Patents

Literature

31 results about "Insensitive munition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insensitive munitions are munitions that are designed to withstand stimuli representative of severe but credible accidents. The current range of stimuli are shock, (from bullets, fragments and shaped charge jets), heat (from fires or adjacent thermal events) and adjacent detonating munitions. A munition can have its vulnerability reduced by a number of means used on their own or in combination such as a reduced vulnerability energetic material, design features, additions or changes to packaging etc. The munition must still retain its terminal effect and performance within acceptable parameters.

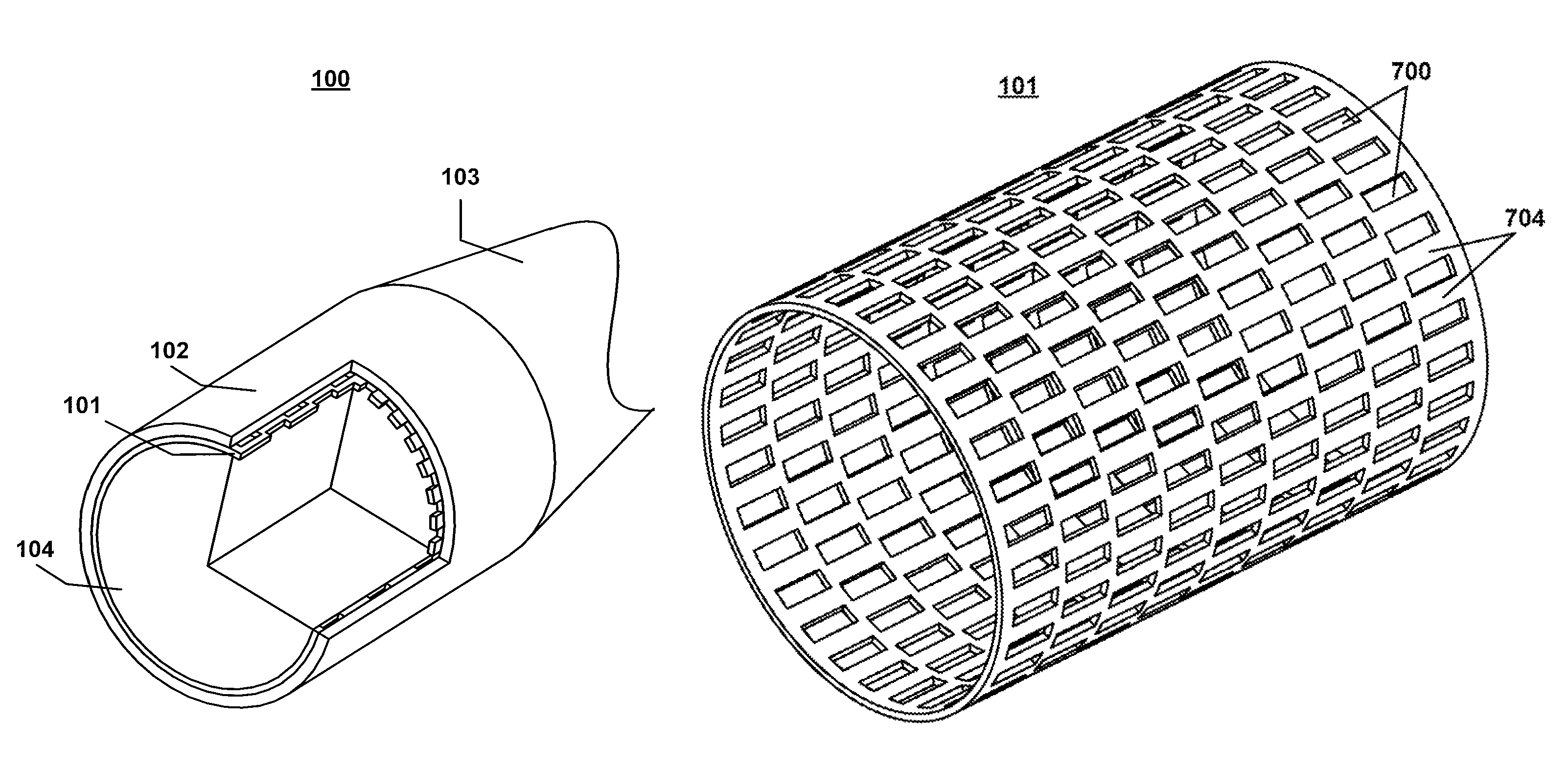

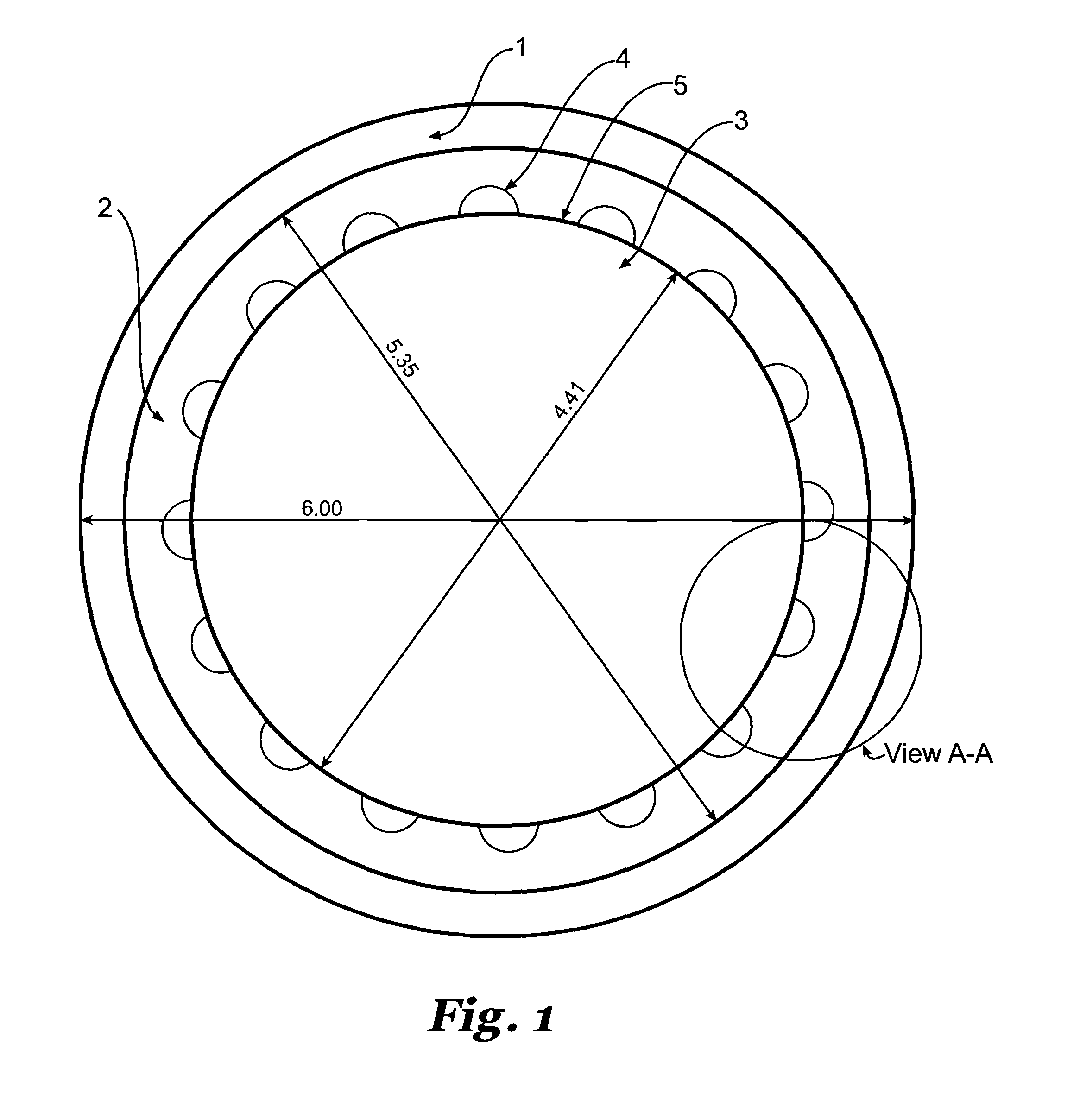

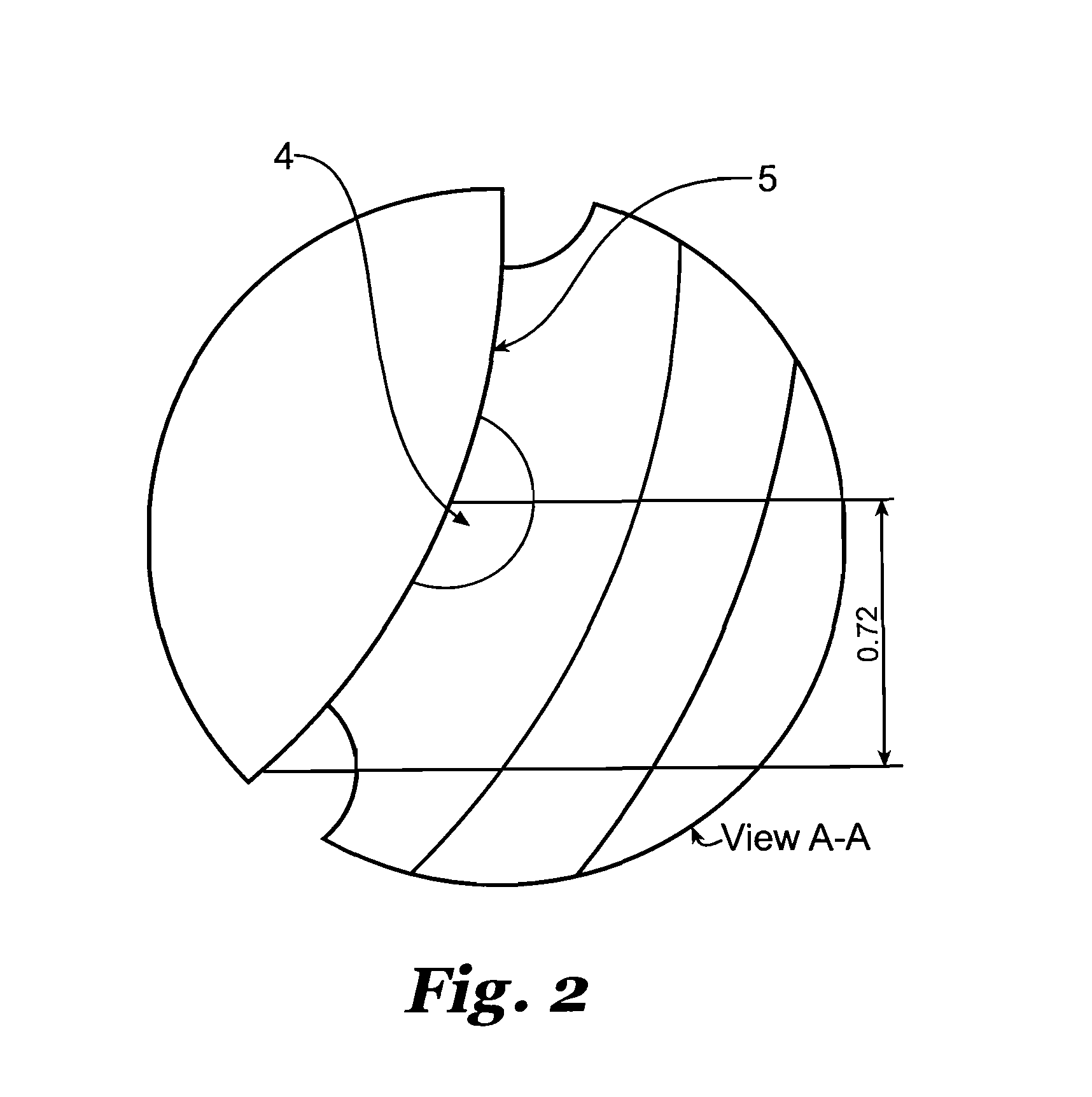

More safe insensitive munition for producing a controlled fragmentation pattern

InactiveUS7886667B1Faster and economical to fabricateReduce weightAmmunition projectilesAdditive manufacturing apparatusDetonationEngineering

