Patents

Literature

262 results about "Potassium bisulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium bisulfate is an inorganic compound with the chemical formula KHSO₄ and is the potassium acid salt of sulfuric acid. It is a white, water-soluble solid.

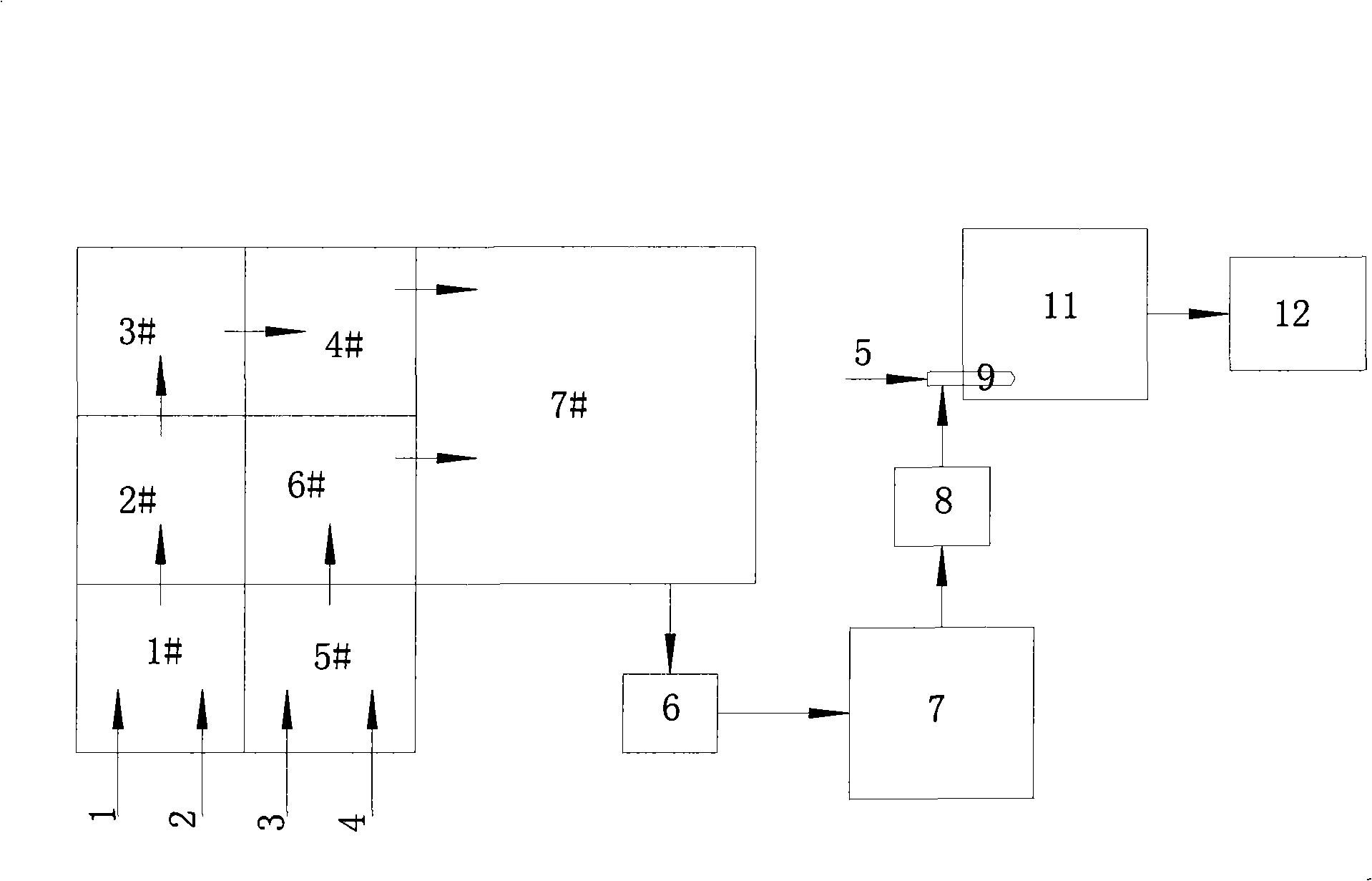

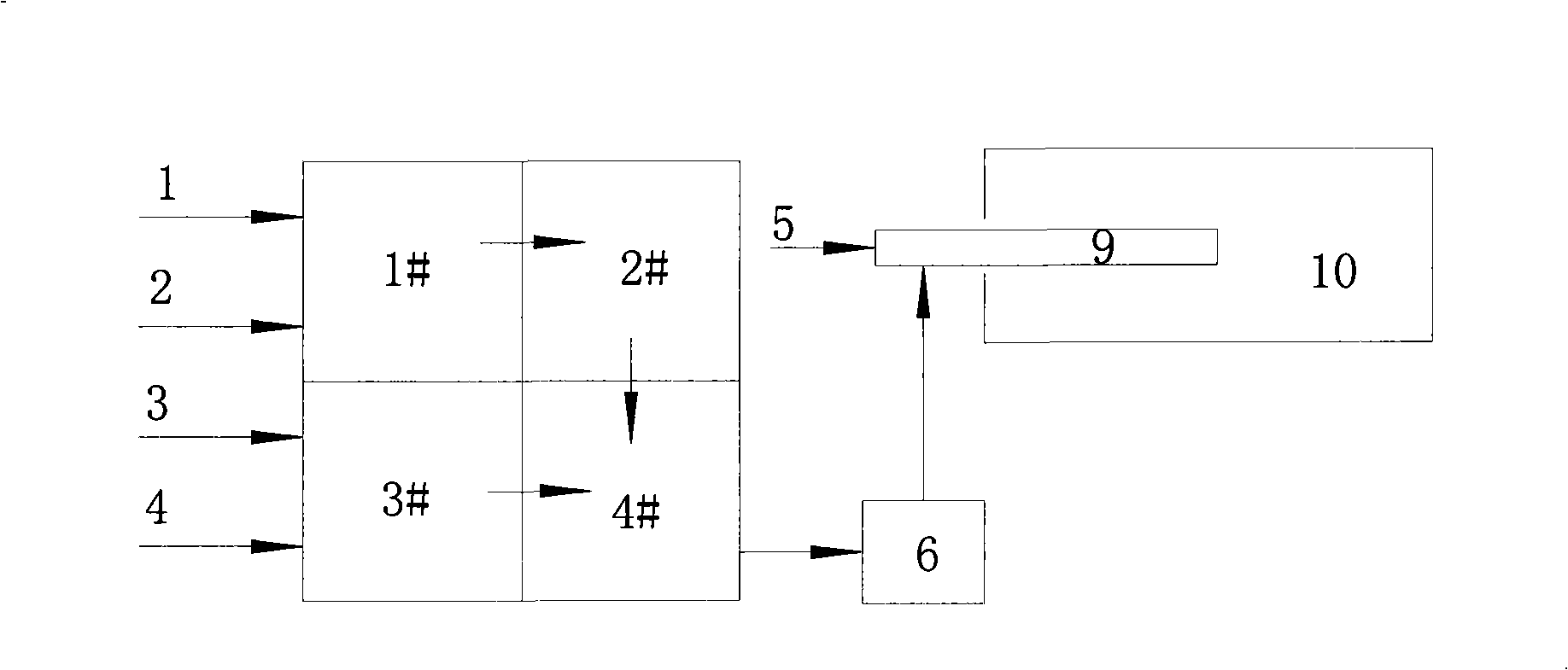

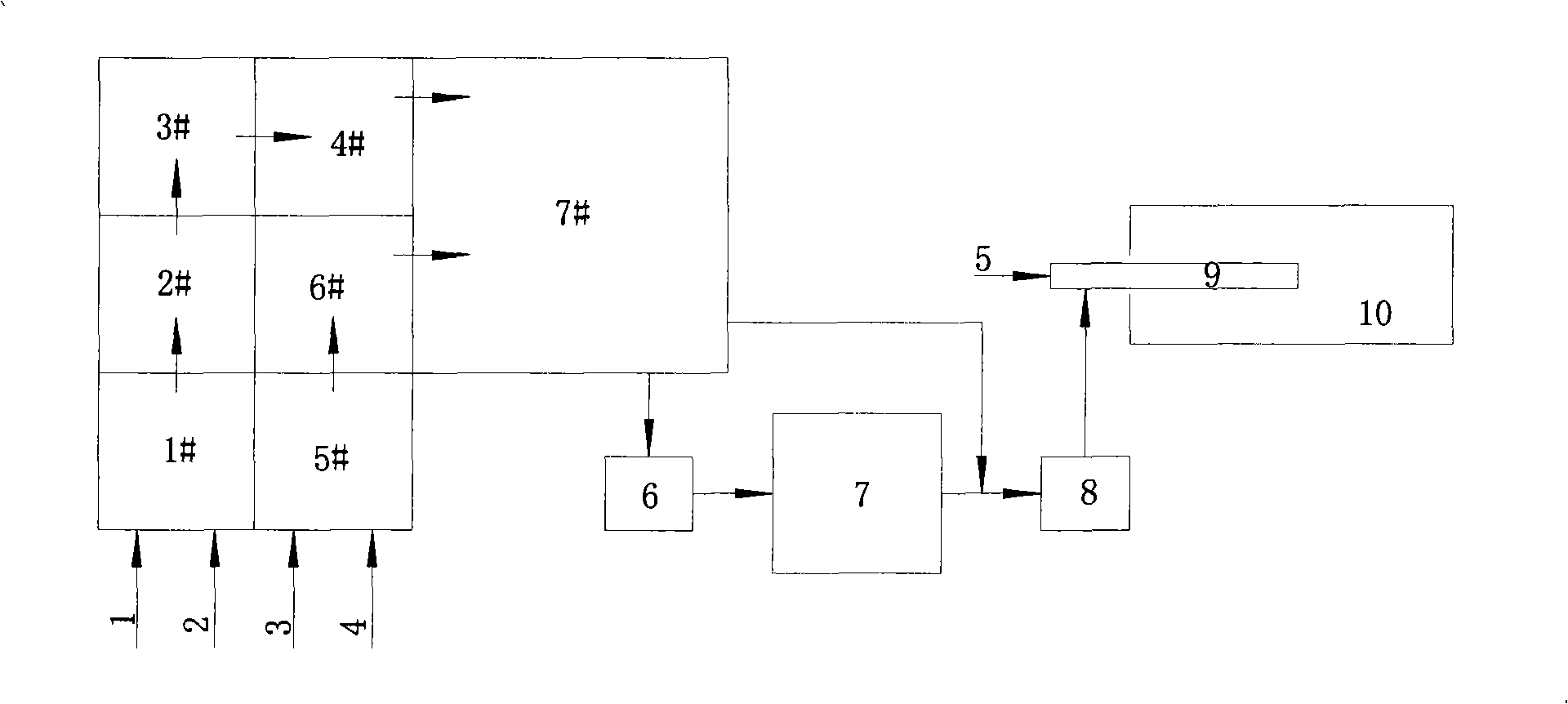

Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process

The present invention relates to a new industrial process for the synthesis of solvate- free 17a-acetoxy-11ss-[4-(N,N-dimethyl-amino)-phenyl]-19-norpregna-4,9-diene-3,20-dione [CDB -2914] of formula (I) which is a strong antiprogestogene and antiglucocorticoid agent. The invention also relates to compounds of formula (VII) and (VIII) used as intermediates in the process. The process according to the invention is the following: i) 3-(ethylene-dioxy)-estra-5(10),9(11)-diene-17-one of formula (X) is reacted with potassium acetilyde formed in situ in dry tetrahydrofuran by known method, ii) the obtained 3-(ethylene-dioxy)-17a-ethynyl-17ss-hydroxy-estra-5(10),9(11)-diene of formula (IX) is reacted with phenylsulfenyl chloride in dichloromethane in the presence of triethylamine and acetic acid, iii) the obtained isomeric mixture of 3-(ethylene-dioxy)-21-(phenyl-sulfinyl)-19-norpregna-5(10),9(11),17(20),20-tetraene of formula (VIII) is reacted first with sodium methoxide in methanol, then with trimethyl phosphite, iv) the obtained 3-(ethylene-dioxy)-17a-hydroxy-20-methoxy-19-norpregna-5(10),9(11),20-triene of formula (VII) is reacted with hydrogen chloride in methanol, then v) the obtained 3-(ethylene-dioxy)-17a-hydroxy-19-norpregna-5(10),9(11l); -diene-20- one of formula (VI) is reacted with ethylene glycol hi dichloromethane in the presence of trimethyl orthoformate and p-toluenesulfonic acid by known method, vi) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-19-norpregna- 5(10),9(11)-diene of formula (V) is reacted with hydrogen peroxide in a mixture of pyridine and dichloromethane in the presence of hexachloroacetone by known method, vii) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-5,10-epoxy-19-norpregn-9(11)-ene of formula (IV), containing approximately a 1:1 mixture of 5a,10a- and 5ss,10ss-epoxides, is isolated from the solution and reacted with a Grignard reagent obtained from 4-bromo-N,N-dimethyl-aniline in tetrahydrofuran.

