Patents

Literature

43results about How to "Change surface topography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

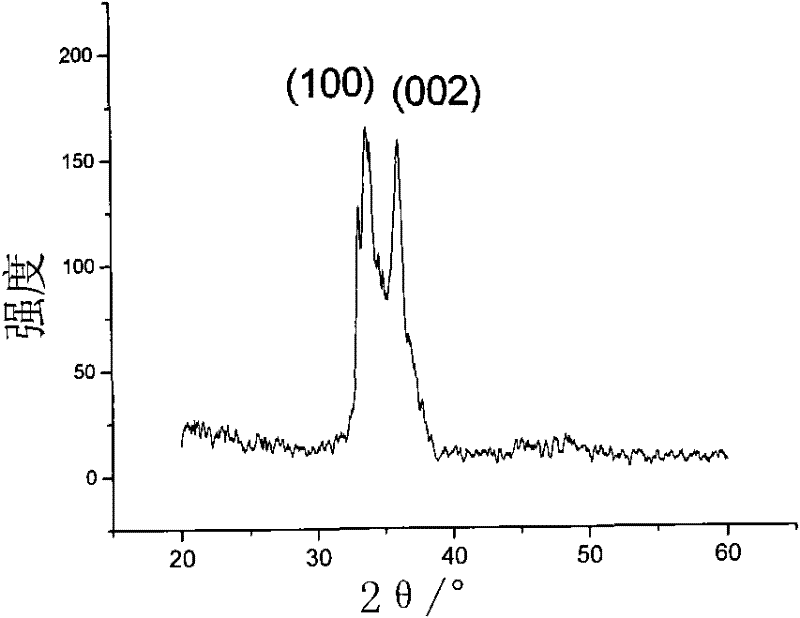

Deposition method capable of enhancing preferred orientation growth of AlN film

ActiveCN101824592AEasy to operateReduce manufacturing costVacuum evaporation coatingSputtering coatingSurface roughnessSurface acoustic wave

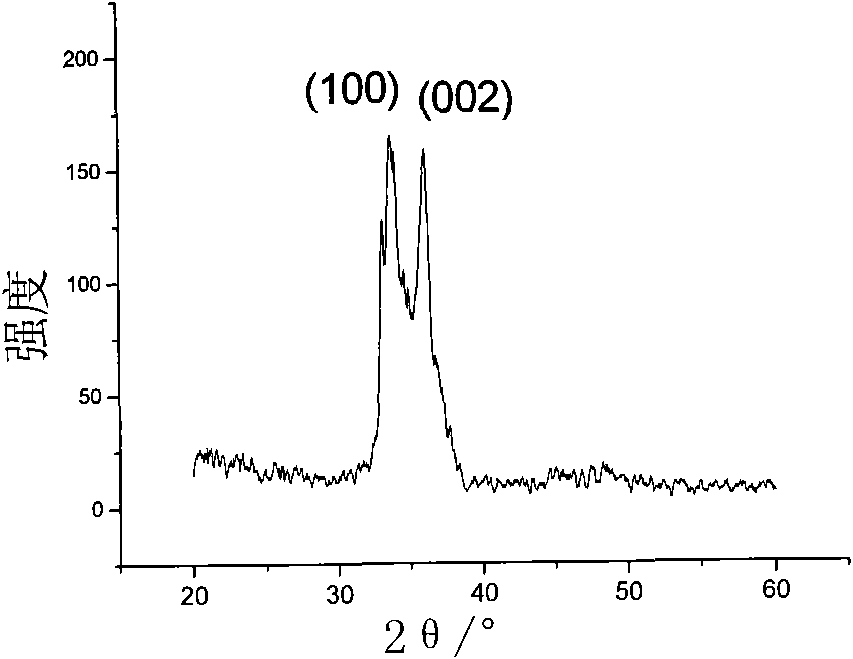

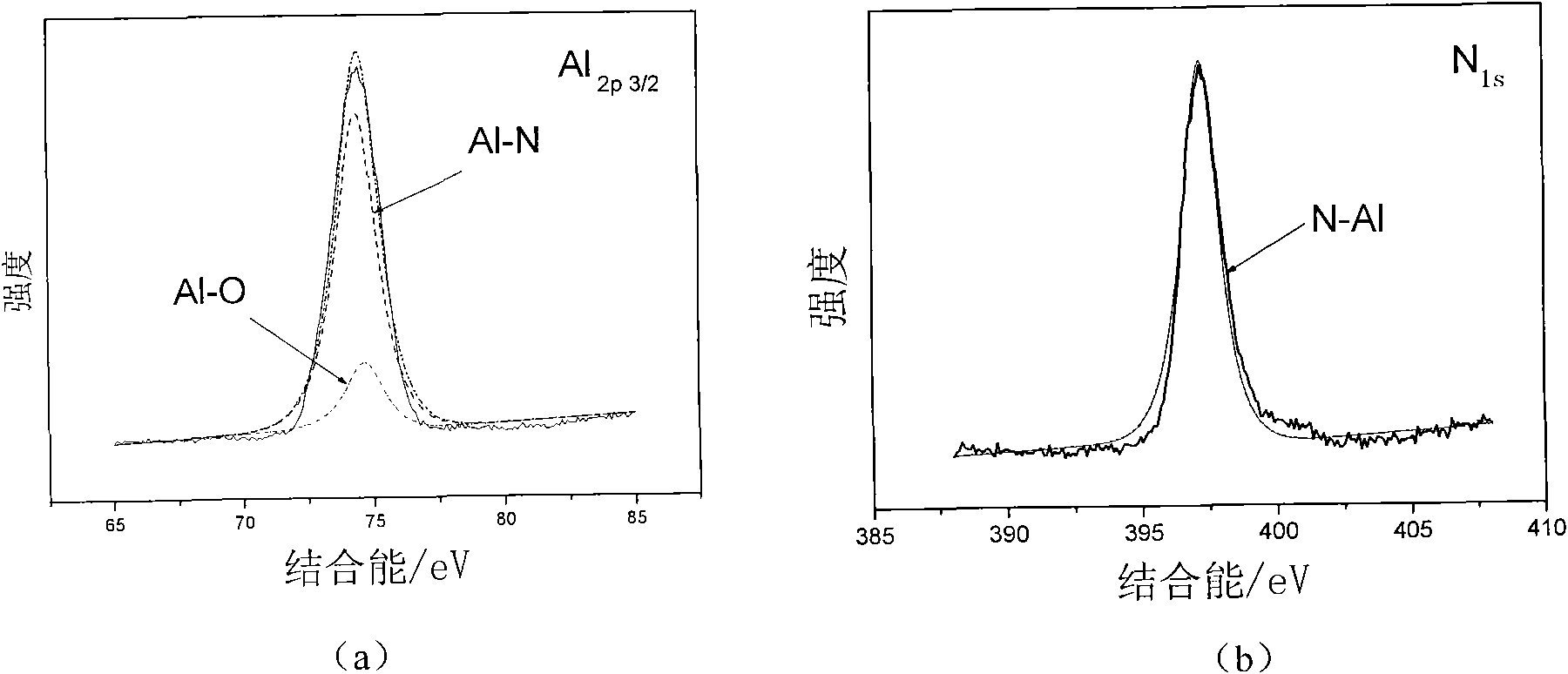

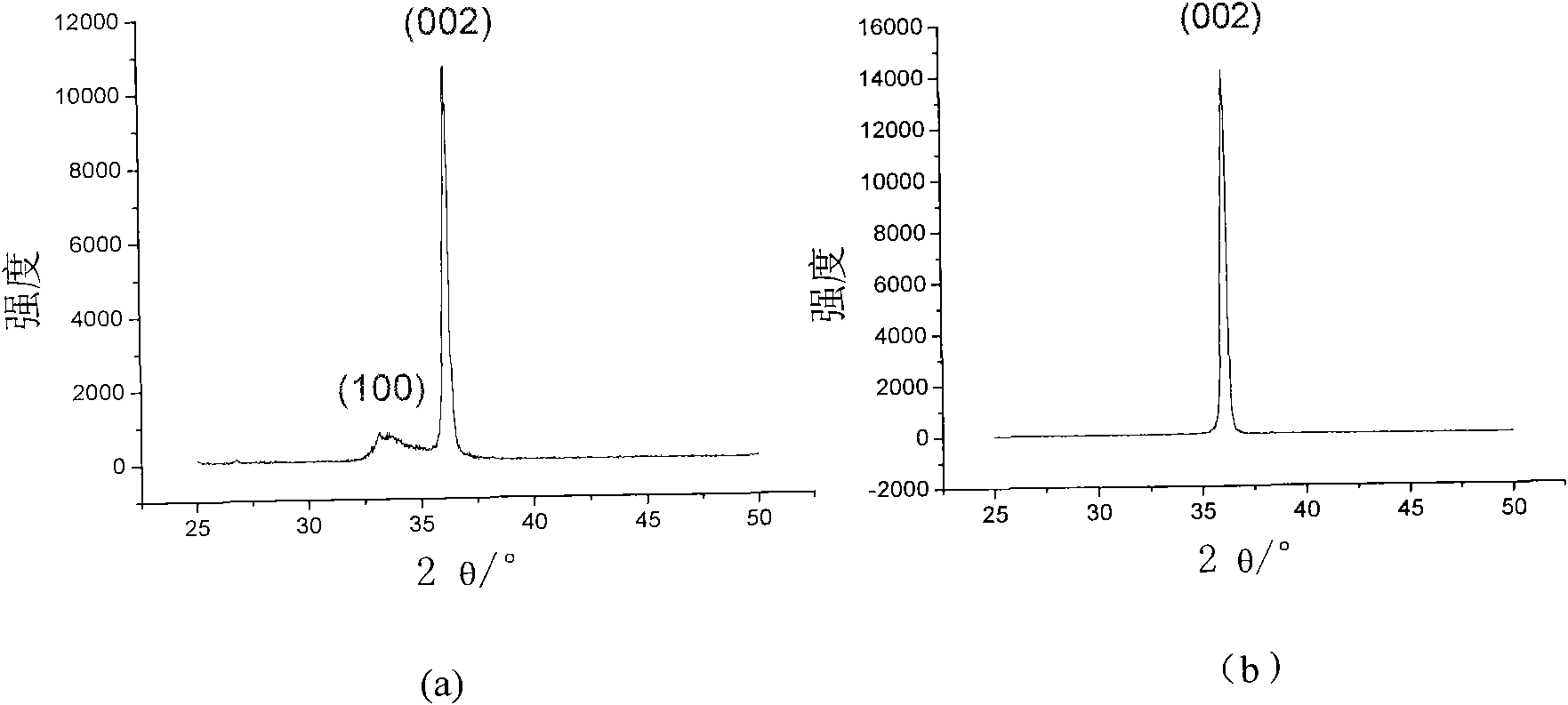

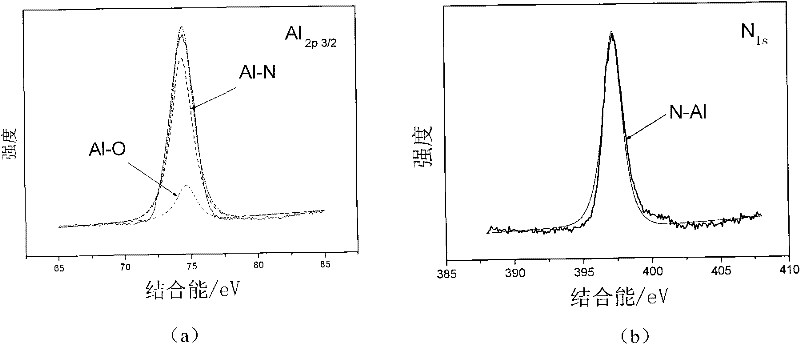

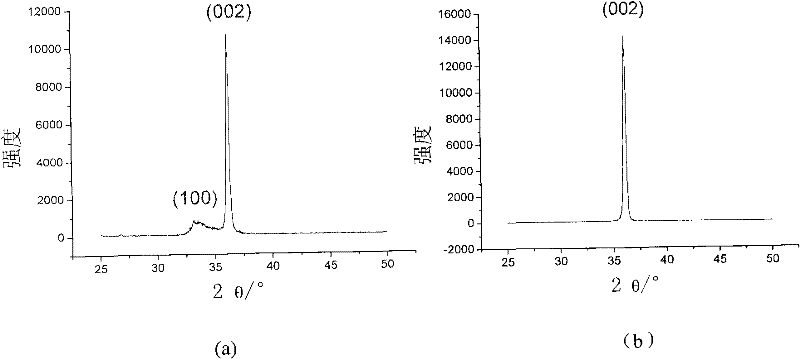

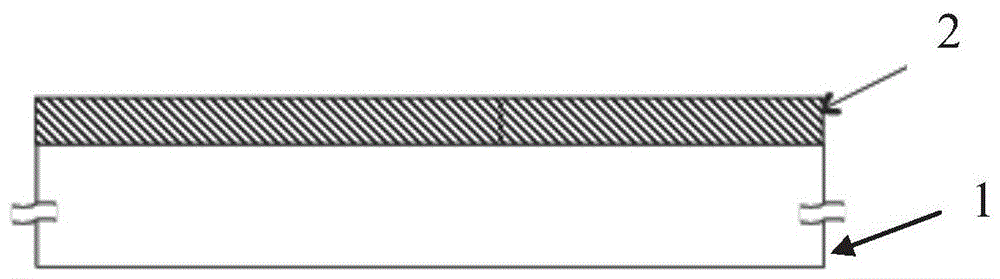

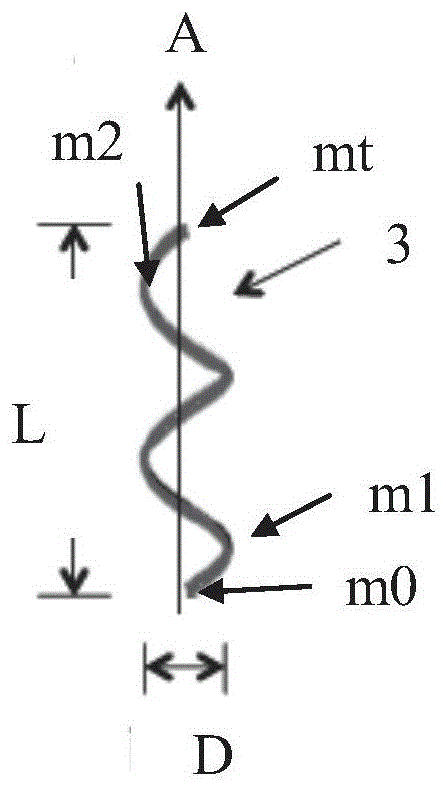

The invention relates to a deposition method capable of enhancing the preferred orientation growth of an AlN film. The deposition method comprises the following steps: adopting an ion beam-assisted deposition technique to prepare an AlN homogeneous transition layer: when using an Ar + ion beam of 2.0-2.5keV / 20-50mA for depositing an Al film in a sputtering way on a substrate, using a moderate-energy N+ ion beam of 20-35keV / 2-8mA for bombarding the Al film in an assisting way; and then depositing the AlN film by adopting magnetron sputtering, wherein base pressure is less than or equal to 5x10<-4>Pa, working air pressure is 0.5-10Pa and substrate temperature is 200 DEG C-500 DEG C. Through pre-depositing the homogeneous transition layer, the invention has the advantages that the internal stress between the film and the substrate can be effectively reduced, the full (002) orientation AlN film is formed, the surface roughness of the film is reduced, the bonding strength between the film and the substrate is increased and the film product can satisfy the requirements on the application in surface acoustic wave devices, acoustic bulk wave devices and other microelectronic devices and power devices.

Owner:湖南特瑞精密医疗器械有限公司

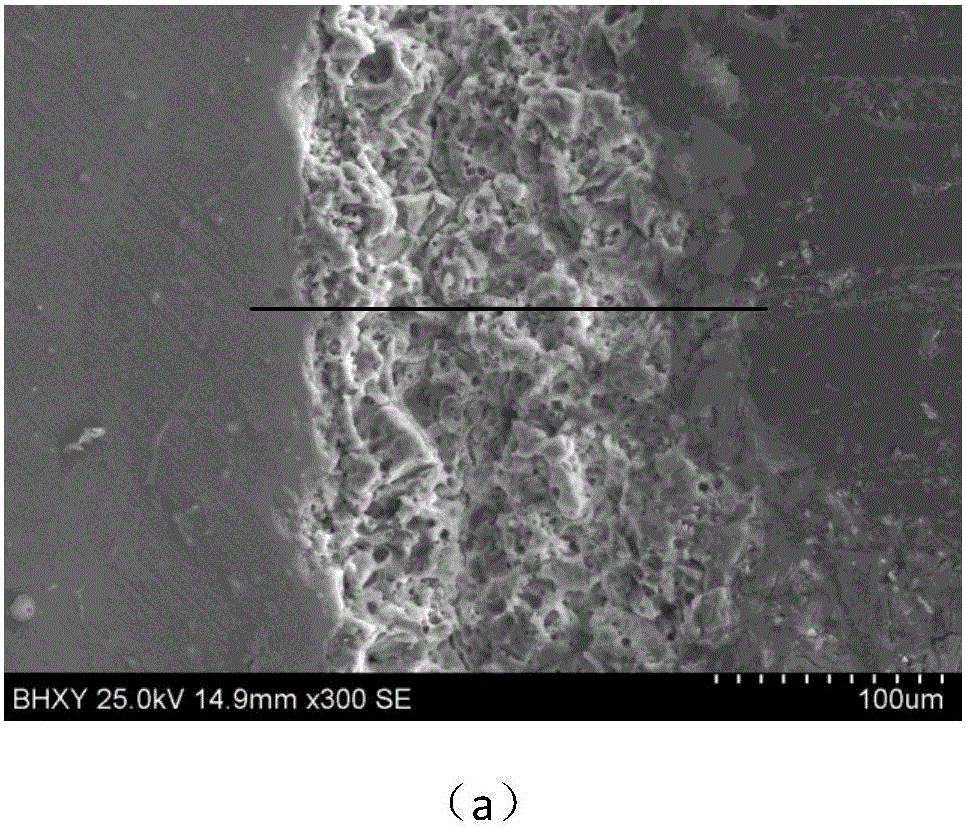

Calcium-phosphorus-silicon biological ceramic coating and preparation method and application thereof

ActiveCN106245094AGood biological propertiesImprove mechanical propertiesAnodisationSurgeryElectrolysisCeramic coating

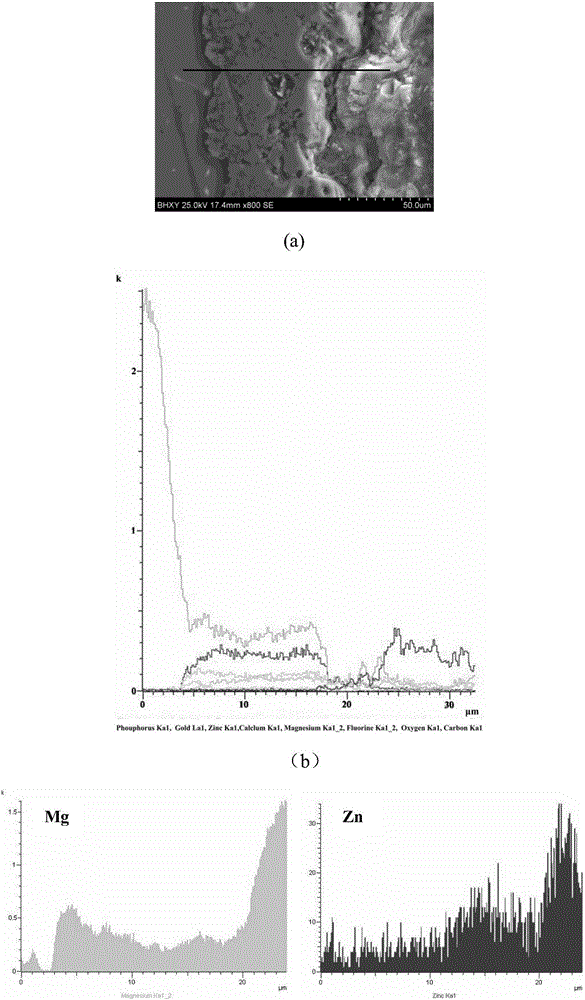

The invention discloses a calcium-phosphorus-silicon biological ceramic coating and a preparation method and application thereof. After magnesium and alloy of magnesium are put in a calcium-phosphorus electrolyte for powered-on electrolysis for a set time, a sample containing a calcium-phosphorus coating is put in a silicon salt electrolyte for powered-on electrolysis, and the target biological ceramic coating is obtained; and the calcium-phosphorus electrolyte is prepared by adding calcium salt and (NaPO3)6 into a basic electrolyte, and the silicon salt electrolyte is prepared by adding silicate into the basic electrolyte. A compact layer is connected with a basal body, the compact layer and the basal body are tightly combined, and the mechanical property of the basal body can be improved; in addition, pores barely exist in the compact layer, body fluid can be prevented from flowing to the surface of the basal body to make contact with the basal body, metal ions generated after the basal body is corroded also can be prevented from being diffused to the human body, toxicity is reduced, and biocompatibility is effectively improved; and a surface layer is a porous loose layer, combination of an implant and a bone can be effectively improved in the presence of micro-pores, growth of adherence bone tissue of bone cells can be effectively improved, and the biological activity of the coating can be improved.

