Neutral compound fertilizer and preparation method thereof

A compound fertilizer and neutral technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of endangering consumers' food safety and health, restricting the level and efficiency of production and planting management, and increasing the cost of pesticide and chemical fertilizer application. Achieve the effect of improving soil structure and ion exchange capacity, improving soil ion exchange capacity, and alleviating cold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

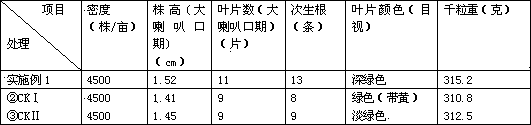

Examples

Embodiment 1

[0031] In order to adapt to the balanced compound fertilizer of the overall demand of field crops and economic crops for nutrients, the proportion of the neutral compound fertilizer is 15 parts of nitrogen, 15 parts of phosphorus pentoxide, and 15 parts of potassium oxide. 5 parts of acid, 0.5 parts of trace elements, 5 parts of magnesium oxide dissolved in citric acid, and 0.055 parts of plant growth regulator.

[0032] Specifically: 1) Weigh 250 kg of urea, 325 kg of monoammonium phosphate, 300 kg of potassium sulfate, 10 kg of zinc sulfate monohydrate, 10 kg of boric acid, and 5 kg of ferrous sulfate monohydrate, and crush them to 40-60 kg After that, the components are mixed evenly and set aside. 2) Weigh 50 kg of humic acid, crush it, and set aside. 3) Weigh 75 kg of magnesium oxide dissolved in citric acid, 500 g of amine fresh fat, and 50 g of auxin, and then mix the above components evenly and set aside. 4) Put the materials in the above 1), 2) and 3) into the mixer,...

Embodiment 2

[0034] In order to adapt to various leafy vegetables, fruit trees, solanaceous high-nitrogen compound fertilizers with high demand for nitrogen nutrition, the proportion of the neutral compound fertilizer is 22 parts of nitrogen and 5 parts of phosphorus pentoxide. 10 parts of potassium oxide, 5 parts of humic acid, 0.5 parts of trace elements, 2 parts of magnesium oxide dissolved in citric acid, and 0.050 parts of plant growth regulator.

[0035]Specifically: 1) Weigh 350 kg of urea, 235 kg of ammonium sulfate, 110 kg of monoammonium phosphate, 200 kg of potassium sulfate, 10 kg of zinc sulfate monohydrate, 10 kg of boric acid, 3 kg of ferrous sulfate monohydrate, and 3 kg of sulfuric acid monohydrate. 2 kilograms of manganese, which are respectively pulverized to 40-60 mesh, and then the components are mixed uniformly and set aside. 2) Weigh 50 kg of humic acid, crush it, and set aside. 3) Weigh 25 kg of magnesium oxide dissolved in citric acid, 450 g of amine fresh fat, an...

Embodiment 3

[0037] In order to adapt to the high-phosphorus type compound fertilizer that various crops, fruit trees, and solanaceae have high demand for phosphorus nutrition, the proportioning of the neutral compound fertilizer is 15 parts of nitrogen and 22 parts of phosphorus pentoxide , containing 8 parts of potassium oxide, 5 parts of humic acid, 0.5 parts of trace elements, 7.5 parts of magnesium oxide dissolved in citric acid, and 0.055 parts of plant growth regulator.

[0038] Specifically: 1) Weigh 210 kg of urea, 480 kg of monoammonium phosphate, 160 kg of potassium sulfate, 10 kg of zinc sulfate monohydrate, 10 kg of boric acid, and 5 kg of ferrous sulfate monohydrate, and crush them to 40-60 kg After that, the components are mixed evenly and set aside. 2) Weigh 50 kg of humic acid, crush it, and set aside. 3) Weigh 75 kg of magnesium oxide dissolved in citric acid, 500 g of amine fresh fat, and 50 g of auxin, and then mix the above components evenly and set aside. 4) Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com