Patents

Literature

154results about How to "Quick Glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photosensitive PRP (platelet-rich plasma) gel and preparation method and application thereof

ActiveCN106822183ATightly boundSeamless integrationSurgical adhesivesAerosol deliveryChemical reactionBlood plasma

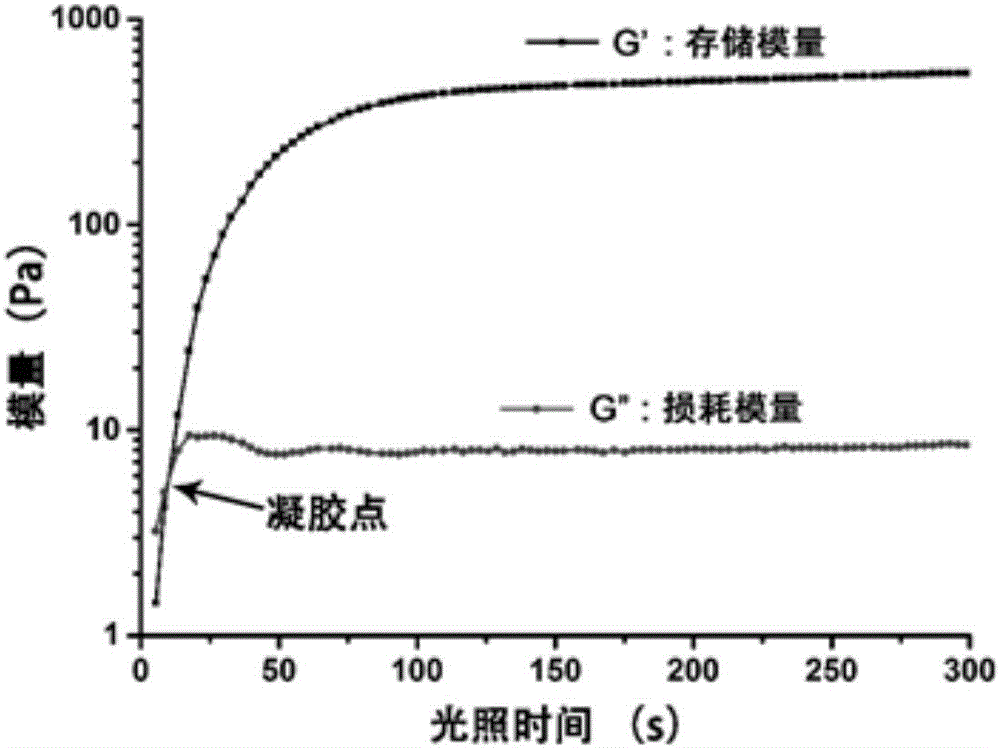

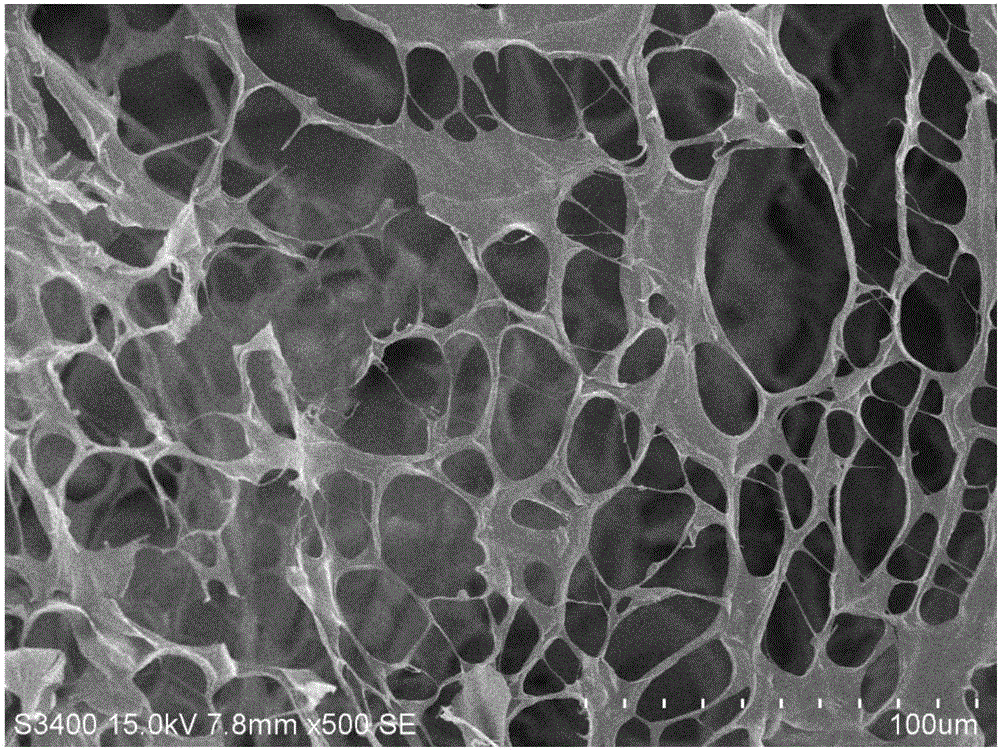

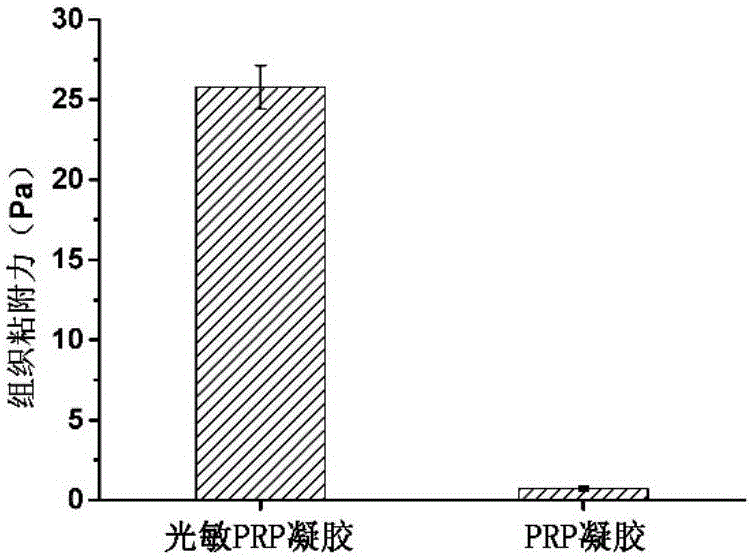

The invention relates to a photosensitive PRP (platelet-rich plasma) gel and a preparation method and application thereof. The preparation method comprises the following steps of mixing a biocompatible medium solution of a macromolecule modified by an o-nitrobenzyl photo response group and an extracted PRP according to a certain ratio, so as to form a gel precursor solution; then, radiating the gel precursor solution by light, and enabling the o-nitrobenzyl group in the macromolecule modified by the o-nitrobenzyl photo response group to generate photochemical reaction under the excitation action of a light source, so as to produce an aldehyde functional group; generating coupling reaction with amino distributed at the surface of the protein in the PRP to form an imine bond, so as to realize the preparation of the photosensitive PRP gel. Compared with the prior art, the photosensitive PRP gel prepared by the method has the advantages that the internal cell factors can be slowly released, and the tight and seamless bonding between the PRP gel and wounds is realized.