Owner:SHANDONG UNIV

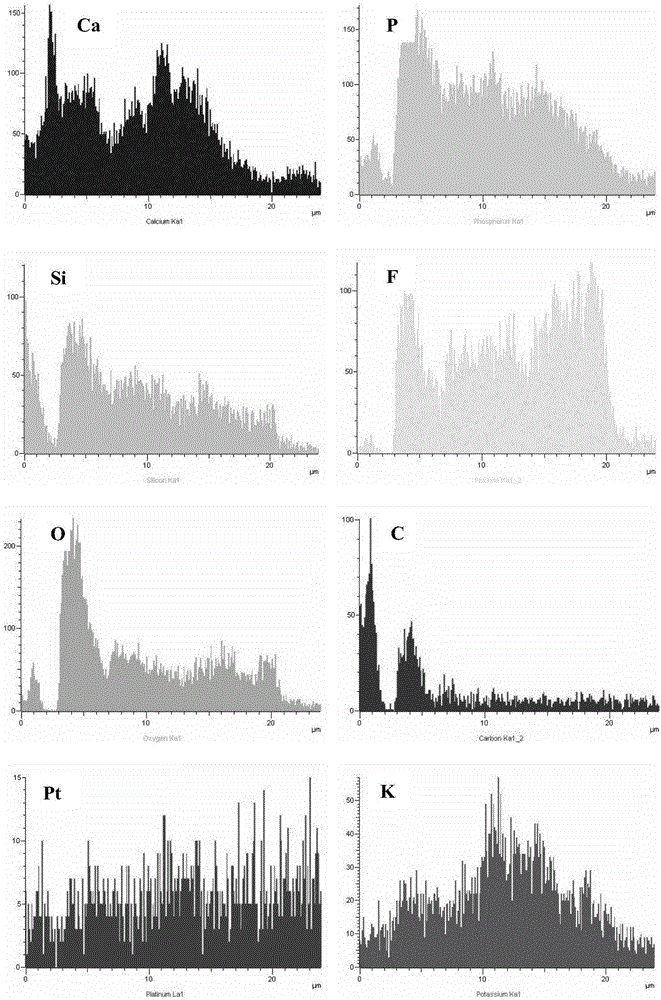

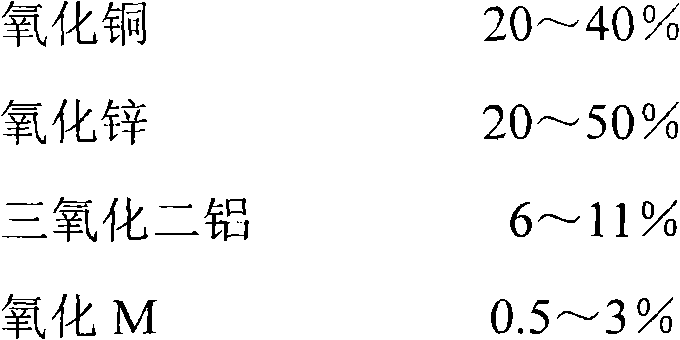

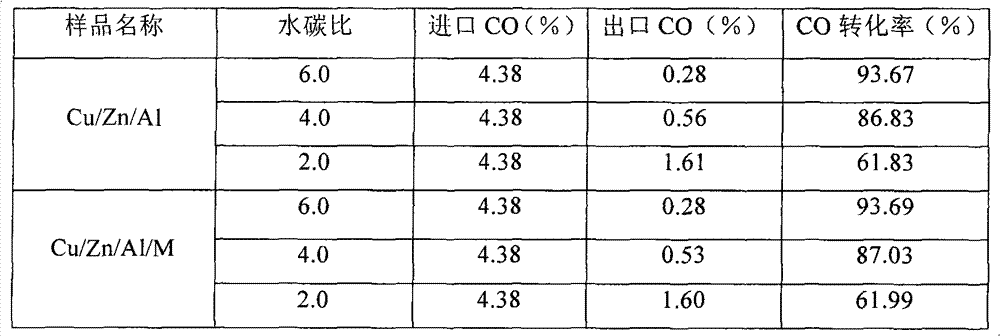

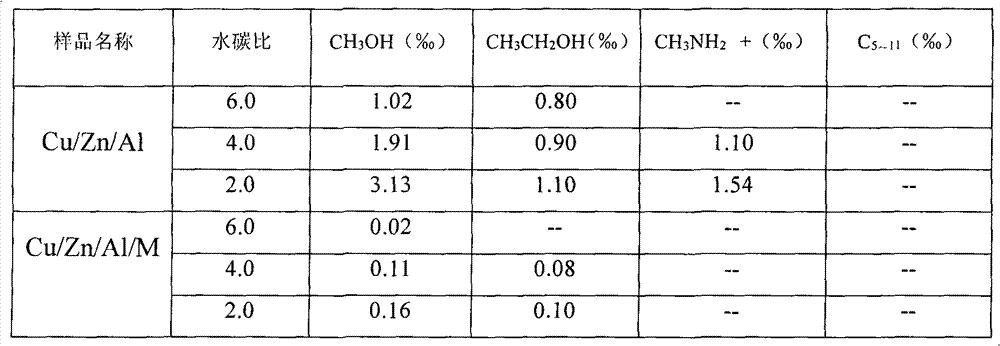

Preparation method of environmentally-friendly low-temperature shift catalyst

The invention relates to a preparation method of an environmentally-friendly low-temperature shift catalyst. Through adding an M (K, Rb, Cs, Mg, Sr, Ba and the like) metal element into the existing Cu / Zn / Al catalyst, the purpose of restraining the methanol synthesis side reaction is achieved. The catalyst is characterized in that under the same water / carbon ratio (vapor-air ratio) conditions, after the Cu / Zn / Al / M catalyst is modified by the M, the selectivity of the low-temperature shift catalyst is remarkably improved, the hydrogen output is high, and the contents of alcohol and amine in condensate are lower so as to provide better conditions for condensate recovery and utilization and environment protection.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

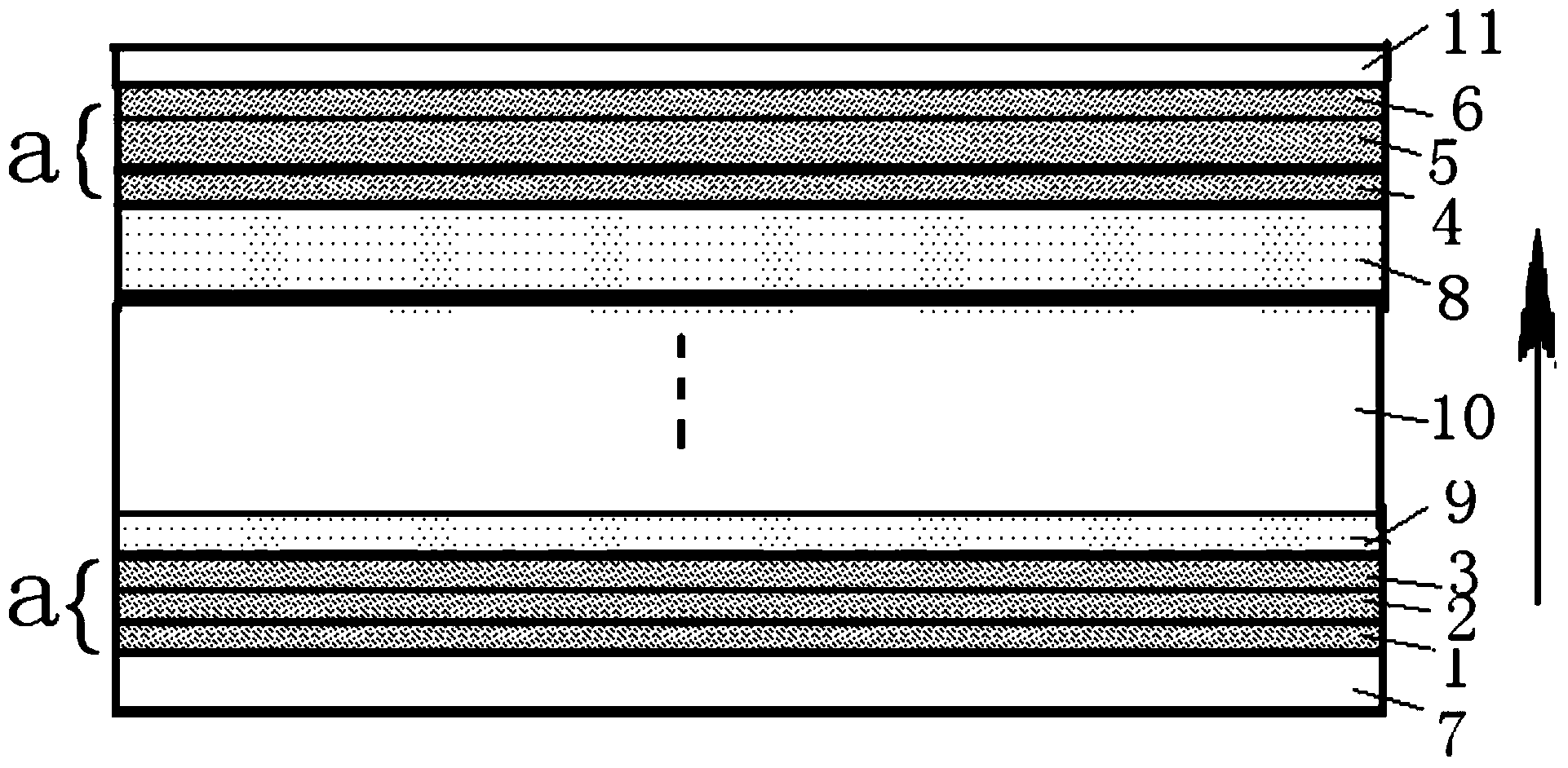

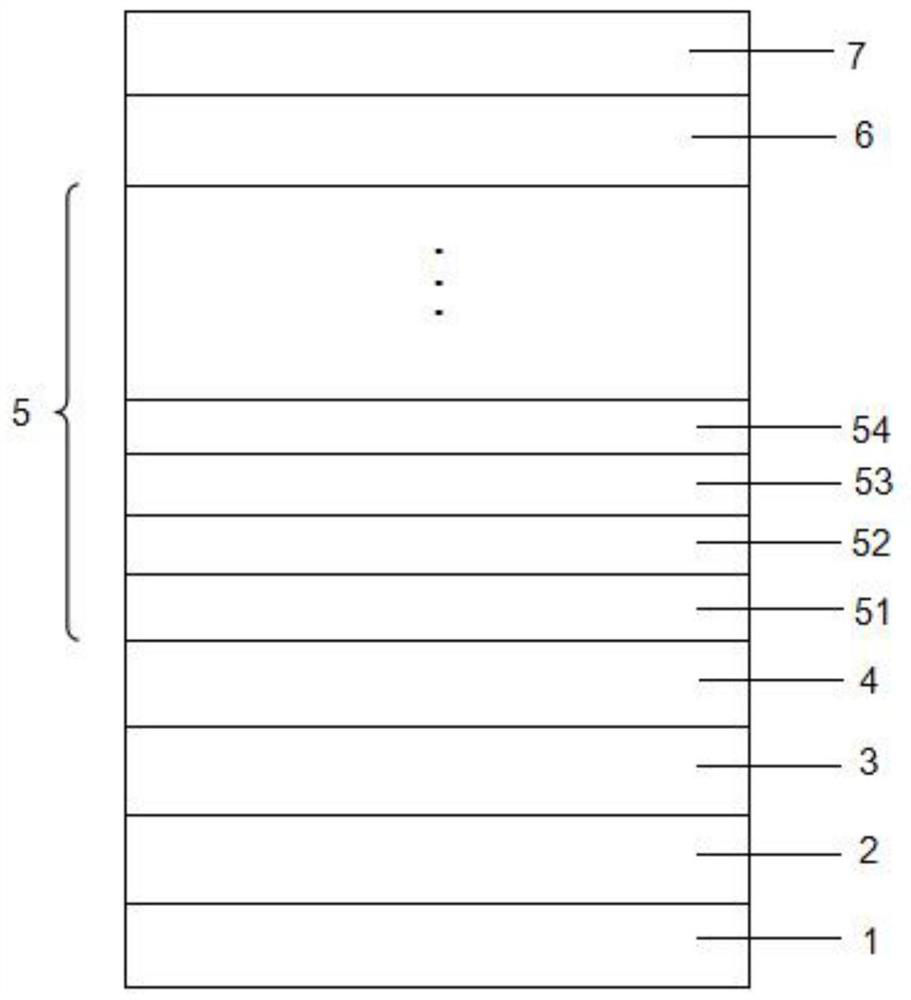

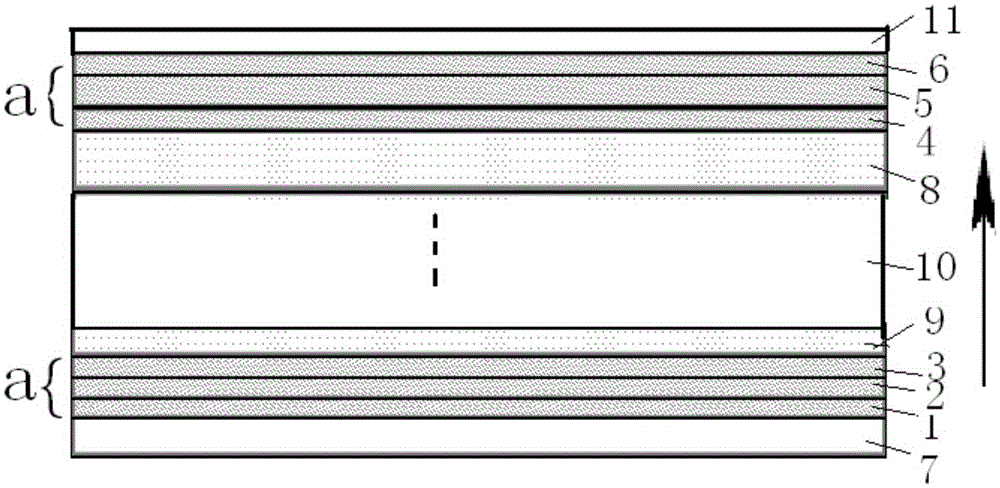

TCO thin film and preparation method thereof

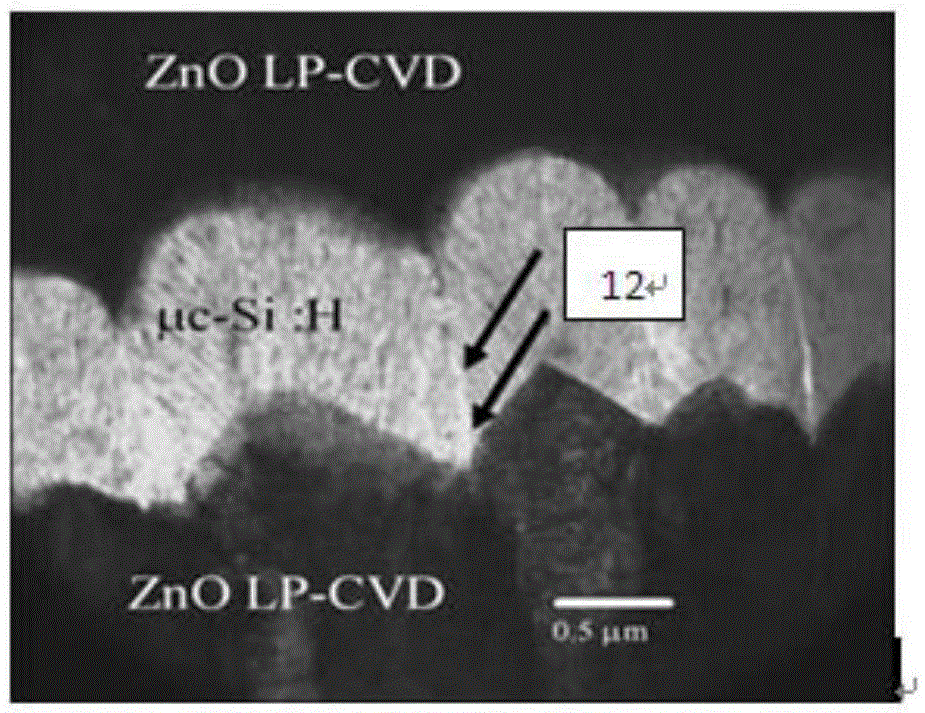

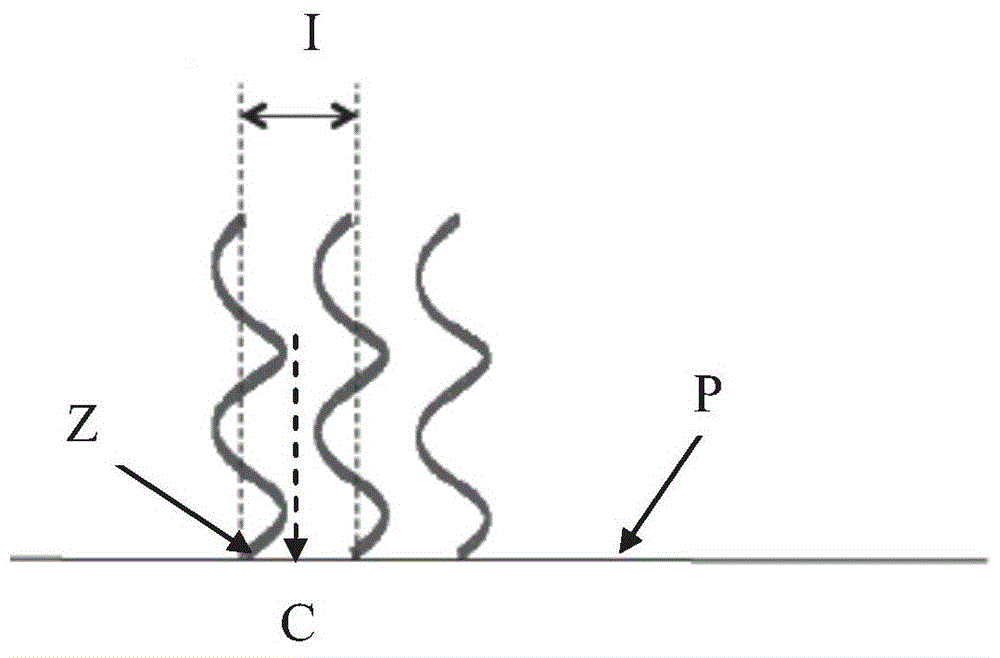

ActiveCN103646972AChange surface topographyIncreased interface conductivityFinal product manufactureChemical vapor deposition coatingElectrical batteryMaterials science

The invention discloses a TCO (transparent conducting oxide) thin film and a preparation method thereof. The TCO thin film comprises three zinc oxide thin film layers containing dopants from top to bottom, wherein the atom ratios of dopants in the zinc oxide thin film layer are different in zinc oxide. In the preparation method, dopant gas flows are adjusted in the thin film growing process to form a multiple-layer structure and modulate a surface microstructure and the optical performance of the TCO thin film, wherein the middle and an interface of the multiple-layer structure are different in dosage concentration. The light trapping effect of the film and the optical transmittance of a near-infrared light region can be greatly improved while good electrical conductivity of the TCO film and the interface of the film are maintained, a haze average value of a 400-1100nm waveband is improved from 27.3% to 34.9 %, the transmittance of a 700-2000nm near-infrared waveband is improved from 76% to 77.7%, and the photoelectric conversion efficiency of batteries is improved.