Owner:RICHTER GEDEON NYRT

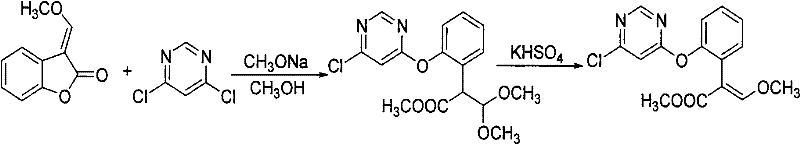

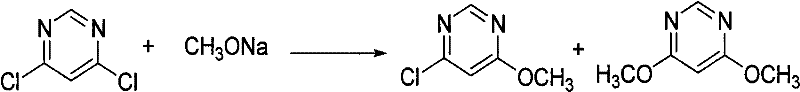

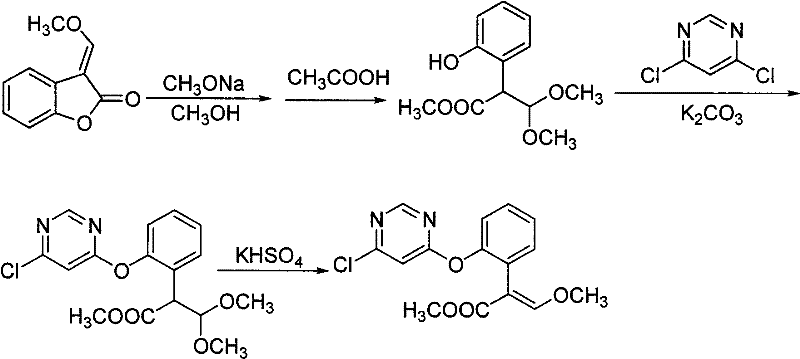

Synthetic method of azoxystrobin and special intermediate for synthesis

The invention relates to a synthetic process of a chemical substance, and particularly relates to a synthetic method for synthesizing (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate and azoxystrobin; the method comprises the following steps: mixing a raw material of 3-(alpha-methoxy)methylene benzofuran-2-(3H)-ketone and potassium carbonate in a toluene solvent, cooling to 0-10 DEG C, adding sodium methoxide, reacting for 0.4-0.6 hours; adding 4,6-dichloropyrimidine and a catalyst of DABCO, reacting for 1-2 hours, filtering to remove inorganic salts, washing the filtrate with water, performing distillation to recover toluene; adding a catalyst of potassium bisulfate into the distillation residues of the above reaction, heating to 132-145 DEG C in a reduced-pressure condition for reaction; directly adding salicylonitrile to synthesize azoxystrobin or performing toluene dissolution, water washing, solvent recovery, recrystallization and filtration to obtain an intermediate. The production and synthesis of (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate by the production process of the invention has high yield, and simple operations, and the used raw materials and processes are routine reagents and methods.

Owner:CHONGQING UNISPLENDOUR CHEM

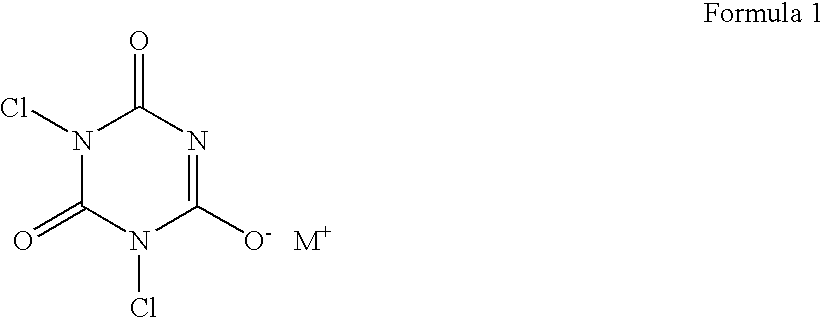

Multi-functional oxidizing composition

A composition comprising a stable anhydrous mixture of an oxidizing agent and an active halogen agent wherein the oxidizing agent is potassium hydrogen peroxymonosulfate and the active halogen agent is an alkali metal salt of dichloro-s-triazinetrione, halogenated dimethylhydantoin, or mixtures thereof, and a method of treating water with such compositions are disclosed.

Owner:LENKSESS CORP

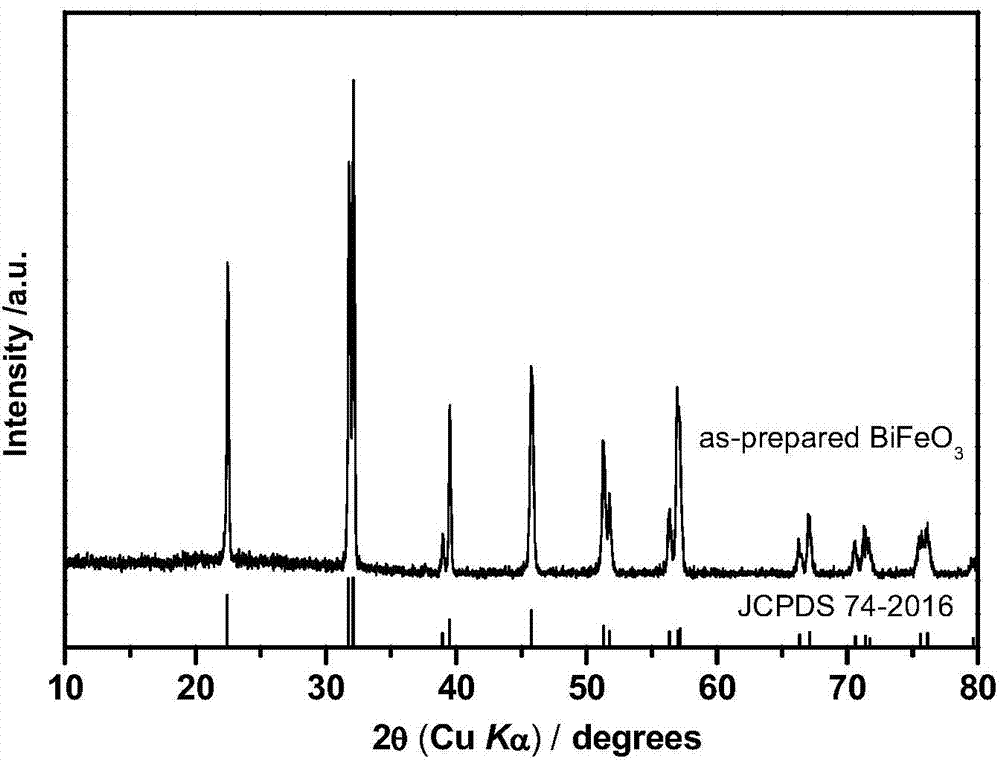

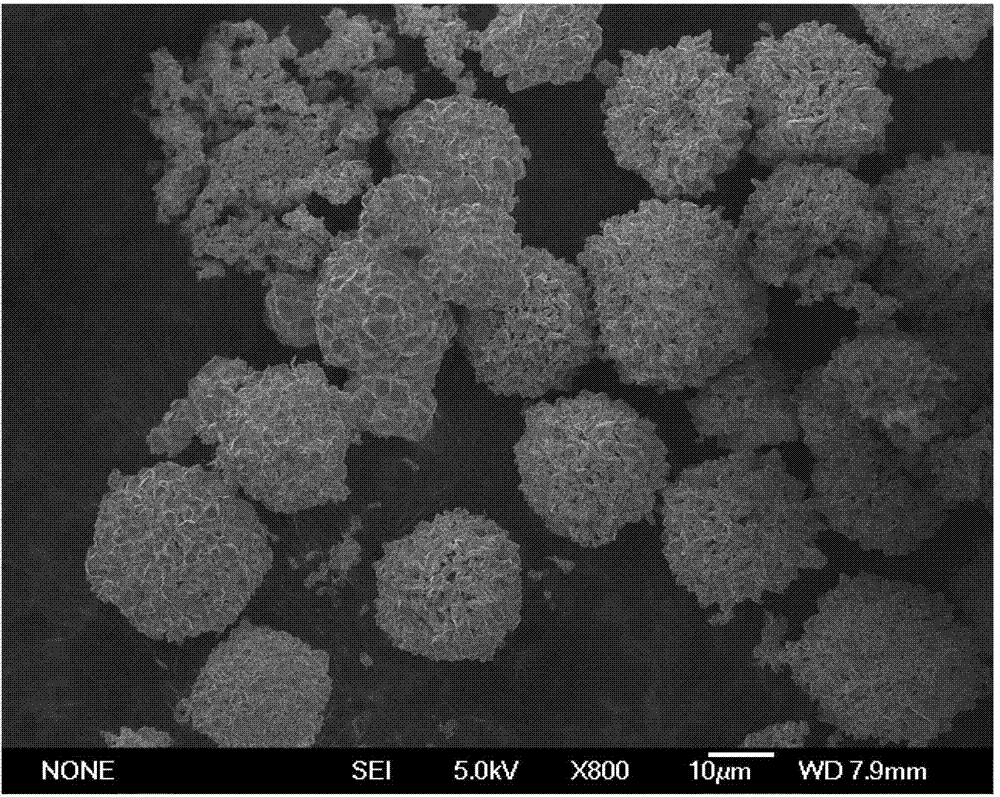

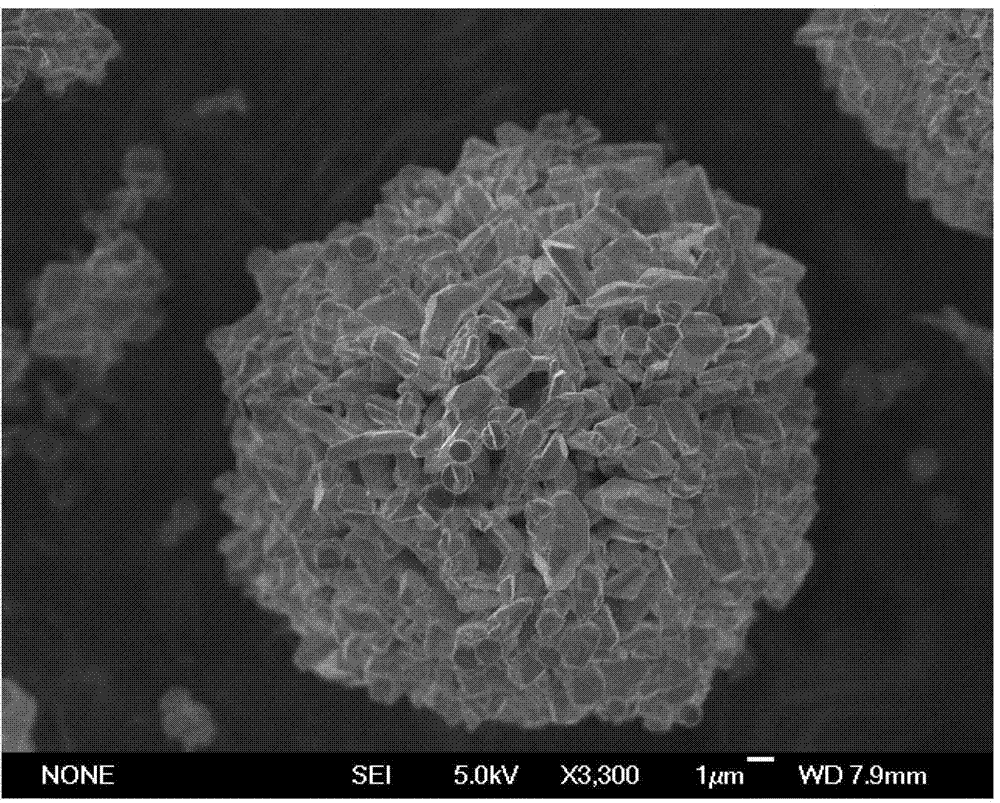

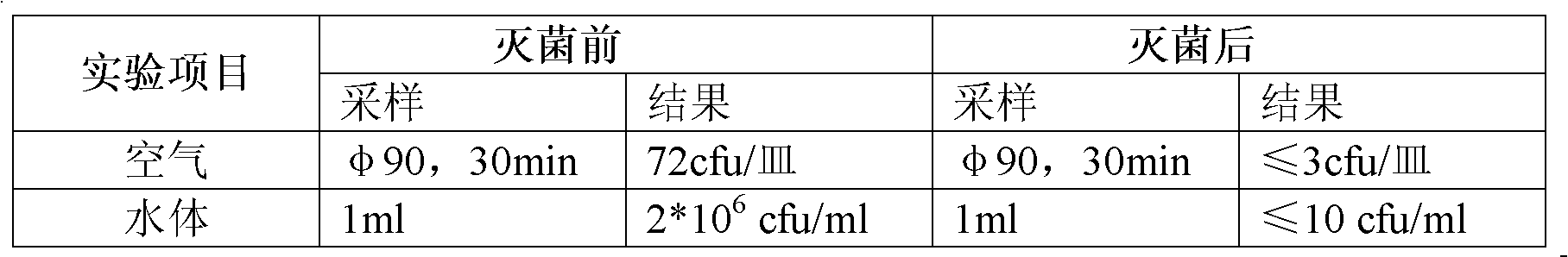

Method for degrading organic waste water by photo-assisted activation of potassium hydrogen persulfate through bismuth ferrite

