Patents

Literature

110results about How to "Simplify subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

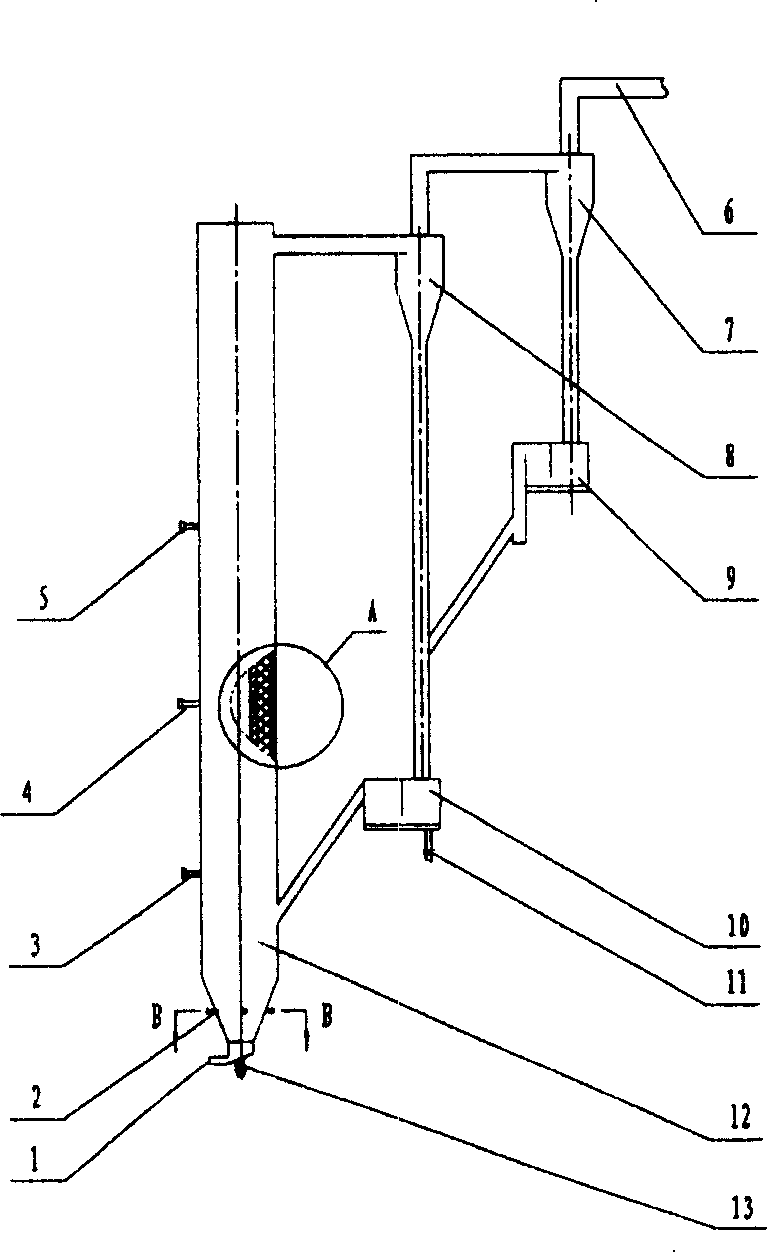

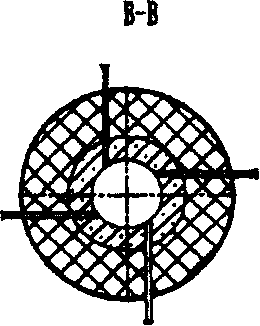

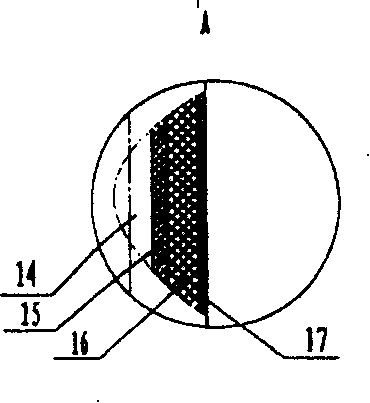

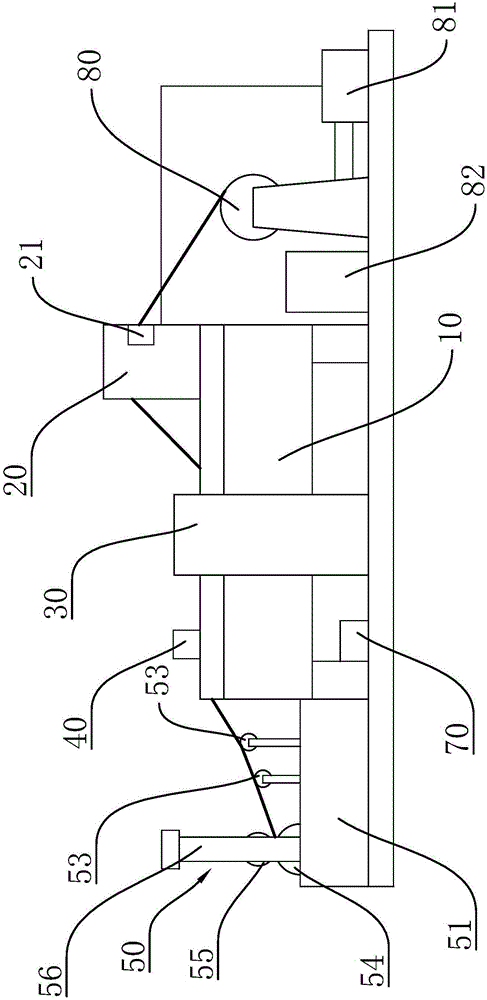

Fine coal pressurization dense phase transporting bed gasification method and device

ActiveCN101240196AIncrease speedGuaranteed to loop multiple timesCombined combustion mitigationGranular/pulverulent flues gasificationHigh rateHigh flux

A pulverized coal pressure dense transport bed gasification method and installation of the invention relates to gasification technology and employs in-furnace desulfurization craft. Pulverized coal and desulfurizer are sent into gasification furnace through the middle and lower part of gasification furnace by a feeder, and then react with a gasifying agent. Reaction mass flow upward from the bottom of the gasification furnace, and enter into a multistage gas-solid separator from an export on the top of the gasification furnace. Most solids are separated in the gas-solid separator and enter into the low part of the gasification furnace by a high flux return feeder to continue to participate in reaction. Gas products with a small amount of solid enter into a gas cooler which can recover gas manifested heat to generate steam. The enter modes of the gasifying agent are bottom once wind and cyclone twice wind, otherwise, the reactor can also be use to burn. Because of the high-rate cycle, high solid content and high gas-solid mixing in the gasification furnace of the invention, the gasification strength and gasification rate of the gasification furnace can be improved and higher gasification efficiency and carbon conversion rate can be obtained.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

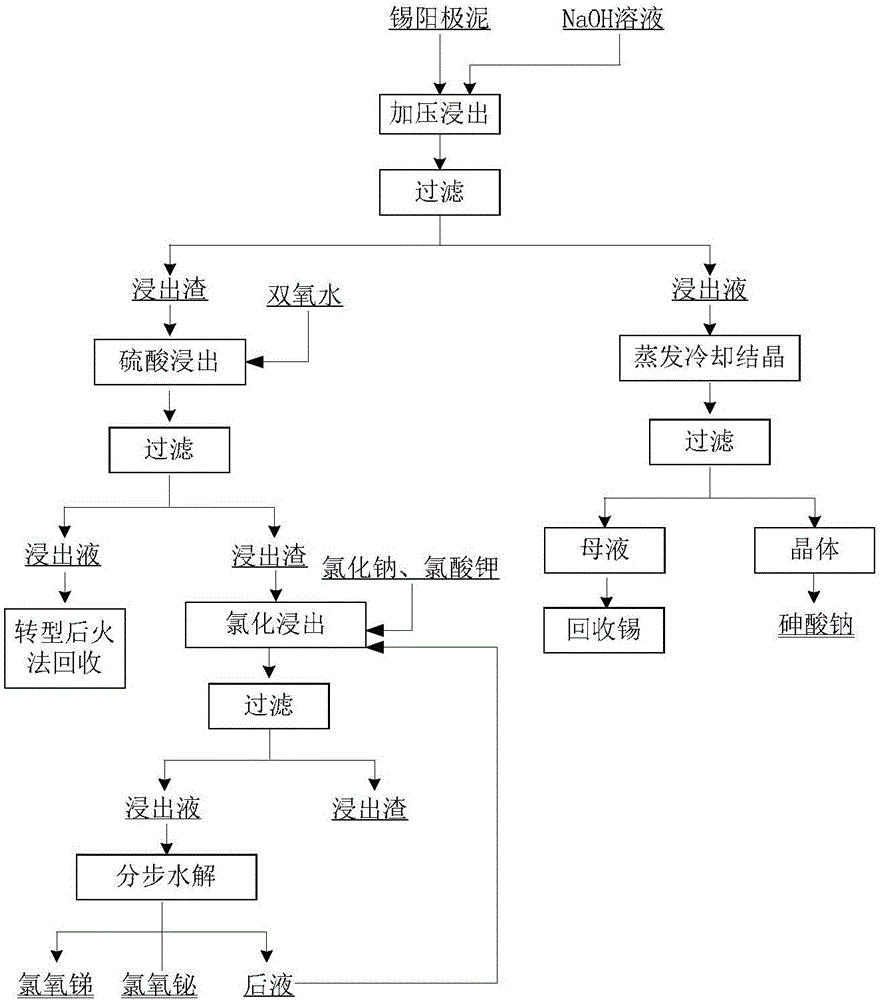

Method for comprehensively recovering valuable metals through oxygen pressure treatment of tin anode mud

ActiveCN105734299ASatisfy the requirements of technical control conditionsAchieve separationProcess efficiency improvementIndiumSeparation technology

The invention discloses a method for comprehensively recovering valuable metals through oxygen pressure treatment of tin anode mud. According to the method, the tin anode mud serves as a raw material, oxygen pressure alkaline leaching, sulfuric acid oxidation leaching, chlorination leaching, separation technology and other wet metallurgy methods are adopted, effective separation and recovery of valuable metals such as tin, arsenic, antimony, copper, bismuth, indium and the like in the tin anode mud can be realized, lead and precious metals are enriched in slag, and subsequent fire process recovery is facilitated. According to the method, arsenic is efficiently removed from the source, the arsenic removal rate is over 95 percent, the precious metals are hardly lost in the wet smelting process, comprehensive recovery and utilization of the valuable metals can be realized, the method has the characteristics such as high raw material adaptability, simplicity in operation, high efficiency in cleaning, low energy consumption, less pollution, high metal recovery rate and the like, and the industrial production requirements are met.

Owner:CENT SOUTH UNIV

Method for preparing WC-Co cemented carbide through microwave sintering

The invention provides a method for preparing WC-Co cemented carbide through microwave sintering. The method comprises the steps of WC powder and Co powder batching and mixing, compacting and sintering, wherein in the step of sintering, compacts, SiC chips, carbon black and alumina powder are put in an alumina fiber insulating bag sleeve and then the alumina fiber insulating bag sleeve is put in a microwave high temperature furnace, the products in the furnace are heated to 500-600 DEG C at a heating speed of 5-10 DEG C / min and the heat is preserved and then the products are heated to 1400-1500 DEG C at a heating speed of 30-80 DEG C / min and the heat is preserved, thus obtaining the WC-Co cemented carbide. The method has the advantages of simple process, convenience in operation, short sintering period and low energy consumption, can replace the existing WC-Co cemented carbide processes, is used for producing the WC-Co cemented carbide by adopting the intermittent or continuous microwave sintering mode and is suitable for industrial application. The prepared WC-Co cemented carbide has excellent performances.