Owner:湖南共创光伏科技有限公司

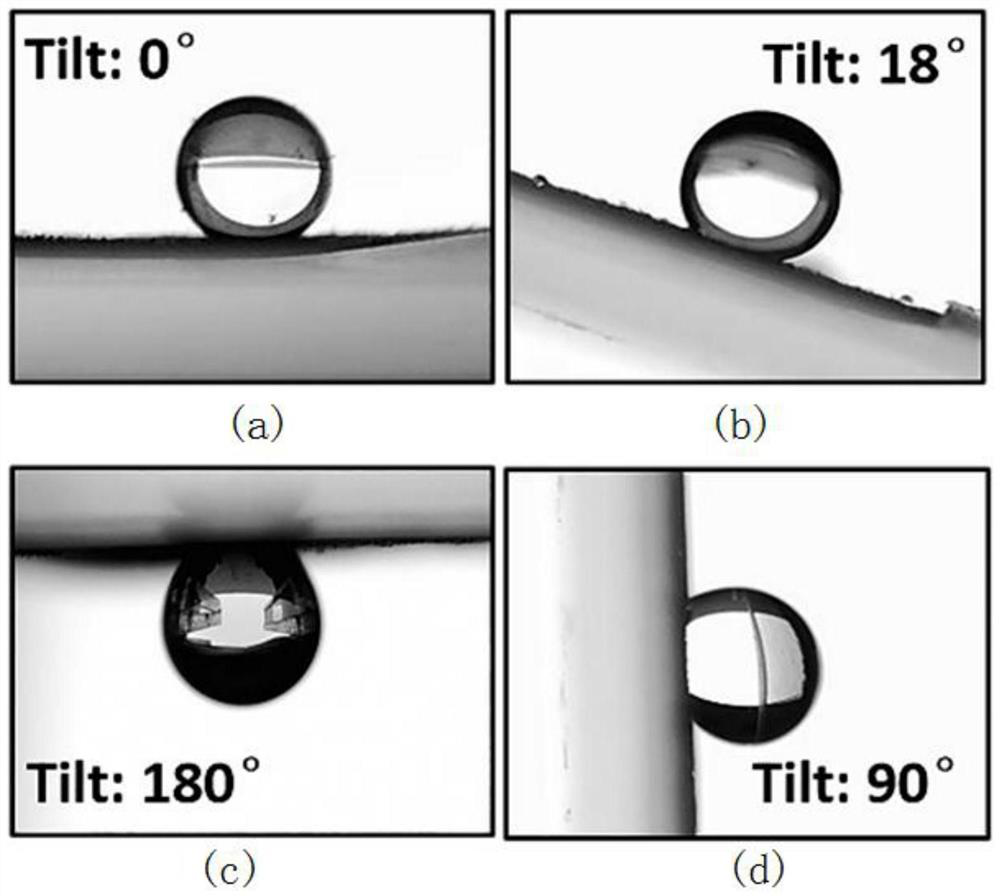

Method for improving wetting and spreading performance of reaction wetting system material

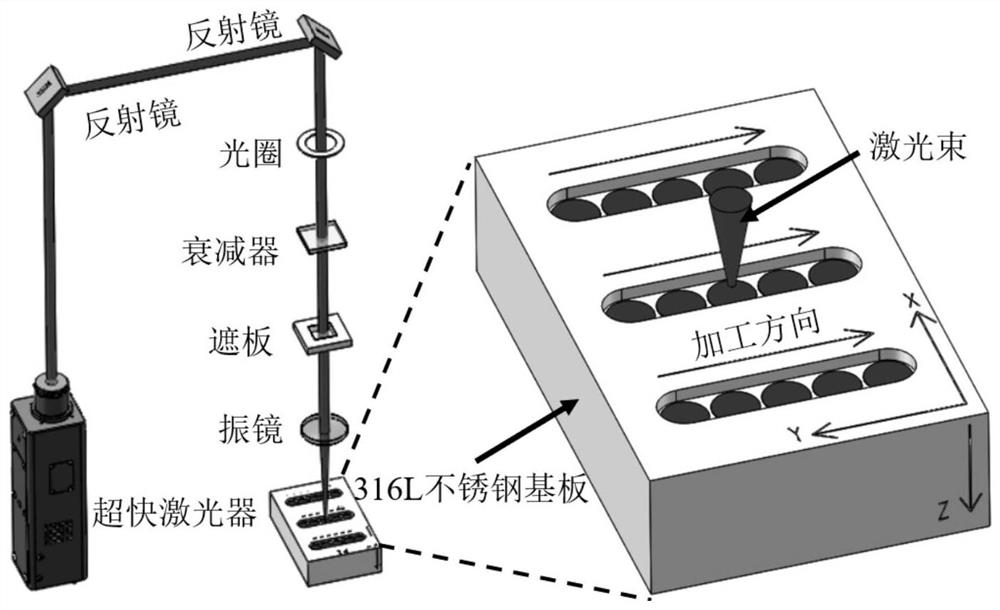

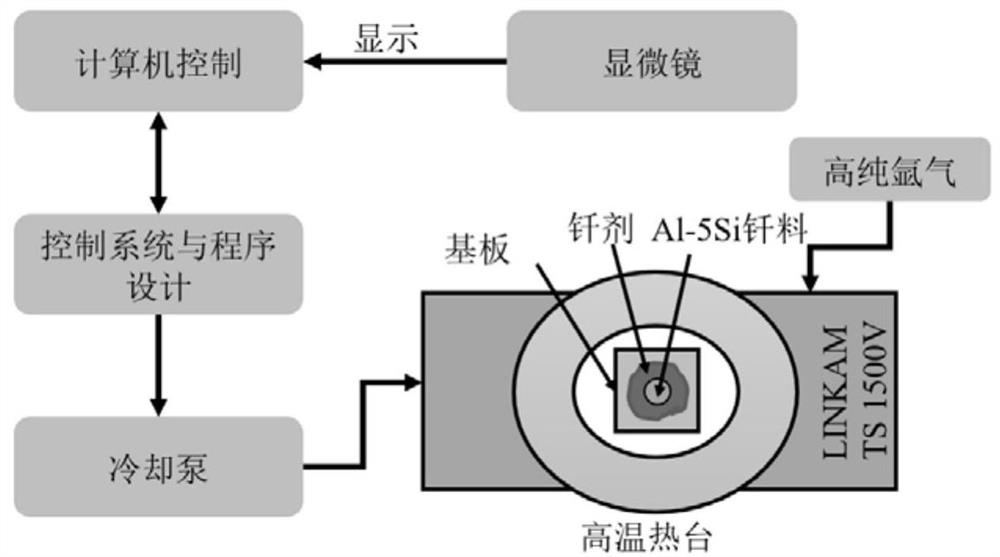

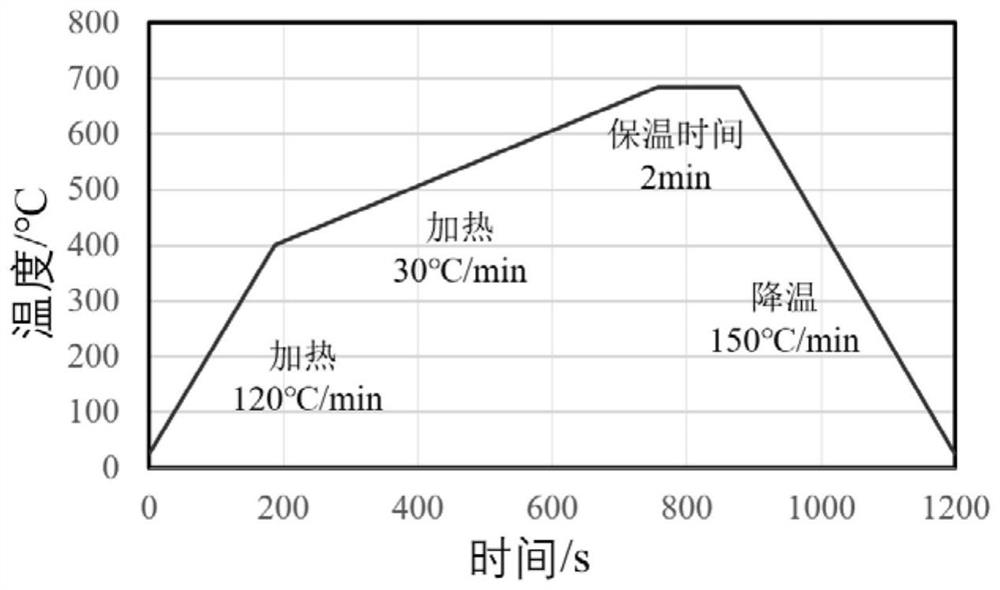

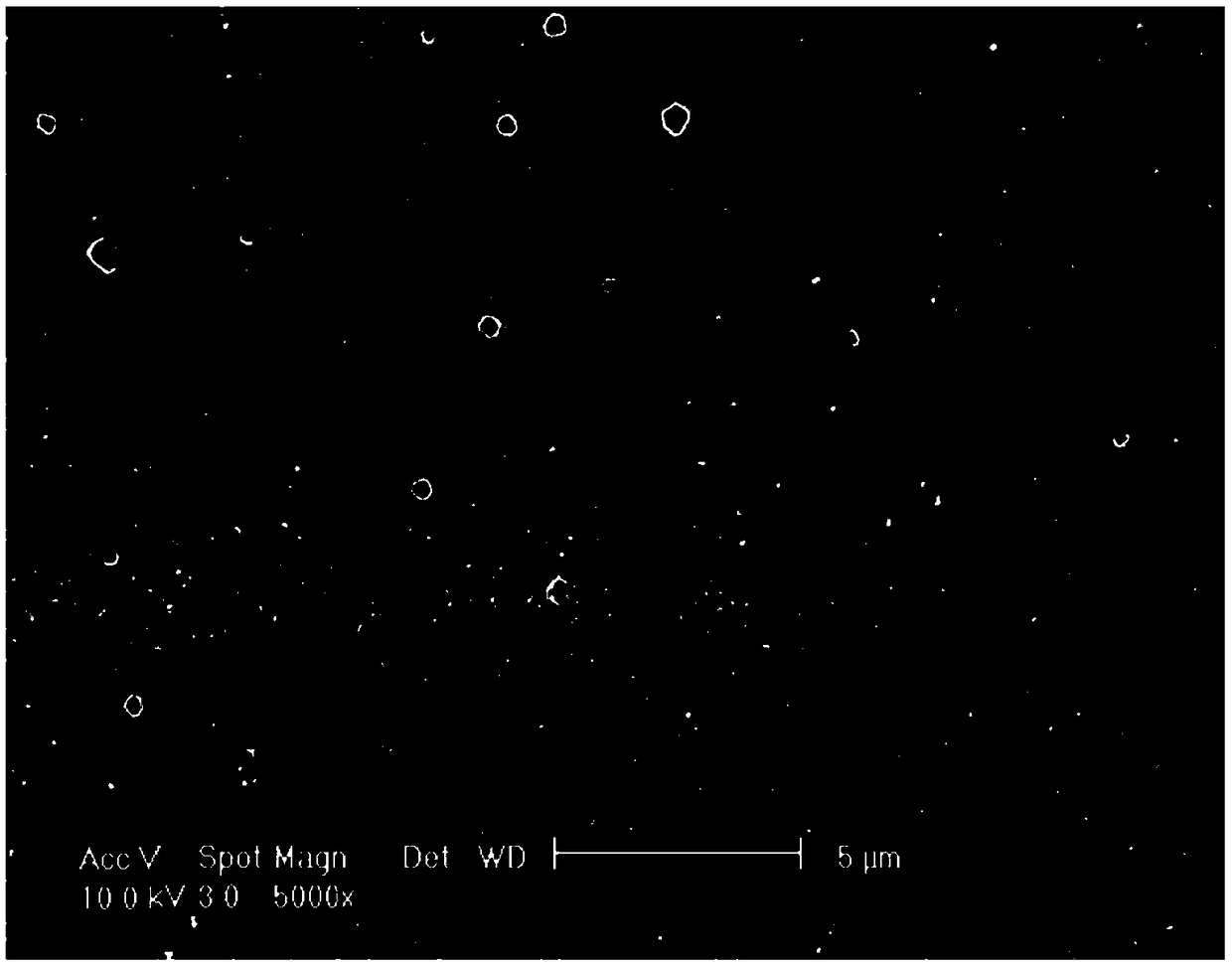

PendingCN111673284AChange surface topographyUnique surface topographyLaser beam welding apparatusMicro nanoLaser processing

The invention discloses a method for improving the wetting and spreading performance of a reaction wetting system material. The method comprises the following steps that the surface of a stainless steel base plate is scanned and processed by adopting an ultrafast laser processing technology to obtain a micro-nano stripe texture of which the stripe average width is 1.2-1.4 microns and the stripe average spacing is 1.4-1.6 microns; and the wetting angle of the same brazing filler metal on the scanned and processed stainless steel base plate is 0.9 degrees - 3.3 degrees smaller than the wetting angle of the same brazing filler metal on an unprocessed stainless steel base plate. According to the method, microtexture processing is carried out on the surface of the reaction wetting system material through ultrafast laser, the surface appearance of the reaction wetting system material is changed, the surface roughness is changed, the unique morphology of the micro-nano stripe texture is obtained, and the unique morphology of the micro-nano stripe texture can greatly enhance the capillary action in the brazing filler metal wetting and spreading process, so that the wetting and spreading power of the brazing filler metal on the surface of the reaction wetting system material is improved, the brazing filler metal reacts with the base plate more sufficiently, and the application prospectis great.

Owner:SHANGHAI UNIV OF ENG SCI

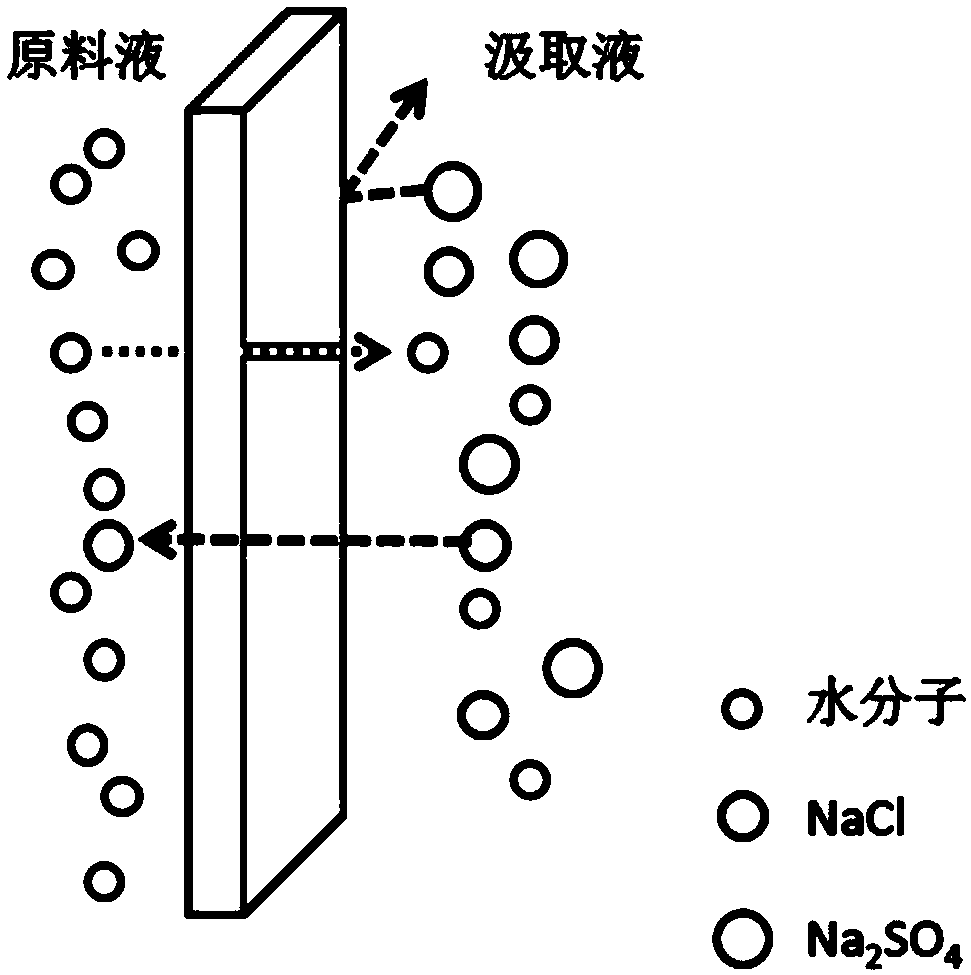

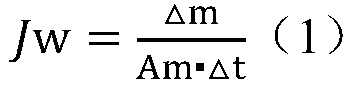

Compound forward osmosis membrane with separation function and preparation method thereof

InactiveCN109012241AAchieve enrichmentChange surface topographySemi-permeable membranesSaline waterChemical physics

The invention discloses a forward osmosis membrane with a separation function. The special forward osmosis membrane with the multivalent separation characteristic is prepared on a polymer based membrane, so that the forward osmosis flux is increased, and separation on multivalent ions in a draw solution is simultaneously achieved; thus, monovalent ions can permeate through the membrane to enter araw material solution, and the multivalent ions cannot permeate through the membrane. The special forward osmosis membrane has special application value in concentrating strong brine and changing a proportion among different saline ions in the strong brine. The special forward osmosis membrane disclosed by the invention not only has a concentrating function, but also has a function of adjusting the proportion among saline components in water. As industrial wastewater zero release projects are propelled in China, the special forward osmosis membrane with the multivalent separation function hasa wide application prospect.

Owner:中煤能源研究院有限责任公司

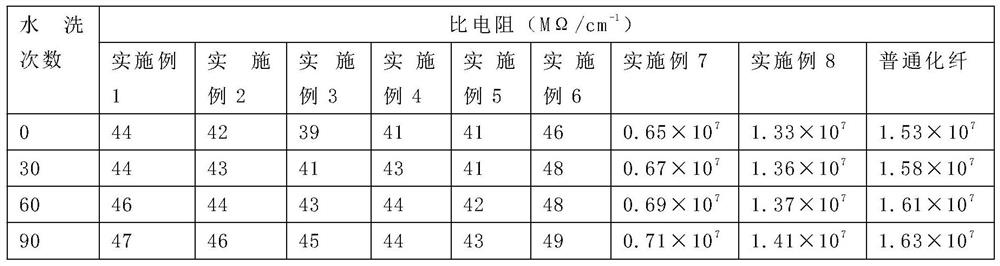

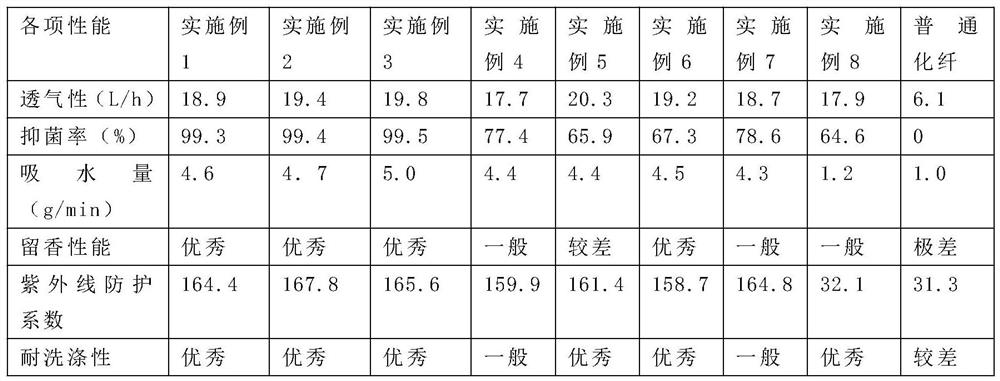

Uvioresistant and anti-static chemical fiber yarn and preparation method thereof

InactiveCN111850764ALarge specific surface areaChange surface topographyBiochemical fibre treatmentLight resistant fibresFiberYarn

The invention discloses a uvioresistant and anti-static chemical fiber yarn and a preparation method thereof. The preparation method comprises the following steps: at first, loading a plurality of silver ions on a modified metal organic framework, blending with spinning solution to obtain chemical fiber, grafting AESO outside the chemical fiber, and carrying out copolymerization on modified microspheres to obtain a chemical fiber inner layer; manufacturing modified microspheres by taking methyl methacrylate as a wall material and taking hexadecane, plant essence and beta-1,4-polyglucosamine ascore materials; and adding an ultraviolet absorbent and dopamine in absorbing film slurry, and soaking the fiber inner layer in the absorbing film slurry for 20-30 hours, and taking the fiber inner layer out. Through synergistic effect of the modified metal organic framework, the modified microspheres, the absorbing film slurry and the like, the problems about hydroscopicity, antibacterial property, fragrance retention property and washability of common chemical fiber fabric are improved to a greater degree, and higher practicality is improved.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