InactiveCN104743633AEfficient degradationLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPhoto assistedMethyl blue

The invention discloses a method for degrading organic waste water by photo-assisted activation of potassium hydrogen persulfate through bismuth ferrite, belonging to the technical field of waste water treatment. A perovskite structure BiFeO3 in the invention has a spherical morphology and is prepared by adding a certain amount of a surface active agent under hydrothermal conditions; the specific surface area is high; and the prepared BiFeO3 self can degrade organic pollutants by photocatalysis under the irradiation of visible light. According to the method disclosed by the invention, BiFeO3 is applied to degrading the organic pollutants by activating potassium hydrogen persulfate; the methyl orange degradation rate within 15 min is 94%; the methyl blue degradation rate within 40 min is 90%; the rhodamine degradation rate within 40 min is 65%; by means of combined use of BiFeO3 and potassium hydrogen persulfate, the organic pollutants are oxidized and degraded; the organic pollutants can be effectively degraded under better illumination conditions; the organic pollutants can also be effectively oxidized and degraded without light or under poor illumination conditions; and therefore, the method has good application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for comprehensively recovering aluminum and potassium from vanadium extraction from stone coal

InactiveCN102424914AHigh recovery rateEfficient recyclingProcess efficiency improvementHydrogen SulfateAluminium hydroxide

The invention discloses a method for comprehensively recovering aluminum and potassium from vanadium extraction from stone coal. The technical process of the method mainly comprises: crystallizing pentaphyllum potassium aluminum sulfate in sulfuric acid leachate of stone coal; purifying pentaphyllum potassium aluminum sulfate recrystals, or adding water to dissolve the pentaphyllum potassium aluminum sulfate recrystals and adding a potassium-containing pH regulator to precipitate aluminum; filtering to obtain aluminum hydroxide and a potassium sulfate or potassium hydrogen sulfate solution; transforming the potassium sulfate or potassium hydrogen sulfate solution by lime to obtain potassium carbonate or potassium hydroxide; and thus, effectively separating and recovering aluminum and potassium. The method has the advantages that: the aluminum and potassium recovery rates are high; the products are diversified; impurities harmful to the recycling of water from vanadium extraction from stone coal are not introduced in the aluminum and potassium recovery technical process; the reagent consumption is small; the production cost is low; environment pollution is avoided; and the like.

Owner:CENT SOUTH UNIV

Method for preparing permonosulfuric hydrogen-pottassium compound salt

InactiveCN1528660AHigh active oxygen contentImprove stabilityPeroxyhydrates/peroxyacidsOleumPotassium hydroxide

The invention is a potassium peroxy-monohydrosulfate compound salt preparing method, using oleum, perhydrol and potassium hydroxide as raw material. Firstly, adding stabilizing agent-containing perhydrol in the reactor, then dropping in the oleum to react, then dropping in potassium hydroxide solution and at the same time adding in crystal shape modifier, vacuum-condensing, cooling and crystallizing, and then drying to obtain its dried product; the perhydrol solution concentration is 45-80% and the oleum concentration 35-65%. It uses oleum to replace the vitriol oil and thick perhydrol solution to replace dilute perhydrol solution, and adds in potassium hydroxide to adjust the components. It has better stability.

Owner:陶华西

Animal hair solvent and preparation method and use of keratin solution

InactiveCN101979428AHigh molecular contentGuaranteed stabilityFibre treatmentAdditive ingredientSulfite salt

The invention discloses an animal hair solvent and the preparation method and use of keratin solution. The solvent is characterized in that tris(2-carboxyethyl)phosphine hydrochloride, tris(2-cyanoethyl)phosphine or trisphosphine is used as a main ingredient and is mixed with 1 to 8 percent of assistant which may be at least one of mercaptoacetic acid, mercaptoethanol, sodium hydrogensulfite, potassium bisulfate, sodium sulfite, potassium sulfite, sodium hypophosphite, ethanol, methanol and urea. The preparation method adopts the following processes: 1, preparing animal hair solution by using the animal hair solvent of the invention; 2, dissolving animal hair in the solution to prepare keratin solution; and 3, adding a proper amount of acid to perform the post-treatment of the keratin solution. The use is to use the keratin solution as textile finishing liquor or the main functional ingredient of the textile finishing liquor.

Owner:TIANJIN POLYTECHNIC UNIV +1

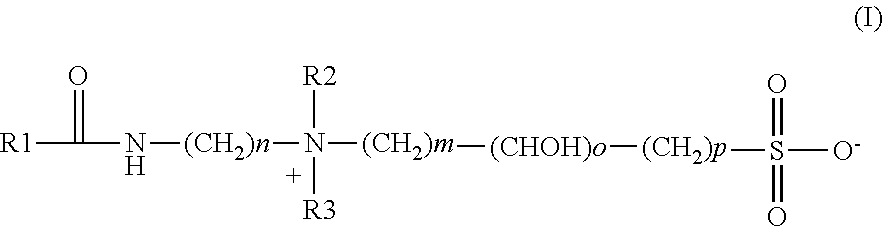

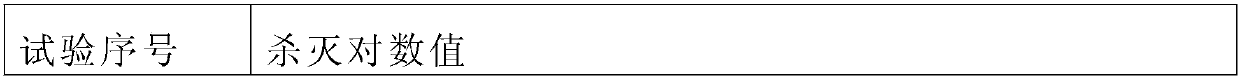

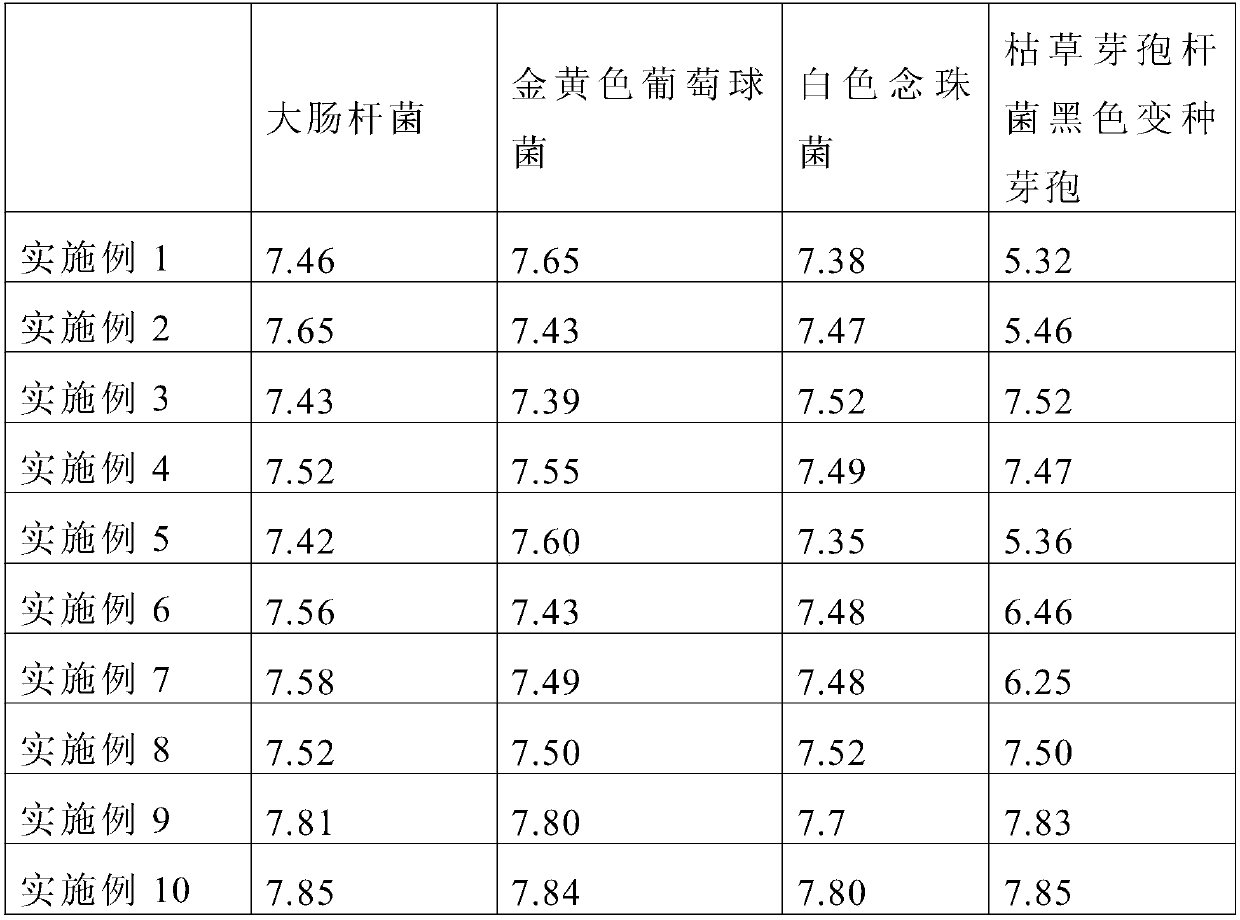

Compound potassium hydrogen persulfate disinfectant

InactiveCN101836659AImprove protectionProduction process updateBiocideDisinfectantsCelluloseDisinfectant

The invention relates to a compound potassium hydrogen persulfate disinfectant prepared from main materials and auxiliary materials, wherein the main materials comprise potassium hydrogen persulfate, citric acid, aminosulfuric acid, sodium chloride, sodium citrate and the like; the auxiliary materials comprise film coating materials, hydroxylpropyl cellulose, hydroxypropyl methyl cellulose, polyvinylpyrrolidone, soluble starch, ethyl cellulose and the like; and the weight ratio of the auxiliary materials to the main materials is 0-0.15:1. Because the prescription of the compound potassium hydrogen persulfate disinfectant is optimized, the compound potassium hydrogen persulfate disinfectant solves the problems of strong irritation, easy moisture absorption, poor stability, short action time and the like, and because P-containing components are not used in the prescription, the compound potassium hydrogen persulfate disinfectant is beneficial to environmental protection.

