Method for producing combustible gas through kitchen garbage and sludge

A technology for kitchen waste and sludge, applied in sludge treatment, biological sludge treatment, electrochemical sludge treatment, etc. reduce slow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

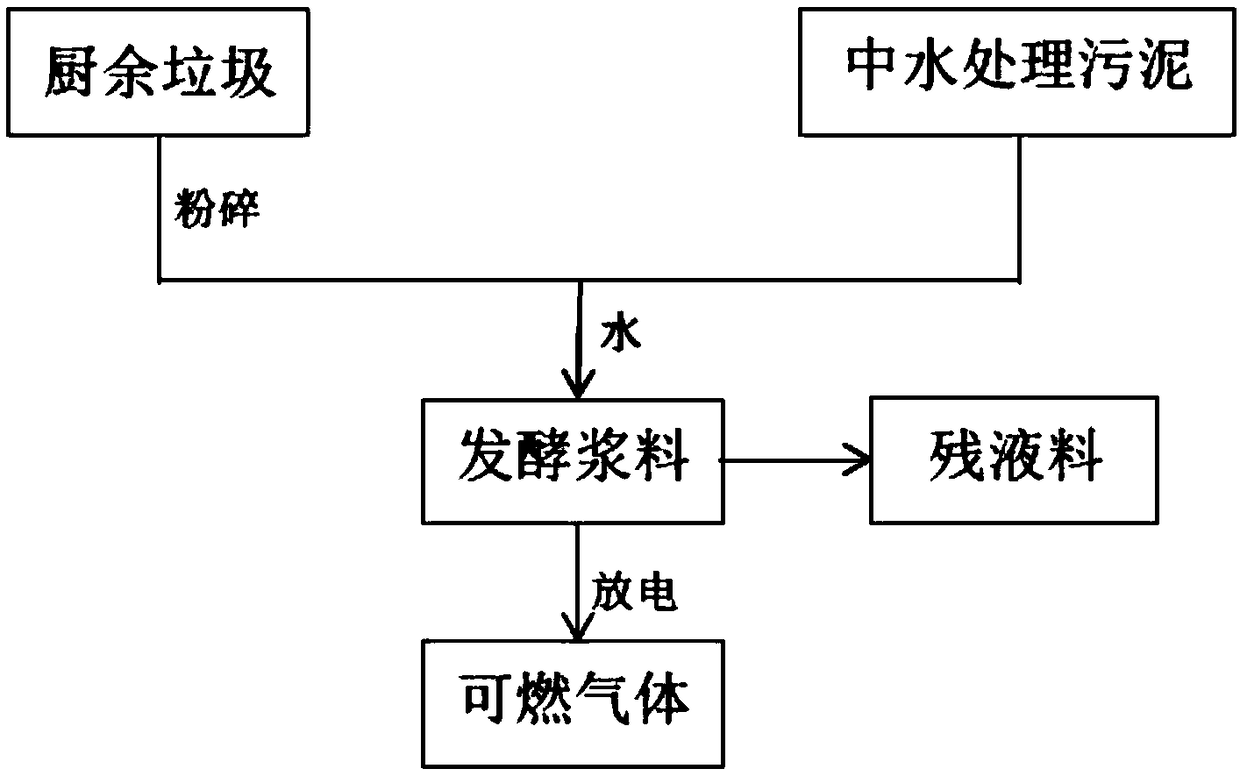

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Production of combustible gas

[0030] A custom-made 50L jacketed reactor is used. There are 5 pairs of electrode rods evenly arranged in an array at the bottom of the reactor. The positive pole is carbon rods, and the negative pole is stainless steel. . The pressure in the tank is greater than 0.20MPa, and the gas is released automatically.

[0031] (1) The kitchen waste containing green plants is pre-crushed into 10 meshes, and then mixed with reclaimed water treatment sludge with a water content of 80% in a mass ratio of 3:1 to form a fermented slurry with a solid content of 8%;

[0032] (2) After the negative pressure of the vacuum fermentation tank is pumped to -0.05MPa, the fermentation slurry is pumped in so that the fermentation slurry does not pass through the electrodes; the discharge treatment is carried out in the first 3 days after feeding, and the discharge is performed when the pressure in the tank is lower than 0.25MPa. Stop discharging when ...