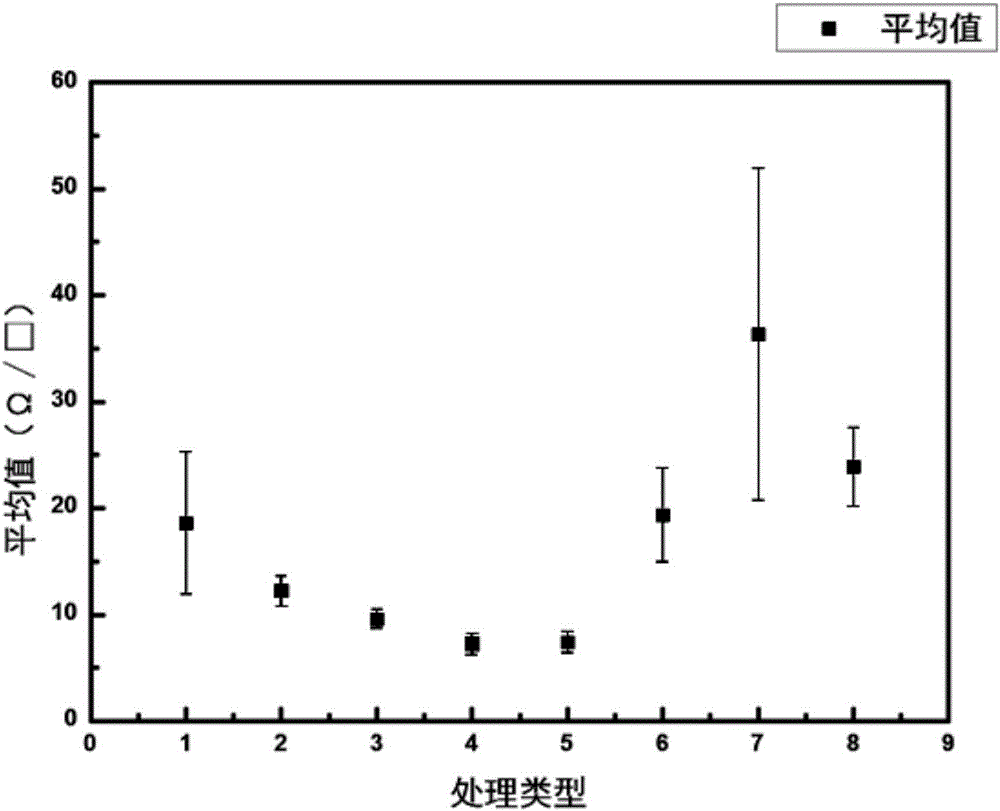

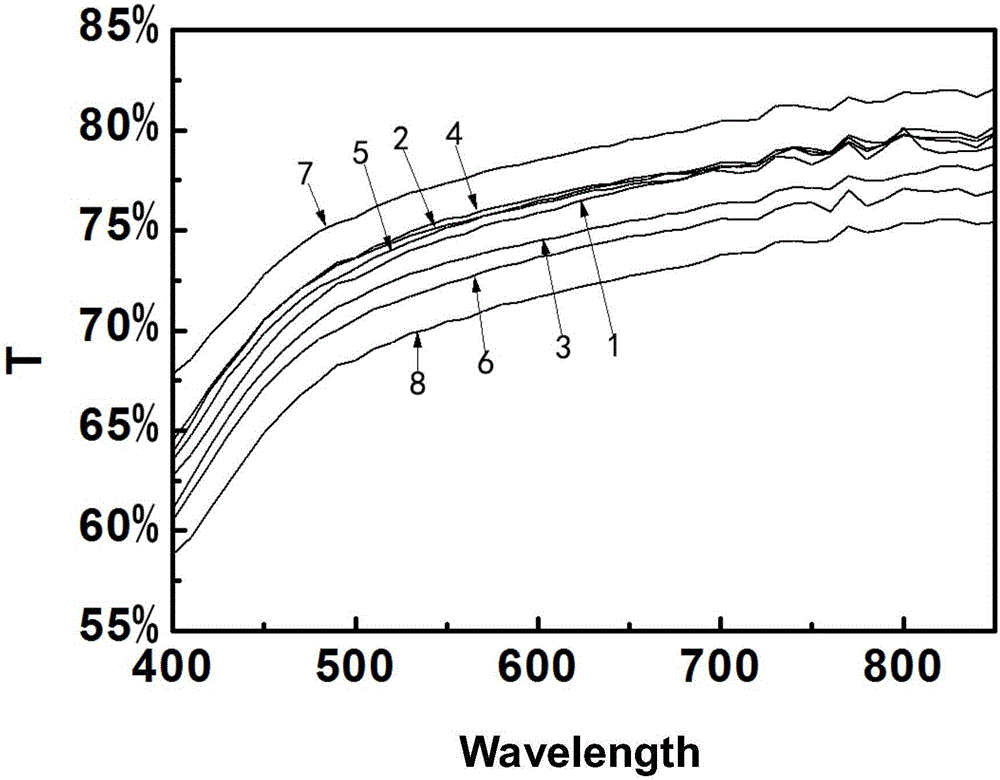

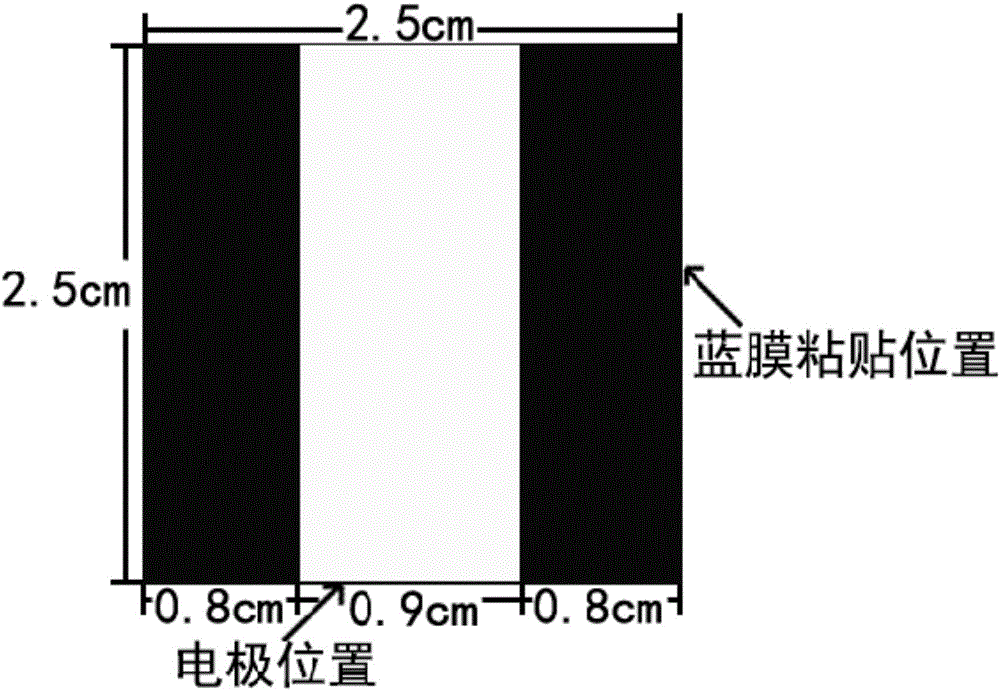

Method of adopting plasma technology to treat silver nanowires and transferring through substrate to prepare organic photoelectronic device flexible electrode

InactiveCN106299160AChange surface topographyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPlasma technologySpins

The invention discloses a method of adopting plasma technology to treat silver nanowires and transferring through a substrate to prepare an organic photoelectronic device flexible electrode and belongs to the technical field of organic photoelectronics. The method includes: preparing a silver nanowire solution, spin-coating the silver nanowires on a silicon wafer to obtain a silver nanowire thin film, and treating the silver nanowire thin film through plasma, wherein PVP on the surfaces of the nanowires is removed, and surface appearance of the silver nanowires is changed; spin-coating photo-crosslinking polymer on the silicon wafer to complete cover the silver nanowire thin film, using an ultraviolet lamp to irradiate, and using a scalpel to separate the photo-crosslinking polymer from the silicon substrate to finally obtain a high-conductivity silver nanowire transparent electrode. By the method, surface roughness of the silver nanowire thin film is lowered while surface uniformity of the same is improved, the OLED flexible electrode obtained by the method is better than electrodes obtained through conventional thermal treatment methods in conductivity, and more time is saved.

Owner:JILIN UNIV

Method for preparing hydrophilic titanium dioxide nano film

The invention relates to a preparation method of a hydrophilic titanium dioxide nano-film, which is characterized in that ammonia is added during the preparation process of the titanium dioxide nano-film. The method comprises the following steps: (1) raw material proportioning; (2) burdening: the raw materials proportioning is selected and a certain amount of the materials are weighted to be made into sol; (3) film painting: the sol is painted on the surface of hardened substance; (4) thermal treatment: the sintering is carried out under the temperature of 600 DEG C to 1000 DEG C with the sintering time of 0.5-3 hours so as to obtain the hydrophilic titanium dioxide nano-film. The invention changes the structure, surface morphology and surface defect degree of nanometer semiconductors so as to improve the visible light absorption within the forbidden bandwidth; in addition, the test indicates that the hydrophilicity of the titanium dioxide nano-film is significantly improved.

Owner:EAST CHINA UNIV OF SCI & TECH

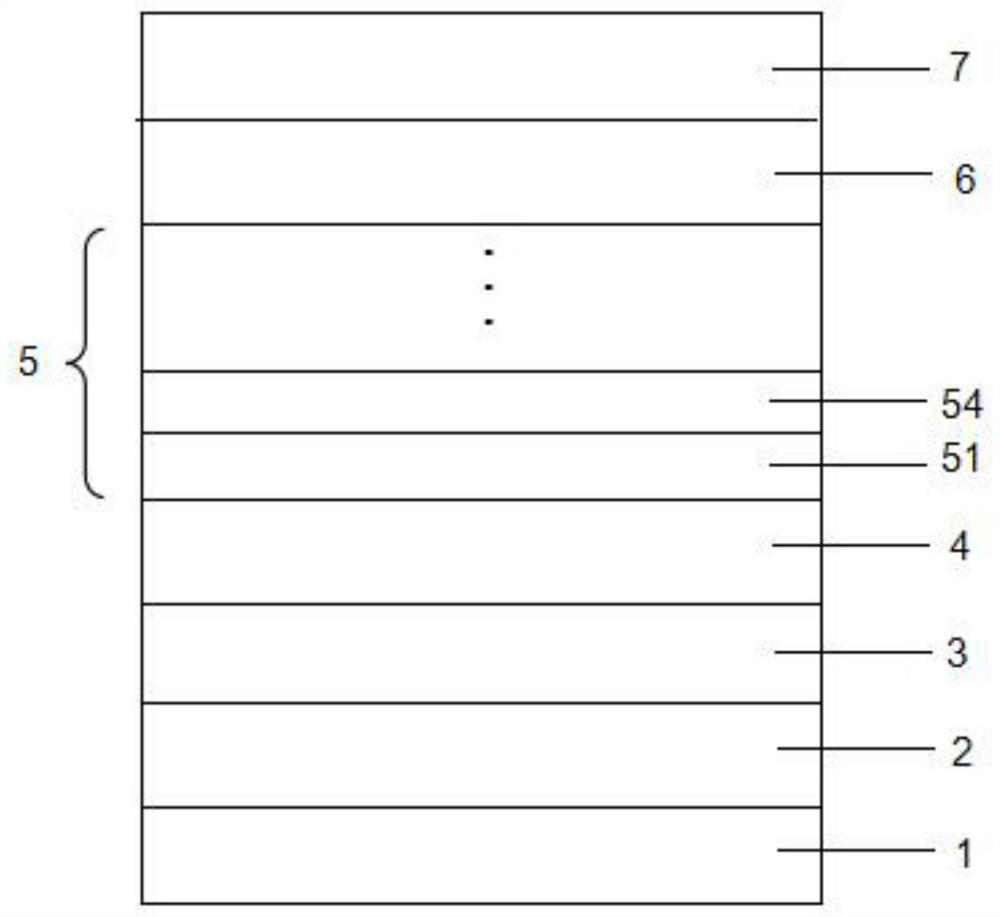

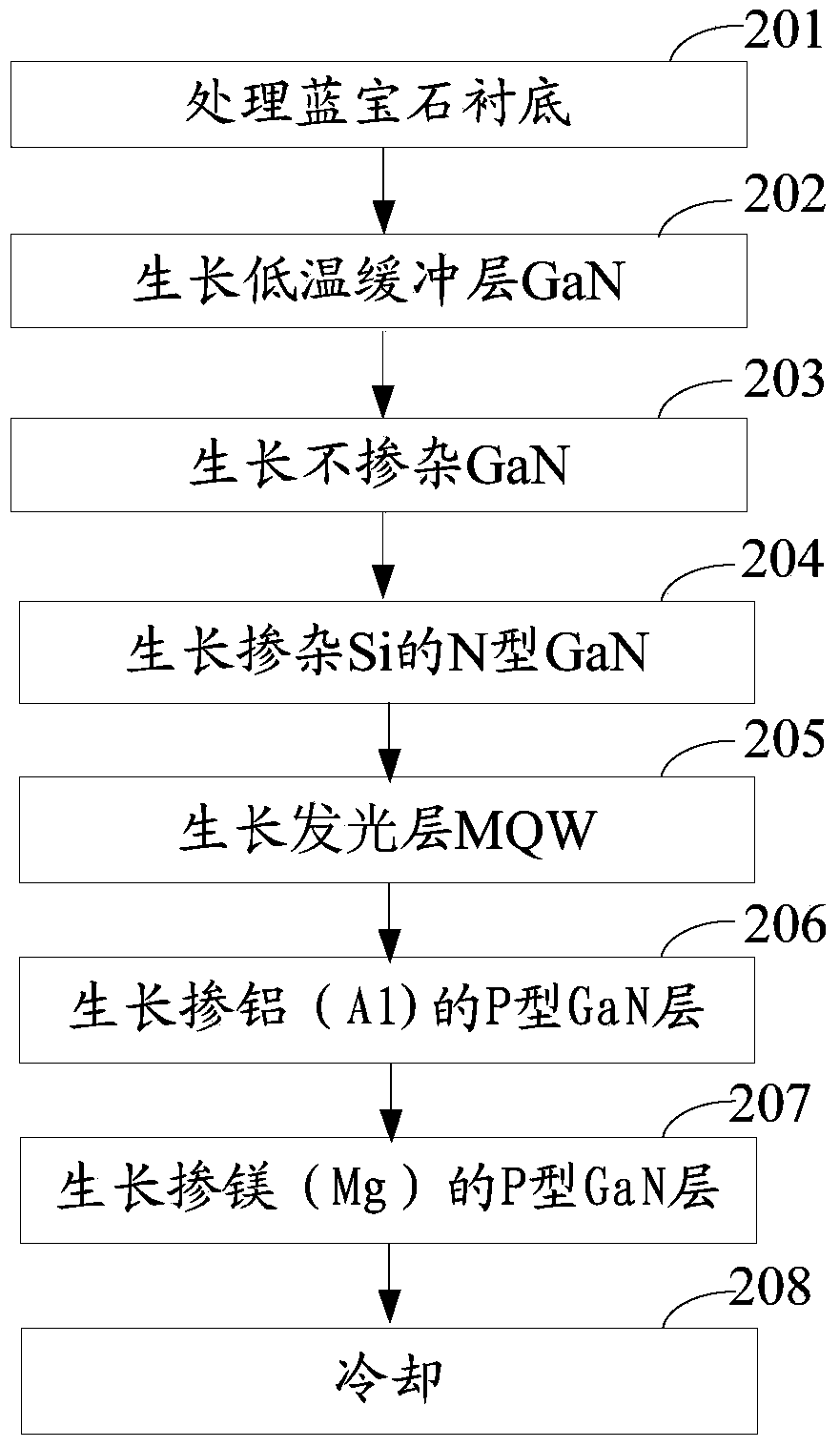

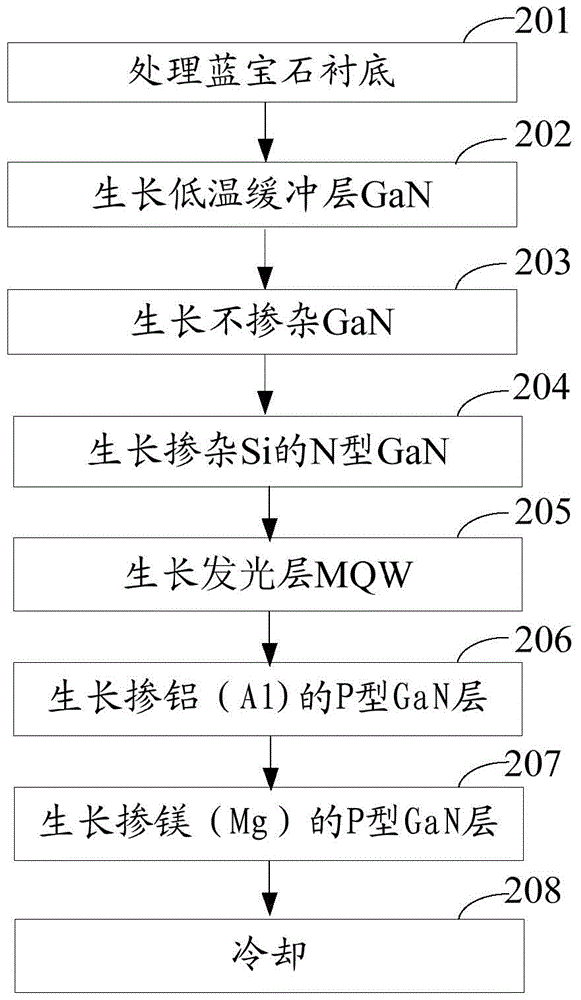

LED epitaxial growth method

PendingCN112687770APromote three-dimensional growthIncrease the number of quantum dotsPolycrystalline material growthAfter-treatment detailsElectron blocking layerMaterials science

The invention discloses an LED epitaxial growth method, which sequentially comprises the steps of processing a substrate, growing a low-temperature GaN buffer layer, growing a non-doped GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing an AlGaN electronic barrier layer, growing a Mg-doped P-type GaN layer, and cooling. Wherein the growth of the multi-quantum well layer sequentially comprises the steps of In-doped pretreatment, InGaN well layer growth, Ga2O3 pre-growth, Ga2O3 layer growth, annealing treatment, GaN gradient layer growth and GaN barrier layer growth. According to the method, the problems of low quantum well growth quality and low quantum well radiation recombination efficiency in the existing LED epitaxial growth method are solved, so that the luminous efficiency of the LED is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

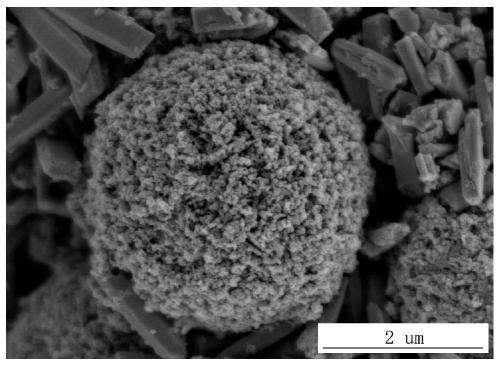

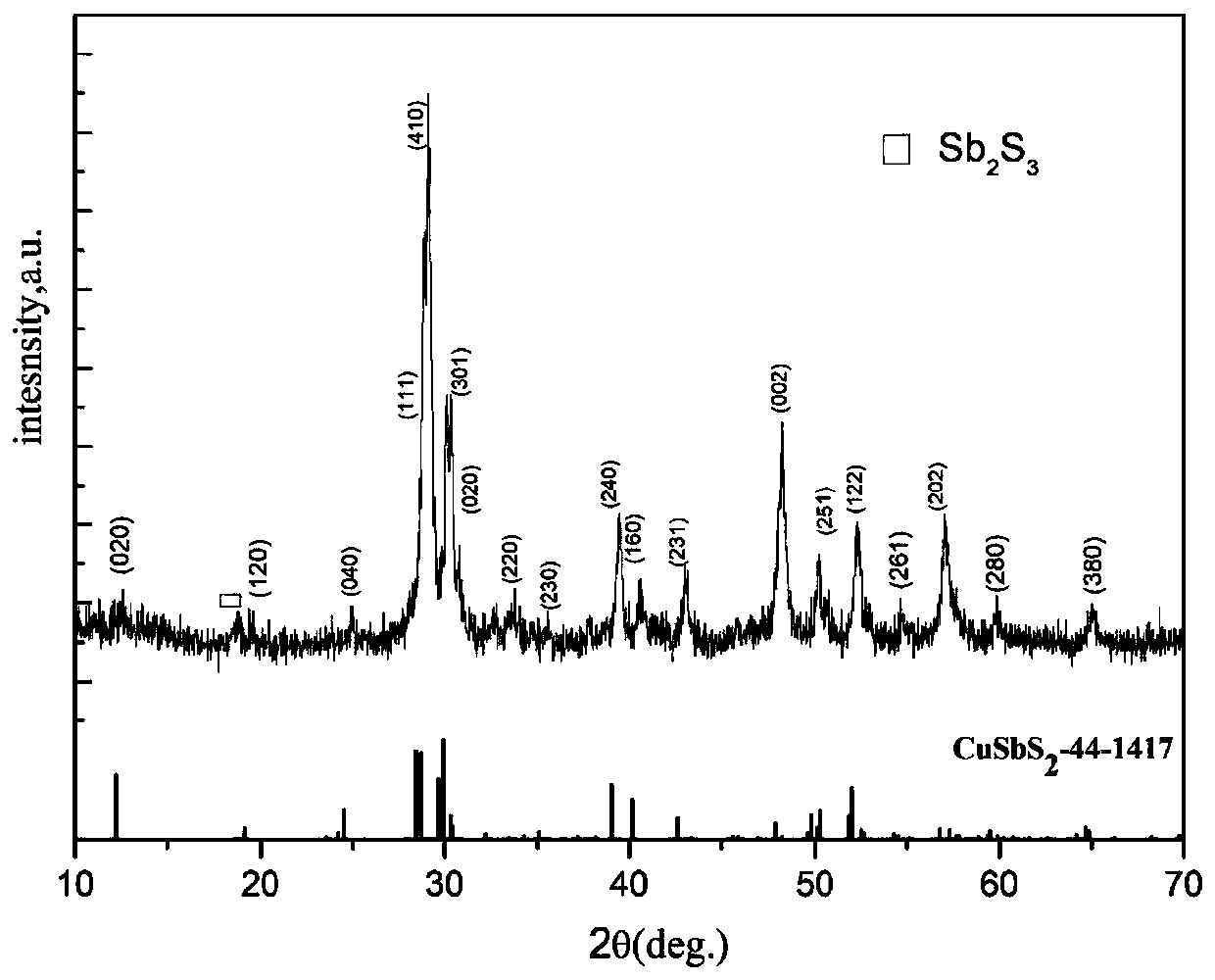

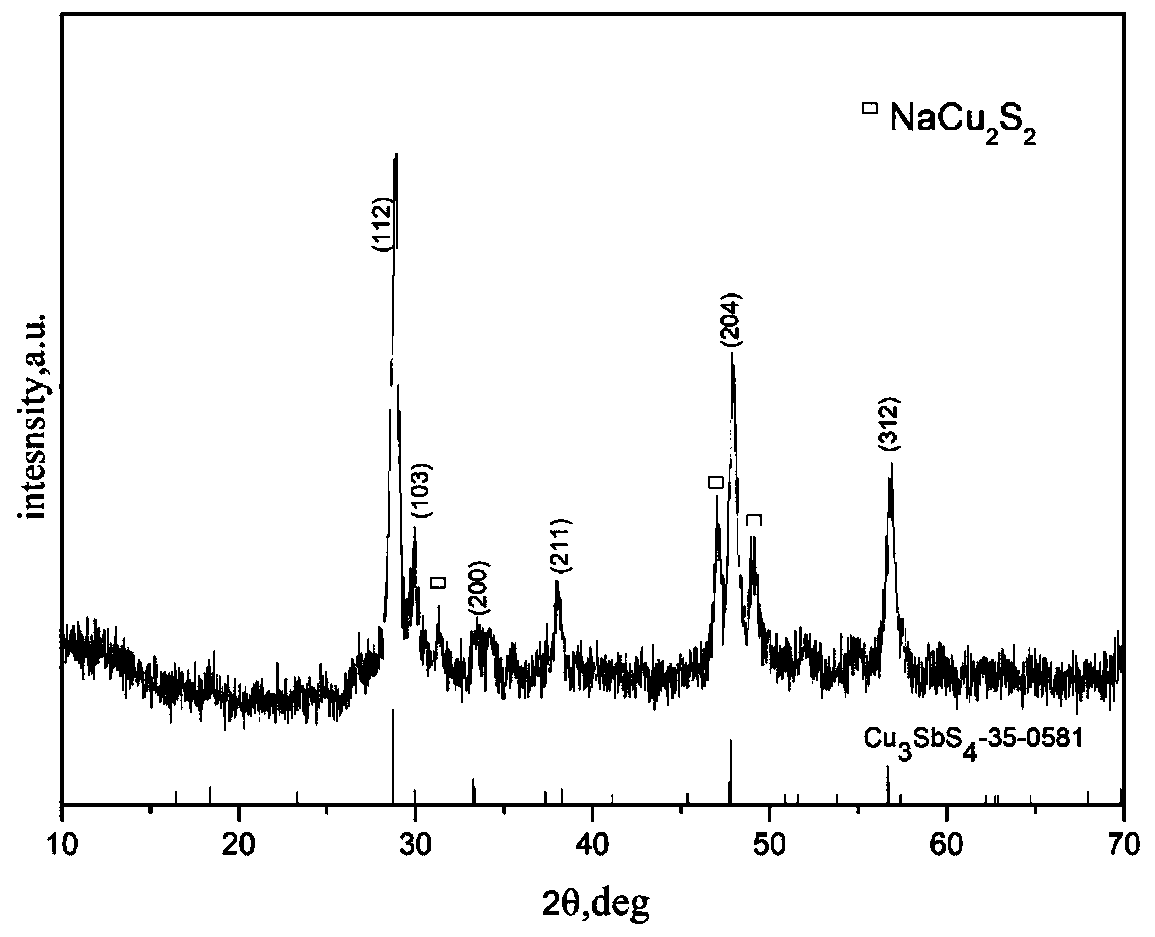

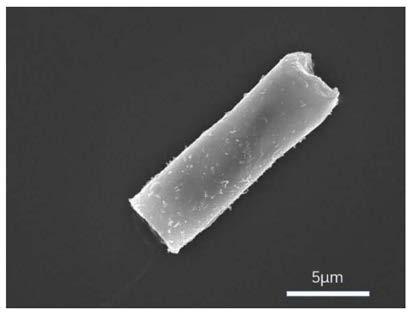

CuSbS2 nanoparticle and preparing method and application thereof

ActiveCN110203971ASingle phaseGood crystallinityPhysical/chemical process catalystsAntimony compoundsSolventNanometre

The invention discloses a preparing method and application of a CuSbS2 nanoparticle. The particle is an agglomerate with a regular square rod-shaped structure. The preparing method comprises the stepsthat copper salt, antimonic salt and a sulfocompound are dissolved in a solvent, and then a precursor solution is prepared after the materials are fully dissolved; a microwave method is adopted for preparing the CuSbS2 nanoparticle; a Na2S solution is added into the obtained CuSbS2 nanoparticle for removing impurity phases. According to the CuSbS2 nanoparticle and the preparing method and application thereof, by regulating preparing technologies and parameters, the purpose of regulating the crystal appearance is achieved, then the ideal crystal surface appearance is prepared, the photocatalytic performance of the CuSbS2 nanoparticle is improved, and the CuSbS2 nanoparticle can increase the degradation rate of rhodamine B under 7 hours of illumination by an xenon lamp of 500 W to 96% from19%.