Owner:CENT SOUTH UNIV

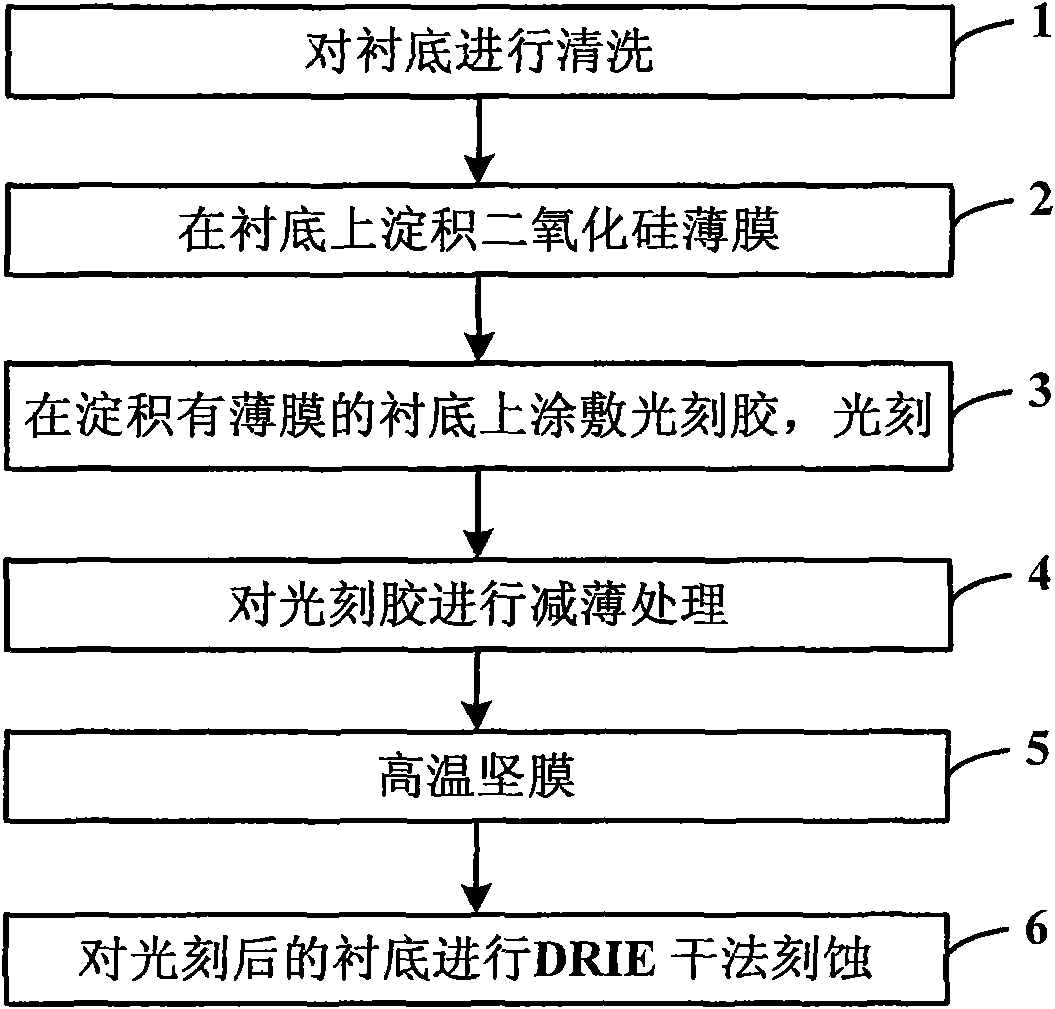

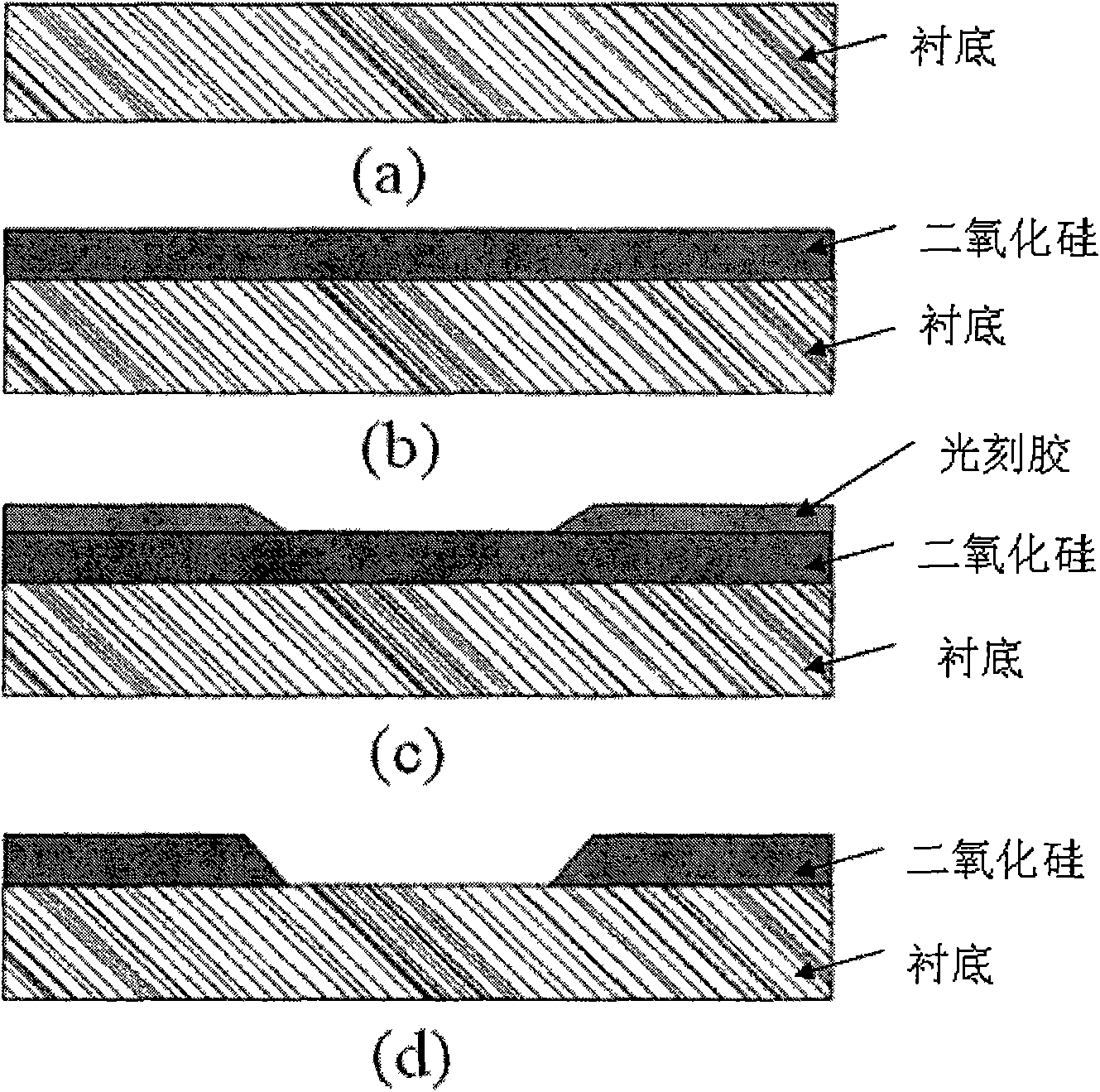

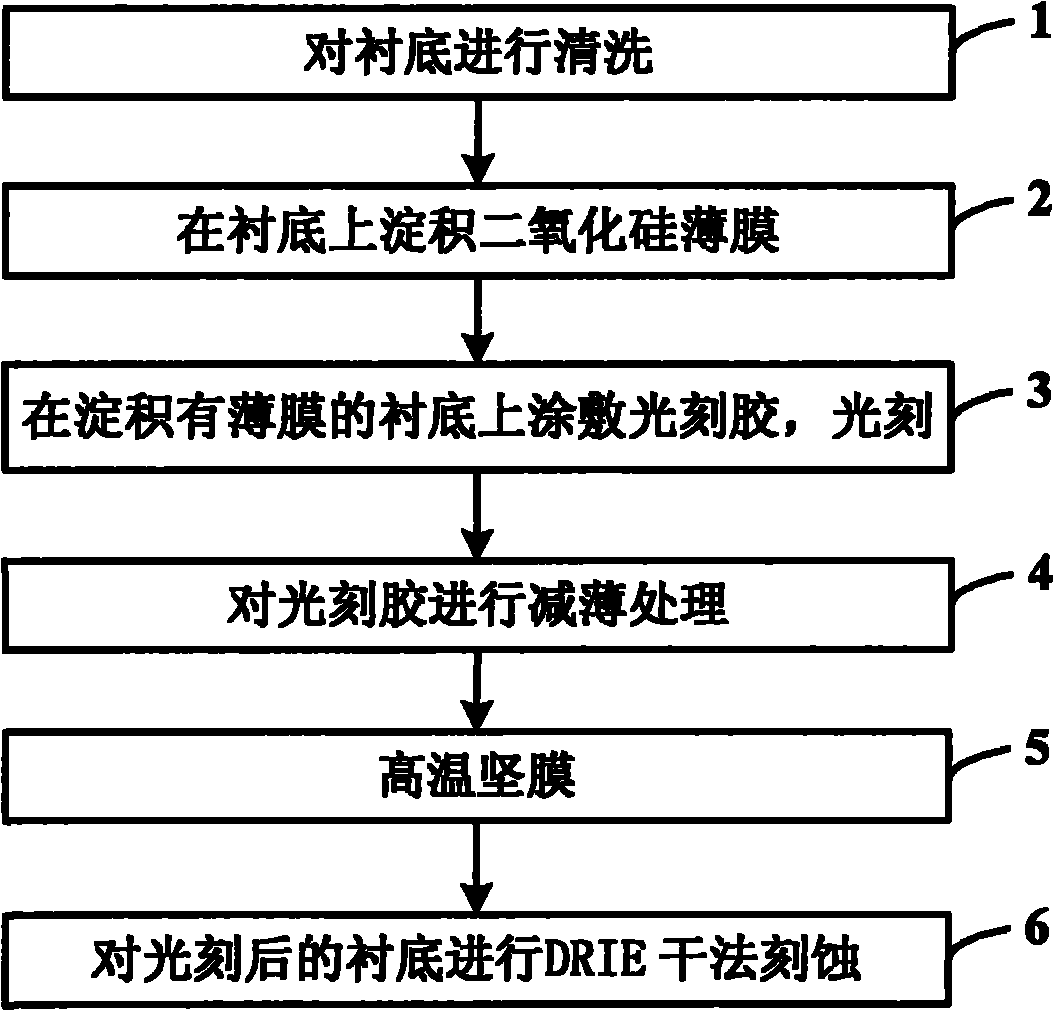

Method for manufacturing sloped sidewall silicon dioxide structure by adopting photoetching and dry etching

InactiveCN101863447AThe method is simple and fastUniversalDecorative surface effectsChemical vapor deposition coatingSilicon dioxidePhotoresist

The invention discloses a method for manufacturing a sloped sidewall silicon dioxide structure by adopting photoetching and dry etching. The method comprises the following steps of: (1) cleaning a substrate; (2) depositing a silicon dioxide thin film on the substrate; (3) coating photoresist on the substrate with the deposited thin film and photoetching; (4) thinning the photoresist; (5) hardening the film at high temperature; and (6) carrying out DRIE (Deep Reactive Ion Etching) dry etching on the photoetched substrate. A sloped silicon dioxide sidewall appearance can be obtained by photoetching and etching only once, and the method is simple and quick and has strong universality.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

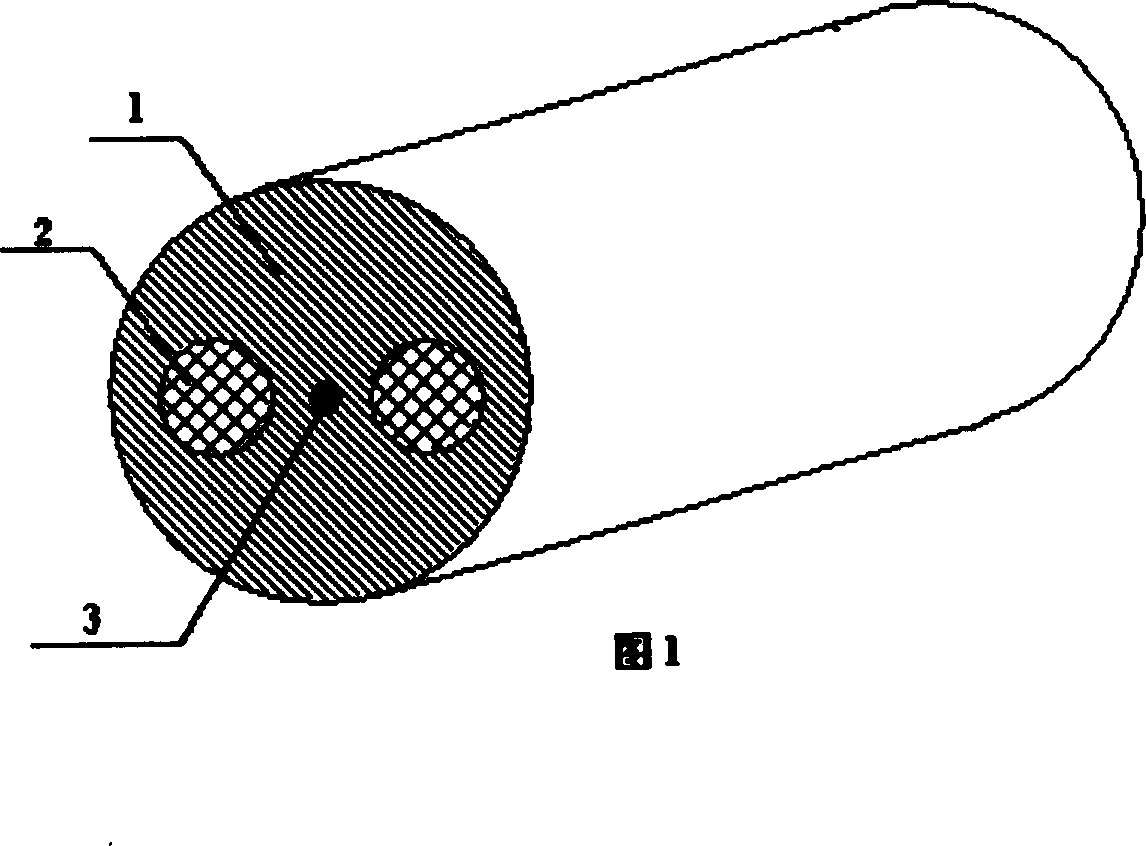

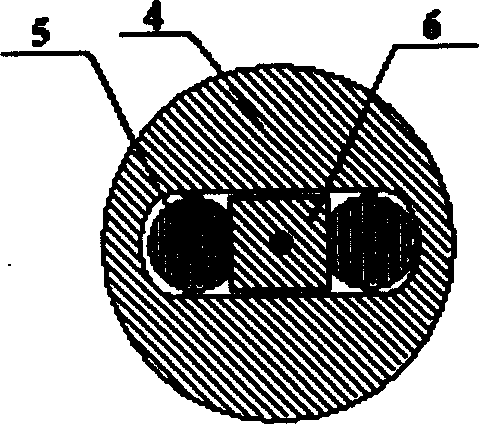

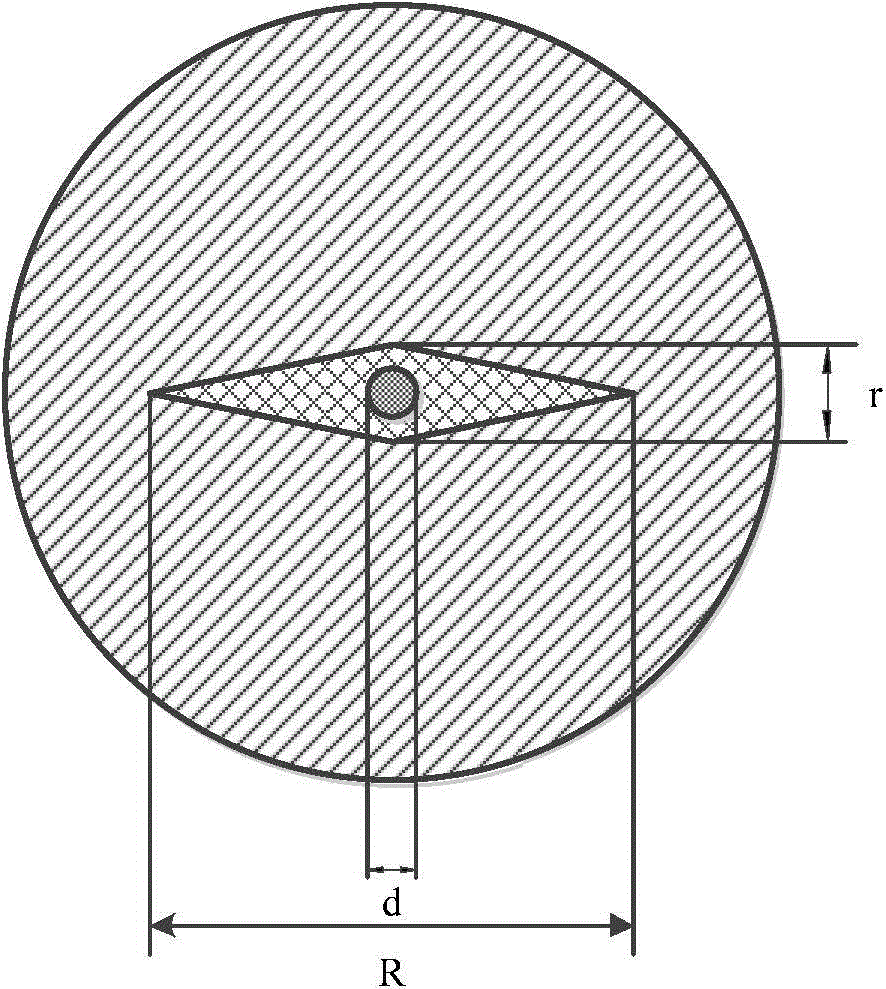

Method for producing polarization maintaining optical fibre

ActiveCN1557754AReduce processing stressReduce residual stressGlass making apparatusOptical light guidesPolarization-maintaining optical fiberEngineering

The making process of circular polarization maintaining fiber includes deposition process to make core rod and stress rod with preserved coating, machining mechanically the matched sides of the core rod and the stress rod to reach the matching interval requirement, machining mechanically the inner hole of quartz casing for fitting the combined cross section of the core rod and the stress rod, setting the machined core rod and stress rod into the quartz casing for matching tightly to constitute prefabricated rod for circular polarization maintaining fiber, drawing, cleaning, and re-drawing to form fiber. The making process has high precision, high product quality and powerful adaptability, and is suitable for mass producing circular polarization maintaining fiber product.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

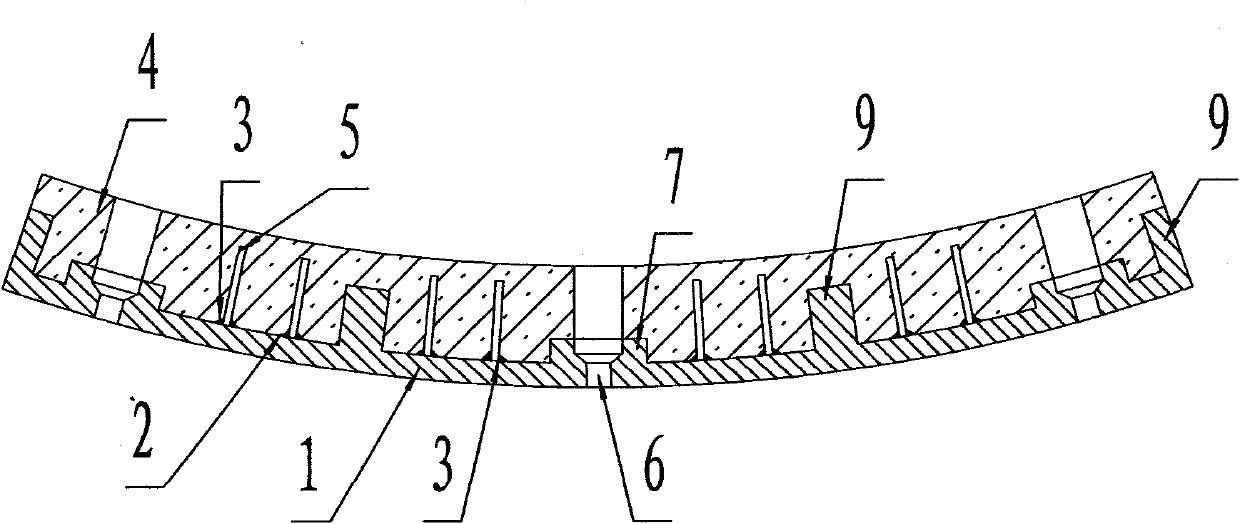

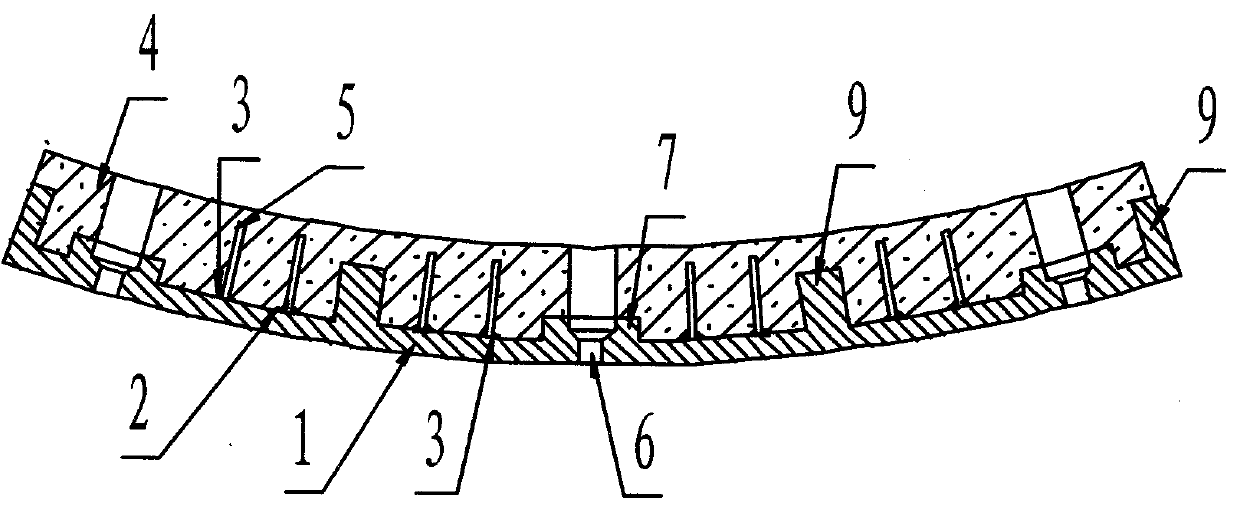

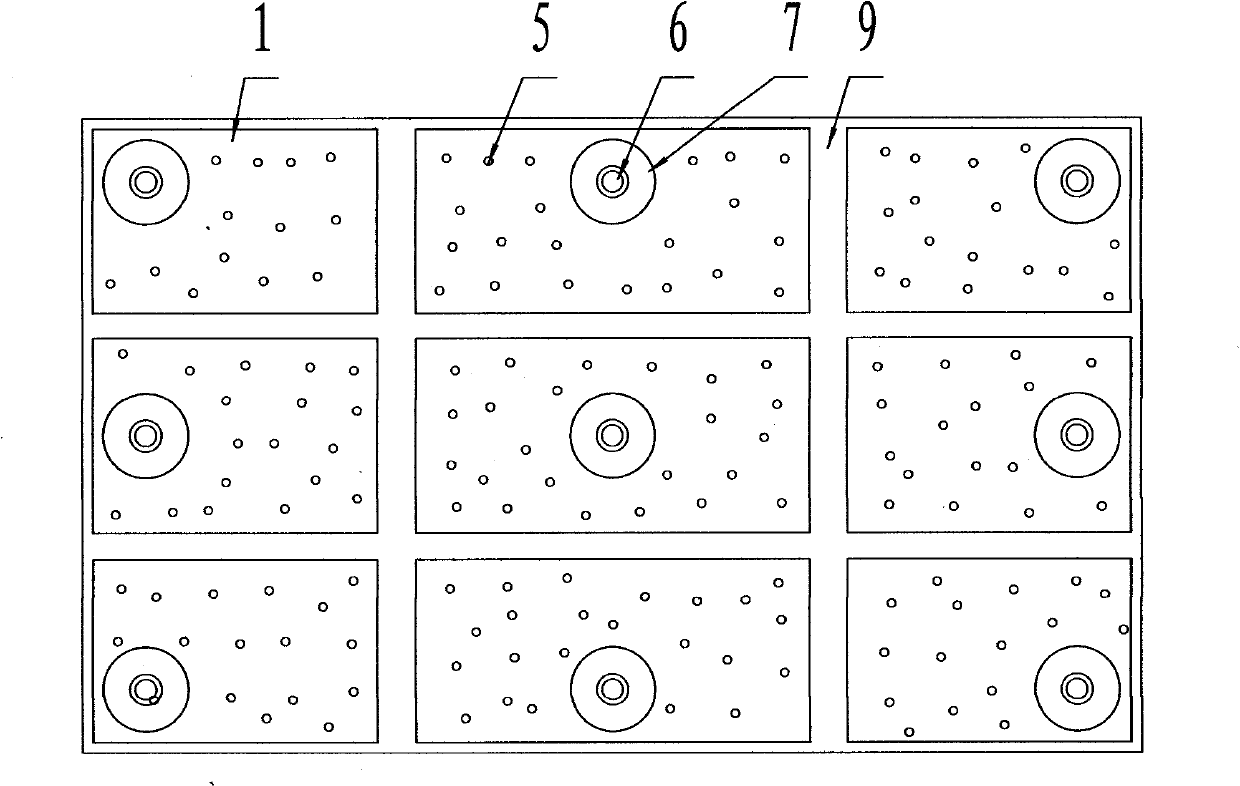

Super wear-resistant ceramic-steel composite lining plate for mixer and preparation method thereof

InactiveCN101816905AAbundant resourcesIncrease resourcesMixer accessoriesCeramic layered productsWear resistantAdhesive

The invention discloses a super wear-resistant ceramic-steel composite lining plate for a mixer and a preparation method thereof. The composite lining plate comprises a metal base plate and a ceramic material layer, wherein a mixture of a ceramic material and an adhesive is pressed on a combining surface of the metal base plate by a pressing force, which is coated with the adhesive so that the ceramic material and the steel are compounded; the metal base plate is provided with a mounting bolt hole; and metal anchoring nails and reinforced ribs are distributed on the combining surface. The preparation method comprises four processes, namely a metal base plate manufacturing process, a ceramic material preparing process, a compounding process, a curing process and the like. The super wear-resistant ceramic-steel composite lining plate has rich raw material resources, simple process, low price and higher cost performance. After the super wear-resistant ceramic-steel composite lining plate is comprehensively constructed, the service life of the lining plate is prolonged by 10 to 15 times; the capital consumption is reduced by 50 percent; the maintenance and replacement time is shortened by over 90 percent; the utilization rate of equipment is improved by about 10 percent; labor intensity and production cost are reduced; human resources and materials are saved; and further potential economic benefit is brought to the society.

