Anti-glare wear-resistant cover plate and manufacturing method thereof

A manufacturing method and cover plate technology, which can be applied to optical components, optics, instruments, etc., can solve problems such as anti-fouling failure, wear, and impact on anti-glare, so as to achieve good anti-wear ability and improve the effect of anti-wear ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

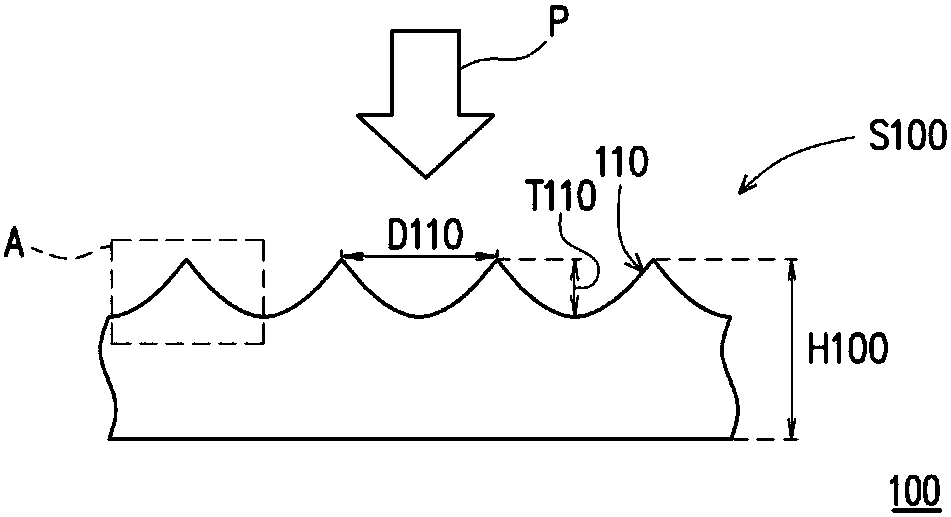

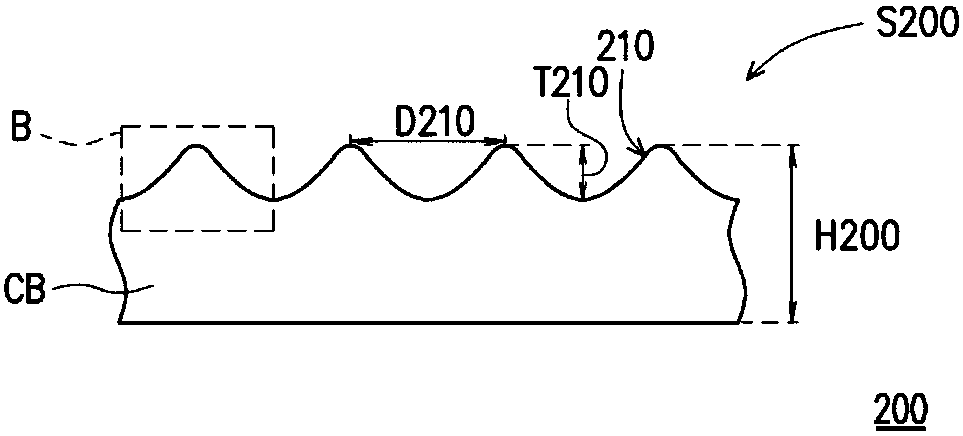

[0039] Figure 1A and Figure 1B It is a partial cross-sectional schematic diagram of a manufacturing process of the manufacturing method of the anti-glare and wear-resistant cover plate of the present invention. Please refer to Figure 1A , Provide anti-glare cover 100. The anti-glare cover 100 has a plurality of microstructures 110 located on the anti-glare side S100 of the anti-glare cover 100. The plurality of microstructures 110 are adapted to scatter the light beam irradiated to the anti-glare side S100 of the anti-glare cover plate 100 to achieve an anti-glare effect. In this embodiment, the anti-glare cover 100 is a glass cover, and the glass transition temperature of the anti-glare cover 100 is T. The plurality of microstructures 110 are formed, for example, by chemically etching a glass cover plate. Compared to forming the anti-glare cover sheet by surface sticking film or vacuum coating, the anti-glare cover sheet 100 formed by etching may have a relatively thin thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com