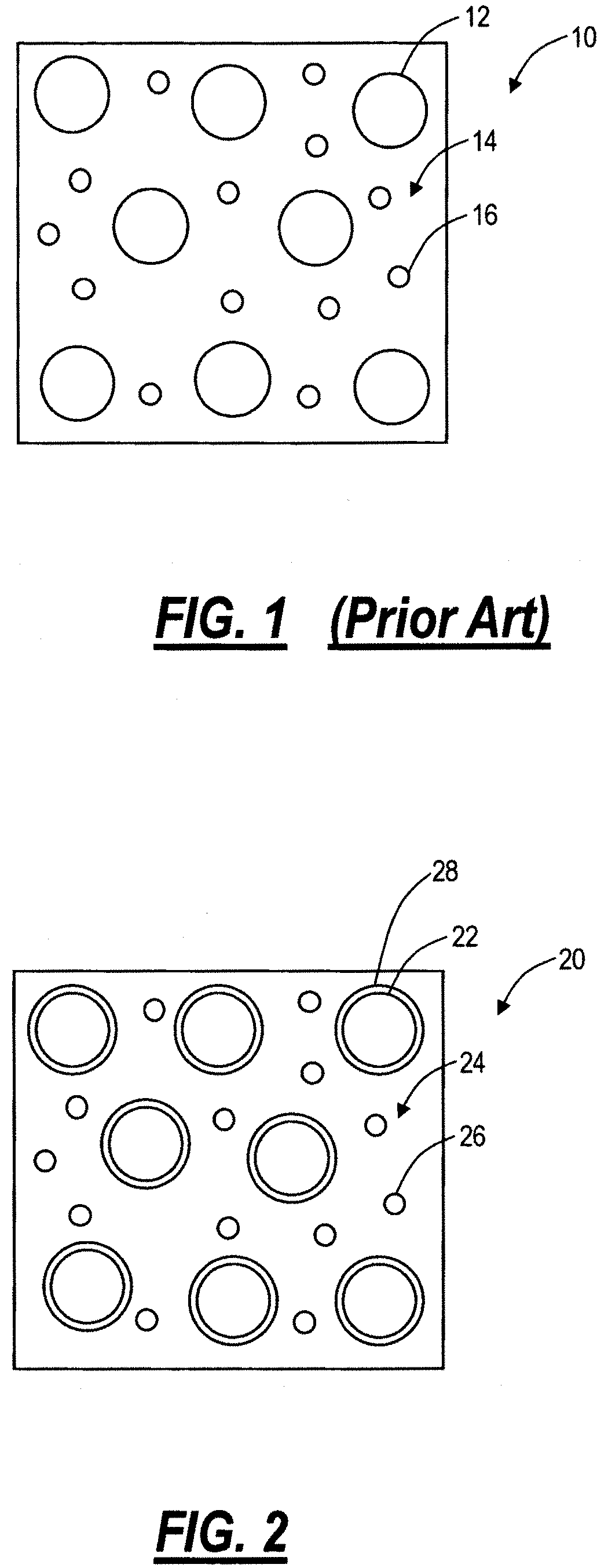

A warhead includes a body, a patterned liner made of plastic, and an explosive charge disposed within the liner. The liner pattern is formed of gaps and liner elements. The explosive charge includes a first set of sections that are disposed adjacent to the liner gaps and a second set of sections that are disposed adjacent to the liner elements. Upon detonation of the explosive charge and because of the temporal delay in transmitting the detonation energy between these two sets of sections, the warhead body is caused to shear and break into fragments with controlled size. The use of plastic as the liner material also provides a welcome safety feature for this warhead. In the event of unwanted heat ignition, the plastic (which is also low melt temperature material), would melt to seal the explosive and would also flow. Because of the plastic, neither sudden pressure nor heat / ignition inside the round, would therefore be as catastrophic.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