Owner:洛阳万晟耐磨科技有限公司

Efficient and non-corrosive hydrate inhibitor

ActiveCN101608111AReduce dosageSimplify subsequent processingDrilling compositionPetroleumCalcium nitrate

The invention provides a high-efficient non-corrosive hydrate inhibitor, relating to the technical field of oil-gas hydrate. The hydrate inhibitor is a mixture of an anti-agglomerant and a urea or a calcium nitrate and is used at the pressure of 1.5 to 25 MPa and at the temperature of minus 20 DEG C to 25 DEG C. The hydrate inhibitor overcomes the defects of the prior art, reduces the nucleary, the growth and the coalescence speed of hydrate after being filled in petroleum fluid in production or conveying by mixing at low concentration and has the characteristics of wide application, low cost and no corrosion to pipelines.

Owner:SOUTH CHINA UNIV OF TECH

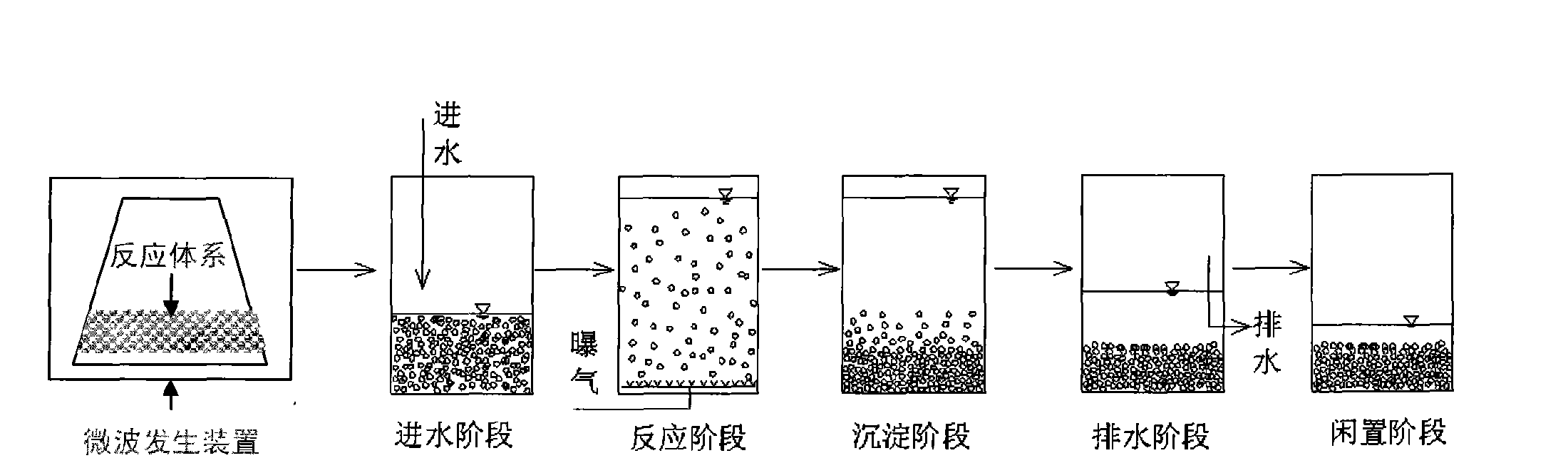

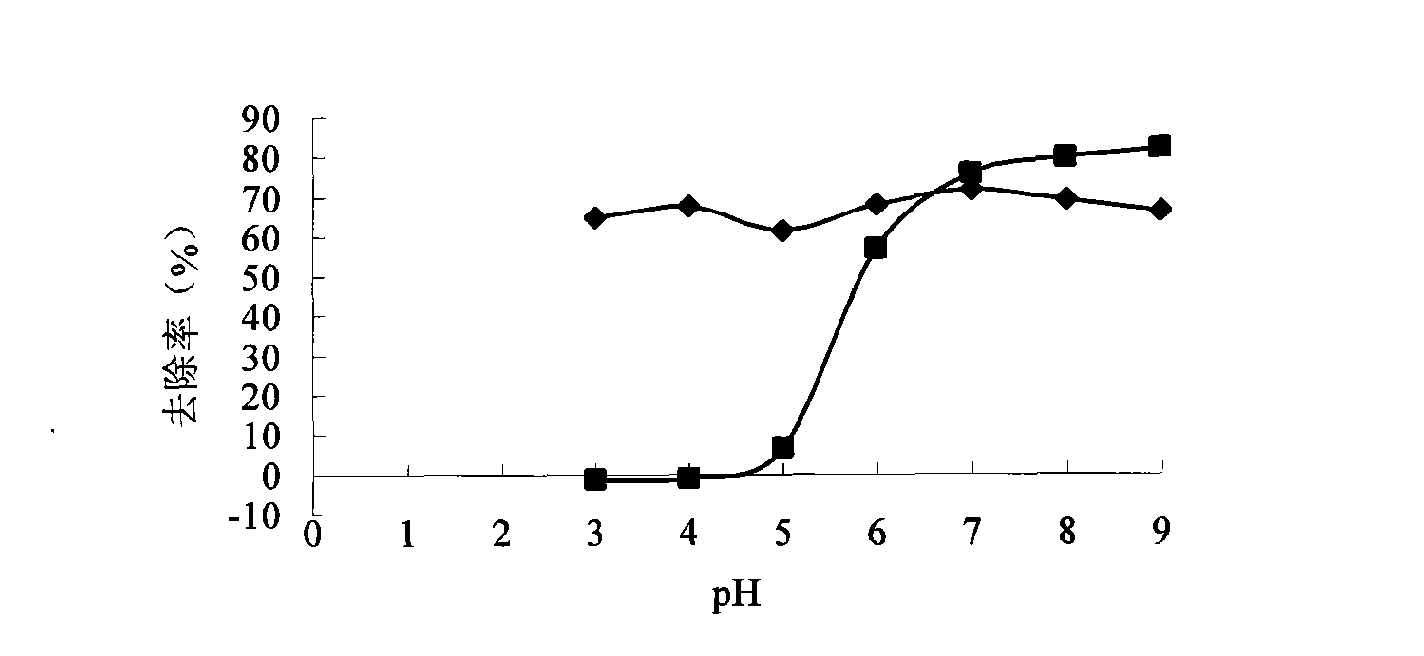

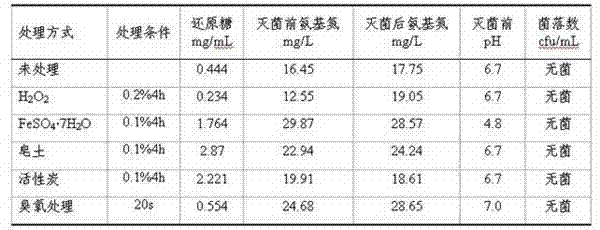

Method for treating garbage leachate

InactiveCN101580325AImprove biodegradabilityReduce pollutionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAeration rateSludge

The invention relates to a method for treating garbage leachate. The invention adopts the technical proposal that the method comprises the following steps: adjusting the pH value of the garbage leachate to between 7 and 9, adding 0.01 to 0.03 mol / L of Fe2SO4.7H2O, 9 to 11 g / L of active carbon and 6 to 8 ml / L H2O2 into a reaction system, and making the mixture react for 5 to 7 minutes at the microwave frequency of 2,450Hz and the microwave power of 300W; delivering the mixture into a reaction tank within 0.4 to 0.6 hour; aerating the mixture for 7 to 9 hours at the aeration rate of 13.5 L / h, and controlling the pH to between 6.5 and 7.5 and the sludge concentration to between 3,000 and 4,000 mg / L; standing the mixture for 2 to 3 hours, and layering the mixture; discharging the liquid at the upper layer within 0.4 to 0.6 hour; and after the reaction tank stood for 0.4 to 0.6 hour, and carrying out SBR post treatment of the garbage leachate of the next period. The method has short pretreatment time, improves the biodegradability obviously, has good pollutant removal effect, and improves the yielding water quality remarkably.

Owner:LIAONING UNIVERSITY

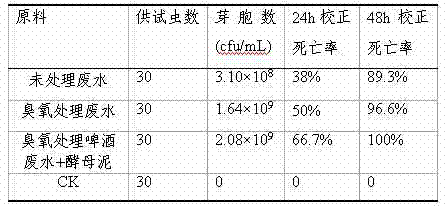

Method for pretreating beer waste for biochemical utilization

InactiveCN102212479AChange membrane permeabilityPromote dissolutionBacteriaPretreatment methodSludge

The invention provides a method for pretreating beer waste for biochemical utilization. The method comprises the following steps: carrying out ozone wall breaking and sterilization on one or mixture of beer waste water, sludge, waste and fresh beer yeast slurry so as to increase leaching of nutrient substances of yeast content, wherein the ozone admission amount is 0.3-0.8g of ozone / g of waste beer dried substances; and carrying out high-pressure steam sterilization on samples subjected to ozone treatment at 121 DEG C for 45 minutes, thus the samples subjected to high-pressure steam sterilization can used for microorganism yeast culture. The beer waste pretreated by the method provided by the invention has the advantages that the nutrient substance release rate can be greatly improved, the content of amino nitrogen in a culture medium is improved by 4-5 times, and the amino nitrogen yield achieves 3-5 percent, thus the pretreated beer waste serving as the culture medium is beneficialto microorganism culture.

Owner:FUJIAN AGRI & FORESTRY UNIV

Preparation method of rosemary extracts

PendingCN109232229AIncrease profitImprove transfer rateEssential-oils/perfumesSteroidsDistillationAdditive ingredient

The invention relates to a preparation method of rosemary extracts. The method comprises the following steps of (1) putting dried rosemary raw materials into an extraction tank; performing extractionto obtain rosemary essential oil; (2) adding an ethanol solution; performing back flow extraction, concentration, separation and drying to obtain carnosic acid, ursolic acid and rosmarinic acid products; (3) performing crushing, extraction, concentration and separation on the carnosic acid products to obtain oily products containing carnosic acid; (4) performing molecular distillation separation on the oily products containing carnosic acid to obtain rosemary essential oil and smell-removed carnosic acid oily products. The raw material utilization rate is high; the effective ingredient transfer rate is high; the industrialized production can be easily realized; the carnosic acid oily products prepared by the method have high anti-oxidization active ingredient content, basically have no rosemary smell, and have good market prospects are realized in aspects in edible grease, meat product fresh keeping and corrosion prevention.

Owner:CHANGSHA LANGLIN BIOLOGY PROD

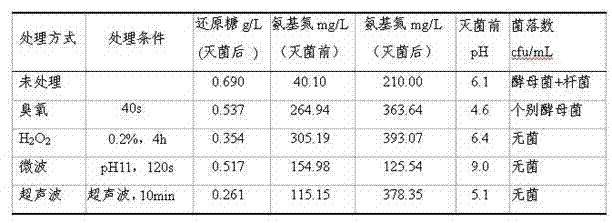

Method for enriching rhodium from rhodium-containing organic waste liquid

InactiveCN102796878ASimple processSimplify subsequent processingProcess efficiency improvementSlagAlloy

The invention discloses a method for enriching rhodium from a rhodium-containing organic waste liquid, which comprises the following steps: mixing a rhodium-containing organic waste liquid with collector, additive and reducer according to a certain ratio; performing reduction smelting to obtain a rhodium-containing alloy; and using dilute acid to leach base metal from the alloy to obtain a rhodium-enriched substance. The method has the advantages of simple operation, concise process, high recovery rate and the like; the noble metal rhodium content of smelting slag is smaller than 0.5g / t; the rhodium-enriched substance content is greater than 25%; and the direct yield is greater than 99.2%.

Owner:KUNMING INST OF PRECIOUS METALS

Method of preparing soyabean isoflarone from low temperature soya dreg

The present invention relates to a method for preparing soybean isoflavone by using low-temperature soybean dregs. Said method is characterized by using low-temperature soybean dregs as raw material and adopting the combination of ethyl alcohol aqueous solution extraction, flocculation under the alkaline condition, ethyl acetate extraction and petroleum ether recrystallization refinery to prepare soybean isoflavone.

Owner:BEIJING UNIV OF CHEM TECH

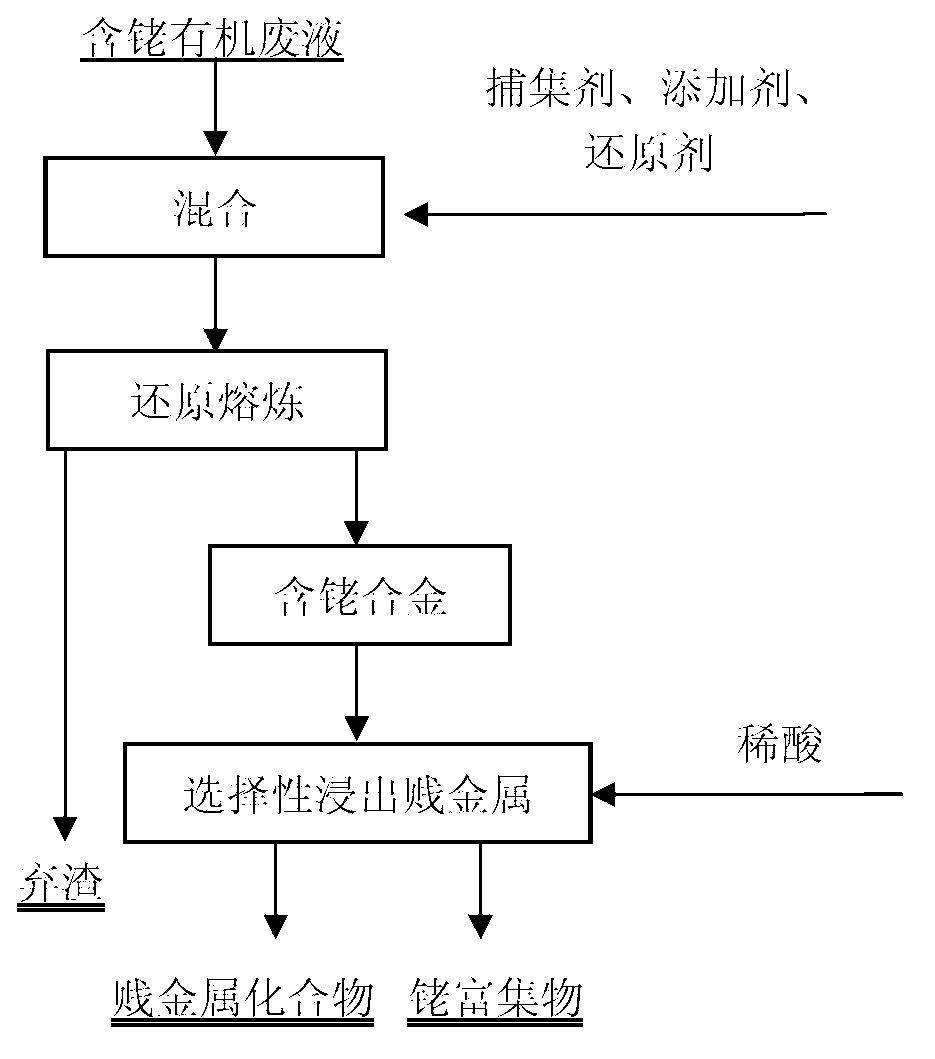

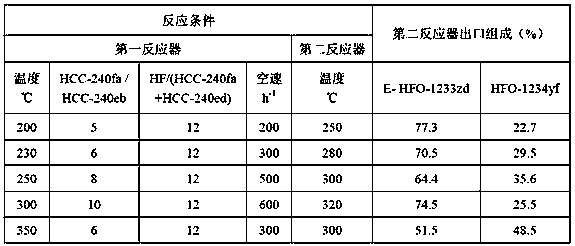

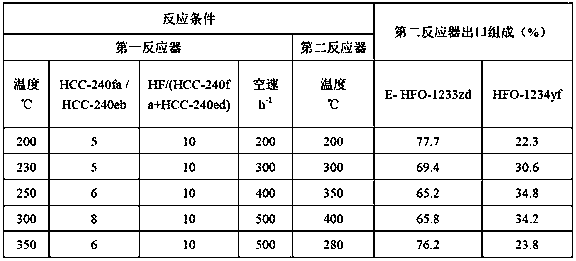

Co-production method of trans-1-chlorine-3,3,3-trifluoropropene and 2,3,3,3-tetrafluoropropene

ActiveCN108383679ANot easy to inactivateSolution to short lifeOrganic chemistry methodsHalogenated hydrocarbon separation/purificationHydrogen fluorideHydrogen

The invention discloses a co-production method of trans-1-chlorine-3,3,3-trifluoropropene and 2,3,3,3-tetrafluoropropene. The co-production method of the trans-1-chlorine-3,3,3-trifluoropropene and the 2,3,3,3-tetrafluoropropene comprises the following steps: mixing 1,1,1,3,3-pentachloropropane and 1,1,1,2,3-pentachloropropane according to proportion, introducing the mixture and hydrogen fluorideinto a first reactor, performing fluorination reaction under the action of a catalyst A to obtain trans-1-chlorine-3,3,3-trifluoropropene, cis-1-chlorine-3,3,3-trifluoropropene, 2-chlorine-3,3,3-trifluoropropene, hydrogen chloride and hydrogen fluoride, not separating the products and directly entering a second reactor, performing reaction under the action of a catalyst B to obtain a mixture of trans-1-chlorine-3,3,3-trifluoropropene, 2,3,3,3-tetrafluoropropene, hydrogen chloride and hydrogen fluoride, and performing separation to obtain the products, namely trans-1-chlorine-3,3,3-trifluoropropene and 2,3,3,3-tetrafluoropropene. The co-production method adopts a cascade reaction mode, and is efficient, energy-saving and simple in process.