Embodiment 2

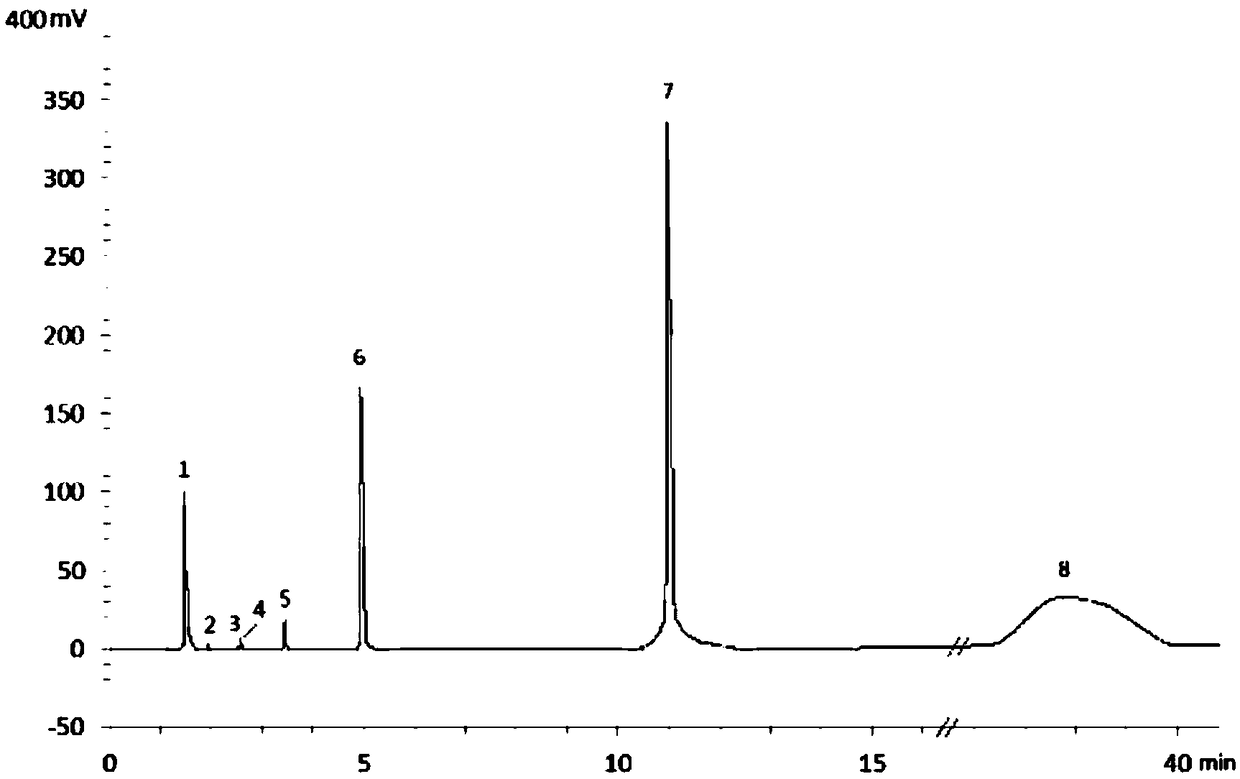

[0053] Example 2 Gas composition detection

[0054] The combustible gas obtained on the 4th day in each embodiment and comparative example was dried by Shimadzu GC-7A gas chromatograph, and then the components were detected. Dry gas chromatographic conditions before detection are as follows:

[0055] Column temperature: 70°C;

[0056] Inlet temperature: 95°C;

[0057] Thermal conductivity detector (TCD) temperature: 80°C;

[0058] Carrier gas: high-purity argon;

[0059] Flow: 30mL / min;

[0060] Chromatographic column: stainless steel column filled with carbon molecular sieve, 3m×3mm;

[0061] Injection volume: 1000 μL;

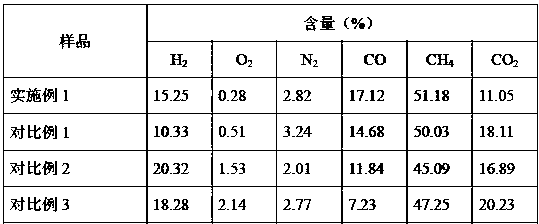

[0062] The gas analysis spectrum of embodiment 1 is as figure 2 shown. The contents of different components in each gas were calculated, and the results are shown in Table 1.

[0063] Table 1 Comparison of gas composition and content in different gas samples

[0064]

[0065] It can be seen from the data in Table 1 that among the gas samples, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com