Owner:JINLING INST OF TECH

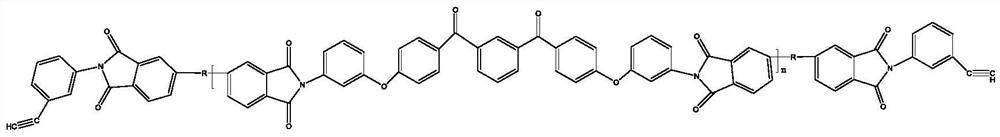

Supercapacitor electrode material and preparation method thereof

InactiveCN112374544AImprove conductivityImprove defectsCarbon compoundsHybrid capacitor electrodesPorous carbonPotassium hydroxide

The invention discloses a supercapacitor electrode material and a preparation method thereof. The preparation method comprises the following steps of: by taking potassium permanganate as a reducing agent and manganese sulfate as a manganese source, preparing sea urchin-shaped nano alpha-MnO2 by adopting a hydrothermal method, then performing hydroxylation modification, grafting polyimide resin tothe sea urchin-shaped nano alpha-MnO2 by adopting a click chemistry mode to obtain the sea urchin-shaped nano alpha-MnO2 grafted polyimide resin, and carrying out high-temperature activation treatmenton the sea urchin-shaped nanometer alpha-MnO2 grafted polyimide resin by adopting potassium hydroxide to obtain the sea urchin-shaped nanometer alpha-MnO2 in-situ modified porous carbon supercapacitor electrode material. By using the electrode material, the defects of MnO2 crystal lattices are improved, the conductivity and stability of electrons are improved, protons and the electrons can freelyflow among the crystal lattices, rapid transmission of ions and the electrons of an interface is guaranteed, the charge transfer path can be shortened, more active sites are provided for charge storage, the electron trapping and transfer capacity is enhanced, and the mechanical stability is also improved.

Owner:犀望新能源科技(昆山)有限公司

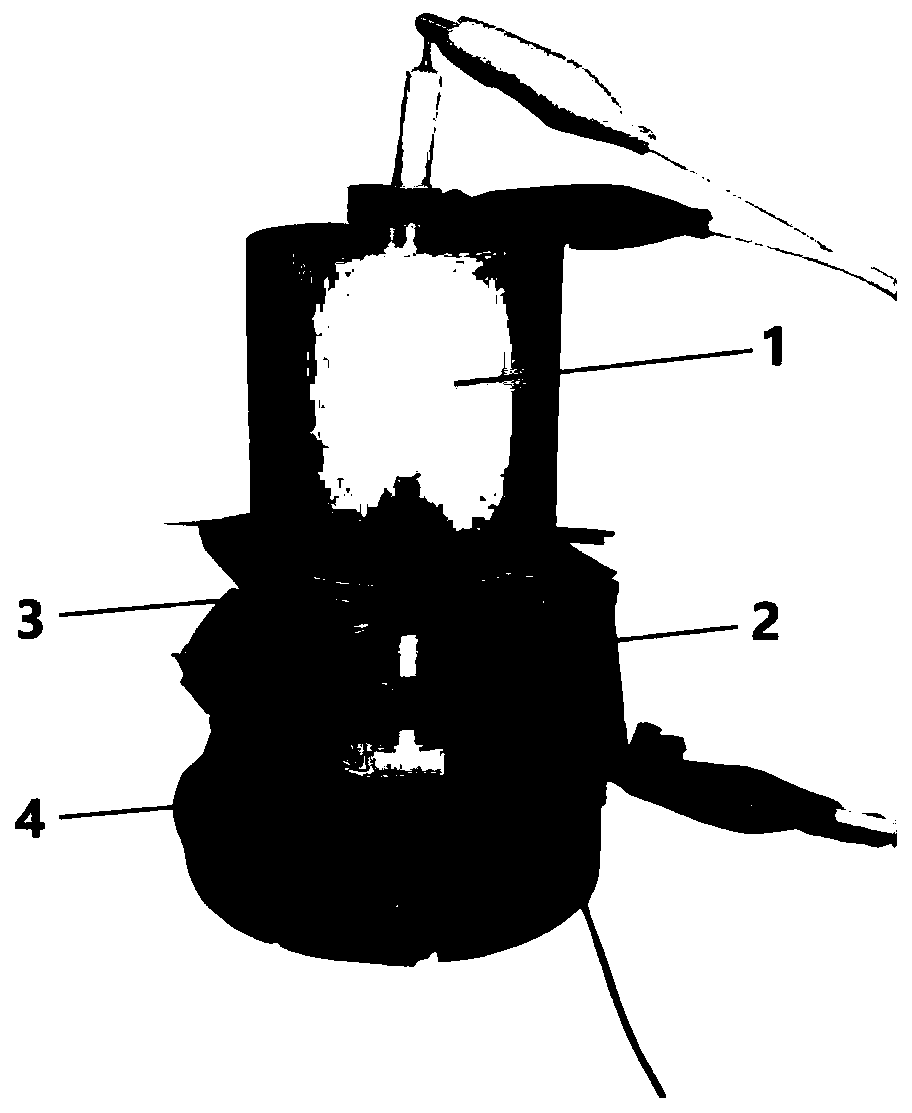

Biocompatible iron-manganese dioxide system micro-nano motor and preparation method thereof

PendingCN111082705AChange elemental compositionChange surface topographyDecorative surface effectsChemical vapor deposition coatingMicro nanoNanomotor

The invention discloses a biocompatible iron-manganese dioxide system micro-nano motor and a preparation method thereof, belongs to the field of micro-motor preparation and application, and can greatly reduce the manganese content in the micro-nano motor and improve the biocompatibility of the micro-nano motor under the condition of not reducing the movement speed of the micro-nano motor. According to the invention, the preparation method combines electrochemical deposition and an ultrasonic field, and comprises the steps of firstly, supporting an outer polyethylene dioxythiophene (PEDOT) layer and a middle Fe layer through electrochemical deposition, and then introducing an ultrasonic field while electrochemically depositing an inner MnO2 layer. The obtained micro-nano motor is of a three-layer hollow tubular structure, the content of manganese is reduced from 17.68% to 4.71%-11.33%, but the movement speed can still reach 300-700[mu]m / s, so that the manganese content of the micro-nanomotor is greatly reduced under the condition that the movement speed of the micro-nano motor is not reduced, and the biocompatibility of the micro-nano motor is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Washing-resistant rubber lining for cyclone and preparation method thereof

InactiveCN108148230AEasy to replaceExtended service lifeReversed direction vortexPolymer scienceNano al2o3

The invention discloses a washing-resistant rubber lining for a cyclone and a preparation method thereof. The rubber lining is prepared by taking the nitrile rubber and butadiene rubber as matrix, taking polyurethane cellosilk, carbon fiber and polyamide fiber as the skeleton fiber, taking the sepiolite powder, carbon black and nano-aluminum oxide powder as filler, taking a aluminic ester couplingagent, liquid coumarone resin and modifying additive as the additive, and mixing the raw materials with anti-wearing auxiliary, a sulfurizing agent BPO and DM, wherein the anti-wearing auxiliary is prepared by mixing nitrile rubber powder, dioctyl phthalate, aluminium oxide, succinic acid and KH580; the modifying additive is prepared by mixing KH570, nanometer aluminum hydroxide, acetone and barium hydroxide. By arranging the rubber lining on the inner wall of the cyclone, thus the ore pulp directly impacts on the rubber lining, and the aim of protecting the inner wall of the cyclone is achieved; the rubber lining is easy to change after being damaged, and the service life of the cyclone is greatly prolonged.

Owner:北京中选耐磨设备有限公司平顶山分公司

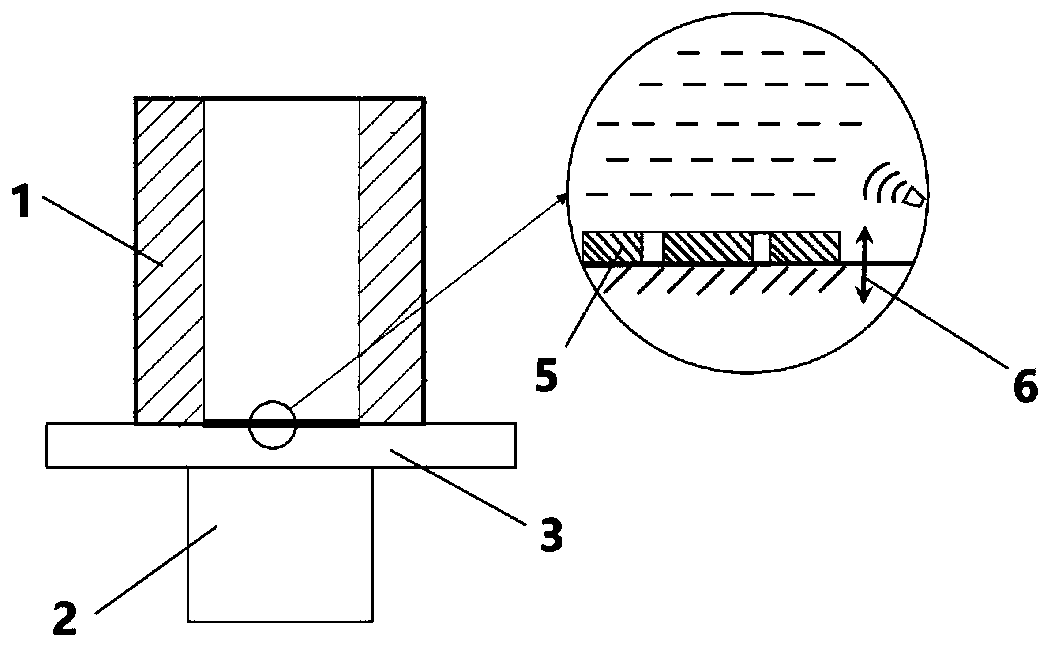

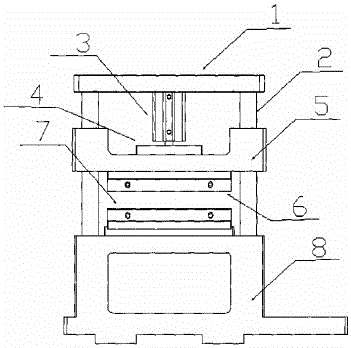

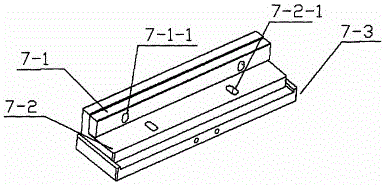

Bus bar bending mechanism

The invention relates to a bus bar bending mechanism. The bus bar bending mechanism is composed of a fixed plate, guide rods, an air cylinder, a transition plate, a connecting plate, an upper pressing block, a lower pressing block and a supporting plate. Micro protrusions in array distribution are arranged on the whole lower surface of the upper pressing block, and pits corresponding to the micro protrusions of the upper pressing block are formed in the whole upper surface of the lower pressing block. After a bus bar is in place through the bending mechanism, the upper pressing block presses the bus bar downwards to complete bending motion. The height of a cushion block on the pressing block can be adjusted freely, the production requirements of various solar battery cells of different specifications can be met, and meanwhile the light reflection characteristic and attractiveness of the bus bar can be improved.