Owner:ZIBO FEIYUAN CHEM CO LTD

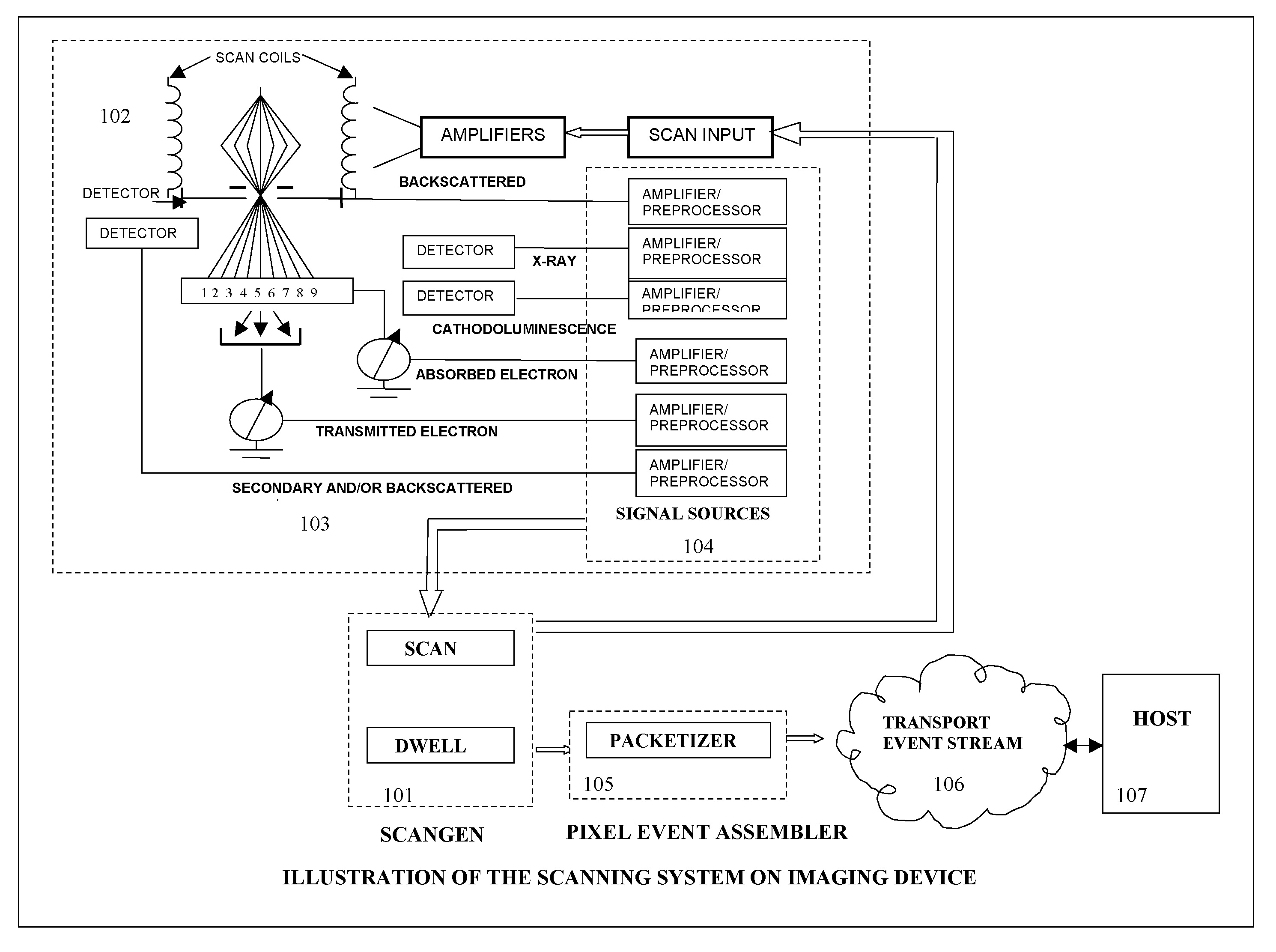

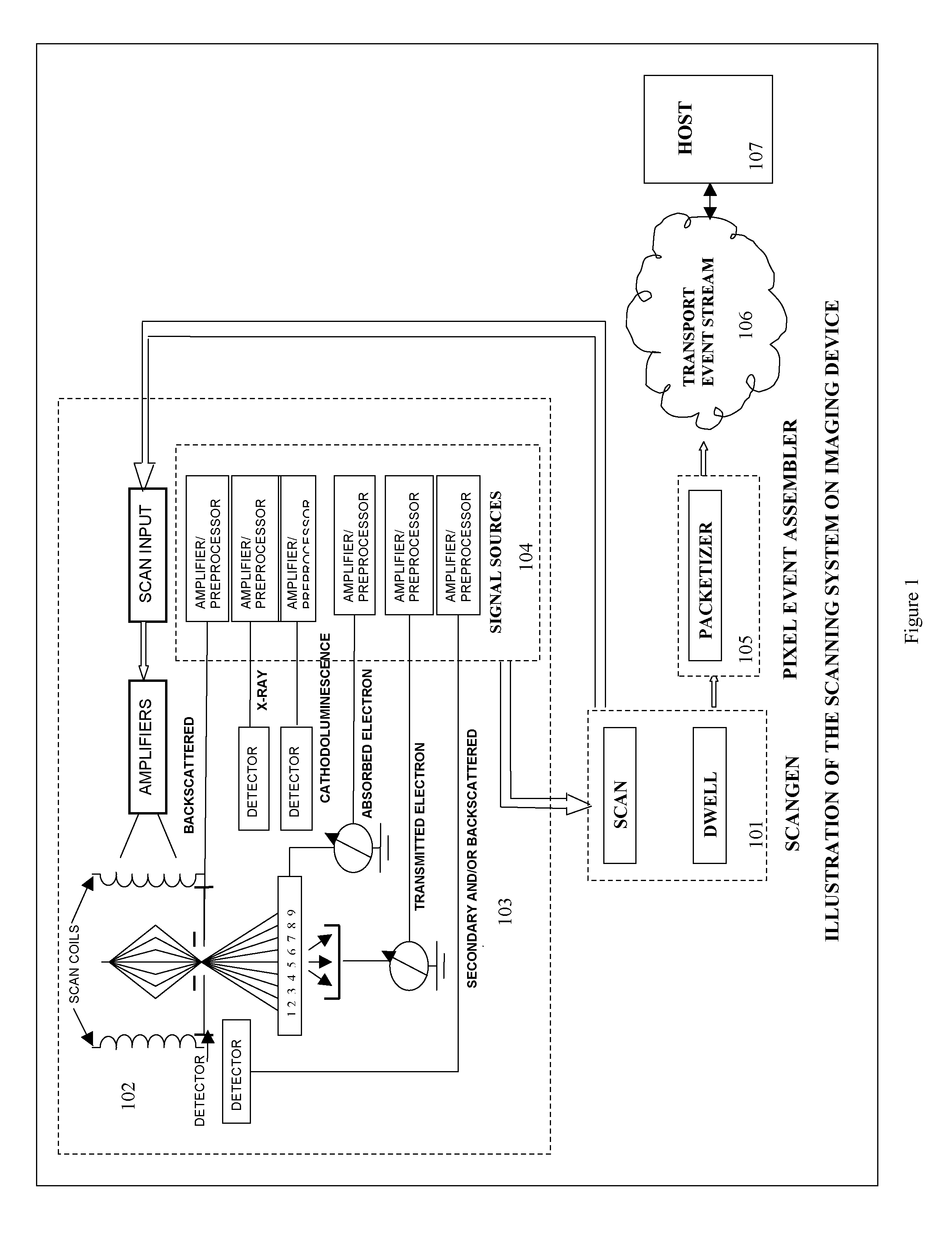

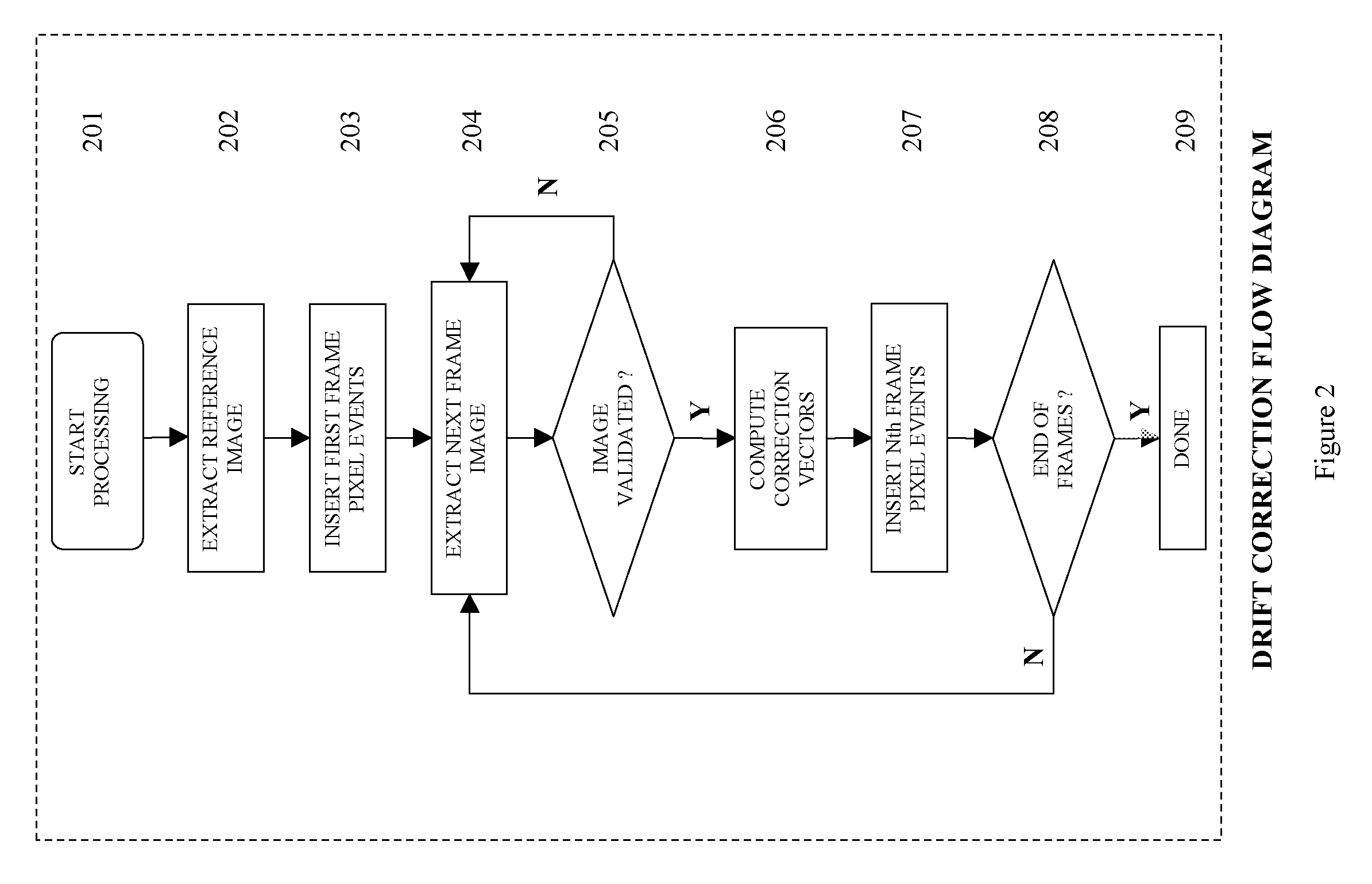

Method and system for drift correction of spectrum images

ActiveUS20080260106A1Easy transferEasy to storeImage enhancementImage analysisFrequency spectrumReference image

A method and system corrects for drift in spectrum images resulting from collection signals. Signals resulting from a scan are collected. A reference image is obtained for determining initial pixel locations. A correction image is extracted, validated and correction vectors generated.

Owner:KEYSIGHT TECH

Process for refining crude glycerin and recovering byproducts

InactiveCN102229521AHigh purityAchieve purificationOrganic compound preparationHydroxy compound separation/purificationGlycerolFatty acid

The invention discloses a process for refining crude glycerin and recovering byproducts. The process for refining the crude glycerin and recovering the byproducts comprises the following steps of: diluting the crude glycerin with water; preheating the crude glycerin to 30 to 60 DEG C; introducing the crude glycerin into an ion exchange column with cation exchange resin; allowing the crude glycerin to enter a storage tank A, preserving the heat to be between 30 and 60 DEG C and standing to layer; after layering, introducing the bottom layer of liquid into an ultrafiltration membrane component and allowing the upper layer of liquid to enter a storage tank B; introducing the permeating liquid of the ultrafiltration membrane into an anion exchange column and then introducing the permeating liquid into a cation exchange column; evaporating, concentrating or distilling effluent to obtain high-purity glycerin; returning the non-permeating liquid to the storage tank A; standing liquid in the storage tank B to layer; separating out the upper layer of oil layer; washing the oil layer with hot water; standing and separating; and taking the upper layer of oil layer to obtain fatty acid. The process is high in processing efficiency, simple in process and low in cost. By the process, the high-purity glycerin can be produced efficiently; the fatty acid can be recovered from the crude glycerin; and production cost is reduced.

Owner:江门市鸿捷精细化工有限公司

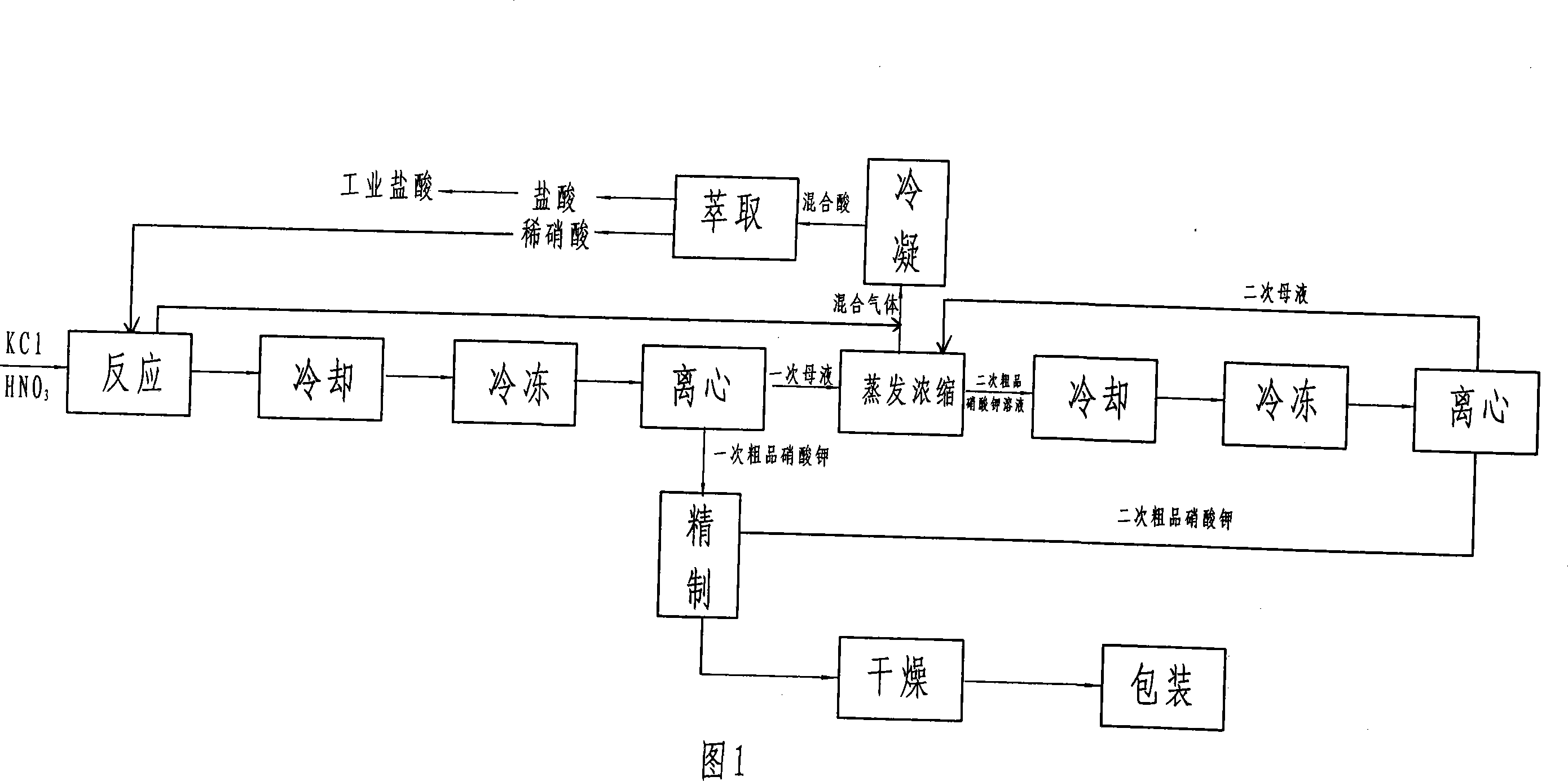

Preparation technique of potassium nitrate

InactiveCN101182014ANo emissionsHigh one-time yieldAlkali metal nitrate preparationWater dischargeHigh energy

The invention relates to the technical field of inorganic chemical industry, specifically a preparation process of potassium nitrate, which solves the problems of limited source of raw materials, high production cost, high energy consumption, low yield of one-time finished products and unrecyclable waste in the existing method. Potassium chloride and dilute nitric acid are mixed in proportion, reacted under the conditions of negative pressure of 0.01-0.02MPa and temperature of 30-40°C, cooling the mixed solution generated by the reaction to normal temperature, continuing to freeze, and then centrifuging to obtain crude potassium nitrate and primary mother liquor, the crude potassium nitrate is refined to obtain the finished product, the primary mother liquor is evaporated and concentrated, and hydrochloric acid and nitric acid are separated, and the two are separated by condensation and extraction, and the concentrated secondary crude potassium nitrate is cooled, frozen, and centrifuged to obtain di Sub-crude potassium nitrate and secondary mother liquor, the mother liquor is returned to the system for recycling. The one-time yield of potassium nitrate in the invention is high, 85-90%, so that the follow-up treatment process is simple, energy consumption is low, and cost is low; no pollution is realized, no waste water is discharged, and the environmental protection problem is completely solved.

Owner:WENSHUI COUNTY ZHENXING CHEM FERTILIZER

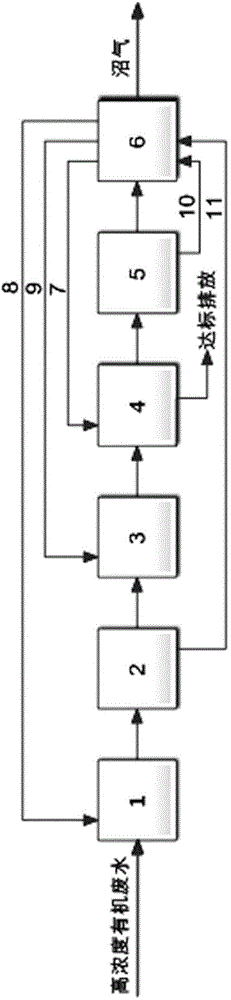

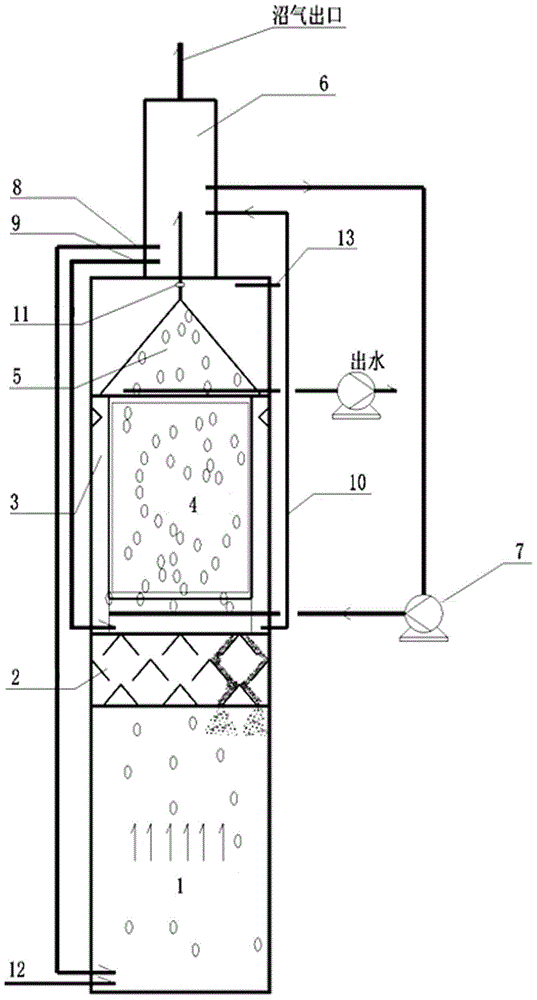

Inner-loop anaerobic membrane bioreactor treatment method and equipment for high-concentration organic wastewater

ActiveCN104445608AHigh removal rateTo achieve the purpose of short processWater contaminantsWaste based fuelCyclic processHigh concentration

The invention discloses inner-loop anaerobic membrane bioreactor treatment method and equipment for high-concentration organic wastewater. The treatment method of the organic wastewater comprises the following steps: A) inoculating anaerobic sludge into a first reaction chamber and a second reaction chamber; B) transporting the organic wastewater to the first reaction chamber through a water inlet pipe, forming an inner loop through a first three-phase separator, the second reaction chamber, a second three-phase separator and a gas-water separator sequentially, and separating a mixed liquid through a membrane component in the circulating process, so as to obtain produced water; C) enriching methane generated in the first reaction chamber and the second reaction chamber through the first three-phase separator and the second three-phase separator sequentially, feeding to the gas-water separator, separating and then producing methane; and D) separating and then producing methane by the gas-water separator, supplying a part of the methane to the membrane component in a pressurizing manner, feeding to the gas-water separator through the second three-phase separator, so as to form methane circulation aeration. The invention also discloses equipment for achieving the method. The high-concentration organic wastewater (such as farm and sideline food processing industry and livestock and poultry breeding wastewater) is processed by adopting the method disclosed by the invention, thus high-load and short-flow one-step standard reaching can be achieved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method for preparing metal and magnesium sulfide with metal sulfide

ActiveCN108118364ALow impurity contentAvoid emissionsElectrolysis componentsElectrolysisWorking temperature

The invention discloses a method for preparing metal and magnesium sulfide with metal sulfide. The method is characterized in that metal sulfide powder or a metal sulfide sheet formed by pressing is compounded with a current collector to be used as a cathode, graphite is taken as an anode, electrolyzation is performed for 1-4h in molten magnesium chloride or a mixture of magnesium chloride and alkali metal chloride with the working temperature being 400-750 DEG C and the electrolysis voltage being 1.0-2.6V, wherein the working temperature is higher than a melting point of a corresponding metalproduct, at the inert atmosphere, and a cathode product is corresponding molten metal and the magnesium sulfide; after the product is cooled, and separated metal is taken out, ultrasonic cleaning isperformed by adopting dimethyl sulfoxide to obtain the magnesium sulfide. The invention provides the method for preparing metal and magnesium sulfide with metal sulfide, which is low in energy consumption and safe in process and is environmentally friendly.