Owner:ZHONGSHAN GUANGHE MEDICAL TECH CO LTD

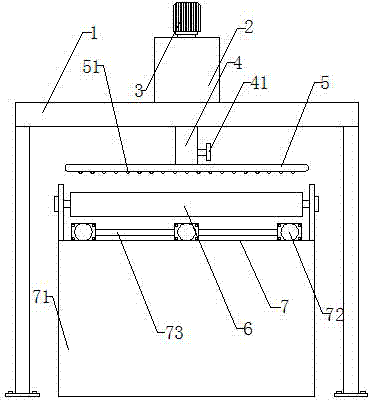

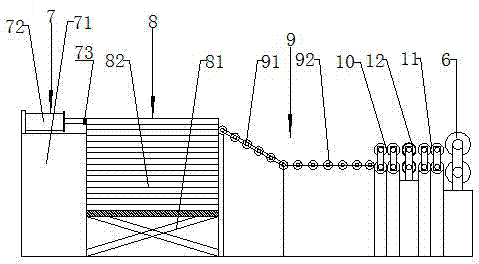

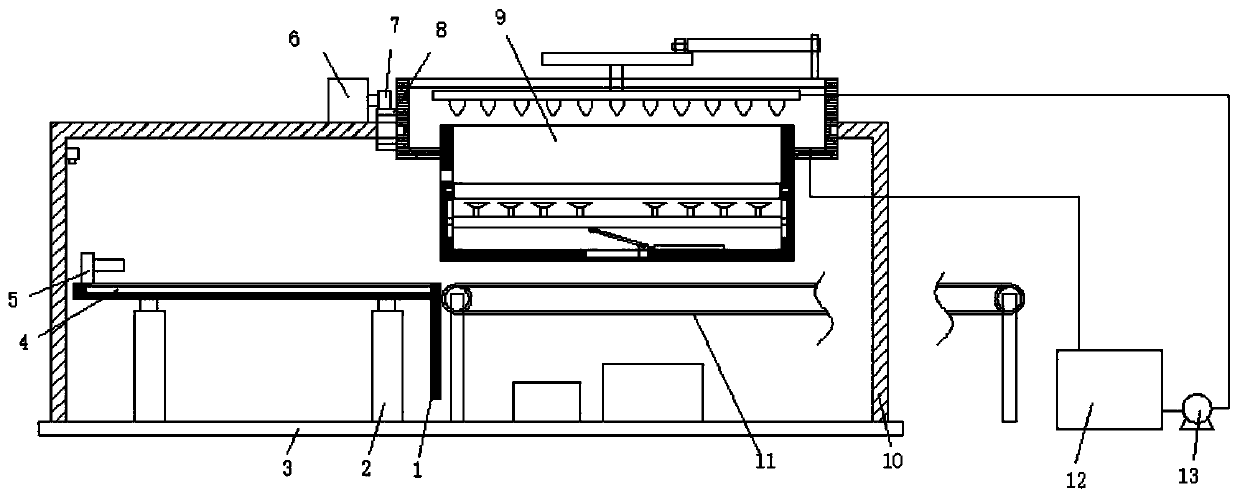

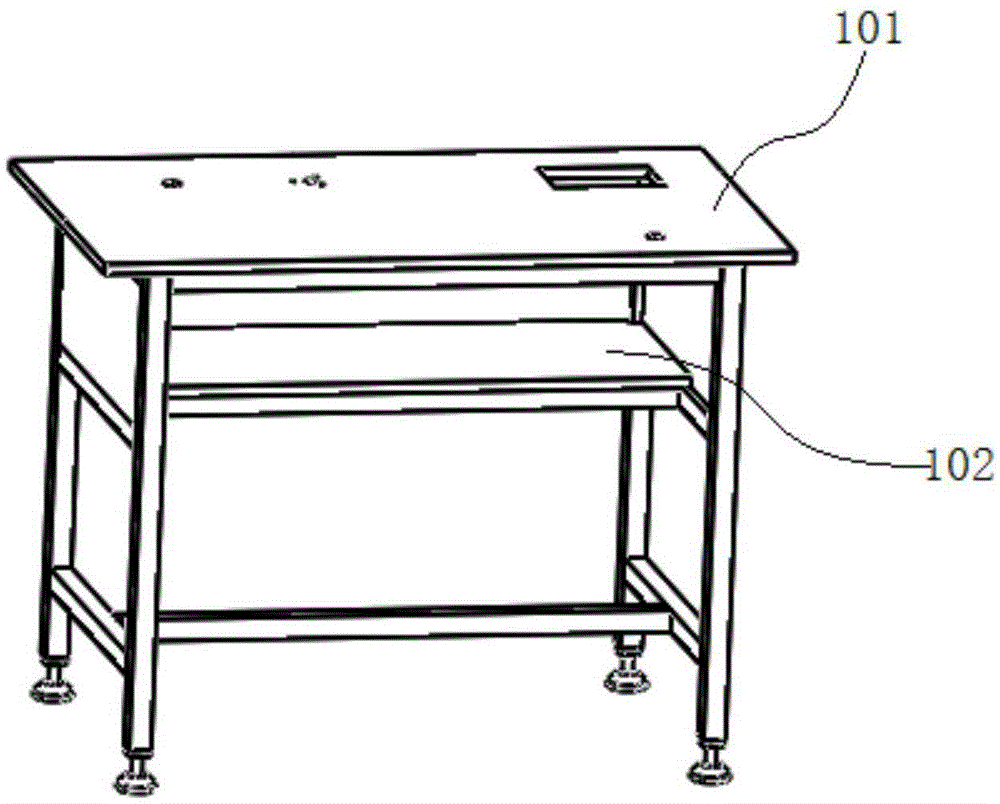

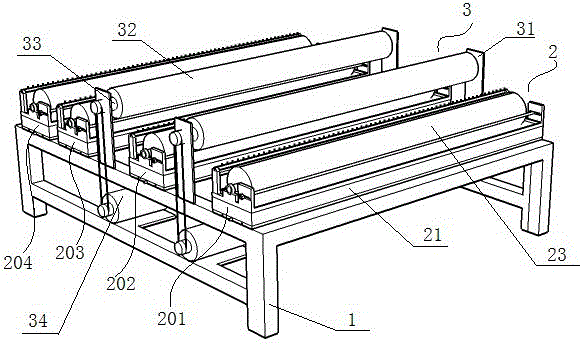

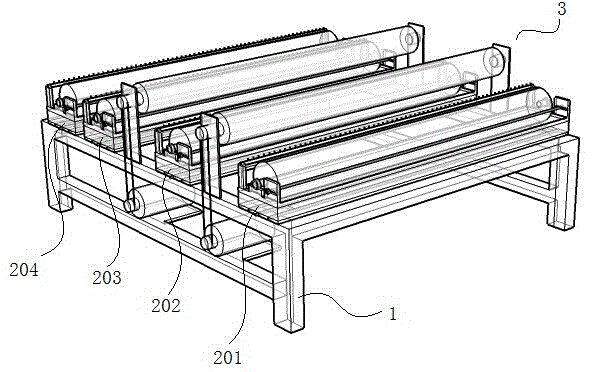

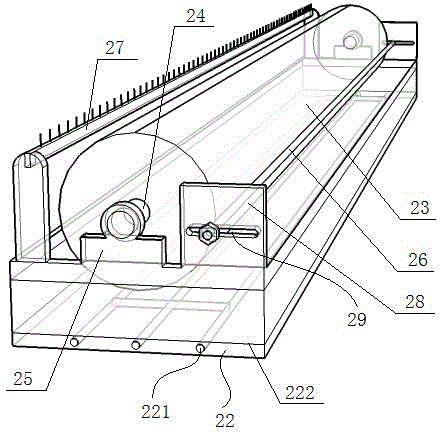

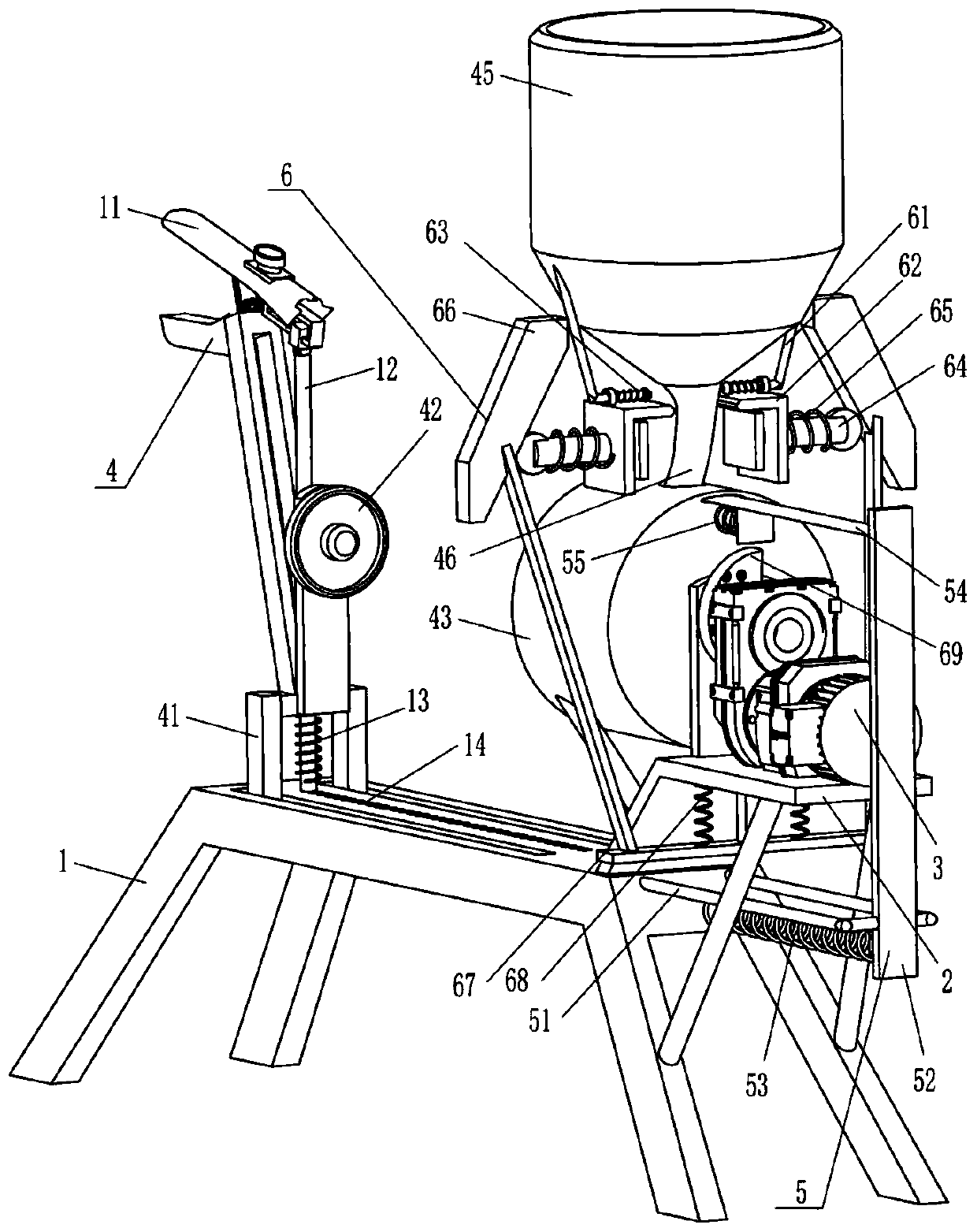

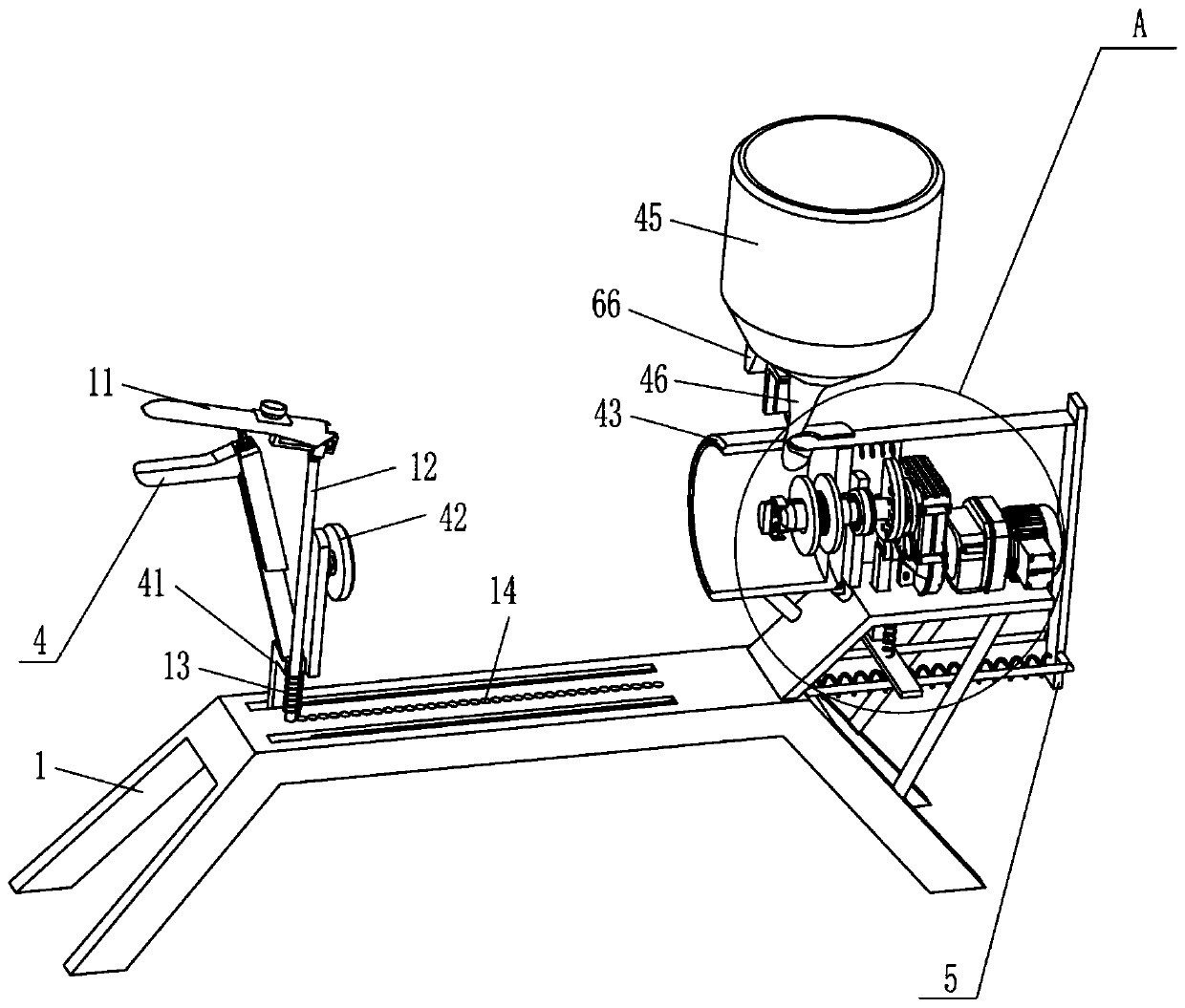

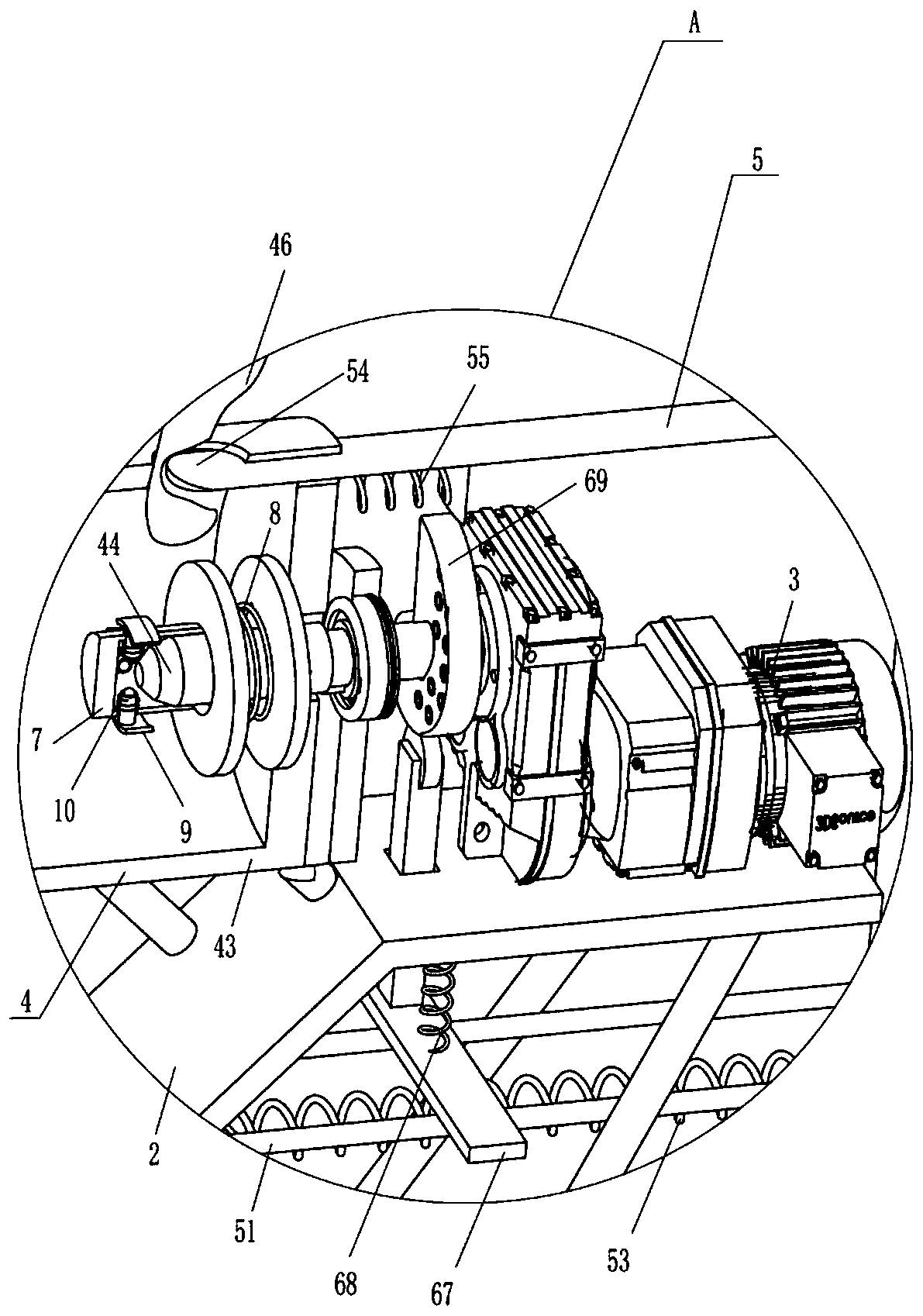

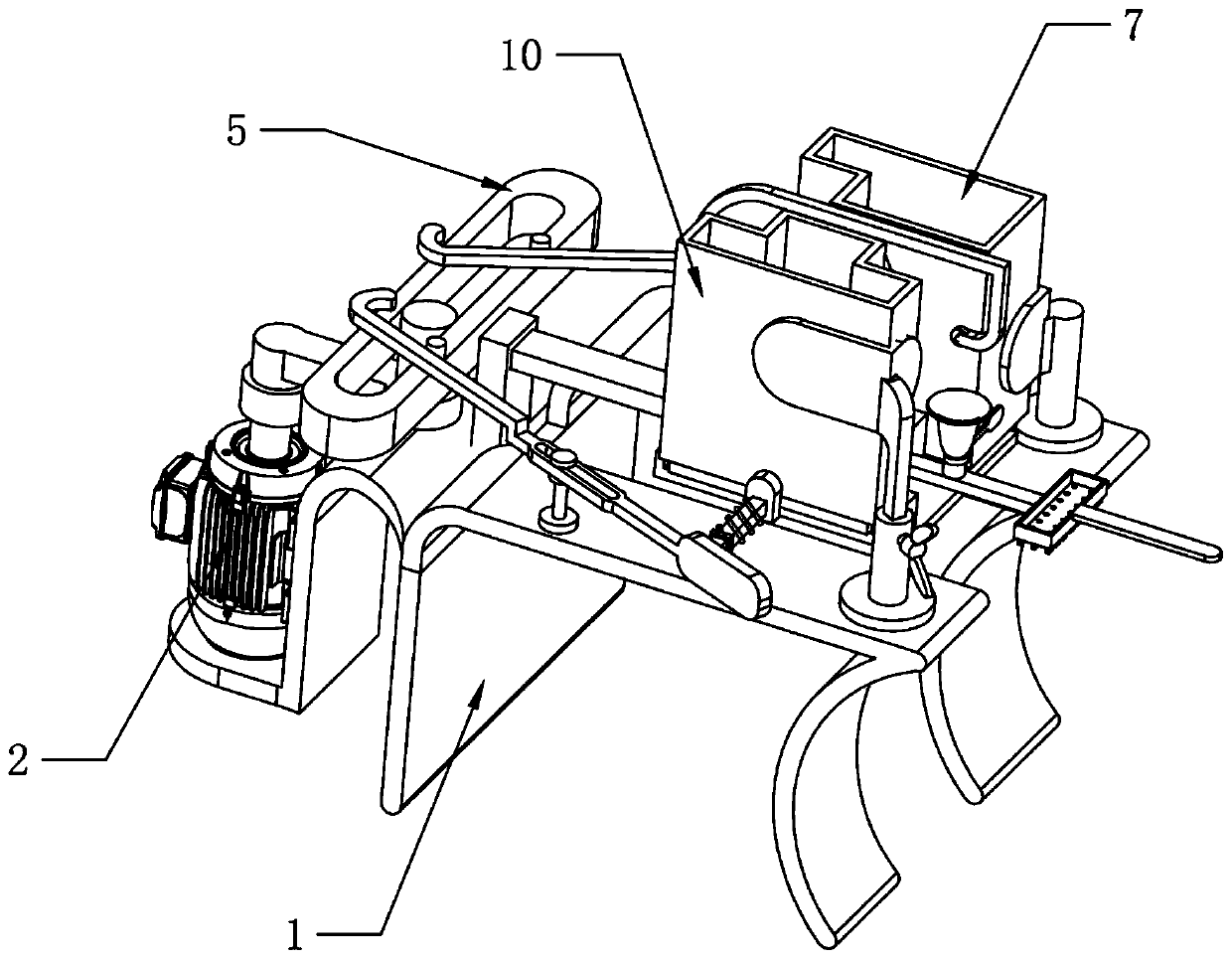

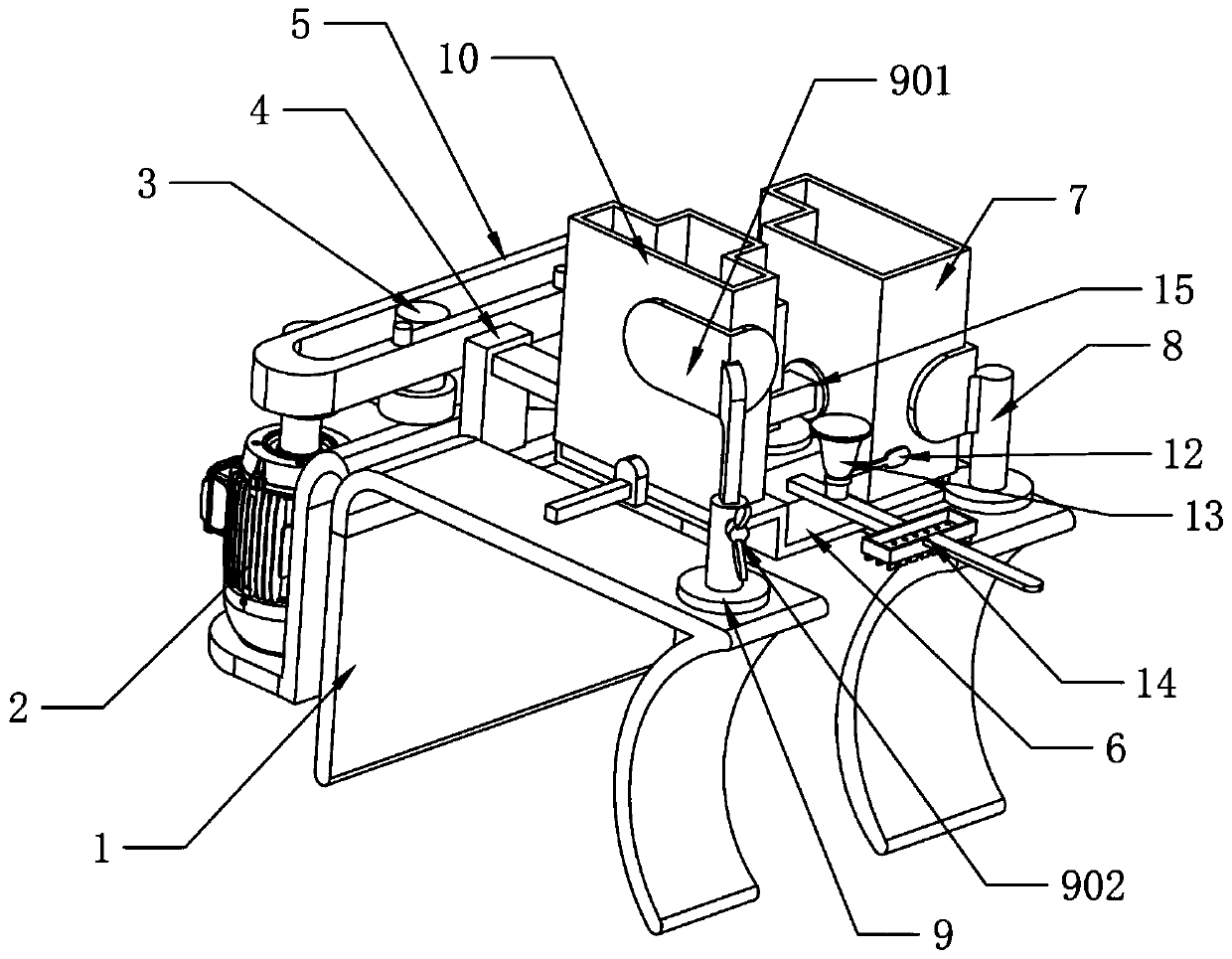

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

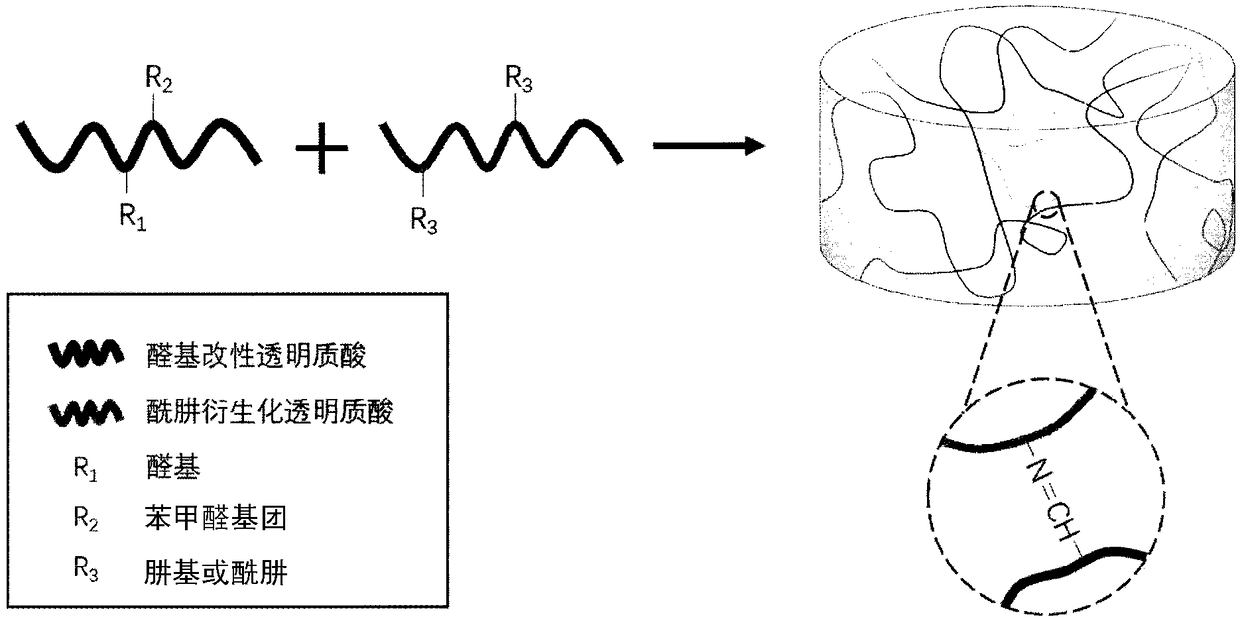

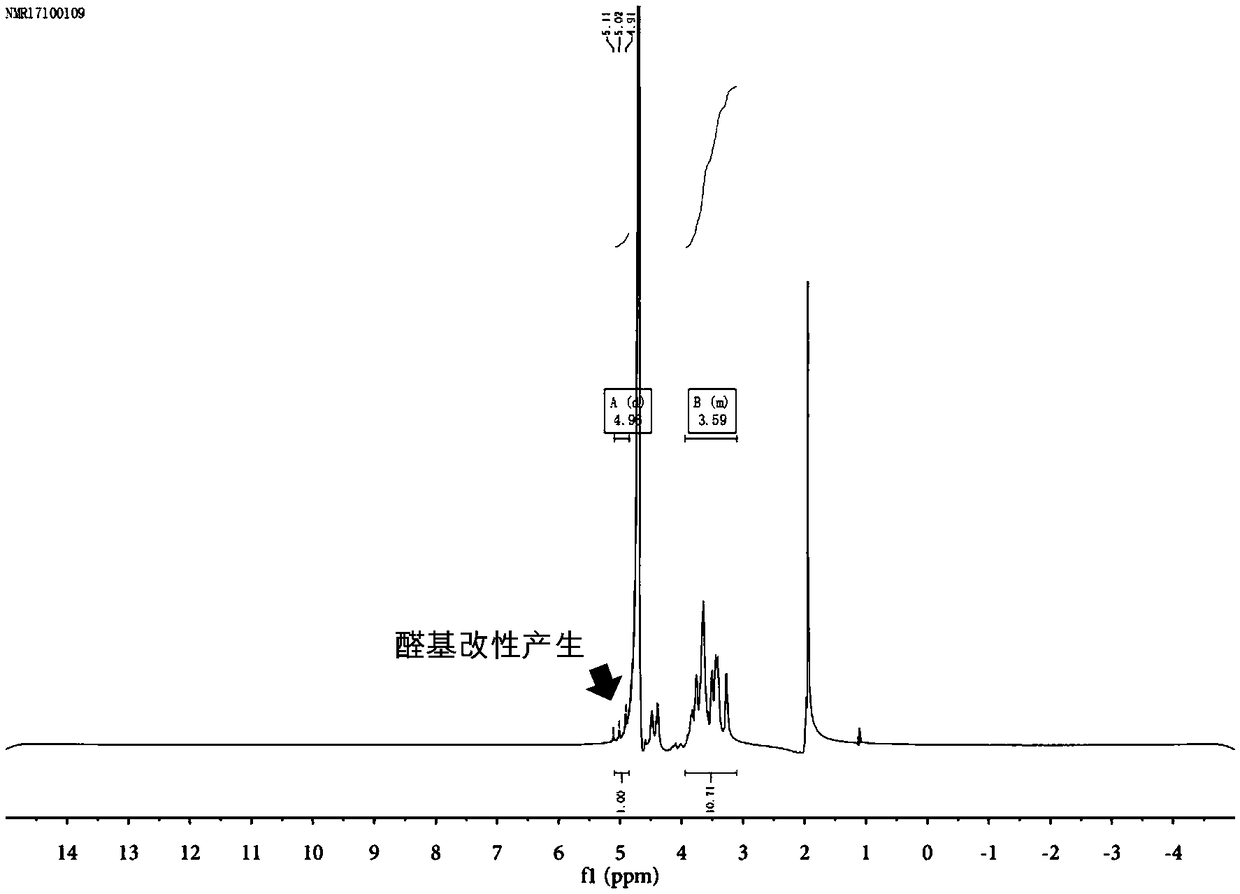

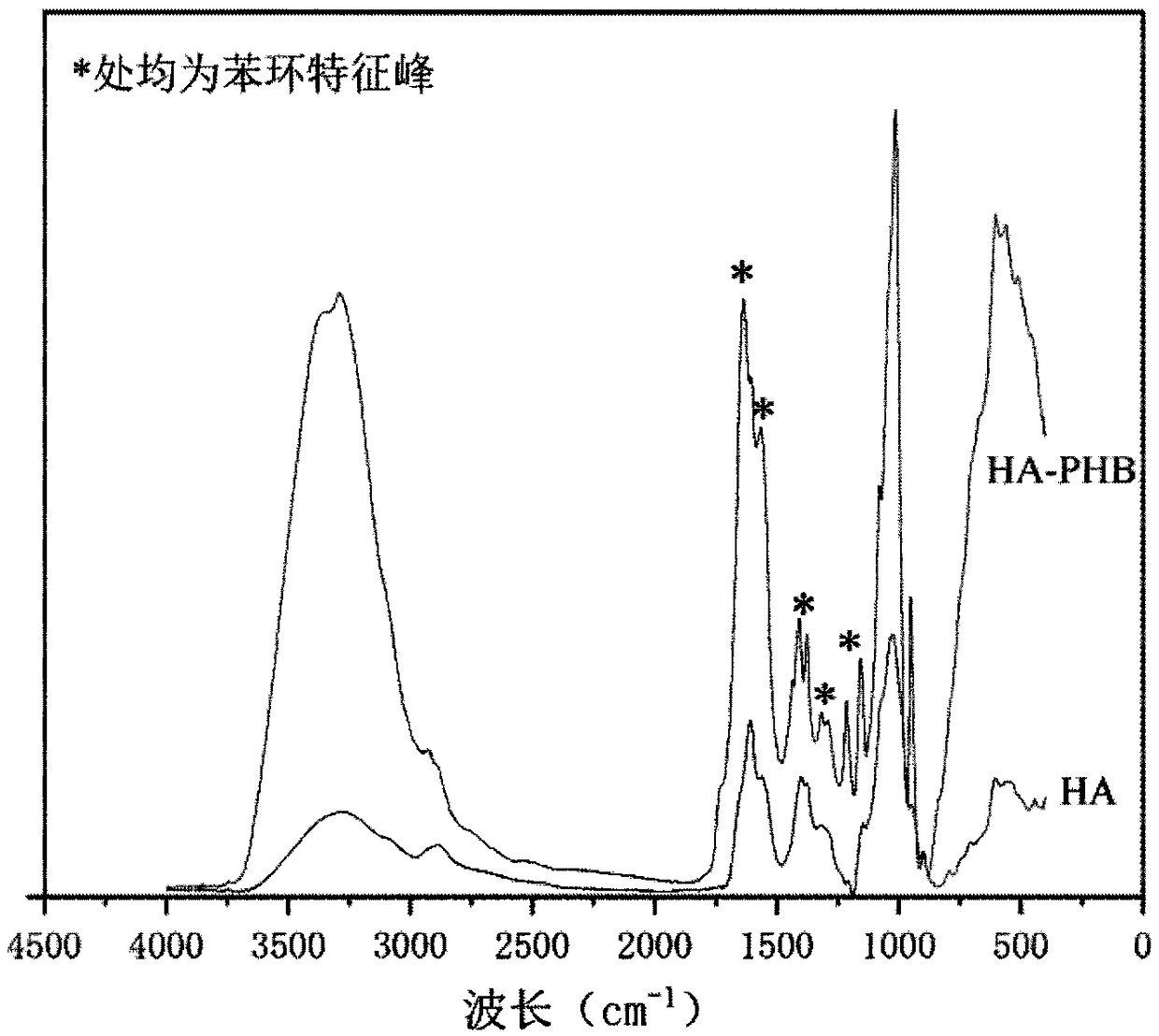

Hydrogel compound, preparation method and application

The invention provides a hydrogel compound, a preparation method and the application. The preparation method comprises the following steps: (1), preparing a hyaluronic acid solution; (2), preparing aldehyde-based modified hyaluronic acid; (3), preparing hydrazide derivatization hyaluronic acid; (4), mixing the aldehyde-based modified hyaluronic acid and the hydrazide derivatization hyaluronic acidinto hydrogel. The method ensures that a final product can be matched with a clinical arthroscopy on the basis of guaranteeing excellent biocompatibility through modification on hyaluronic acid, ensures that hydrogel is rapidly formed in any defective parts through one-time minimally invasive injection, can be further tightly adhered to the defective parts, so as to reduce burden of patients as far as possible, and achieve the effect of promotion of cartilage repair.

Owner:JIANGSU DISSUETECH MEDICAL TECH CO LTD

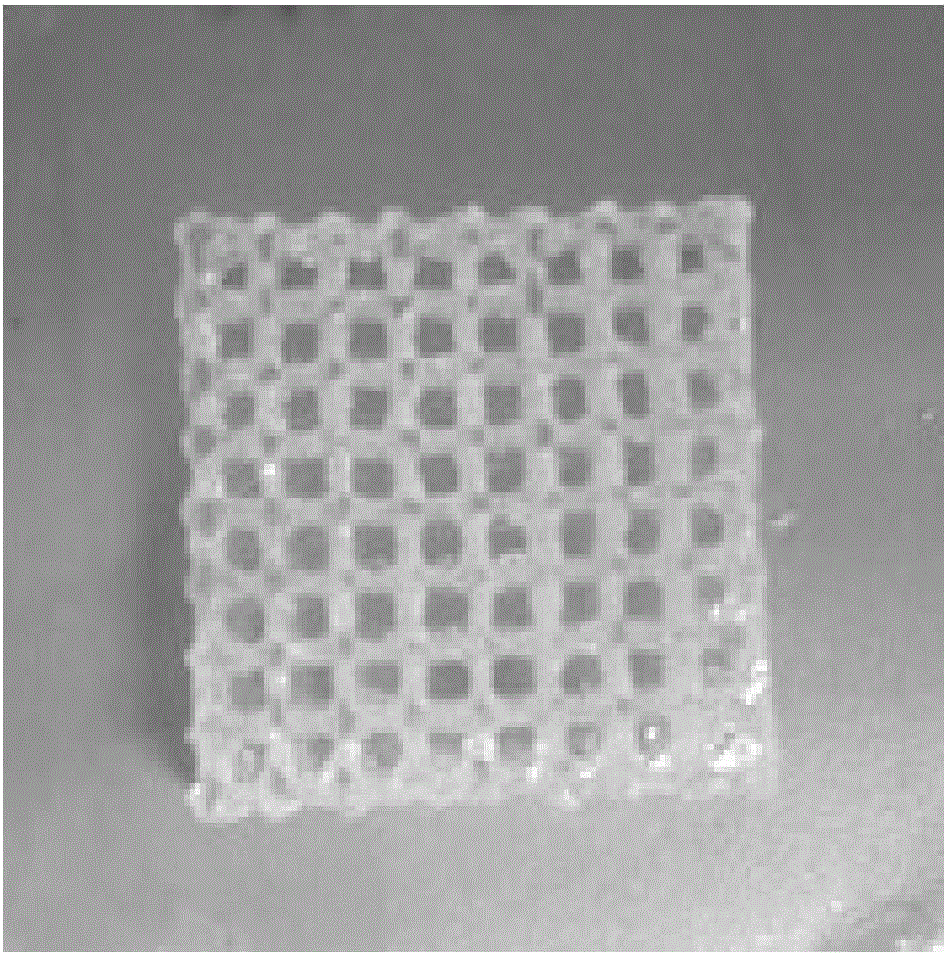

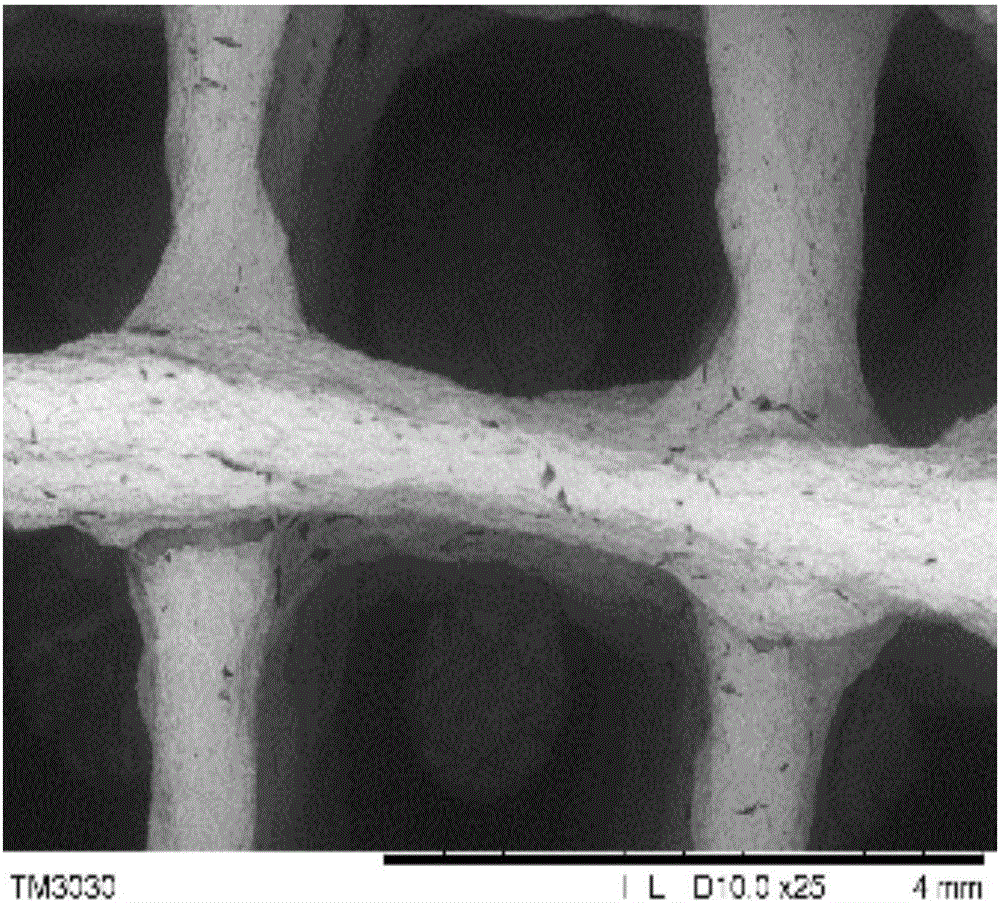

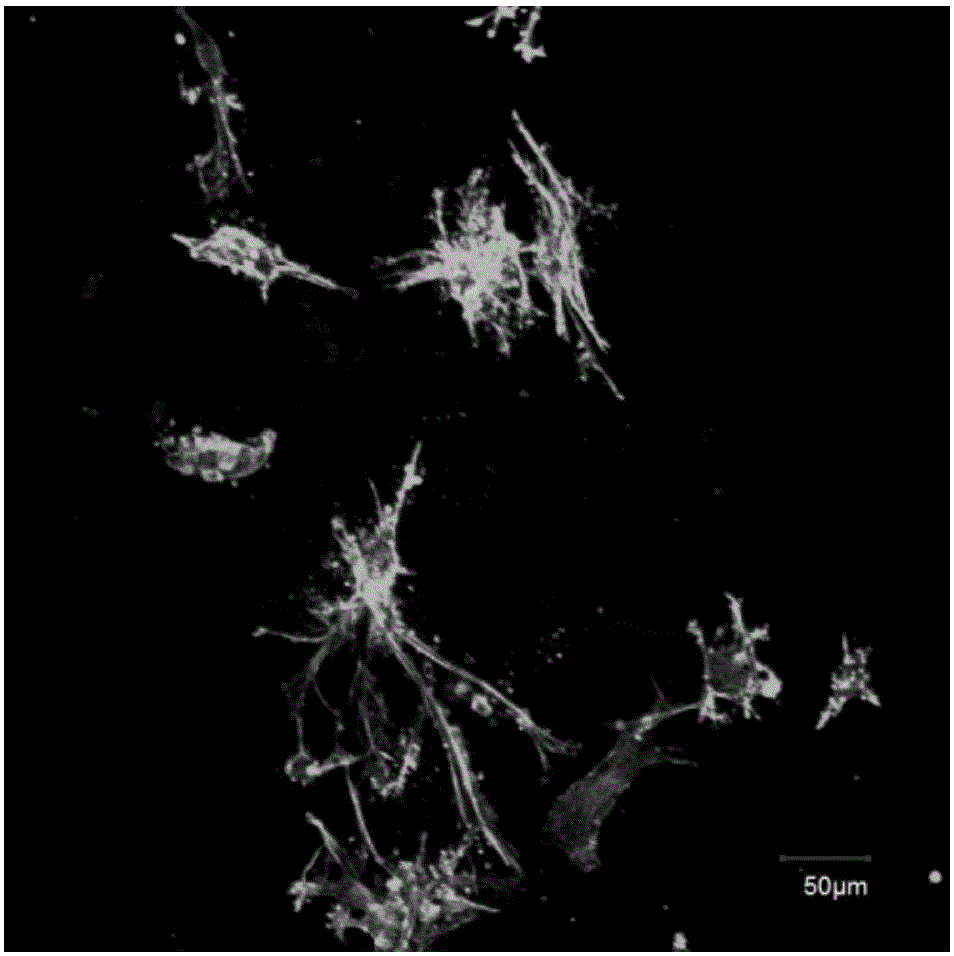

Hydrogel material for 3D bioprinting and preparation method and application of hydrogel material

ActiveCN106474560AGood compatibilityImprove structural stabilityAdditive manufacturing apparatusProsthesisHigh cellSolvent

The invention belongs to the technical field of biological materials, and discloses a hydrogel material for 3D bioprinting and a preparation method and application of the hydrogel material. The hydrogel material comprises the following components in percentages by mass: 0.5-10% of gellan gum and / or derivatives, 0.1-20% of PEG and / or derivatives thereof, 0-1% of a crosslinking initiator, 0-15% of biologically active components and the balance of a solvent. The hydrogel material is double-network hydrogel based on the gellan gum and PEG; interpenetrating double-network structures are formed in a physiological environment; and the hydrogel material has good structure and dimensional stability, and has the advantages of quick gum formation under physiological conditions, excellent cell compatibility, small immunological rejection, high cell encapsulation efficiency, controllable mechanical strength, biodegradability and the like. The hydrogel material is applied to 3D bioprinting; the shortcomings of low curing speed, harsh curing conditions, limited mechanical properties, poor cell compatibility and the like are overcome; and the hydrogel material has obvious advantages and good industrialized prospect.

Owner:JINAN UNIVERSITY

Efficient gluing device for plywood

InactiveCN110027066AApply glue evenlyGood gluing effectGlue gunsLoading/unloadingEngineeringAutomation

The invention belongs to the field of plywood processing, and particularly relates to an efficient gluing device for plywood. The efficient gluing device for the plywood aims to solve the problems that an existing gluing device is not uniform in gluing, and automatic feeding and discharging cannot be realized. The device comprises a base, a feeding conveying belt, a supporting frame and a gluing mechanism, wherein a plurality of first telescopic rods are fixed at one end of the base, and the output shaft of the first telescopic rods are connected with a feeding plate with an L-shaped verticalsection; a mounting groove is formed in the top end of the feeding plate, and a rodless air cylinder is arranged in the mounting groove; the output shaft of the rodless air cylinder is connected witha material pushing plate slidably connected to the top end of the feeding plate, one end of the feeding plate is provided with the feeding conveying belt, and one end of the feeding conveying belt isarranged on the base; the upper end face of the feeding conveying belt and the upper end face of the feeding plate are located on the same plane, and a gluing mechanism positioned on one side of the feeding plate is arranged above the feeding conveying belt; according to the device, the automation degree is high, the automatic feeding and discharging of plates can be realized, the gluing is uniform, and the gluing effect is good.