Owner:CHENGDU JUZHI IND DESIGN

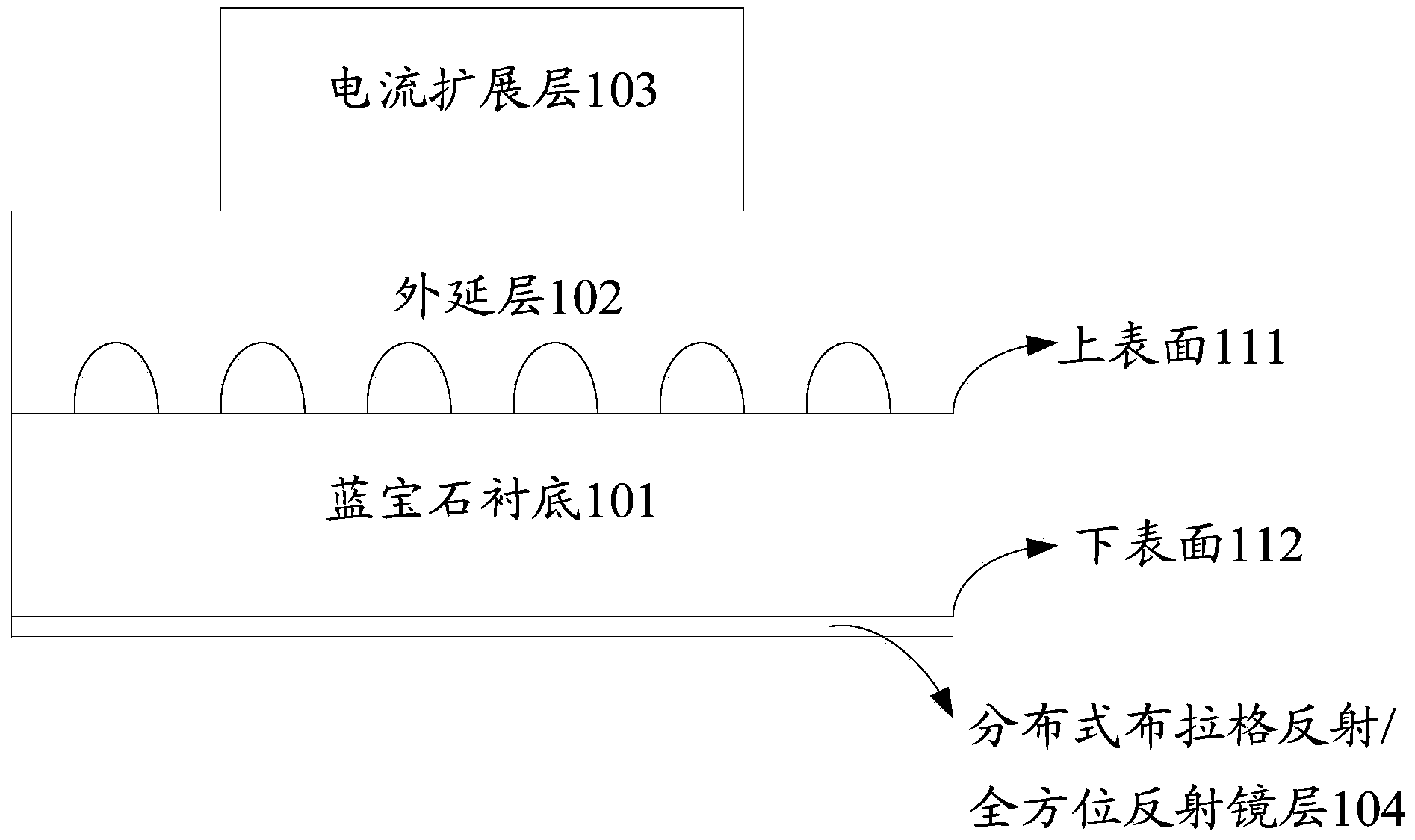

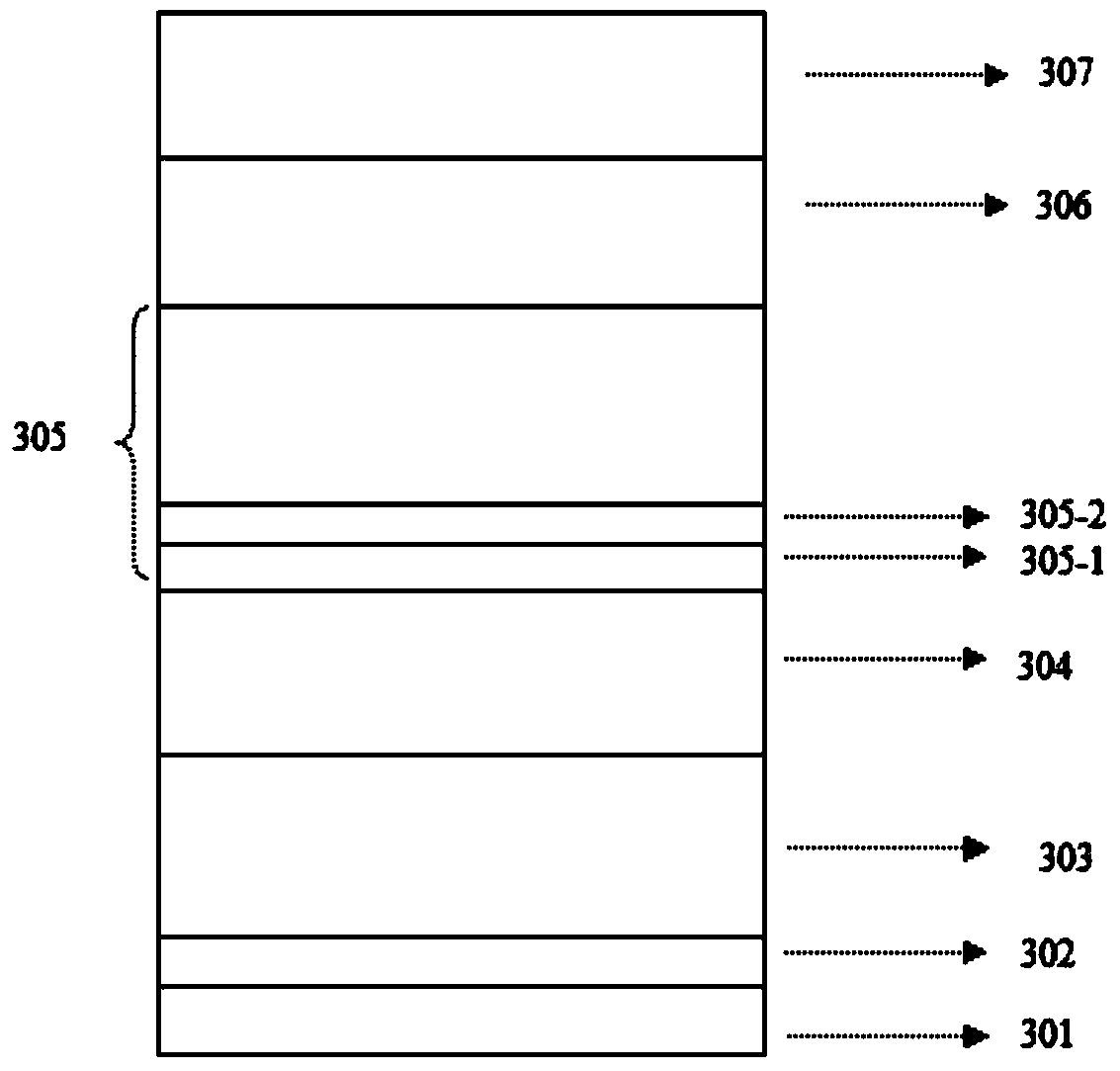

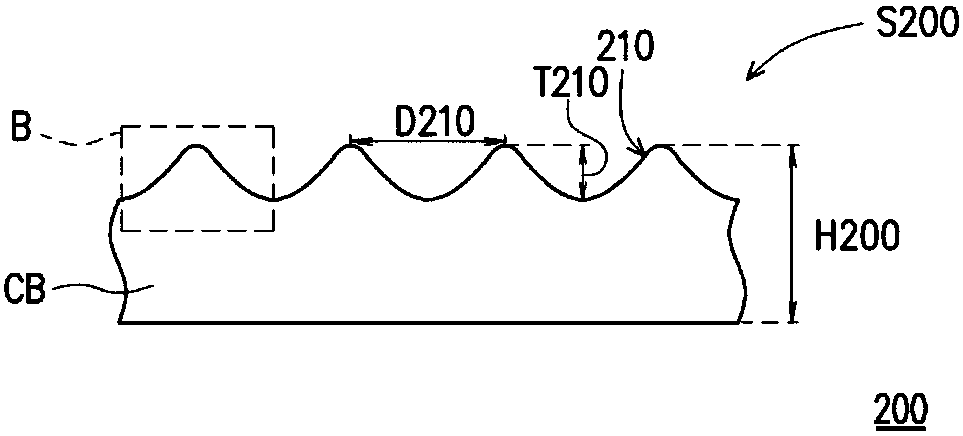

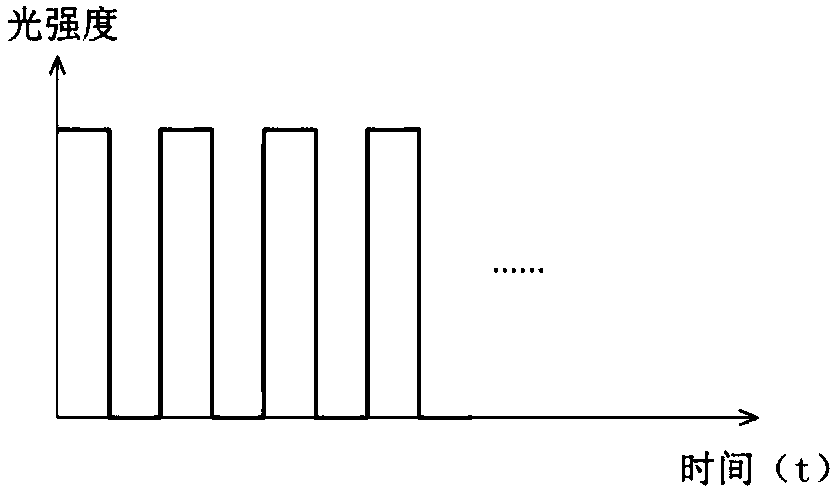

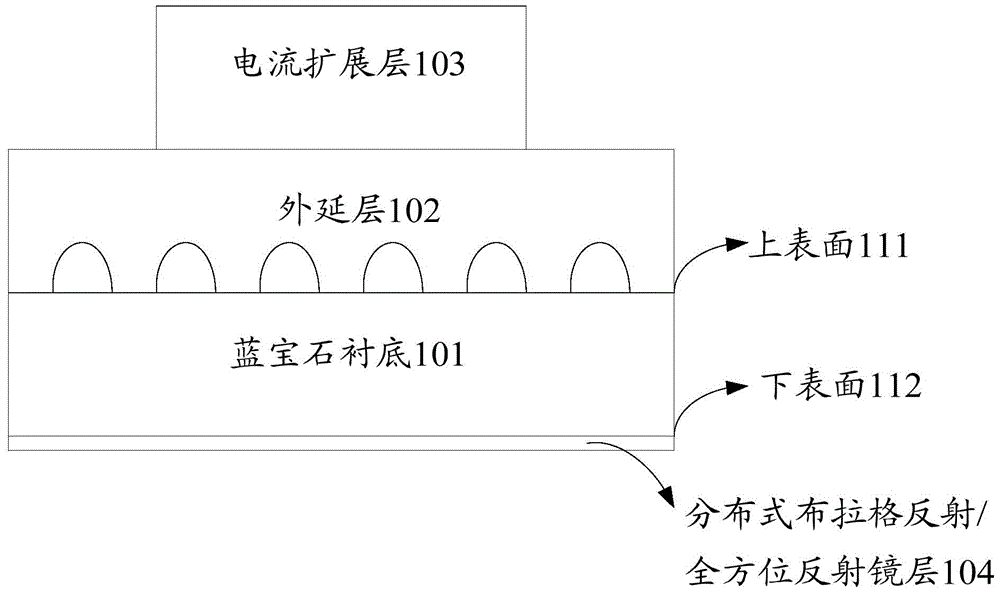

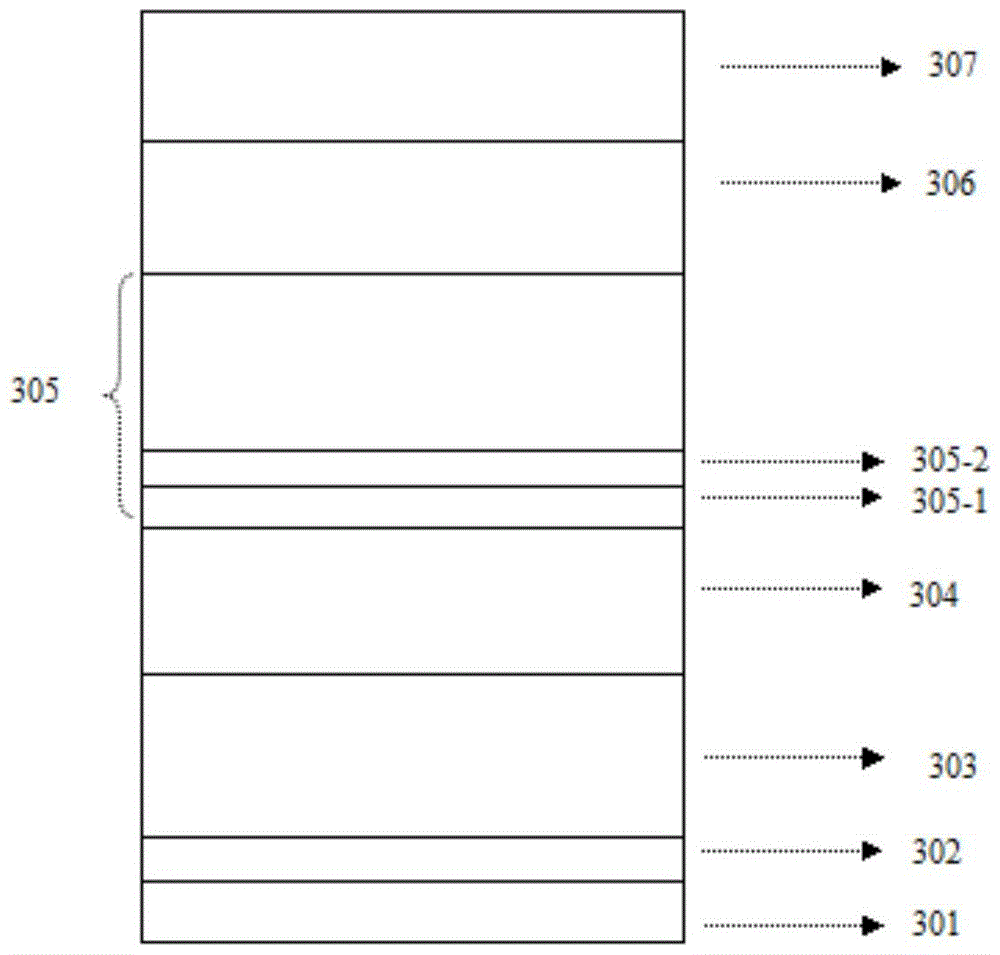

Epitaxial wafer of light emitting diode and manufacturing method of epitaxial wafer of light emitting diode

ActiveCN104269475AImprove surface mobilityChange surface topographySemiconductor devicesPhysicsEpiwafer

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method of the epitaxial wafer of the light emitting diode. The manufacturing method relates to a low-temperature buffer layer GaN, an undoped GaN layer, a Si-doped N-type GaN layer, a light emitting layer, a P-type GaN layer and a high-temperature P-type GaN layer, wherein the undoped GaN layer is located on the low-temperature buffer layer GaN, the Si-doped N-type GaN layer is located on the undoped GaN layer, the light emitting layer is located on the Si-doped N-type GaN layer, the P-type GaN layer is located on the light emitting layer, and the high-temperature P-type GaN layer is located on the P-type GaN layer. The light emitting layer comprises InGaN layers and GaN layers in a plurality of periods, and the InGaN layer in each period grows through time slicing. By means of the epitaxial wafer of the light emitting diode and the manufacturing method of the epitaxial wafer of the light emitting diode, InGaN of the light emitting layer grows in a subsection mode, the feature of the surface can be changed, the surface migration rate of In atoms is improved, and the light emitting rate of the light emitting diode is accordingly improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

A kind of tco thin film and preparation method thereof

ActiveCN103646972BChange surface topographyIncreased interface conductivityFinal product manufactureChemical vapor deposition coatingInfraredDopant

The invention discloses a TCO (transparent conducting oxide) thin film and a preparation method thereof. The TCO thin film comprises three zinc oxide thin film layers containing dopants from top to bottom, wherein the atom ratios of dopants in the zinc oxide thin film layer are different in zinc oxide. In the preparation method, dopant gas flows are adjusted in the thin film growing process to form a multiple-layer structure and modulate a surface microstructure and the optical performance of the TCO thin film, wherein the middle and an interface of the multiple-layer structure are different in dosage concentration. The light trapping effect of the film and the optical transmittance of a near-infrared light region can be greatly improved while good electrical conductivity of the TCO film and the interface of the film are maintained, a haze average value of a 400-1100nm waveband is improved from 27.3% to 34.9 %, the transmittance of a 700-2000nm near-infrared waveband is improved from 76% to 77.7%, and the photoelectric conversion efficiency of batteries is improved.

Owner:湖南共创光伏科技有限公司

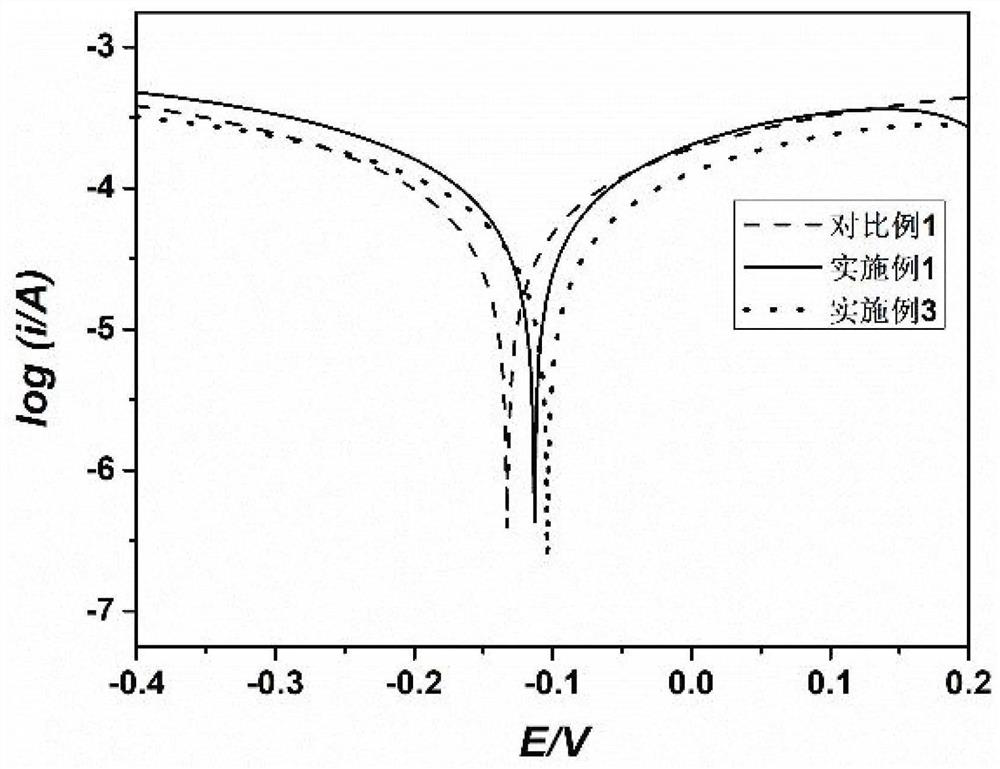

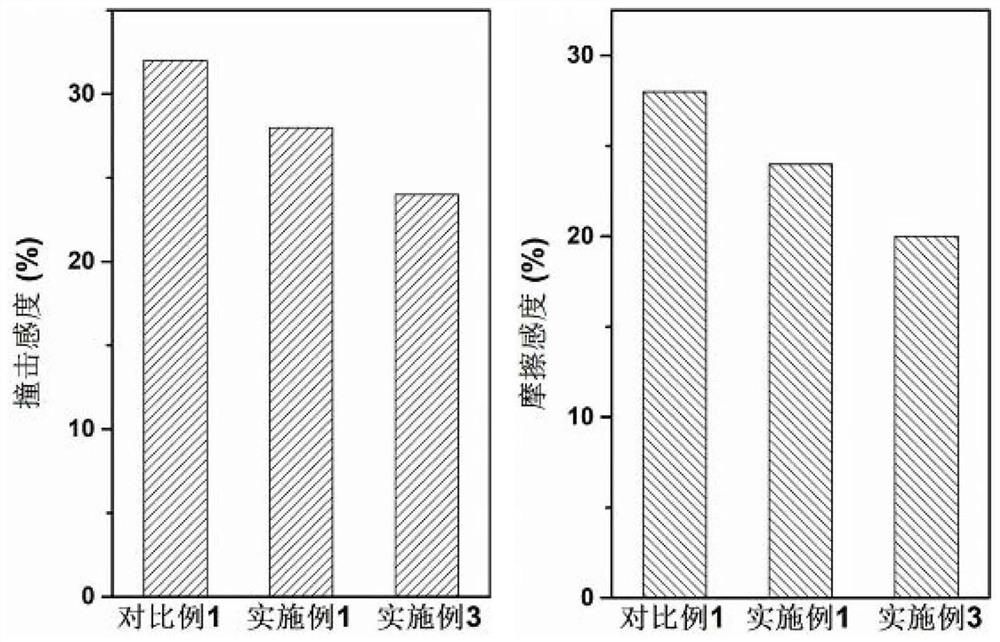

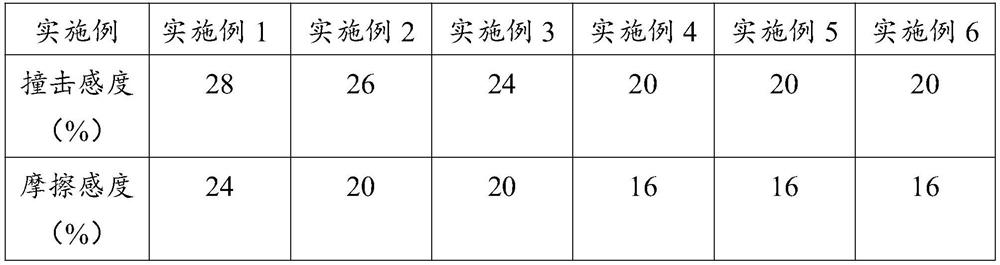

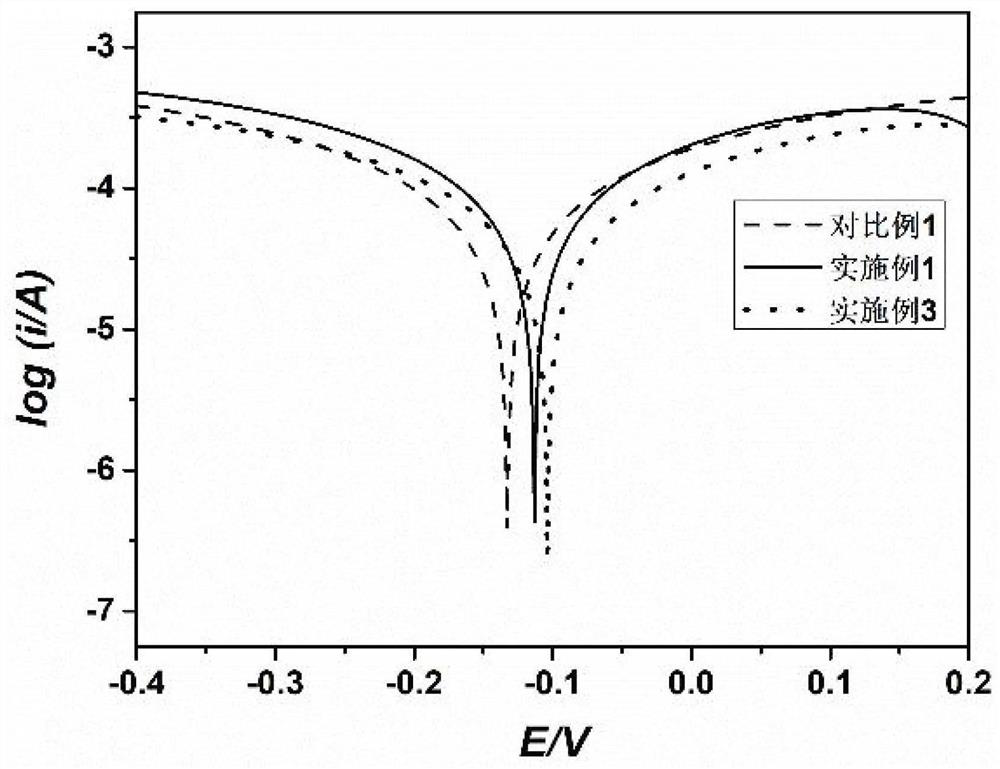

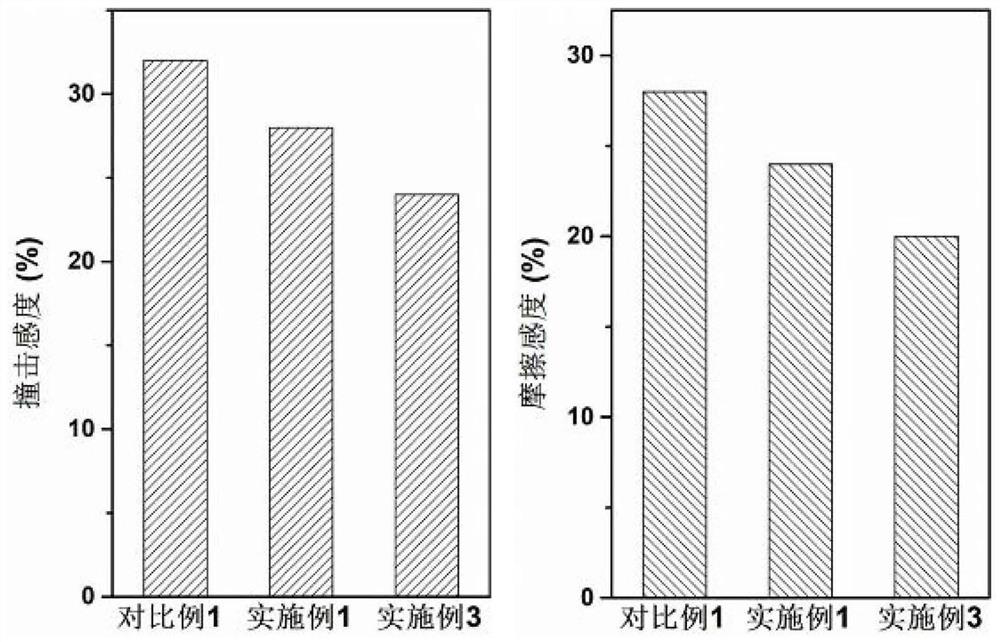

Metal corrosion resistant insensitive ammunition and preparation method thereof

ActiveCN113916066AImprove conductivityImproves metal corrosion resistanceVibration crystallizationAmmunitionNitrotriazoloneInsensitive munition

The invention relates to the technical field of energetic materials, and particularly discloses a metal corrosion resistant insensitive ammunition and a preparation method thereof. The metal corrosion resistant insensitive ammunition is prepared from, by weight, 0-10% of layered MXene and 90-100% of 3-nitro-1, 2, 4-triazole-5-ketone. The preparation method comprises the following steps of firstly, etching an aluminum layer in an MAX phase with hydrofluoric acid to obtain layered MXene, dissolving the layered MXene and NTO raw materials in absolute ethyl alcohol in proportion, and finally, carrying out evaporative crystallization to obtain the metal corrosion resistant insensitive ammunition. According to the metal corrosion resistant insensitive ammunition, the metal corrosion resistance of NTO is enhanced, and the impact sensitivity and friction sensitivity of NTO are further reduced; and the preparation method is simple, the MAX phase is etched by hydrofluoric acid to obtain conductive MXenes, then the MXenes and NTO are prepared by a recrystallization method, and the preparation method has practical application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

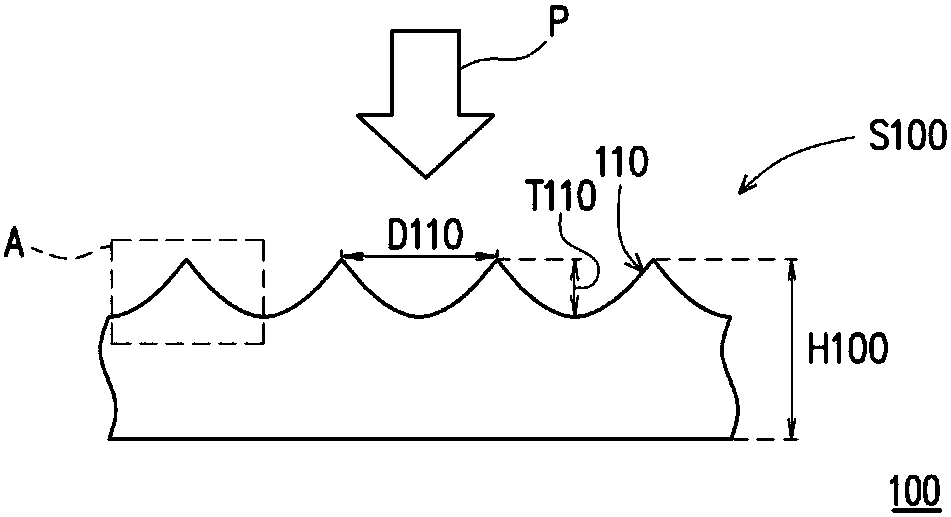

Anti-glare wear-resistant cover plate and manufacturing method thereof

InactiveCN108693573AHigh hardnessChange surface topographyOptical elementsWear resistantMechanical engineering

An anti-glare wear-resistant cover plate including a cover plate body and a manufacturing method thereof are provided. The cover plate body has a plurality of microstructures located at an anti-glareside of the cover plate body. The plurality of microstructures has a plurality of top surfaces, wherein a change in slope of a section line of each of the plurality of top surfaces on a reference plane perpendicular to the cover plate body is continuous. A manufacturing method of the anti-glare wear-resistant cover plate is also provided.