Owner:GUANGDONG INST OF RARE METALS

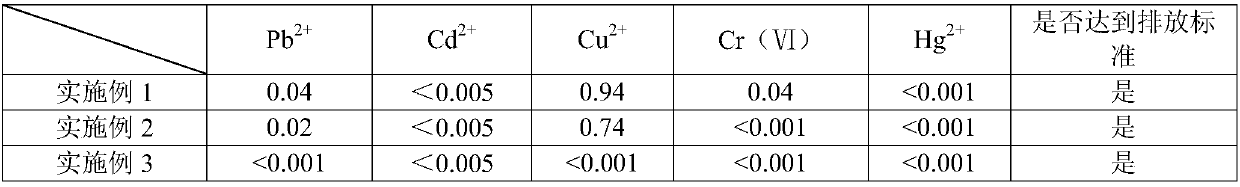

Spheroidal composite adsorbent for sewage treatment

ActiveCN109621921AHigh densityHigh mechanical strengthOther chemical processesWater contaminantsSorbentPolyacrylamide

The invention relates to the field of sewage treatment and aims to provide a spheroidal composite adsorbent for sewage treatment. The spheroidal composite adsorbent is prepared from 8-10 parts of lignin, 6-9 parts of sulfydryl modified polyacrylamide, 2-3 parts of sodium alginate, 30-40 parts of sulfydryl modified quartz sand and 20-30 parts of sepiolite. The spheroidal composite adsorbent has thefunctions of adsorbing and removing organic matter, suspended matter and heavy metals in sewage, and has the good removal effect on the heavy metals in the acidic sewage and has the integrated effectof adsorption, flocculation and sedimentation, the contents of COD, SS, lead, cadmium, copper and mercury in treated river channel sewage all reach the stipulations of national standard surface waterenvironmental quality standard GB3838-2002 of the People's Republic of China, and the removal rate of heavy metals in acid heavy-metal heavily polluted wastewater reaches 99% or above.

Owner:浙江省环境科技有限公司

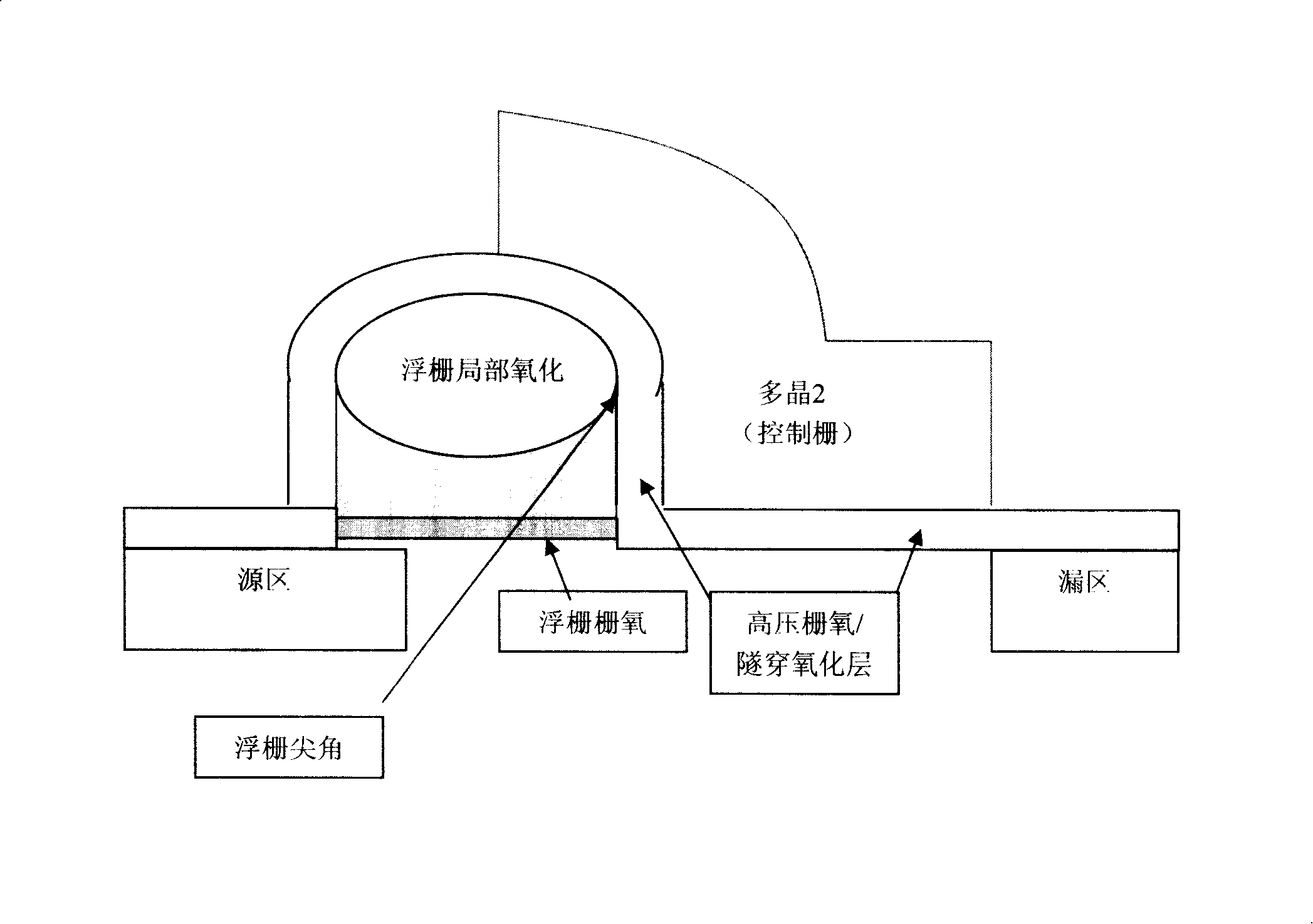

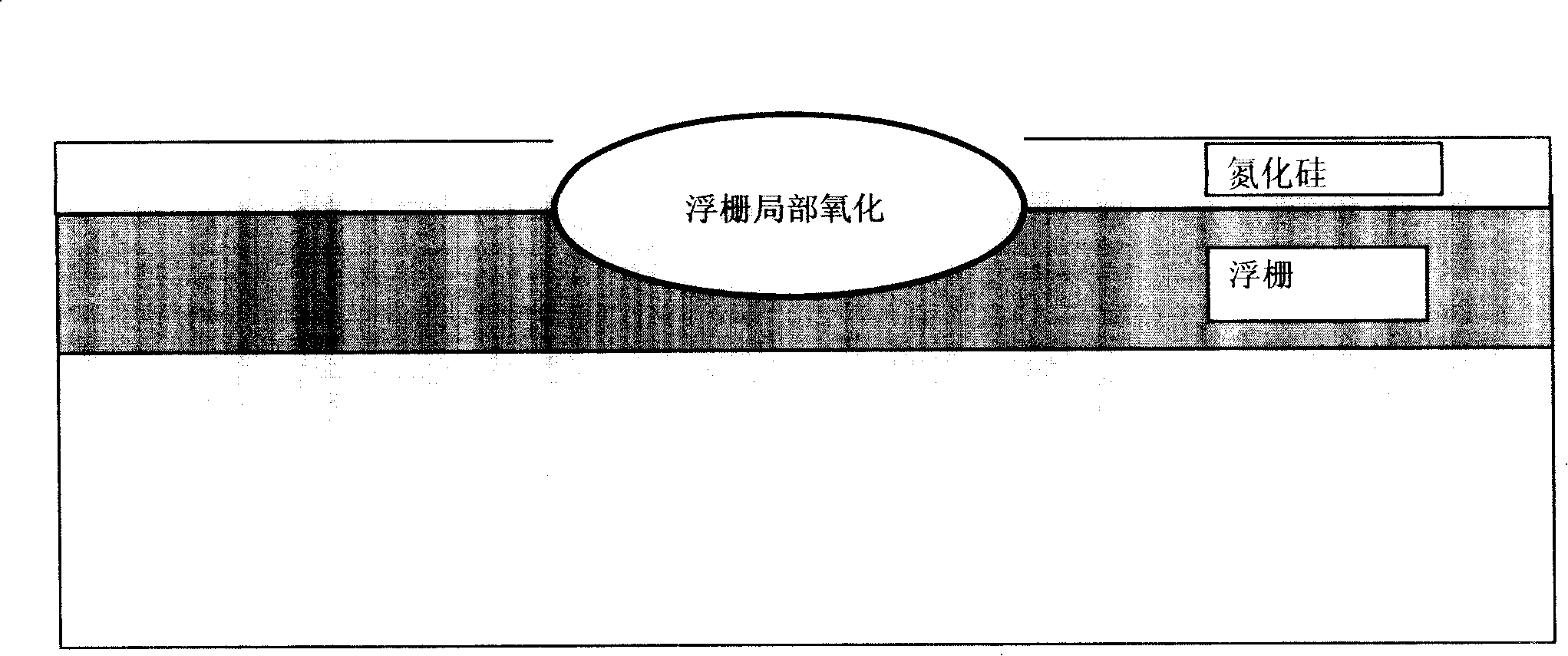

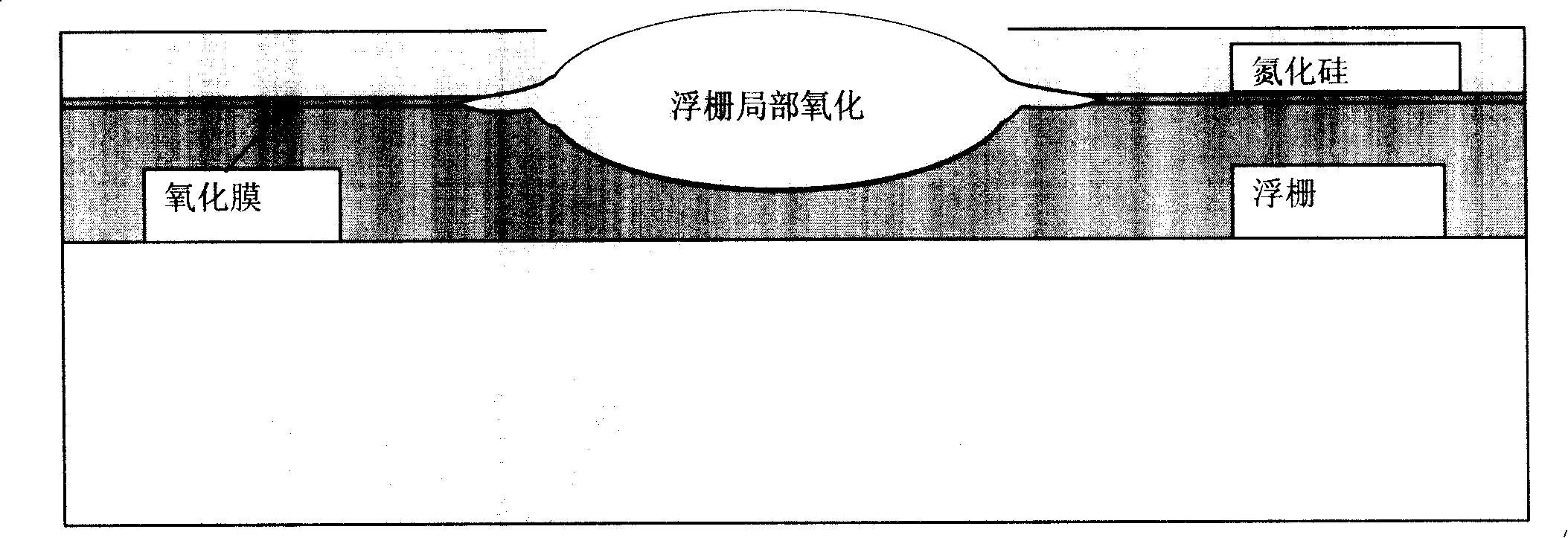

Making technology method for flash memory

ActiveCN101170082AIncreased process windowImprove Erase and Write PerformanceSolid-state devicesSemiconductor/solid-state device manufacturingPerformance improvementThin oxide

The invention discloses a method of manufacturing a flash memory. In the prior flash memory process, after floating boom polycrystal deposits, the floating boom generates a thin oxide film with the thickness of 20-50 . The invention can effectively control the beak shape with partial oxidization, expand process window and is good for floating boom sharp corner control, stability, evenness and the whole chip erasing performance improvement.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP +1

