Method of adopting plasma technology to treat silver nanowires and transferring through substrate to prepare organic photoelectronic device flexible electrode

A silver nanowire and plasma technology, which is applied in the manufacture of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problems of excessive heat generation, high surface roughness of silver nanowire films, and burnt-out devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

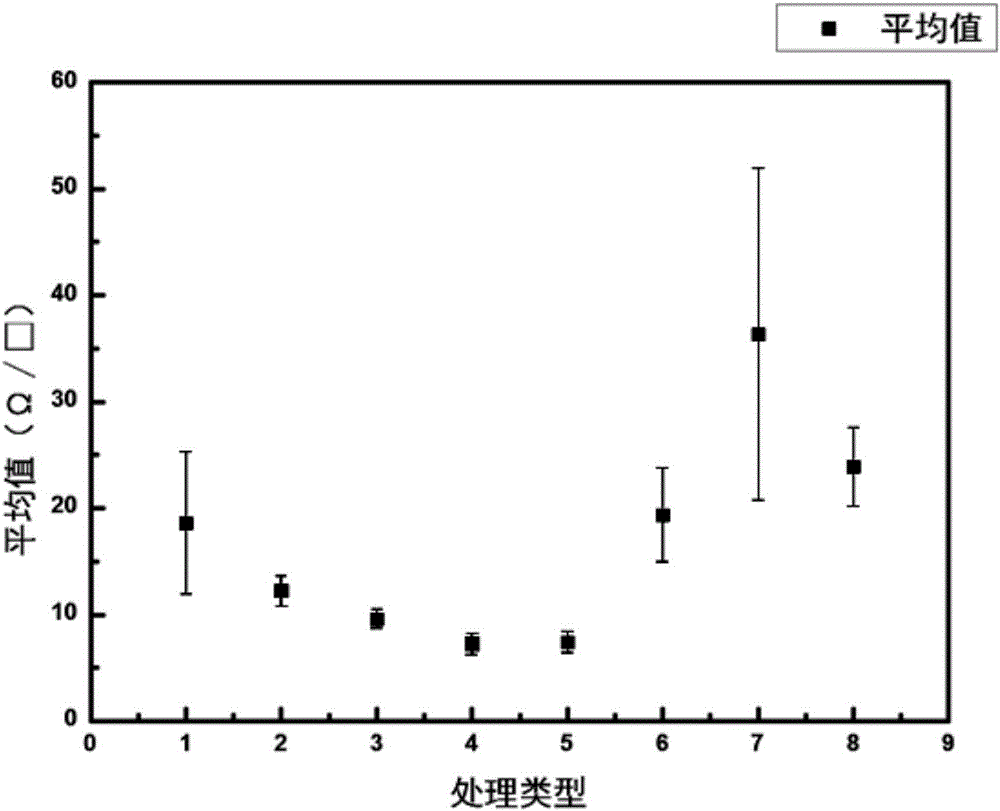

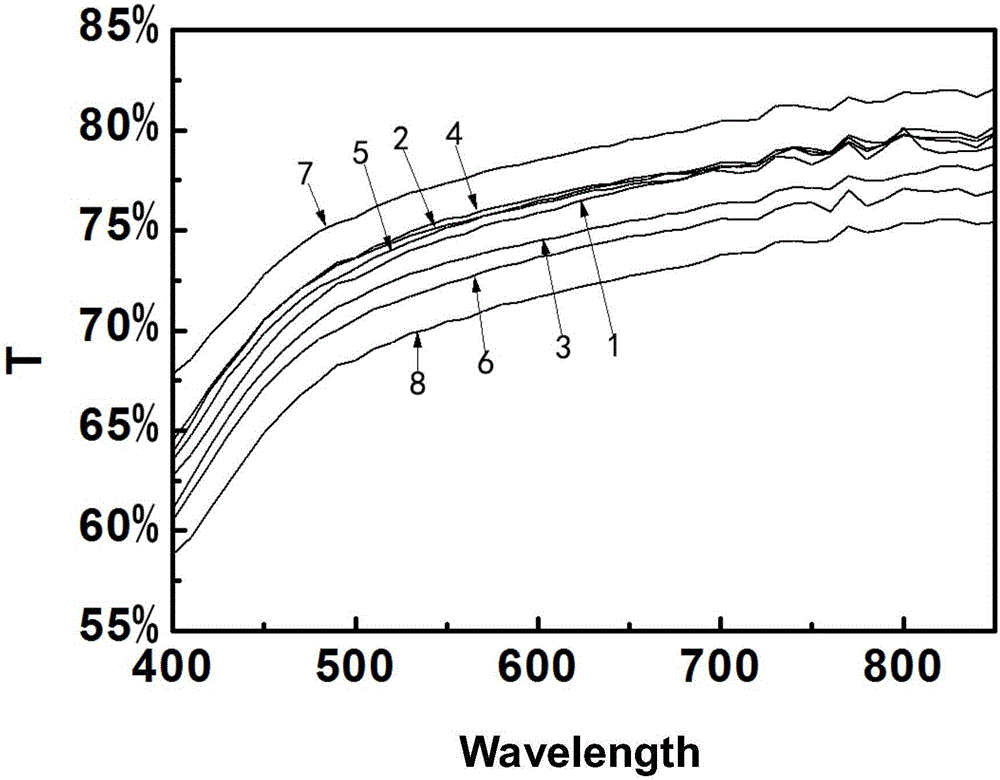

[0024] In order to verify the feasibility and superiority of this method, we fabricated silver nanowire electrodes according to the steps described in the summary of the invention, and tested the sheet resistance and transmittance of the electrodes. The specific implementation steps are as follows:

[0025] 1) Prepare eight 2.5cm×2.5cm silicon wafers, wipe the surface of the silicon wafers with a cotton ball dipped in acetone and ethanol in sequence, and then rinse the silicon wafers with deionized water to remove cotton residue on the surface. Then put it into acetone, ethanol and deionized water successively for ultrasonic treatment, the time of ultrasonic treatment is 5 minutes. After the treatment is completed, use a nitrogen air gun to dry the surface of the silicon wafer;