Owner:湖南圣雅凯生物科技有限公司

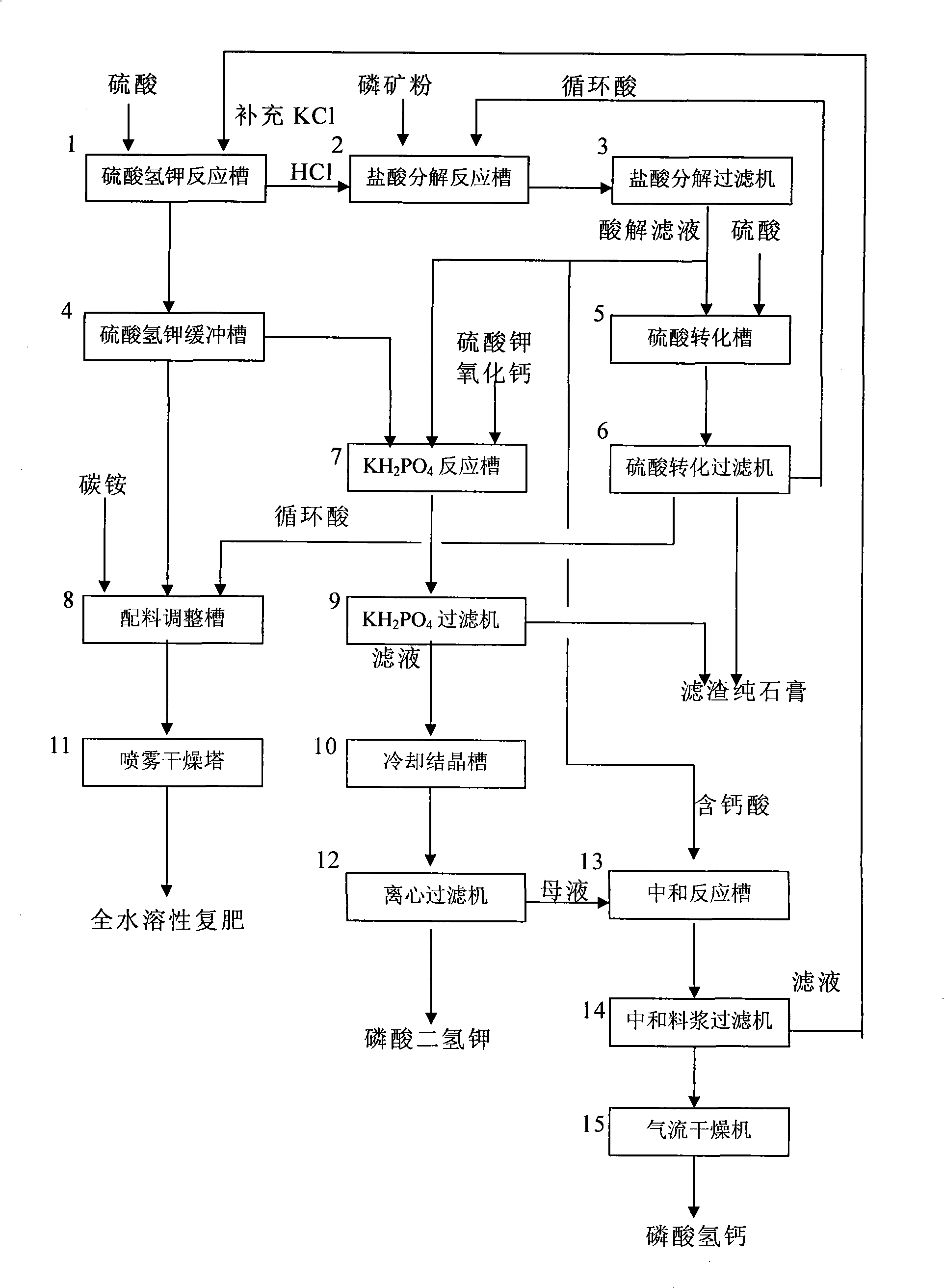

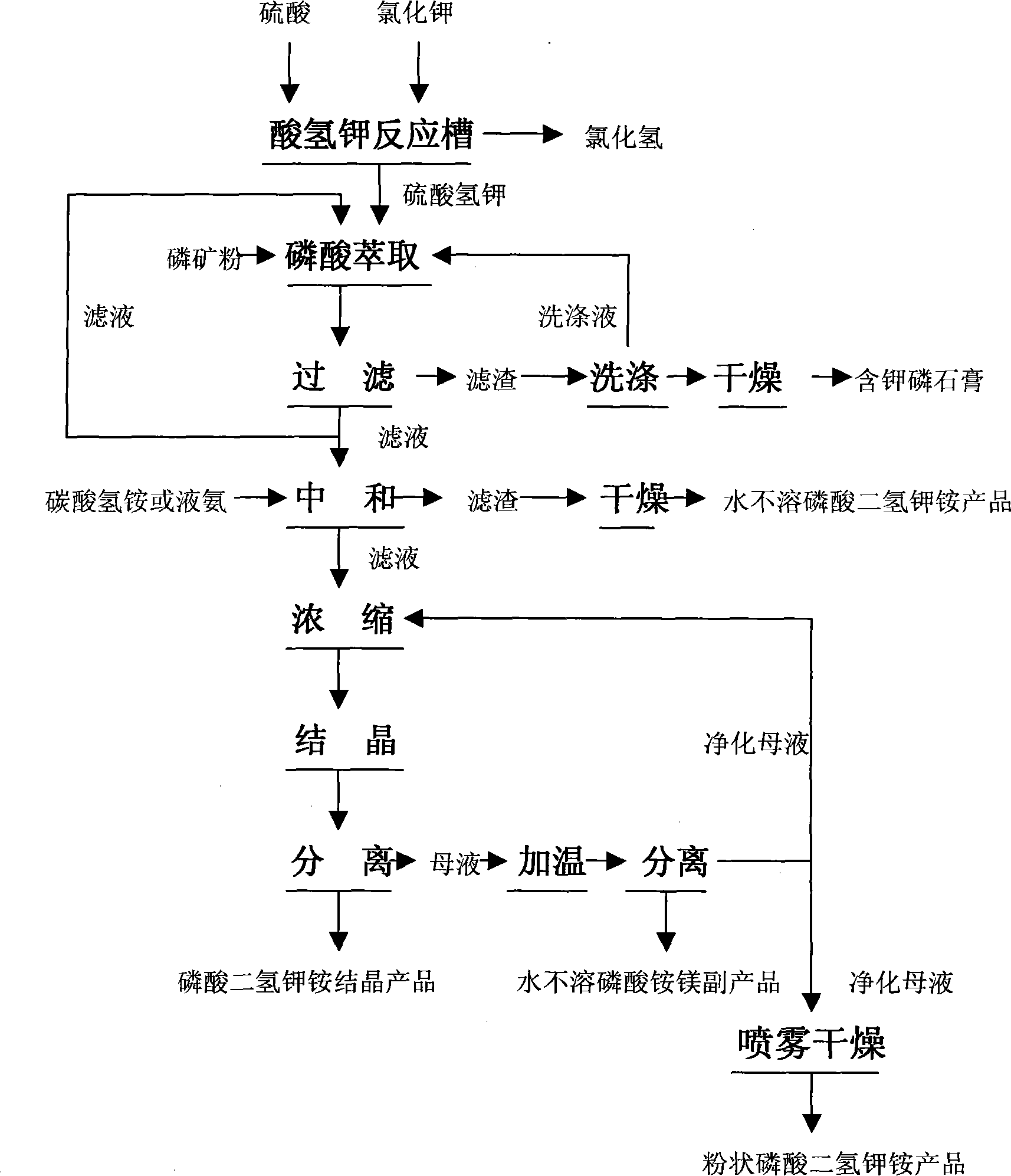

Process for disassembling phosphate ore by mixed acid and coproducing potassium dihydrogen phosphate, hydrogen phosphate and combined fertilizer

InactiveCN101337657ASolve processing problemsSolving Phosphogypsum ProblemsChlorine/hydrogen-chlorideSulfate/bisulfate preparationSolubilitySlurry

A method for the joint production of monopotassium phosphate, calcium hydrophosphate and compound fertilizers through by subjecting phosphorite to mixed acid resolution is characterized in that the method comprises the steps of taking sulphuric acid and potassium chloride to prepare chlorine hydride and acid potassium sulfate; conducting acidolysis reaction after phosphorite slurry absorbs chlorine hydride; preparing monopotassium phosphate through the reaction between an acidolysis filtrate and calcium oxide and lemery; agitating a mixture of the acidolysis fitrate with monopotassium phosphate crystallization mother liquor to neutralize and prepare calcium hydrophosphate; preparing recycle acid through the reaction between the acidolysis filtrate with sulphuric acid; preparing full water-solubility compound fertilizers through the reaction between recycle acid and an acid potassium sulfate solution and ammonium hydrogen carbonate or ammonia, etc. The method can successfully solve the impurity interference problem in the production of phosphate by using phosphorite of middle-low grade, and increase the reclaim rate of phosphorus pentoxide to approximate 100%. The method has the advantages of fully utilizing resources, simplifying process and devices, reducing corrosion, saving energy, reducing acid consumption and cost, eliminating pollution, and achieving good technical and economic effects.

Owner:黄明科 +1

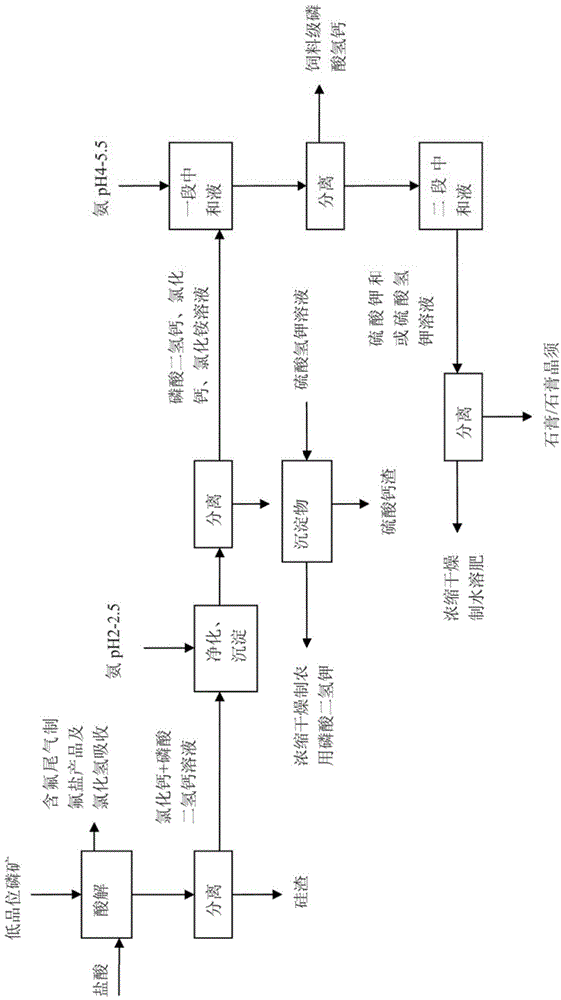

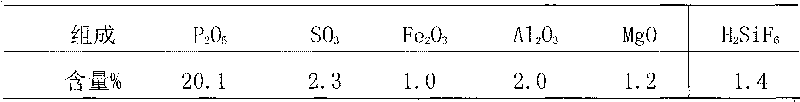

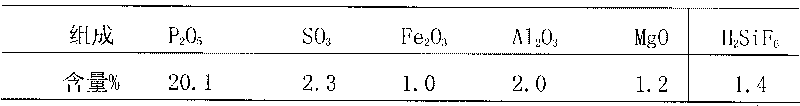

Method of combined production of multiple phosphates and phosphate fertilizer from low grade phosphate ore

The invention relates to a method of combined production of multiple phosphates and a phosphate fertilizer from low grade phosphate ore. The method comprises the following steps: decomposing low grade phosphate ore powder by using hydrochloric acid to obtain an extract liquid containing calcium dihydrogen phosphate and calcium chloride; neutralizing the extract liquid by using ammonia by two segments to respectively obtain fertilizer-grade potassium dihydrogen phosphate and feed-grade calcium hydrogen phosphate, carrying out reaction on the neutralization liquid from the two segments and potassium sulfate and / or potassium bisulfate, and concentrating a filtrate to prepare a great amount of element water soluble fertilizers, or adding low molecular weight ammonium polyphosphate into the filtrate to prepare a suspended water soluble fertilizer. According to the method disclosed by the invention, by utilizing the characteristic of high decomposition rate by extracting phosphate ores by hydrochloric acid, with the combination of the technical characteristics of different phosphates and phosphate fertilizer products and different product standard requirements, the process technical requirements among the products are effectively jointed with one another, and the products including the feed-grade calcium hydrogen phosphate, the fertilizer-grade potassium dihydrogen phosphate, the water soluble fertilizer and gypsum whiskers are in combined production, so that the production process technology of each product is simple and feasible, phosphorus, calcium, magnesium and fluorine in the phosphate ores are fully utilized and the production cost of each product is also lowered.