Owner:融安县华荣木业有限公司

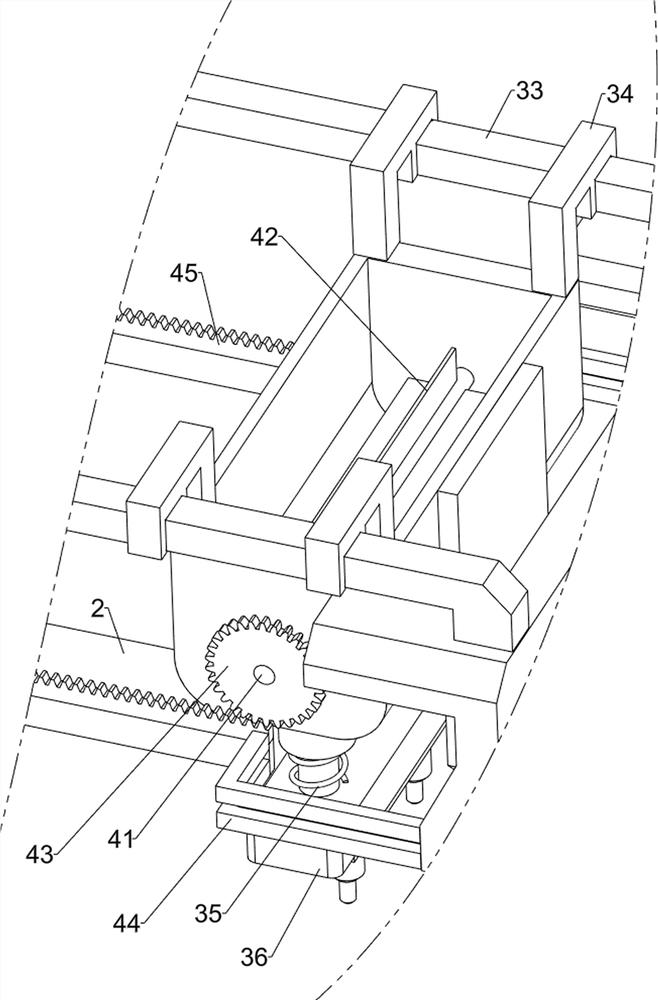

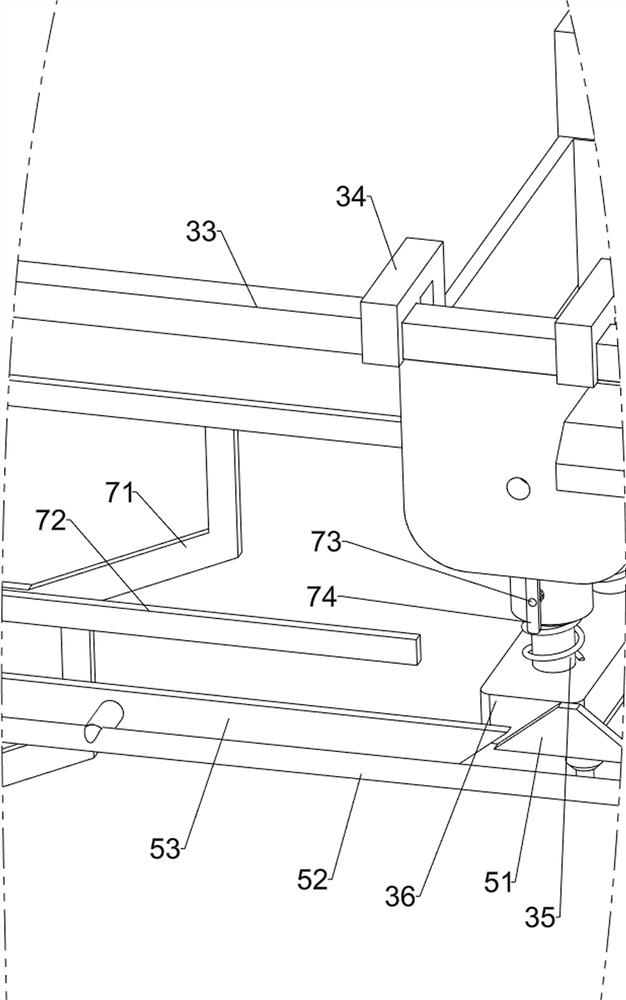

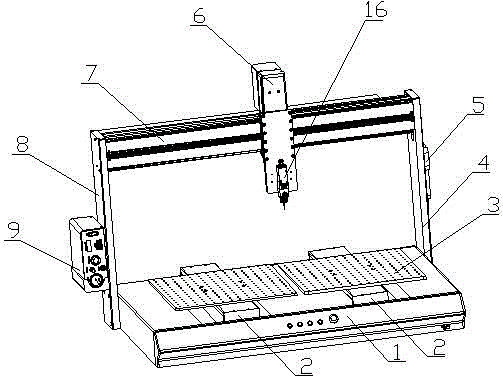

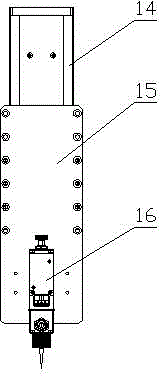

Glue filling device and glue filling method thereof

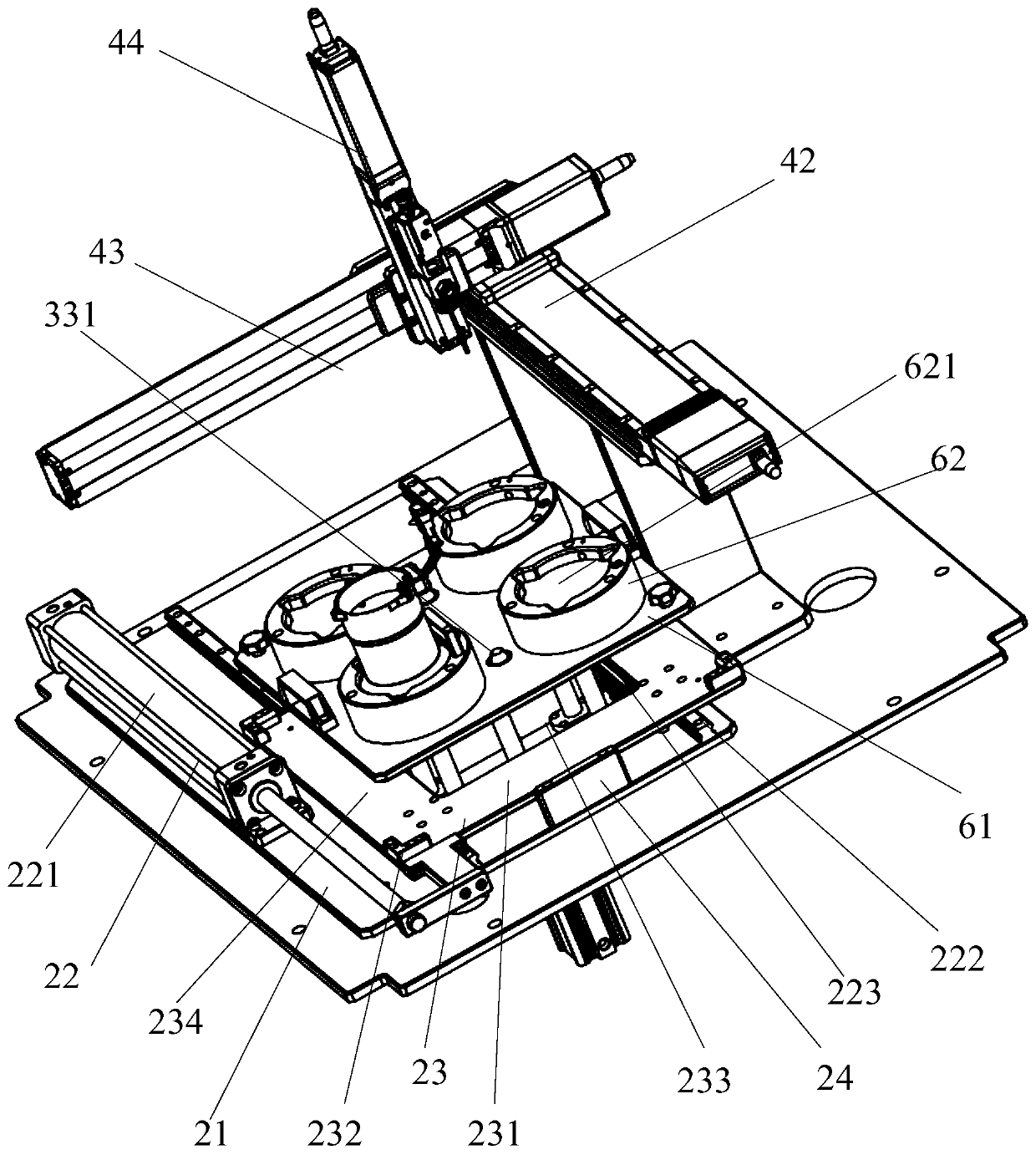

InactiveCN110449316APrecise positioningStable deliveryPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a glue filling device and a glue filling method thereof. The glue filling device comprises a fixed frame, a transverse push mechanism, a top push mechanism, a glue filling mechanism, a heating mechanism and a positioning mechanism, wherein the fixed frame is provided with a base plate; the transverse push mechanism is arranged on the base plate; the top push mechanism is arranged on the base plate; the glue filling mechanism is arranged on the base plate; the heating mechanism is positioned above the transverse push mechanism; the positioning mechanism is accommodated in the transverse push mechanism and is used for positioning a workpiece to be subjected to glue filling; and the mechanisms cooperate with one another, the workpiece to be subjected to glue filling ispositioned accurately, each part is conveyed stably, and rapid and safe glue filling can be realized.

Owner:苏州涵富汽车零部件科技有限公司

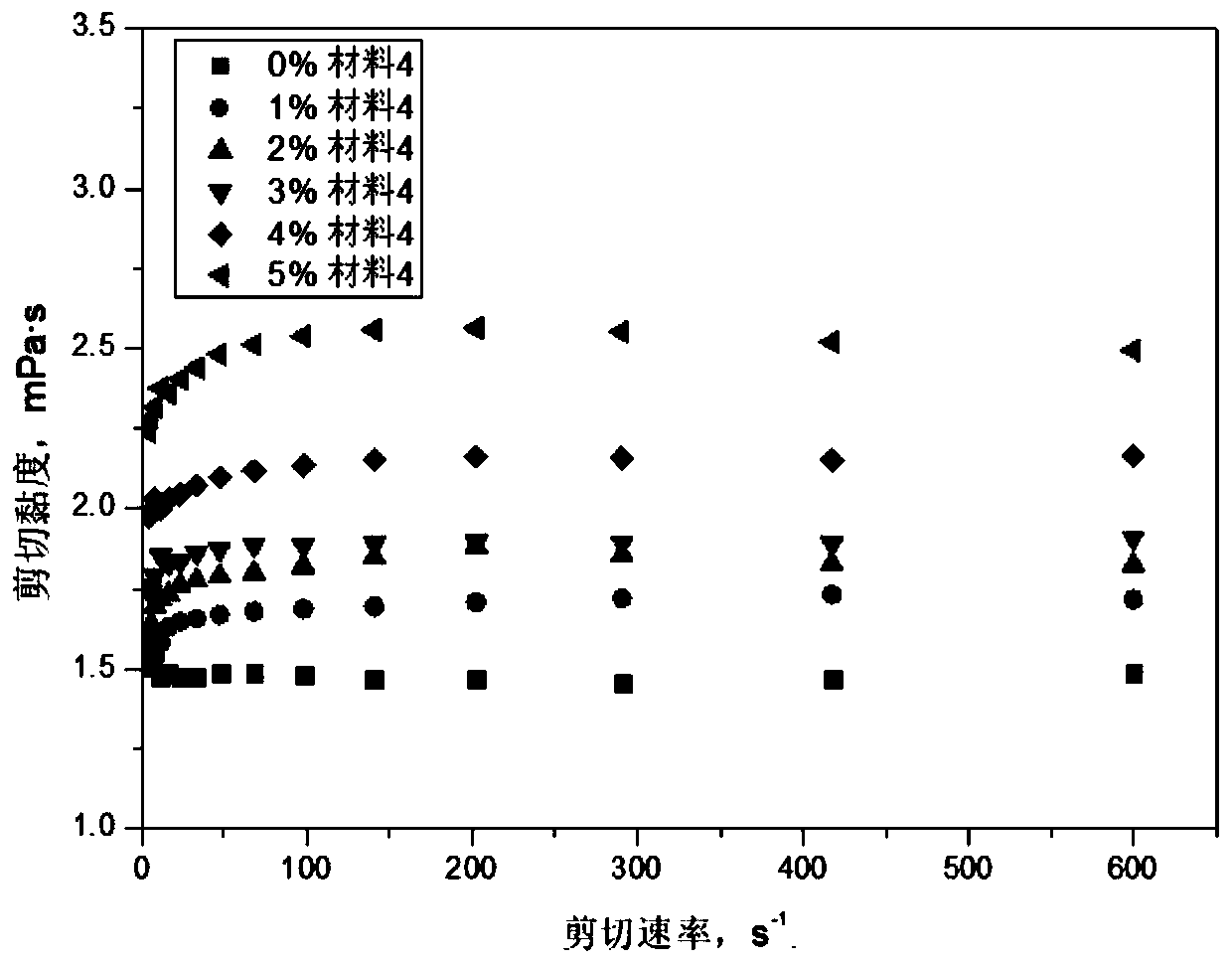

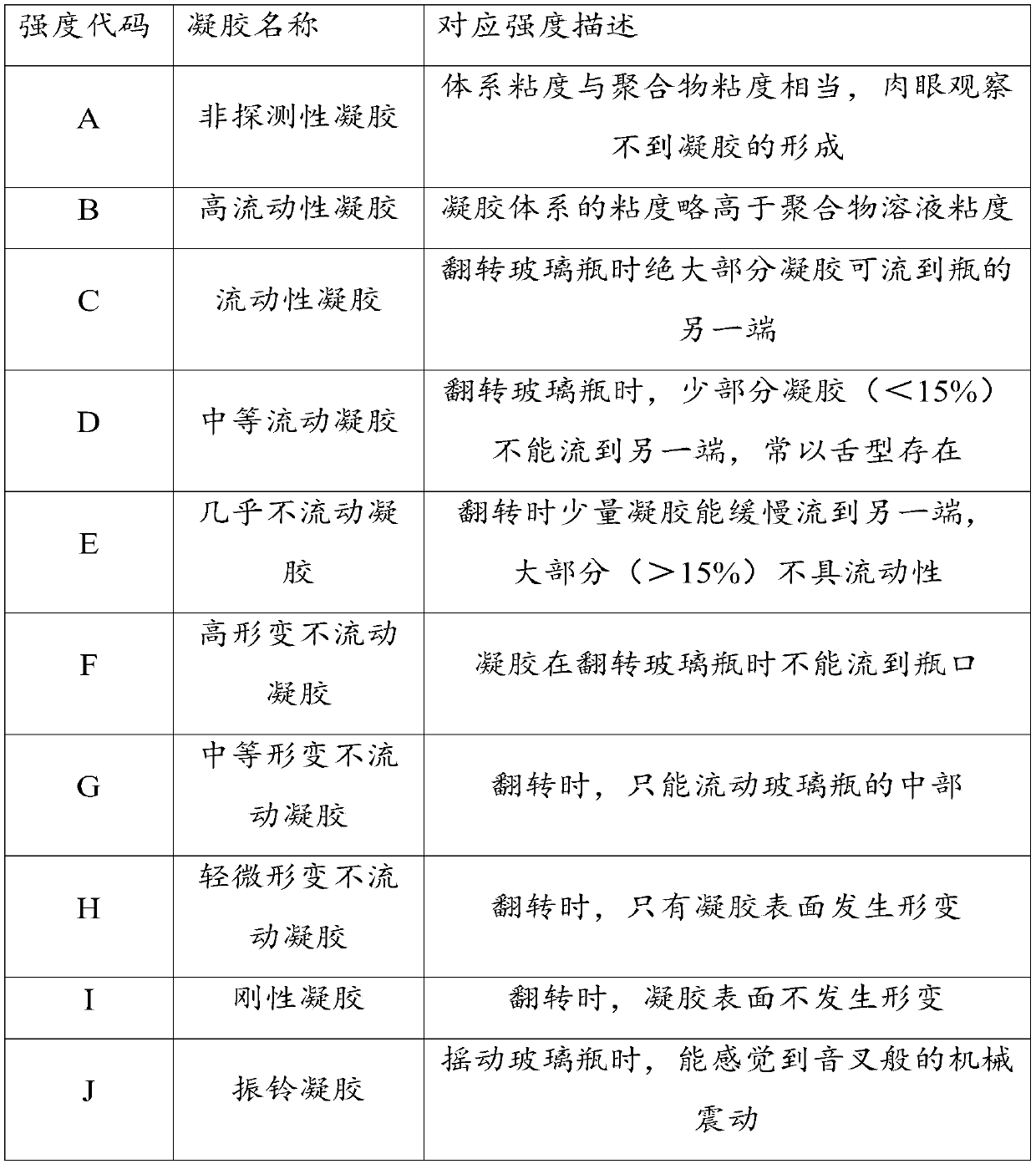

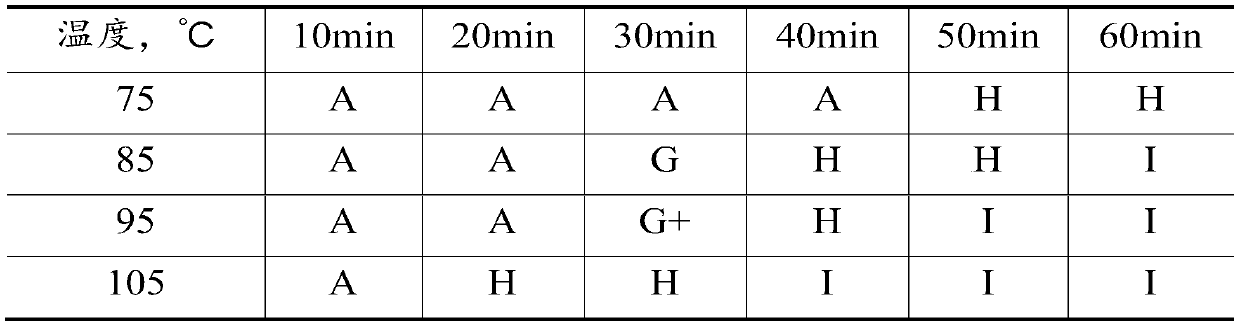

Liquid temporary plugging agent for rubber plugs, and preparation method thereof

The invention relates to the field of oil and gas chemical industry, and concretely relates to a liquid temporary plugging agent for rubber plugs, and a preparation method thereof. The raw materials of the liquid temporary plugging agent for rubber plugs mainly include, by mass, 10-25% of a monomer, 0.05-0.5% of a crosslinking agent, 0.1-0.5% of an initiator 1-5% of inorganic aggregates and 0.01-0.1% of an additive, wherein the additive comprises at least one of ethylenediaminetetraacetic acid, disodium ethylenediaminetetraacetate, thiourea and sodium citrate. At least one of ethylenediaminetetraacetic acid, disodium ethylenediaminetetraacetate, thiourea and sodium citrate is combined with the monomer, the crosslinking agent, the initiator and the inorganic aggregates to make the liquid temporary plugging agent for rubber plugs have the advantages of fast gel formation and high strength. The liquid temporary plugging agent can fast form a gel at a low oil reservoir temperature, and hasstable gel properties.

