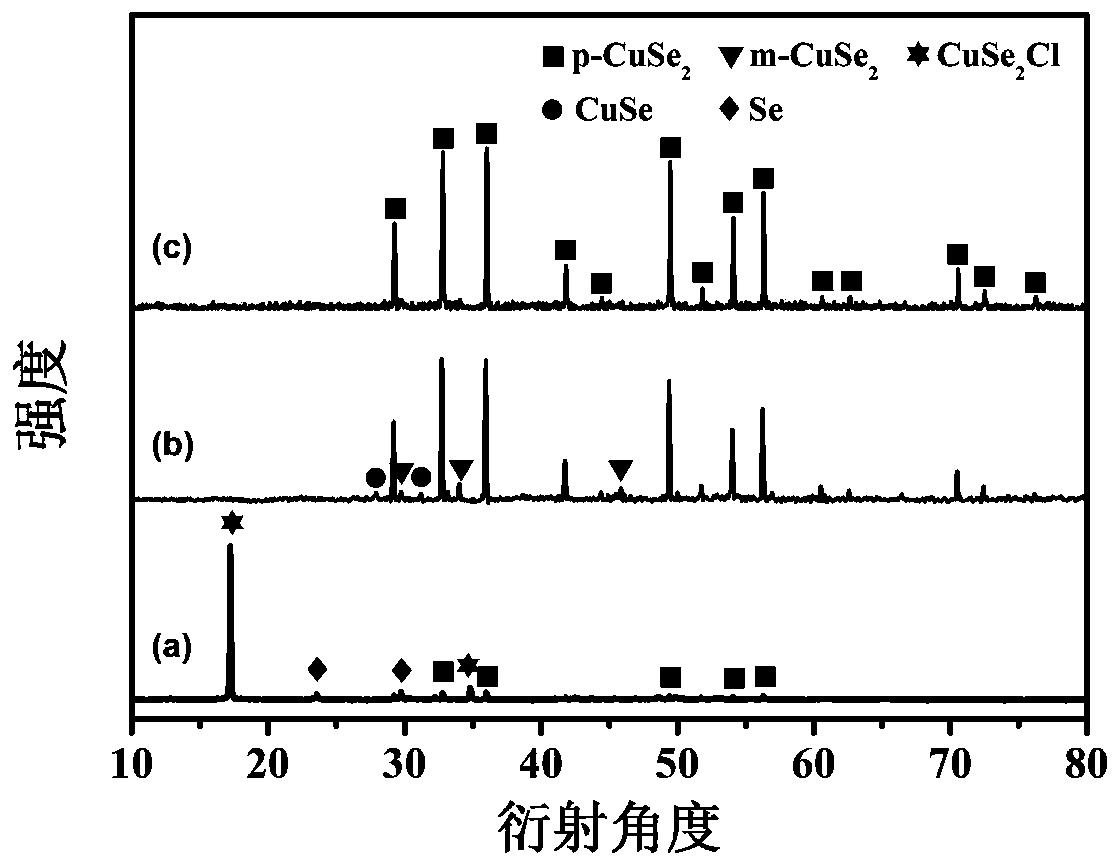

P-CuSe2 (pyrite CuSe2) and preparation method thereof

A technology of pyrite type, copper selenide, applied in binary selenium/tellurium compounds, metal selenide/telluride and other directions, can solve the problem of difficulty in obtaining pure metastable pyrite type copper diselenide, safety hazards The problem of uneven environment and reducibility, to achieve the effect of suitable large-scale production, high safety and suitable reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of pyrite type copper diselenide, comprises the following steps:

[0027] (1) Copper chloride is mixed with triethylene glycol to obtain a cationic precursor solution;

[0028] (2) heating glucose, selenium powder, polyvinylpyrrolidone and triethylene glycol after mixing to obtain anion precursor solution;

[0029] (3) performing a displacement reaction after mixing the cation precursor solution in the step (1) with the anion precursor solution in the step (2), to obtain pyrite-type copper diselenide;

[0030] The mol ratio of described cupric chloride and selenium powder is 1:2;

[0031] The steps (1) and (2) have no chronological relationship.

[0032] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0033] The invention mixes copper chloride and triethylene glycol to obtain a cationic precursor solution....