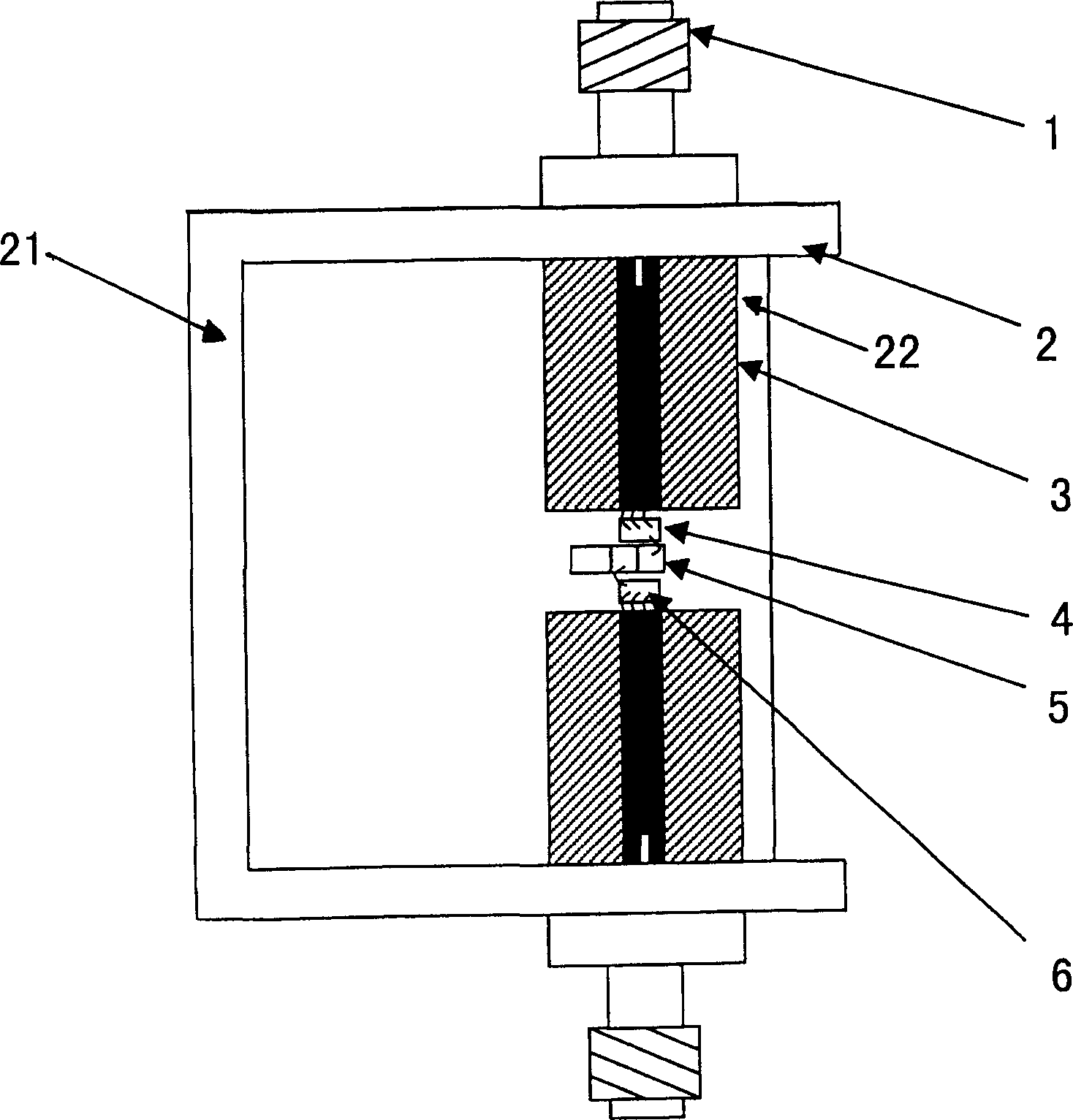

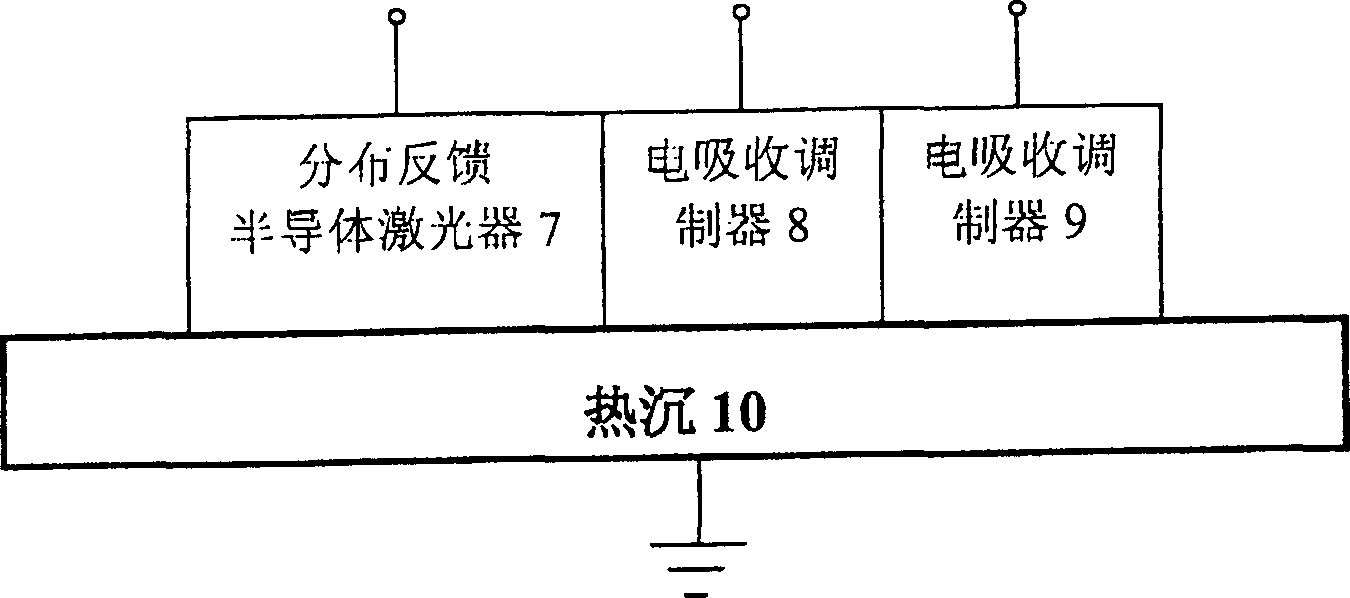

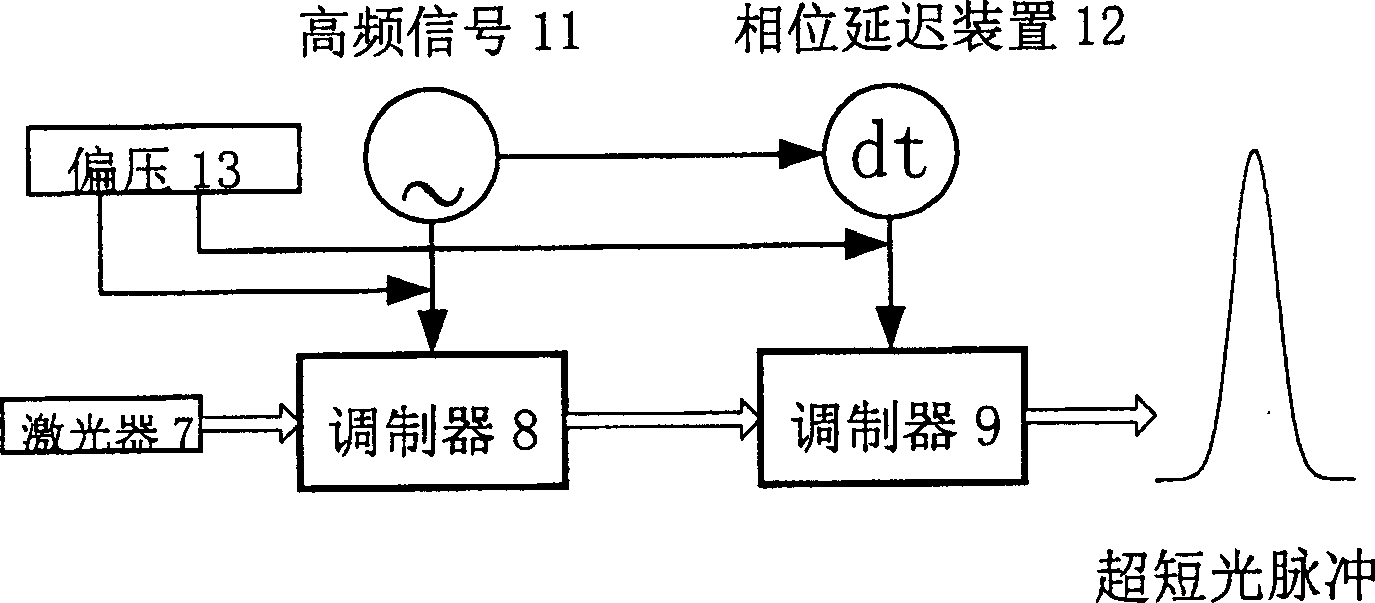

Testing clamp and method of producing super-short optical palse based on cascade electrical sucking modulator

InactiveCN1834600ASimplify subsequent processingLow costElectrical testingElectrical resistance and conductanceElectricity

The invention relates to a testing clamping device based on cascade electric adsorbing modulator to generate super short light pulse. The feature is that it includes a frame, a base board, two radio frequency coaxial connectors, two sections of micro strips and two resistances that is fixed between two ends of the micro strips and has a preset distance.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

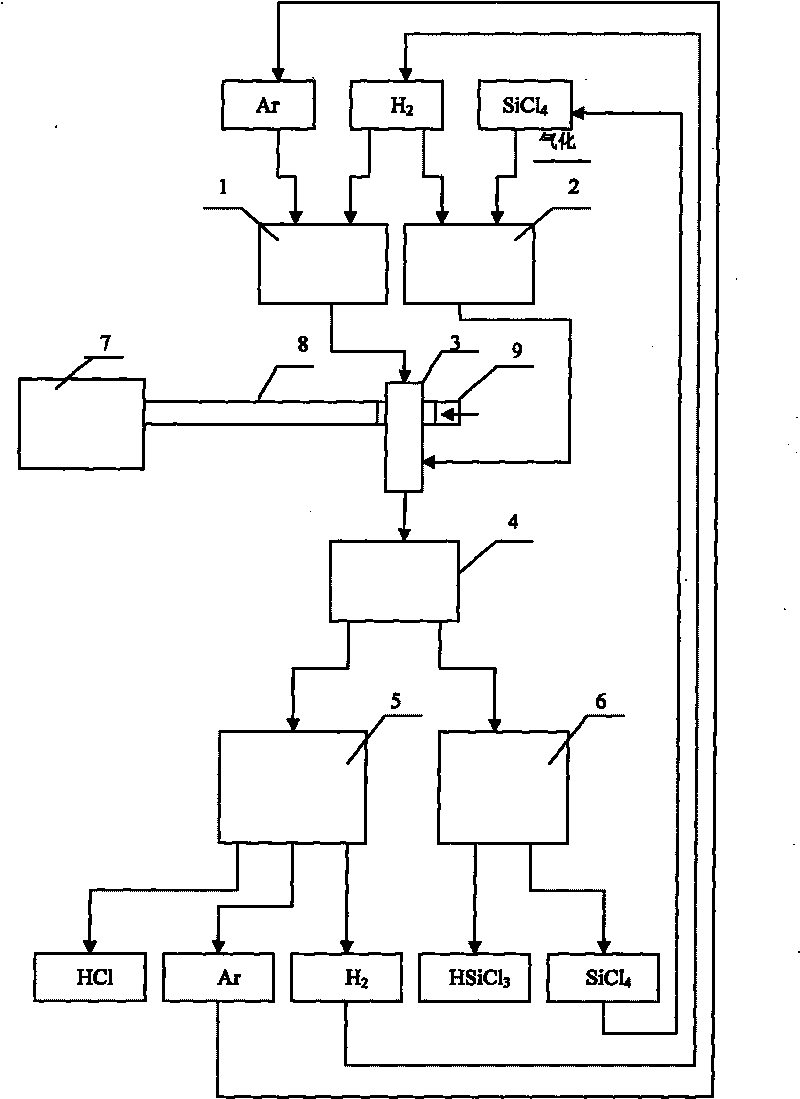

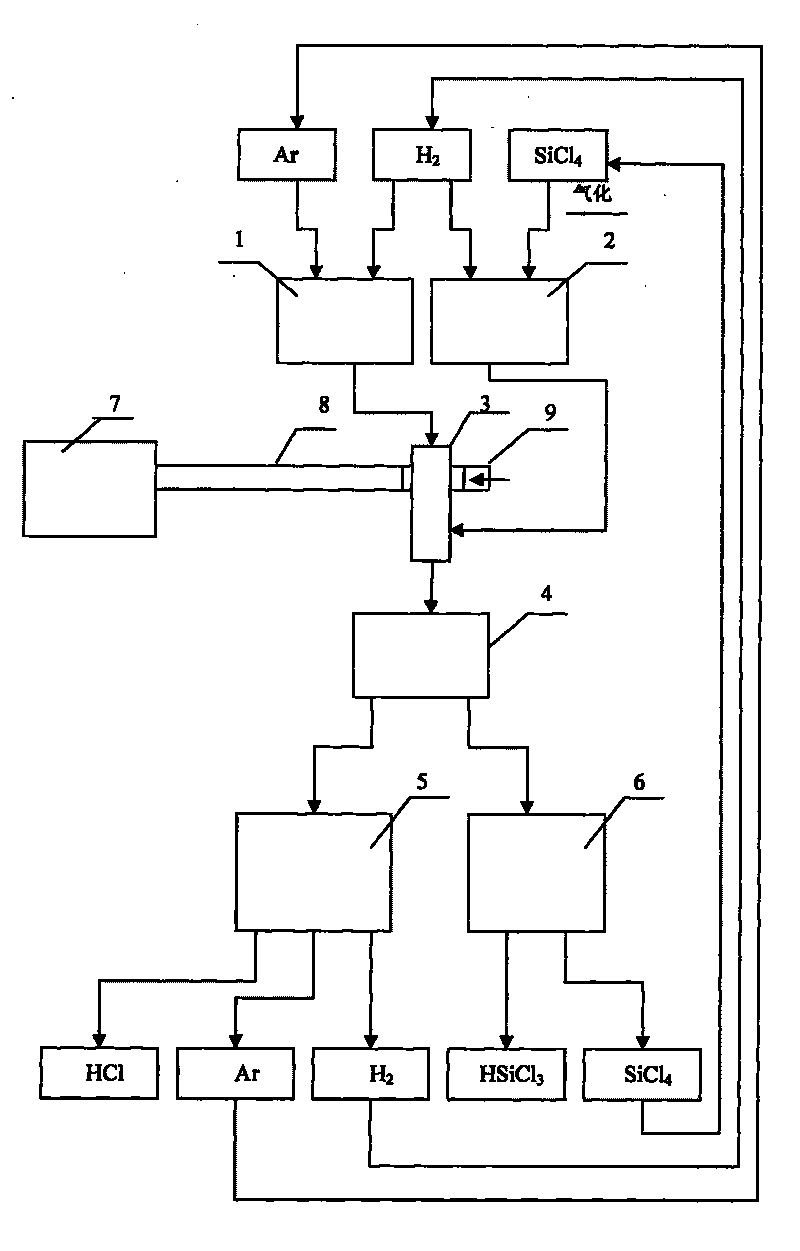

Method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma

The invention provides a method for preparing trichlorosilane and dichlorosilane by hydrogenating silicon tetrachloride through microwave plasma, which aims to solve the problems of high energy consumption, low single-pass conversion rate and high equipment investment in the catalytic hydrogenation of the silicon tetrachloride by a Siemens method and problems of high energy consumption and material consumption and difficult industrialization in hydrogenating the silicon tetrachloride by a conventional thermal plasma method and a radio-frequency induction plasma method in the conventional polysilicon industry. The method comprises the following steps: forming a stable cold plasma through arced hydrogen, argon or a mixture of the two under excitation of microwaves; forming a plasma jet flow by a plasma torch under the condition of the flow of the arced gas; and ejecting feed gas into a specific area of the plasma jet flow to form an active particle consumption zone in which the silicon tetrachloride is hydrogenated into trichlorosilane. The single-pass conversion rate of the silicon tetrachloride of the method reaches about 60 percent; and the method has the advantages of simple subsequent treatment of a product, low requirement on equipment and operation control, and easy realization of industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Bipolar asymmetric supercapacitor energy storage apparatus and bipolar assembly thereof

InactiveCN108199094AIncrease specific energyIncrease powerAccumulators with bipolar electrodesBatteriesElectricityPartial charge

The invention discloses a bipolar assembly for a bipolar asymmetric supercapacitor energy storage apparatus. The bipolar assembly comprises: a substrate, wherein the substrate is insulated, and comprises two opposite surfaces; a positive electrode, wherein the positive electrode comprises a lead-containing active material and is positioned on one surface of the substrate; and a negative electrodepositioned on the other surface of the substrate, wherein the substrate has an electrical connection circuit so as to form electrical connection between the positive electrode and the negative electrode, and the negative electrode comprises a carbon-containing active material. According to the present invention, the carbon-lead battery technology and the bipolar battery technology are successfullycombined so as to effectively improve the performance of the energy storage device during the bidirectional high-power and high-frequency partial charging and discharging.

