Energy-saving sterilization unit and use method

A technology of unit and sterilizer, applied in botany equipment and methods, applications, sanitary equipment for toilets, etc., can solve the problems of water vapor generated by sterilized materials, low working efficiency of sterilizer, and long time-consuming, etc. Achieve the effects of lowering the temperature, shortening the sterilization cycle, and reducing heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

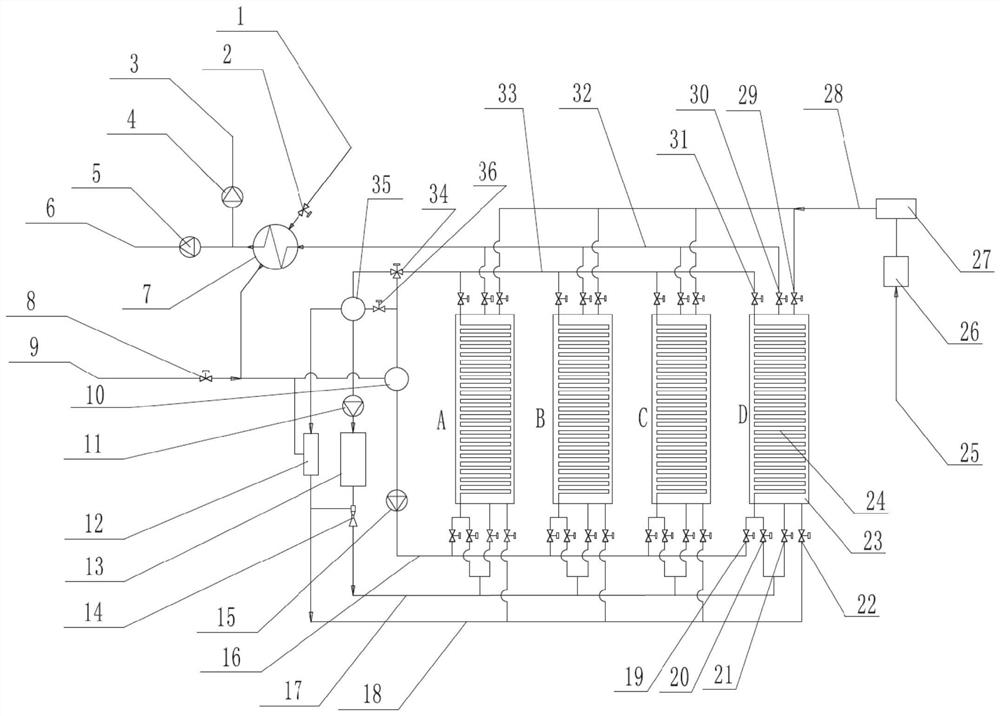

[0059] An energy-saving sterilization unit, comprising an air filter (26), an air compressor (27), a steam compressor (12), a steam injection pump (14), a hot water storage tank (35) and at least two high-pressure sterilization device (23), the inner wall of the autoclave (23) is provided with an inner heat exchanger (24), and the outlet of the inner heat exchanger (24) passes through the tenth valve (31), the water outlet pipe (33) and The three-way reversing valve (34) is connected, and the other two interfaces of the three-way reversing valve (34) are connected with the hot water storage tank (35), and the other is connected with the warm water storage tank (10). The top steam outlet of (35) communicates with the steam inlet of the steam compressor (12) through a pipeline, and the steam outlet of the steam compressor (12) is connected to the sterilization valve through a low-temperature steam pipeline (18), the seventh valve (22) The inner chamber of the device (23) communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com