Owner:SOUTHWEST PETROLEUM UNIV

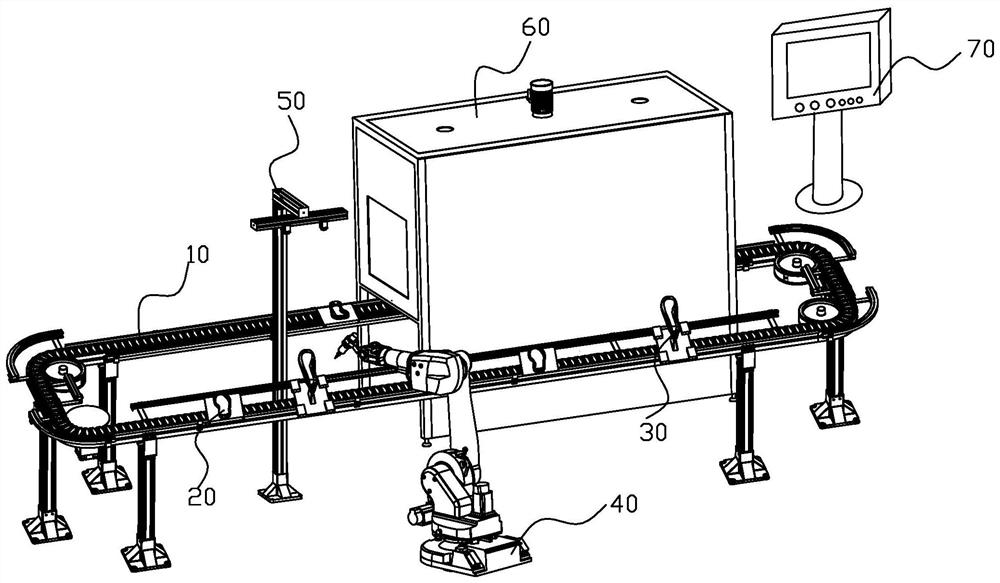

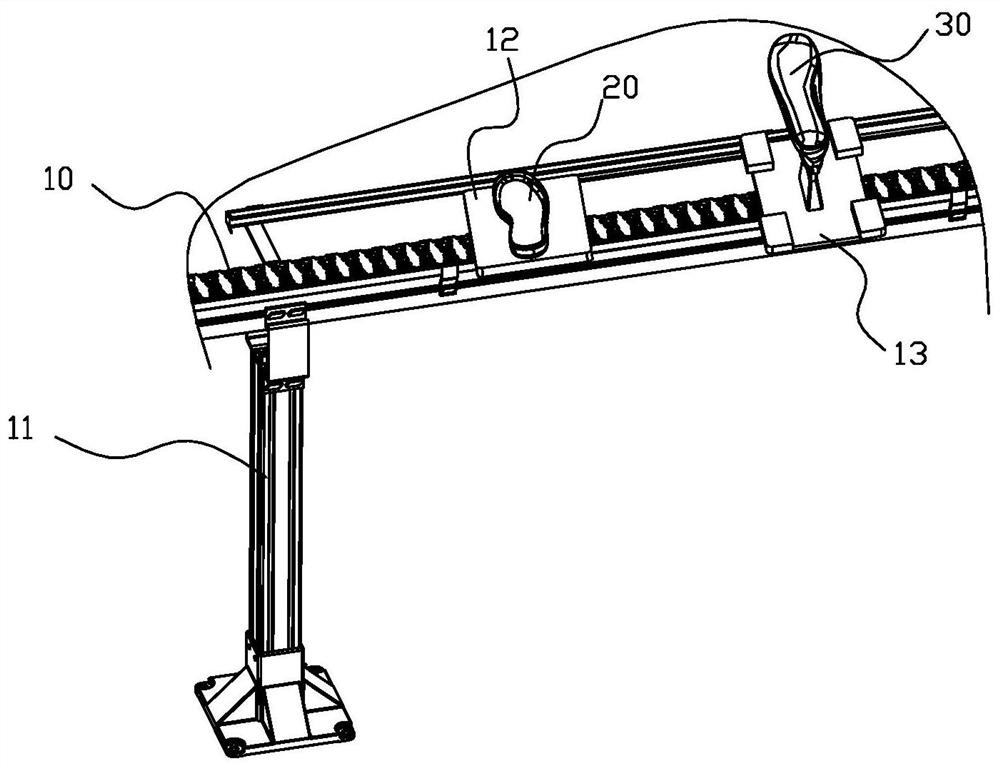

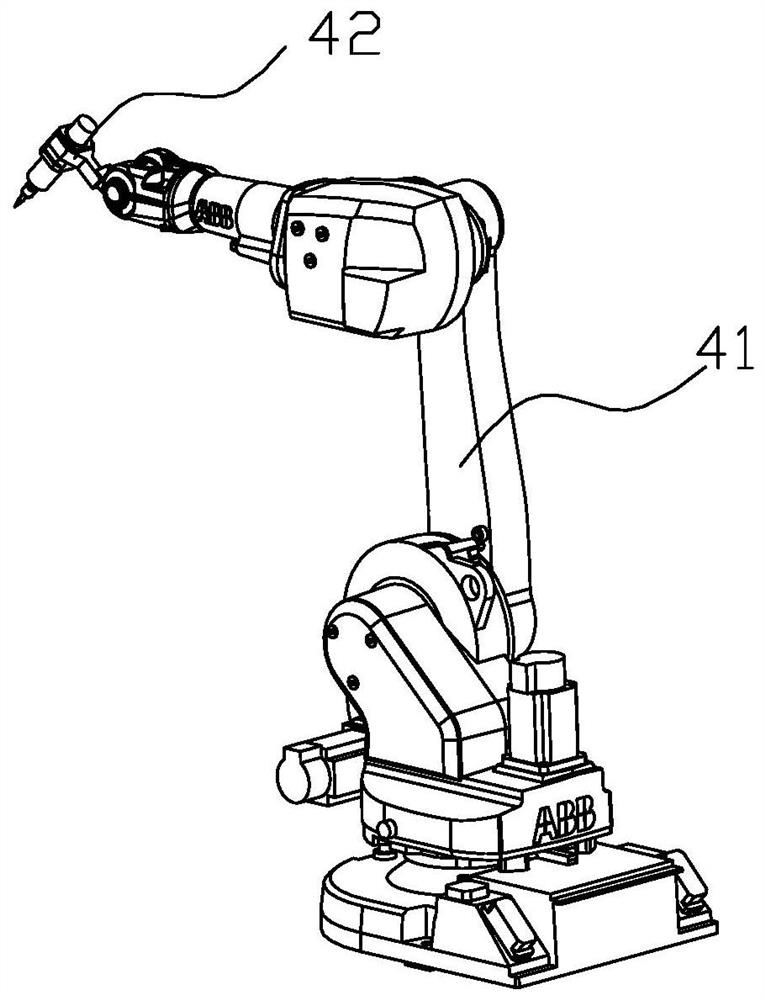

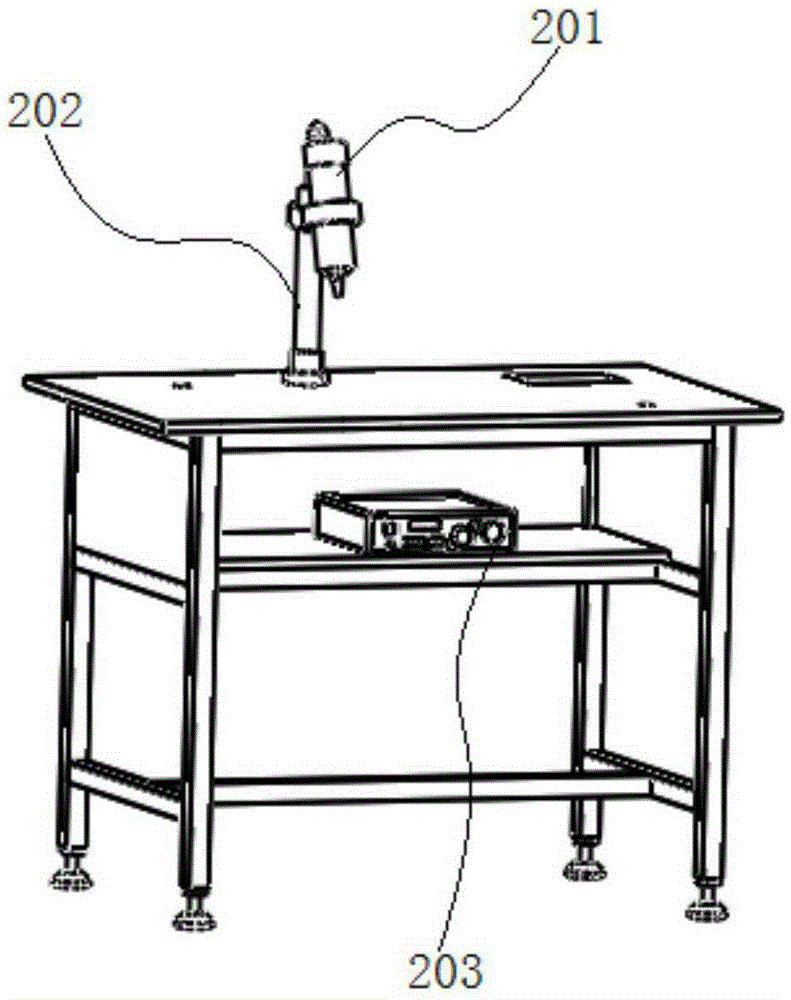

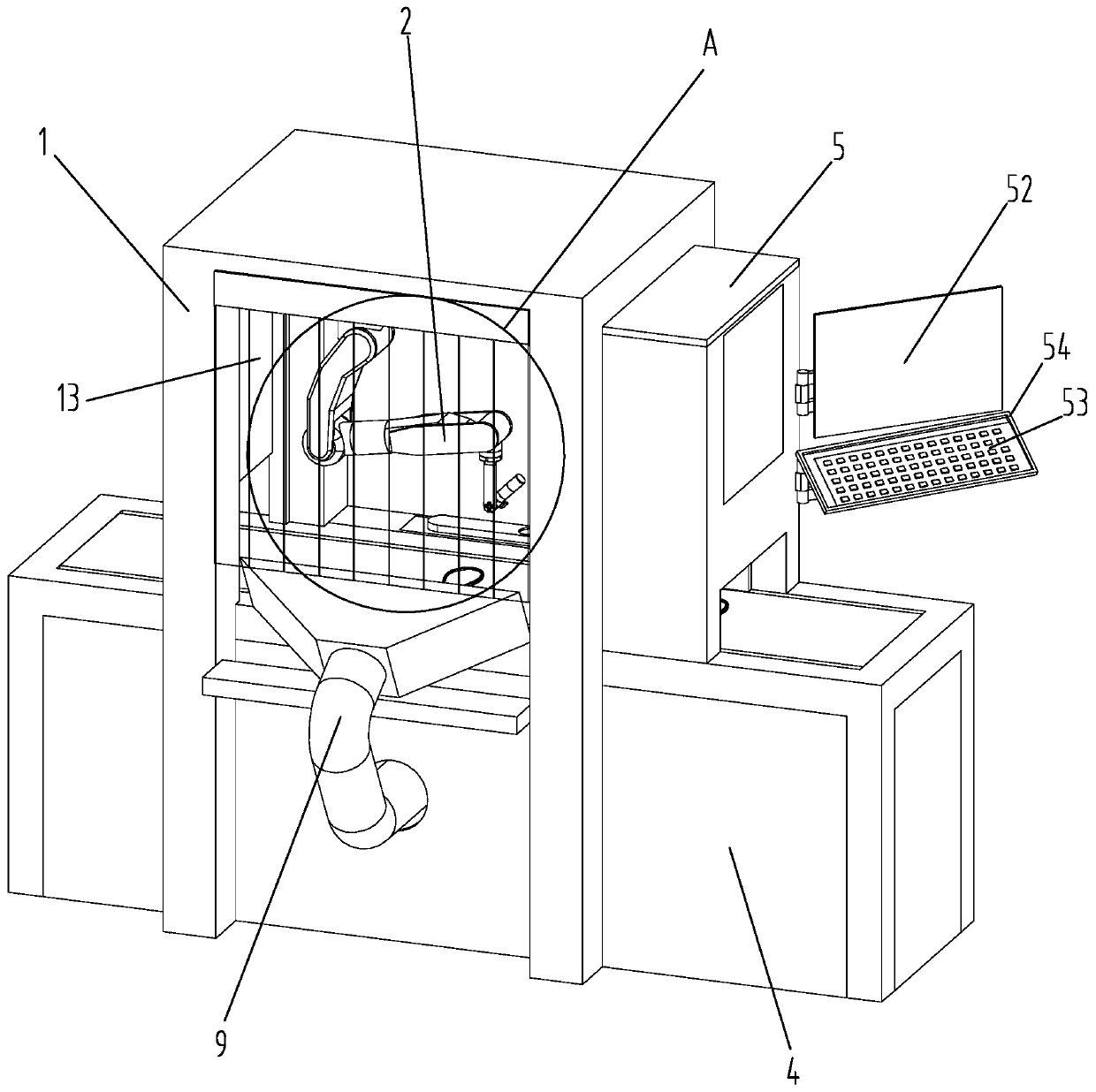

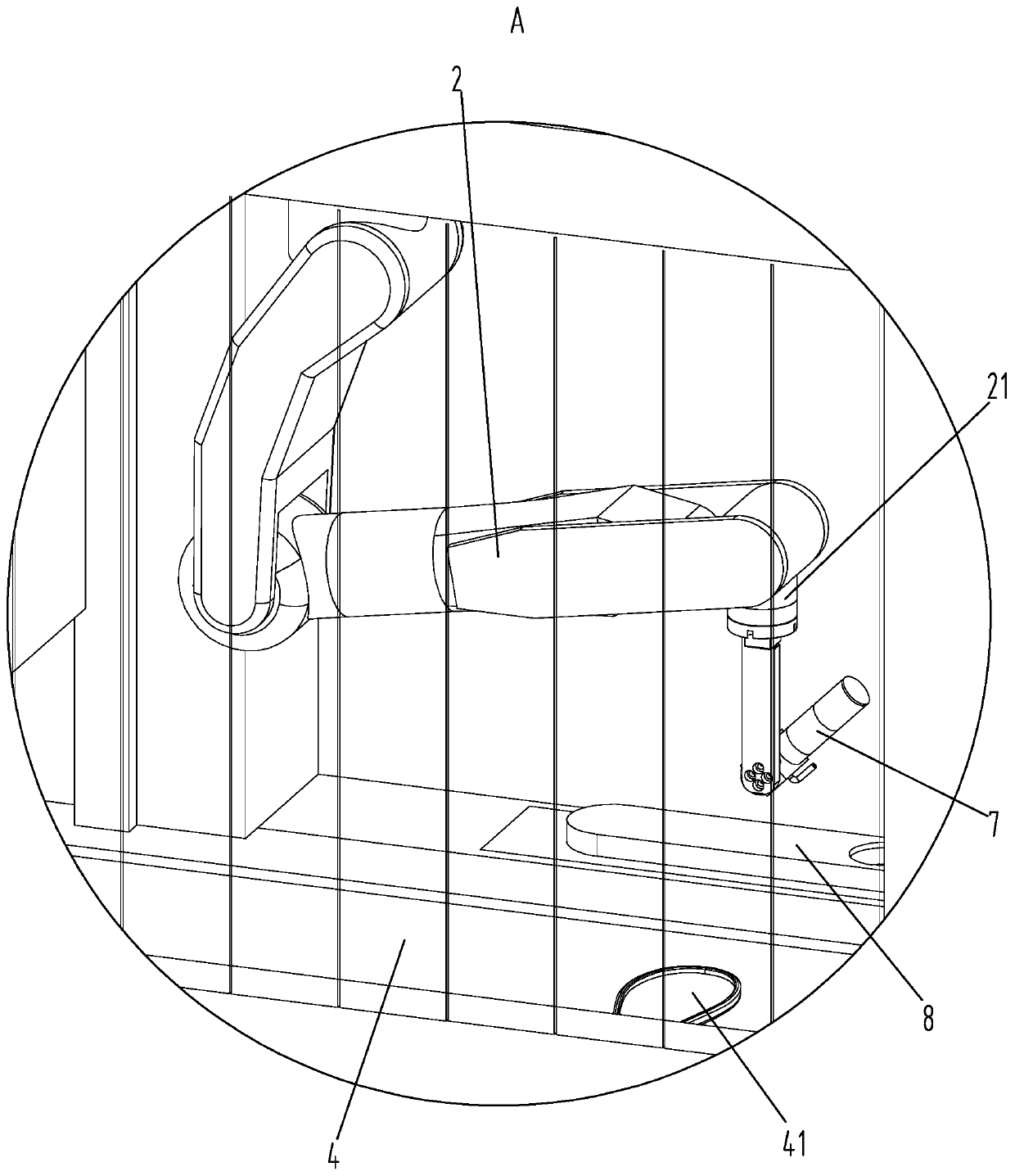

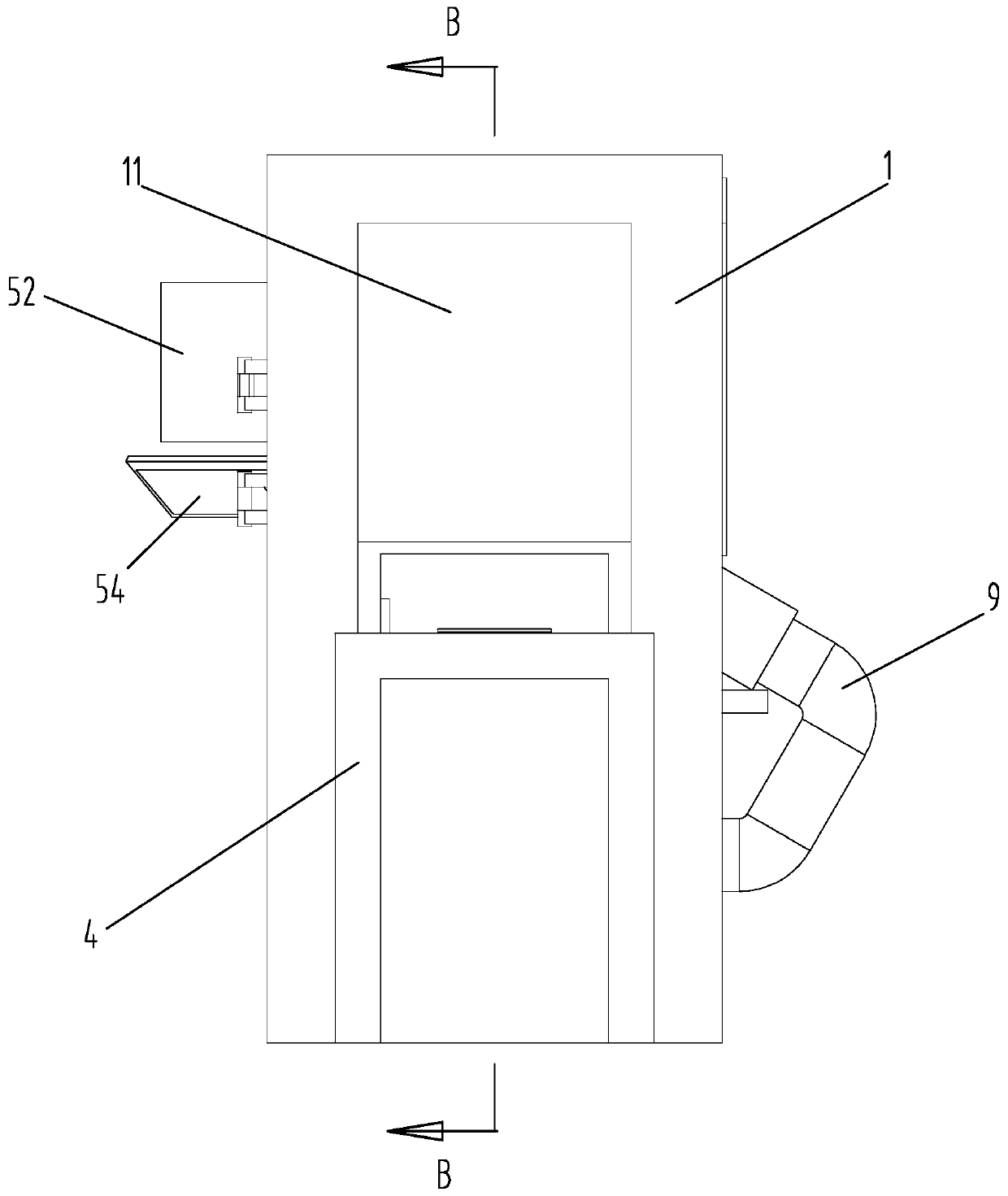

Rapid identification glue spraying method and system for vamps and soles

PendingCN112189948AAccurate identificationPrecise positioningShoe gluingMachine visionControl system

The invention discloses a rapid glue spraying method and system for vamps and soles based on machine vision guidance. The method comprises the steps of feeding, positioning, path recognition, glue spraying and drying. The system comprises a control system, a conveying belt, a visual system, a glue spraying robot and an oven. According to the method and the system, the positions and the shapes of the vamps and the shoe trees are recognized through the visual system and are quickly converted into a working path of the glue spraying robot, and the glue spraying robot is guided to complete glue spraying work on the vamps and the soles with different sizes and shapes. In the glue spraying process, the glue spraying robot does not need to perform time-consuming path calibration on each shoe typeand size in advance, so that the shoe types and sizes on the same production line can be flexible and variable, the current market requirements of small batch and multiple changes are met, and the production efficiency is greatly improved.

Owner:泛擎科技(深圳)有限公司

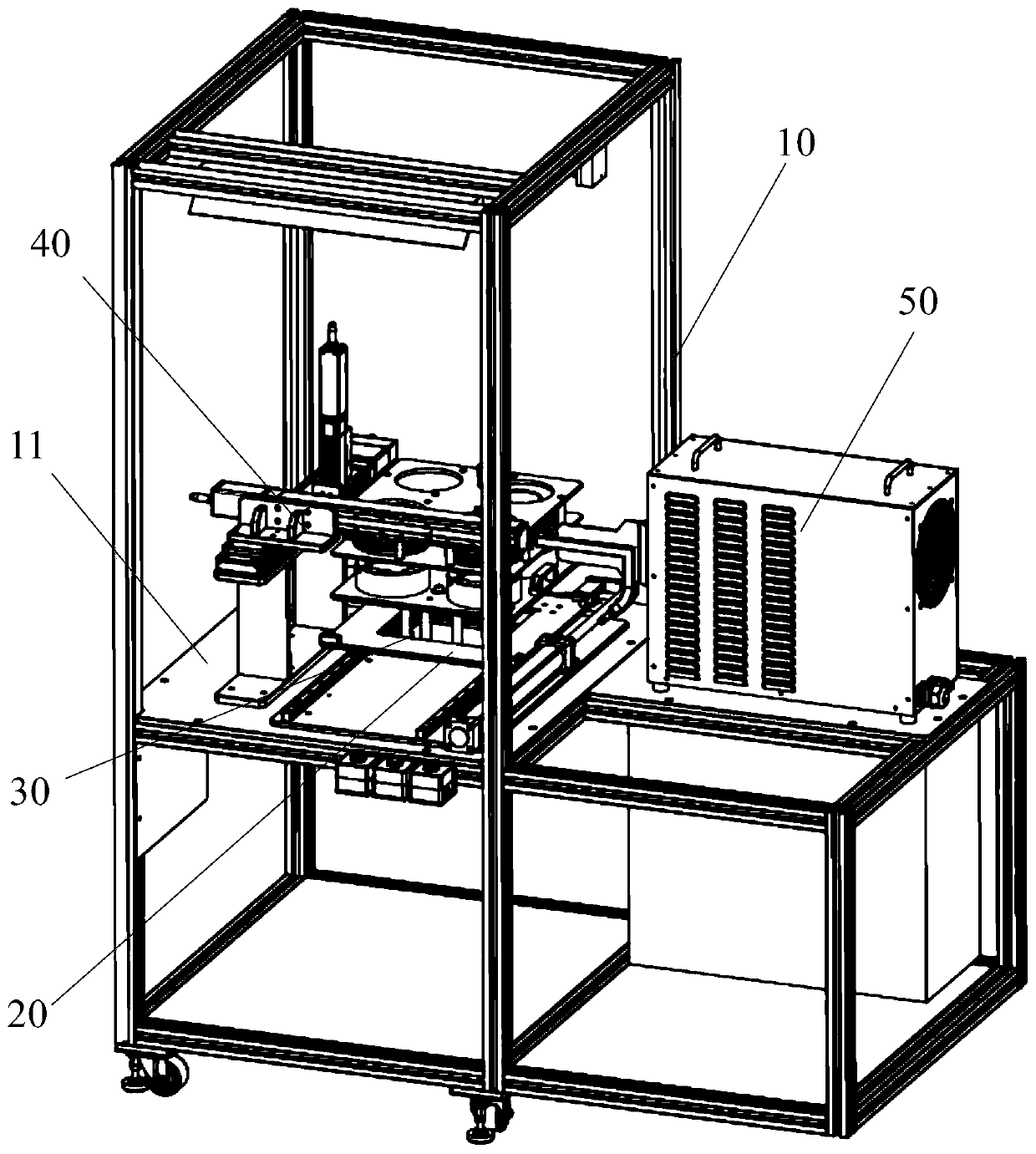

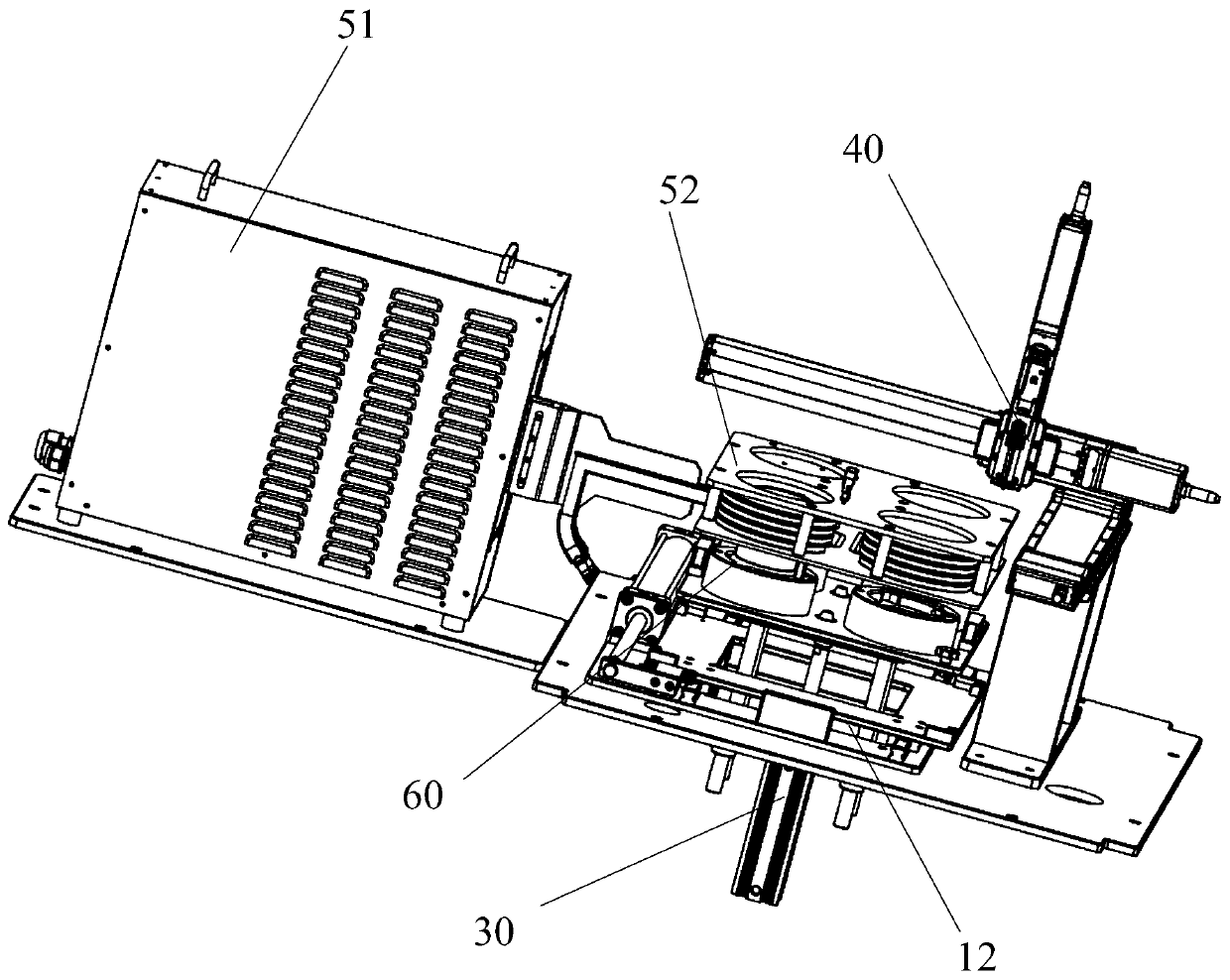

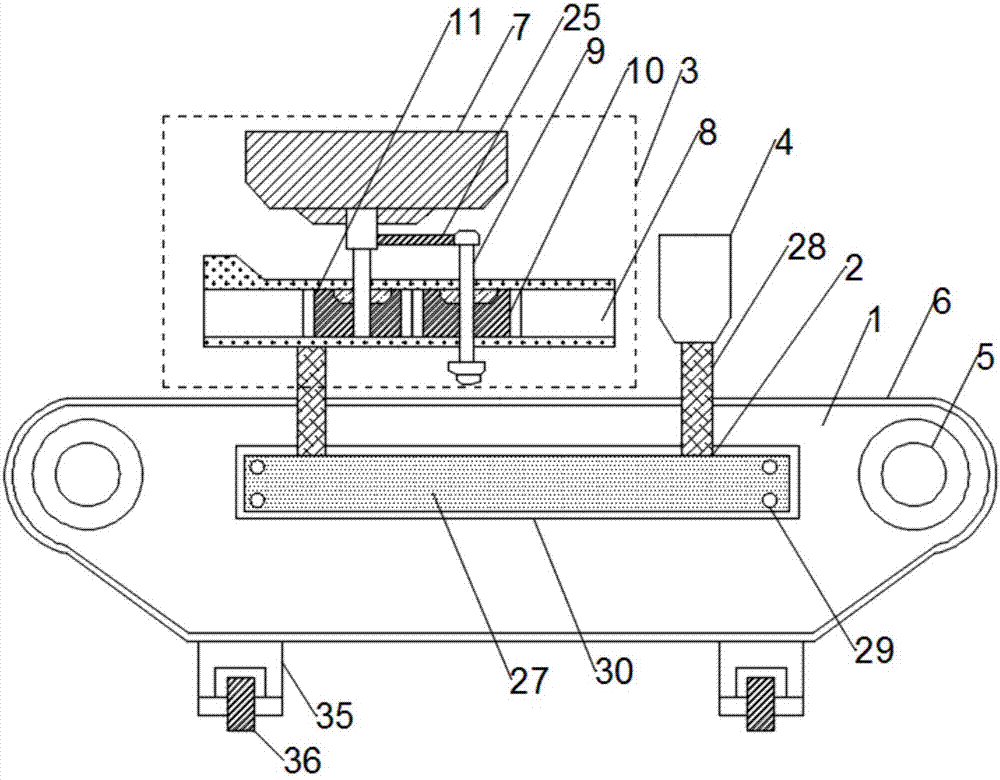

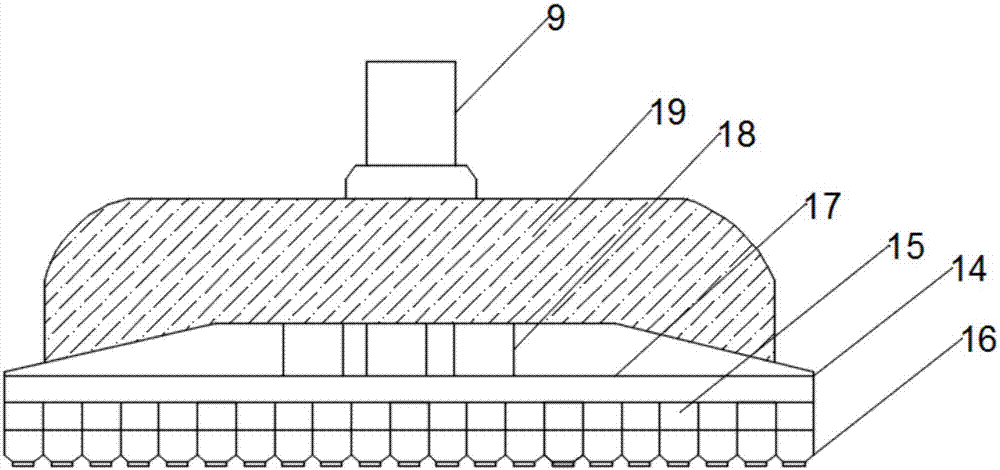

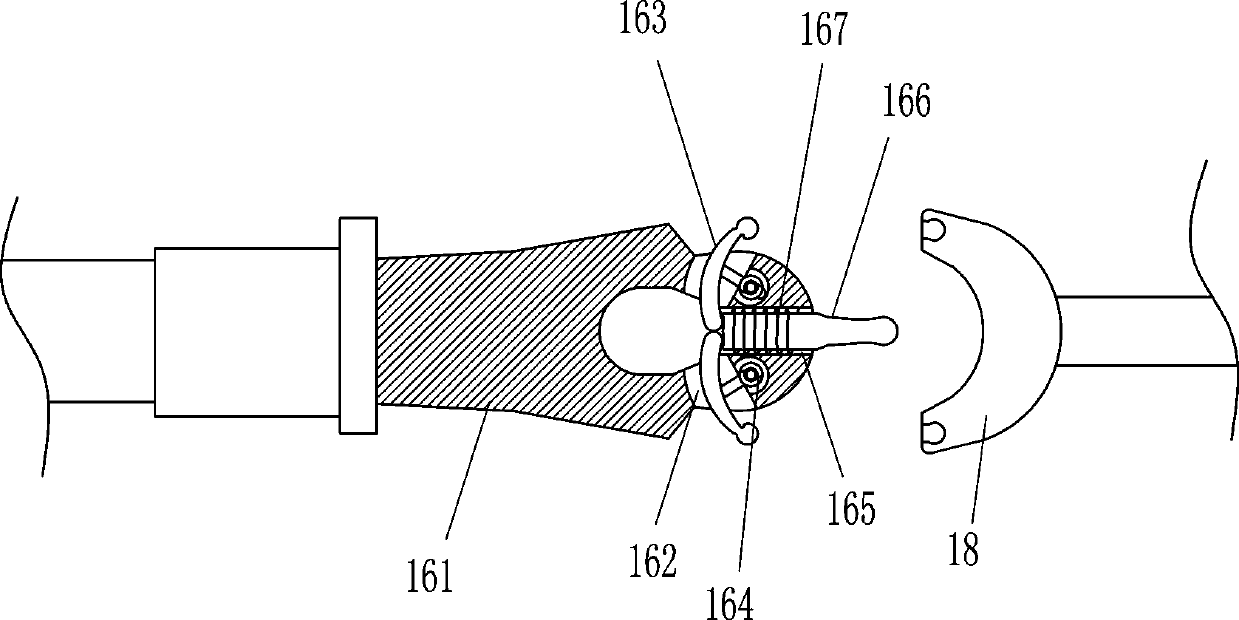

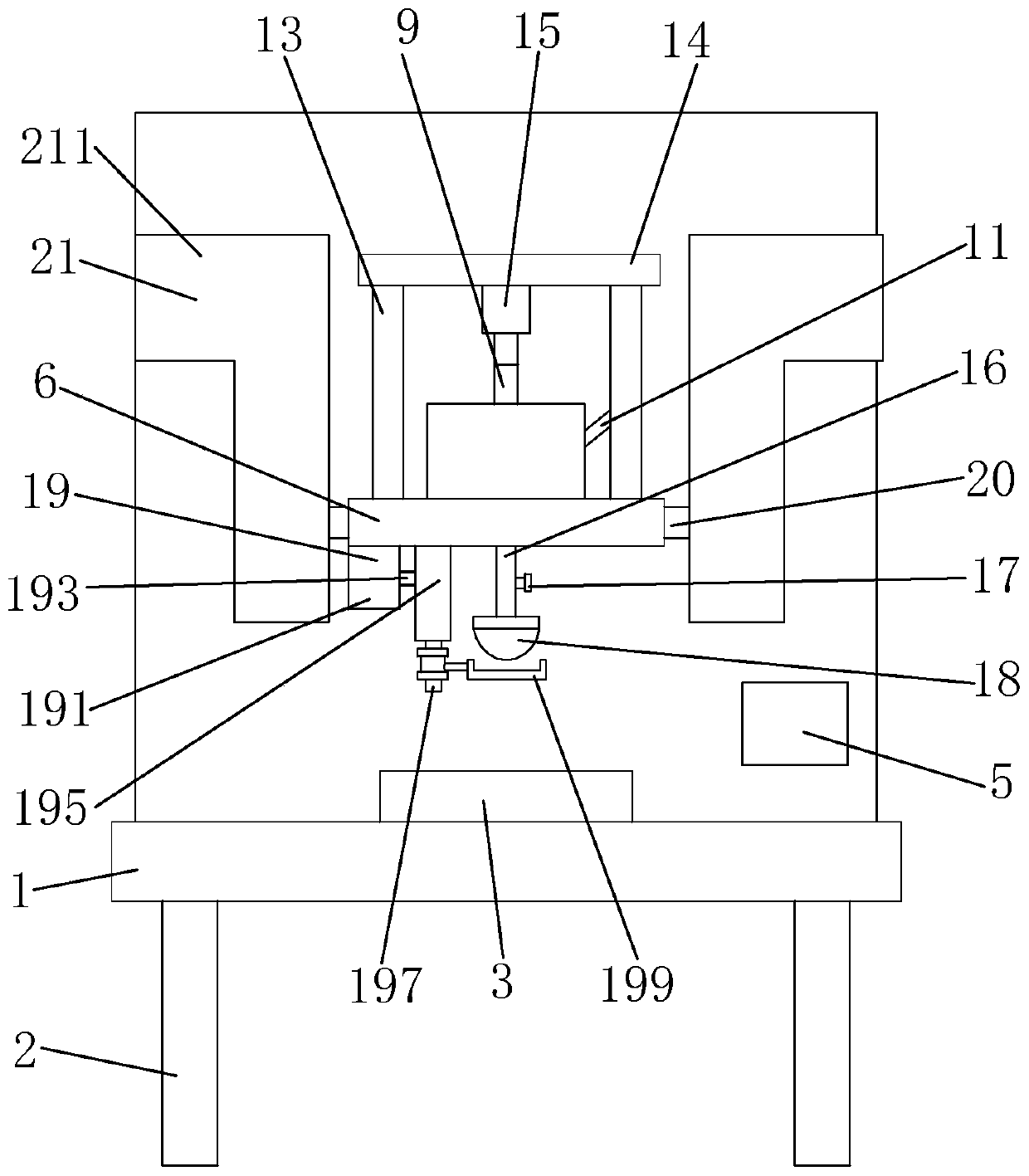

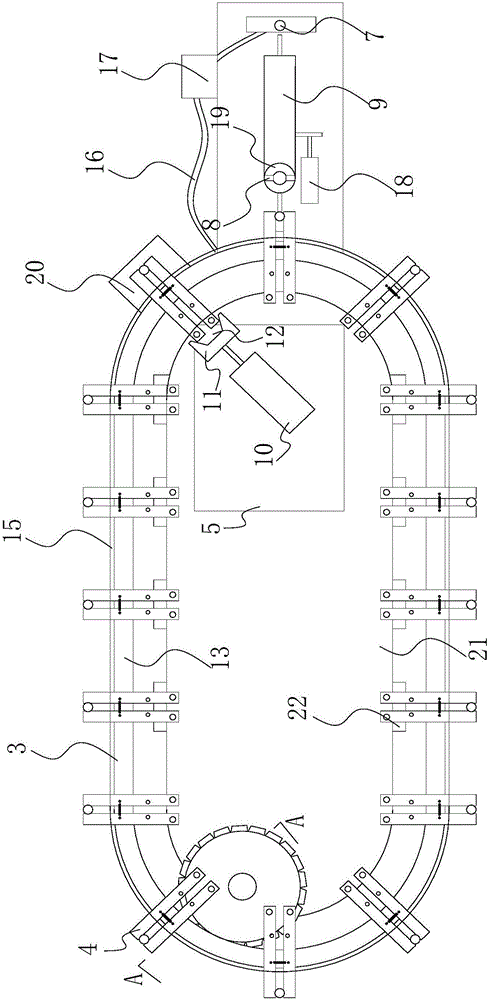

Gluing apparatus and gluing method for gluing magnetic steel for permanent magnet servo motor

ActiveCN105322737AAutomatic glue applicationQuick GlueManufacturing stator/rotor bodiesAtmospheric pressureCooperative work

The invention discloses a gluing apparatus and a gluing method for gluing magnetic steel for a permanent magnet servo motor. The apparatus comprises an equipment table frame, an air pressure gluing apparatus, a rotor clamping and driving apparatus, and a control mechanism; the air pressure gluing apparatus is arranged on the equipment table frame; the rotor clamping and driving apparatus is arranged on the equipment table frame; the driven and clamped rotors helically move relative to the air pressure gluing apparatus, so that the surfaces of the rotors pass through the air pressure gluing apparatus in sequence; the control mechanism is connected with the air pressure gluing apparatus and the rotor clamping and driving apparatus, and controls the air pressure gluing apparatus and the rotor clamping and driving apparatus for realizing cooperative work. In the gluing process, the control mechanism determines a gluing track on the surface of a to-be-glued rotor initially; then the rotor clamping and driving apparatus is controlled based on the track; the rotor clamping and driving apparatus drives the to-be-glued rotors to rotate and move to enable the surfaces of the to-be-glued rotors to pass through the air pressure gluing apparatus in sequence according to the determined gluing track. The rapid gluing in gluing the magnetic steel for the permanent magnet servo motor is realized according to the scheme.