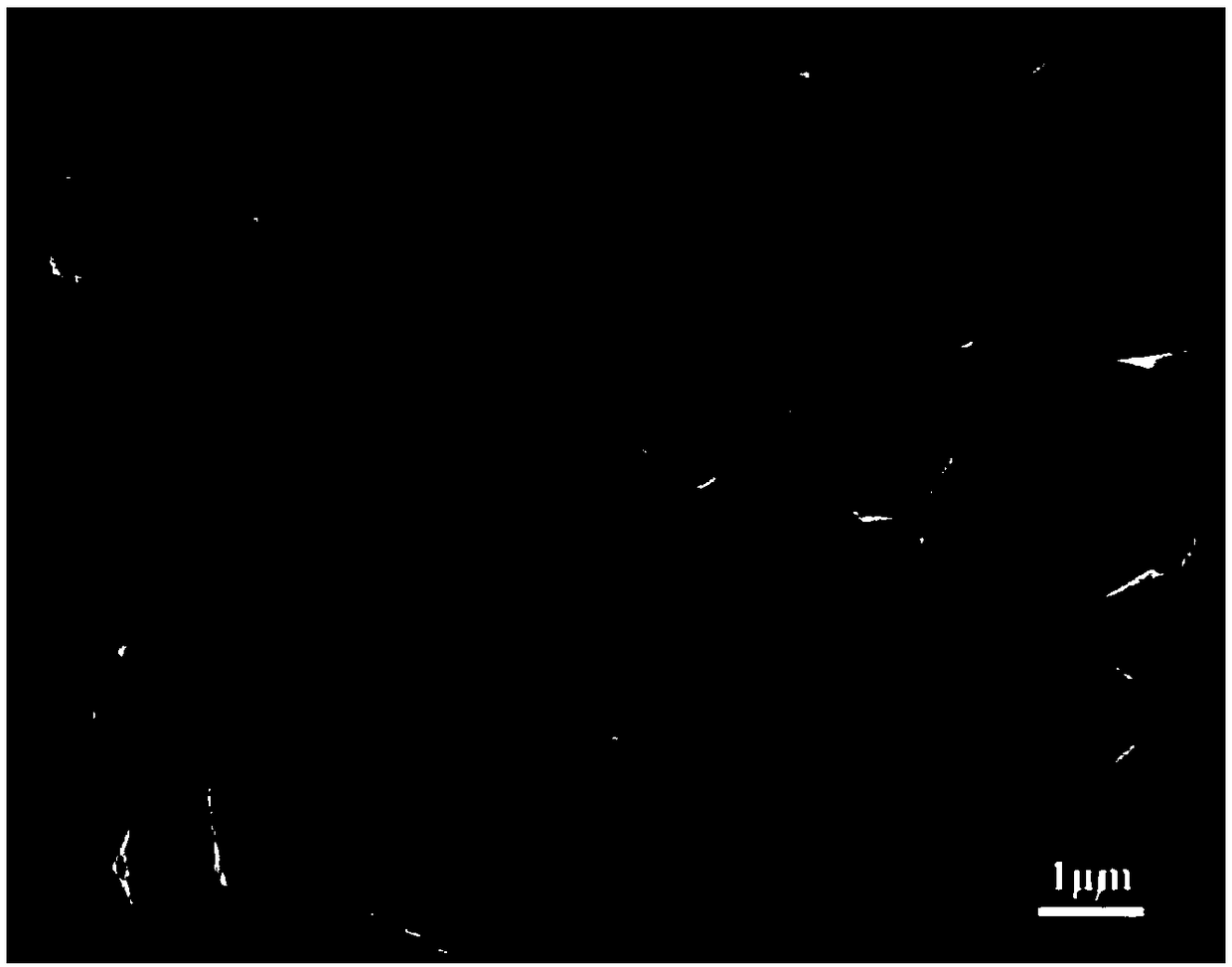

Embodiment 1

[0050] Dissolve 0.5 mmol of copper chloride dihydrate in 10 mL of triethylene glycol, stir at 40°C for 30 min until dissolved, and the stirring rate is 200 r / min to obtain a cationic precursor solution with a concentration of 0.05 mol / L;

[0051] Add 0.10 g of glucose, 1.0 mmol of selenium powder and 0.20 g of polyvinylpyrrolidone into the three-necked flask, then add 35 mL of triethylene glycol, stir for 5 min at a speed of 400 r / min, and then place the three-necked flask in a thermal reaction reflux device , the system is evacuated first, and then nitrogen gas is introduced, so that it is alternately carried out 3 times, and nitrogen gas is fed after the last vacuum pumping, and the continuous feeding of nitrogen gas is maintained; wherein, the vacuum degree during the vacuum pumping is 0.08MPa, The vacuuming time is 2min; the flow rate of the nitrogen gas is 60mL / min; the above-mentioned mixed solution is heated at a heating rate of 8°C / min, and stirred at a speed of 400r / mi...

Embodiment 2

[0056] Dissolve 1.0 mmol of copper chloride dihydrate in 8 mL of triethylene glycol, stir at 60°C for 30 min until dissolved, and the stirring rate is 200 r / min, to obtain a cationic precursor solution with a concentration of 0.125 mol / L;

[0057] Add 0.20 g of glucose, 2.0 mmol of selenium powder and 0.15 g of polyvinylpyrrolidone into the three-necked flask, then add 40 mL of triethylene glycol, stir for 5 min at a speed of 400 r / min, and then place the three-necked flask in a thermal reaction reflux device , the system is first vacuumed, and then nitrogen is introduced, so that it is alternately carried out 5 times, and nitrogen is introduced after the last vacuuming, and the continuous introduction of nitrogen is kept until the end of the replacement reaction; wherein, the vacuum during the vacuum The temperature is 0.08MPa, and the time of vacuuming is 2min; the flow rate of the nitrogen gas is 60mL / min; Stir at a rotating speed until the temperature of the system reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com