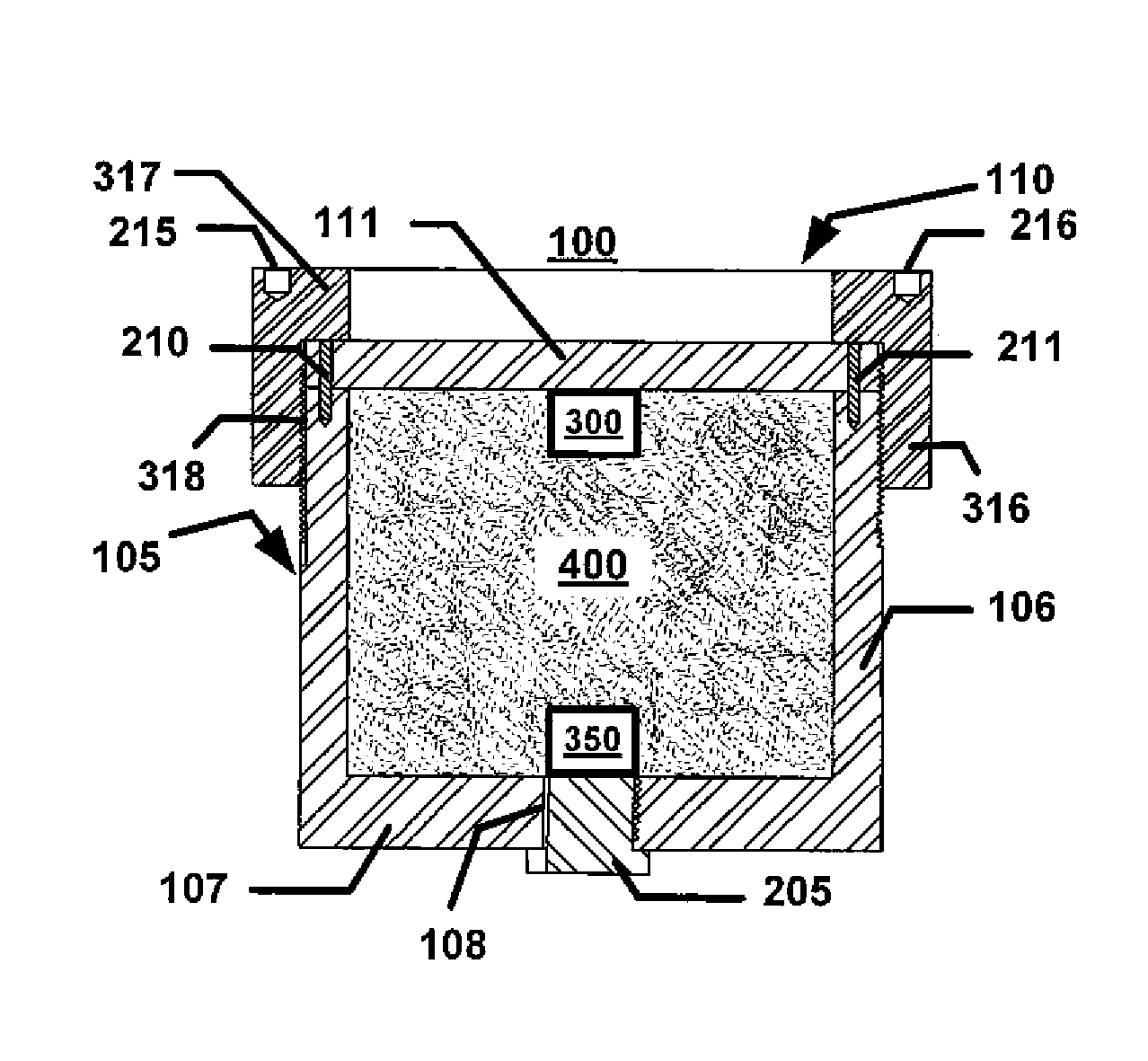

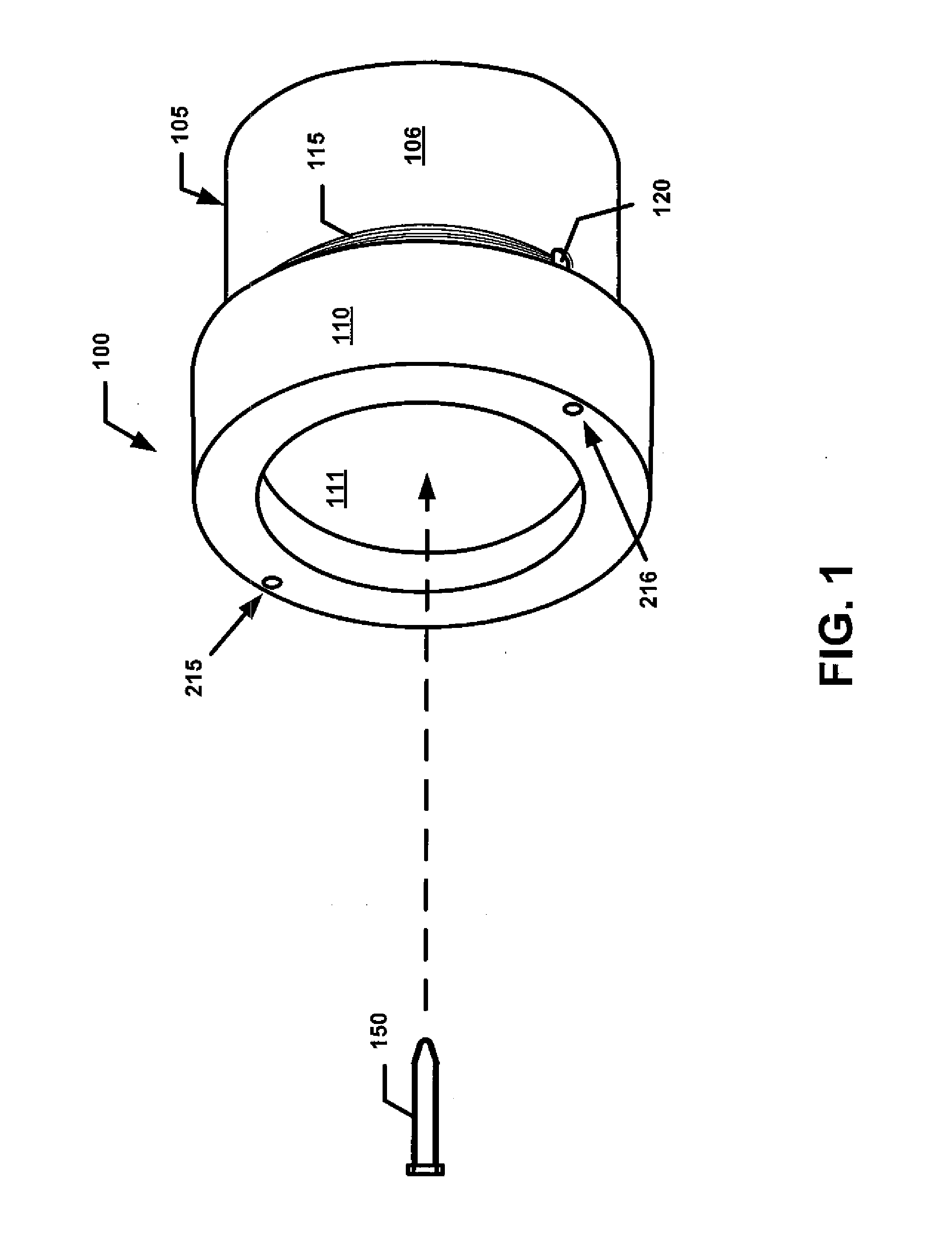

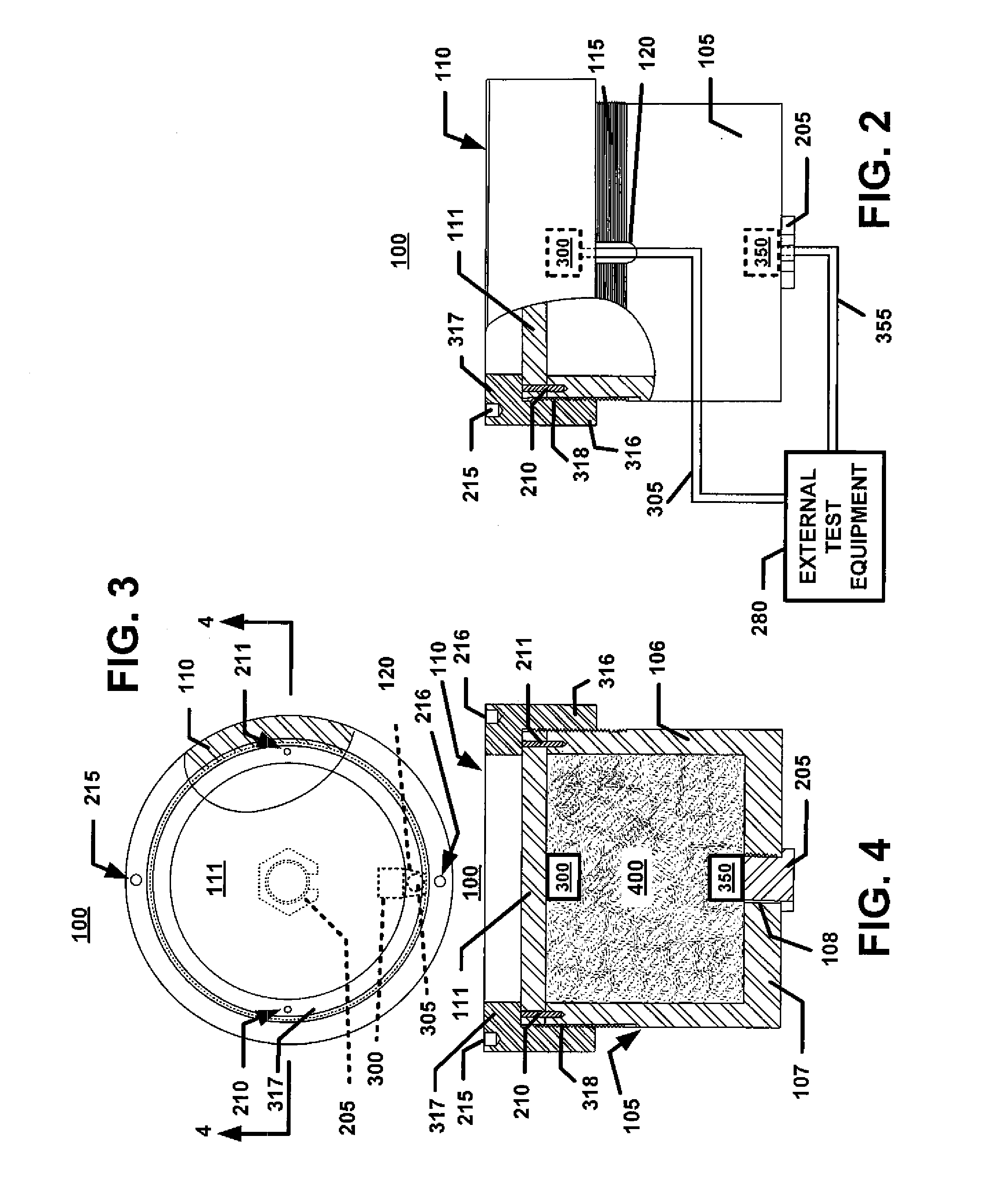

Assembly and method for standardized insensitive munitions testing

InactiveUS8707764B1Decreased shock sensitivityLess brittleAmmunition testingFuel testingShock waveDetonation

A test assembly for building a safety profile and a sensitivity profile of an explosive, by impacting the test assembly with a projectile. The safety profile of the explosive is built by determining a detonation threshold of the explosive in reaction to the projectile. The sensitivity profile is built by measuring a pressure difference between pressures acquired by the top sensor and the bottom sensor, resulting from a shock wave that travels through the explosive.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

