CuSbS2 nanoparticle and preparing method and application thereof

A nanoparticle and particle technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of poor photocatalytic performance and uncontrollable shape of nanoparticles, and achieve improved photocatalytic performance , short preparation cycle, and the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

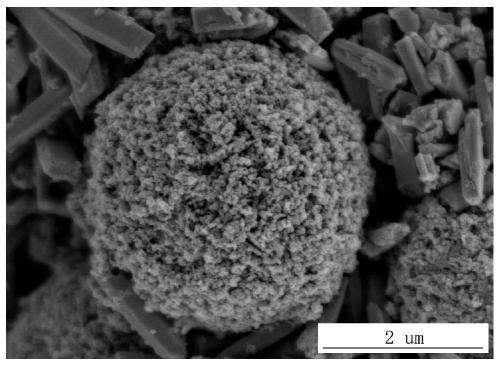

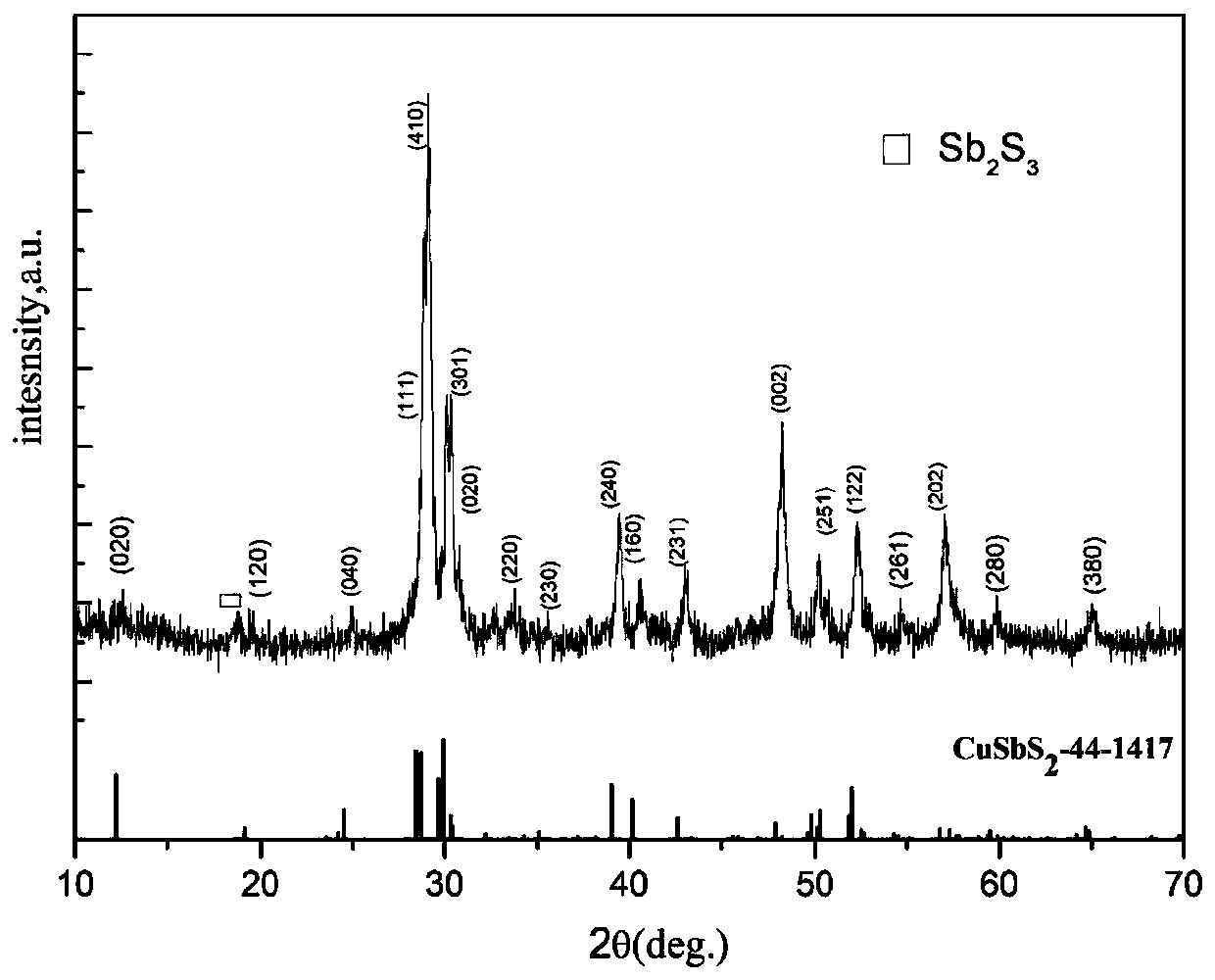

[0043] A preparation of CuSbS by microwave liquid phase method 2 A method for nanoparticles comprising the steps of:

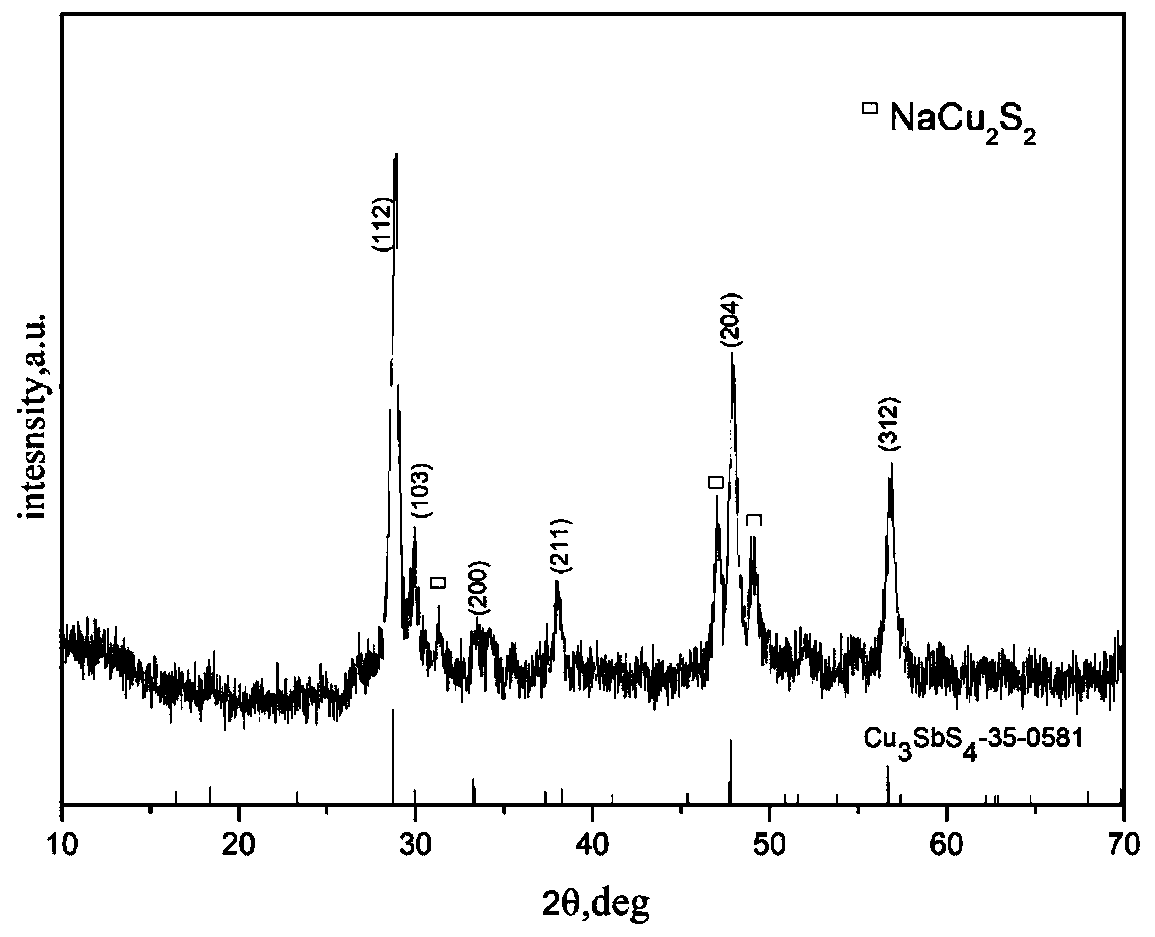

[0044] Weigh 0.001mol copper nitrate trihydrate, 0.002mol antimony trichloride, 0.003mol thiourea, and 30mg / mL polyvinylpyrrolidone and dissolve them in 50mL of ethylene glycol in turn, and prepare a precursor solution after it is completely dissolved to adjust the pH= 5. Using the microwave method, the precursor solution was irradiated with microwaves, the microwave power was 400W, the microwave time was 4min, and then the microwave power was adjusted to 240W, and the microwave time was 6min to prepare CuSbS 2 black solution. The black solution was washed three times with ultrapure water and ethanol, and the CuSbS 2 The black solution was centrifuged to obtain CuSbS 2 nanoparticles. Then the CuSbS 2 Nanoparticles placed in 0.2mol / L NaS 2 CuSbS in solution with ultrasonic vibration for 20 min and magnetic stirring at 25 °C for 60 min 2 nanoparticles. ...

Embodiment 2

[0048] Weigh 0.001mol cupric chloride, 0.0011mol antimony acetate, 0.0042mol thioacetamide, 24mg / mL hexadecyltrimethylammonium bromide and dissolve them in polyethylene glycol-200 and ethylene glycol at a ratio of 5:5 50mL solution mixed in the proportion of the mixture, after it was completely dissolved, it was prepared as a precursor solution and hydrochloric acid was added to adjust the pH=2. The precursor solution was heated by microwave with a microwave power of 600W and a microwave time of 6min, then a microwave power of 160W and a microwave time of 4min to prepare CuSbS 2 black solution. The black solution was washed three times with ultrapure water and ethanol, and the CuSbS 2 CuSbS was separated from the black solution by centrifugation 2 nanoparticles. Then the CuSbS 2 Nanoparticles placed in 0.36mol / L NaS 2 CuSbS in solution with ultrasonic vibration for 20 min and magnetic stirring at 60 °C for 30 min 2 nanoparticles. The cleaned CuSbS 2 Nanoparticles dry. ...

Embodiment 3

[0050] Weigh 0.001mol copper chloride, 0.0025mol antimony nitrate, 0.0175mol L-cysteine, 12mg / mL sodium dodecylbenzenesulfonate and dissolve them in 50mL glycerol in turn, and prepare Precursor solution and adding hydrochloric acid to adjust pH=1. Microwave the precursor solution by microwave heating, the microwave power is 200W, the microwave time is 2min, and then the microwave power is adjusted to 480W, and the microwave time is 12min to prepare CuSbS 2 black solution. The black solution was washed three times with ultrapure water and ethanol, and the CuSbS 2 The black solution was centrifuged to obtain CuSbS 2 nanoparticles. Then the CuSbS 2 Nanoparticles placed in 0.68mol / L NaS 2 CuSbS in solution with ultrasonic vibration for 30 min and magnetic stirring at 40 °C for 20 min 2 nanoparticles. The cleaned CuSbS 2 Nanoparticles dry. CuSbS 2 The morphology and photocatalytic properties of the nanoparticles are consistent with the results of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com