Owner:TONGLING CHEM IND GRP

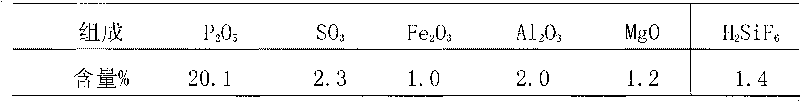

Method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer

InactiveCN101717290AIncrease profitSave resourcesFertilizer mixturesChemical industryPhosphoric acid

The invention relates to a method for producing defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer, which belongs to the technical field of production in the chemical industry. The method comprises the following steps of: firstly, adding soluble sylvite (or sodium salt) into fluosilicic acid in wet phosphoric acid to generate potassium fluosilicate (or sodium fluosilicate) precipitate, wherein after separating the potassium fluosilicate (or sodium fluosilicate) precipitate, the potassium fluosilicate (or sodium fluosilicate) precipitate is used as byproduct; then mixing the defluorinated wet phosphoric acid with converted potassium bisulfate at low temperature, carrying out neutralization reaction on mixed acid and gas ammonia; and granulating, drying, sieving, cooling and packing the neutralized slurry to prepare the defluorinated sulfenyl nitrogen-phosphorus-potassium compound fertilizer. The invention is mainly used for producing chemical fertilizers.

Owner:SHANDONG HONGRI ACRON CHEM

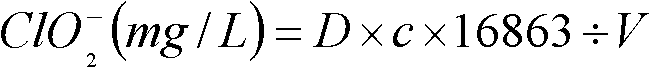

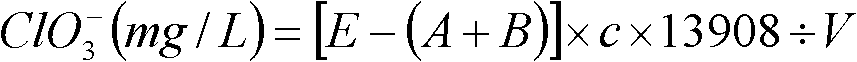

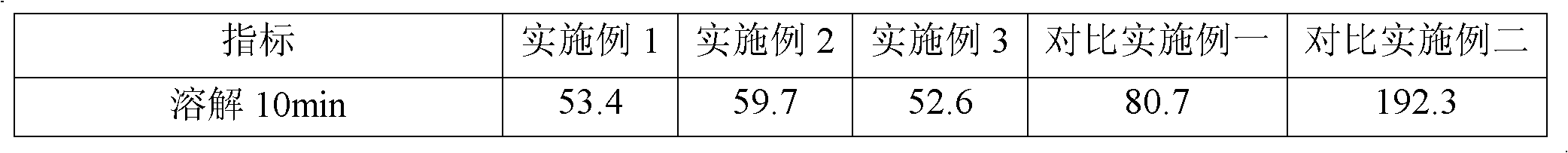

Unitary solid chlorine dioxide sustained-release generating agent and preparation method thereof

ActiveCN101999405AAvoid harmImprove the bactericidal effectBiocideDisinfectantsChlorine dioxideAdhesive

The invention discloses a unitary solid chlorine dioxide sustained-release generating agent and a preparation method thereof. The generating agent does not contain solid acid; potassium hydrogen persulfate composite salt is reacted with stable acidic chlorite in a solution system under the synergy of synergist to generate chlorine dioxide; the generating agent consists of the chlorite, the potassium hydrogen persulfate composite salt, the synergist, stabilizer, forming agent, dryer, adhesive and effervescing agent; and the preparation method comprises the following steps of: drying the chlorite and the potassium hydrogen persulfate composite salt respectively, mixing the dried chlorite, the dried potassium hydrogen persulfate composite salt and the other materials uniformly according to acertain proportion, and preparing the mixture into tablets of different specifications under certain environmental humidity and pressure. The composite tables dissolved to water can sustainedly release the chlorine dioxide gas and have the characteristics of long effect, sustained release, environment friendliness, safety and the like.

Owner:定州市荣鼎水环境生化技术有限公司

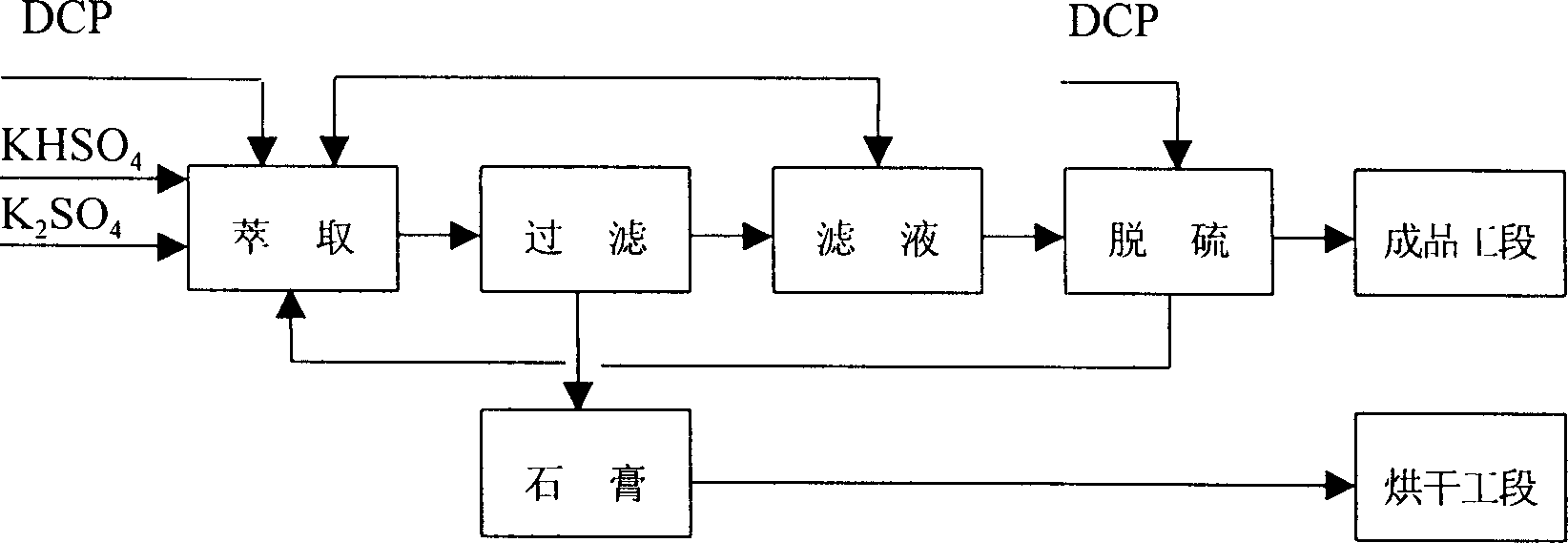

Method for preparing monopotassium phosphate from fertilizer grade calcium hydrophosphate

The invention relates to a method for preparing monopotassium phosphate from fertilizer grade calcium hydrophosphate. The method comprises the following steps of: slowly adding the fertilizer grade calcium hydrophosphate used as a material into a reaction tank containing potassium hydrogen sulfate solution at 60-68 DEG C, controlling the reaction solid-to-liquid ratio at (1:3)-(1:5) and the reaction time at 6.5-8 hours; controlling the sulphur and phosphorus mass ratio of the potassium hydrogen sulfate to the calcium hydrophosphate in reaction to S to P being (1-1.2):(1-1.4); adjusting the pH value of the filtrate by use of 85% industrial phosphoric acid; generating byproduct calcium sulfate whisker by filtering after the reaction is finished, adjusting the pH value of the filtrate to 4.5-5.5, and preparing the monopotassium phosphate product of meeting the top-quality goods of the national industry standard from the filtrate by purifying, concentrating, crystallizing, dewatering and drying, and controlling the drying temperature at 80-100 DEG C. By adopting the method, the technological process of producing the monopotassium phosphate is simple in flow, low in production cost, free of the three wastes, and easy for realization of large-scale and industrial production.

Owner:WENGFU (GRP) CO LTD

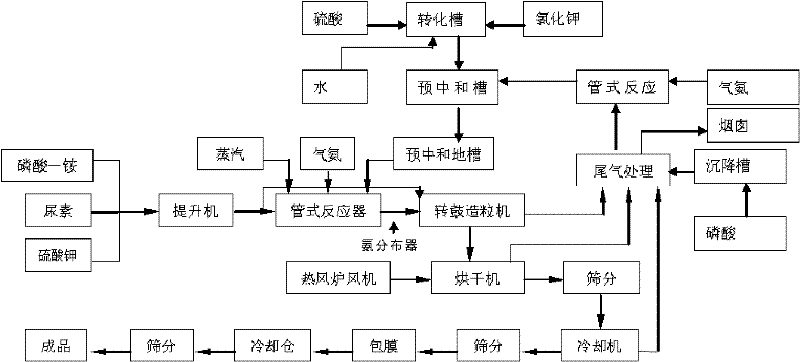

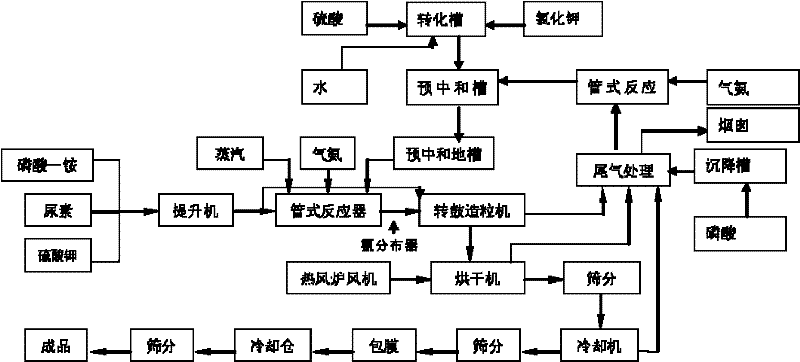

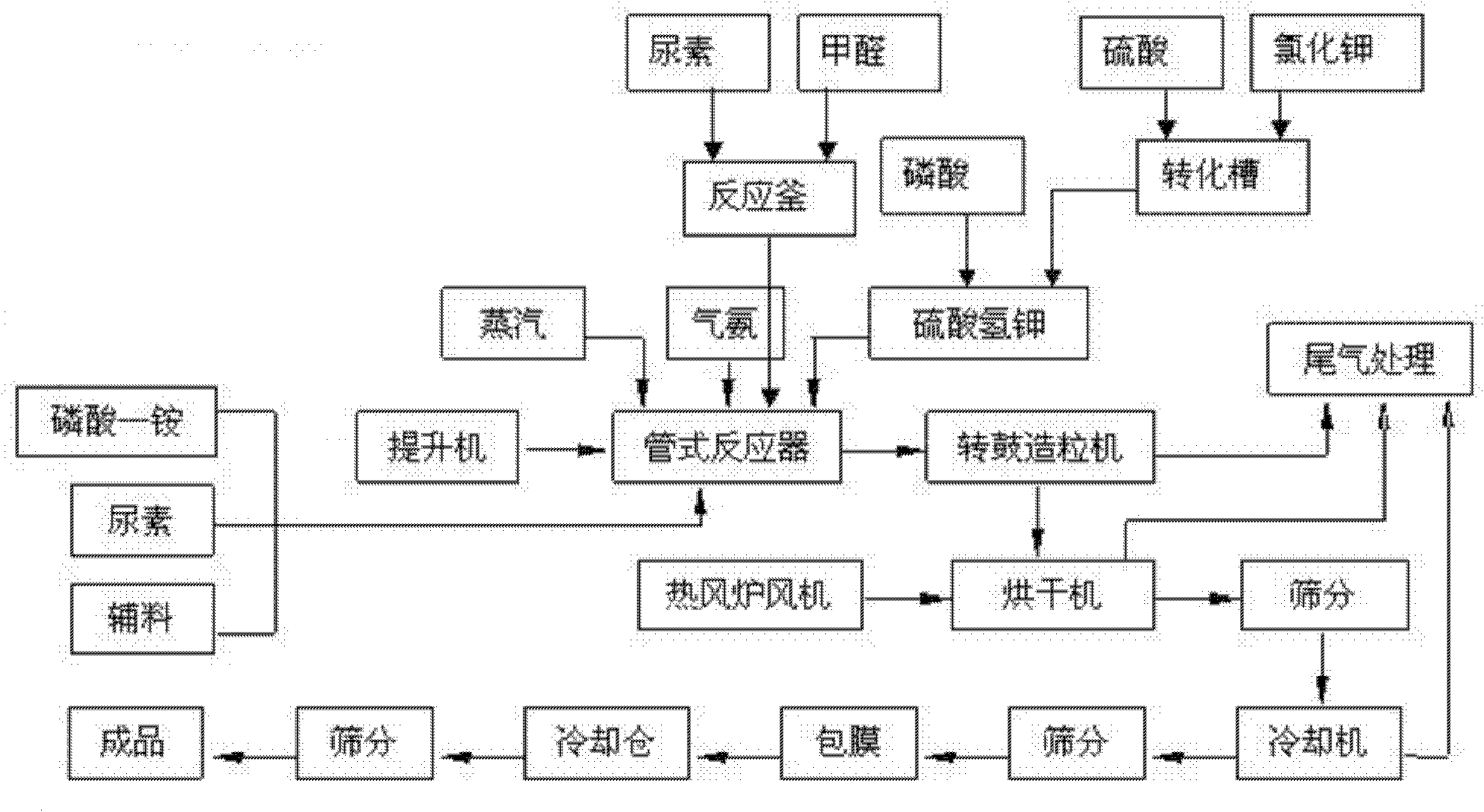

Production method for ammoniated sulfur-based compound fertilizer by chemical synthesis

