Rapid identification glue spraying method and system for vamps and soles

A technology of spraying glue and shoe uppers, which is applied in the direction of shoemaking machinery, footwear, applications, etc., can solve the problems of reducing production efficiency, prolonging the processing time of parts, and affecting shoe production, so as to improve production efficiency and reduce glue spraying The time and the effect of simplifying the glue spraying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to express the present invention more clearly, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

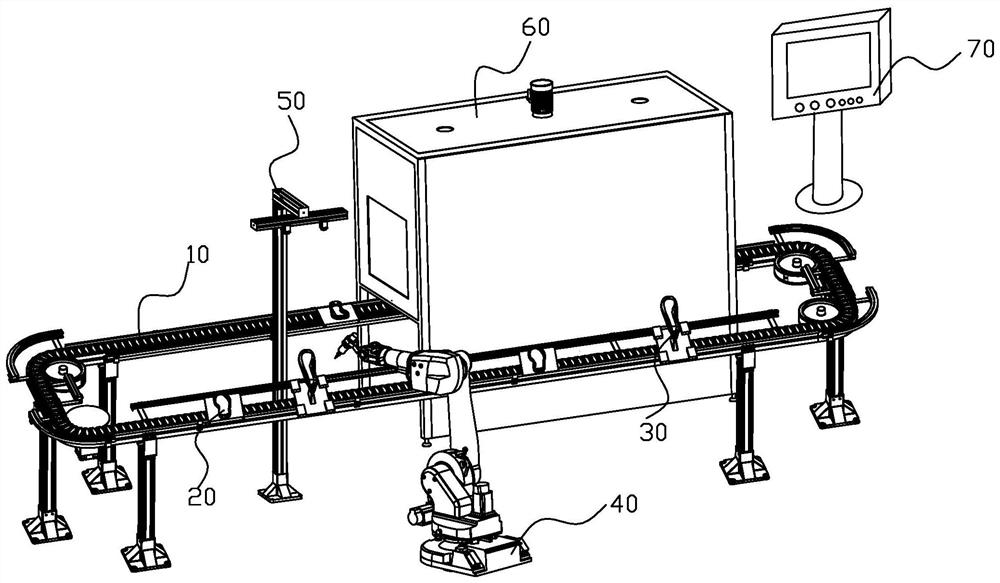

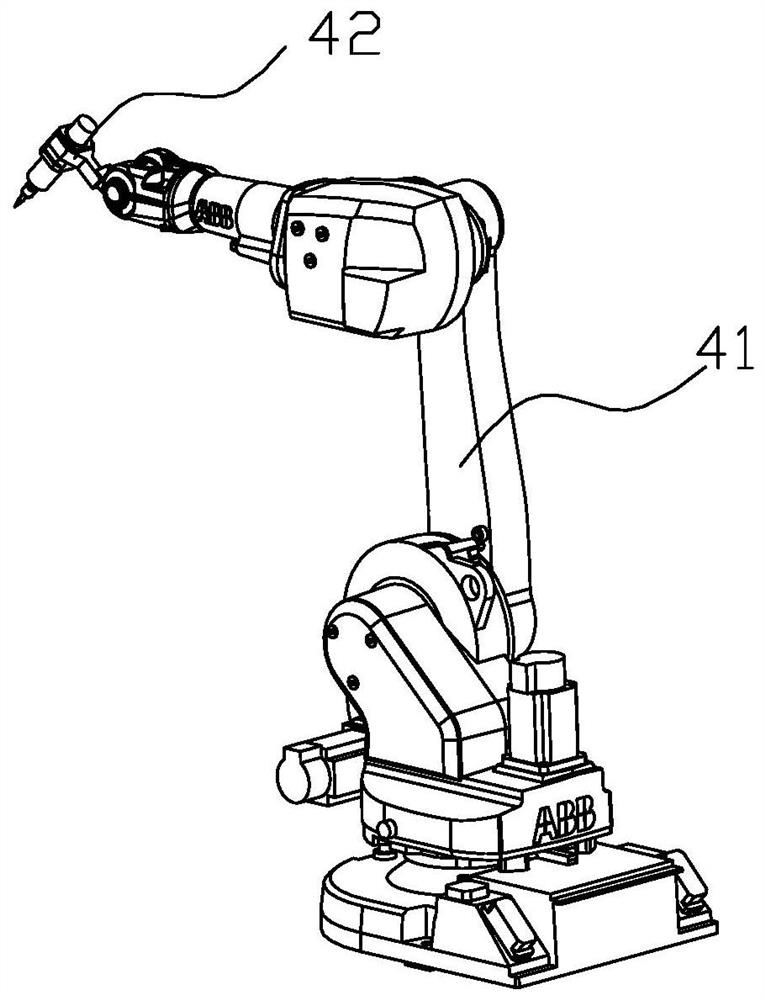

[0055] combine figure 1 Shown, the shoe upper that the present invention realizes based on machine vision guidance, sole fast glue spraying method, comprises the following steps:

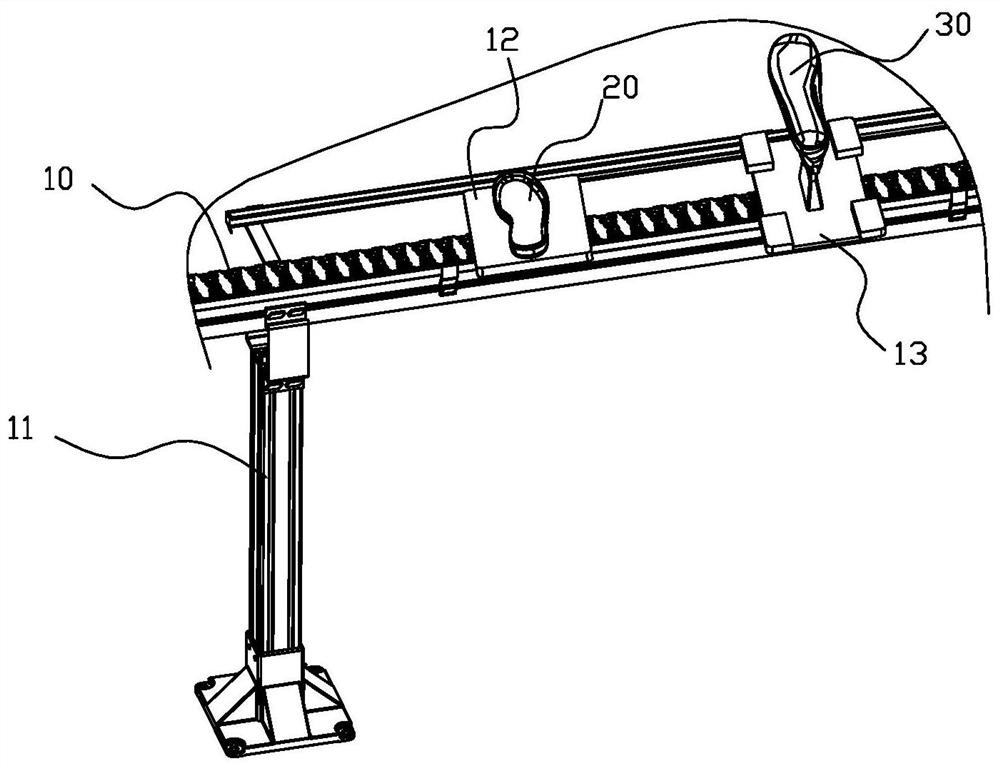

[0056] S1, feeding. The material (comprising the sole 20 and the vamp 30, usually both the sole 20 and the vamp 30) to be sprayed is put into the conveyor belt;

[0057] A control system 70 (the control system is usually implemented by a main control computer) controls the operation of the conveyor belt 10; materials include soles and vamps, specifically, the vamps to be glued are put into the shoe last, and then placed on the conveyor belt or put the soles directly on the working tray, and then put the tray on the conveyor belt; the conveyor belt 10 is a flexible conveyor belt, so as to facilitate the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com