Production method of potassium dihydrogen phosphate

A technology of potassium dihydrogen phosphate and production method, applied in chemical instruments and methods, sulfate/bisulfate preparation, phosphorus compounds, etc., can solve the problems of extractant poisoning, high product cost, high energy consumption, and achieve reaction conditions The effect of mildness, good product quality and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

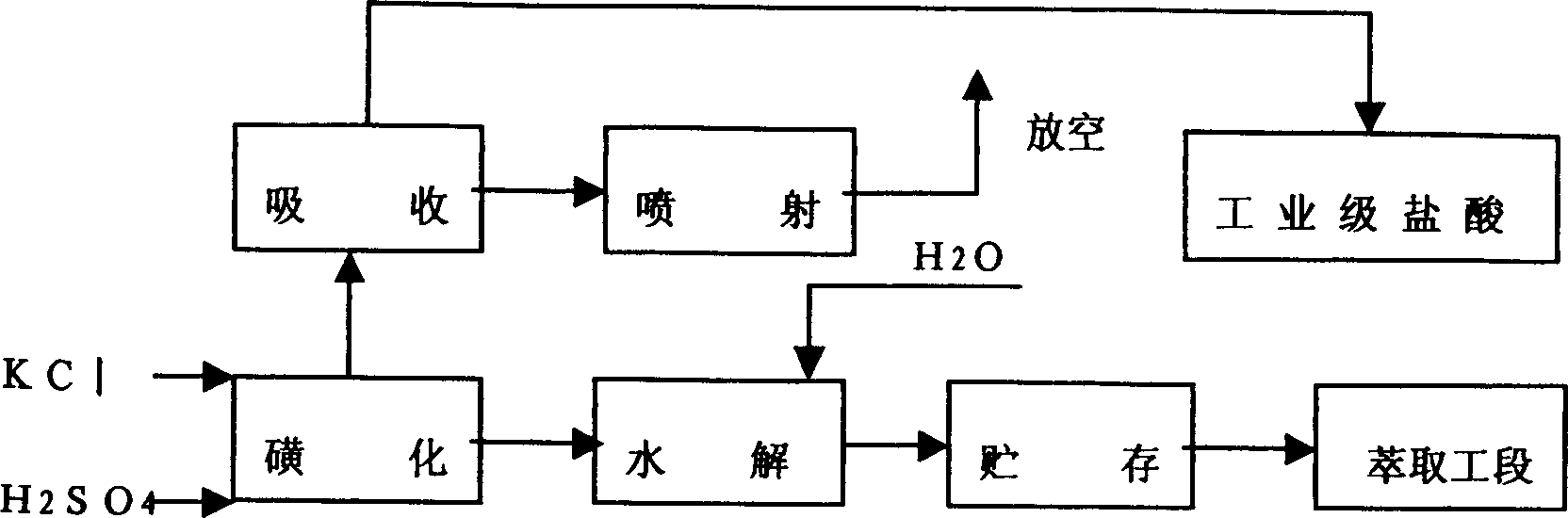

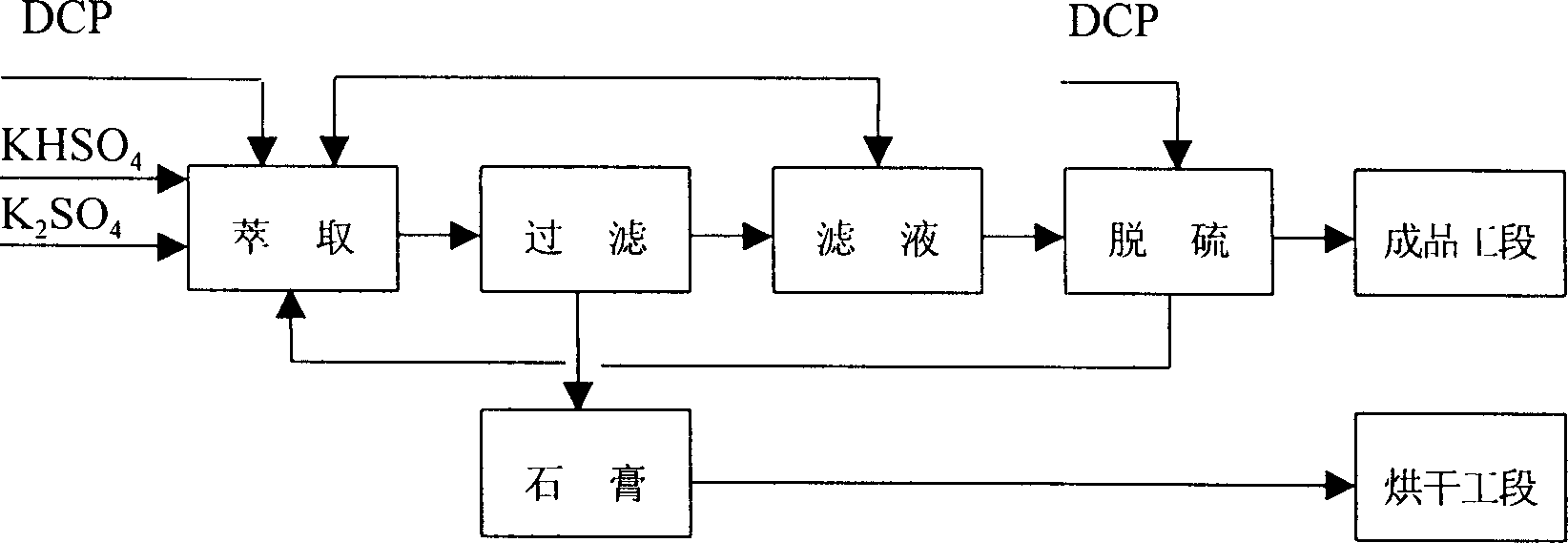

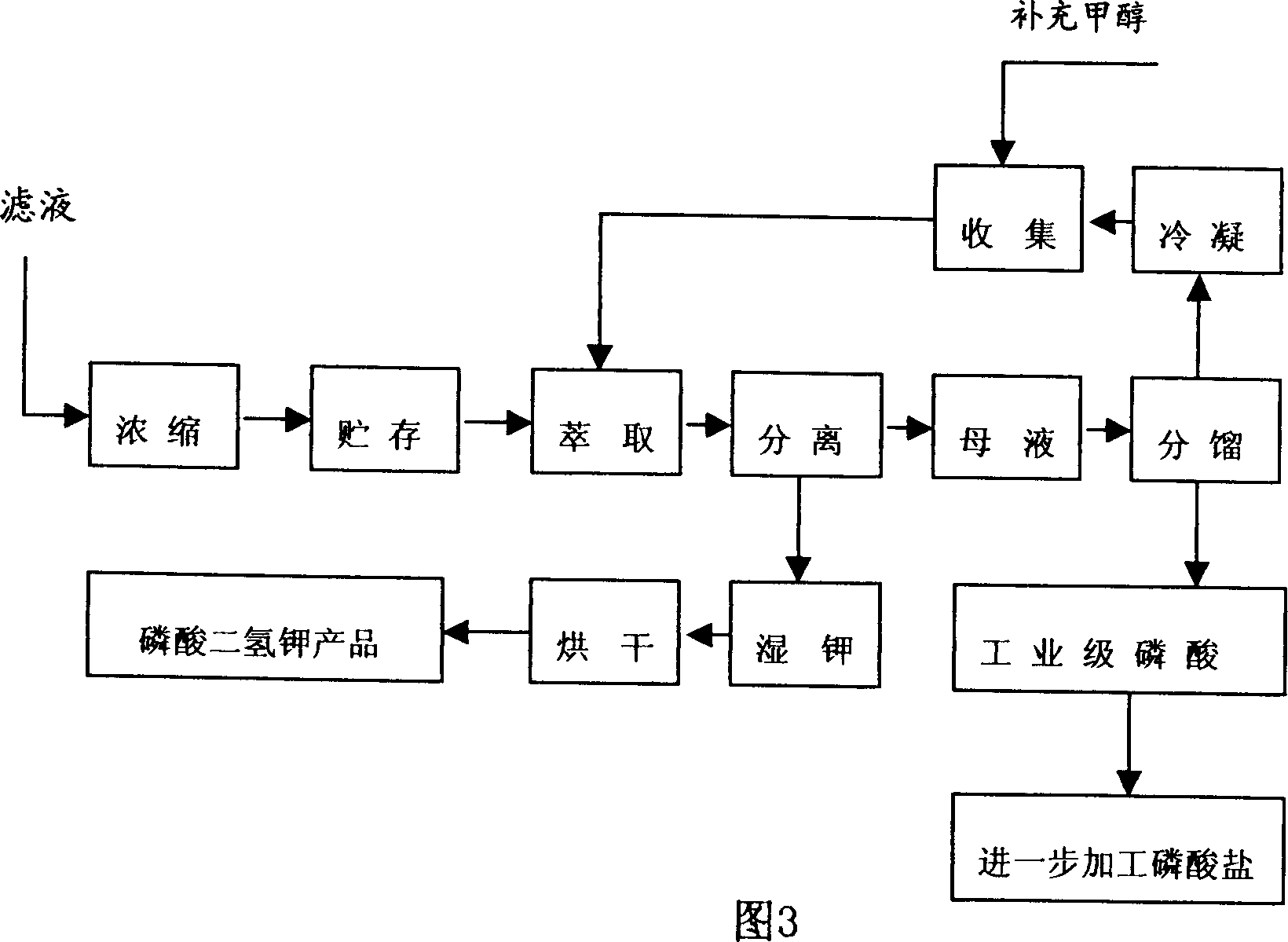

[0045] Whole technological process of the present invention sees figure 1 , figure 2,image 3. The production method consists of five sections including preparation of potassium hydrogen sulfate, solution extraction, crystallization and separation of potassium dihydrogen phosphate, fractionation of methanol and phosphoric acid, and phosphate processing. The following combination figure 1 , figure 2 , Fig. 3 further illustrate the production method of the present invention, this production method operates by following sulfonation, hydrolysis, extraction, filtration, filtrate concentration, crystallization and separation, drying, fractionation steps:

[0046] (1), sulfonation: first add hot water and potassium chloride to a corrosion-resistant reaction kettle with a heating jacket (such as an enamel reaction kettle) in a ratio of 1:1, start the agitator and feed steam into the jacket to raise the temperature, Then slowly add sulfuric acid (excess 20%), the reaction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com