Owner:HENGHAO TECH CO LTD

Deposition method capable of enhancing preferred orientation growth of AlN film

ActiveCN101824592BEasy to operateReduce manufacturing costVacuum evaporation coatingSputtering coatingSurface roughnessSurface acoustic wave

Owner:湖南特瑞精密医疗器械有限公司

A light-transmitting alumina substrate and its preparation method

InactiveCN104111486BChange surface topographyReduce the effect of interface reflectionNanoopticsOptical elementsOptical coatingOptical transmittance

The application discloses a light-transmitting aluminum oxide substrate and a preparation method thereof. The light-transmitting aluminum oxide substrate comprises a light-transmitting aluminum oxide base. At least partial part of the area of at least one surface of the light-transmitting aluminum oxide base is coated with a discontinuous optical coating layer which comprises multiple nano-scale growth axial deviation growth bodies formed by first material. The surface profile of the light-transmitting aluminum oxide base can be changed and a refractive index matching layer can be formed by utilizing the discontinuous optical coating layer so that influence of interface reflection can be reduced and light transmittance can be enhanced.

Owner:MECO TECH

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN104269475BImprove surface mobilityChange surface topographySemiconductor devicesLight-emitting diodeSi doped

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method of the epitaxial wafer of the light emitting diode. The manufacturing method relates to a low-temperature buffer layer GaN, an undoped GaN layer, a Si-doped N-type GaN layer, a light emitting layer, a P-type GaN layer and a high-temperature P-type GaN layer, wherein the undoped GaN layer is located on the low-temperature buffer layer GaN, the Si-doped N-type GaN layer is located on the undoped GaN layer, the light emitting layer is located on the Si-doped N-type GaN layer, the P-type GaN layer is located on the light emitting layer, and the high-temperature P-type GaN layer is located on the P-type GaN layer. The light emitting layer comprises InGaN layers and GaN layers in a plurality of periods, and the InGaN layer in each period grows through time slicing. By means of the epitaxial wafer of the light emitting diode and the manufacturing method of the epitaxial wafer of the light emitting diode, InGaN of the light emitting layer grows in a subsection mode, the feature of the surface can be changed, the surface migration rate of In atoms is improved, and the light emitting rate of the light emitting diode is accordingly improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

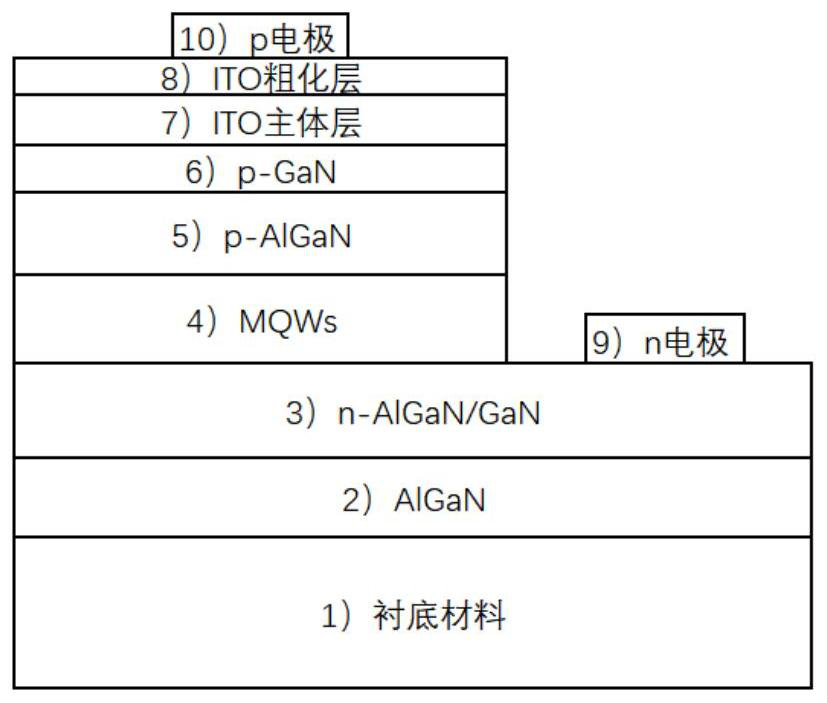

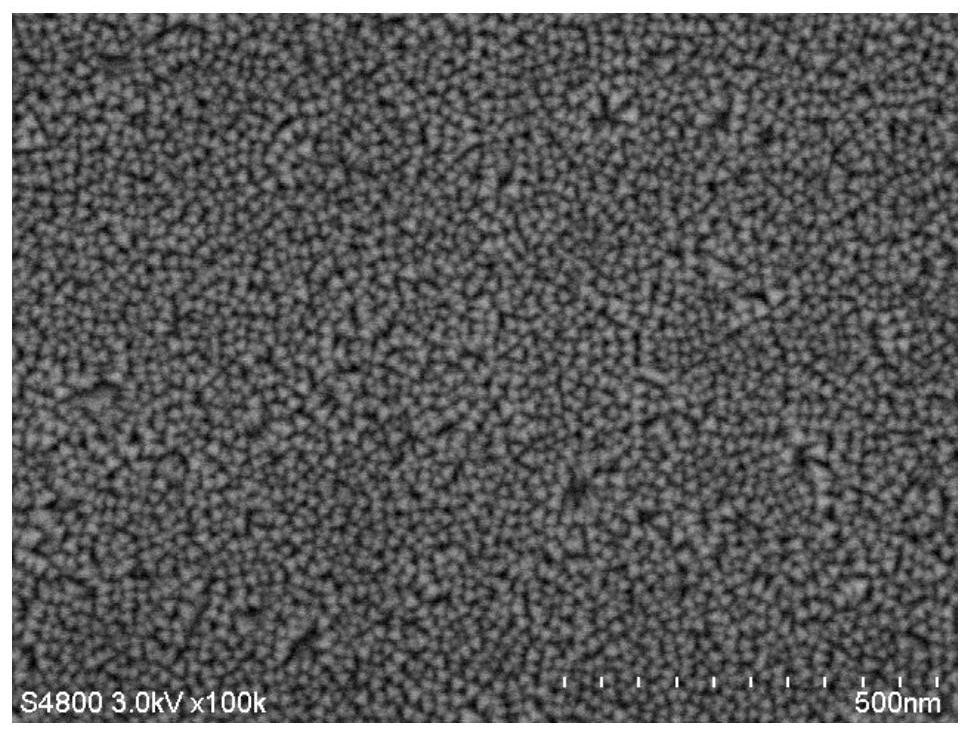

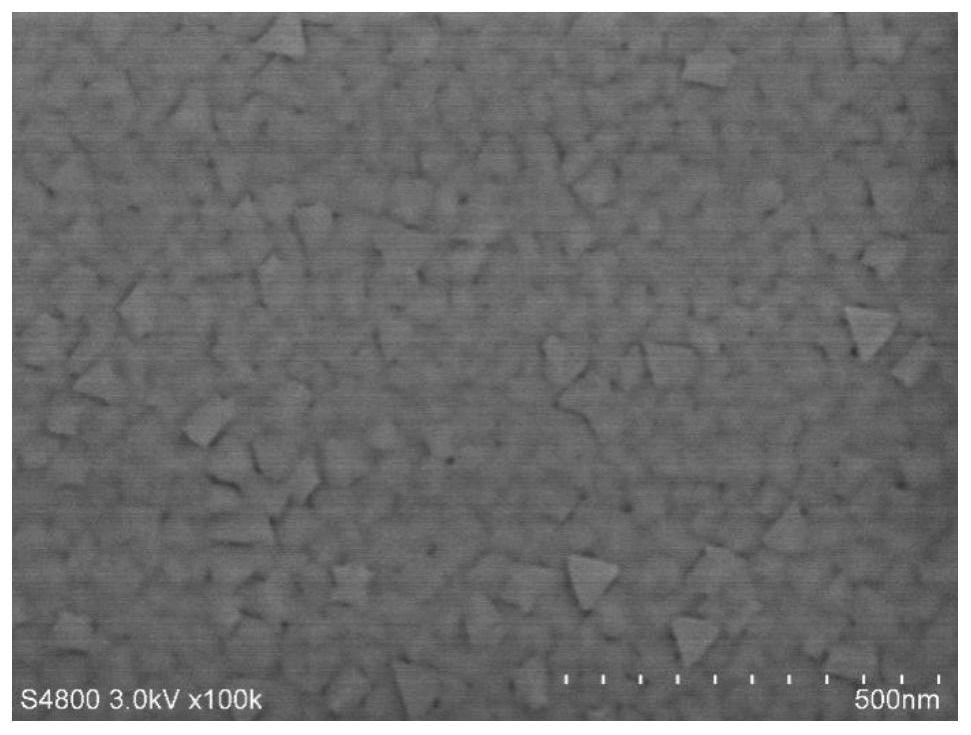

A kind of transparent electrode of light-emitting diode and preparation method thereof

ActiveCN109638136BImprove light extraction efficiencyLow resistivitySemiconductor devicesIndiumChemical cleaning

The invention provides a transparent electrode of a light-emitting diode. A preparation method of the transparent electrode comprises the following steps: S1, carrying out chemical cleaning on the surface of an epitaxial wafer, then putting the epitaxial wafer into an MOCVD reaction chamber with temperature of 300-900 DEG C and pressure of 3-100 Torr, and treating for 1-60 minutes; S2, under the protective atmosphere, adjusting the growth temperature to 450-650 DEG C, adjusting the pressure of the reaction chamber to 3-80 Torr, then, introducing an indium source, a tin source and an oxygen source, controlling the growth speed to 0.1-3 nm / min, and growing an ITO main body layer with the thickness of 40-500 nm on the surface of the pretreated epitaxial wafer; and S3, under the protective atmosphere, adjusting the growth temperature to 300-450 DEG C, adjusting the pressure of the reaction chamber to 3-80 Torr, then, introducing an indium source, a tin source and an oxygen source, controlling the growth speed to 1-10 nm / min, and growing an ITO coarsening layer with the thickness of 20-200 nm on the ITO main body layer. The method for in-situ growth of the coarsening layer is very matched with the preparation method of a main body layer of the ITO transparent electrode, subsequent complex process treatment is avoided, and the light extraction efficiency of the LED can be effectivelyimproved.

Owner:SUN YAT SEN UNIV +1

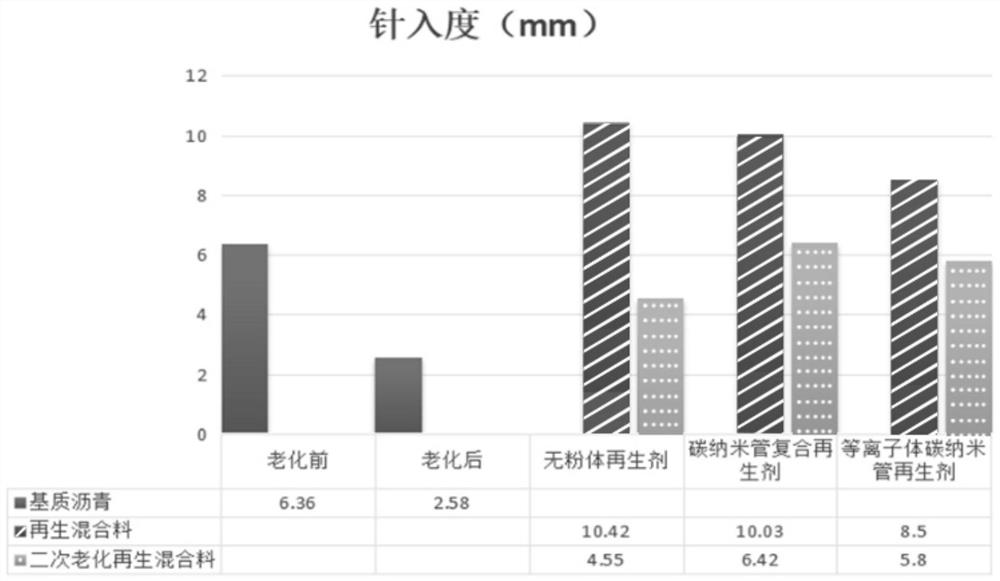

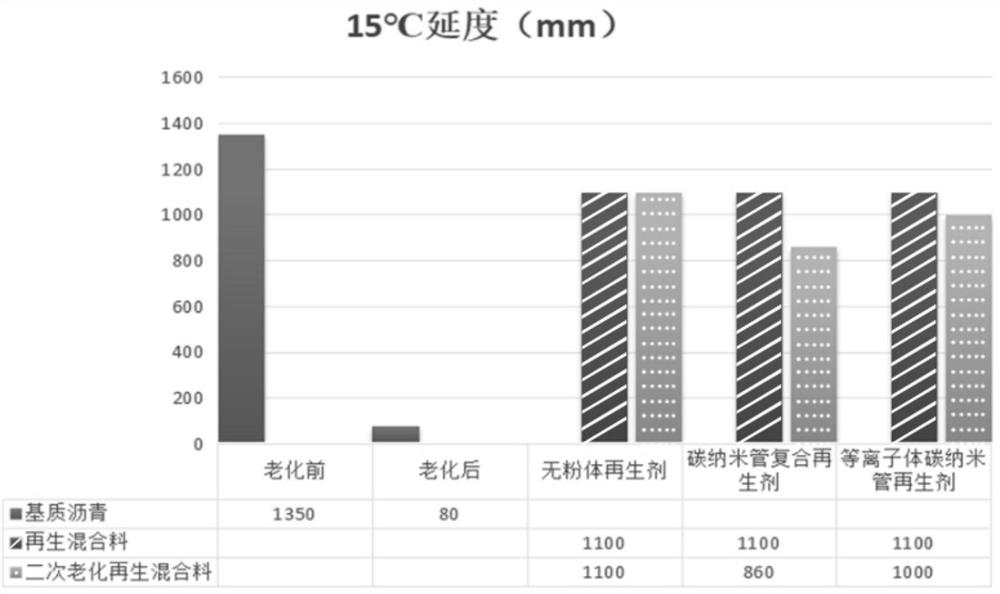

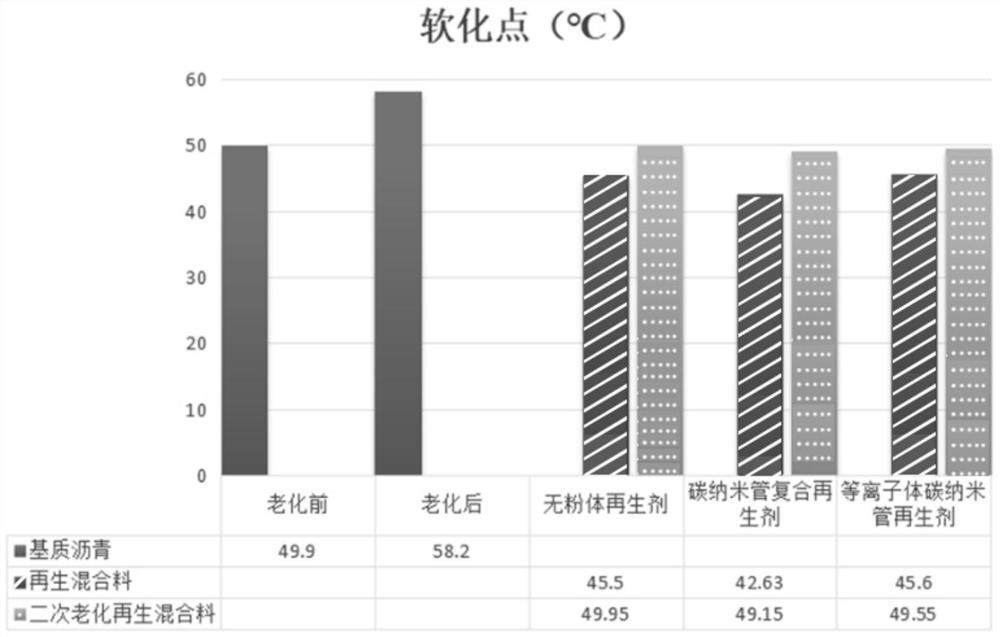

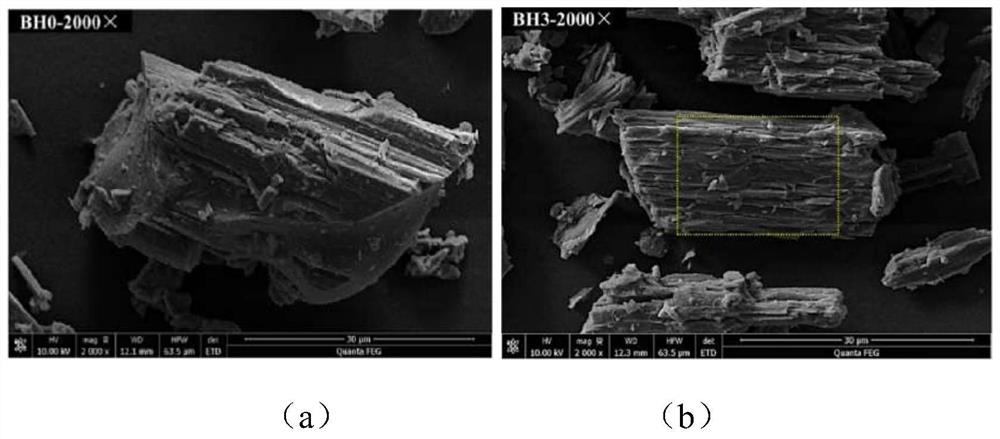

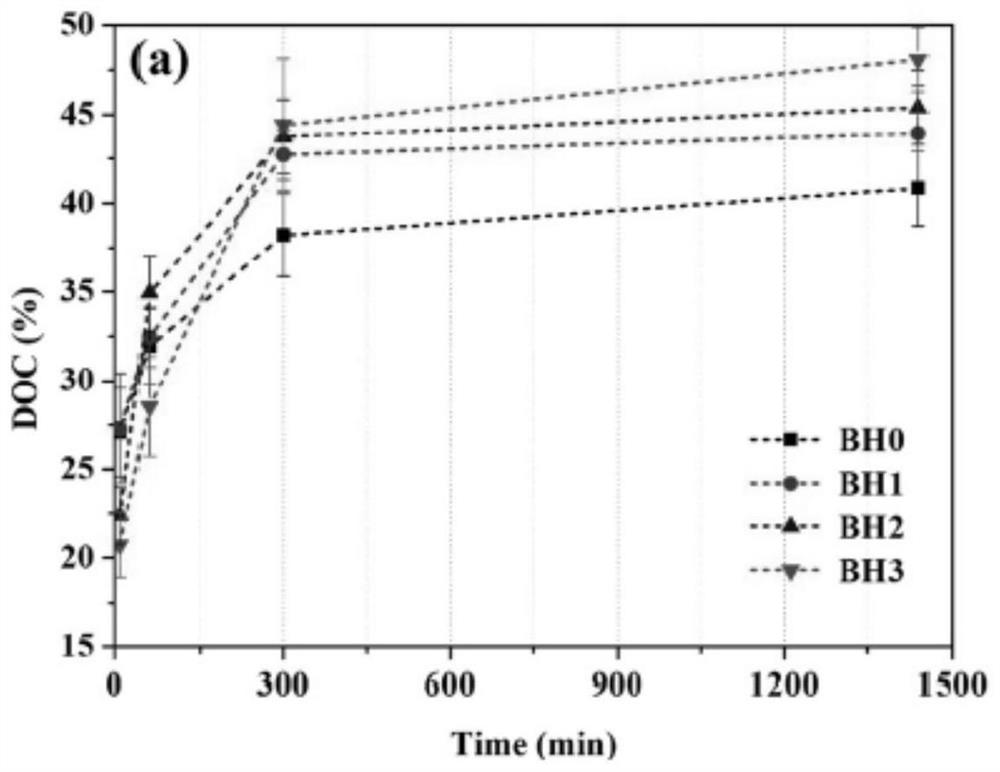

A kind of enhanced asphalt regenerant and preparation method thereof

ActiveCN109735122BReduce reunionGood compatibilityBuilding insulationsProcess engineeringRoad surface

An enhanced asphalt rejuvenator and its preparation method, the asphalt rejuvenator includes the following components in parts by mass: 10-60 parts of regeneration components, the regeneration components include mixing light oil and heavy oil in an appropriate proportion 1-30 parts of ultra-fine powder, the ultra-fine powder is a porous structure ultra-fine powder obtained through low-temperature plasma modification, and the average particle size of the powder is less than 100 μm. The invention can obtain the superfine powder reinforced asphalt rejuvenator with good dispersing effect and high compatibility. The improvement is relatively large, especially its anti-secondary aging performance has been greatly improved, thereby prolonging the service life of the pavement paved with recycled asphalt mixture, and it is expected to reduce the post-maintenance cost of the paved road in engineering.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