Owner:SHANGHAI LEIZHI MOTOR

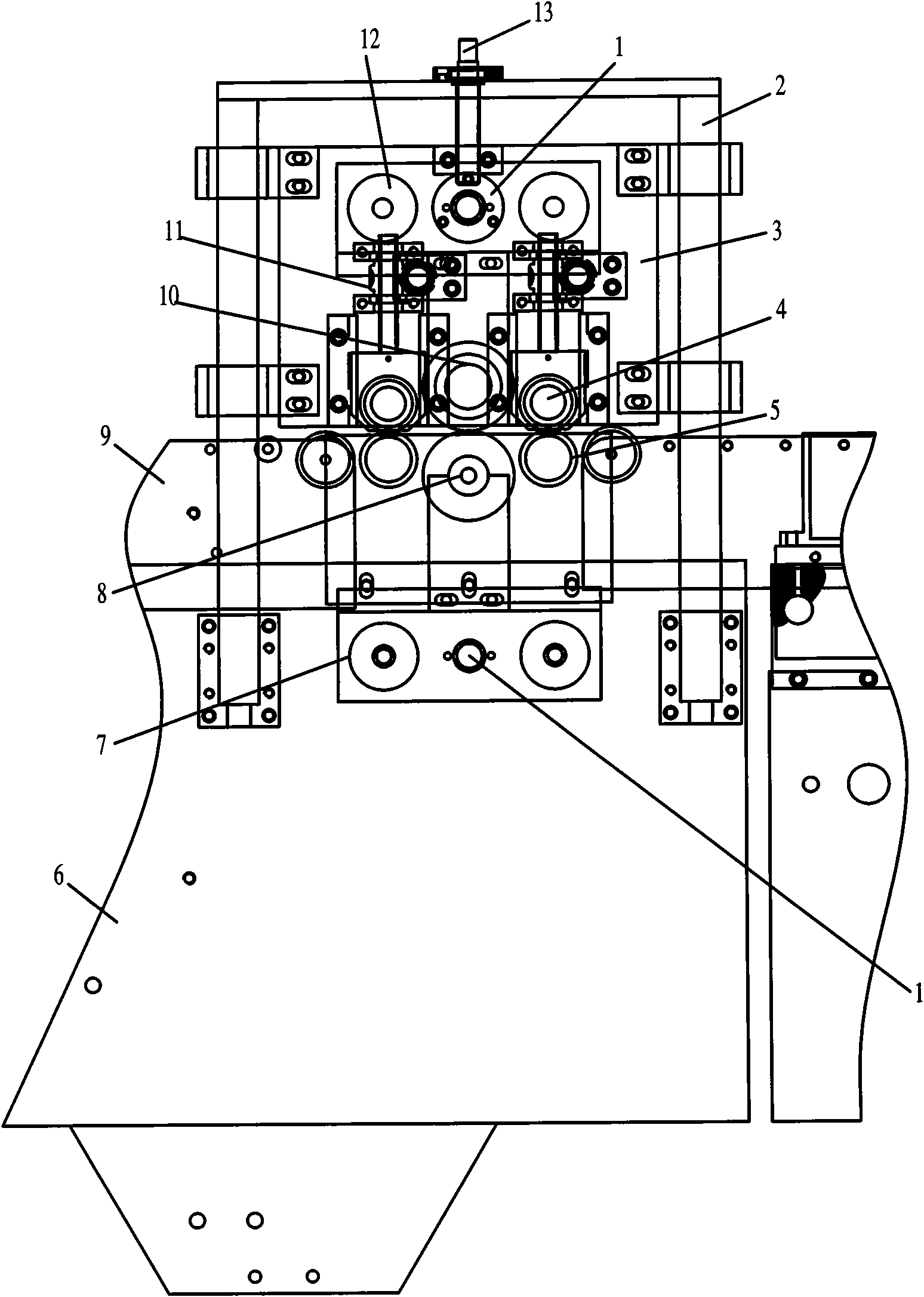

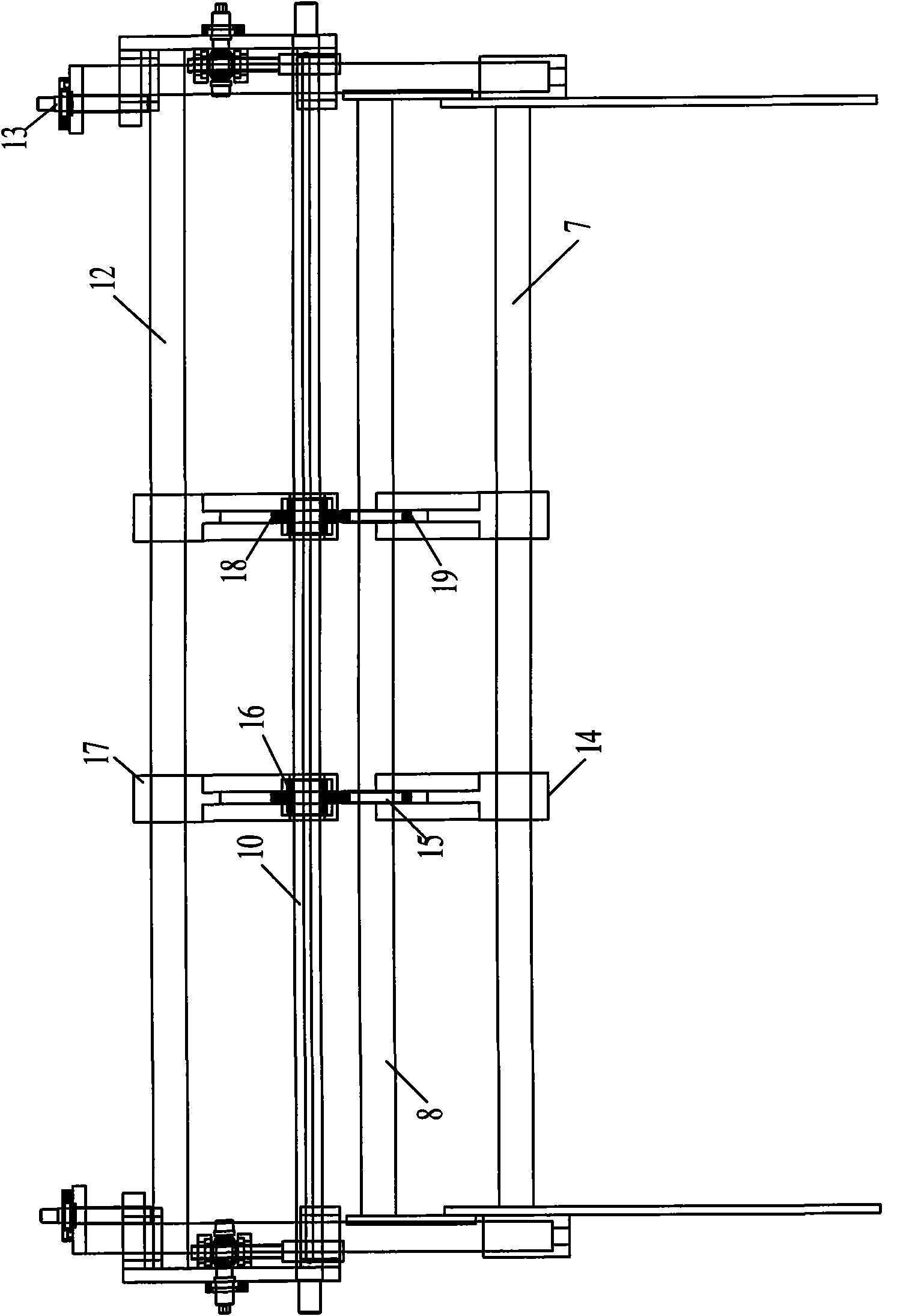

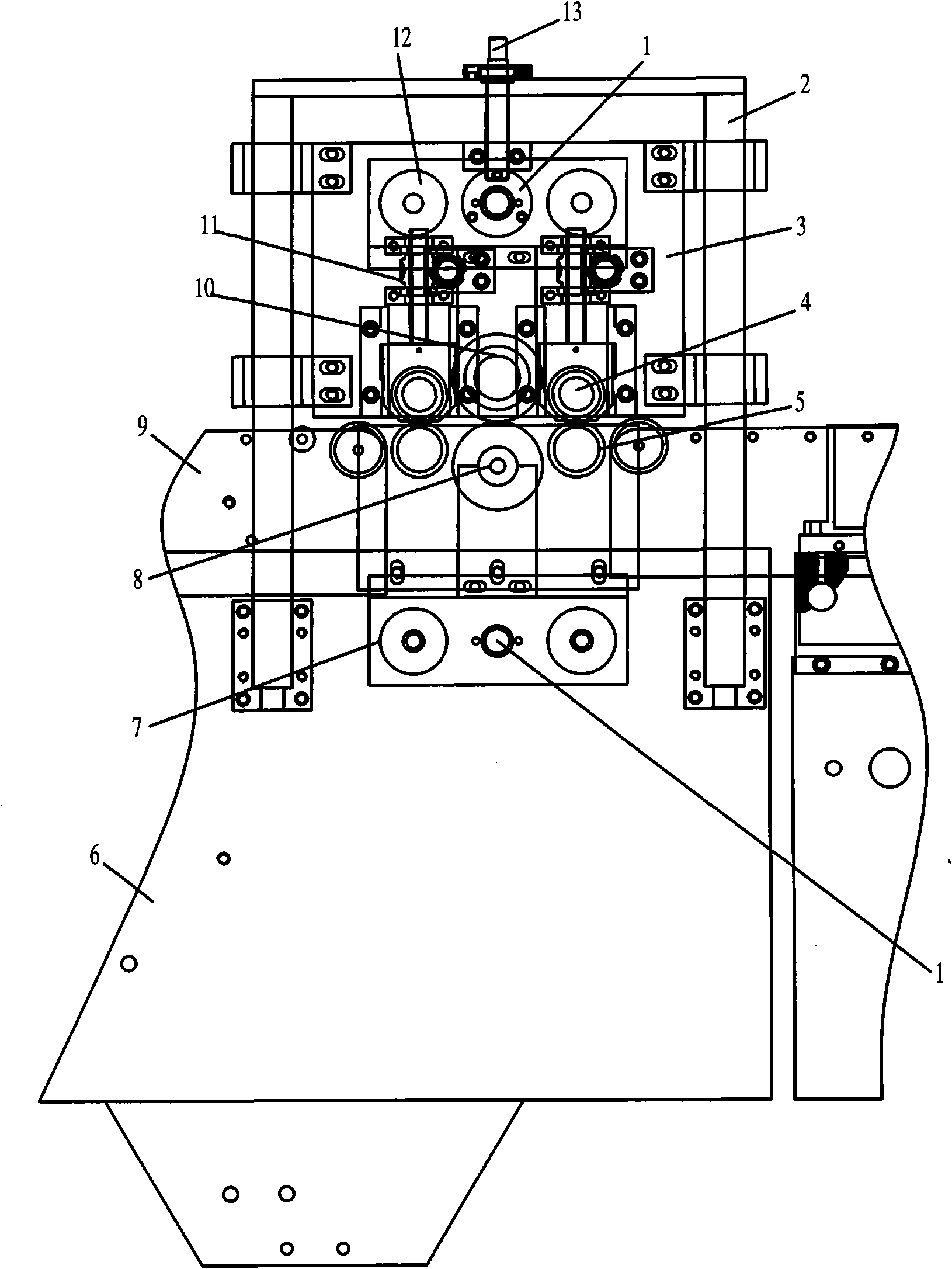

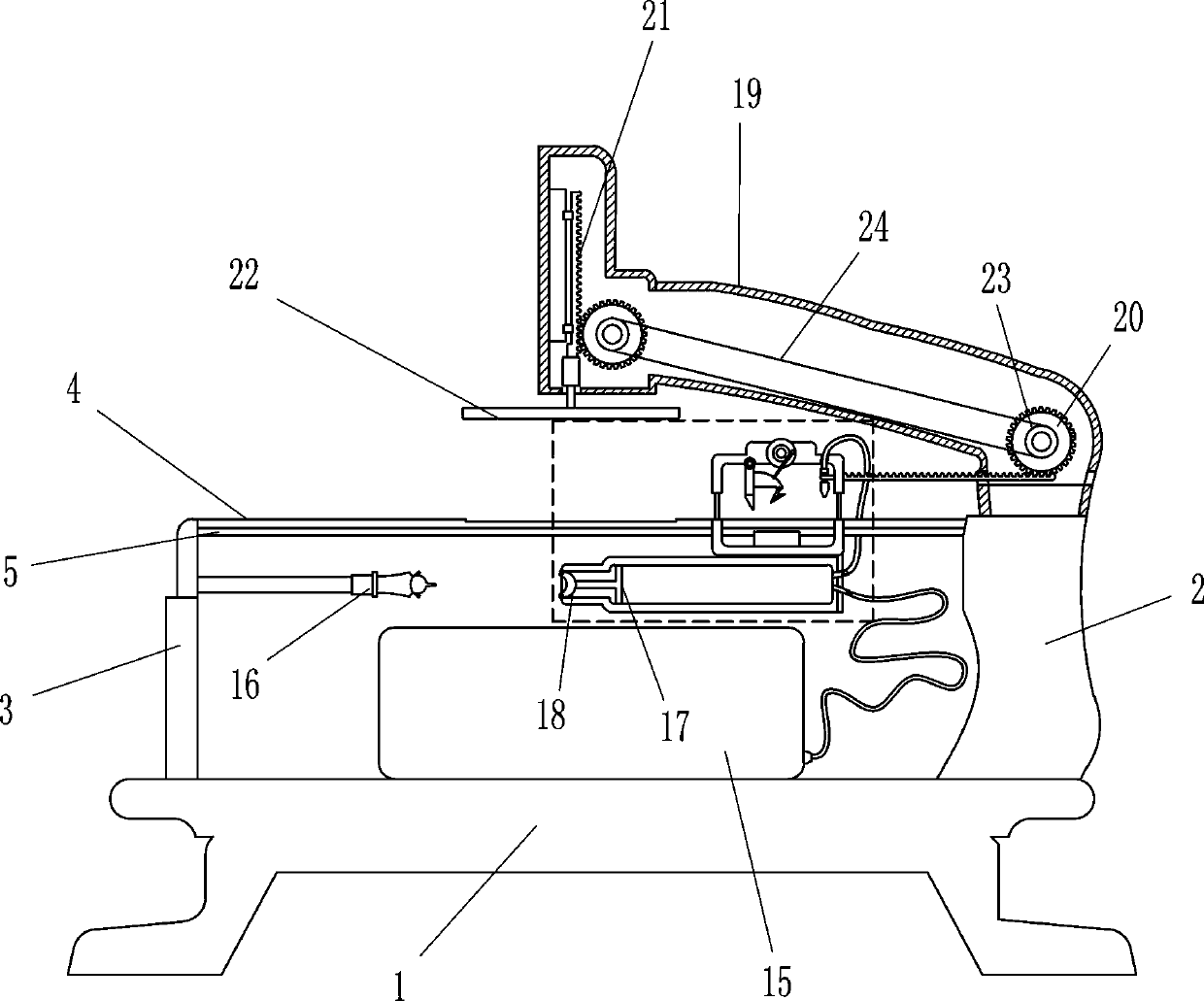

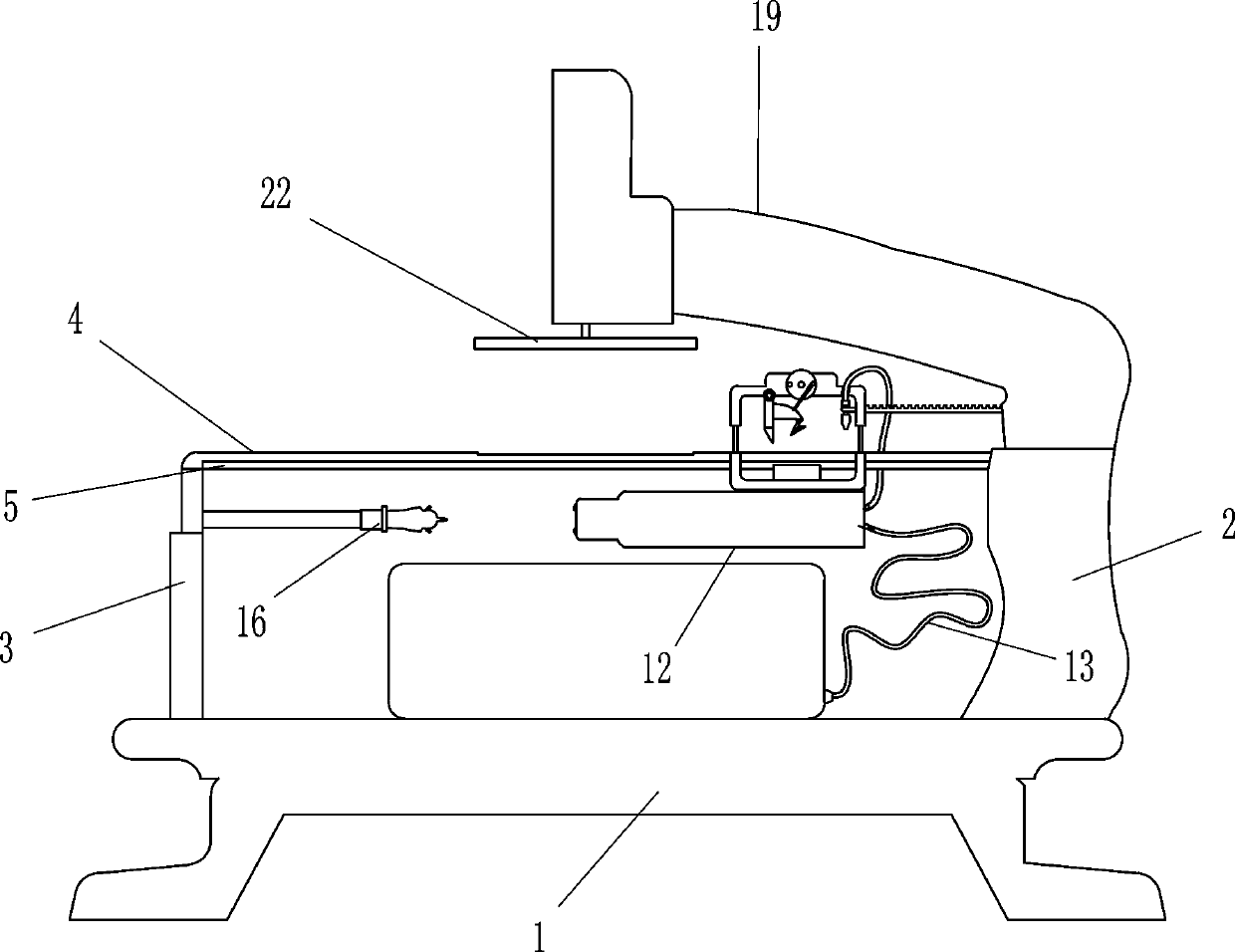

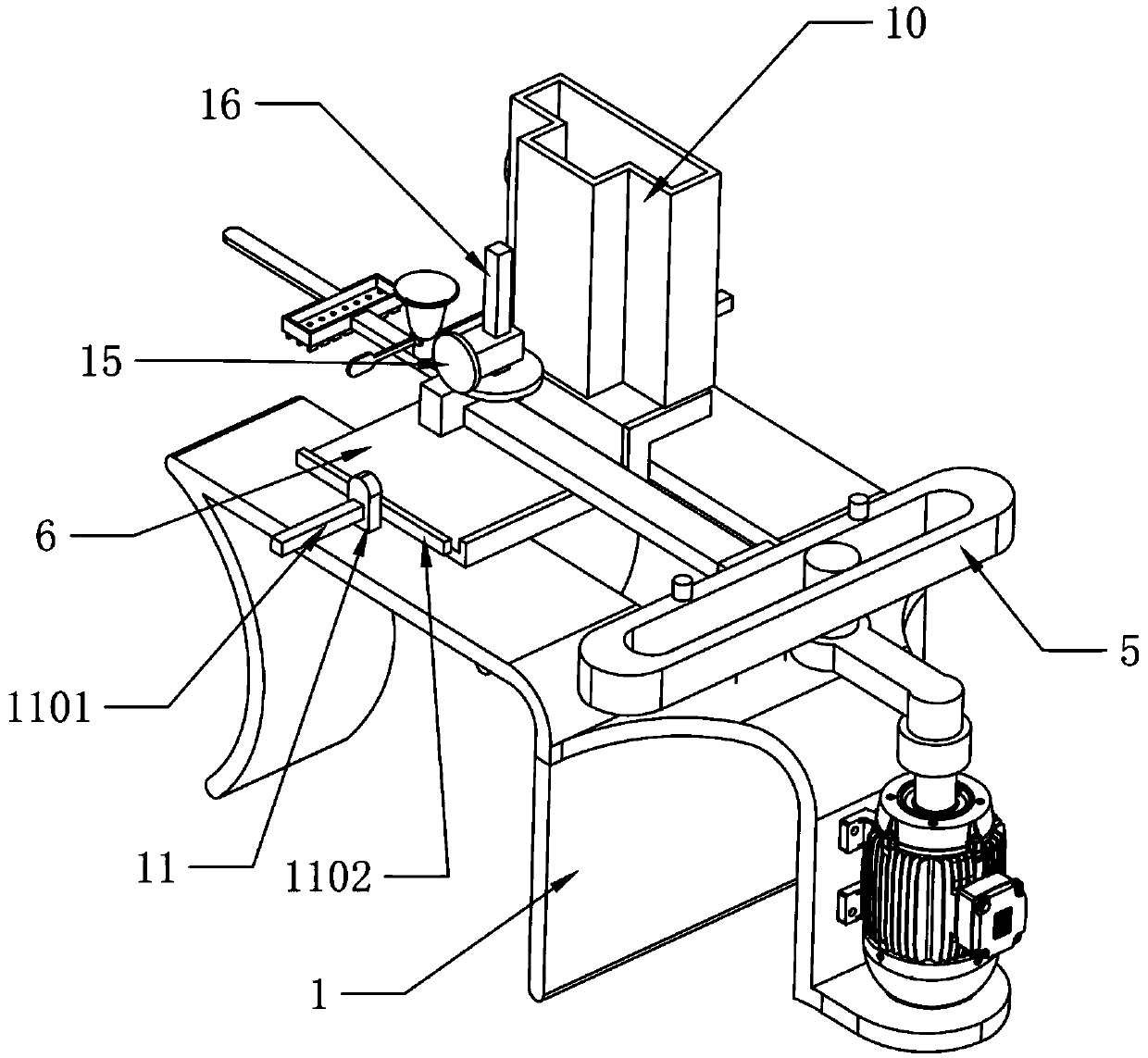

Efficient plywood gluing device

PendingCN107053385AImprove molding qualityQuick GlueDrying gas arrangementsGlue gunsDrive shaftEngineering

The invention discloses an efficient plywood gluing device. The efficient plywood gluing device comprises a conveying table, a mounting rack, a gluing device and a drying device. The mounting rack is fixedly installed on the side face of the conveying table. The gluing device comprises a rotating motor, a supporting shell and a screw rod. A first planetary gear and a second planetary gear are arranged inside the supporting shell and are further engaged together with each other. A transmission shaft is arranged at the center position of the inside of the first planetary gear, and the other end of the transmission shaft and a rotating shaft of a rotating motor are connected together. The transmission shaft is driven by the rotating shaft to rotate. The other end of the screw rod is connected with a nozzle table, and a plurality of nozzle holes are adjacently formed in the surface of the nozzle table. Gluing nozzles are installed in the corresponding nozzle holes, and the gluing nozzles communicate with one another through a communicating pipe to be connected together. By the adoption of the efficient plywood gluing device, plywood of different thicknesses can be reasonably glued, and gluing is uniform and free of leakage; and the drying speed is high after gluing, forming quality of the plywood is high, and production efficiency is greatly improved.

