Air conditioner pipe continuous multi-station gluing processing device

A processing device and multi-station technology, which is applied to the device for coating liquid on the surface, coating, etc., can solve the problems of low work efficiency, secondary glue coating, and heavy labor, so as to improve processing efficiency and uniform coating glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

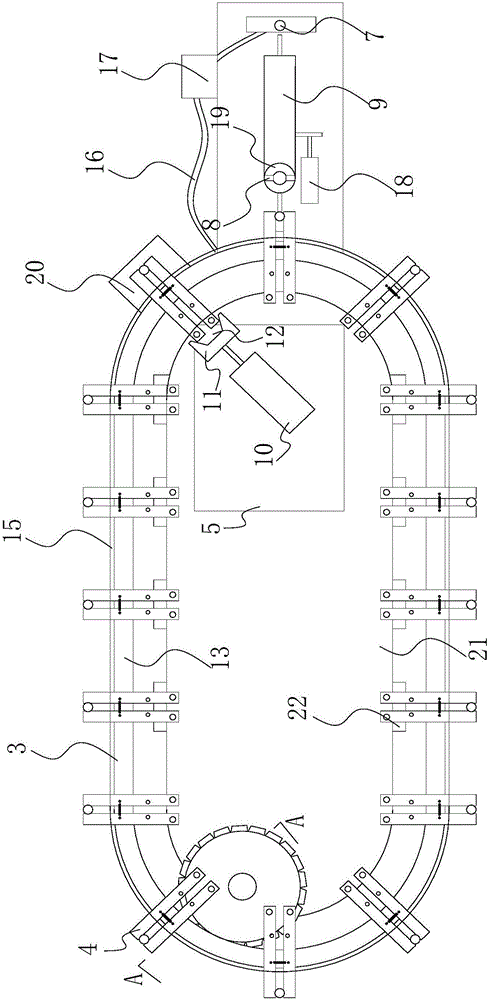

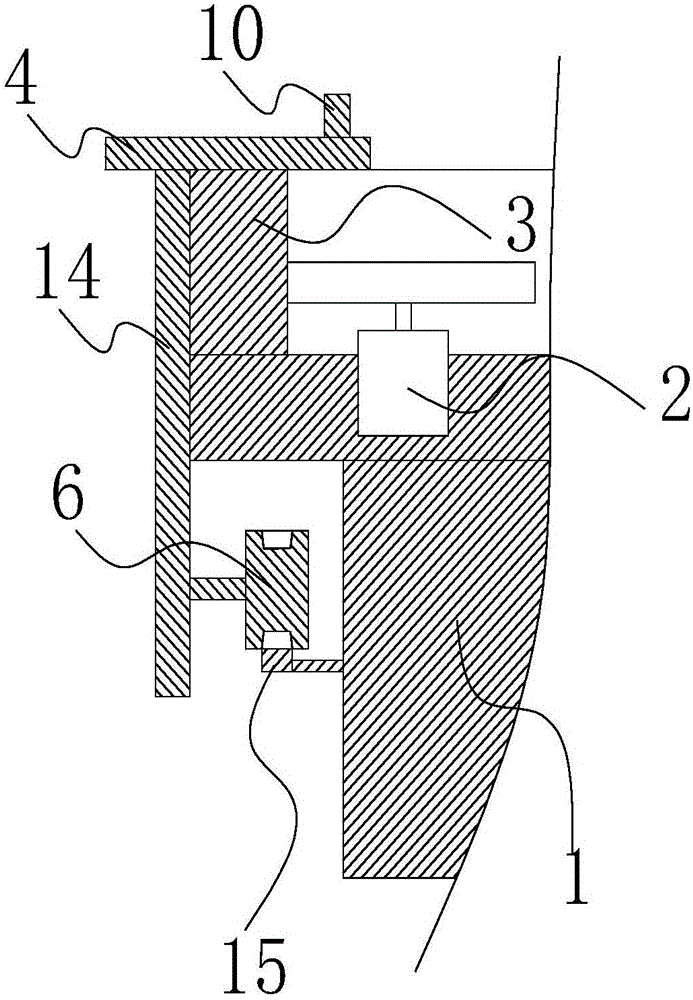

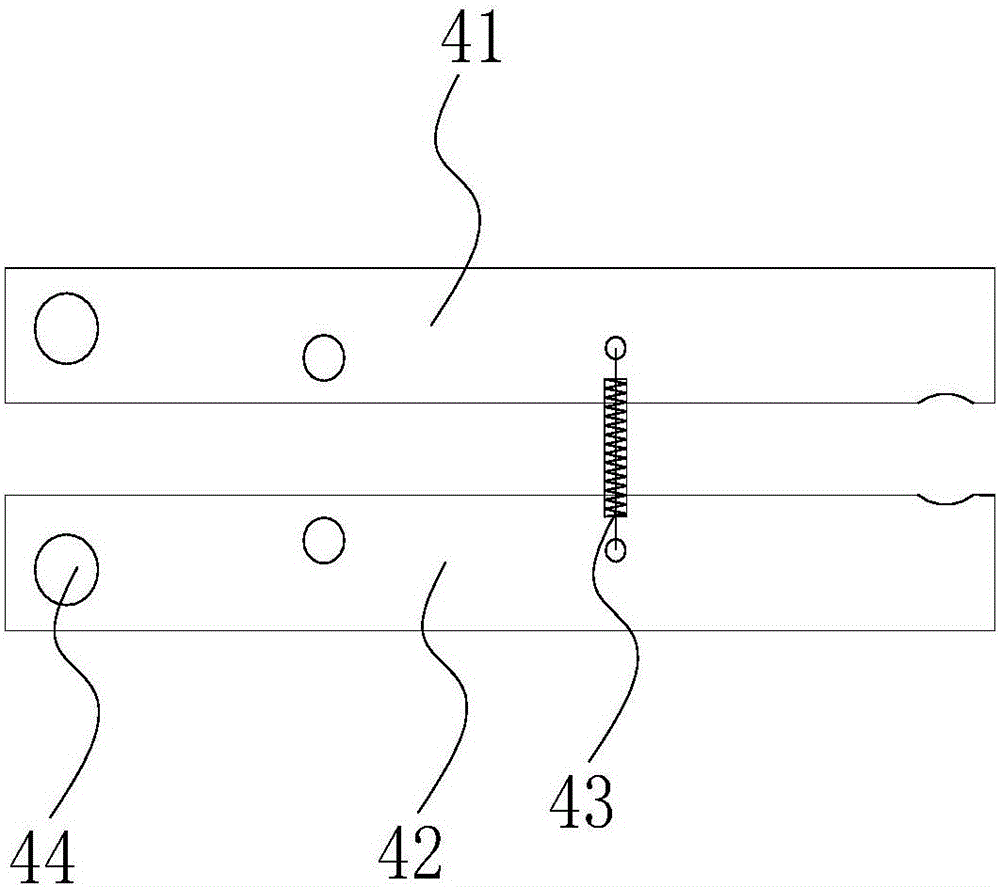

[0021] refer to Figure 1 to Figure 3 , the present invention includes a frame 1 and a turntable 3 which is set on the frame 1 and is driven by a motor 2 to rotate. A plurality of clamps 4 which can be opened and closed are arranged on the turntable. The control assembly for opening and closing the clamp 4, one side of the clamp 4 is provided with a glue spray head 7 connected to the glue box 5 for extruding glue, and the frame 1 is provided with a glue spray head that can move through the glue spray The glue brush 8 attached to the head 7 and the glue liquid is rotatably connected to the reciprocating frame 9, and the reciprocating frame 9 can drive the glue brush 8 on the glue spray head 7 and the clamp 4 Between reciprocating movement, described fixture 4 below is provided with start-up switch, and described start-up switch is connected with motor 2 and reciprocating frame 9. In the present invention, a plurality of clamps 4 are arranged on the turntable 3, and each clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com