ActiveCN102249777AHigh nitrogen contentNot easy to agglomerateFertilizer mixturesChemical synthesisPhosphoric acid

The invention relates to a production method for ammoniated sulfur-based compound fertilizer by chemical synthesis, comprising the following steps: generating potassium bisulfate by the reaction of sulfuric acid and potassium chloride; mixing phosphoric acid and potassium bisulfate to generate a mixed acid; adding ammonia into the mixed acid to be pre-neutralized; neutralizing the pre-neutralizedslurry with the ammonia; atomizing to spray the slurry by heat released by neutralization; and spraying slurry, introducing in ammonia and pelleting by adding urea. According to the product produced by the technology, the nitrogen content of the compound fertilizer can be improved by above 4%, and the compound fertilizer has small possibility of blocking; in addition, the amount of potassium can be kept to be above 14.5%; the compound fertilizer which contains 48% total nutrition and over 14.5% of each single nutrition, can satisfy nitrogen16-phosphorus 16-potassium 16 marking requirements and conforms to the national standard is obtained; and in addition, the mixed acid is neutralized for several times, the soil is not acidized or hardened after the produced compound fertilizer is applied.

Owner:山东聊城鲁西化工第五化肥有限公司

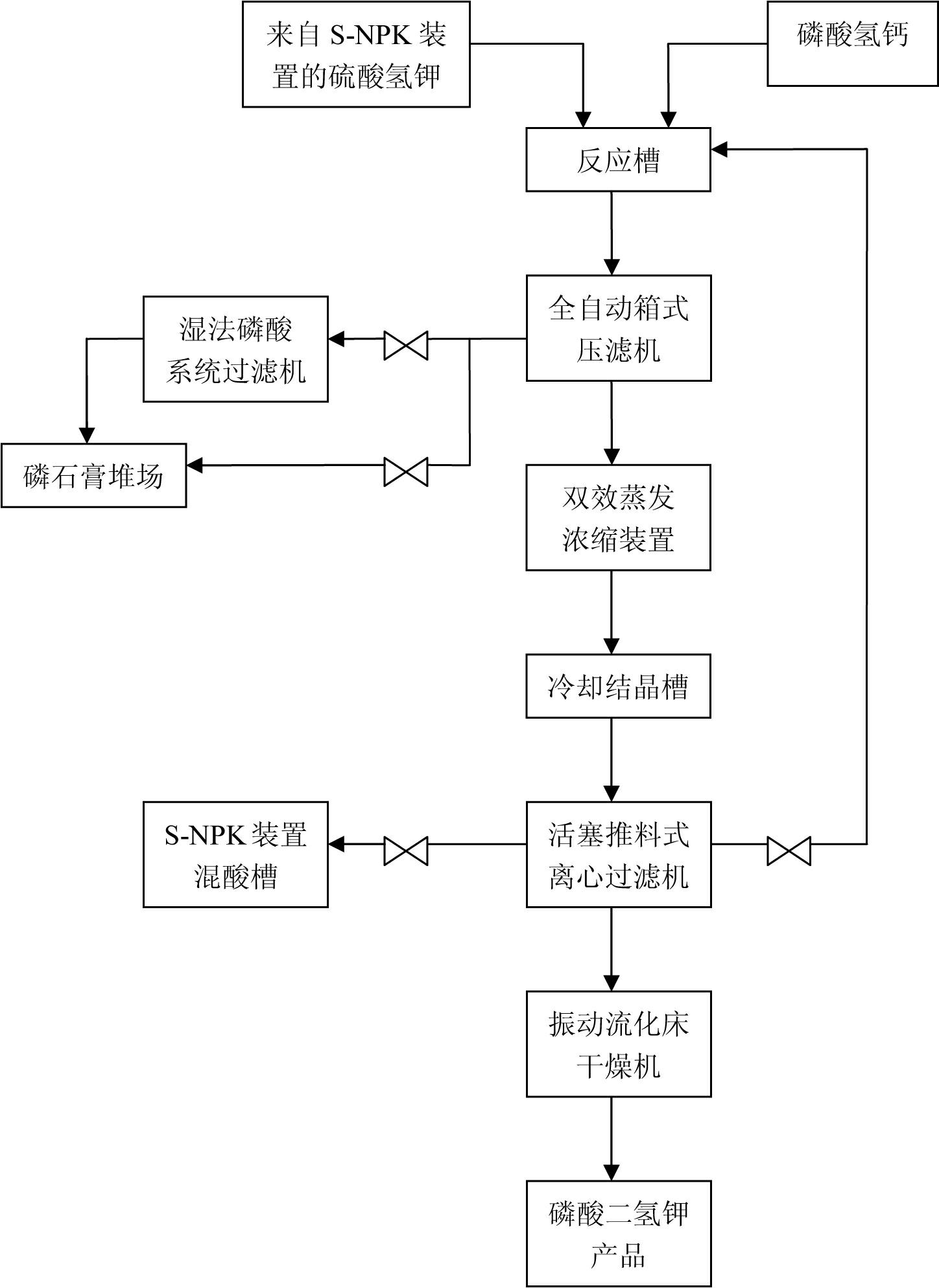

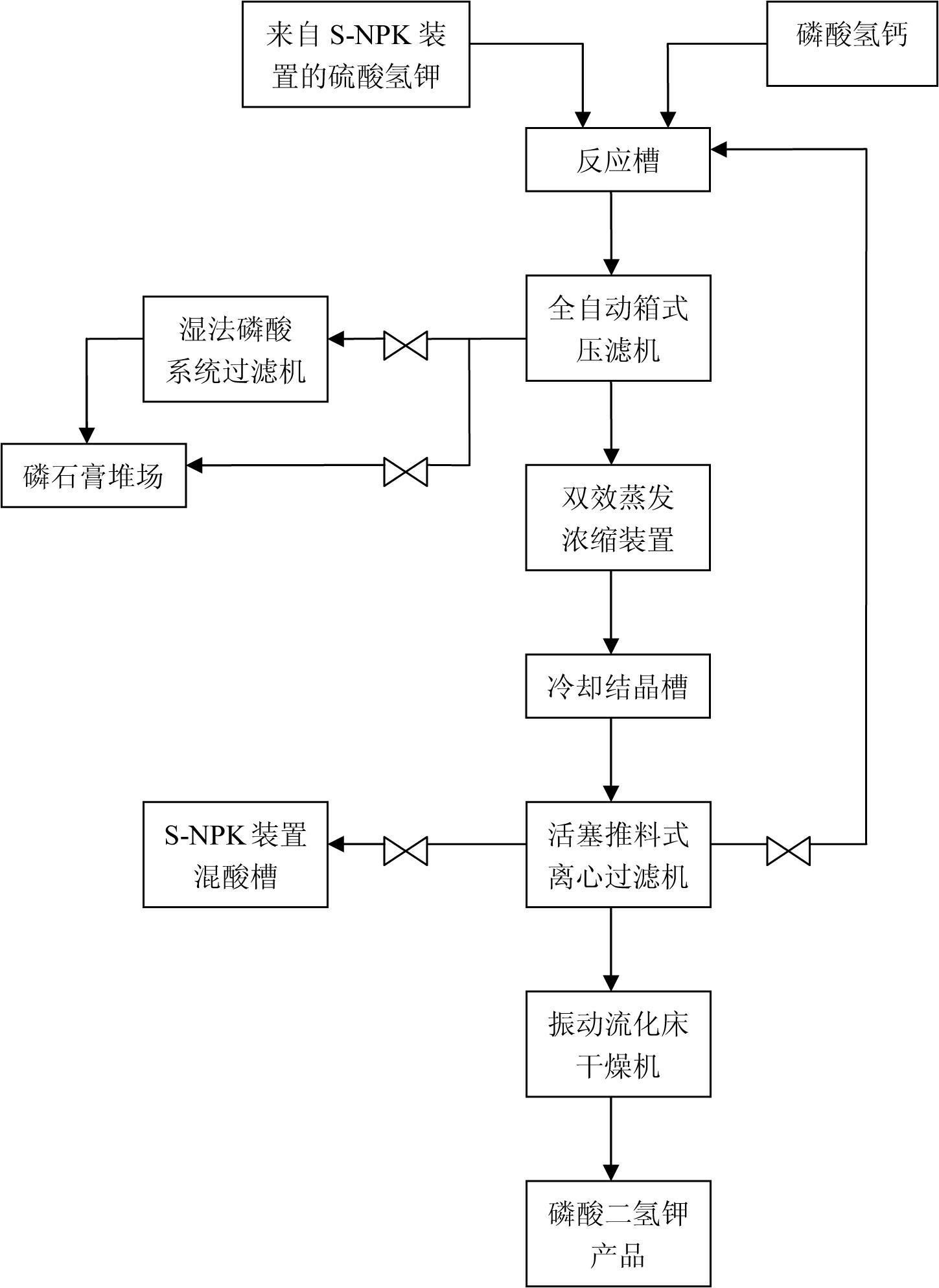

Production method of potassium dihydrogen phosphate

InactiveCN102424374AReduce investmentLess investmentPhosphorus compoundsHigh concentrationFiltration

A production method of potassium dihydrogen phosphate comprises the following steps: adding a potassium bisulfate solution and powdery calcium hydrogen phosphate into a potassium dihydrogen phosphate reaction tank for reaction, filtering the material slurry after the reaction, delivering the filter residues to a wet-method phosphoric acid system filter for filtration, delivering to a phosphogypsum stockyard or directly stacking in a stockyard, delivering the filtrate into an evaporation concentration device for concentration; allowing the concentrated supersaturated solution to enter a cooling crystallization tank, filtering the material slurry after cooling crystallization by a centrifugation filter, returning the filtered mother liquor to the potassium dihydrogen phosphate reaction tank and a mixed acid tank of a device for producing sulfur-base composite fertilizer, wherein the crystal obtained from filtration is potassium dihydrogen phosphate, drying to obtain the potassium dihydrogen phosphate finished product. The invention is applicable to all enterprises with a high-concentration sulfur-base composite fertilizer device, and has the advantages of low cost, good product quality, and less equipment investment.