Owner:颍上县亚森木业有限责任公司

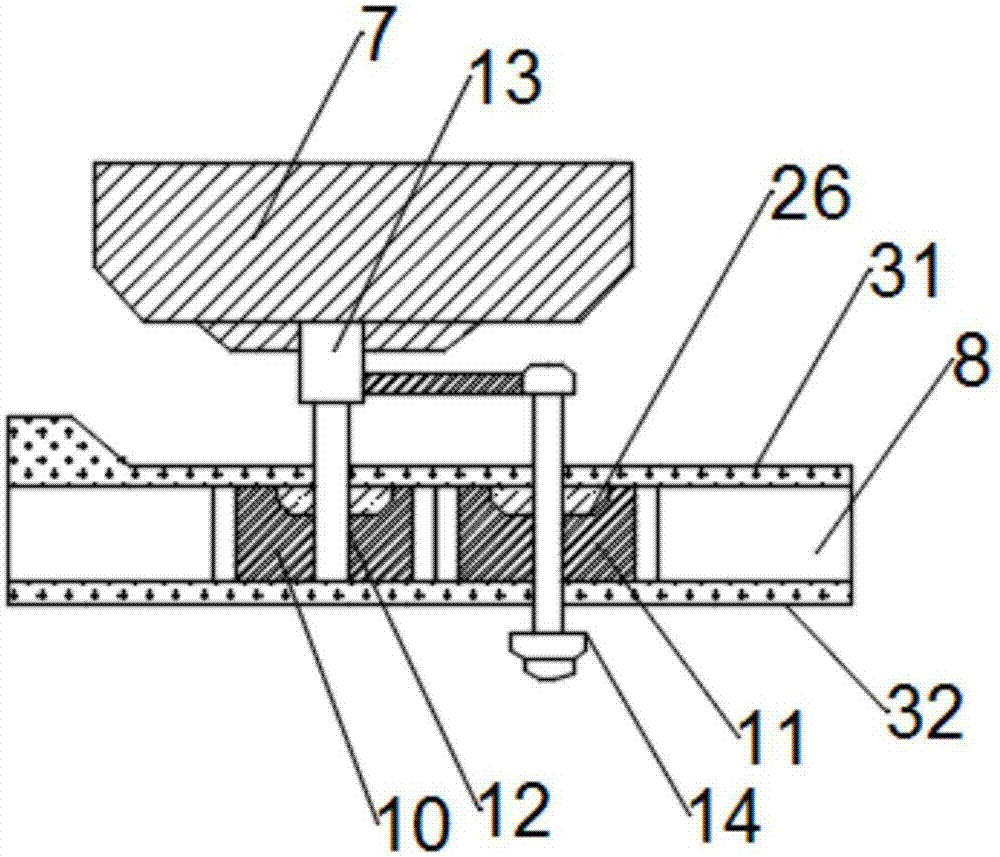

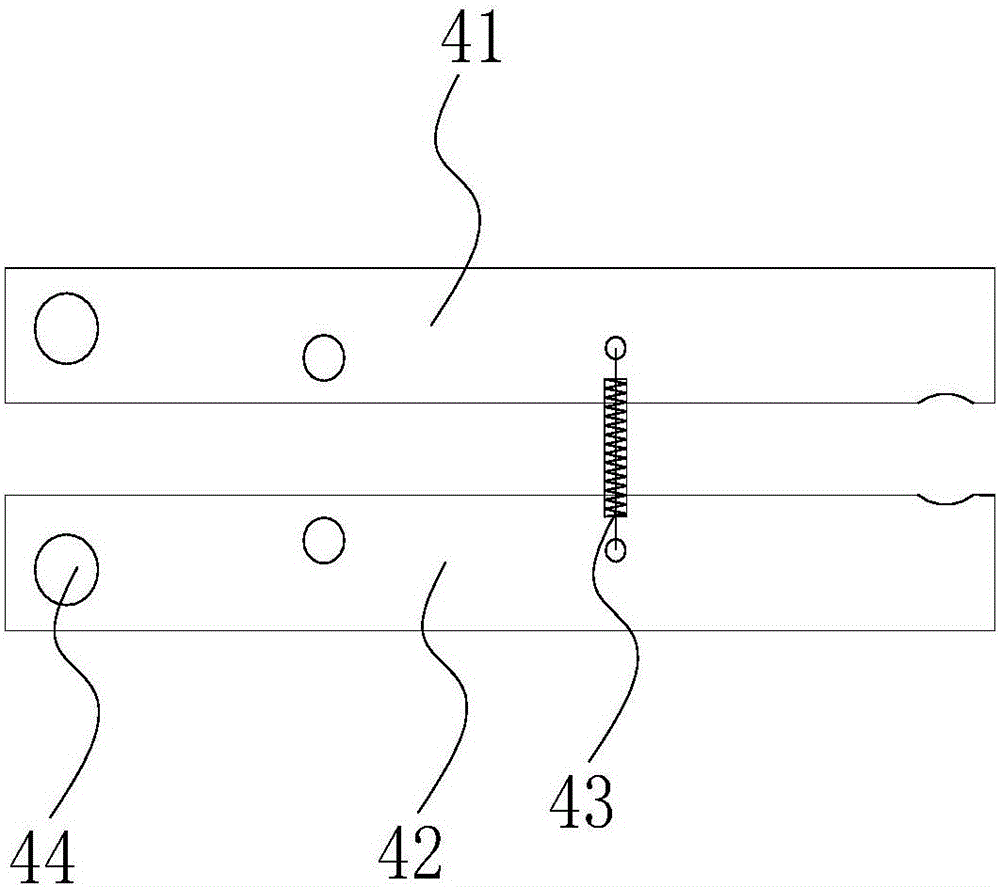

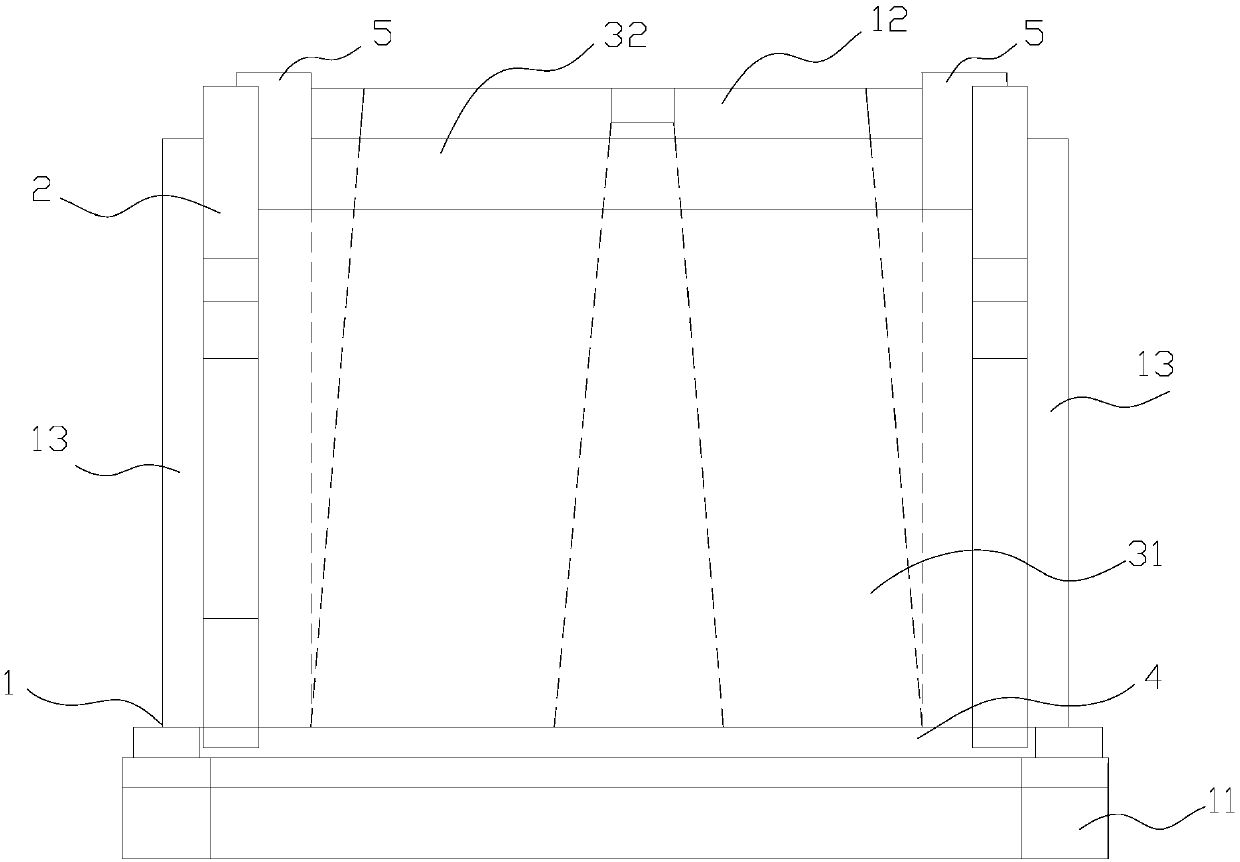

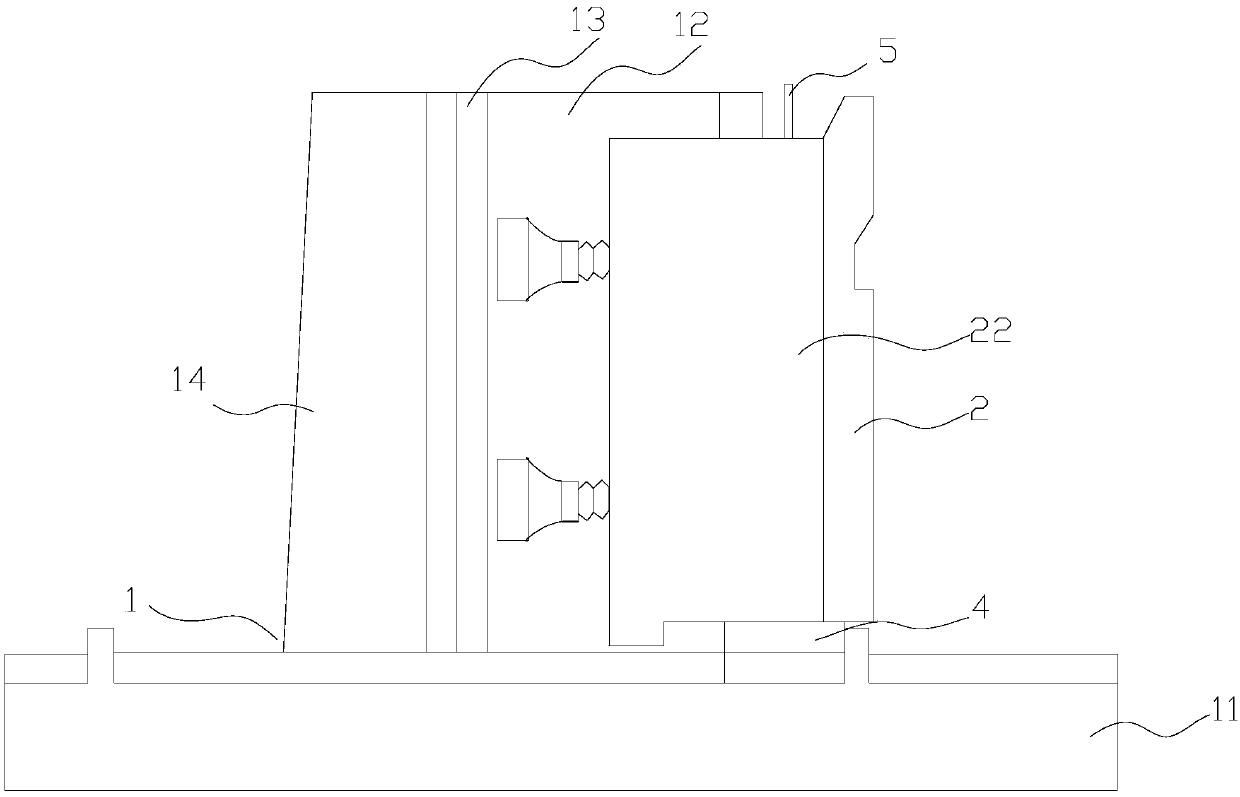

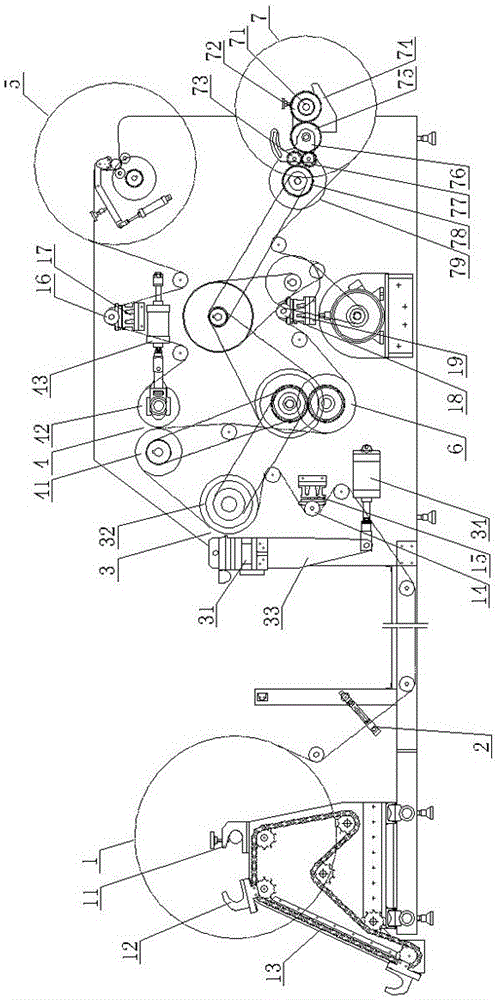

Impressing device for full-automatic corrugated cardboard box gluer

InactiveCN102173100AReduce mistakesQuick GlueBox making operationsPaper-makingInternational standardEngineering

The invention relates to an impressing device for a full-automatic corrugated cardboard box gluer. The impressing device comprises two outer wall plates and two pairs of rubber rollers, wherein the two outer wall plates are fixed on the lower parts of two sides of the machine body; the impressing device comprises movable guide posts, movable side plates, a half support plate, support guide rails, positioning blocks, impressing shafts and impressing wheels; an upper support guide rail and a lower support guide rail are provided with an upper positioning block and a lower positioning block in a sliding way; and an upper impressing wheel and a lower impressing wheel are arranged on the inwards protruding end parts of the upper positioning block and the lower positioning block. By the technical scheme, under the matching action of a pair of impressing wheels in concave-convex shapes, original punched pre-impression on a folding part of a corrugated cardboard box is strengthened, and two sides of the original impression are provided with two reinforcing and fixing ribs, so that an error of two ends of an adhering part of the glued box is obviously lower than the international standard; therefore, requirements on high box gluing speed, high precision, low rejection rate and the like are met, and mechanical or manual correction is not needed any more.

Owner:温州市高田包装机械有限公司

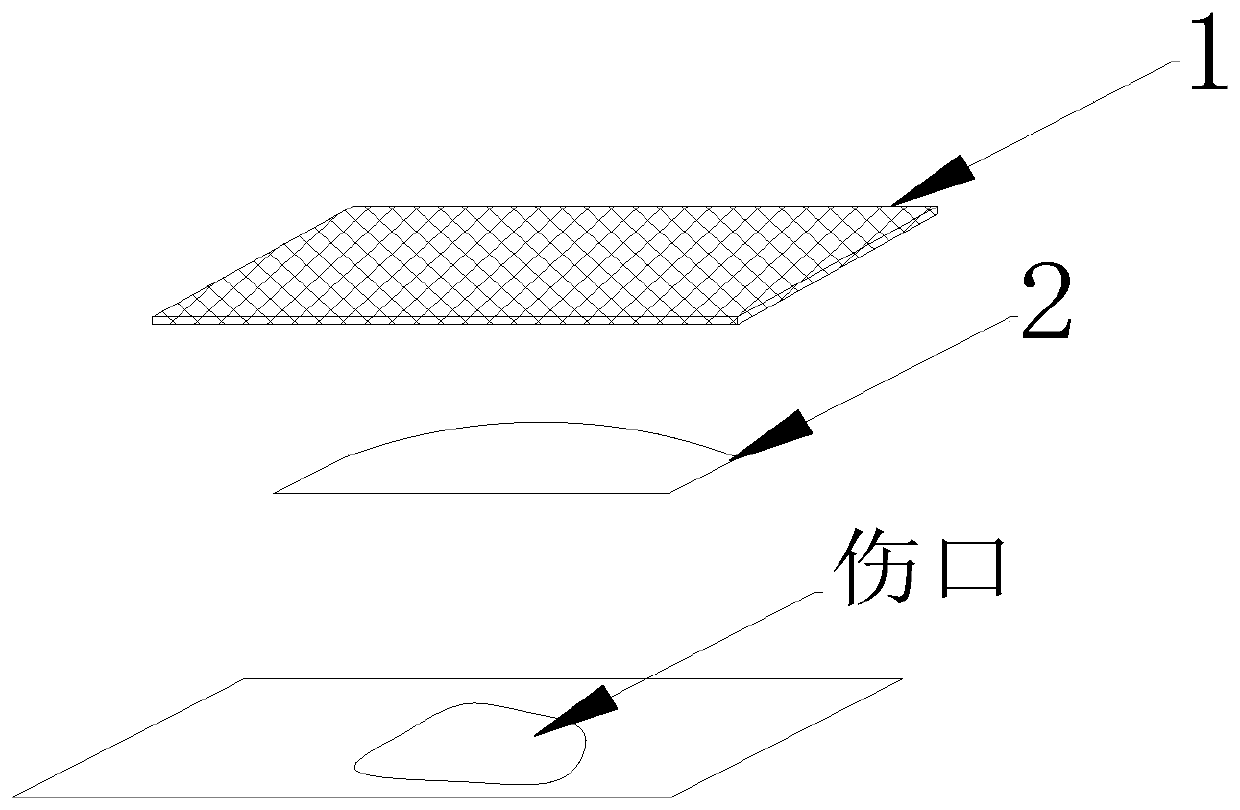

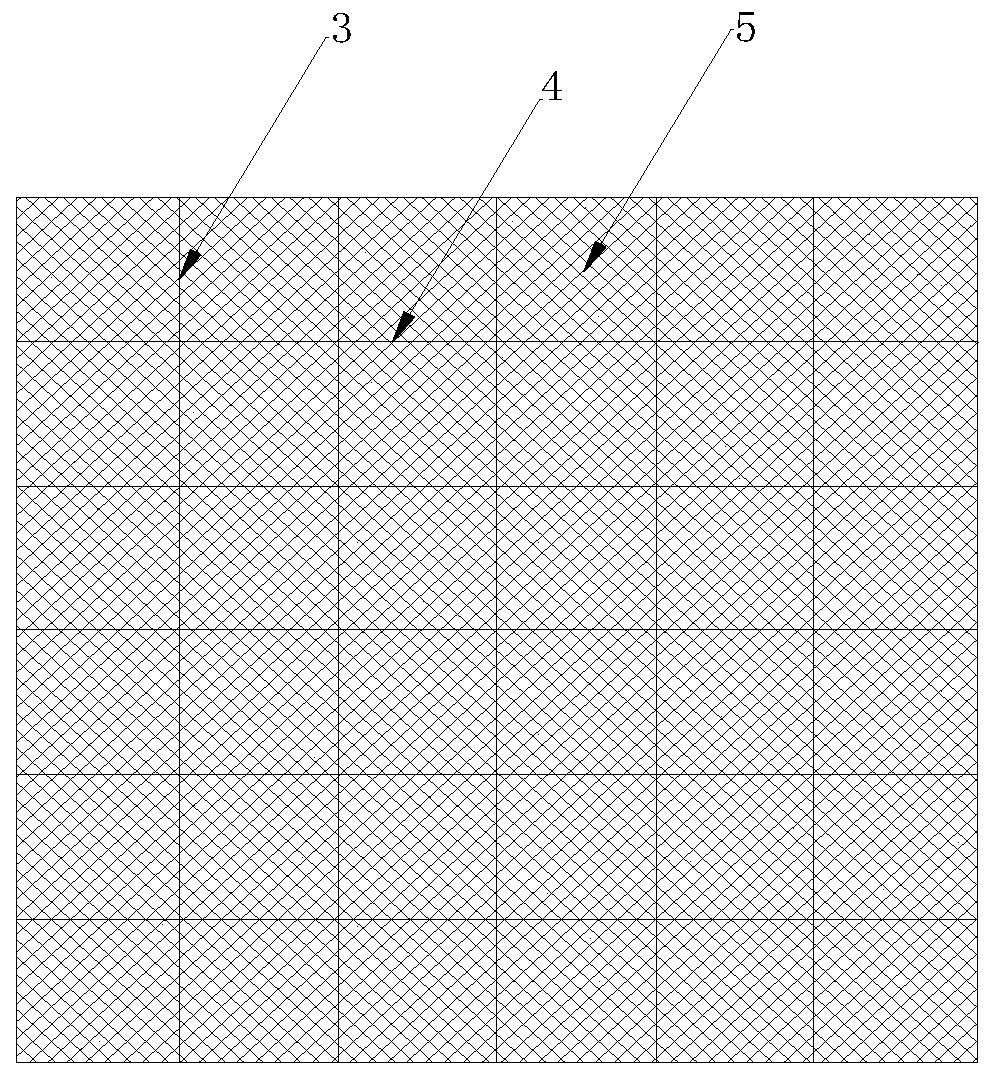

Hemostatic material for war wounds as well as preparation method and application thereof

InactiveCN110975002AEasy to removeAvoid infectionSurgical adhesivesPharmaceutical delivery mechanismTissue repairPolyethylene glycol

The invention discloses a hemostatic material for war wounds as well as a preparation method and an application thereof, which relate to the technical field of biomedical materials, and the hemostaticmaterial is characterized by comprising an electrostatic spinning outer membrane and hydrogel applied to the surface of the electrostatic spinning outer membrane, and the components of the electrostatic spinning outer membrane and the hydrogel are respectively one of PEG-NHS (polyethylene glycol-succinimide ester) or PEG-NH2 (polyethylene glycol amino). The preparation method comprises the following steps: 1) preparing preparation materials; 2) preparing the electrostatic spinning outer membrane; and 3) preparing the hydrogel. The hemostatic material is a hemostatic product applied to trauma,wound, thoracic cavity and abdominal cavity operations or internal organs and vascular bleeding. The hemostatic material has the properties of rapid coagulation hemostasis, moisture retention, bacteriostasis, tissue repair promotion, high mechanical strength, strong wound adhesion and the like, so that an efficient and convenient self-rescue and mutual-rescue material can be provided for war wound wounded persons, the death rate is conveniently reduced, and the war wound treatment level is improved.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

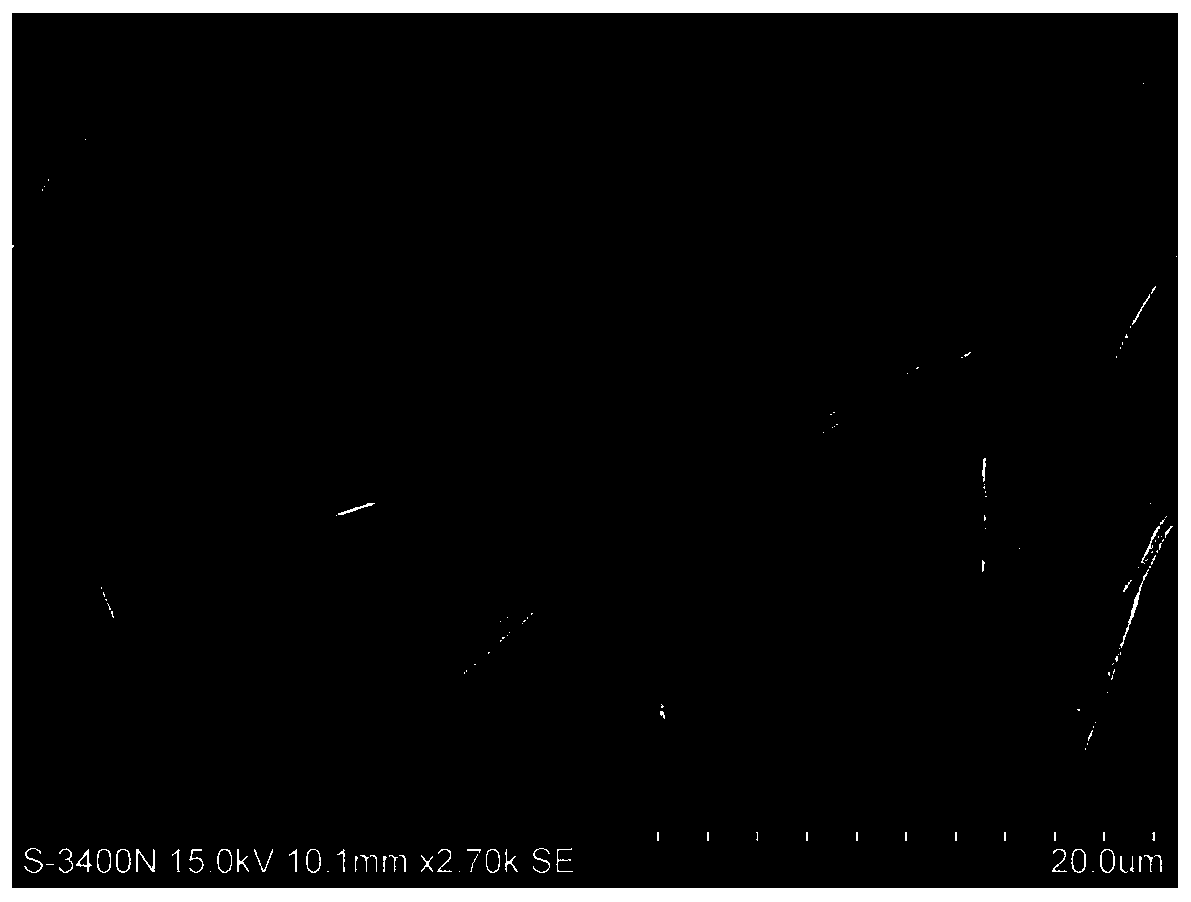

Sulfhydrylated hyaluronic acid as well as preparation method and application thereof

PendingCN112842929AThe degree of substitution is controllableDissolve fastCosmetic preparationsToilet preparationsDisulfide bondingDisulfide bond reduction

The invention discloses sulfhydrylated hyaluronic acid as well as a preparation method and application thereof. The sulfhydrylated hyaluronic acid is obtained by sulfhydrylation modification of hydroxyl sites of hyaluronic acid or salt thereof. According to the invention, the hyaluronic acid or salt thereof reacts with a disulfide compound to generate a hyaluronic acid disulfide compound, and then a reducing agent is added to reduce disulfide bonds into a sulfydryl group, so the sulfhydrylated hyaluronic acid is obtained. The sulfhydrylated hyaluronic acid has the characteristics of controllable sulfydryl substitution degree, fast dissolution, fast gelling and good biocompatibility, and can be applied to the fields of skin care products, joint injection, tissue filling, cell culture and the like.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

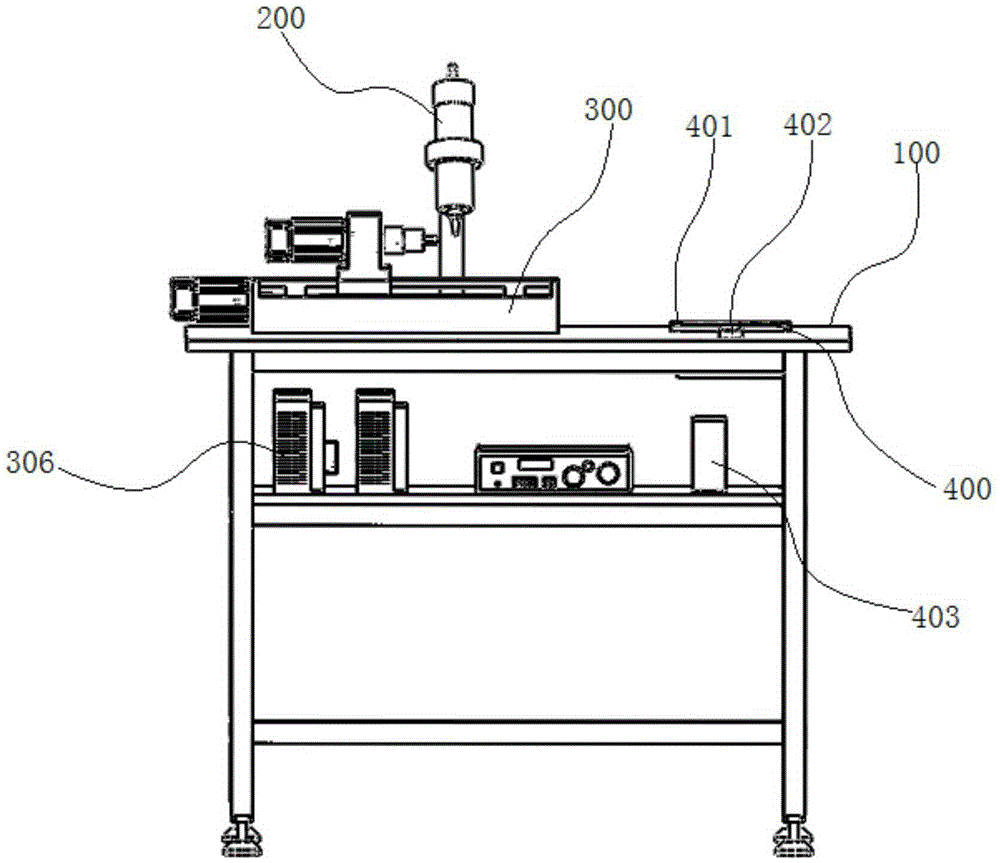

3D visual outsole glue spraying workstation and using method thereof

InactiveCN111185330ANovel structureReal-time adjustment of glue spray volumeSpraying apparatusShoe gluingAdhesive glueElectric control

The invention relates to the technical field of shoemaking, and particularly relates to a 3D visual outsole glue spraying workstation and a using method thereof. The 3D visual outsole glue spraying workstation is characterized in that the 3D visual outsole glue spraying workstation comprises a support frame, an intelligent manipulator, a photoelectric sensor, a conveying platform, an electric control cabinet and a 3D contour scanner, wherein the electric control cabinet is arranged on one side of the support frame, the 3D contour scanner is arranged right above the feeding end of the conveyingplatform, the photoelectric sensor is fixedly arranged at the feeding end of the conveying platform, the intelligent manipulator is arranged on the inner top surface of the support frame, the conveying platform is horizontally arranged below the intelligent manipulator, a glue spraying gun is arranged on the claw seat at the tail end of the intelligent manipulator,a plurality of glue outlet smallopenings for spraying glue independently are formed in the glue spraying gun, and a cleaning device for cleaning the head of the glue spraying gun is arranged on one side of the support frame. According to the 3D visual outsole glue spraying workstation and the using method thereof, the overall structure is novel, the head of the glue spraying gun can be cleaned in time, and the spraying amount of glue is conveniently controlled; and in addition, the effect of spraying different types of glue can also be achieved.

Owner:福建中泰德玛智能设备有限公司

Leather adhesion assistant gluing equipment

ActiveCN110509655ARealize SupplementApply evenlyLamination ancillary operationsLaminationEngineeringExtrusion

The invention belongs to the technical field of leather processing, in particular relates to leather adhesion assistant gluing equipment and aims to solve the technical problem of providing the leather adhesion assistant gluing equipment which is capable of implementing rapid gluing and has an extrusion function. According to the technical scheme, the leather adhesion assistant gluing equipment comprises a base, a fixing rack, a connecting rack, and the like, wherein the fixing rack and the connecting rack are arranged on the base. The equipment is capable of implementing rapid gluing and hasthe effect of an extrusion function; according to the equipment, by pushing a mounting rack to move leftwards, the surface of leather can be scraped by a scraper till a rough state, and meanwhile, automatic gluing can be achieved; and according to the equipment, by pushing the mounting rack to move rightwards, a glue can be uniformly smeared, the glue in a cylinder can be replenished, a pressing plate can be also driven to move downwards, and two pieces of leather to be bonded can be extruded and bonded tightly.

Owner:广州市创坤金葱粉皮革有限公司

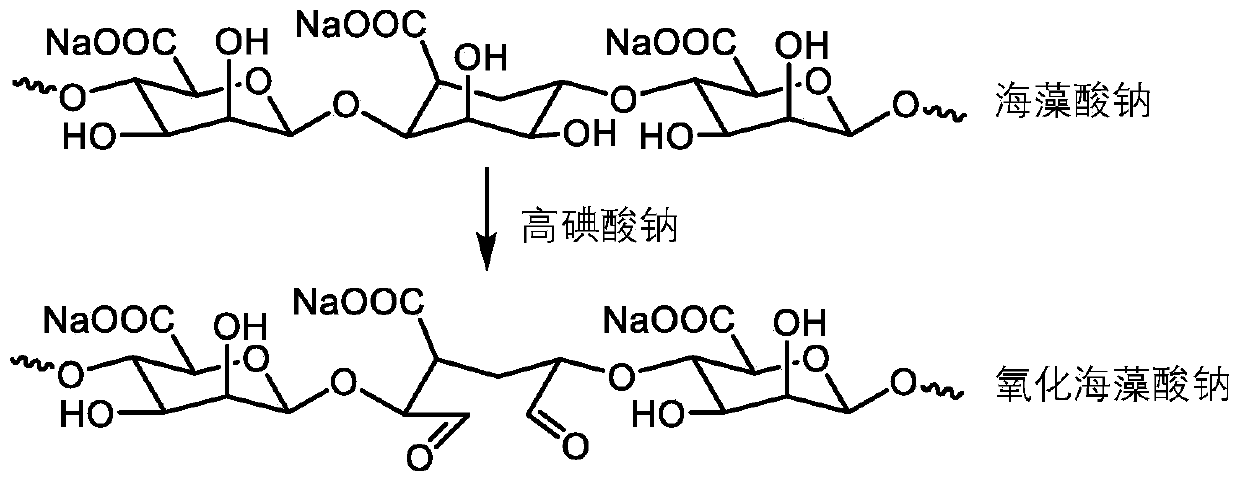

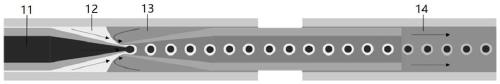

Degradable core-shell type oxidized calcium alginate gel microsphere, and preparation method and application thereof

ActiveCN111569798AUniform size and structureGood monodispersityMicroballoon preparationMicrocapsule preparationOrganic acidMicrosphere

The invention belongs to the technical field of materials, and particularly relates to a degradable core-shell type oxidized calcium alginate gel microsphere, and a preparation method and applicationthereof. According to the preparation method disclosed by the invention, the degradable core-shell type oxidized calcium alginate gel microsphere is prepared on the basis of micro-fluidic control; andan inner oil-phase fluid, a water-phase fluid and an outer oil-phase fluid form oil / water / oil double emulsion droplets, an acidic oil phase fluid containing organic acid is introduced into the downstream position of the oil / water / oil double emulsion droplets, calcium hydrochloride nanoparticles in a water phase of the oil / water / oil double emulsion droplets are rapidly dissolved, and free calciumions are released, so oxidized alginate in a water phase and the calcium ions are initiated to undergo rapid cross-linking so as to form a gelatinous oxidized alginate layer, and the degradable core-shell type oxidized calcium alginate gel microsphere is obtained. The degradable core-shell type oxidized calcium alginate gel microsphere prepared by the preparation method has the advantages that a size structure is uniform and monodispersity is high.

Owner:SUN YAT SEN UNIV

Glue coating apparatus for glued door

InactiveCN105750153AQuick GlueApply glue evenlyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a glue coating apparatus for a glued door. The glue coating apparatus comprises a base, wherein a glue rolling device is arranged on the base; a flattening and plate-feeding device is arranged above the glue rolling device; the glue rolling device comprises a glue box arranged on the base; a glue dissolving device is arranged at the bottom of the glue box; a glue roller is arranged in the glue box, and is erected on bearing seats located at the two ends of the glue box by a rotary shaft; a glue scraping rod is arranged on the front side of the glue roller; and a glue coating brush which is as high as and coaxial with the glue roller is arranged on the rear side of the glue roller. According to the glue coating apparatus, the flattening and plate-feeding device drives a fireproof plywood to be fed so the fireproof plywood is rapidly glued in a feeding process; the flattening and plate-feeding device can be used for flattening the concave-convex fireproof plywood; two adjacent glue coating devices which are arranged at the rear end of the base can be used for uniformly coating the feeding top end of the fireproof plywood with the glue; and the glue coating apparatus can be operated by only two persons for rapid and uniform coating of glue, so production efficiency is greatly improved.

Owner:QINGDAO MUCHENG DOORS IND GRP

Composite board surface gluing equipment for building material

ActiveCN112277105AQuick GlueImprove work efficiencyAdhesive application devicesConstruction engineeringAdhesive glue

The invention relates to gluing equipment, in particular to composite board surface gluing equipment for a building material. The technical aim of the composite board surface gluing equipment is thatthe working efficiency is high. The composite board surface gluing equipment for the building material comprises a base and a placing table and further comprises a movable discharging mechanism; the lower portion in the base is fixedly connected with the placing table; and the movable discharging mechanism is installed on the base and used for smearing glue on a composite board. According to the composite board surface gluing equipment, movable gluing can be conducted through the movable discharging mechanism, so that the glue uniformly falls onto the composite board, gluing can be conducted quickly, and the working efficiency is improved; the distance between a discharging assembly and the composite board can be shortened through a downward-pressing mechanism, and the glue falling onto the composite board is prevented from splashing; and the glue on the composite board can be trowelled through a troweling mechanism, so that the glue is smoother.

