Method for pretreating beer waste for biochemical utilization

A pretreatment and waste technology, applied in biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of complex process, low yeast nutrient release rate and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0028] Fresh beer yeast sludge containing 21.1% dry yeast, beer raw wastewater, ozone generator, fermenter, 8010 strain;

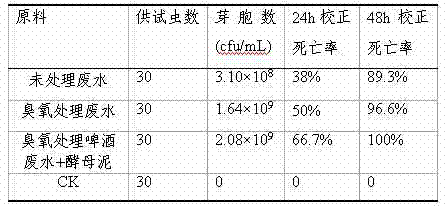

[0029] The following three culture media were used for cultivation: (1) Beer wastewater without ozone treatment, sterilized by high-pressure steam at 121°C for 45min. (2) Beer wastewater is directly fed into the ozone generated by the ozone generator. The amount of ozone feeding is controlled as follows: the treatment time is 2 minutes, the total feeding amount is 0.5g ozone / g yeast slime dry matter, and sterilized by high-pressure steam at 121°C for 45 minutes. (3) The 6 times diluted fresh waste yeast sludge is directly fed into the ozone generated by the ozone generator. The amount of ozone input is controlled as follows: the treatment time is 2 minutes, and the total amount of input is 0.5g ozone / g yeast sludge dry matter, 121°C under high pressure Steam sterilization for 45min. The pretreated yeast sludge and (2) pretreated beer wastewater are mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com