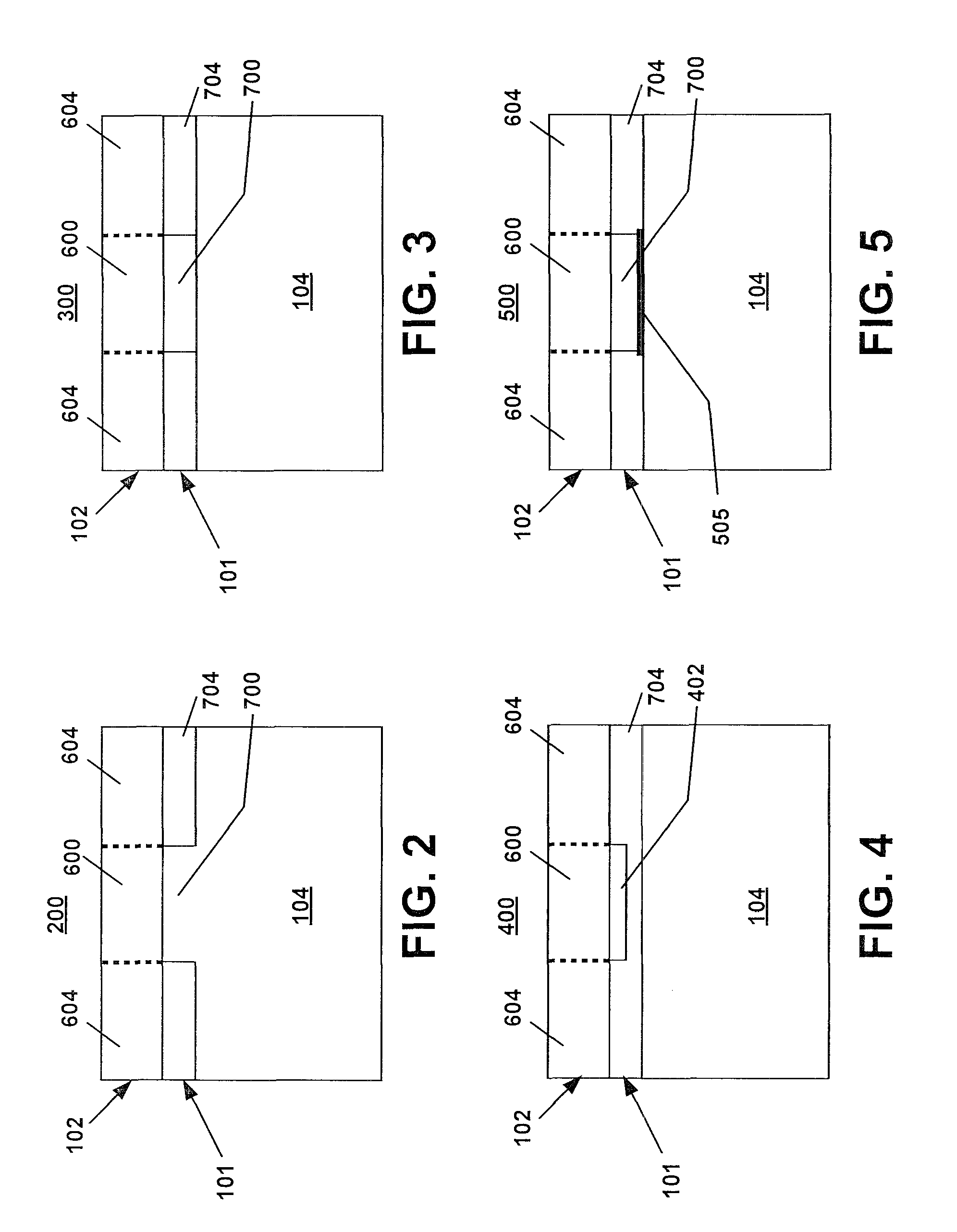

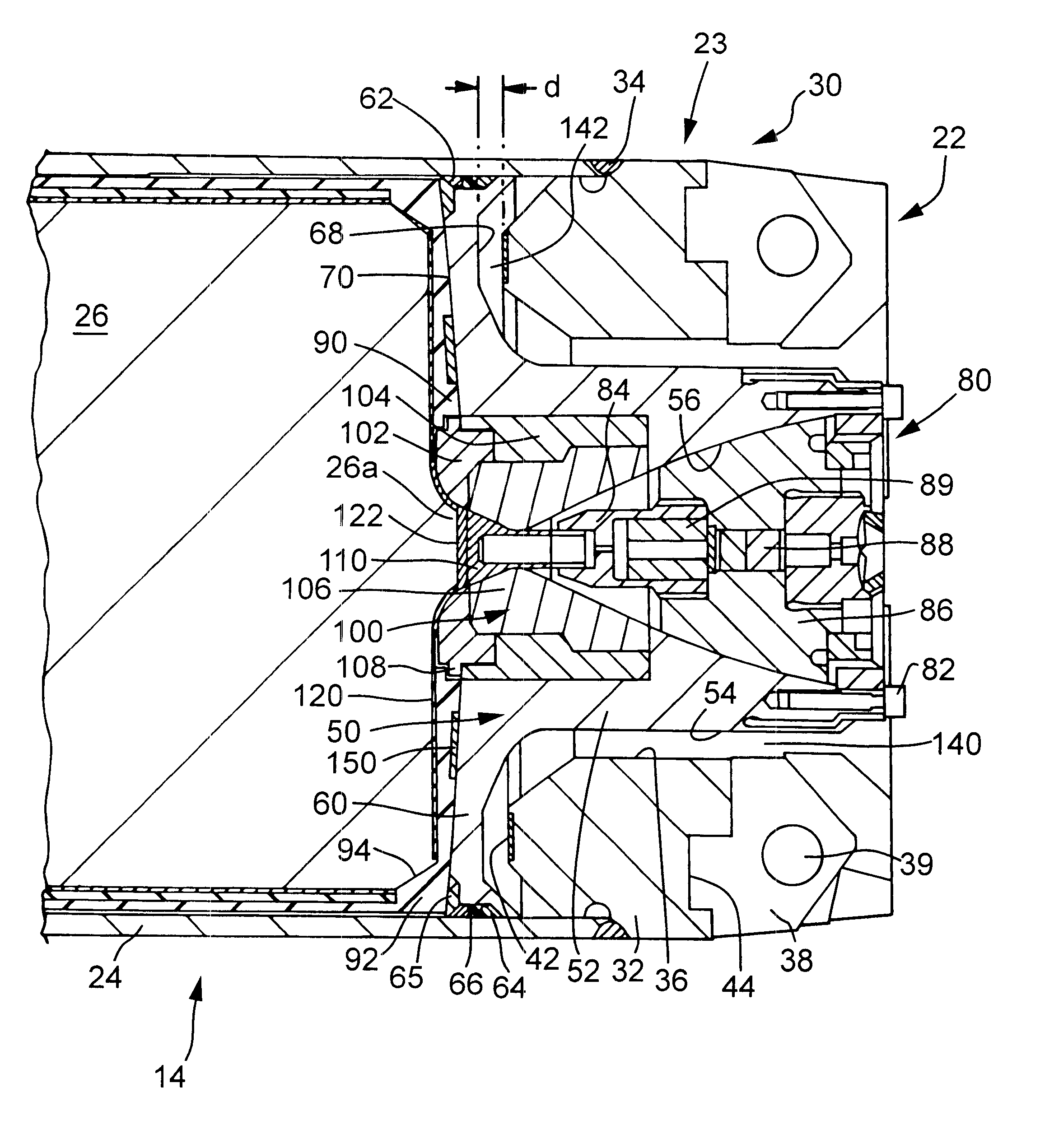

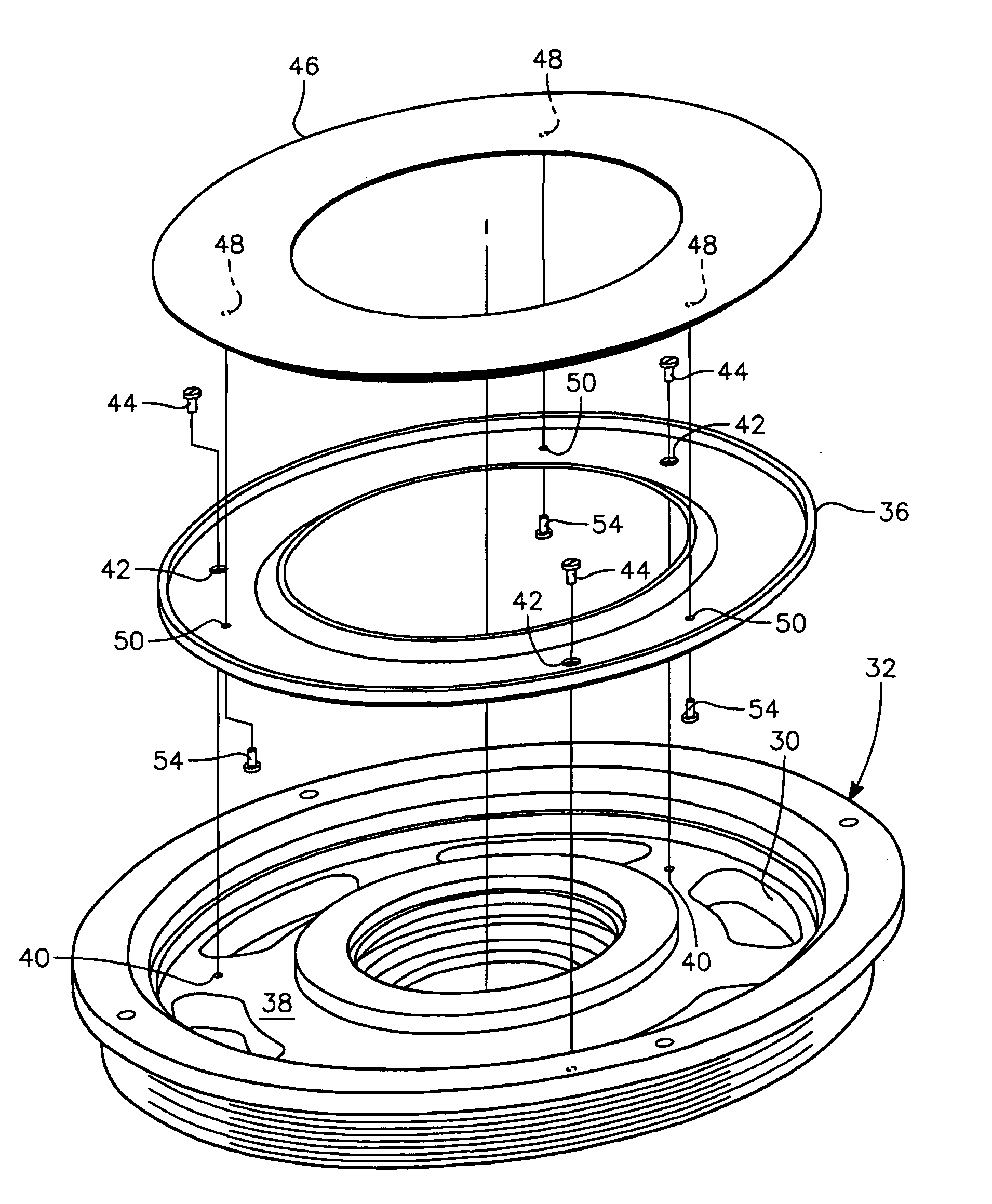

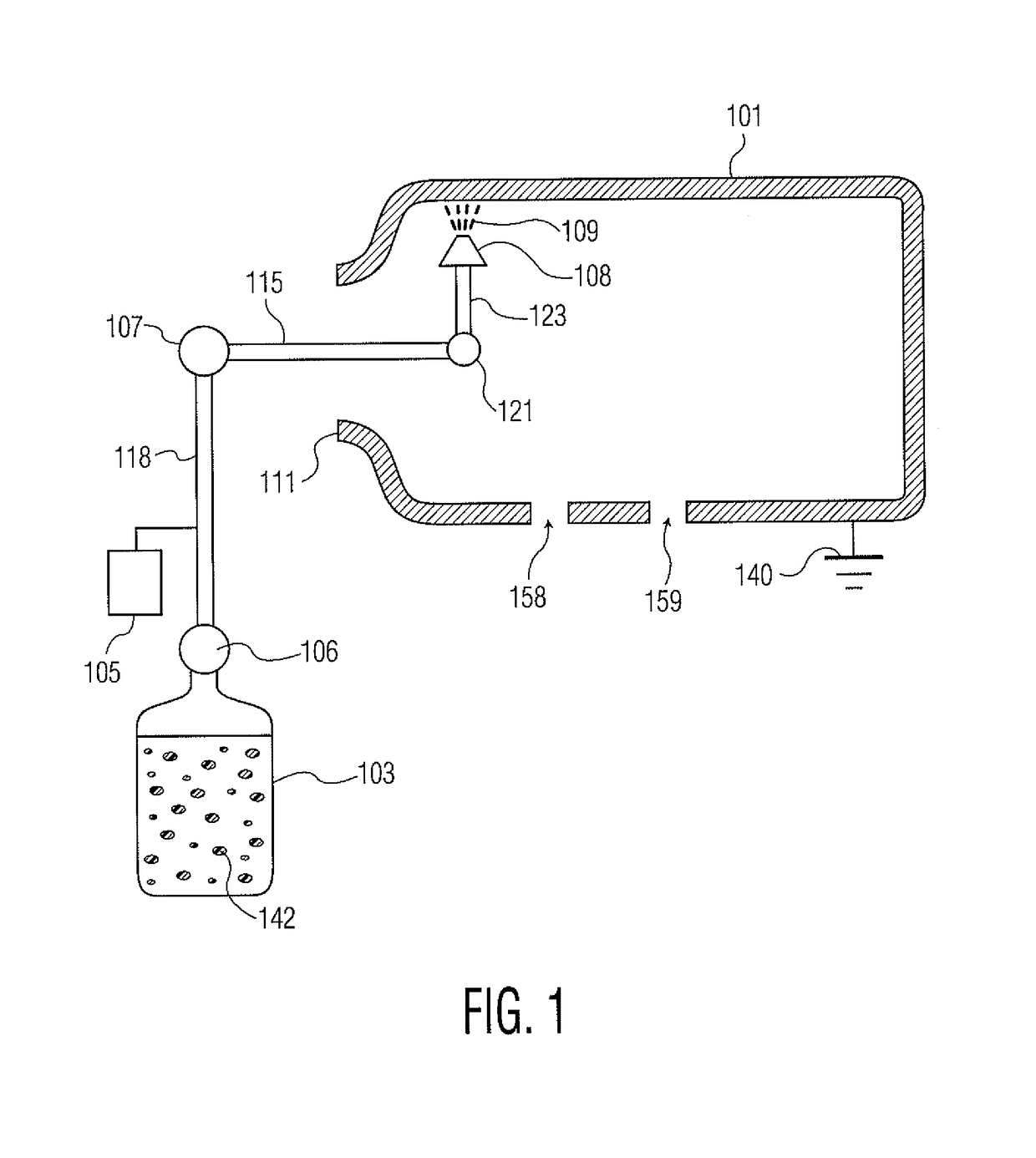

Insensitive munitions warhead explosive venting system

A venting system for a casing containing an explosive material includes a base plug having one or more venting ports. A ring-shaped failure mechanism mounted to the base plug seals the venting ports. The failure mechanism has a selected melting temperature such that raising the temperature of the failure mechanism to its melting temperature causes the failure mechanism to unseal the venting port to allow controlled burning of the explosive material. An insert ring formed of a durable material to protect the failure mechanism from being damaged may be mounted on an outer surface of the failure mechanism. An adhesive may be used to seal gaps between the failure mechanism, the insert ring and the base plug. The failure mechanism may have a peripheral tab formed to fit within a corresponding groove in the base plug to mount the failure mechanism securely to the base plug.