Owner:阜南盛原木业有限公司

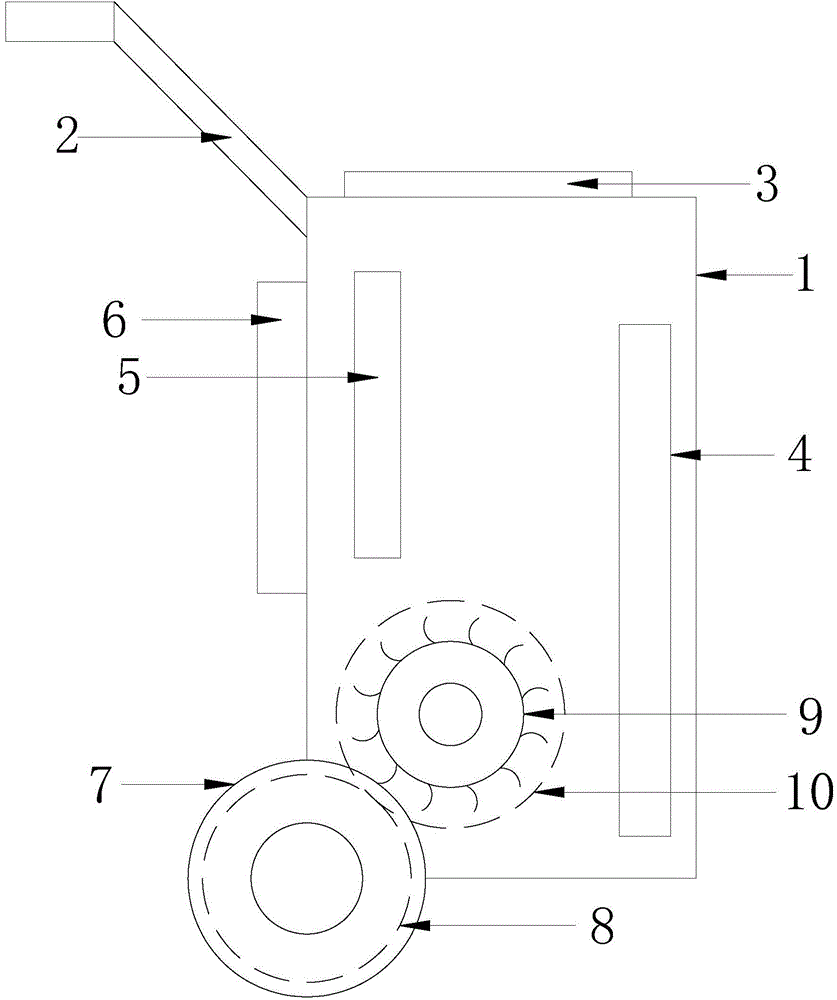

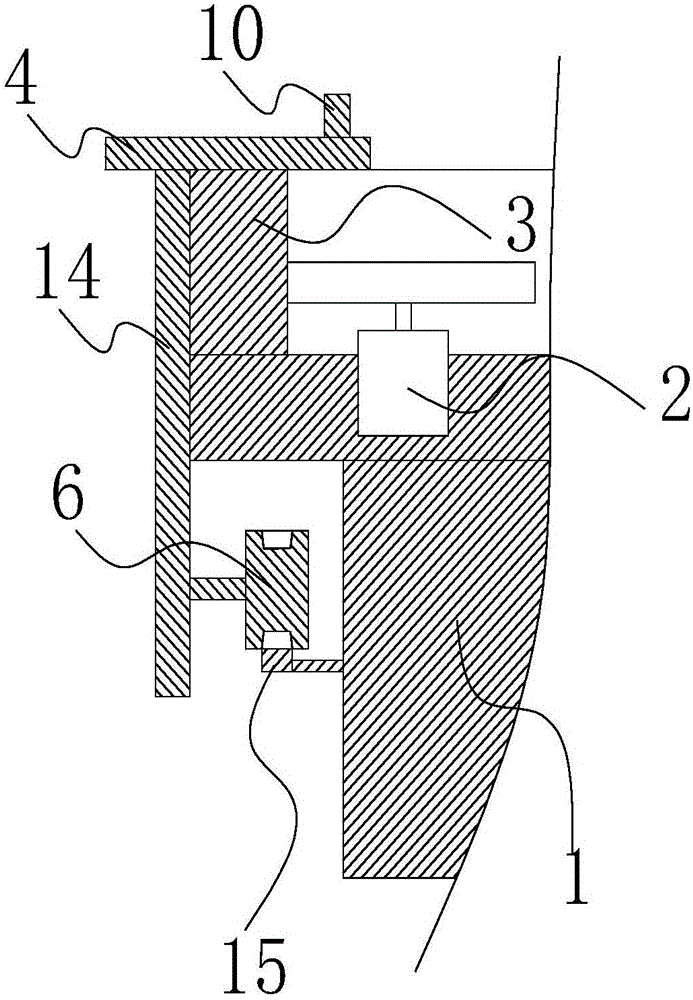

Pipeline sealant gluing device for floor heating pipeline mounting

ActiveCN110860429AAvoid cloggingQuick GlueLiquid surface applicatorsSpraying apparatusCircular discElectric machine

The invention relates to a sealant gluing device, and particularly relates to a pipeline sealant gluing device for floor heating pipeline mounting. The pipeline sealant gluing device for floor heatingpipeline mounting aims at achieving the technical purposes that the pipeline thread position can be automatically glued, a sealant cannot flow into a pipeline, and the gluing speed is high. The pipeline sealant gluing device for floor heating pipeline mounting comprises a bottom frame, a mounting plate and the like, wherein the mounting plate is fixedly connected to one side of the bottom frame.According to the pipeline sealant gluing device, a sliding handle is pushed, a disc and a T-shaped solid rod can be driven to fix a floor heating pipeline, the floor heating pipeline can be driven torotate through a speed reduction motor, a top plate can be driven to make contact with or be separated from a rubber pipe through movement of the sliding handle, accordingly, the sealant can be discharged to the floor heating pipeline, and the floor heating pipeline thread position can be glued.

Owner:江西万上实业有限公司

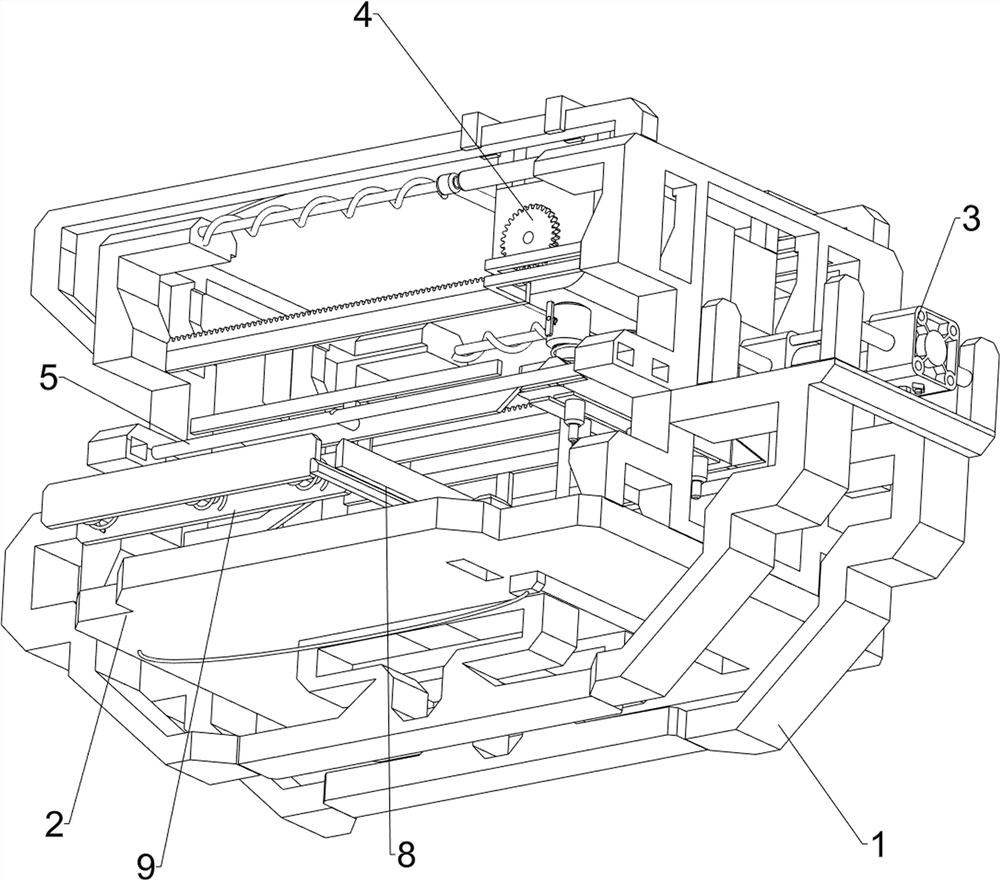

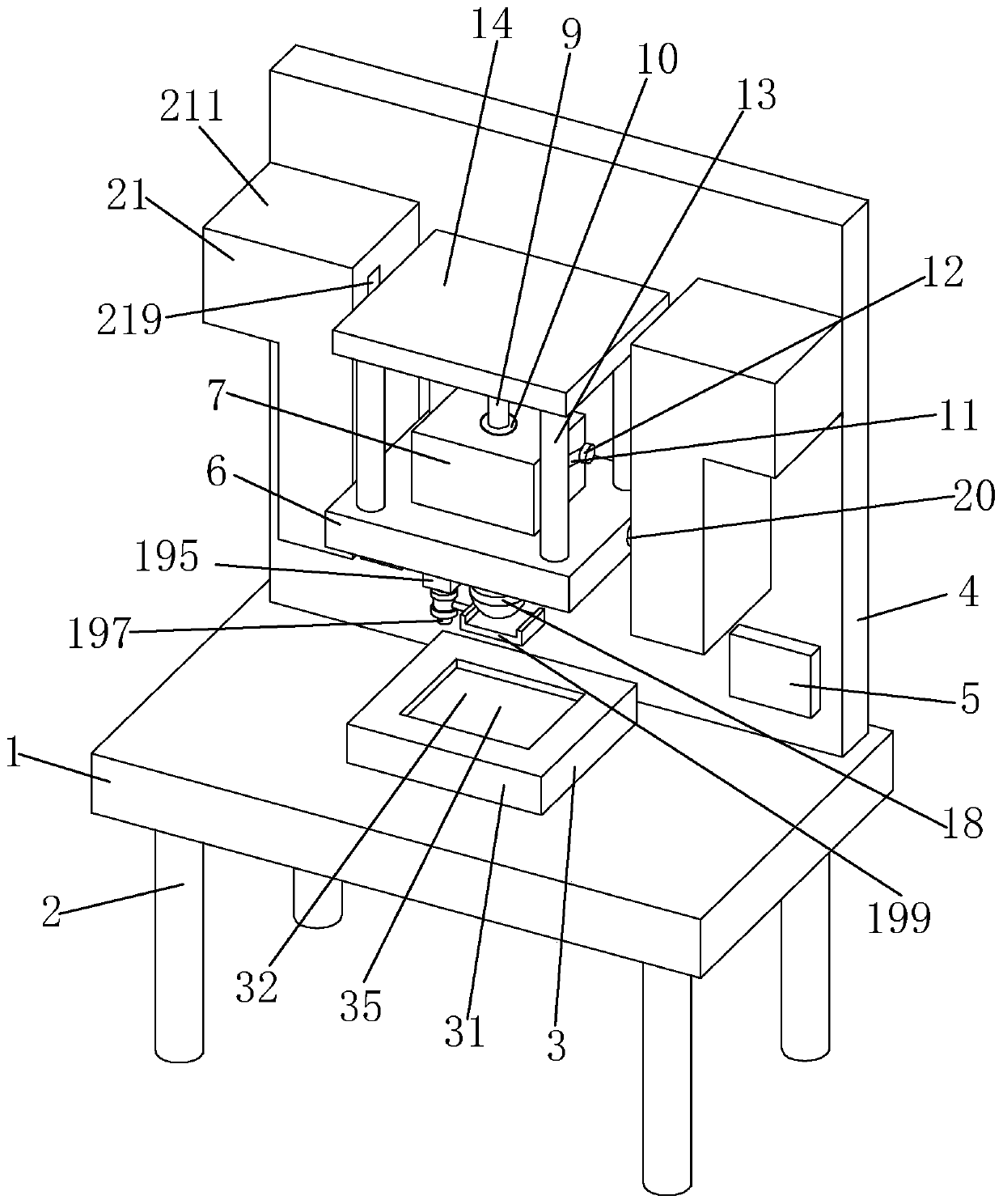

Automatic FPC reinforcing board laminating machine

InactiveCN111315150AAvoid Alignment AssemblyImprove assembly efficiencyCircuit bendability/stretchabilityNon-metallic protective coating applicationEngineeringReliability engineering

The invention relates to a laminating machine, in particular to an automatic FPC reinforcing board laminating machine. The technical problem to be solved is to provide the automatic FPC reinforcing board laminating machine which automatically glues a reinforcing board, automatically aligns an FPC board and the reinforcing board and performs full-automatic lamination. According to the technical scheme, the automatic FPC reinforcing board laminating machine comprises a rack, a pushing mechanism and material pushing mechanisms, the pushing mechanism is arranged on the rack; the machine also comprises a support frame fixed on the rack; a reinforcing board placing box which is positioned on the rack, is positioned on one side of the pushing mechanism, is mounted on the rack through a support frame and is used for placing the reinforcing board, a movable seat mechanism which is connected with the rack; and an FPC board placing box. According to the automatic FPC reinforcing board laminatingmachine, the functions of automatic feeding and rapid glue application are achieved, manual glue application on the reinforcing board and the aligned assembling of the FPC board and the reinforcing board are avoided, and the final assembling efficiency of the FPC reinforcing board can be effectively improved.

Owner:肖承福

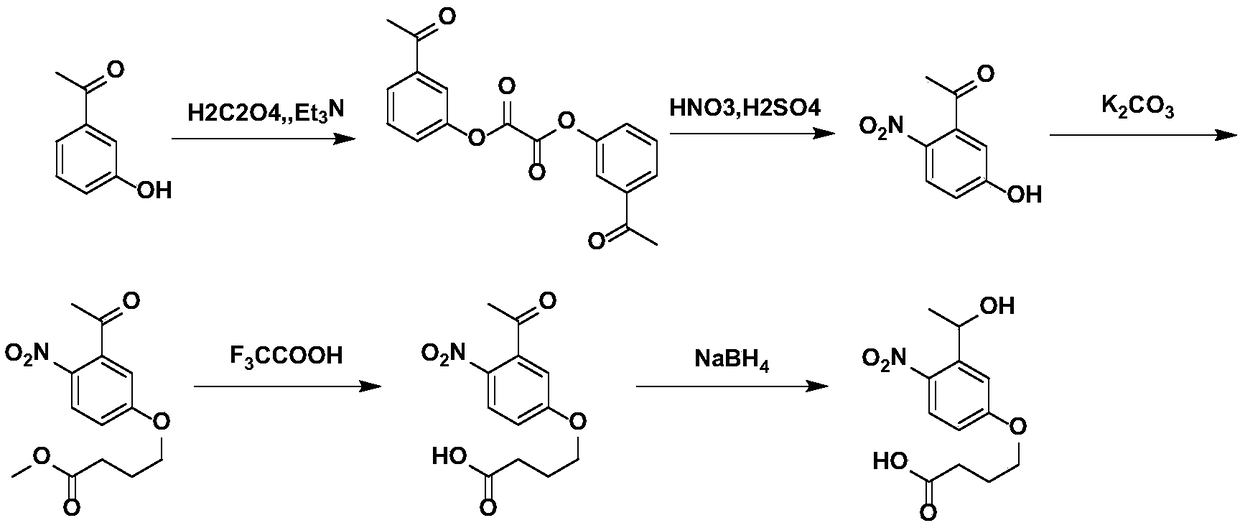

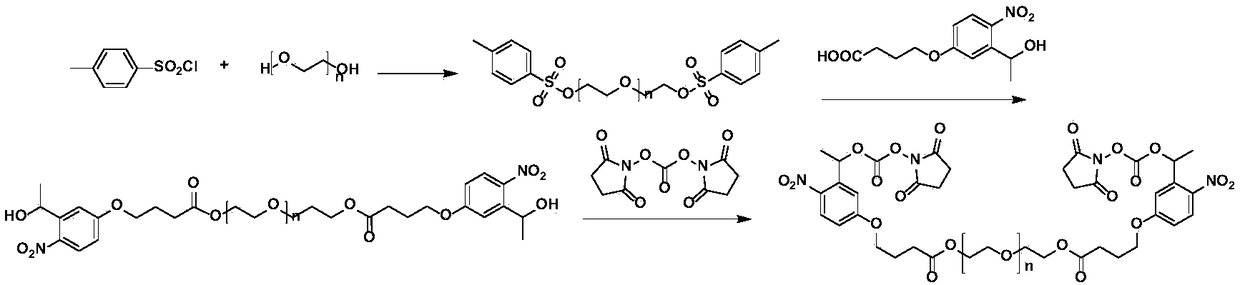

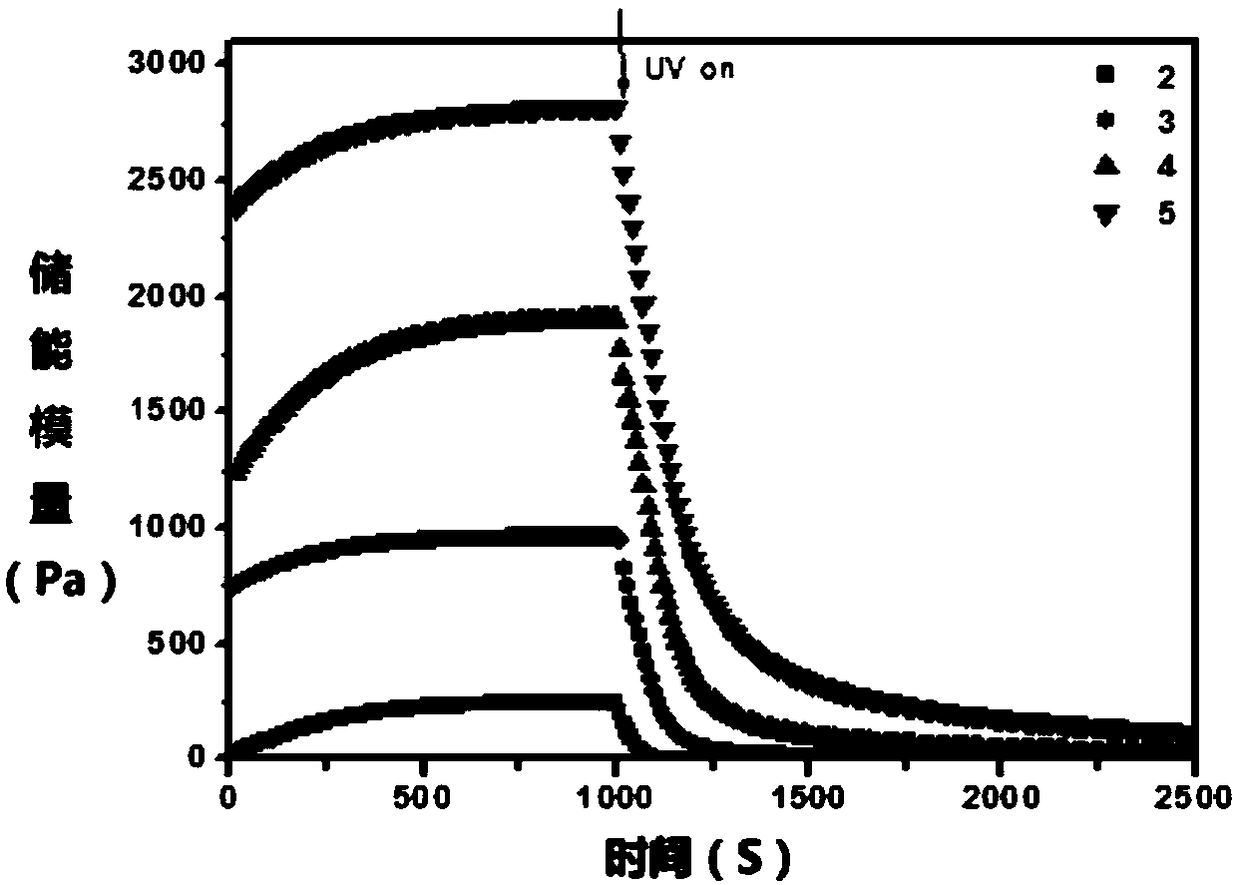

End-capped modified polyethylene glycol cross-linking agent having ultraviolet light response function, preparation method and hydrogel dressing containing cross-linking agent and preparation method thereof

The invention belongs to the technical field of biomedical dressings and relates to an end-capped modified polyethylene glycol cross-linking agent having an ultraviolet light response function, a preparation method and a hydrogel dressing containing the cross-linking agent and a preparation method thereof. The technical problem is solved that wound pain and secondary wounds care caused by when anexisting hydrogel dressing is removed for secondary wound treatment. The modified polyethylene glycol cross-linking agent having the ultraviolet light response function is formed by adopting an injectable in-site gel forming mode, and the gel forming mode has very good adaptability to wound shapes and meanwhile has better fitting property compared with a blocky dressing to be gelled without auxiliary fixing materials. When wounds need to be further treated, regional selective irradiation can be performed through 10 mw / cm<2> ultraviolet light of 365 nm, gel softening and degradation are achieved. Compared with other dressings, the function can prevent wound pain during gel removal and prevent newly growing tissues from being physically harmed to cause secondary wounds.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

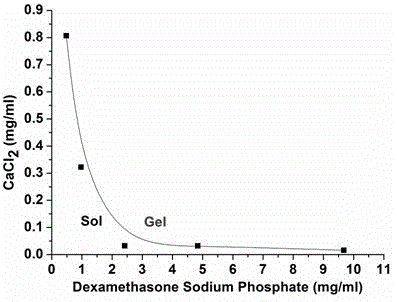

Preparation method of dexamethasone calcium phosphate hydrogel

InactiveCN105796481AEasy to makeQuick GlueOrganic active ingredientsAntipyreticCalcium biphosphateMedicine

Provided is a preparation method of a dexamethasone calcium phosphate hydrogel. By mixing a dexamethasone sodium phosphate solution with a Ca<2+> containing aqueous solution, the dexamethasone sodium phosphate solution and the Ca<2+> containing aqueous solution can spontaneously form the dexamethasone calcium phosphate hydrogel in a self-assembly mode. The preparation method of the dexamethasone calcium phosphate hydrogel has the advantages of being simple in preparation, quick in hydrogel forming and accurate and controllable in drug loading capacity.

Owner:WENZHOU MEDICAL UNIV

Floor glue brushing device for construction engineering

InactiveCN104563457AQuick GlueAvoid easy cloggingBuilding constructionsArchitectural engineeringBrush device

The invention discloses a floor glue brushing device for construction engineering, and relates to the technical field of construction engineering. A push handle is arranged at the upper end of a casing, a sealing cover is arranged at the upper end of the casing, a liquid level window is arranged on the casing, a heater is arranged in the casing, and is connected with an operation mechanism, a glue brushing roller is arranged at the left lower end of the casing, a gear I is arranged on a rotary shaft of the glue brushing roller, a mixing roller is arranged in the casing, and a gear II is arranged on the rotary shaft of the mixing roller, and is engaged with the gear I. The floor glue brushing device has the advantages that the quick glue brushing is conveniently realized, the easiness in blockage is avoided, the operation is simple and convenient, the convenience in use is realized, and the working efficiency is high.

Owner:HENAN GAODUAN FLOOR ENG

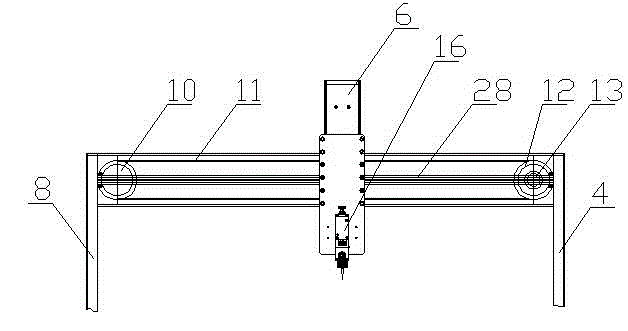

Rapid glue spraying device for processing of leather shoes

The invention relates to the technical field of shoe processing, especially to a rapid glue spraying device for processing of leather shoes. The rapid glue spraying device comprises a baseboard. A machining table is fixedly connected to the central position of the upper surface of the baseboard. A shifting board is arranged above the machining table. A glue storage box is fixed on the shifting board. A movable plate is arranged inside the glue storage box. Two sides of the movable plate are both provided with sealing gaskets. The central position of the upper surface of the movable plate is fixedly connected with a push rod. The central position of the lower surface of a top plate is fixedly connected with a telescopic cylinder. The bottom of the glue storage box is fixedly connected witha conduit. One end of the conduit, far from the glue storage box, penetrates through the movable plate. The conduit is provided with a valve. One end of the conduit, far from the glue storage box, isfixedly connected with a nozzle. The lower surface of the movable plate at one side of the nozzle is fixedly connected with a glue covering device. Two sides of the shifting board are both fixedly connected with connecting rods. One end of each connecting rod, far from the shifting board, is fixedly connected with a lifting device. The glue spraying device of the invention has a simple structure and is worth of promotion.

Owner:WENZHOU POLYTECHNIC

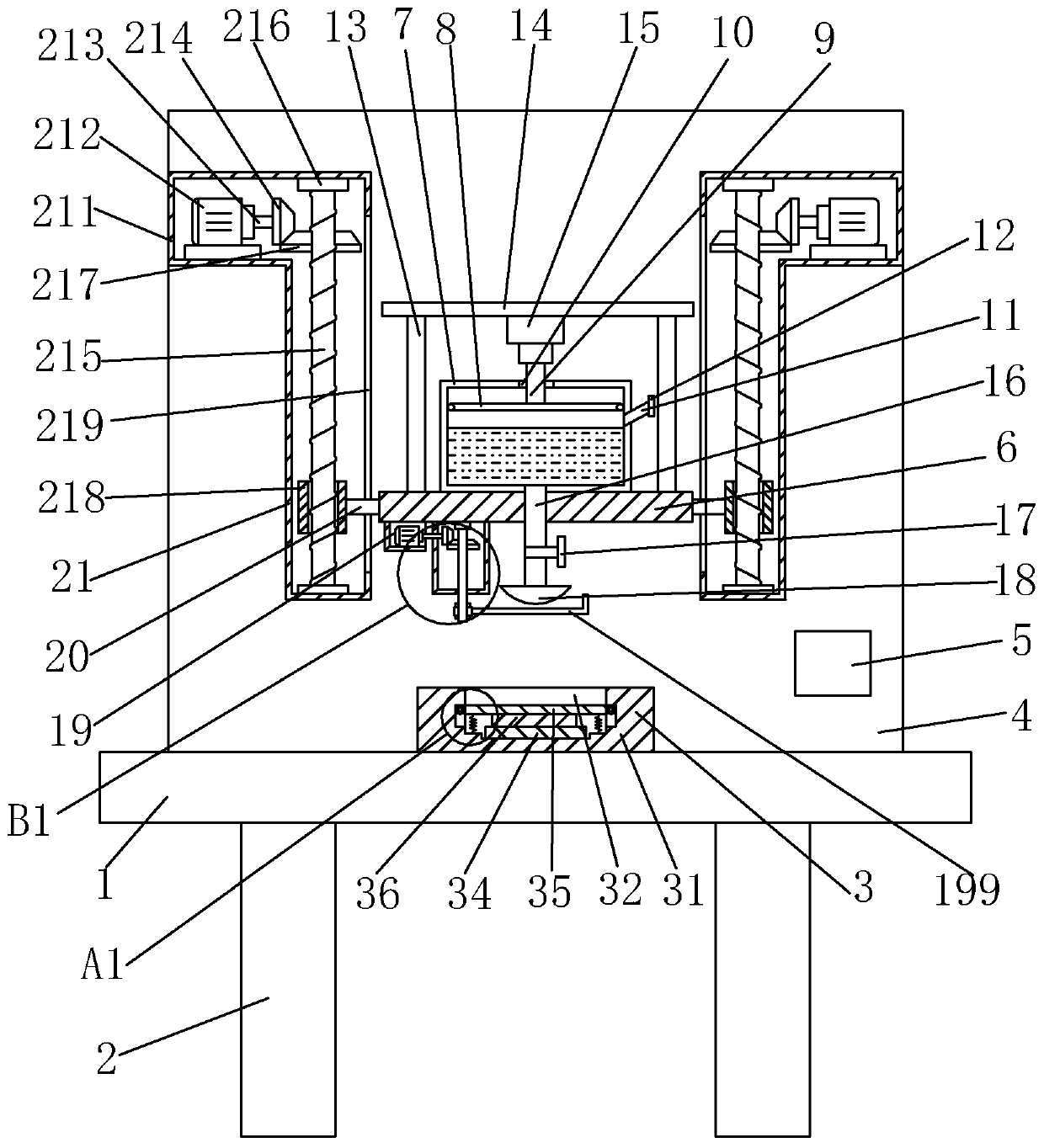

Intelligent fuse glue sealing machine of environment-friendly firework

InactiveCN104525439AGlue fastGlue size, thickness and speedLiquid surface applicatorsCoatingsRobotic armFireworks

The invention relates to an intelligent fuse glue sealing machine of environment-friendly firework. The intelligent fuse glue sealing machine comprises a glue pressing bucket, a dispensing head, an X-axis mechanical arm, a Y-axis mechanical arm, a Z-axis mechanical arm, a bottom box, a worktable, a left stand column and a right stand column, wherein the Y-axis mechanical arm is arranged on the bottom box; the left stand column and the right stand column are arranged on the two sides of the bottom box respectively; the tops of the left stand column and the right stand column are connected with the X-axis mechanical arm; the Z-axis mechanical arm is arranged on the X-axis mechanical arm; and the dispensing head is arranged on the Z-axis mechanical arm and is connected with the glue pressing bucket by a hose. The intelligent fuse glue sealing machine has the advantages of uniformity in glue coating, high production efficiency, stable product quality, automation in operation and environmental friendliness.

