High-resilience antibacterial medical polyvinyl chloride (PVC) plastic and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of medical polyvinyl chloride materials, can solve the problems of unsecured patient safety, low sterilization efficiency, long-term ventilation, etc., and achieves good chemical and biological properties. , The effect of shortening the sterilization cycle and improving the sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

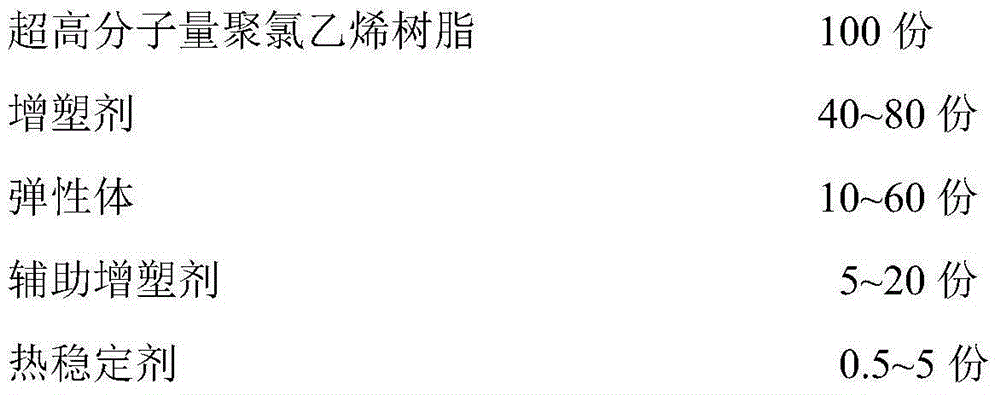

[0033] Components and proportions by weight:

[0034]

[0035]

[0036] The degree of polymerization of polyvinyl chloride resin is 2000;

[0037] The heat stabilizer is a mixture of calcium stearate and zinc stearate with a weight ratio of 1:1;

[0038] Preparation

[0039] (1) Add polyvinyl chloride resin, plasticizer, auxiliary plasticizer, and elastomer into the high-speed mixer, heat and stir at 30rpm to 80°C, add antibacterial materials and heat stabilizers, and run at 450rpm until the temperature reaches 120°C, Add lubricant. Stir continuously to 140°C and discharge to the cooling mixer with a rotation speed of 30rpm. When the temperature of the material is cooled to 50°C, the material is discharged.

[0040] (2) The material obtained in step (1) is granulated using a twin-screw extruder. The screw speed of the main engine is 60rpm, the temperature of each section of the extruder: the first section is 110°C, the second section is 130°C, the third section is 1...

Embodiment 2

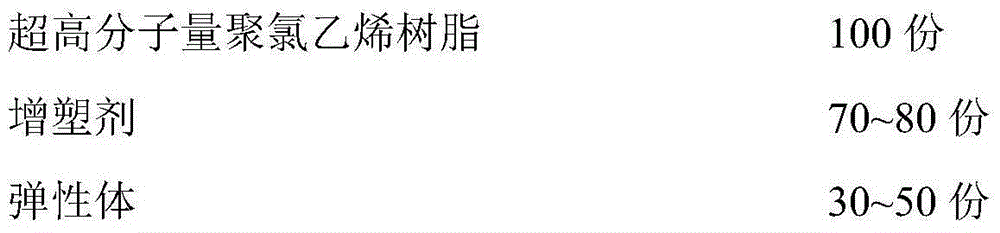

[0042]

[0043] The degree of polymerization of polyvinyl chloride resin is 2300;

[0044] The heat stabilizer is a mixture of calcium stearate and zinc stearate with a weight ratio of 1:1;

[0045] The preparation method is the same as in Example 1.

Embodiment 3

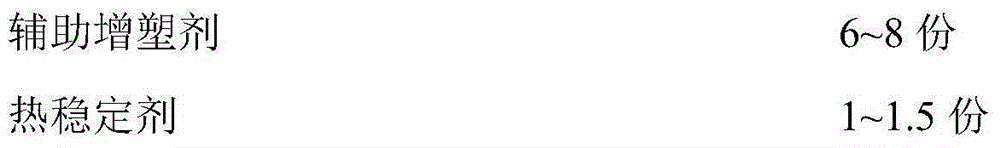

[0047]

[0048]

[0049] The degree of polymerization of polyvinyl chloride resin is 2500;

[0050] The elastomer is a mixture of styrene-ethylene-butylene-styrene block copolymer (SEBS), nitrile rubber (NBR), polyurethane (TPU) or ethylene-octene copolymer (POE) in the weight ratio:

[0051] Styrene-Ethylene-Butene-Styrene Block Copolymer: Nitrile Rubber: Polyurethane: Ethylene Octene Copolymer Elastomer

[0052] =1:0.2:0.35:0.25;

[0053] The styrene content in the styrene-ethylene-butylene-styrene block copolymer is 30%, and the molecular weight is 70,000;

[0054] The average molecular weight of nitrile rubber is 650,000;

[0055] The average molecular weight of polyurethane is 30,000;

[0056] The octene content in the ethylene octene copolymer is 40% to 60%;

[0057] The heat stabilizer is a mixture of calcium stearate and zinc stearate with a weight ratio of 1:1;

[0058] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com