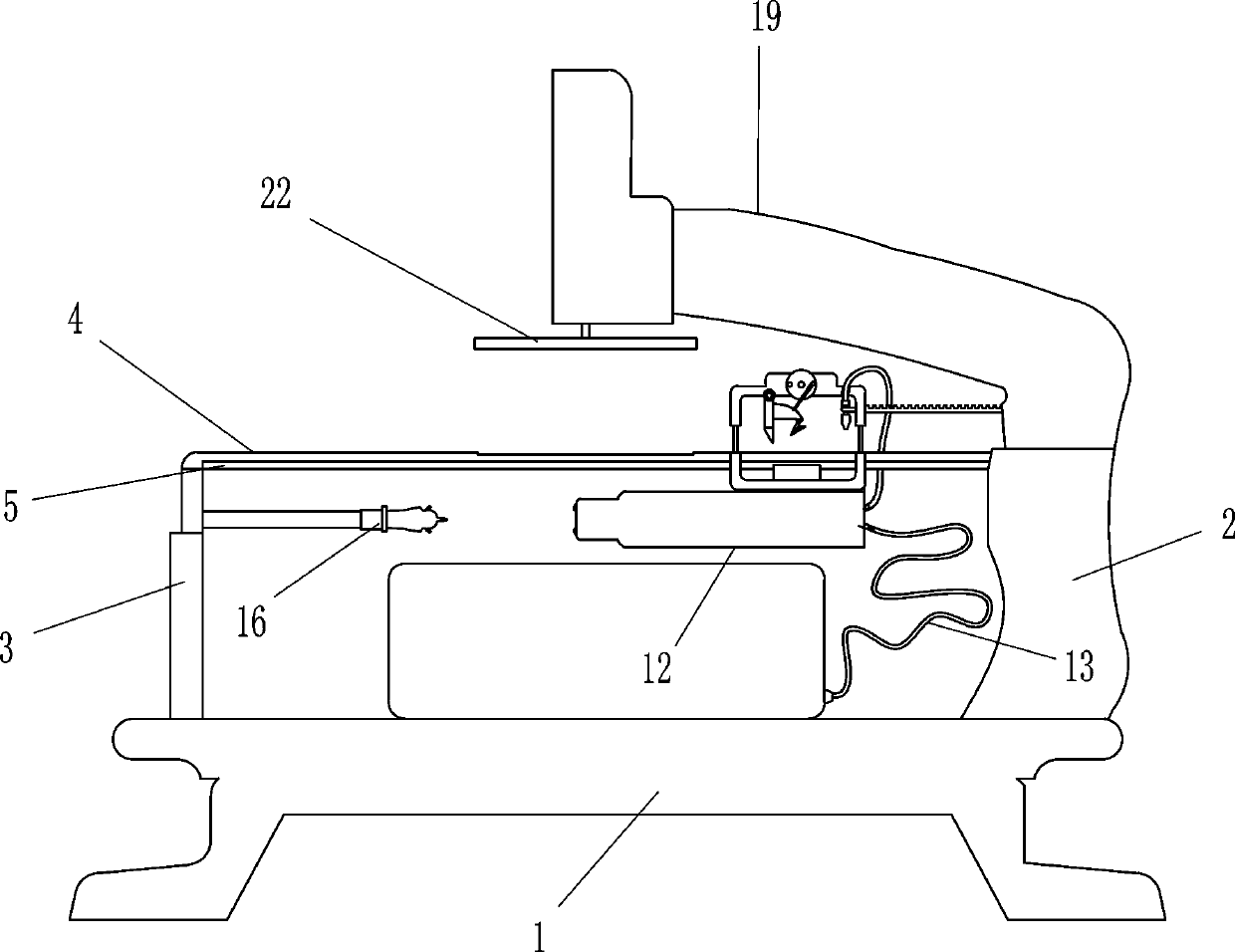

[0018] Such as Figure 1-4 As shown, a leather bonding auxiliary gluing equipment includes an organic base 1, a fixed frame 2, a connecting frame 3, a workbench 4, a sliding track 5, a sliding block 6, a U-shaped frame 7, a sliding rod 8, a first elastic Part 9, installation frame 10, nozzle 11, cylinder body 12, hose 13, one-way valve 14, rubber box 15, pushing device 16, piston 17 and clamping block 18, and frame 1 is provided with fixed frame 2, connecting The frame 3 and the plastic box 15, the fixed frame 2 and the connecting frame 3 are provided with a workbench 4, and the front and rear side walls of the workbench 4 are all provided with a sliding track 5, and the slide track 5 is slidably provided with a sliding block 6, and the sliding block 6 are provided with a U-shaped frame 7, and the U-shaped frame 7 has a cylindrical groove, and a sliding rod 8 is slidably arranged in the cylindrical groove, and a first elastic member 9 is arranged between the sliding rod 8 and ...

Embodiment 2

[0023] Such as Figure 1-3 Shown, on the basis of embodiment 1, also comprise frame 19, gear 20, tooth bar 21, pressing plate 22, belt pulley 23 and flat belt 24, be connected with frame 19 by the mode of bolt connection on the fixed mount 2, machine The left side and the right side in the frame 19 are all rotatably provided with gears 20, and the front sides of the two gears 20 are all provided with pulleys 23, and a flat belt 24 is wound between the two pulleys 23, and the left wall of the frame 19 is slidably provided with racks. 21. The rack 21 meshes with the left gear 20. The lower part of the rack 21 passes through the frame 19 and is connected with a pressure plate 22 through bolt connection. The right side of the mounting frame 10 is provided with a rack 21, and the rack 21 passes through the frame 19 Meshes with the right gear 20.

[0024] This device is used in this way, and the specific usage method is as follows: the staff pushes the mounting frame 10 to move to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com