Owner:浏阳世纪红烟花制造销售有限公司 +1

Air conditioner pipe continuous multi-station gluing processing device

The invention discloses a continuous multi-station gluing processing device for air-conditioning pipe fittings, which includes a frame and a rotatable turntable set on the frame and driven by a motor. One side of the fixture is connected with a rubber box for extruding glue The glue spray head is provided with a glue brush on the frame. The glue brush is rotatably connected to the reciprocating frame. The reciprocating frame can drive the glue brush to reciprocate between the glue spray head and the fixture. There is a start switch under the fixture. The start switch is connected with the motor and the reciprocating frame. Compared with the prior art, the present invention triggers the start switch by installing the pipe to be processed in the fixture, so that the clamp is controlled by the control component to complete the clamping action, so that the fixture with the newly installed pipe is rotated to the position that matches the glue brush , the glue spray head provides glue for the gluing brush, and drives the gluing brush to move to the fixture through the reciprocating frame to apply glue to the parts to be glued on the fixture, thereby realizing mechanized gluing processing and achieving fast and uniform gluing , improve processing efficiency.

Owner:ZHEJIANG LONGTENG AIR CONDITIONER

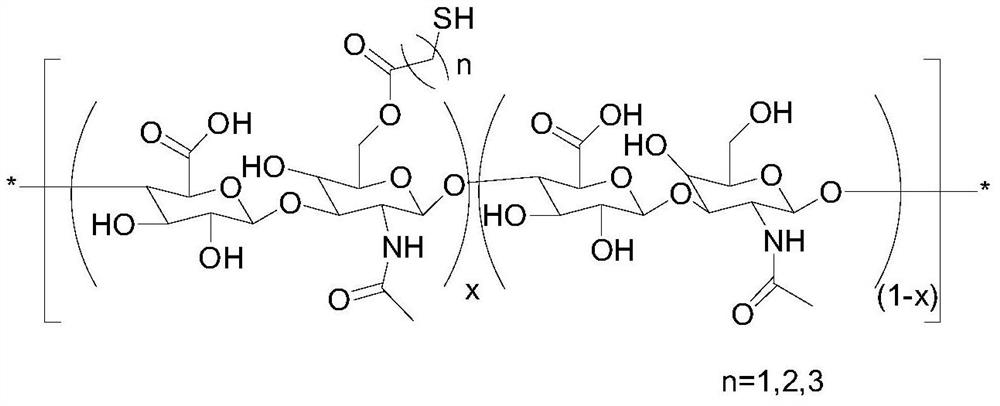

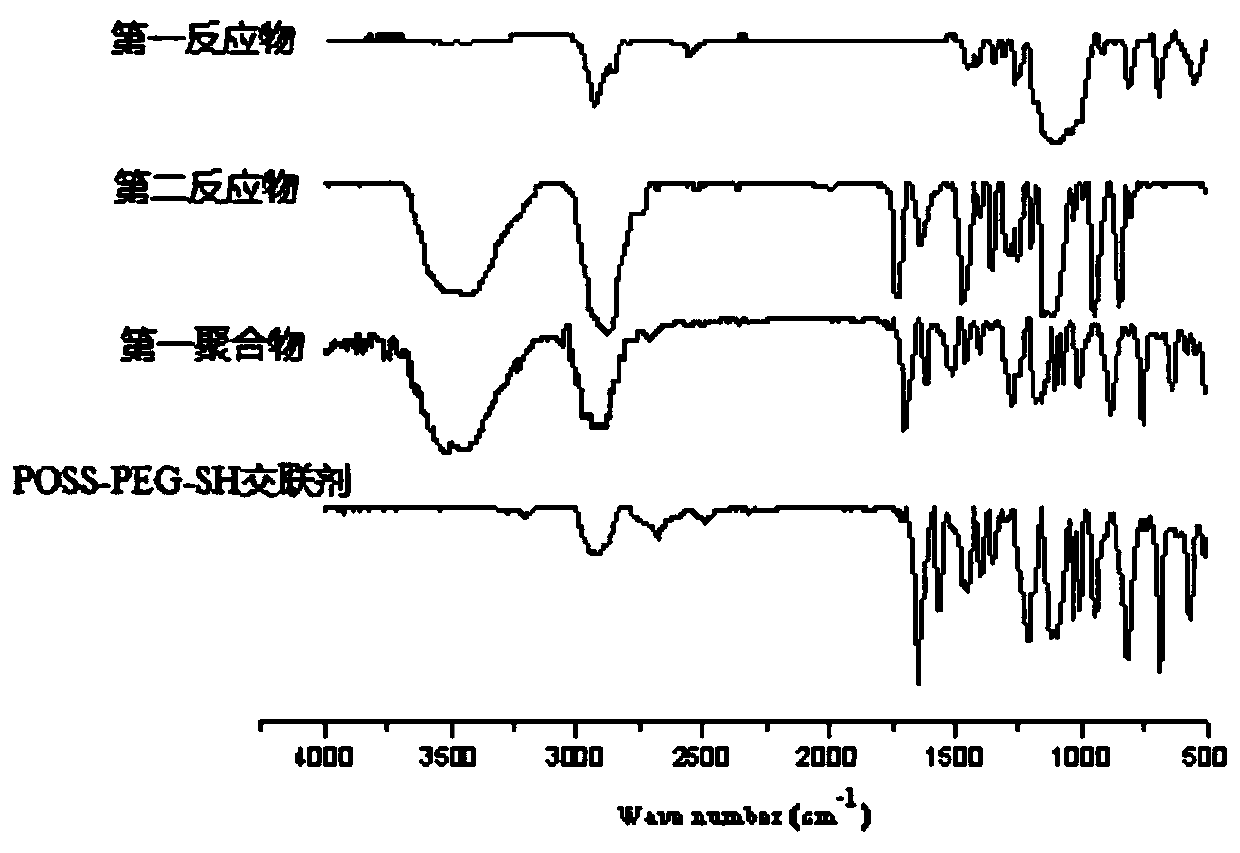

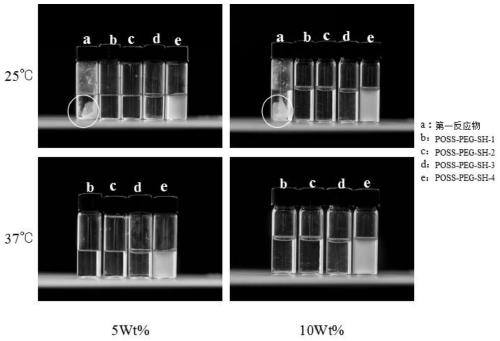

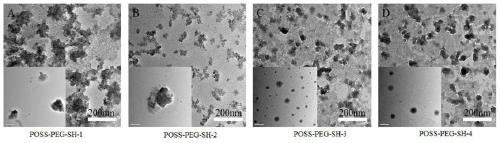

Water-soluble mercaptan-terminated PEG-functionalized POSS cross-linking agent, preparation method and applications thereof

The invention relates to a water-soluble mercaptan-terminated PEG-functionalized POSS cross-linking agent, a preparation method and applications thereof, wherein the macromolecular polymer has a structure represented by the following formula defined in the specification. According to the present invention, the water-soluble mercaptan-terminated star-shaped macromolecular polymer POSS-PEG-SH can beused as a cross-linking agent to react with a compound containing a double bond and other functional groups so as to prepare hydrolytically degradable hydrogels, enzyme-sensitive hydrogels and otherhydrogels, and due to the introduction of the polyfunctional POSS nanoparticles, a plurality of cross-linking sites can be added during the gelation so as to effectively improve the mechanical properties of the hydrogel.

Owner:HUBEI UNIV

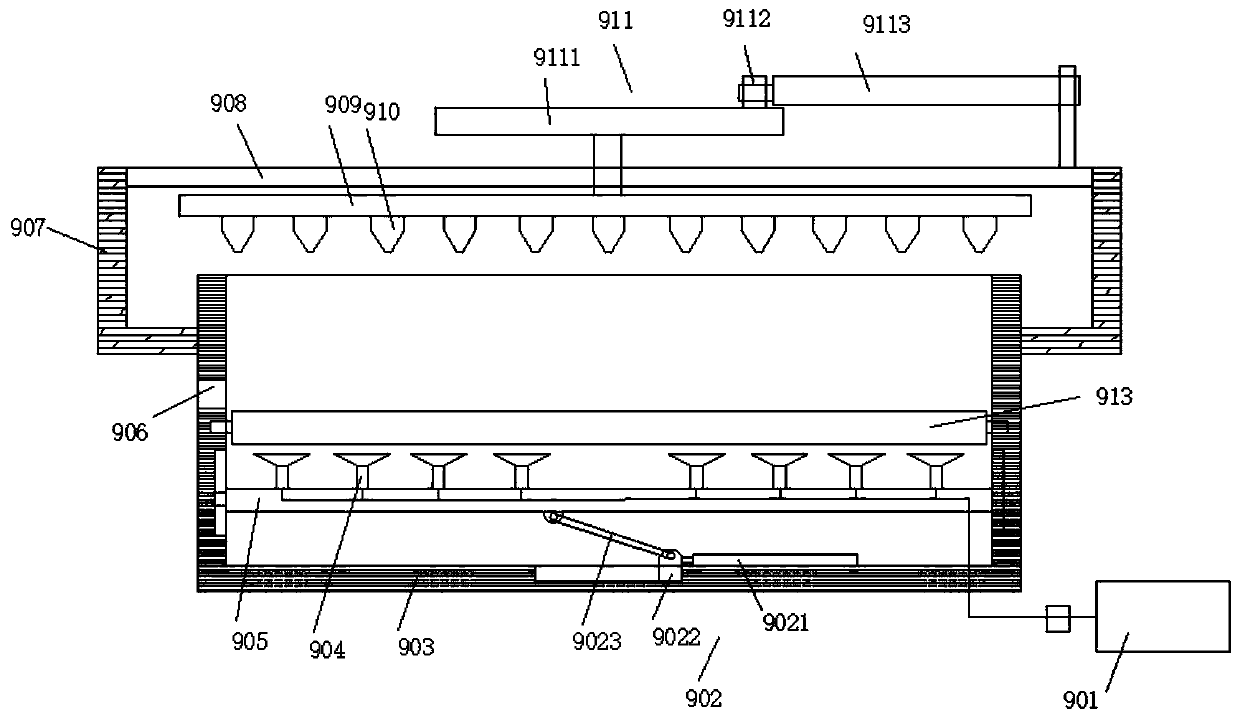

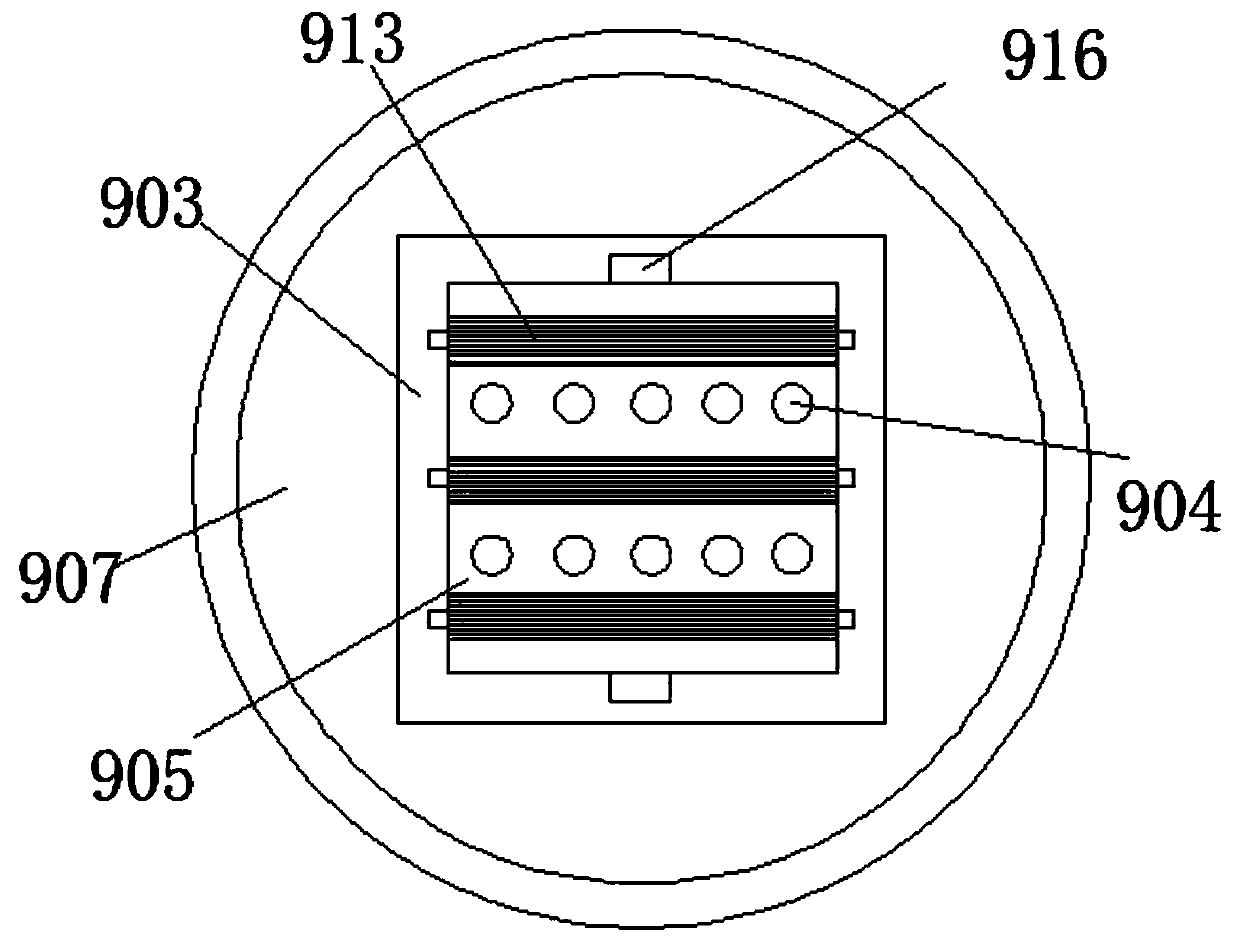

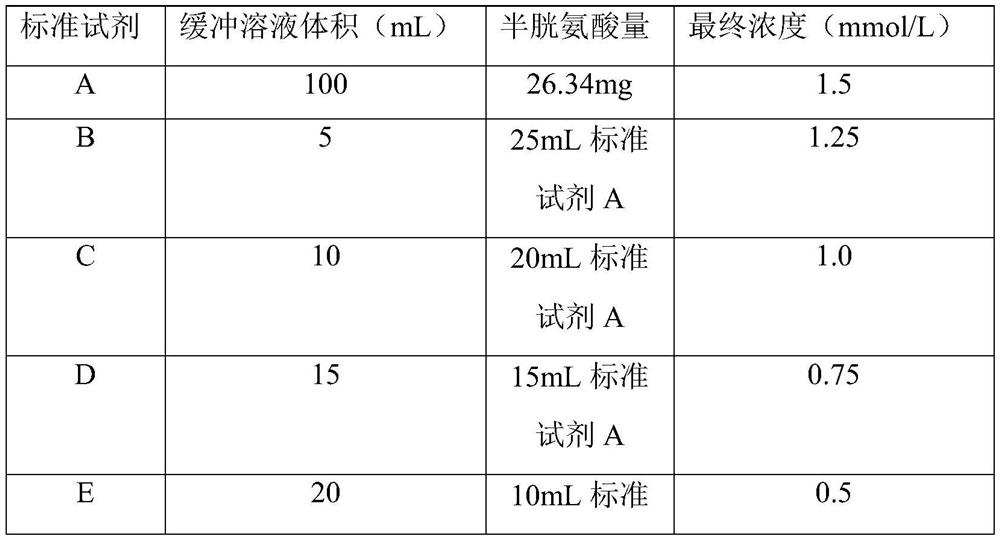

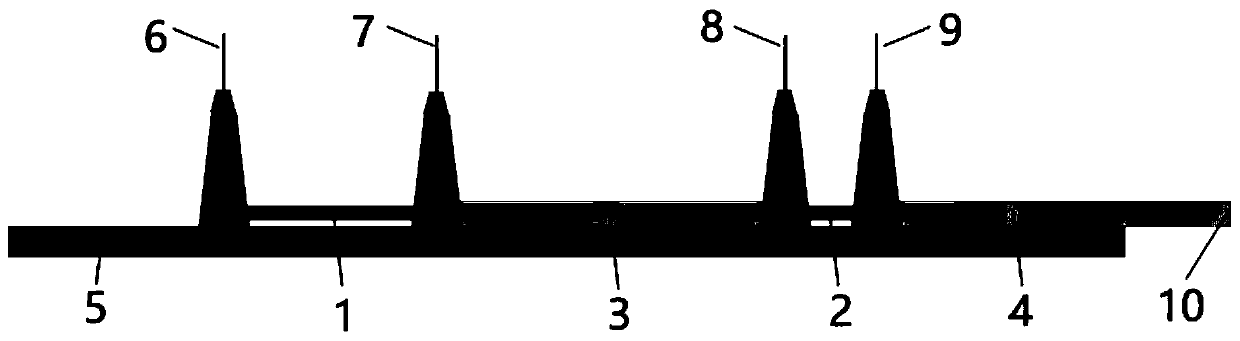

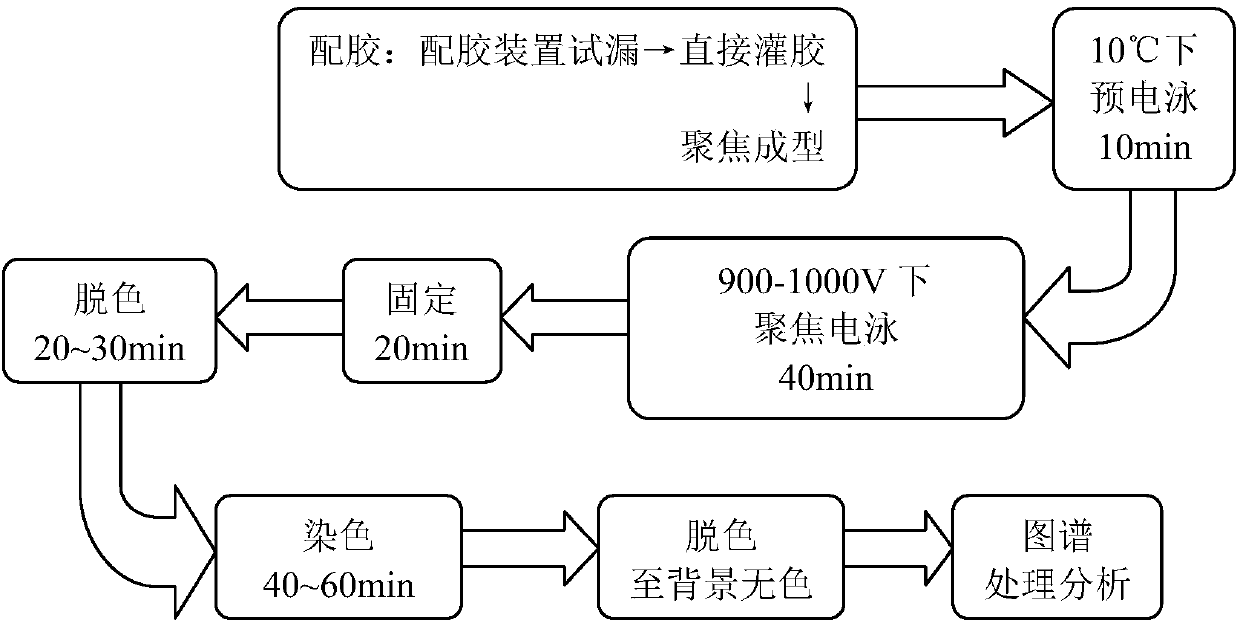

Protein isoelectric focusing electrophoresis method and glue preparation device

ActiveCN107860814AChange voltageChange timeMaterial analysis by electric/magnetic meansGeneral water supply conservationElectrophoresesGel electrophoresis of proteins

The invention discloses a protein isoelectric focusing electrophoresis method and glue preparation device, and belongs to the technical field of bioseparation detection. The method comprises the stepsof glue preparation, glue filling, pre-electrophoresis, electrophoresis, gel fixing, decoloration, dyeing and the like. According to the method, the feeding mode of a sample and voltage and electrophoresis time of pre-electrophoresis and electrophoresis are changed, so that obtained protein electrophoresis bands are clear, good in separation degree and do not diffuse or trail, the problem that inthe prior art, the electrophoresis time is long, and protein diffuses and trails is effectively solved, and the glue preparation success rate is greatly increased. The glue preparation device comprises a glue preparation support, a fixed frame, glue preparation glass, a gasket, an anti-leakage pad and other components. By improving the structure of the glue preparation device, the consumption ofa reagent is reduced, glue filling is fast, no bubble is generated, glue gathering is even, the glue preparation success rate is greatly increased, and meanwhile the inspection cost is reduced.

Owner:LIVZON GROUP LIVZON PHARMA FACTORY

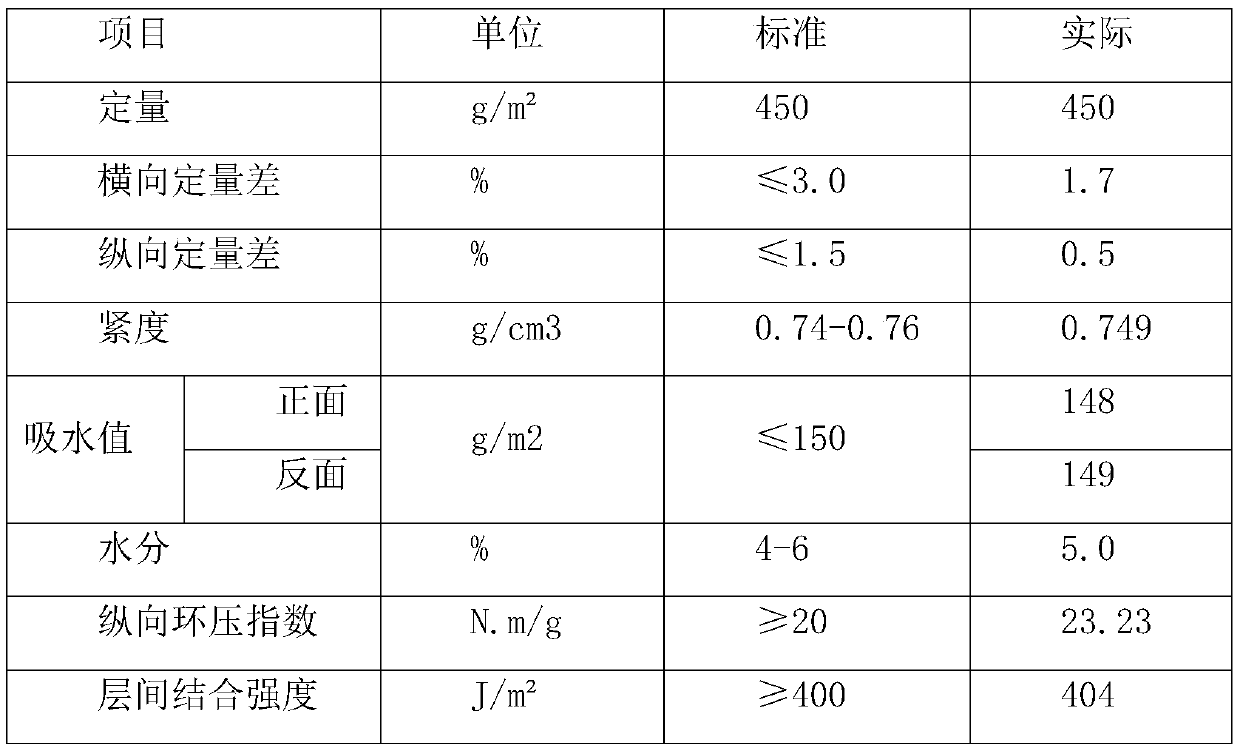

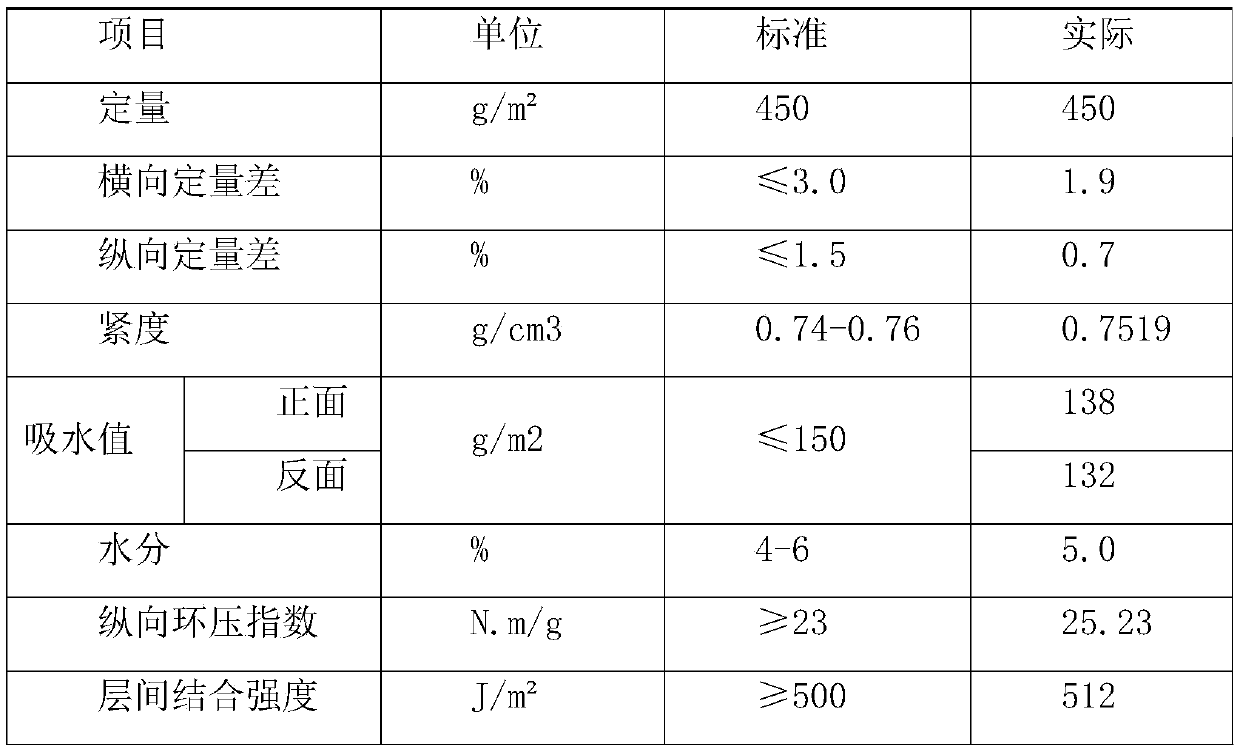

TF-series base paper of paper tube and preparation process thereof

ActiveCN110258155ASlow down moisture absorptionNo moisture absorptionNon-fibrous pulp additionSpecial paperPapermakingMoisture absorption

The invention discloses TF series paper tube base paper and a preparation process thereof, and mainly relates to the technical field of papermaking, and the paper is divided into two levels of TF400 and TF500. The paper has the following technical indexes: the quantification is 450 g / m<2>, the transverse quantification allowable error range is + / -3.0%, the longitudinal quantification allowable error is + / -1.5%, the tightness is 0.74 to 0.76 g / cm<3>; the longitudinal ring crush index of TF400 is larger than or equal to 20 N*m / g, the interlayer bonding strength is larger than or equal to 400 J / m<2>, the longitudinal ring crush index of TF500 is larger than or equal to 23 N*m / g, the interlayer bonding strength is larger than or equal to 500 J / m<2>, the water absorption value (60s) is smaller than or equal to 150 g / m<2>, and the finished paper moisture content is 4-6%. The manufacturing process of the paper tube base paper comprises the steps of performing pulping, papermaking and rewinding to obtain the paper tube base paper, and then packaging the finished paper. Pulping is carried out in the pulping process, and starch in pulp is added in the paper forming process. The invention has the advantages of low cost, low water content, low possibility of moisture absorption, high glue absorption speed, high pipe forming pressure, short drying time and the like.

Owner:ZHONGTIAN PAPER

Butyl rubber coating machine

ActiveCN105946334AChange the squeegee angleGlue accurateControlling laminationLaminationMagnetic powderTension control

The invention discloses a butyl rubber coating machine which comprises first and second unreeling mechanisms, an automatic skew adjustment mechanism, a rubber scraping and coating mechanism, a compounding mechanism, a cooling forming mechanism and a rolling-up mechanism, and is characterized in that a first discharge material of the first unreeling mechanism enters the compounding mechanism after passing through the automatic skew adjustment mechanism, a first tension control roller and the rubber scraping and coating mechanism; a second discharge material of the second unreeling mechanism enters the compounding mechanism after passing through a second tension control roller; a compound material compounded by the compounding mechanism enters the rolling-up mechanism after passing through the cooling forming mechanism and a third tension control roller; the first, second and third tension control rollers are respectively arranged on first, second and third tension sensors; the first tension sensor is electrically connected with a first magnetic powder brake of the first unreeling mechanism; the second tension sensor is electrically connected with a second magnetic powder brake of the second unreeling mechanism; and the third tension sensor is electrically connected with a third magnetic powder brake of the rolling-up mechanism. The butyl rubber coating machine can be applicable to coating of poor materials of high-viscosity runners, such as butyl rubber, is good in coating quality, and can improve the production efficiency.

Owner:RUIAN JIAYUAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com