Owner:HUBEI SANNING CHEM

Method for producing nitrate-and-sulfur-based compound fertilizer and co-producing gypsum by utilizing potassium hydrogen sulfate

InactiveCN102126737ARealize comprehensive utilizationHigh removal rateCalcium/strontium/barium sulfatesFertilizer mixturesHydrogen SulfatePhosphoric acid

The invention discloses a method for producing a nitrate-and-sulfur-based compound fertilizer and co-producing gypsum by utilizing potassium hydrogen sulfate, belonging to the technical field of compound fertilizers. The method comprises the following steps: decomposing phosphrite with nitric acid; filtering and removing acid-insoluble substances and organic suspended matters; adding industrial ammonium sulfate or sulfuric acid in the purified acidolysis solution for decalcification; filtering so as to obtain decalcified byproduct high-purity gypsum; producing the nitrate-and-sulfur-based compound fertilizer by using the decalcified acidolysis solution; directly carrying out neutralization reaction on the decalcified acidolysis solution and gas ammonia so as to obtain nitrophosphate fertilizer slurry containing ammonium nitrate and monoammonium phosphate; evaporating the slurry, and then adding potassium hydrogen sulfate; and then granulating and drying so as to obtain the nitrate-and-sulfur-based compound fertilizer. In the invention, the calcium in the acidolysis solution generated after the phosphrite is decomposed by phosphoric acid is removed by using the ammonium sulfate or sulfuric acid, and other impurity ions are not added; and as a nutrient, the ammonia in the ammonium sulfate is remained in a finished product when the calcium is removed by using the ammonium sulfate. The removal rate of the calcium in the acidolysis solution is up to above 95%.

Owner:KINGENTA ECOLOGICAL ENG GRP

Preparation of ammonium potassium dihydrogen phosphate

ActiveCN101348244AIncrease profitReduce energy consumptionPhosphorus compoundsEvaporationPhosphate product

The invention provides a method for preparing potassium dihydrogen phosphate. In the method, phosphate ores, sulphuric acid and potassium chloride are taken as base materials and subjected to phosphoric acid extraction, filtering, neutralization and separation, concentration and crystallization to obtain a full water-soluble potassium dihydrogen phosphate product, and the potassium dihydrogen phosphate solution prepared is high in concentration, the solid content reaches 40 percent, thereby reducing the load of the concentration process; in particular, the method adopts a process of neutralization first and concentration second, so that the corrosivity of concentration liquids is small, the boiling point is low, and the conventional multi-effect concentration by evaporation can be performed by the common equipment, and the equipment investment and the energy consumption are greatly lowered; because in the phosphoric acid extraction process, the potassium bisulfate is added, thereby effectively lowering the emission of fluorine-containing exhaust gases and facilitating the environmental protection; adding with the development and the utilization of potassium-containing phosphogypsum, the method of the invention can avoid the environmental pollution caused by the phosphogypsum, improve the material utilization ratio and make the material utilization ratio reach 100 percent.

Owner:昆明隆祥化工有限公司

Production method of novel slow release urea-formaldehyde compound fertilizer

ActiveCN102153392AHigh strengthPoor strengthUrea compound fertilisersFertilizer mixturesHydrogen SulfatePhosphoric acid

The invention discloses a production method of a novel slow release urea-formaldehyde compound fertilizer, which comprises the following steps: (1) mixing a potassium hydrogen sulfate solution and phosphoric acid to generate mixed acid slurry; (2) ammoniating to pre-neutralize the mixed acid slurry, and then adding urea-formaldehyde slurry; (3) ammoniating to neutralize the obtained slurry, and granulating by carrying out atomization spray in a granulation device; and (4) after the granulation process, producing the required product by using the conventional technology. The product produced by using the method has uniform and stable quality, smooth particles, good color degree, high strength and obvious slow release effect, is white in color, is difficult to agglomerate, and can meet the nutrient demands of different crops at different growth periods, thereby ensuring that the nutrient release amounts are basically in agreement with the nutrient demands of the crops at different growth periods, and achieving better social and economic benefits.

Owner:山东聊城鲁西化工第五化肥有限公司

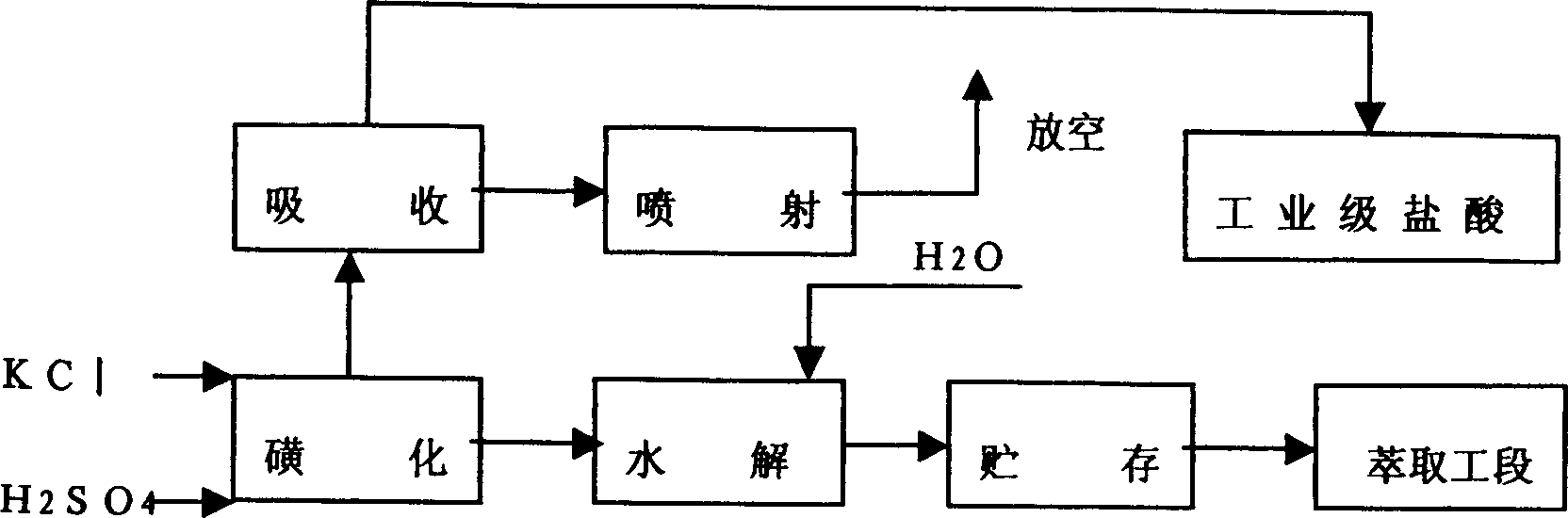

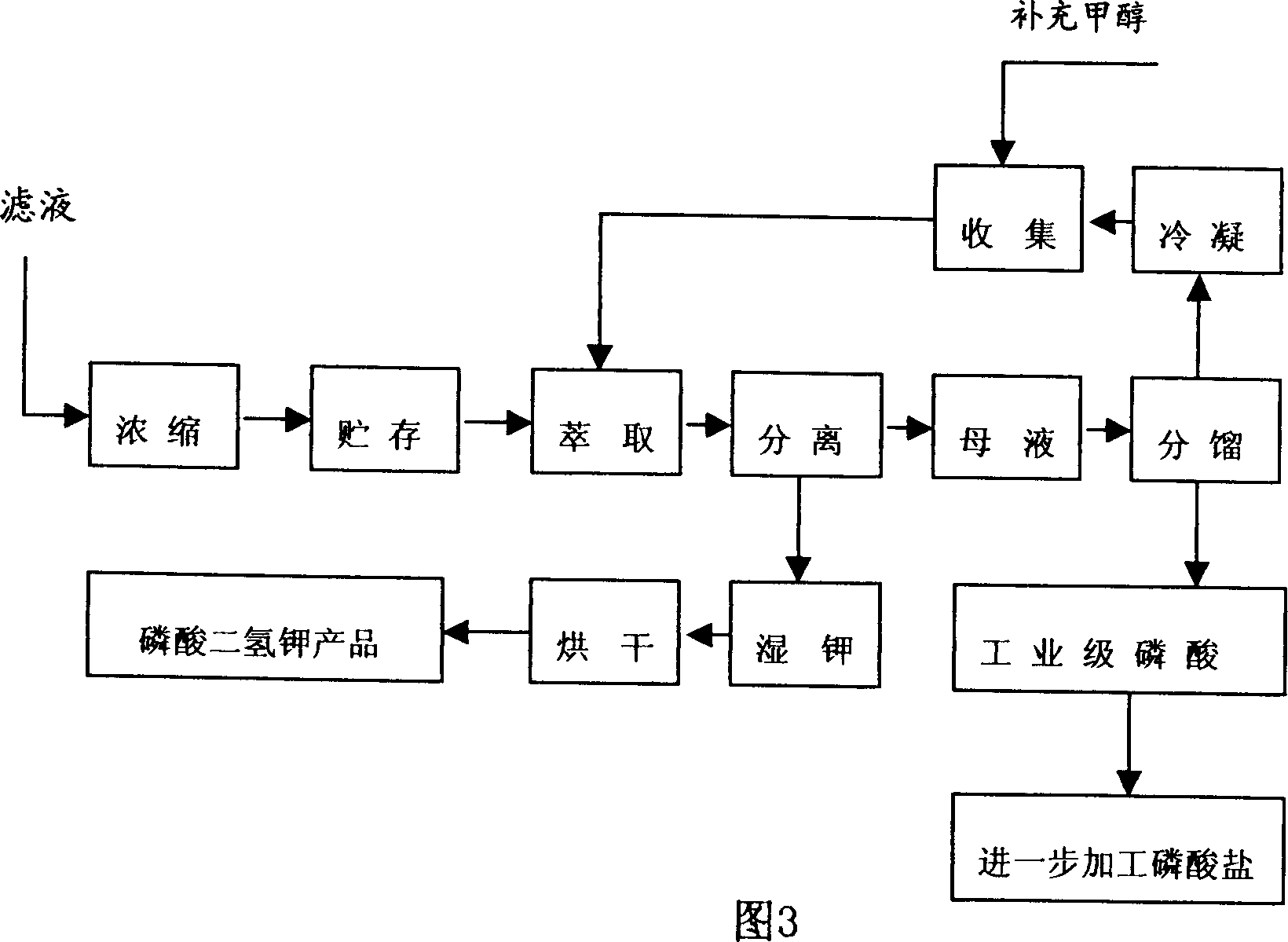

Production method of potassium dihydrogen phosphate

InactiveCN1412107AImprove qualityReliable technologySulfate/bisulfate preparationLiquid solutions solvent extractionHydrogen SulfateFiltration

The production method of potassium dihydrogen phosphate uses the calcium hydrogen phosphate whose impurities of iron, aluminium, fluorine and sulfur are low as raw material, and is implemented by adopting technological processes of potassium hydrogen sulfate preparation, solution extraction, potassium dihydrogen phosphate crystallization and separation ,and its operation includes the following steps: fulfonation, hydrolysis, extraction, filtration, filtrate concentration, crystallization and separation, drying and fractionation. Its reaction condition is moderate, its potassium yield is high,at the same time the quality of potassium dihydrogen phosphate and phosphoric acid can be ensured.

Owner:SICHUAN HONGDA (GRP) CO LTD

Tobacco foliage fertilizer

InactiveCN101200388AIncrease the areaIncrease widthMagnesium fertilisersOrganic fertilisersNicotiana tabacumAdditive ingredient

The invention discloses a tobacco foliar fertilizer, which is mainly comprises the ingredients according to the part by weight: zinc sulfate of 30 to 45 parts, boric acid of 5 to 15 parts, potassium bisulfate of 10 to 20 parts, bitter salt of 15 to 25 parts and green copperas of 1 to 6 parts. Since the invention adopts the ingredients to prepare the fertilizer, the area of the upper leaves can be enlarged by fertilizing when the green tips are pruned, and particularly the width of the leaves can be enlarged, and the structure of the upper leaves can be optimized, and the nicotine content in tobacco leaves can be lowered and the potassium content can be increased greatly, thereby the leaves can be thinned and is easy to be roasted, so the quality of tobacco leaves and appearance is improved, and the industrial application is enhanced.

