Degradable core-shell type oxidized calcium alginate gel microsphere, and preparation method and application thereof

A technology for oxidizing sodium alginate and calcium alginate, applied in the field of materials, can solve the problems of poor monodispersity of shell-core structure microspheres, and achieve the effects of controllable release, uniform size and structure, and high monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

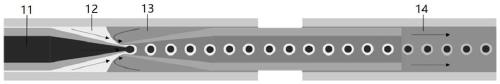

[0056] This embodiment provides a method for preparing degradable core-shell oxidized calcium alginate gel microspheres based on microfluidics, including the following steps:

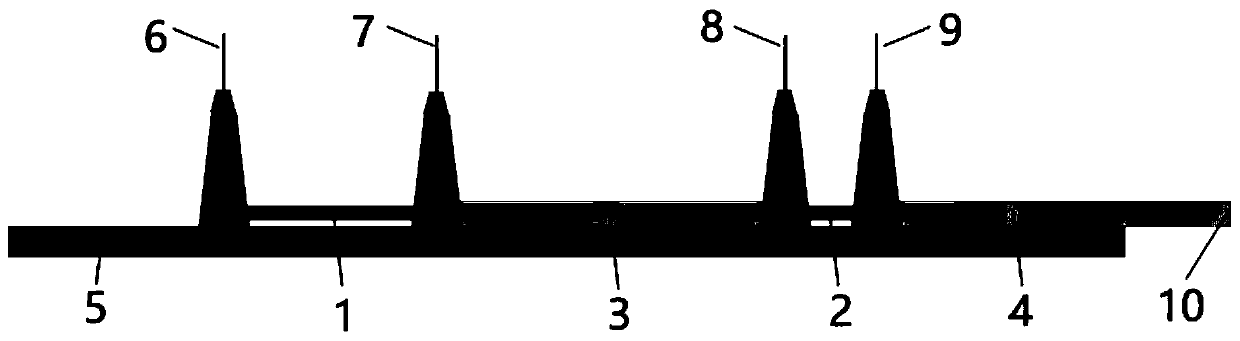

[0057] First, fabricate the microfluidic device, see figure 1 , is a schematic structural diagram of the microfluidic device used in the embodiment of the present invention. A circular capillary glass tube is drawn into two sections of tapered capillary glass tubes with a specific inner diameter of the tip using a capillary glass tube drawing instrument, and one of the capillary glass tubes is named the first tapered capillary tube 1, and the other The tip of the first capillary glass tube is ground into a larger opening with sandpaper, named as the second tapered capillary tube 2;

[0058] Use trimethyl[3-(2-methoxy)propyl]silane liquid to do hydrophilic treatment on the surface of the first tapered capillary 1, and dry it with nitrogen; Do hydrophobic treatment on the surface of the shaped capillary...

Embodiment 1

[0067] In this embodiment, the fabrication of a microfluidic device includes the following steps:

[0068] Step 1) Draw a circular capillary glass tube (inner diameter 580 μm, outer diameter 1.0 mm) into two tapered capillary glass tubes with a tip inner diameter of about 40 μm using a capillary glass tube drawing apparatus;

[0069] Step 2) Sand the tip of one of the capillary glass tubes into a larger opening (with an inner diameter of about 380 μm), and name it the second tapered capillary 2; the other one is not polished, and is named the first tapered capillary 1;

[0070] Step 3) Treat the first conical capillary 1 with a trimethyl[3-(2-methoxy)propyl]silane liquid (purity greater than 99%) for 5 minutes, take it out and dry it with nitrogen;

[0071] Step 4) Soak the second conical capillary 2 with a toluene solution of 0.1% (v / v) octadecyltrichlorosilane for 20 minutes, take it out and dry it with nitrogen;

[0072] Step 5) Insert the tip of the first tapered capilla...

Embodiment 2

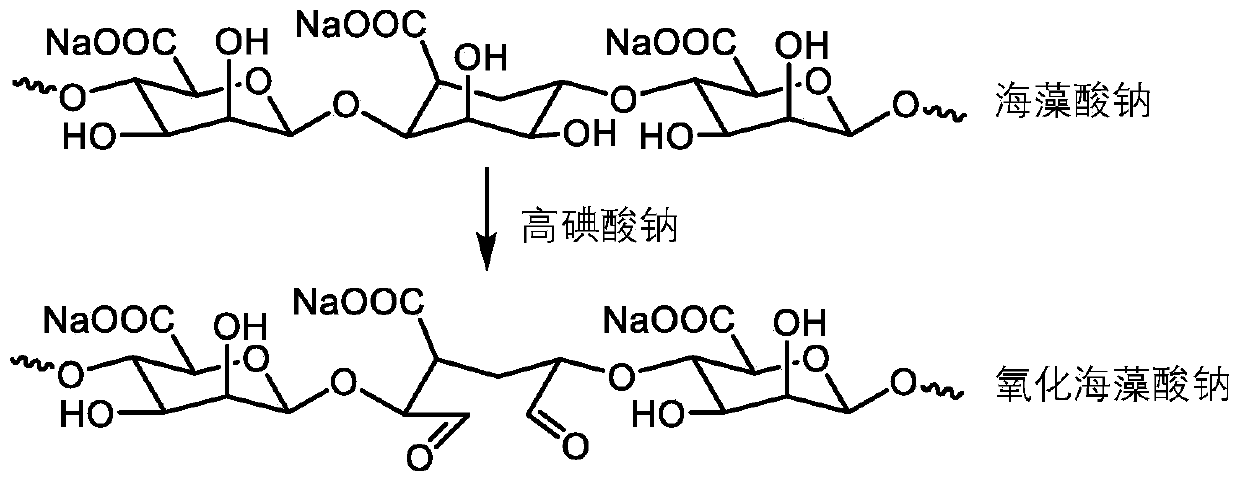

[0076] The present embodiment carries out the preparation of oxidized sodium alginate, comprises the following steps:

[0077] Step 1) disperse 4.0 g of sodium alginate in 20 mL of ethanol solution to obtain sodium alginate ethanol solution;

[0078] Step 2) dissolving 1.07g of sodium periodate in 20mL pure water to obtain sodium periodate solution;

[0079] Step 3) mixing sodium alginate ethanol solution and sodium periodate solution to obtain a mixed solution, and performing a magnetic stirring reaction on the mixed solution for 6 hours at room temperature in the dark;

[0080] Step 4) transfer the reacted solution to a dialysis bag (MWCO 12,000), and dialyze in pure water for 2 days;

[0081] Step 5) After the dialysis is completed, the solution in the dialysis bag is collected, and purified oxidized sodium alginate is obtained by freeze-drying. The degree of oxidation of the oxidized sodium alginate obtained in this example is about 25%.

[0082] see Figure 4 , is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com