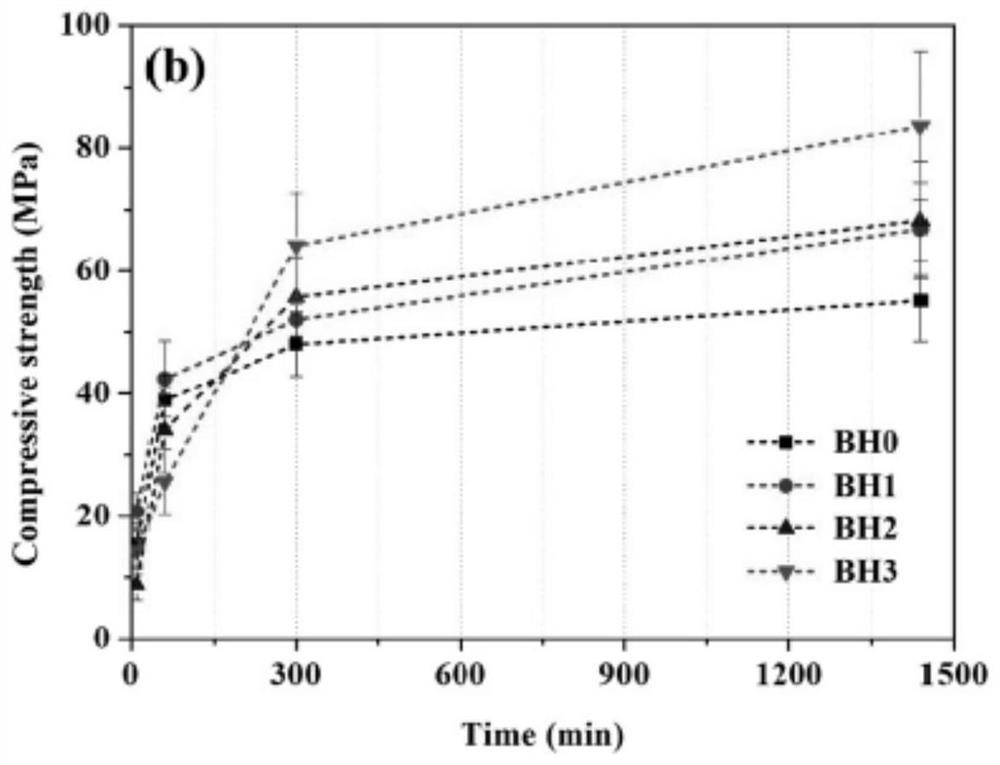

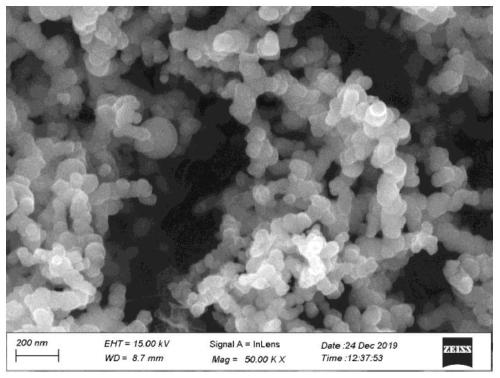

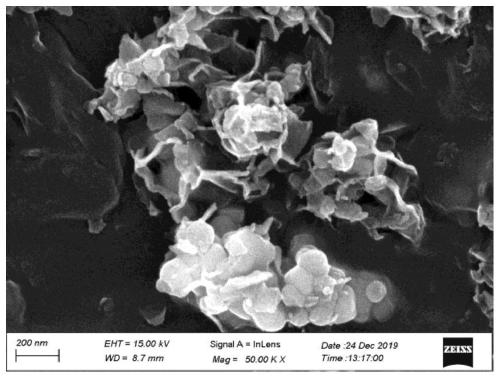

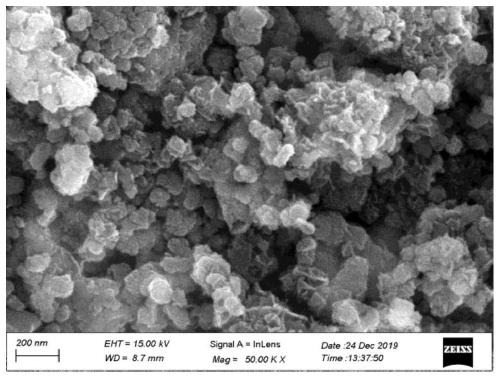

a gamma-c 2 s activation modification method

ActiveCN111393049BEnhance carbonization activityHigh degree of carbonationCement productionSilenesCarbonization

The present invention provides a γ-C 2 The activation modification method of S, the activation modification method, comprises the following steps: 1) according to the calcium-silicon molar ratio of 2:1, mixes the calcium raw material and the silicon raw material, then, adds the metal ion compound, mixes by ball milling, and obtains sintering raw materials; 2) mixing the sintering raw materials with 10% alcohol, pressing them into green bodies, drying, sintering, and natural cooling to obtain metal ion-doped γ-C 2 S. The present invention adopts metal ion doping firing pair γ-C 2 S was modified to prepare γ‑C with high specific surface area and high carbonization activity 2 S, and after being doped with metal ions and fired, the metal ions are enriched at the grain boundaries and replace part of the calcium ions to form a continuous solid solution. The carbonized products prepared by the activated γ-C2S have a higher degree of carbonization and resistance to carbonization. compressive strength.

Owner:山东汉博昱洲新材料有限公司

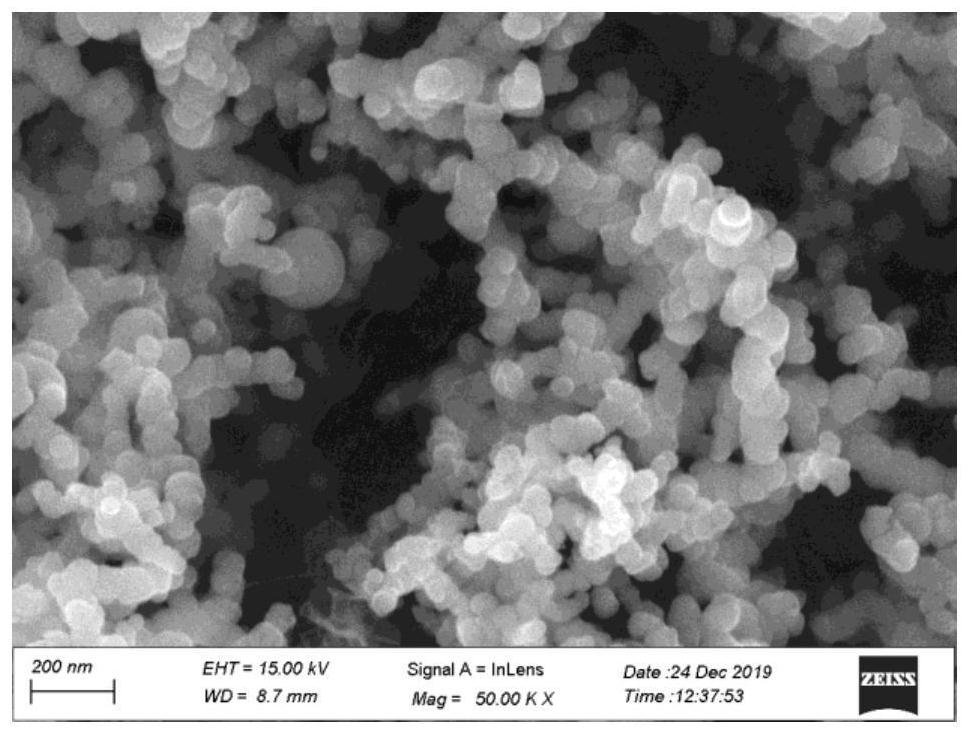

Method for strengthening arsenic removal effect of nano zero-valent iron by regulating and controlling oxygen content

ActiveCN111362390ASimple way to remove arsenicLow costWater treatment parameter controlWater contaminantsWastewaterOxygen content

The invention discloses a method for strengthening the arsenic removal effect of nano zero-valent iron by regulating and controlling the oxygen content. According to the method, the content of oxygenin the arsenic-containing wastewater and / or underground water is regulated and controlled to a proper range in an air / oxygen or inert gas aeration mode, the surface appearance of the nanoscale zero-valent iron is changed through a reaction of a proper amount of oxygen and the nanoscale zero-valent iron, and the arsenic removal effect of the nanoscale zero-valent iron is enhanced. The method disclosed by the invention has an obvious strengthening effect on removing arsenic (As (III) or As (V)) in different valence states from the nano zero-valent iron. The method can enhance the arsenic removaleffect of the in-situ or ex-situ nano zero-valent iron, and has the advantages of simple regulation and control mode, obvious enhancement effect, high treatment speed, environment friendliness, no secondary pollution and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

A kind of metal corrosion resistant insensitive ammunition and preparation method thereof

ActiveCN113916066BImproves metal corrosion resistanceImprove conductivityVibration crystallizationAmmunitionNitrotriazoloneInsensitive munition

The invention relates to the technical field of energetic materials, and specifically discloses a metal corrosion resistant insensitive ammunition and a preparation method thereof, wherein the metal corrosion resistant insensitive ammunition comprises the following components by weight: 0-10% of layered MXene and 90-100% of 3-nitro-1,2,4-triazole-5-ketone; the preparation method firstly etches the aluminum layer in the MAX phase with hydrofluoric acid to obtain layered MXene, and then combines the layered MXene with NTO The raw materials are dissolved in anhydrous ethanol in proportion, and finally the metal corrosion-resistant insensitive ammunition is obtained through evaporative crystallization. In the invention, the anti-metal corrosion type insensitive ammunition not only enhances the anti-metal corrosion performance of NTO, but also further reduces the impact sensitivity and friction sensitivity of NTO; the preparation method is simple, and the MAX phase is etched with hydrofluoric acid to obtain conductive MXenes, and then The MXenes and NTO were prepared by recrystallization method, which has practical application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

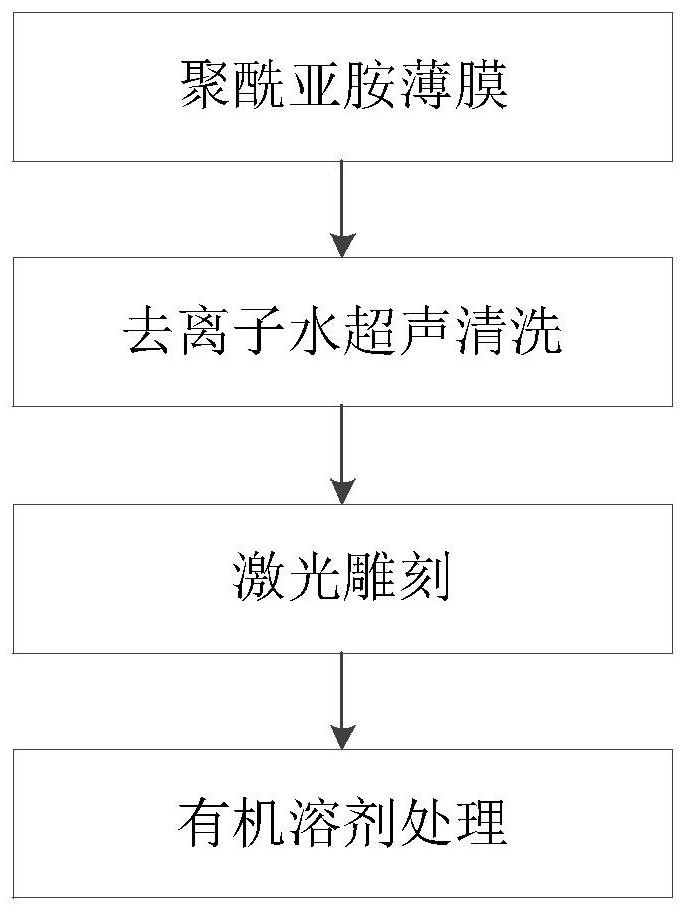

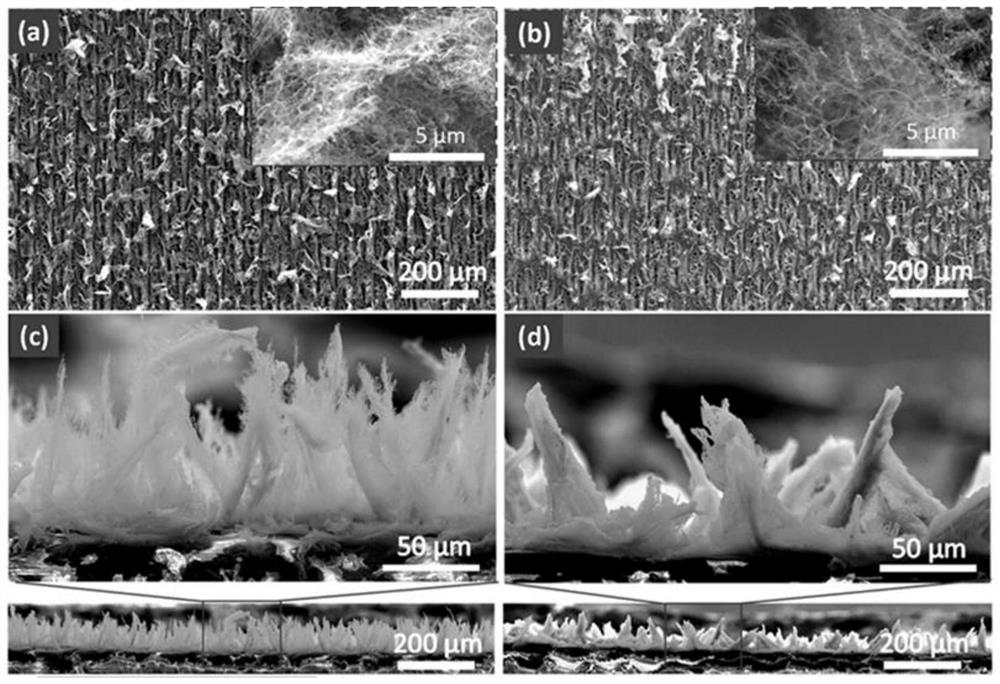

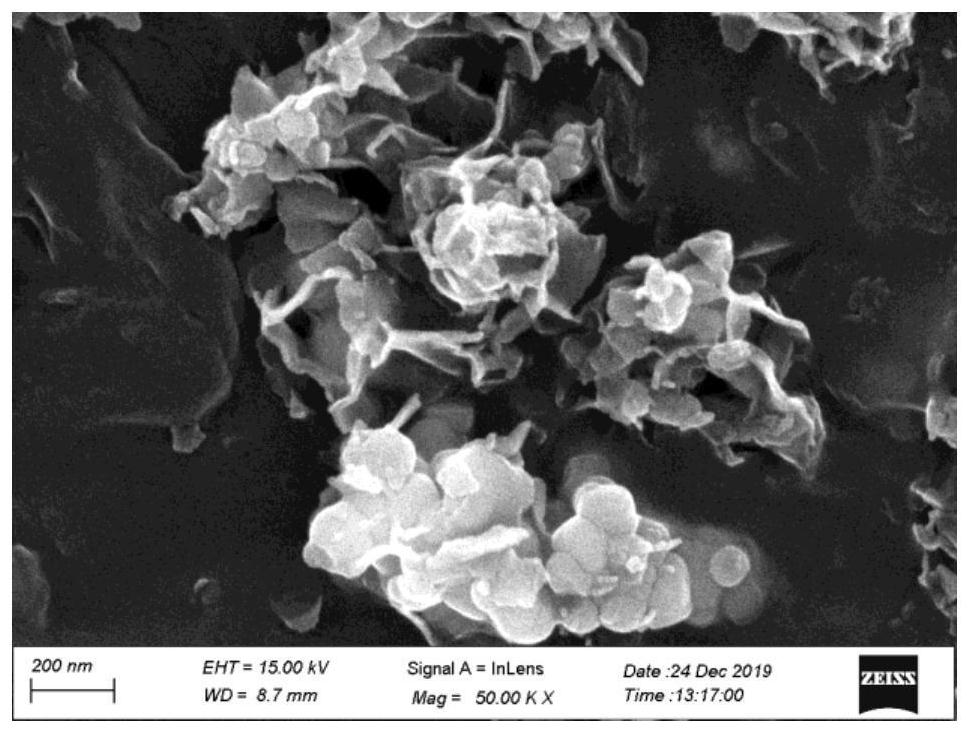

Preparation method and application of laser-induced graphene without pinning effect

ActiveCN114323852AChange surface topographyChange structureGeneral water supply conservationPreparing sample for investigationOrganic solventLaser engraving

The invention relates to the technical field of super-hydrophobic materials, and discloses a preparation method and application of pinning-effect-free laser-induced graphene, and the preparation method comprises the following steps: ultrasonically cleaning a polyimide film with deionized water; designing a graphene pattern needing to be processed, and guiding the pattern into a laser engraving machine; setting the laser power and the engraving speed of a laser engraving machine, and carrying out laser treatment on the polyimide film to obtain laser-induced graphene with a pinning effect; the method comprises the following steps: dropwise adding an organic solvent on the surface of graphene or soaking graphene in the organic solvent, and airing at room temperature to obtain the laser-induced graphene without pinning effect. According to the method disclosed by the invention, the laser-induced graphene without the pinning effect can be prepared, the process cost is low, and the method is efficient and stable, and the prepared laser-induced graphene without the pinning effect has super-hydrophobicity and has a good application prospect in the fields of analyte concentration detection, oil-water separation, icing prevention and the like.

Owner:SHANDONG UNIV

A method for enhancing the arsenic removal effect of nanometer zero-valent iron by regulating the oxygen content

ActiveCN111362390BSimple way to remove arsenicLow costWater treatment parameter controlWater contaminantsSoil scienceWastewater

The invention discloses a method for enhancing the arsenic removal effect of nanometer zero-valent iron by adjusting and controlling the oxygen content. The invention adjusts the oxygen content of arsenic-containing wastewater and / or groundwater to a suitable range by aeration of air / oxygen or inert gas, changes the surface morphology of the nano-zero-valent iron by reacting an appropriate amount of oxygen with the nano-zero-valent iron, and strengthens its arsenic removal effect. The invention has obvious strengthening effect on the removal of arsenic (As(III) or As(V)) in different valence states by the nanometer zero-valent iron. The invention can enhance the arsenic removal effect of in-situ or ex-situ nanometer zero-valent iron, and has the advantages of simple control mode, obvious strengthening effect, fast processing speed, environmental protection and no secondary pollution.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

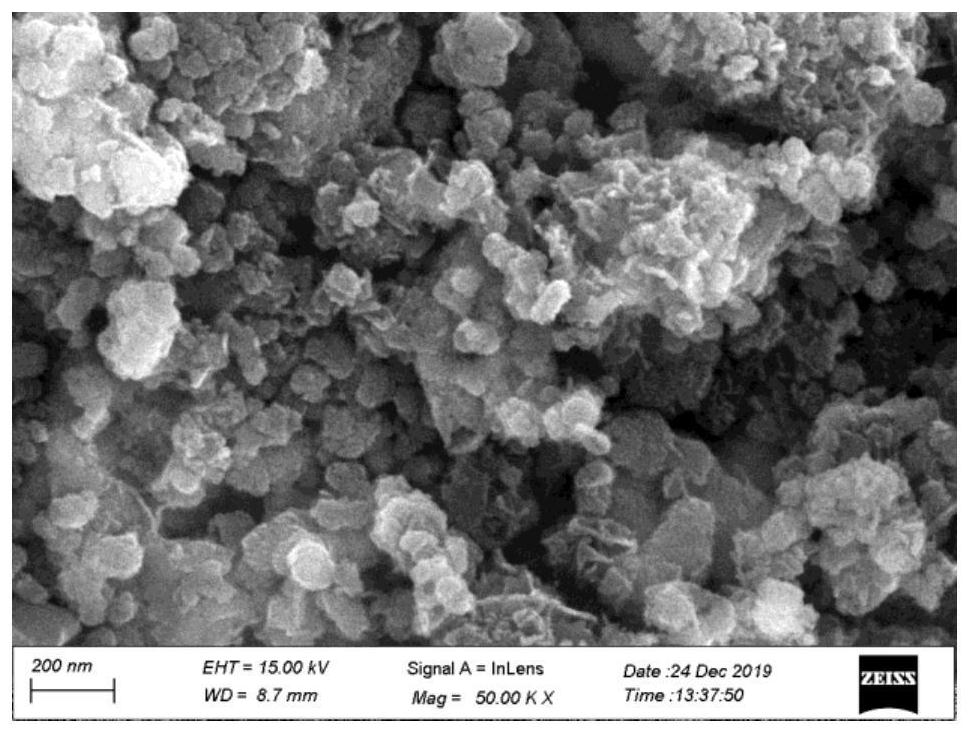

Copper sheet surface treatment method

ActiveCN113799002AEliminate streaky defectsChange surface topographyAbrasive feedersNano structuringSand blasting

The invention provides a copper sheet surface treatment method, which is characterized in that a sand blasting process is used for treating a copper sheet, and carborundum suspension is sprayed to a copper surface at a high speed so as to change the surface appearance of the copper surface and eliminate stripe-shaped defects of the copper sheet in a machining process; when the copper surface defects (impurities, oil stains, stains and oxidation) are removed, certain roughness can be formed on the surface of the copper sheet, a certain surface area is increased for the subsequent process (copper sheet oxidation), and the wettability of DCB sintering is improved; then, nanometer copper coated with the titanium dioxide and the copper sheet subjected to sand blasting are connected in a physical melting mode through laser, a first-stage coarse structure obtained after sand blasting treatment of the copper sheet is modified and optimized to form a third-stage micro-nano structure, the surface roughness of the copper sheet can be adjusted and controlled, and the surface roughness of the copper sheet is made to be uniform; and the nano-copper coated with the titanium dioxide and the micropore structure on the copper sheet synergistically improve the anti-rust hydrophobicity of the copper sheet, so that the service life of the copper sheet is prolonged.

Owner:江苏富乐华半导体科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com