Owner:SEC OF THE NAVY AS REPRESENTED BY THE UNTITED STATES OF AMERICA

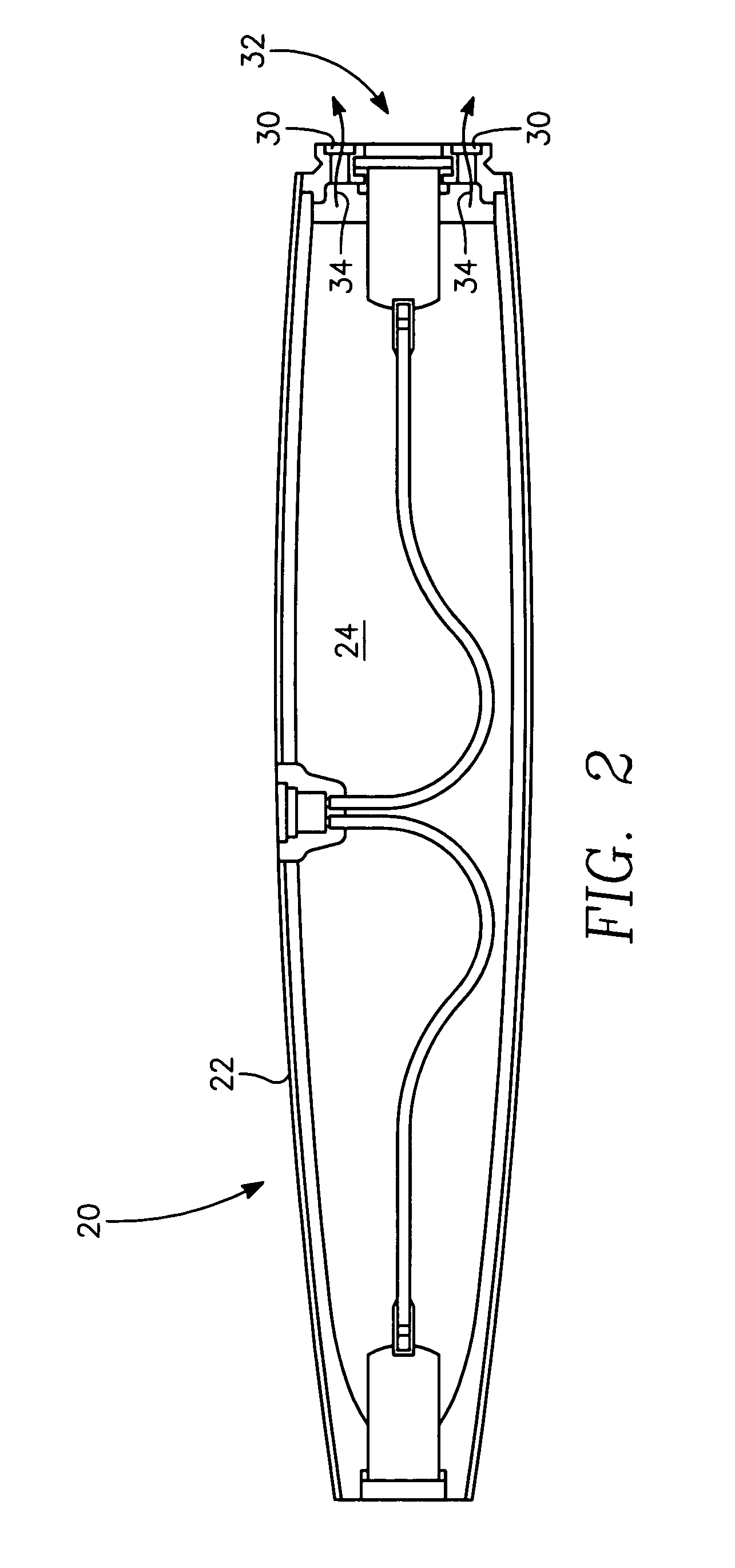

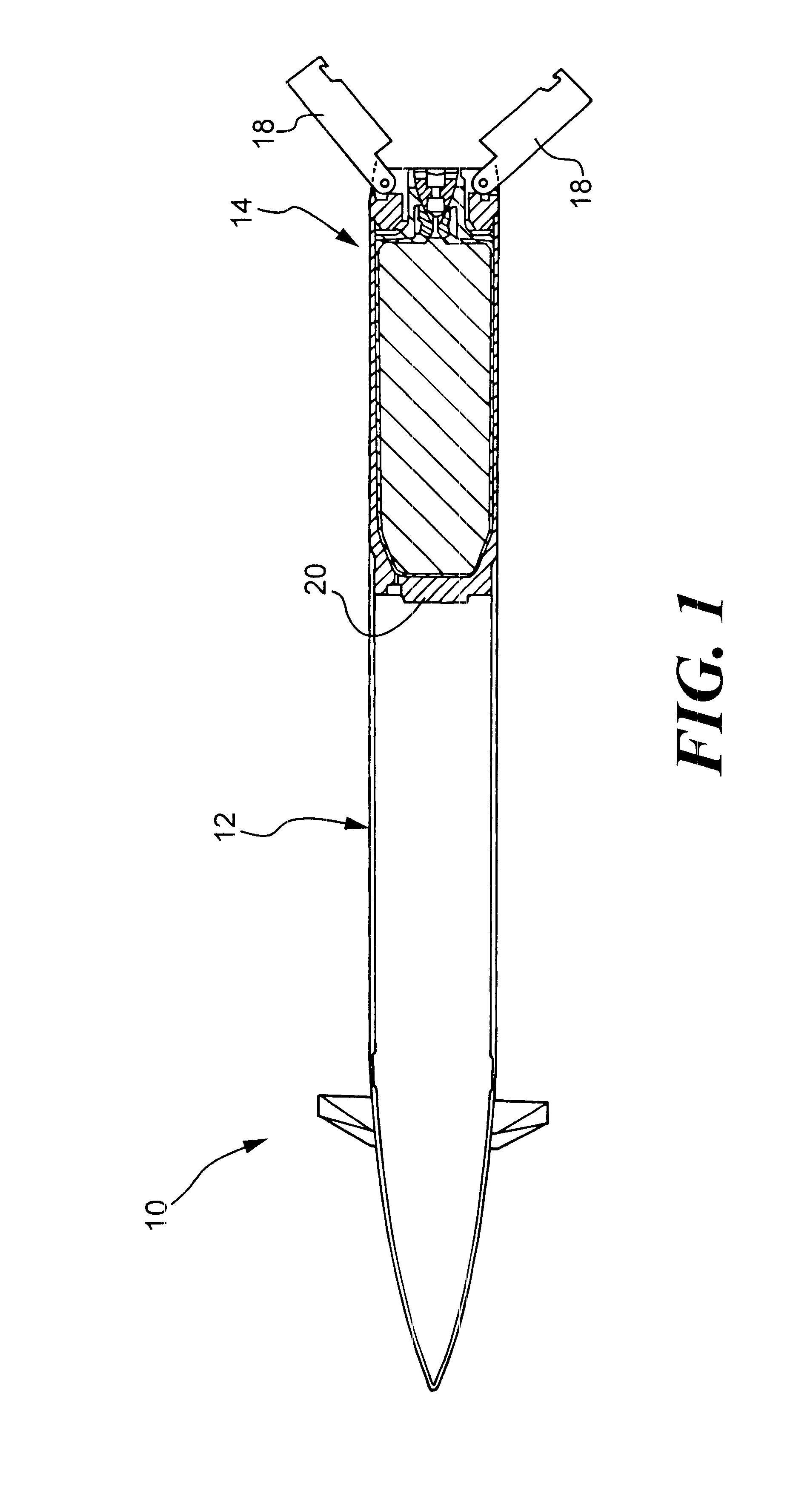

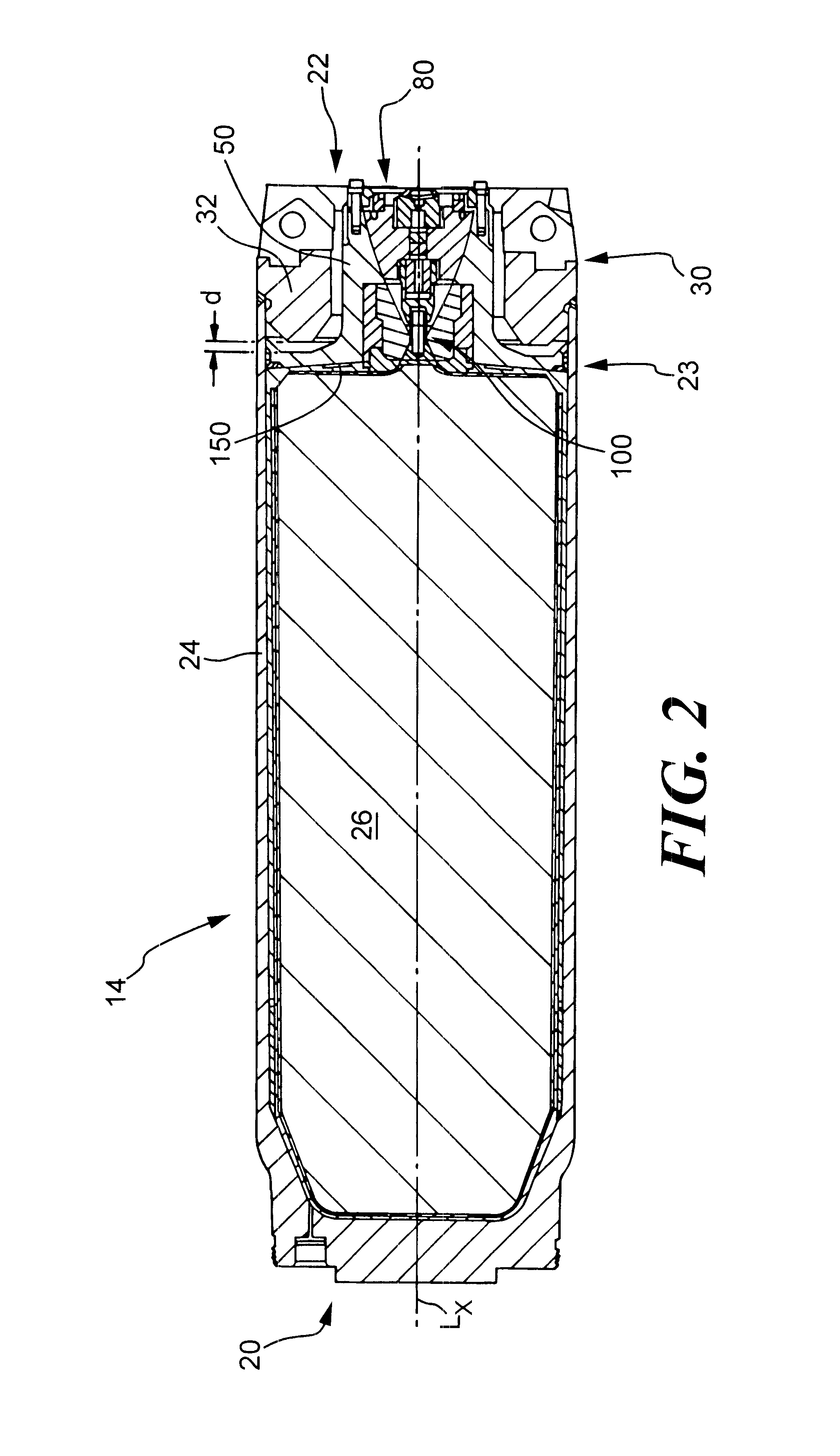

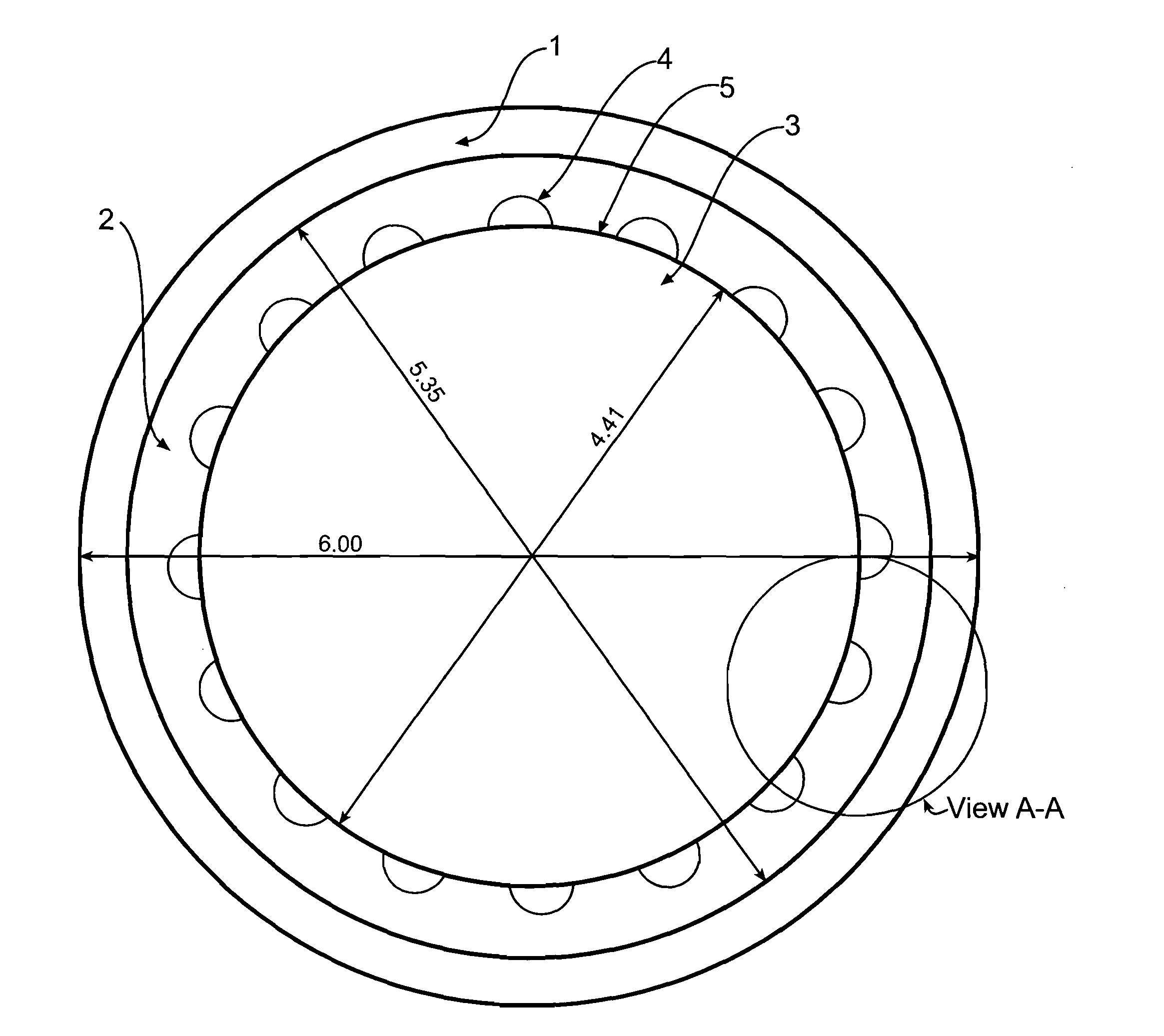

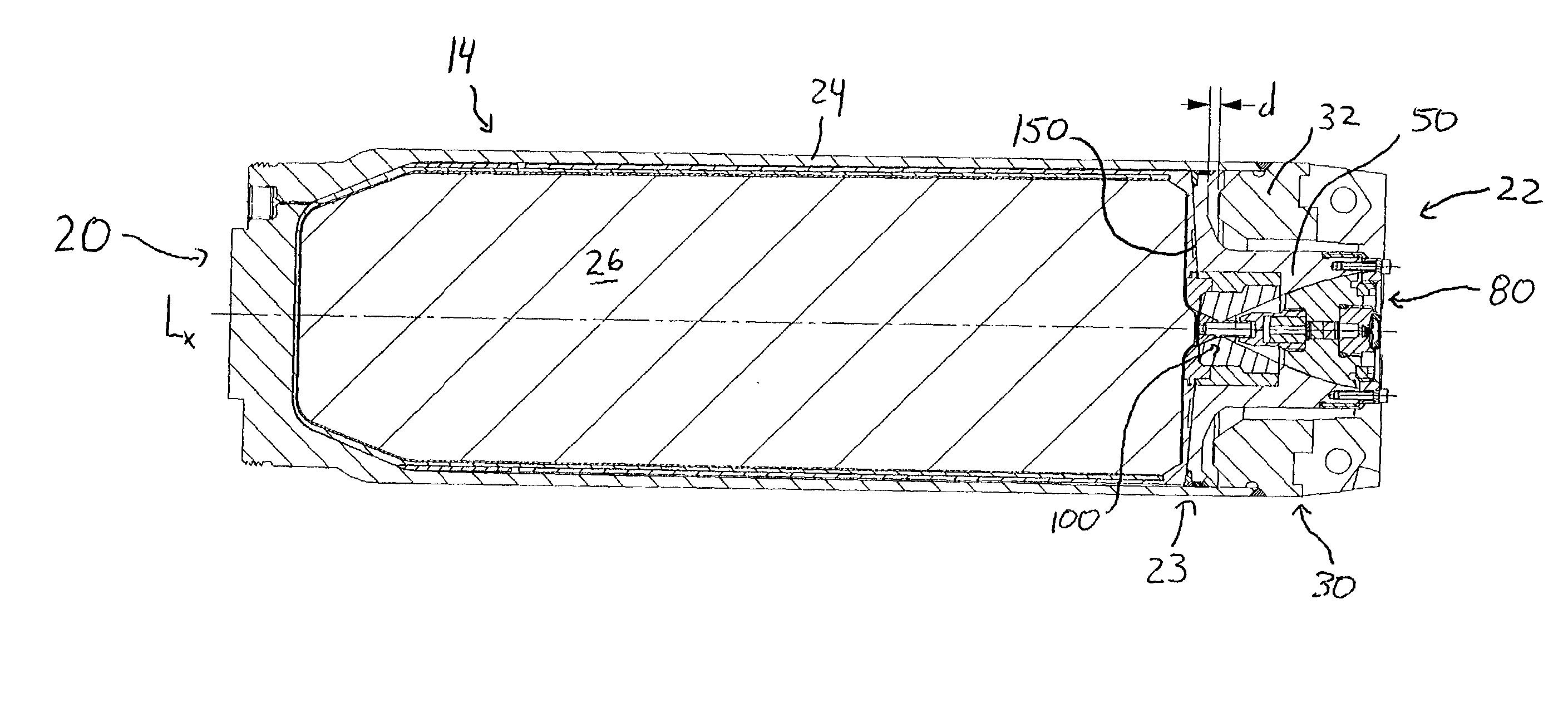

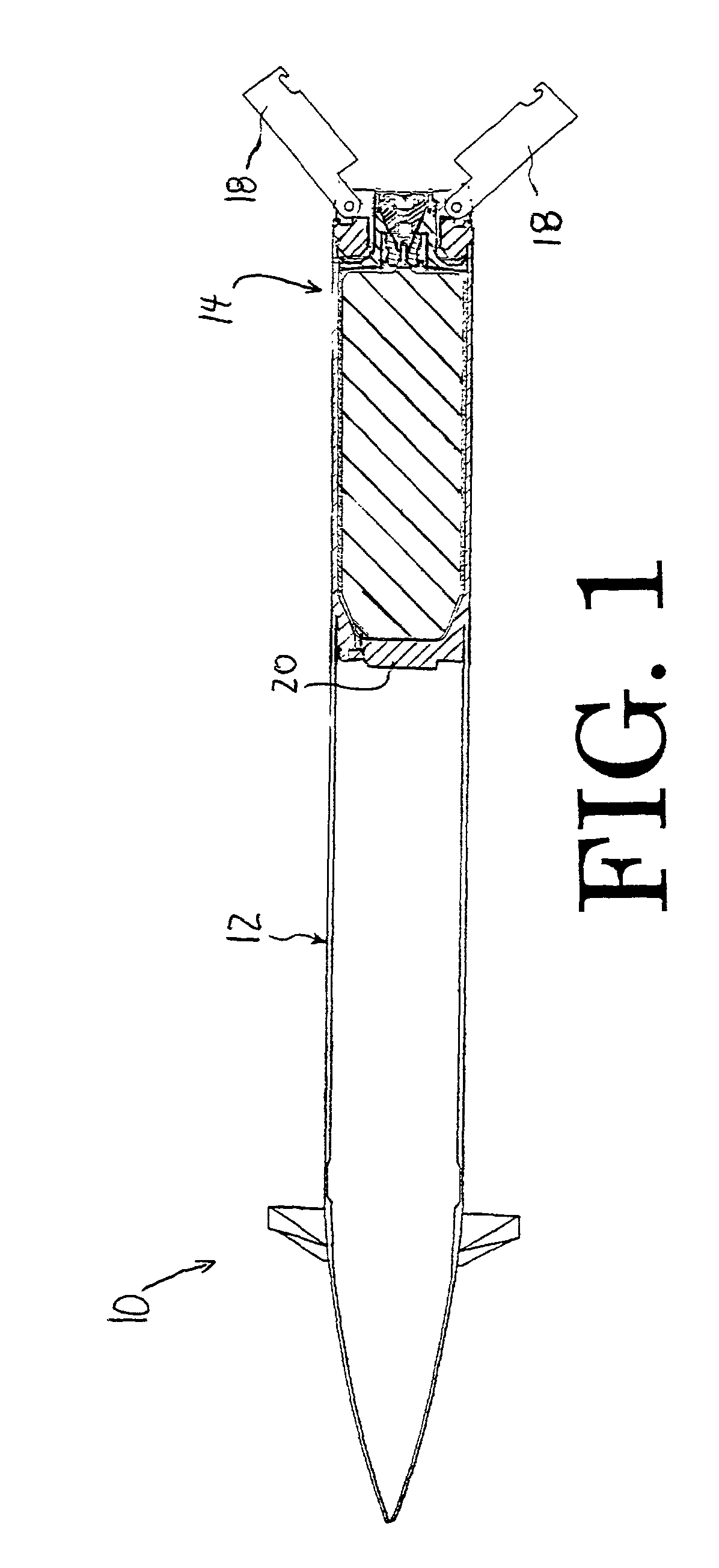

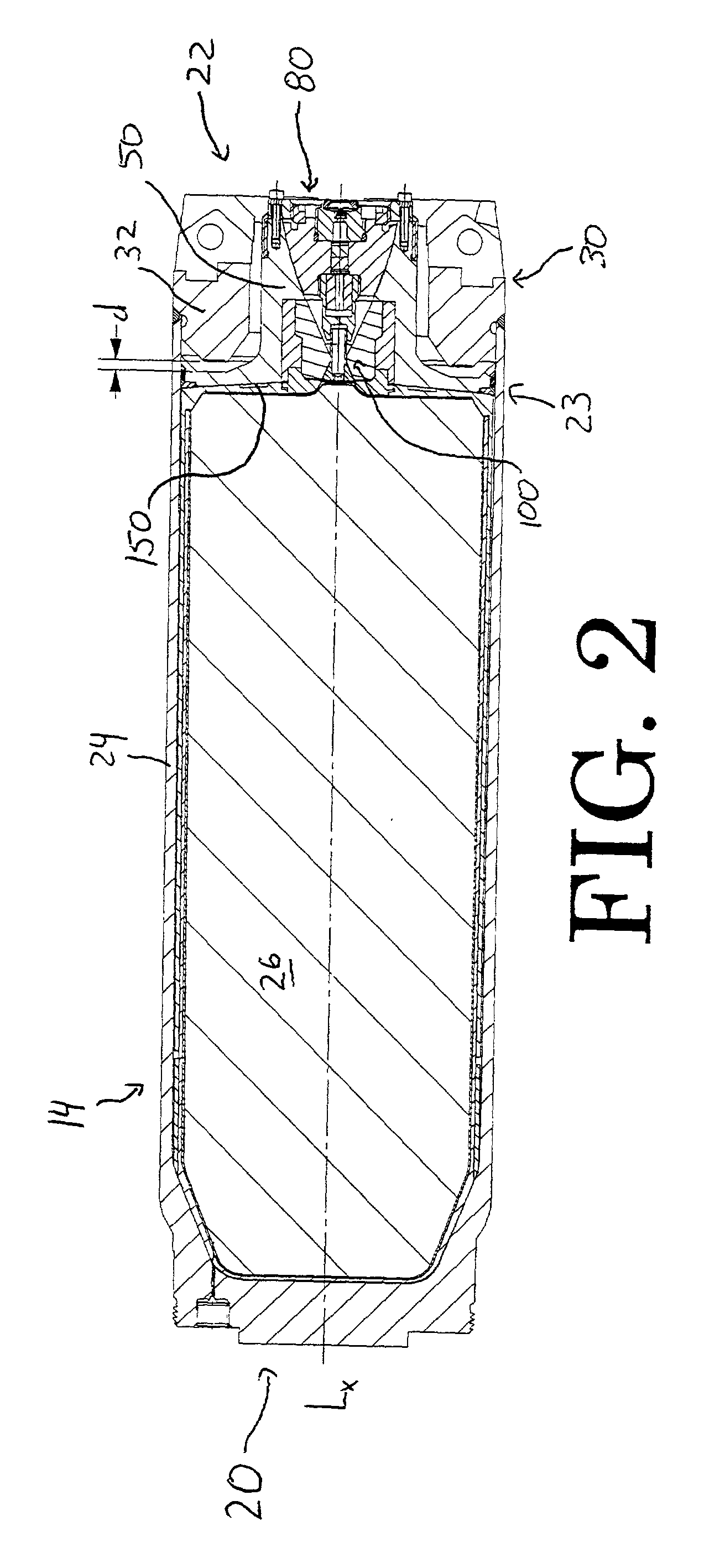

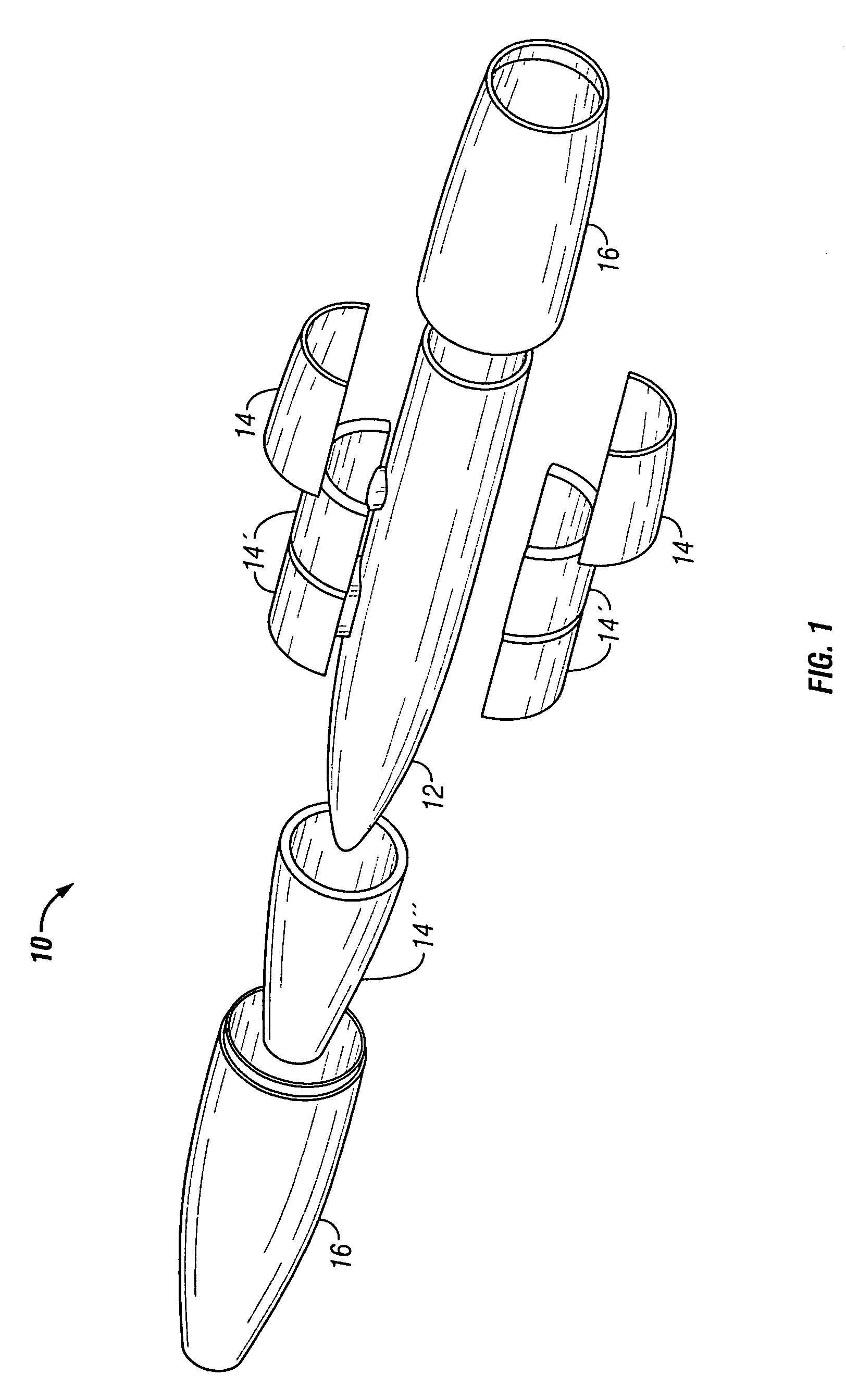

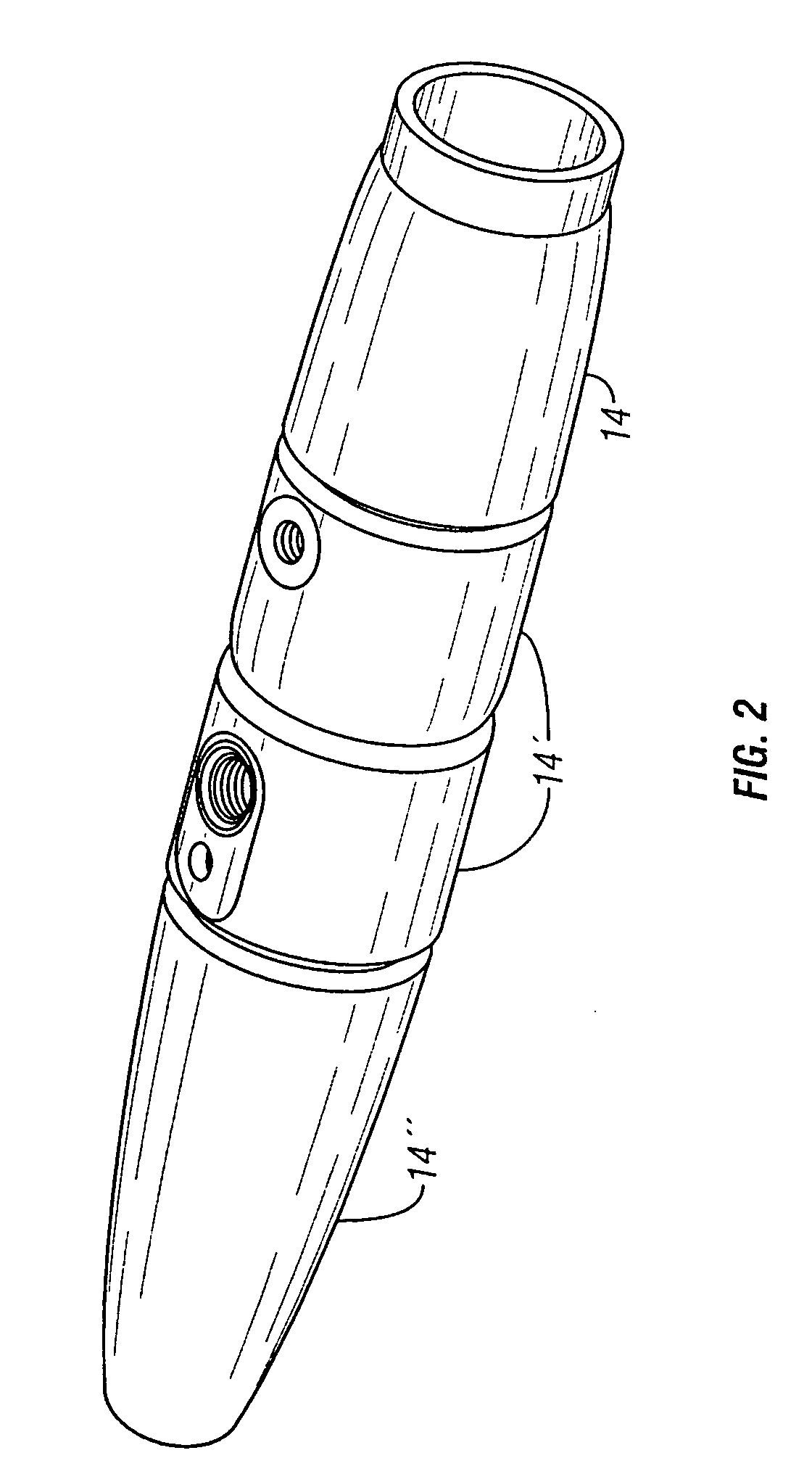

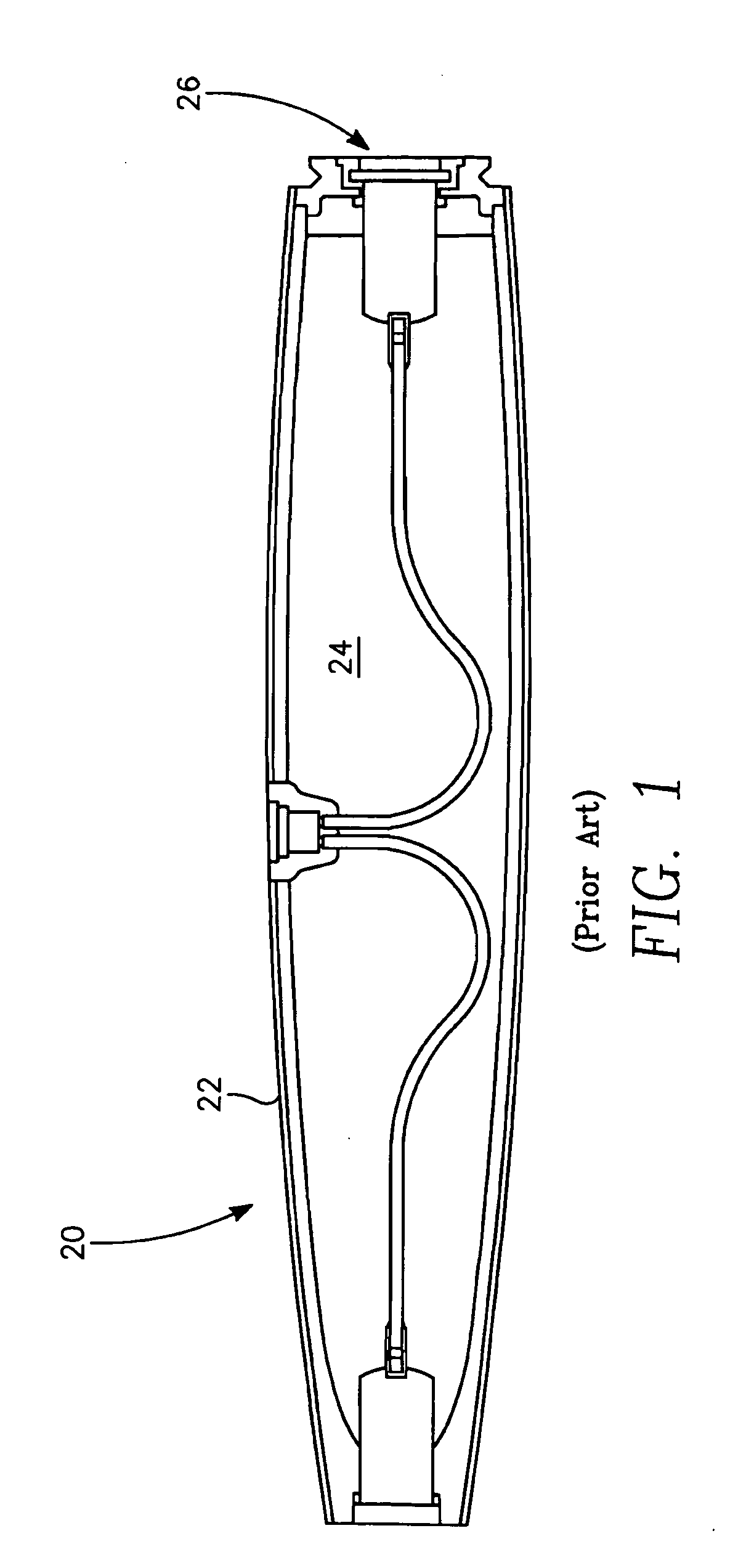

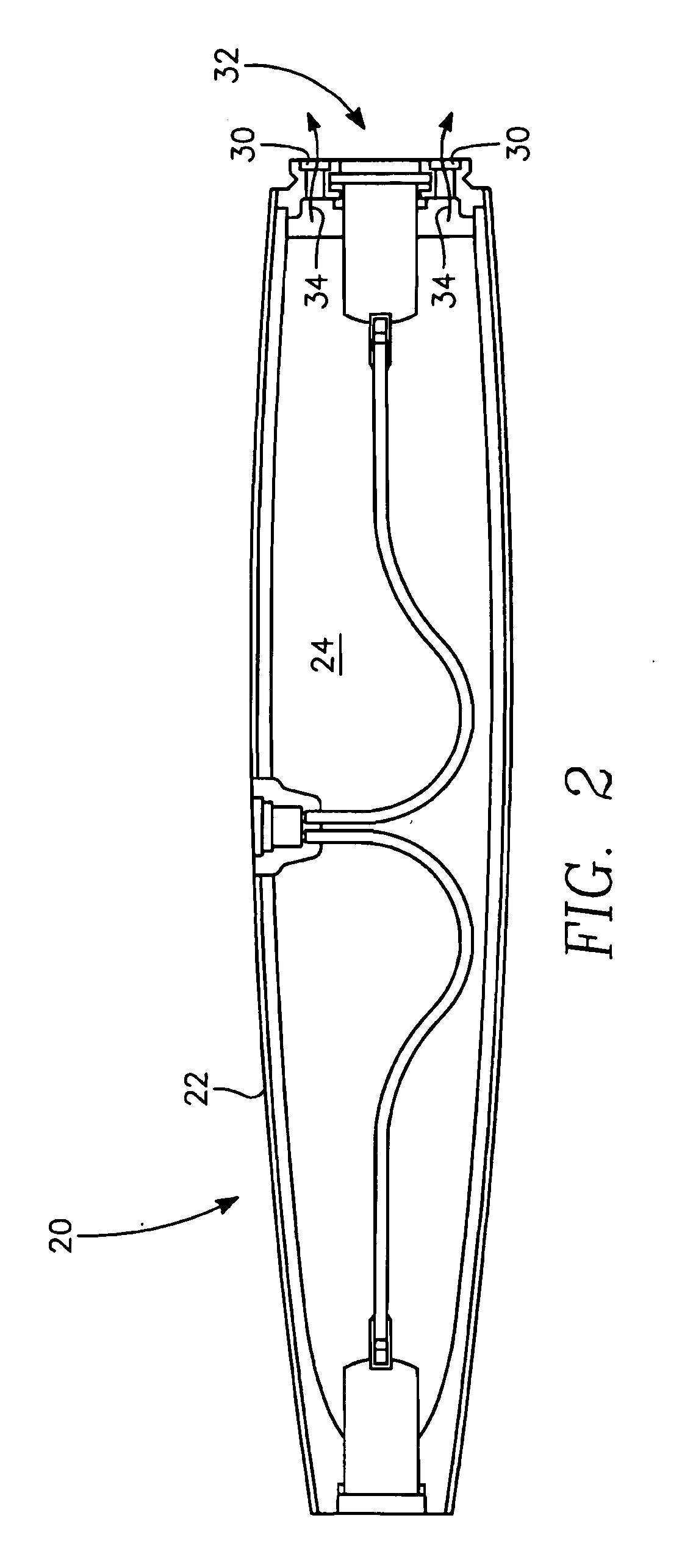

Rocket motors with insensitive munitions systems

InactiveUS6619029B2Rocket engine plantsSelf-propelled projectilesThermal expansionPressure equilibrium

An embodiment of the rocket motor of this invention employs an insensitive munitions approach that, when subjected to elevated external temperatures, is activated by thermal expansion of the main propellant and gas generation from a secondary insensitive munitions charge. In a preferred embodiment, the rocket motor also includes a pressure equalizing system that accommodates changing temperature conditions during storage as well as varying gas pressure inherent in gun-launched systems in a manner that allows for thinner case cylinder design and increased propellant volume.

Owner:NORTHROP GRUMMAN SYST CORP

Sculpted reactive liner with semi-cylindrical linear open cells

InactiveUS8387539B1Increase impactIncreases ejection velocityAmmunition projectilesProjectilesDetonationEngineering

Bombs lined with reactive liners that improve the blast and fragmentation of the bombs is disclosed. The effect is caused by the Richtmyer-Meshkov instability which is introduced at the explosive / reactive liner interface by introducing semi-cylindrical open linear cells between the reactive liner and the explosive that are void. This geometry produces a turbulent flow effect which readily mixes the reactive liner when accelerated by the grazing shock wave generated during detonation, which moves through the liner and case material. The geometry produces the added effect of creating faster and more plentiful fragments that are lighter in mass than those produced by typical bombs that are annularly lined with reactive liners, while maintaining insensitive munitions capability.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