Owner:LCB INT

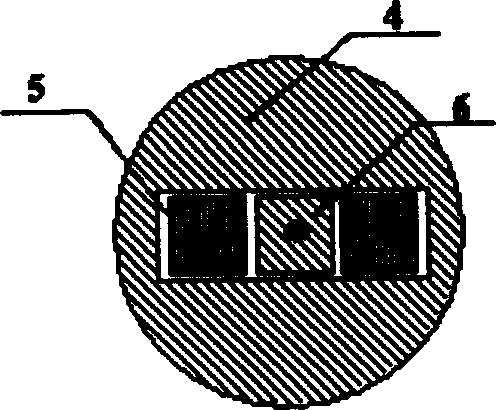

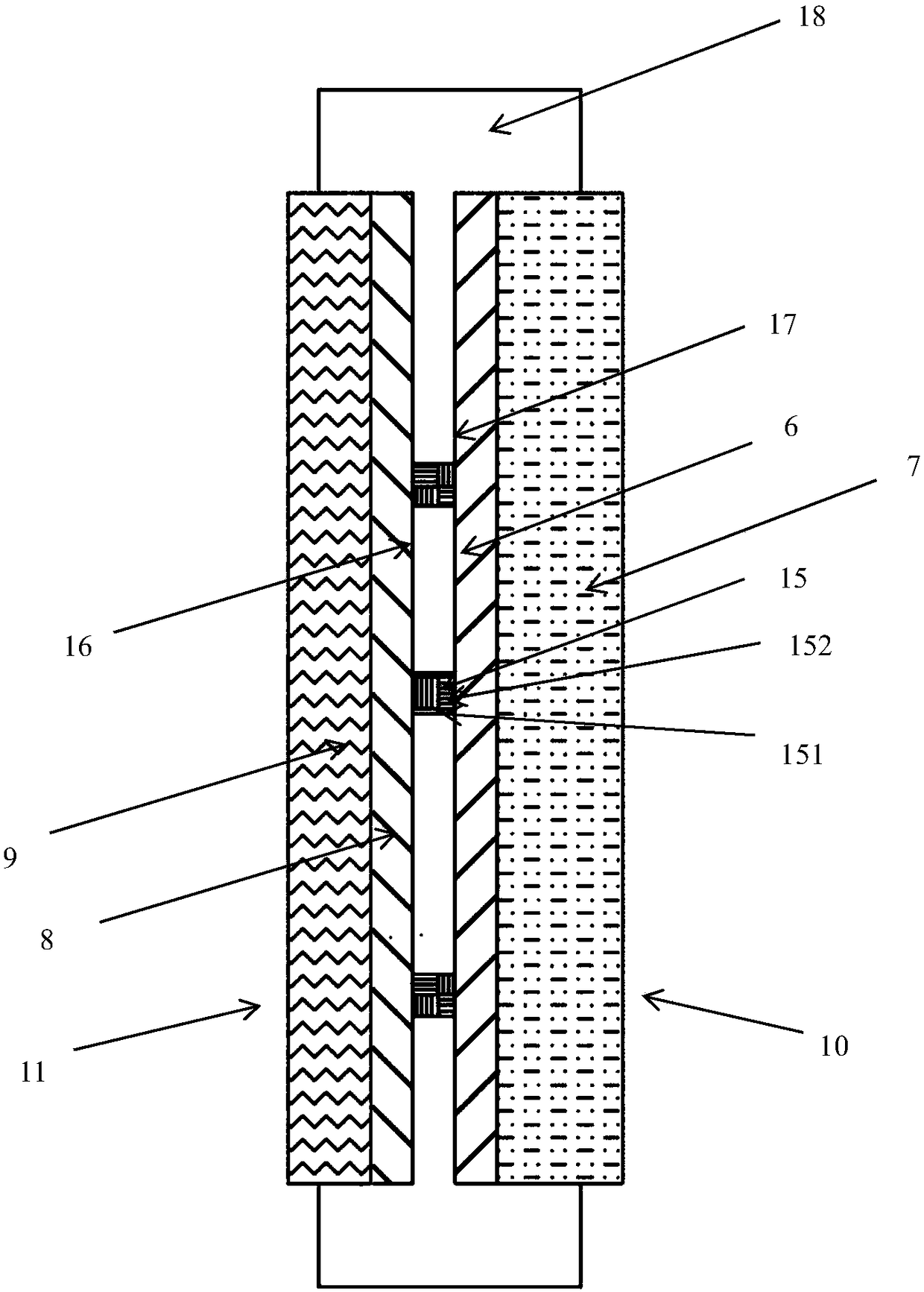

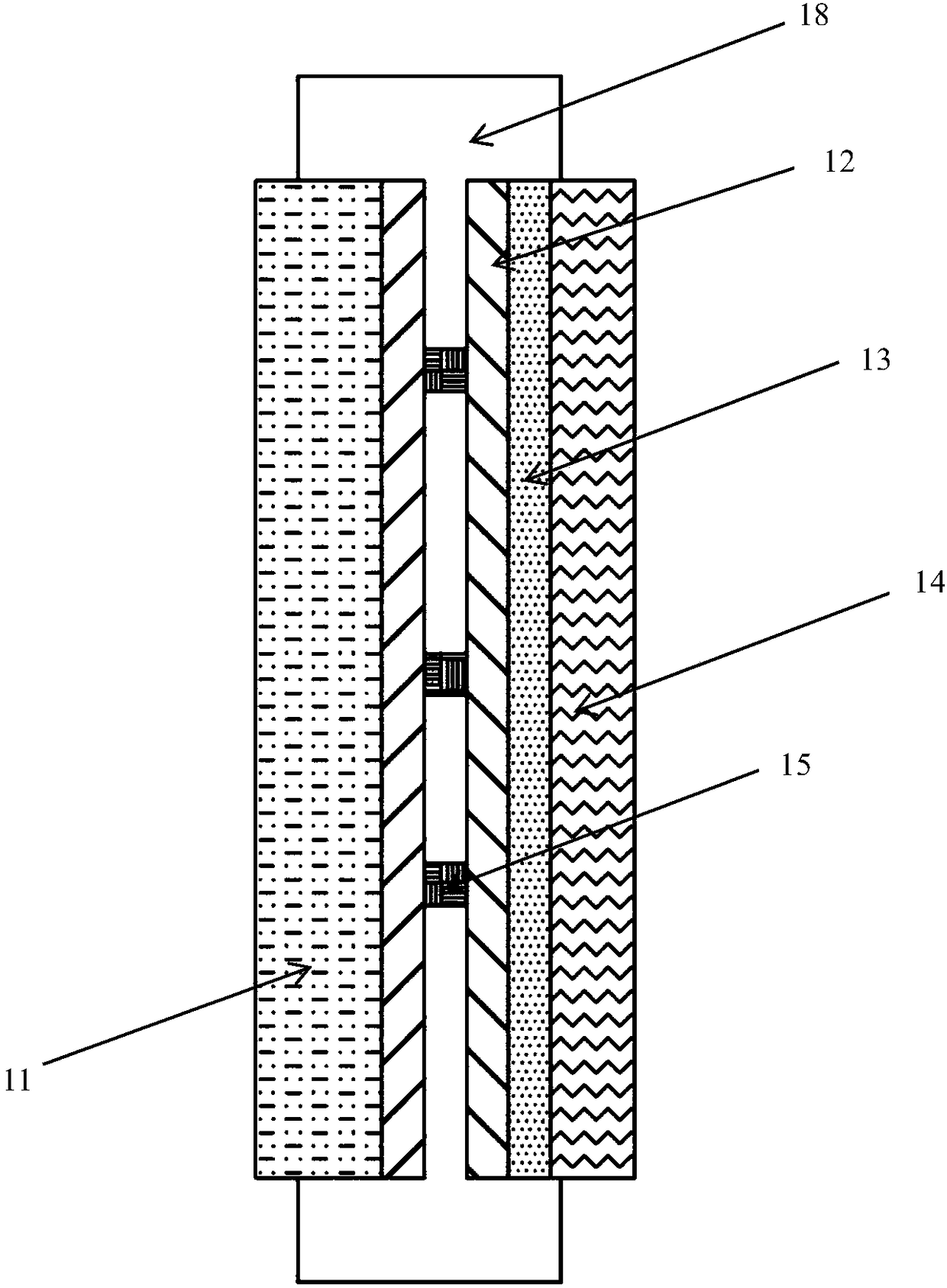

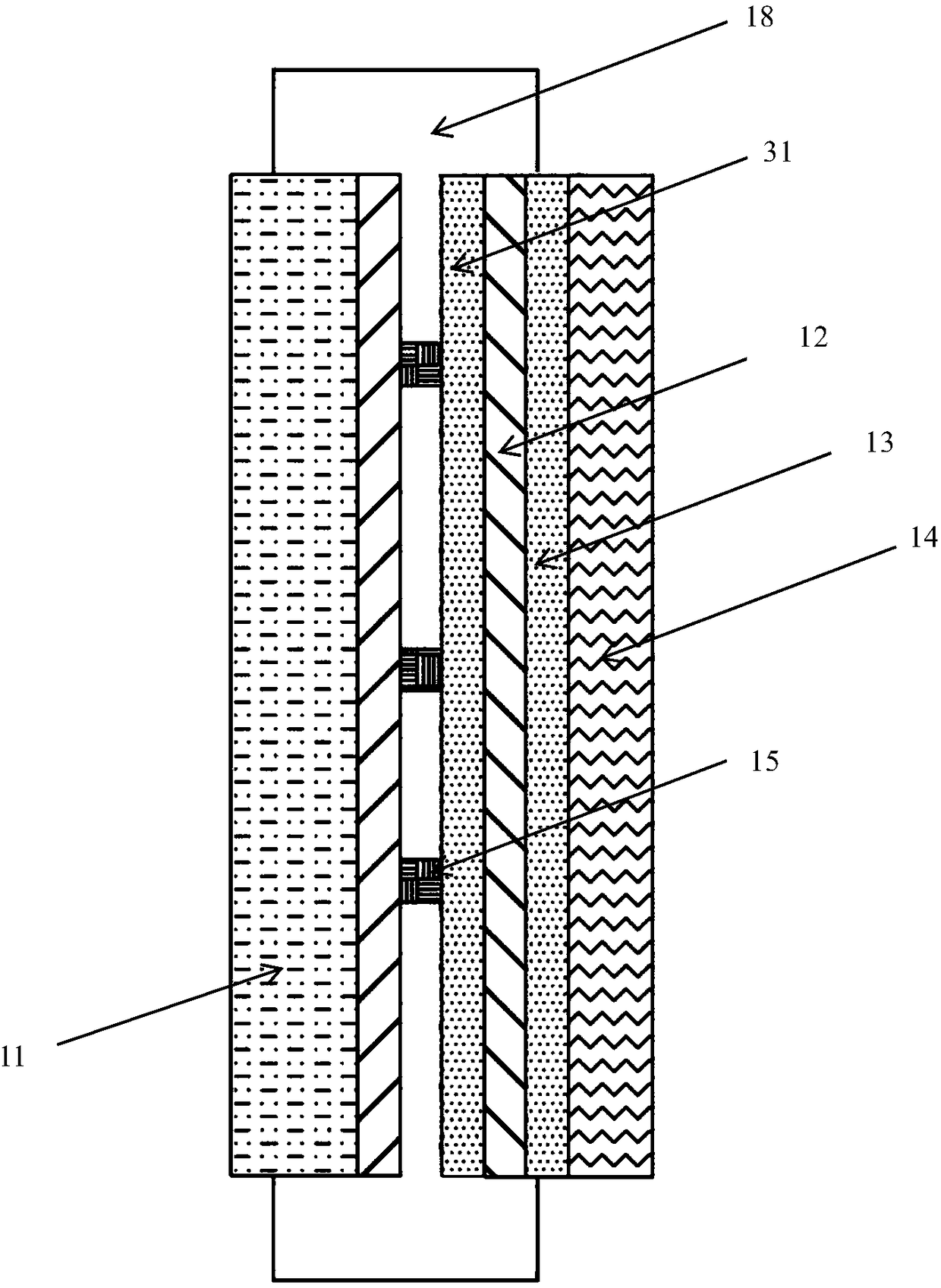

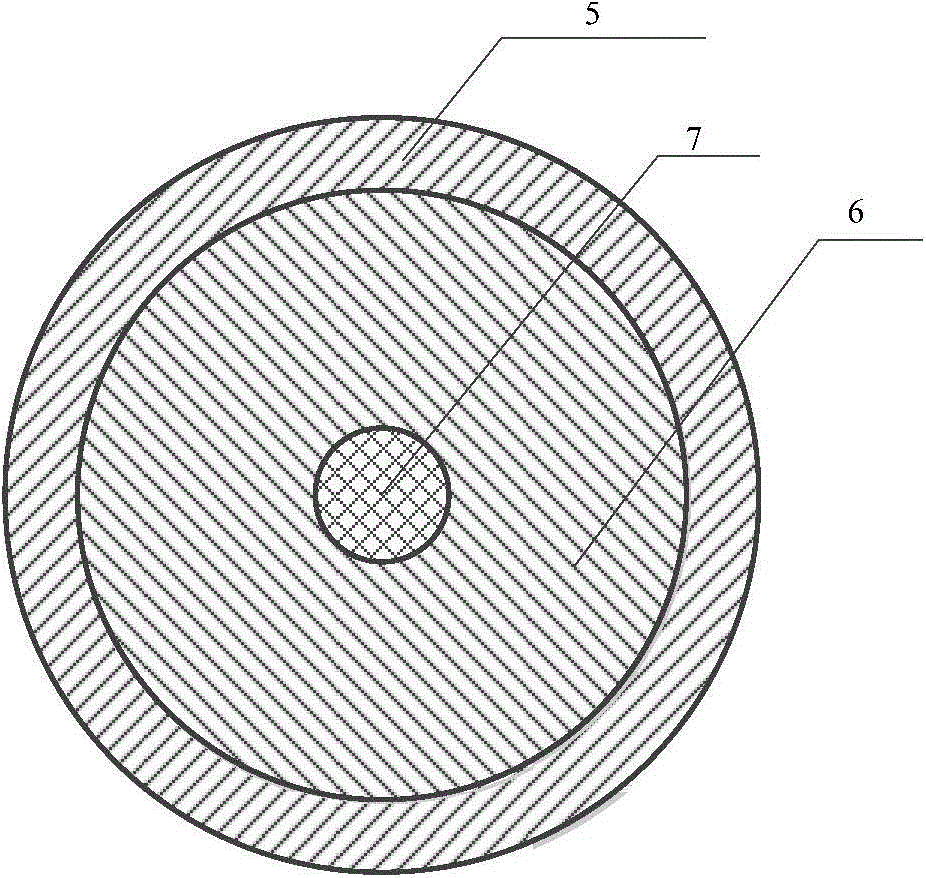

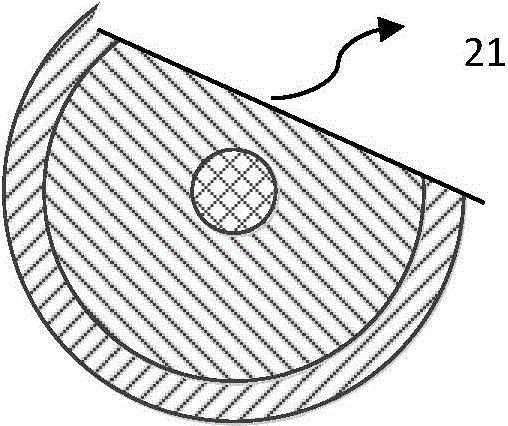

Diamond cladded polarization maintaining optical fiber and manufacturing method thereof

ActiveCN105985014AStrong process scalabilityGood process scalabilityGlass making apparatusOptical fibre with polarisationBatch productionCore (optical fiber)

The invention discloses a diamond cladded polarization maintaining optical fiber and a manufacturing method thereof. The manufacturing method comprises the following steps that a chemical vapor deposition method is adopted to manufacture a core stress integrated rod, wherein the core stress integrated rod comprises a core layer, a stress layer and an outer cladding layer; the core stress integrated rod is machined to make a cross section diamond; a target rod with a diamond cross section is manufactured and is put inside a quartz glass sleeve, an outer spraying process is adopted to conduct deposition on the quartz glass sleeve, the target rod is removed to form a pure quartz glass diamond inner-hole sleeve after the deposition process is completed; the core stress integrated rod with the diamond cross section is placed in the pure quartz glass diamond inner-hole sleeve to form a polarization maintaining optical fiber perform, the olarization maintaining optical fiber perform is subjected to drawing to form the diamond cladded polarization maintaining optical fiber. The polarization maintaining optical fiber I good in process performance and product quality, high in manufacturing precision and finished product rate, good in machining adaptability and suitable for batch production.

Owner:武汉长盈通光电技术股份有限公司

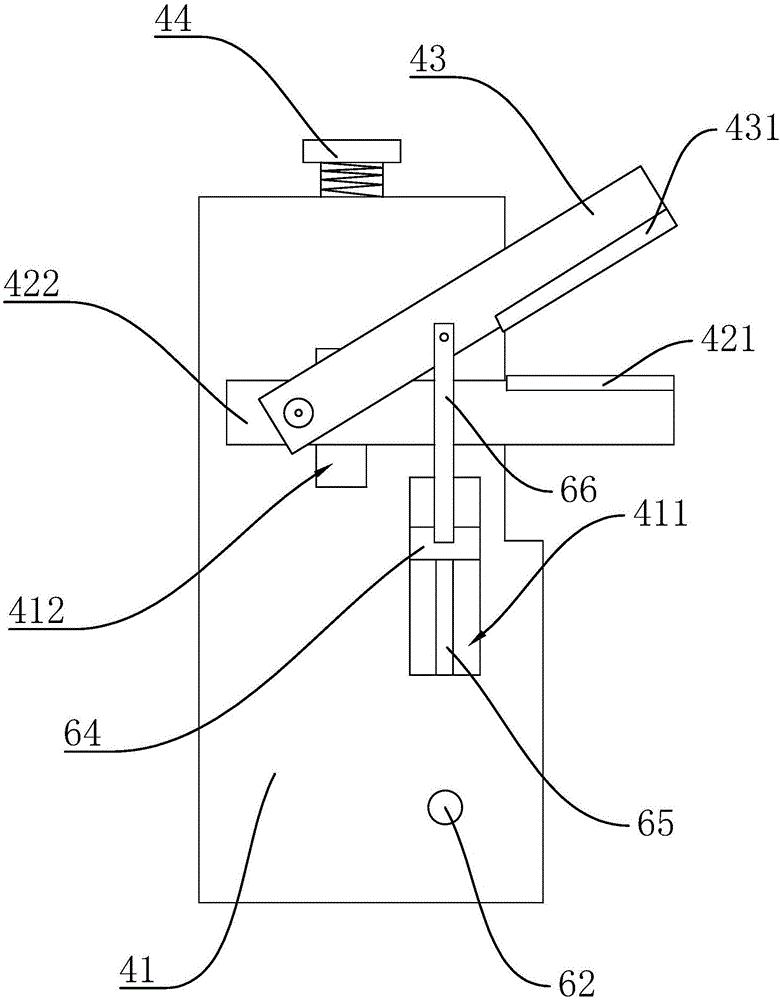

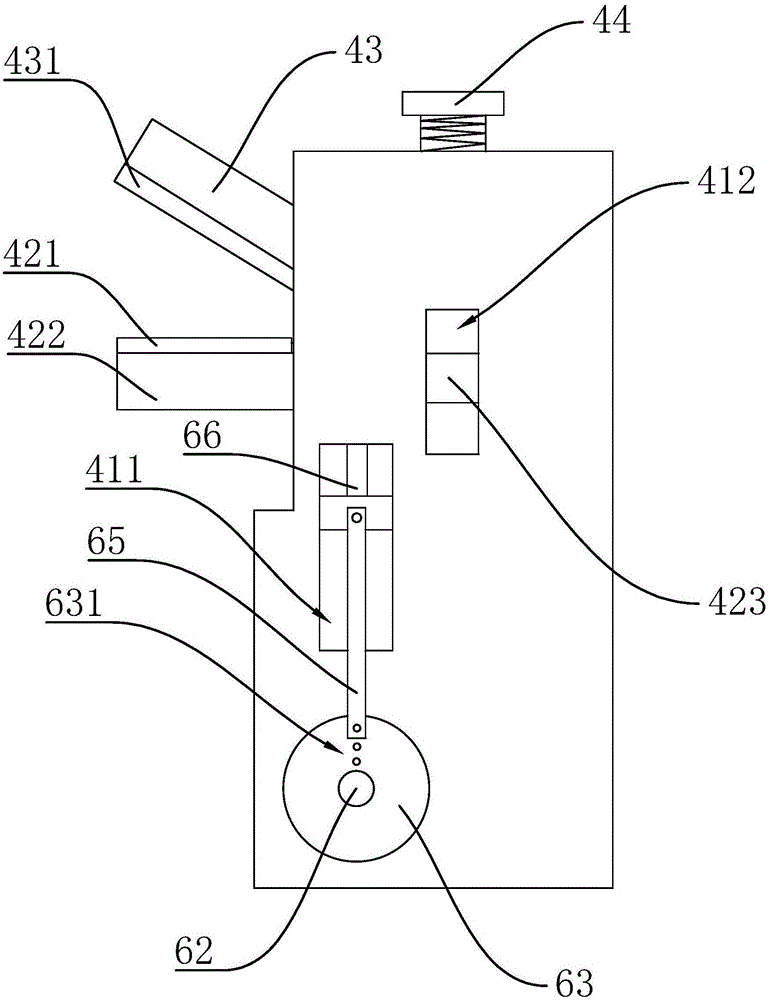

Rapier loom

ActiveCN106048864AImprove surface qualityAccurate and fast resetLoomsAuxillary apparatusPush and pullMotor drive

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

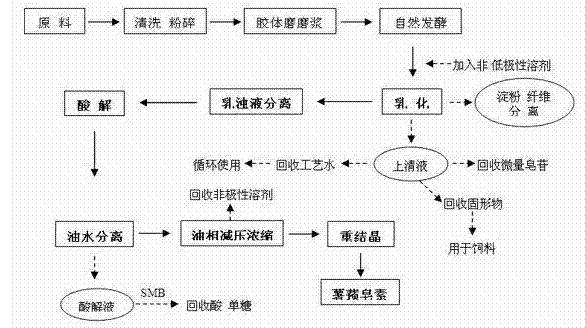

Green process for preparing diosgenin

The invention discloses a green process for preparing diosgenin and belongs to the technical field of natural product extraction. The main procedure of the process comprises the steps of washing, smashing, naturally fermenting, emulsifying, separating fibers, separating starch, separating emulsion, performing acidolysis, separating oil and water, performing reduced-pressure condensing, and recrystallizing to get the product; recovering acid and monosaccharide in the acidolysis solution through a simulated moving bed; and adding a nonpolar solvent into a natural fermentation solution while grinding by a colloid mill, emulsifying the diosgenin to form the emulsion fixed in the water, and separating to get the cellulose, starch, supernate and emulsion after emulsifying. The emulsion is directly acidolysis processed so that the hydrolysis condition is reduced, the diosgenin is free of being damaged, and the quality of the diosgenin is increased; the pollution source is completely eliminated by the acid and the monosaccharide in the acidolysis solution. The process meets the standards of high purity, high yield, low cost and pollution free. The prepared diosgenin content is greater than 98%, the yield is greater than 80%, the recovery rate of the cellulose, the starch and the like is greater than 95%, the production cost is reduced by 30%, the ton cost is reduced by **-** and no pollution is discharged.

