Calcium-phosphorus-silicon biological ceramic coating and preparation method and application thereof

A technology of bioceramics and coatings, applied in coatings, tissue regeneration, prostheses, etc., can solve problems such as patient pain, rapid coating degradation, tissue damage and even canceration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

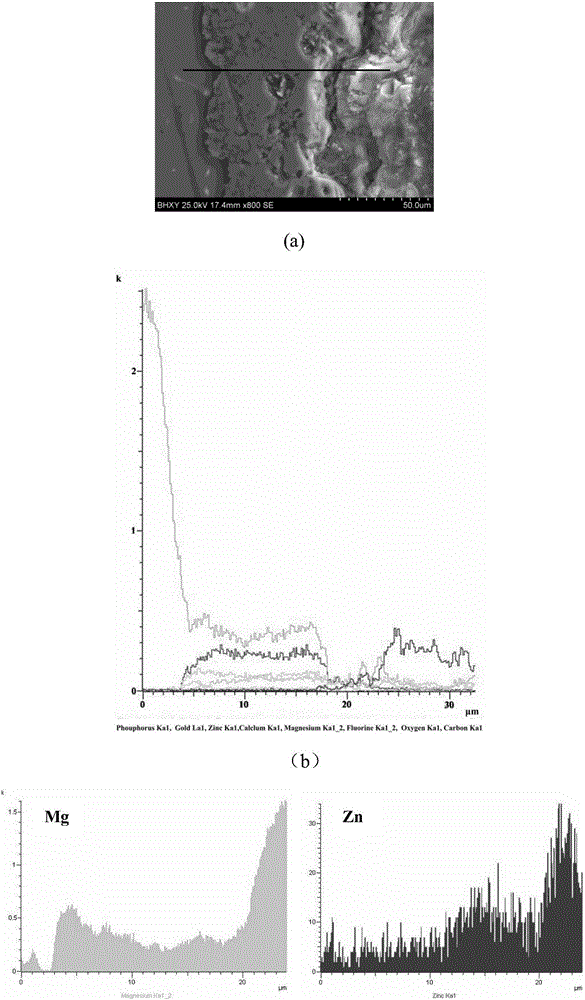

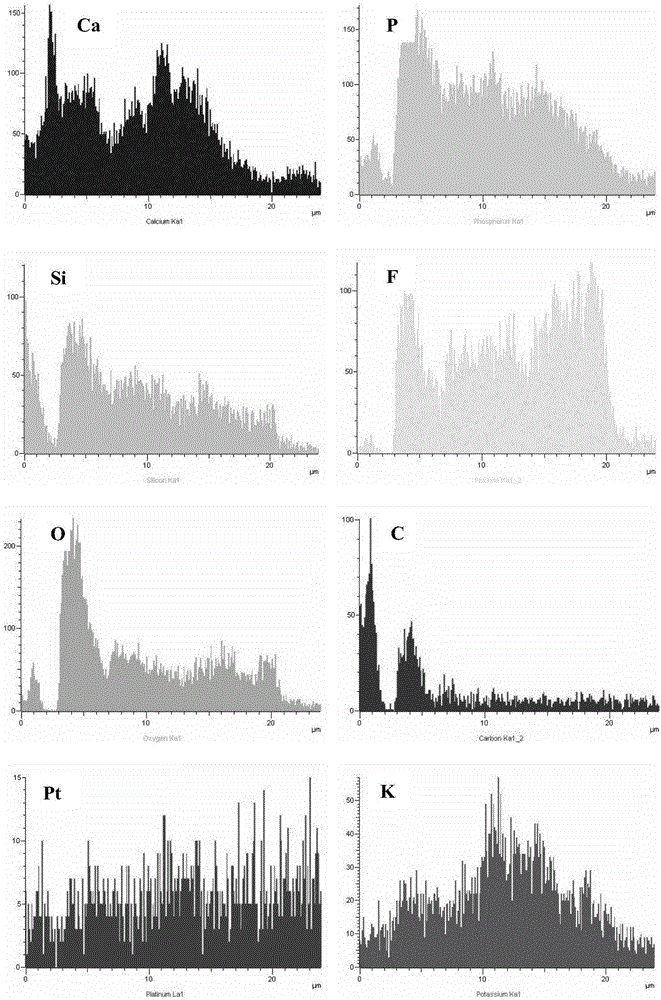

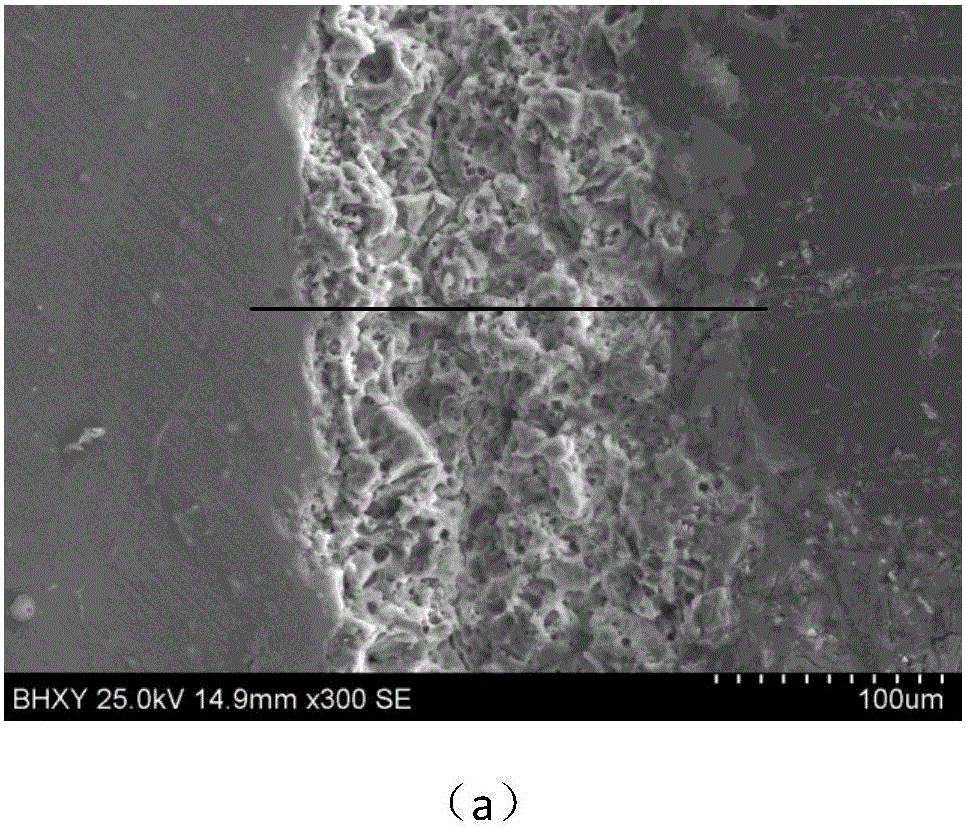

Image

Examples

Embodiment 1

[0073] The preparation method of the calcium phosphorus silicon bioceramic coating on the surface of embodiment 1 magnesium alloy, the steps are as follows:

[0074] (1) Prepare the electrolyte: add calcium glycerophosphate as a calcium source to the basic electrolyte, and add (NaPO 3 ) 6 As a phosphorus additive, prepare an electrolyte containing calcium and phosphorus salts; add Na at a concentration of 7.5 g / L to the base electrolyte 2 SiO 3 9H 2 O is formulated into an electrolyte solution containing silicate;

[0075] The basic electrolyte is composed of deionized water, KOH, NH 4 HF 2 It is formulated with glycerin, wherein the concentration of KOH is 0.125mol / L, and the concentration of NH 4 HF 2 The concentration of glycerin is 0.087mol / L, and the concentration of glycerin is 10ml / L. Calcium glycerophosphate and (NaPO 3 ) 6 The specific content of is shown in Table 1-1;

[0076] (2) Preparation of matrix material: take magnesium-zinc-calcium alloy as base ma...

Embodiment 2

[0089] The preparation method of the calcium phosphorus silicon bioceramic coating on the surface of embodiment 2 magnesium alloy, the steps are as follows:

[0090] (1) Preparation of electrolyte: add 7.5g / L calcium glycerophosphate as calcium source to the basic electrolyte, and add 7.5g / L (NaPO 3 ) 6 As a phosphorus additive, prepare an electrolyte containing calcium and phosphorus salts; add different concentrations (2.5g / L, 7.5g / L, 12.5g / L) of Na to the base electrolyte 2 SiO 3 9H 2 O is formulated into an electrolyte solution containing silicate;

[0091] The basic electrolyte is composed of deionized water, KOH, NH 4 HF 2 It is formulated with glycerin, wherein the concentration of KOH is 0.125mol / L, and the concentration of NH 4 HF 2 The concentration of glycerin is 0.087mol / L, and the concentration of glycerin is 10ml / L.

[0092] (2) Preparation of matrix material: using magnesium-zinc-calcium alloy as the base material, the plate-shaped material is divided in...

Embodiment 3

[0103] The preparation method of the calcium phosphorus silicon bioceramic coating on the surface of embodiment 3 magnesium alloy, the steps are as follows:

[0104] (1) Preparation of electrolyte: add 7.5g / L calcium glycerophosphate as calcium source to the basic electrolyte, and add 7.5g / L (NaPO 3 ) 6 As a phosphorus additive, prepare an electrolyte containing calcium and phosphorus salts; add 7.5g / L Na to the basic electrolyte 2 SiO 3 9H 2 O is formulated into an electrolyte solution containing silicate;

[0105] The basic electrolyte is composed of deionized water, KOH, NH 4 HF 2 It is formulated with glycerin, wherein the concentration of KOH is 0.125mol / L, and the concentration of NH 4 HF 2 The concentration of glycerin is 0.087mol / L, and the concentration of glycerin is 10ml / L.

[0106] (2) Preparation of matrix material: using magnesium-zinc-calcium alloy as the base material, the plate-shaped material is divided into 10×10×8mm by wire cutting 3 Drill holes an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com