A kind of preparation device and method of polyaniline nanofiber

A nanofiber and preparation device technology, applied in the field of polyaniline nanofiber preparation device, can solve the problems of insufficient regularity of polyaniline nanofiber structure, easy entanglement of polyaniline nanofibers, inconsistent product size and structure, etc. Processing steps, high reproducibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

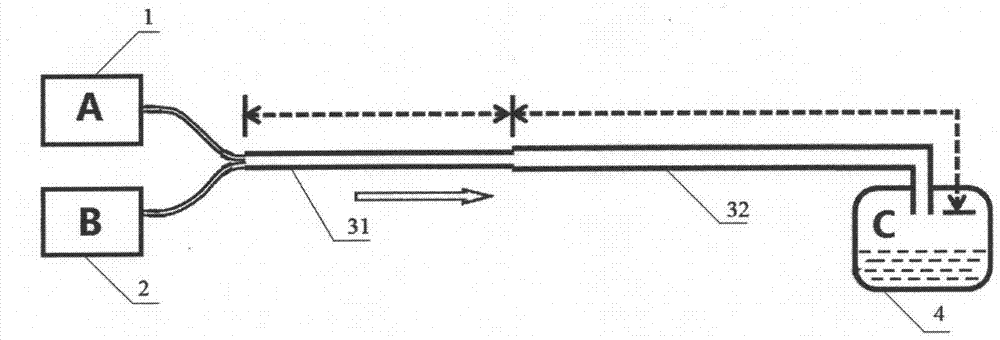

[0027] like figure 1 Shown, the preparation device of the polyaniline nanofiber of the present invention comprises reaction tube, first container 1, second container 2 and collecting container 4, and described reaction tube is made up of thin tube part 31 and thick tube part 32, the first The container 1 and the second container 2 are respectively connected to the front end of the thin tube part 31 through pipelines, the rear end of the thin tube part 31 is connected to the front end of the thick tube part 32, and the rear end of the thick tube part 32 is connected to the collection container 4. A peristaltic pump is arranged on the pipeline. The thin tube part 31 has an inner diameter of 1.5 mm and a length of 2 m, and the thick tube part 32 has an inner diameter of 3 mm and a length of 4 m. The first container 1 and the second container 2 are respectively used to contain the dopant-containing monomer and the initiator solution, and the collection container 4 collects the fi...

Embodiment 2

[0030] like figure 1Shown, the preparation device of the polyaniline nanofiber of the present invention comprises reaction tube, first container 1, second container 2 and collecting container 4, and described reaction tube is made up of thin tube part 31 and thick tube part 32, the first The container 1 and the second container 2 are respectively connected to the front end of the thin tube part 31 through pipelines, the rear end of the thin tube part 31 is connected to the front end of the thick tube part 32, and the rear end of the thick tube part 32 is connected to the collection container 4. A flow injector is provided on the pipeline. The thin tube part 31 has an inner diameter of 0.2 mm and a length of 0.1 m, and the thick tube part 32 has an inner diameter of 1.5 mm and a length of 0.1 m. The first container 1 and the second container 2 are respectively used to contain the dopant-containing monomer and the initiator solution, and the collection container 4 collects the ...

Embodiment 3

[0033] like figure 1 Shown, the preparation device of the polyaniline nanofiber of the present invention comprises reaction tube, first container 1, second container 2 and collecting container 4, and described reaction tube is made up of thin tube part 31 and thick tube part 32, the first The container 1 and the second container 2 are respectively connected to the front end of the thin tube part 31 through pipelines, the rear end of the thin tube part 31 is connected to the front end of the thick tube part 32, and the rear end of the thick tube part 32 is connected to the collection container 4. A push pump is provided on the pipeline. The thin tube part 31 has an inner diameter of 0.6 mm and a length of 0.2 m, and the thick tube part 32 has an inner diameter of 1.3 mm and a length of 2 m. The first container 1 and the second container 2 are respectively used to contain the dopant-containing monomer and the initiator solution, and the collection container 4 collects the final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com