Owner:HENAN AGRICULTURAL UNIVERSITY

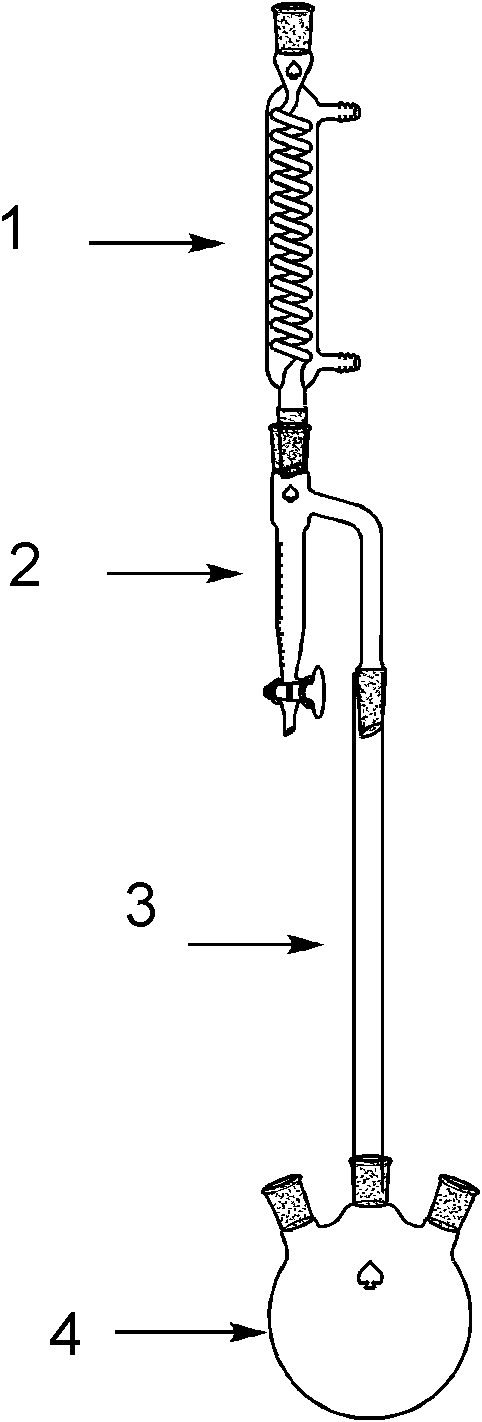

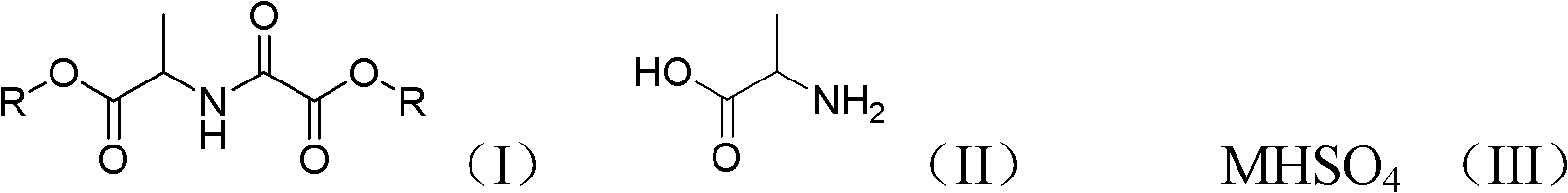

Chemical synthesis method of N-alcoxyloxalyl alanine ester

ActiveCN101830821AFast esterificationHigh reaction yieldOrganic compound preparationCarboxylic acid amides preparationChemical synthesisAfter treatment

The invention relates to a chemical synthesis method of N-alcoxyloxalyl alanine ester shown as a formula (I). The method comprises the following steps of: reacting alanine shown and oxalic acid which are shown as the formula (I) in alcohol of C1-C8 for 5-150 hours at 50-150 DEG C under the catalysis of bisulfate shown as a formula (II), wherein water generated in the reaction is timely evaporatedout with a water taking agent through a rectifying column and a water knockout drum; and after the reaction ends, carrying out after-treatment on reaction liquid to obtain the N-alcoxyloxalyl alanineester, wherein the mass ratio of the alanine to the oxalic acid to the bisulfate is 1:(1-10):(0.001-1), and the bisulfate is sodium bisulfate or potassium bisulfate or a mixture of the sodium bisulfate and the potassium bisulfate in arbitrary proportion. In the invention, since the bisulfate is used as a catalyst, and the method has high esterification speed, high reaction yield, low production cost, high catalyst activity, good selectivity, basically no monoesterification by-product, high product purity, easy separation and purification, moderate reaction condition and easy industrialization.

Owner:ZHEJIANG UNIV OF TECH +1

Water environment improver for aquiculture

InactiveCN101585576AImprove living conditionsPrevent diseaseWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by sorptionHazardous substanceWater quality

The invention relates to a water environment improver for aquiculture, which comprises potassium bisulfate compound salt, sodium bromide and zeolite powder. The components are weighed in proportion, evenly mixed at the normal temperature and packed. The improver has fast action and stable effect, greatly reduces the ammonia nitrogen, nitrite, sulfurated hydrogen and COD in water, enhances the water oxygen solubility, decreases alga density, inhibits the pathogenic microorganism, improves the transparence, water quality and bottom quality environment quality, prevents cultured organism diseases and sudden death and increases the yield and quality of the cultured organisms.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Decolorization of dyed keratin fibers

The invention relates to agents for the reductive decolorization of dyed keratin fibers, in particular human hair, containing in an aqueous cosmetic carrier (a) one or more reduction agents from the group consisting of sodium dithionite, zinc dithionite, potassium dithionite, sodium sulfite, sodium hydrogen sulfite, potassium sulfite, potassium hydrogen sulfite, ammonium sulfite, sodium thiosulfate, potassium thiosulfate, ammonium thiosulfate, hydroxymethanesulfinic acid, aminomethanesulfinic acid, cysteine, thiolactic acid, sulfanylacetic acid (thioglycolic acid), and / or ascorbic acid, and (b) one or more zwitterionic surfactants, each of which has at least one quaternary ammonium group and a grouping of —SO3— as structural units.

Owner:HENKEL KGAA

Etchant composition for indium oxide layer and etching method using the same

ActiveUS7329365B2Improve etch selectivityStable temperatureDecorative surface effectsSemiconductor/solid-state device manufacturingCompound aIndium

An etchant for removing an indium oxide layer includes sulfuric acid as a main oxidizer, an auxiliary oxidizer such as H3PO4, HNO3, CH3COOH, HClO4, H2O2, and a Compound A that is obtained by mixing potassium peroxymonosulfate (2KHSO5), potassium bisulfate (KHSO4), and potassium sulfate (K2SO4) together in the ratio of 5:3:2, an etching inhibitor comprising an ammonium-based material, and water. The etchant may remove desired portions of the indium oxide layer without damage to a photoresist pattern or layers underlying the indium oxide layer.

Owner:SAMSUNG DISPLAY CO LTD +1

Low-corrosion potassium monopersulfate compound salt disinfectant

InactiveCN107624785ASolve the irritatingSolve corrosiveBiocideWaste water treatment from animal husbandrySulfate radicalsIrritation

The invention relates to a low-corrosion potassium monopersulfate compound salt disinfectant. The disinfectant is prepared from raw materials in parts by weight as follows: 30-60 parts of an oxidizingagent, 20-30 parts of an activator, 5-10 parts of a synergist, 1-5 parts of a pH regulator, 0.2-2 parts of a surfactant and 3-10 parts of a complexing agent. The disinfectant powder overcomes the defects of strong irritation and poor stability of disinfectant powder, the effective sterilization duration is prolonged, and the dosage of the disinfectant is reduced. Potassium monopersulfate compoundsalt produces hydroxyl radicals and sulfate radicals after being dissolved in water, has higher oxidation and disinfection effects and can produce continuous chain reactions and cyclic effects in thepresence of the activator, the synergist and the like, and the disinfection and sterilization effects are guaranteed.

Owner:杨强 +1

Method for preparing sulphur based compound fertilizer by decomposing rock phosphate with hydrogen nitrate and system thereof

ActiveCN101343200AThe production process is straightforward and simpleReduce intermediate stepsFertilizer mixturesHydrogen NitratePhosphate

The invention relates to a method and a system for using nitric acid decomposed phosphate rock powder to produce a sulfur-based compound fertilizer, comprising the steps of: (1) preparing potassium bisulfate for obtaining a mixed acid I; (2) decomposing phosphate rock powder with nitric acid for acquiring a mixed acid II; (3) mixing the mixed acid I with the mixed acid II; and (4) having the mixed acid III obtained in the step (3) to react with liquid ammonia or gas ammonia for getting the sulfur-based compound fertilizer. The method and the system have a more direct and simple production process flow than that of the current nitryl sulfur-based fertilizer, and fully utilize the nitrate nitrogen and acidity of nitric acid and the heat of reaction, as well as low temperature dechlorination and sensible heat of concentrated sulfuric acid potassium chloride, thereby cutting the intermediate step, obviously reducing the energy consumption and corrosion, and lowering the capital construction and equipment investment.

Owner:中国-阿拉伯化肥有限公司

Etchant composition for indium oxide layer and etching method using the same

ActiveUS20060043332A1Improve etch selectivityStable operating temperatureDecorative surface effectsSemiconductor/solid-state device manufacturingIndiumPotassium bisulfate

An etchant for removing an indium oxide layer includes sulfuric acid as a main oxidizer, an auxiliary oxidizer such as H3PO4, HNO3, CH3COOH, HClO4, H2O2, and a Compound A that is obtained by mixing potassium peroxymonosulfate (2KHSO5), potassium bisulfate (KHSO4), and potassium sulfate (K2SO4) together in the ratio of 5:3:2, an etching inhibitor comprising an ammonium-based material, and water. The etchant may remove desired portions of the indium oxide layer without damage to a photoresist pattern or layers underlying the indium oxide layer.

Owner:SAMSUNG DISPLAY CO LTD +1

Recovery method of benzene series nitration waste acid

ActiveCN105858627AIncrease added valueProcess environmental protectionChemical industrySulfate/bisulfate preparationRecovery methodPotassium hydroxide

The invention provides a recovery method of benzene series nitration waste acid. The recovery method includes: mixing waste acid from a benzene series nitration reaction process with activated carbon for decolorizing, adding decolorized waste acid and solid potassium nitrate into an intermittent reactive distillation column bottom sequentially, heating to 60-70 DEG C with stirring for 0.5-3 hours, performing rectification operation while reaction is conducted, collecting overhead distillate, namely recovery liquid, adding water into the intermittent reactive distillation column bottom, heating with stirring to dissolve residues in the bottom, regulating a pH value of 1.4-2.1 by a potassium hydroxide water solution, filtering immediately, naturally cooling filtrate to separate out solids, filtering to obtain potassium bisulfate and recycling mother liquor. The recovery method of the benzene series nitration waste acid has the advantages that the waste acid is utilized effectively to obtain nitric acid required by the reaction and the high-added-value potassium bisulfate, so that the whole technological process is more environment friendly.

Owner:QUZHOU UNIV

Preparation method of high purity butyl lactate

ActiveCN103102269AImprove conversion rateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateSodium bisulfate

The invention relates to a preparation method of high purity butyl lactate. The method is characterized by: taking industrial lactic acid and n-butyl alcohol as raw materials, and adopting benzene as a water-carrying agent, subjecting them to an esterification reaction in the presence of a catalyst, then carrying out vacuum distillation and refining, thus obtaining the high purity butyl lactate. Specifically, the catalyst is a composite catalyst of potassium hydrogen sulfate and ferric trichloride, or a composite catalyst of p-toluenesulfonic acid and sodium hydrogen sulfate. The method provided in the invention shortens the esterification reaction time, increases the yield of butyl lactate, simplifies refining operation, and is easy to realize industrialization.

Owner:JIANGSU YIDA CHEM

Production method for dual acid chelate inorganic compound fertilizer

InactiveCN102718592ASimple production processEasy to operateFertilizer mixturesContinuous croppingHydrogen Sulfate

The invention discloses a production method for a dual acid chelate inorganic compound fertilizer, and the product belongs to the field of compound fertilizer manufacture. Apart from containing abundant nitrogen, phosphorus and potassium, the fertilizer also contains medium and trace elements in a variety of amino acids and humic acid chelates. By long-term use of the product, soil structure can be regulated efficiently, soil can be activated, the equalization, stability and lasting effects of the nitrogen, phosphorus and potassium elements can be coordinated, abilities of plants to resist droughts, cold, adversities, continuous cropping, withering and yellowing, and root rot can be improved, and immune functions can be enhanced. The raw materials used in the production of the product include urea, monoammonium phosphate, potassium hydrogen sulfate molten mass, iron amino acid chelate, boron amino acid chelate, copper amino acid chelate, manganese amino acid chelate, molybdenum amino acid chelate, zinc humic acid chelate, calcium humic acid chelate, magnesium humic acid chelate, a controlled release agent, and gaseous ammonia.

Owner:訾兆举

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00221.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00231.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00232.PNG)