Method for strengthening arsenic removal effect of nano zero-valent iron by regulating and controlling oxygen content

A nano-zero-valent iron and oxygen content technology, which is applied in chemical instruments and methods, water treatment parameter control, contaminated groundwater/leachate treatment, etc., can solve the problems of increased cost and complicated preparation process, and improve the utilization rate , simple method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

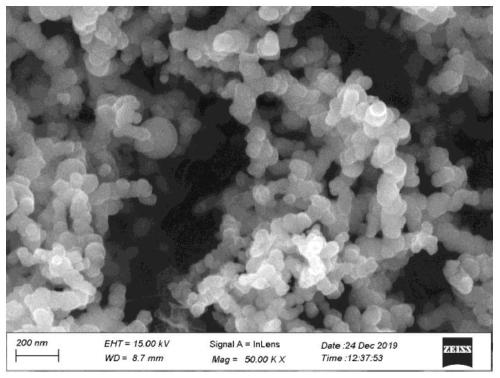

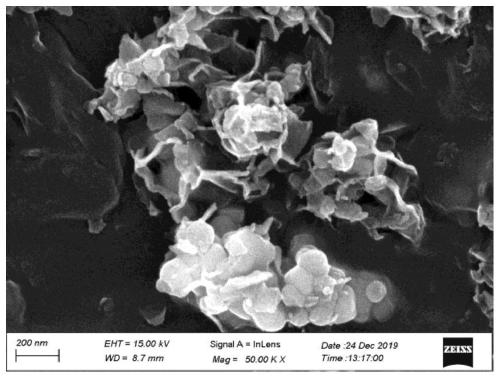

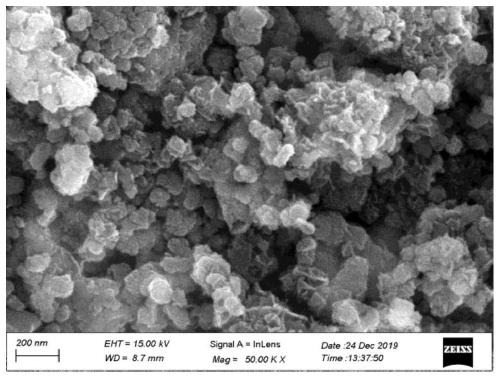

Image

Examples

Embodiment 1

[0044] Embodiment 1, the treatment of the waste water containing As (III)

[0045] 30mL of As(III)-containing wastewater (As(III) concentration 50mg·L -1 , pH value 7.2) were added to seven groups of vials respectively, and the dissolved oxygen in one group was adjusted to 2.05mg·L by aeration -1 , at the same time adjust the dissolved oxygen in other groups of reaction flasks by aeration to 0, 0.21, 0.51, 1.03, 4.10, 8.20mg·L -1 as a control group. Then add 0.2g·L respectively -1 Nano zero valent iron into the reaction bottle. After 6 hours of airtight reaction, the dissolved oxygen is 2.05mg·L -1 The concentration of As(III) in the vial dropped to 1.79mg·L -1, the removal rate was 96.41%; the concentration of As(III) in the control group decreased to 19.27, 12.78, 7.11, 2.51, 6.77, 9.88mg L -1 , and the removal rates were 61.23%, 74.28%, 85.70%, 94.96%, 86.39%, and 80.13%, respectively. When dissolved oxygen is 2.05mg·L -1 The removal rate of As(III) in the experimen...

Embodiment 2

[0046] Embodiment 2, the treatment of the waste water containing As (V)

[0047] 30mL of As(V)-containing wastewater (As(V) concentration 50mg·L -1 , pH value 7.2) were added to seven groups of vials respectively, and the dissolved oxygen in one group was adjusted to 2.05mg·L by aeration -1 , at the same time adjust the dissolved oxygen in other groups of reaction flasks by aeration to 0, 0.21, 0.51, 1.03, 4.10, 8.20mg·L -1 as a control group. Then add 0.2g·L respectively -1 Nano zero valent iron into the reaction bottle. After 6 hours of airtight reaction, the dissolved oxygen is 2.05mg·L -1 The concentration of As(V) in the vial dropped to 24.32mg·L -1 , the removal rate was 51.75%; the concentration of As(V) in the control group decreased to 38.01, 34.51, 30.62, 27.06, 33.76, 31.07mg L -1 , and the removal rates were 24.61%, 31.54%, 39.25%, 46.32%, 33.03%, and 38.36%, respectively. When dissolved oxygen is 2.05mg·L -1 The removal rate of As(V) in the experimental gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com