Owner:DALIAN POLYTECHNIC UNIVERSITY

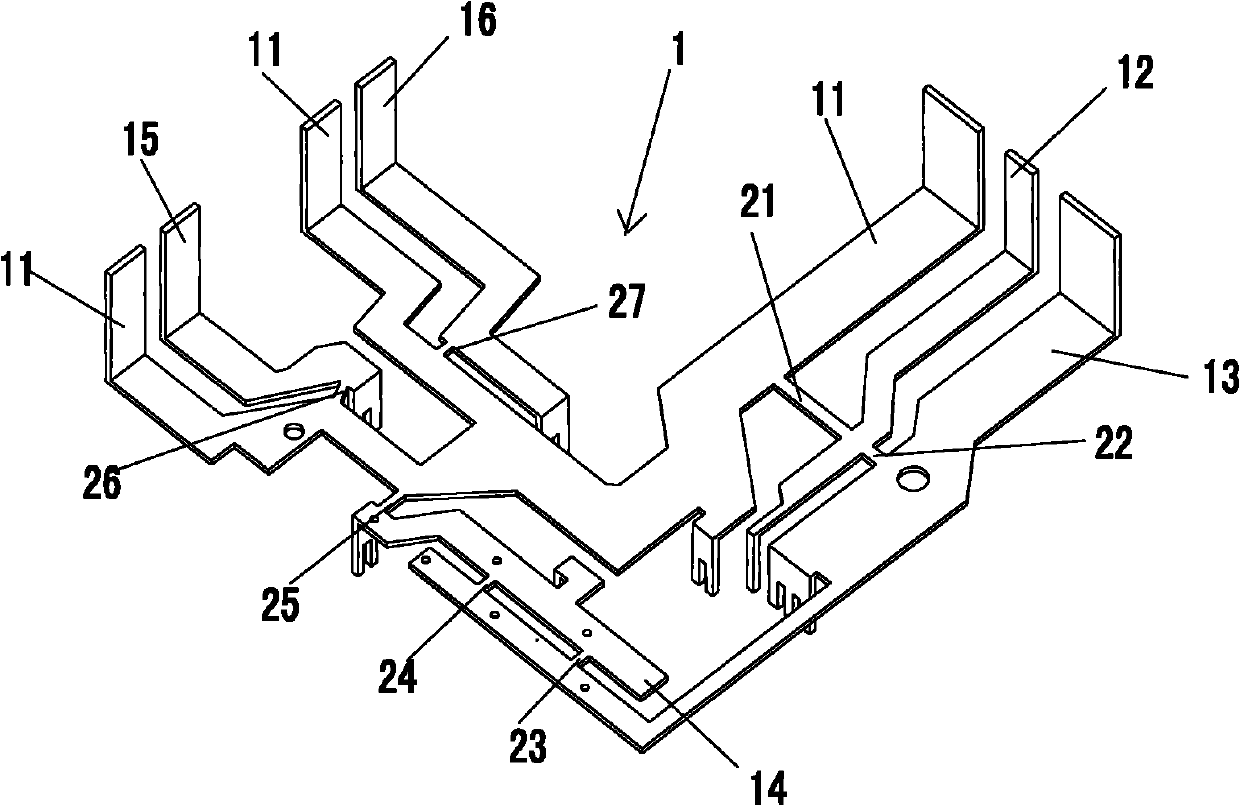

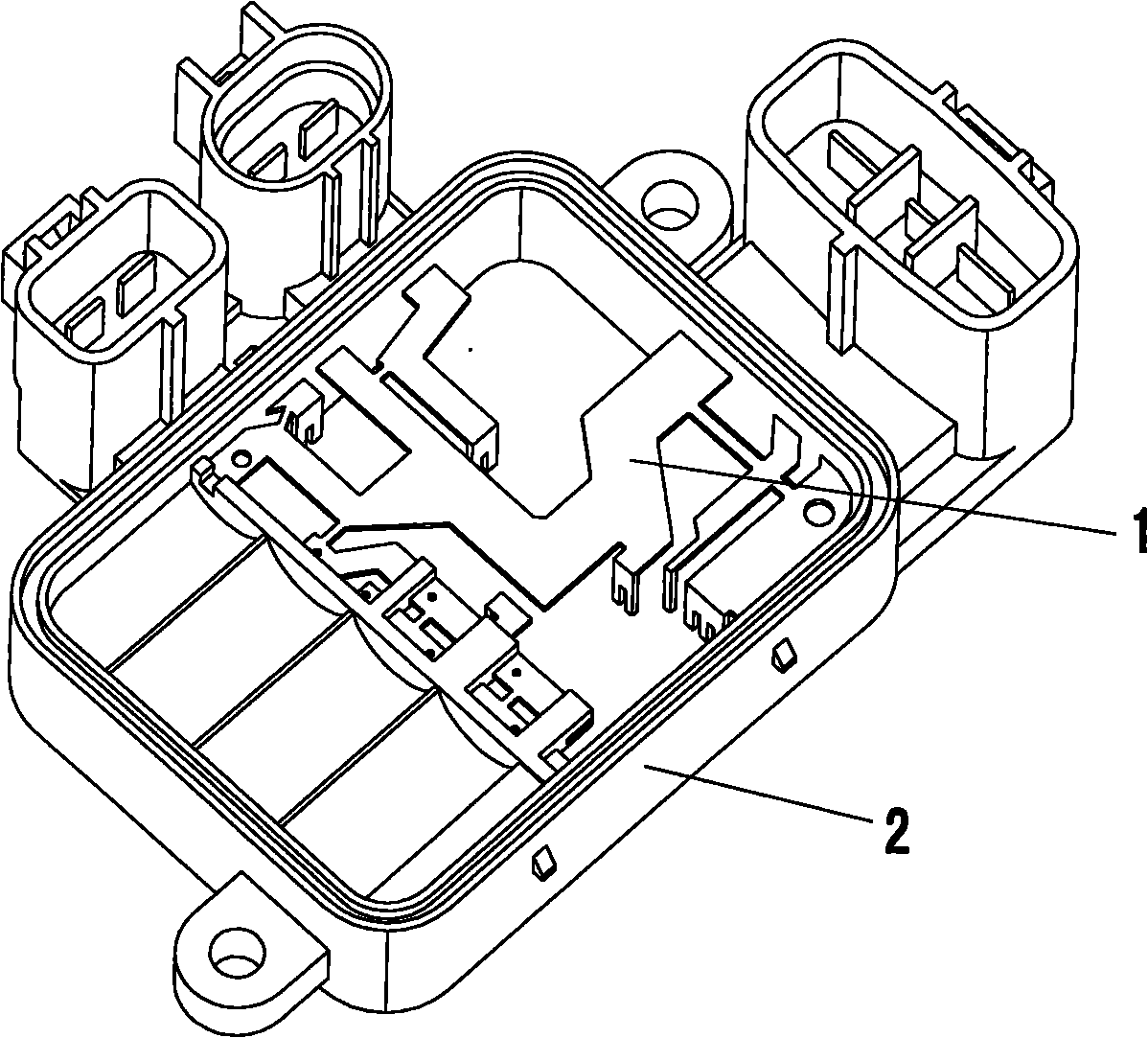

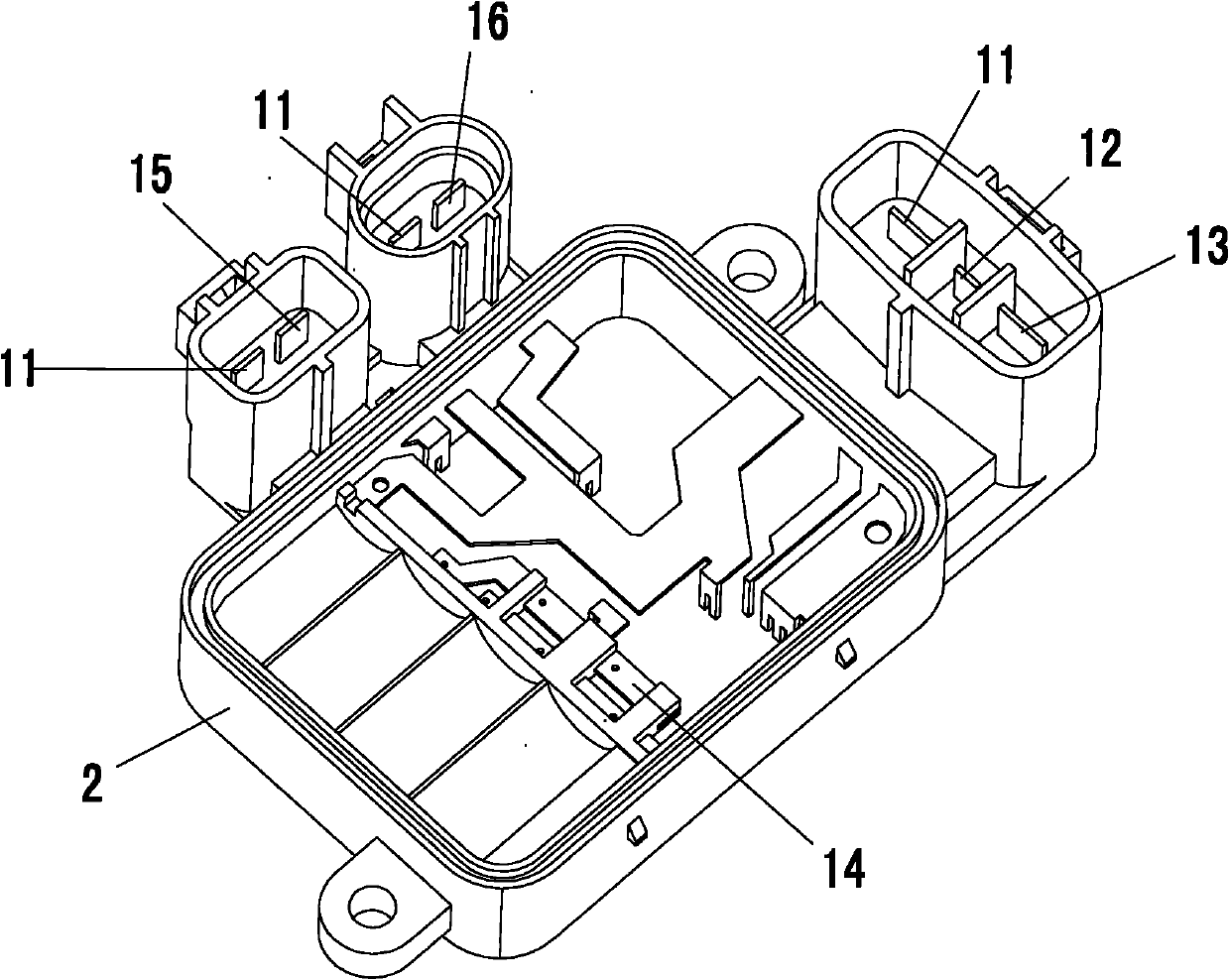

Injection molding method of PWM (Pulse Width Modulation) controller shell body and metal pins

InactiveCN101791839AReduce the number of positioning clampsEasy to installDomestic articlesInjection molding machineInjection moulding

The invention provides an injection molding method of a PWM (Pulse Width Modulation) controller shell body and metal pins, which comprises the following steps of: A, integrating a plurality of molded metal pins to be separated; mutually connecting and punching an integral metal piece by a plurality of connecting blocks; B, positioning and putting the punched integral metal piece into a mould for molding the PWM controller shell body for injection molding; and C, removing the connecting blocks for connecting the metal pins for separating the metal pins. Compared with the prior art of the separation injection of the metal pins, the injection molding method of the PWM controller shell body and the metal pins can reduce the positioning and holding quantity of the pins, simplify the installation of the pins, enhance precision, reduce technological difficulty, shorten injection time, simplify subsequent processing technology, and reduce the total cost of products.

Owner:SHANGHAI RIYONG JEA GATE ELECTRIC

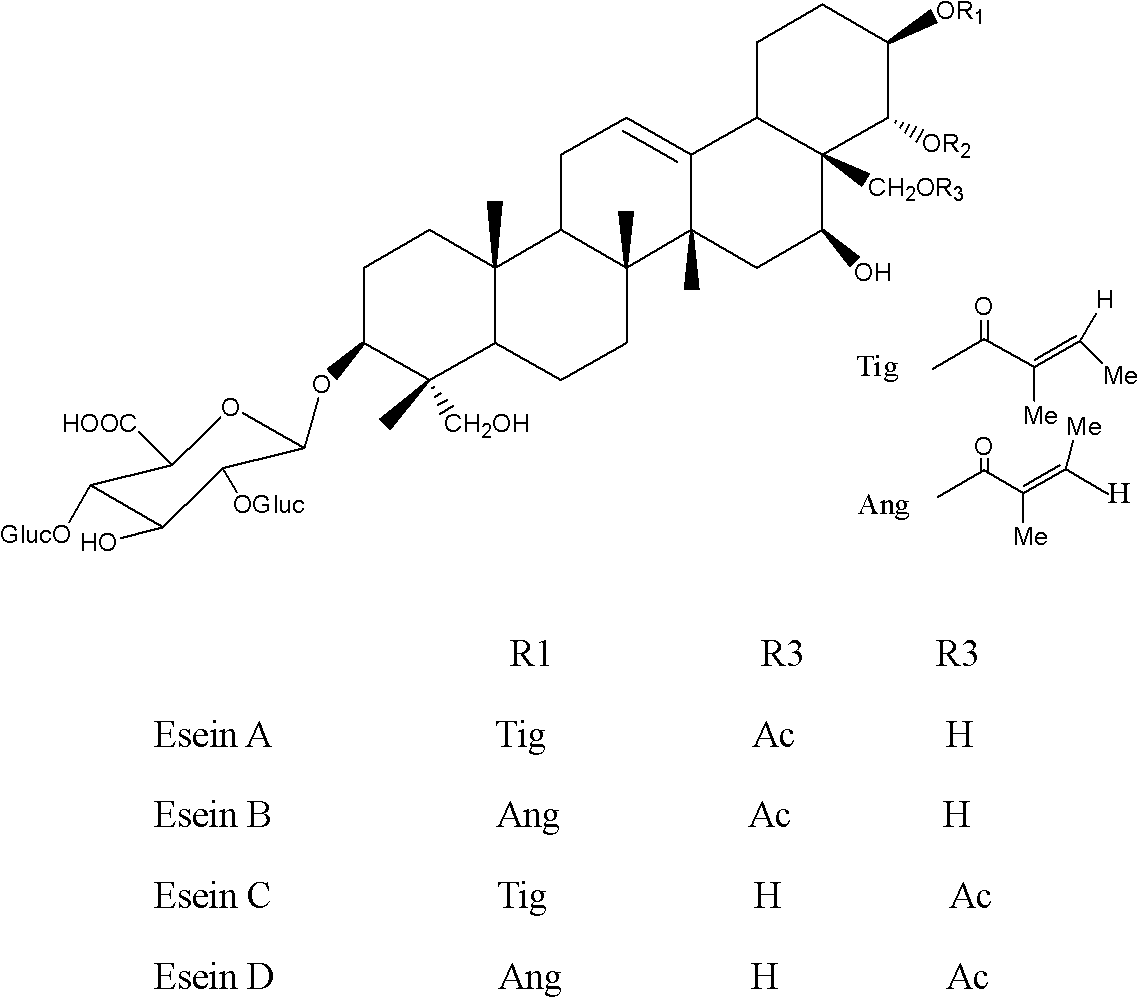

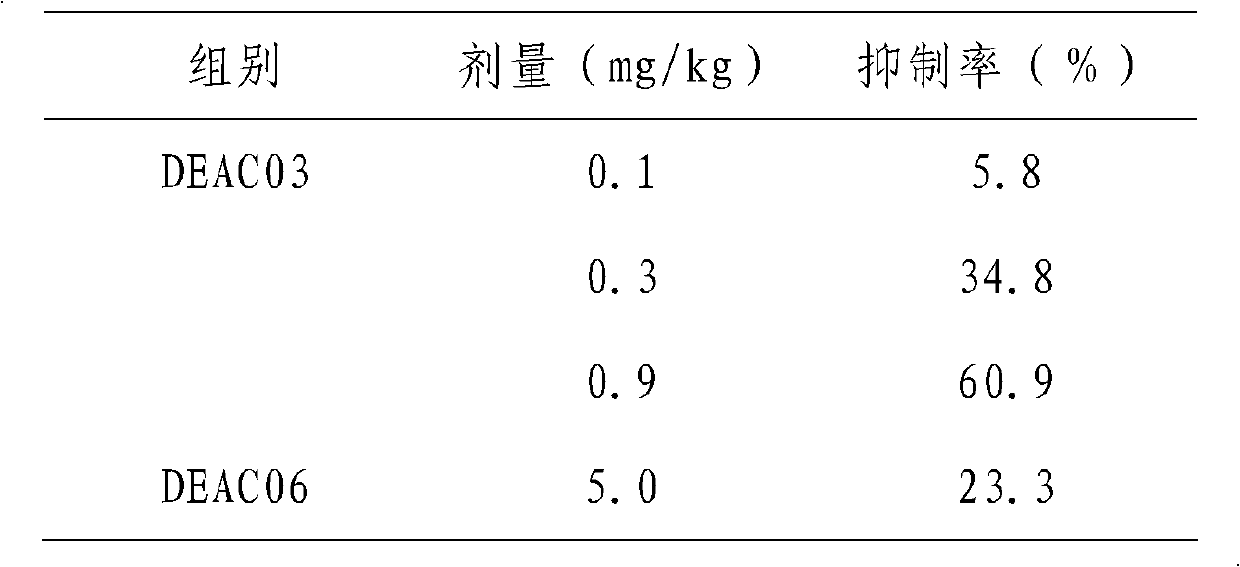

High purity aescine B bulk drug, its preparation method and medical application

InactiveCN102746363ANo risk of environmental pollutionReduce manufacturing costOrganic active ingredientsSugar derivativesMedical treatmentAnti-inflammatory analgesics

Belonging to the field of medicinal technologies, the invention particularly relates to a high purity aescine B bulk drug, its preparation method and application as anti-inflammatory exudation and edema bulk drugs. The bulk drug provided in the invention has the advantages of simple preparation process, environmental protection, controllable quality, stronger activity than existing aescine drugs, good safety, and good application prospects.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

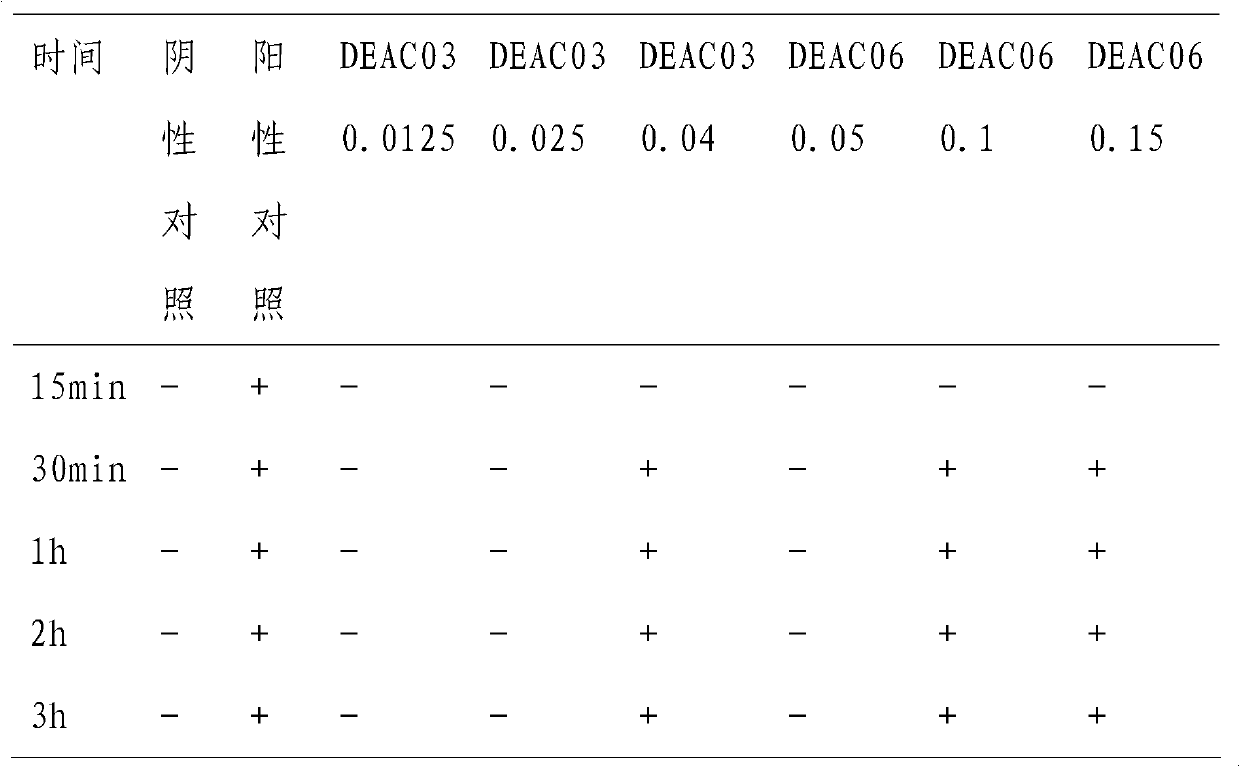

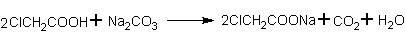

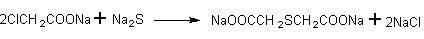

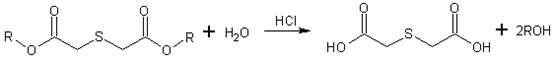

Method for preparing thiodiglycolic acid

InactiveCN102001981AConvenient sourceReduce manufacturing costSulfide preparationAlcoholDiethyl ester

The invention discloses a method for preparing thiodiglycolic acid, which comprises the following steps: adding thiodiglycolic acid dialkyl ester in acidic liquid; heating and refluxing for 1 to 6 hours; recovering a byproduct, namely alcohol, and water; and cooling the residual reaction mixture, crystallizing, filtering and drying and obtaining finished product. The thiodiglycolic acid dialkyl ester may be thiodiglycolic acid dimethyl ester, thiodiglycolic acid diethyl ester, thiodiglycolic acid dipropyl ester or thiodiglycolic acid dibutyl ester. In the method, the process is simple, the reaction yield is high, the product colour and luster and purity are high, extractant is not used, the mother liquid can be recycled, and the environment in an entire preparation process is good. The method has a bright industrial application prospect.

Owner:三门峡奥科化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com