[0026] 2) configure the silver nanowires with a concentration of 5 mg / mL, the solvent of the silver nanowires is ethanol, the diameter of the silver nanowires is 90 nanometers, and the length is 20 t...

Embodiment 2

[0042] In order to confirm that the treated silver nanowire electrodes are suitable for flexible OLEDs, we fabricated OLED devices using the above electrodes. Specific steps are as follows:

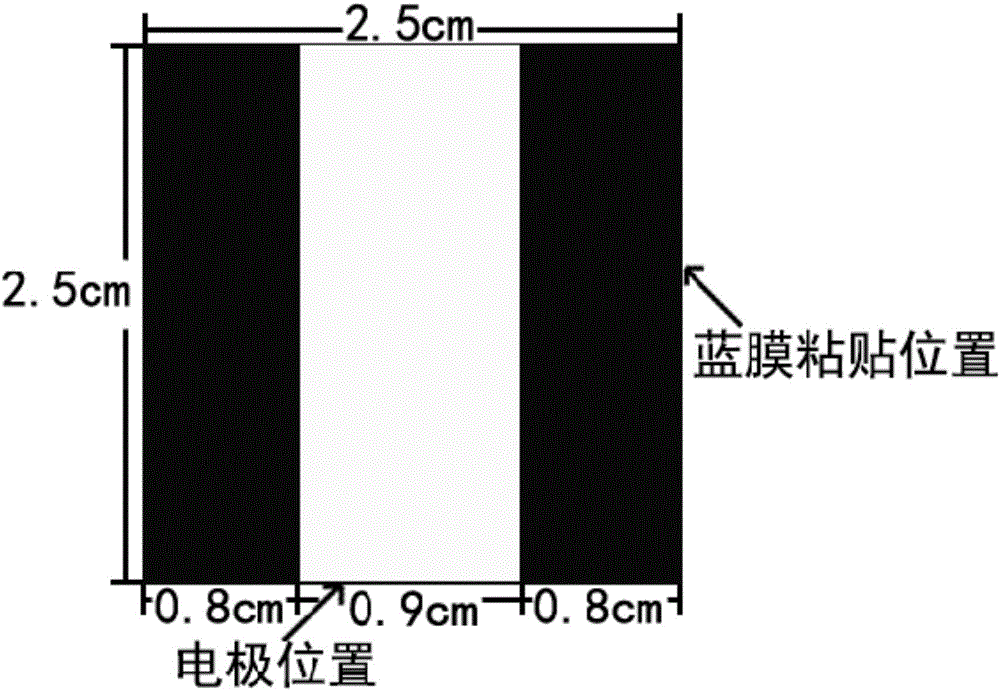

[0043] 1) Use the method mentioned in Example 1 to make silver nanowire electrodes, because OLED devices need to be made, so after step 2), you need to add a step, that is, stick a strip structure on both sides of the upper surface of the substrate near the edge. PVC blue film tape, and then spin coating, so that the silver nanowire film can only be spin-coated on the substrate in the middle area, so as to realize the preparation of strip electrodes, the position of the blue film paste and the shape of the electrode are as follows: image 3 shown. Since the samples that can be put in once are limited when preparing the OLED device, the best 15 minutes in Example 1 are selected for the treatment time of the plasma;

[0044] 2) Use an evaporation coating machine to make an OLED device. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com