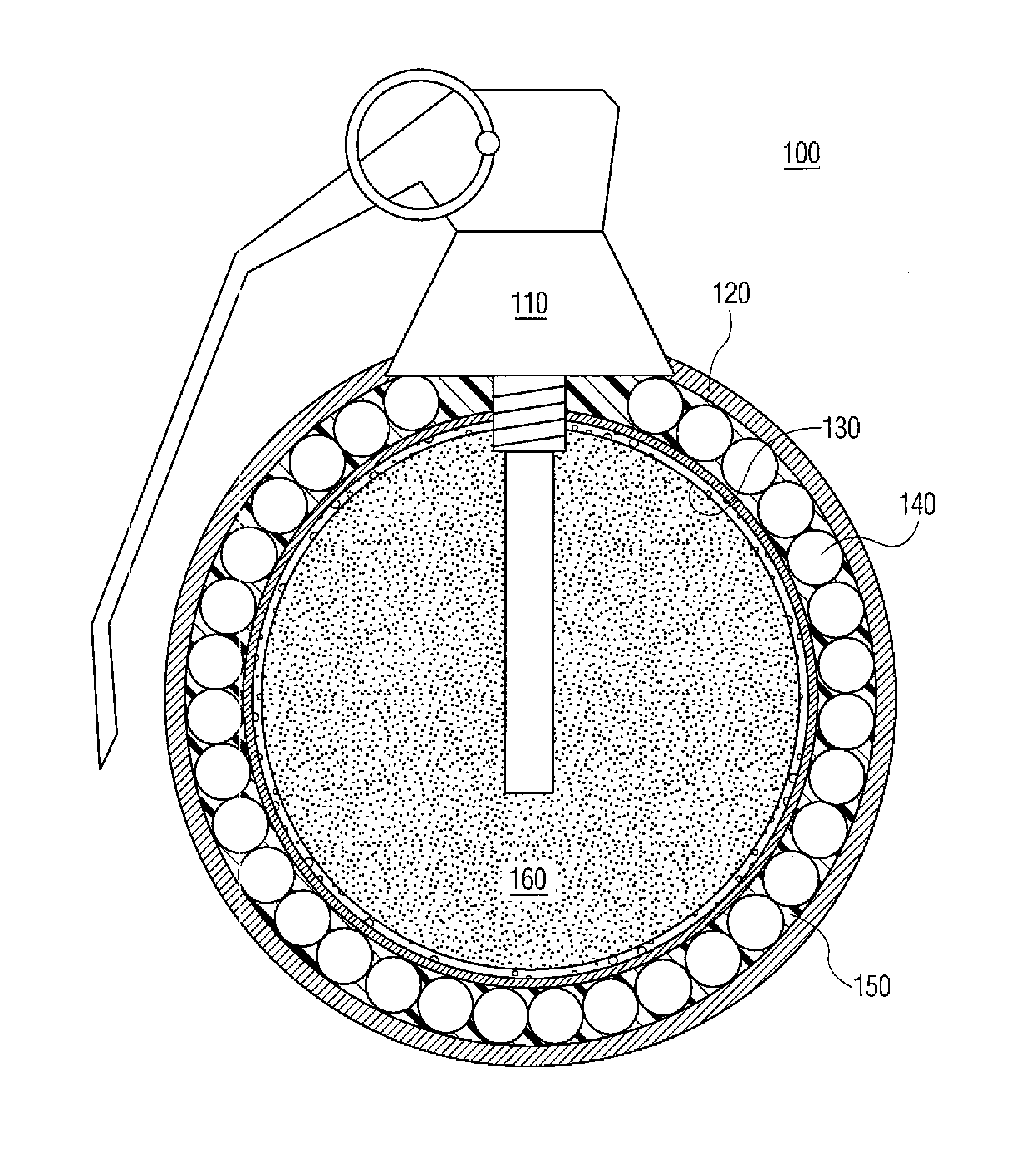

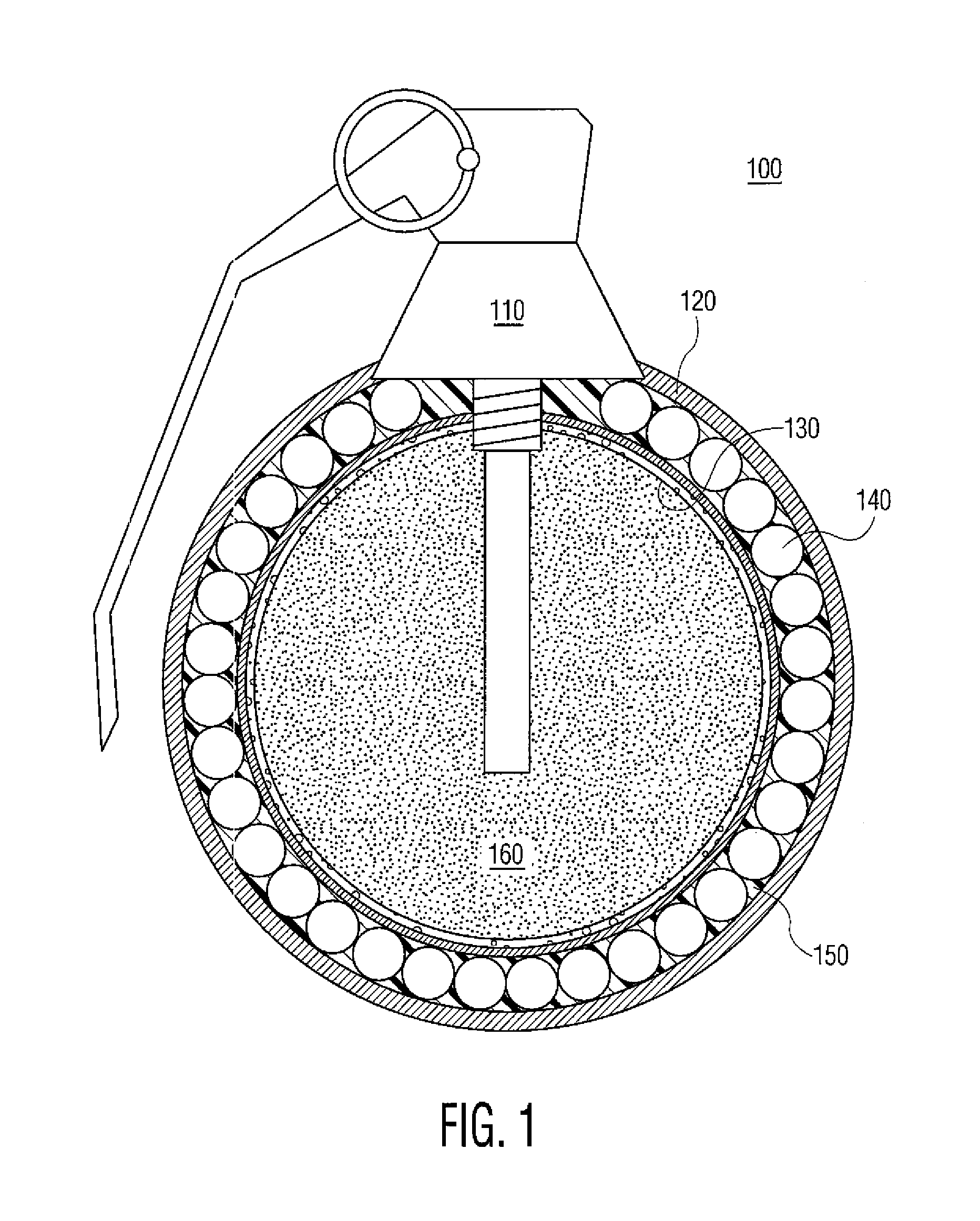

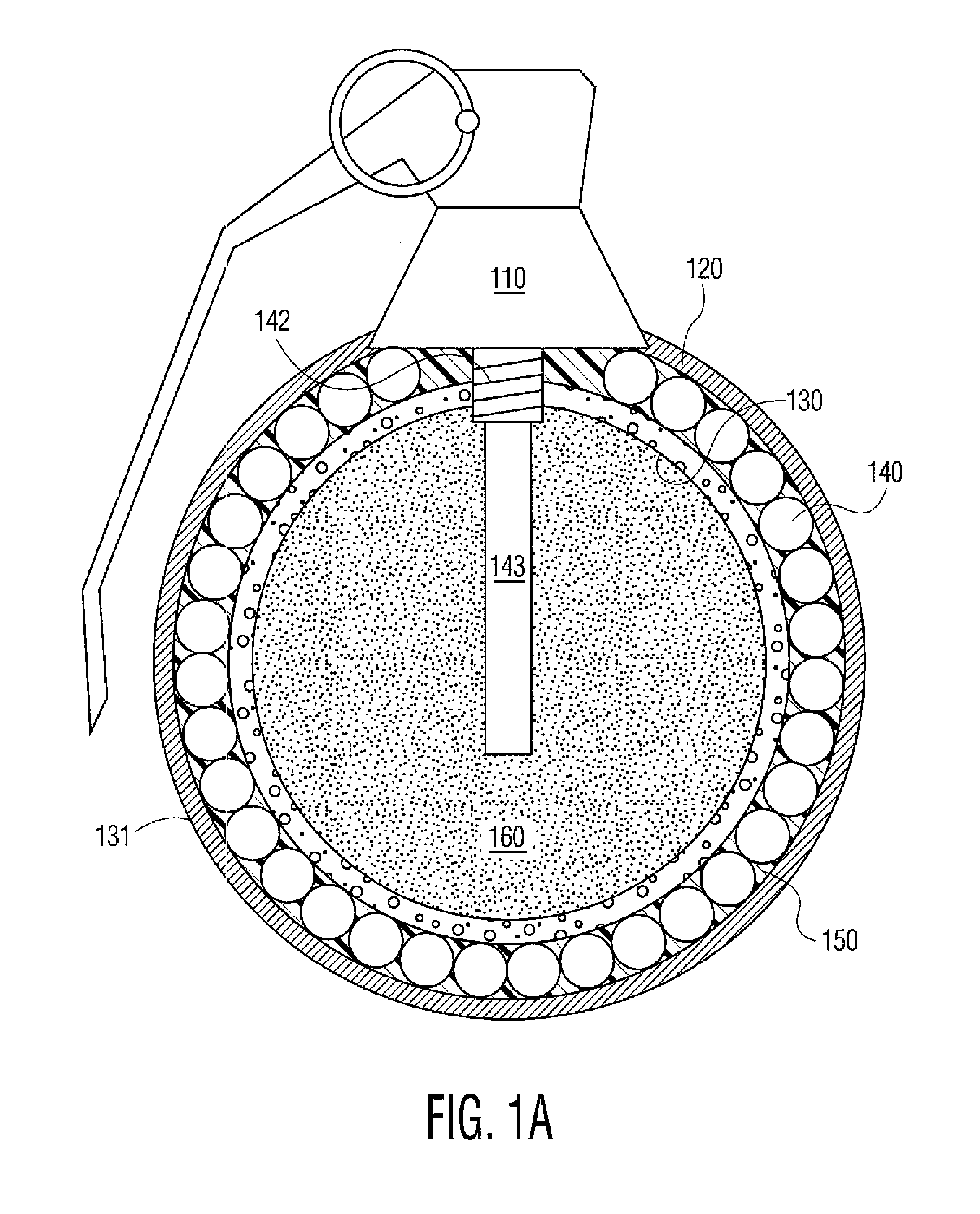

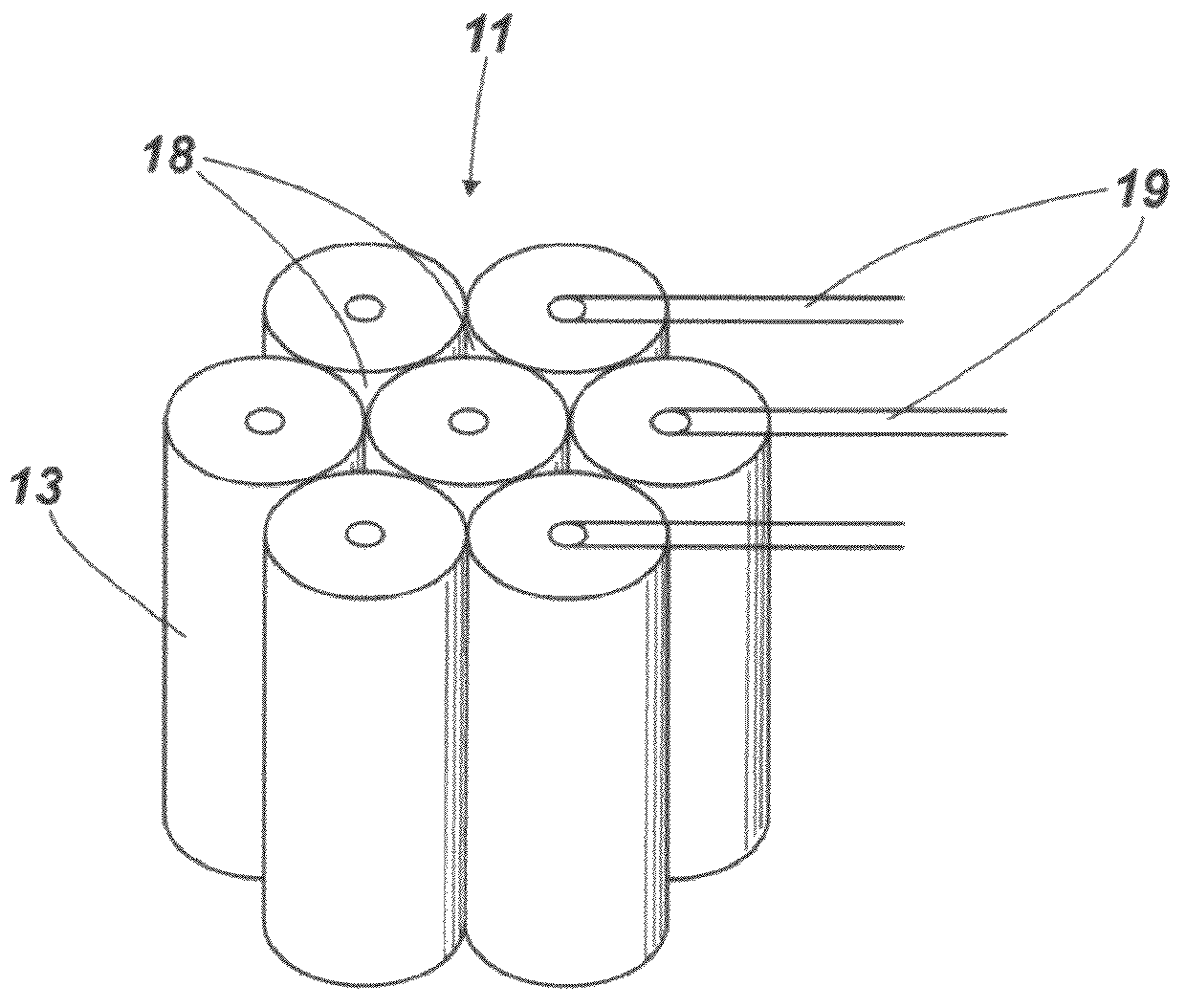

Insensitive munition

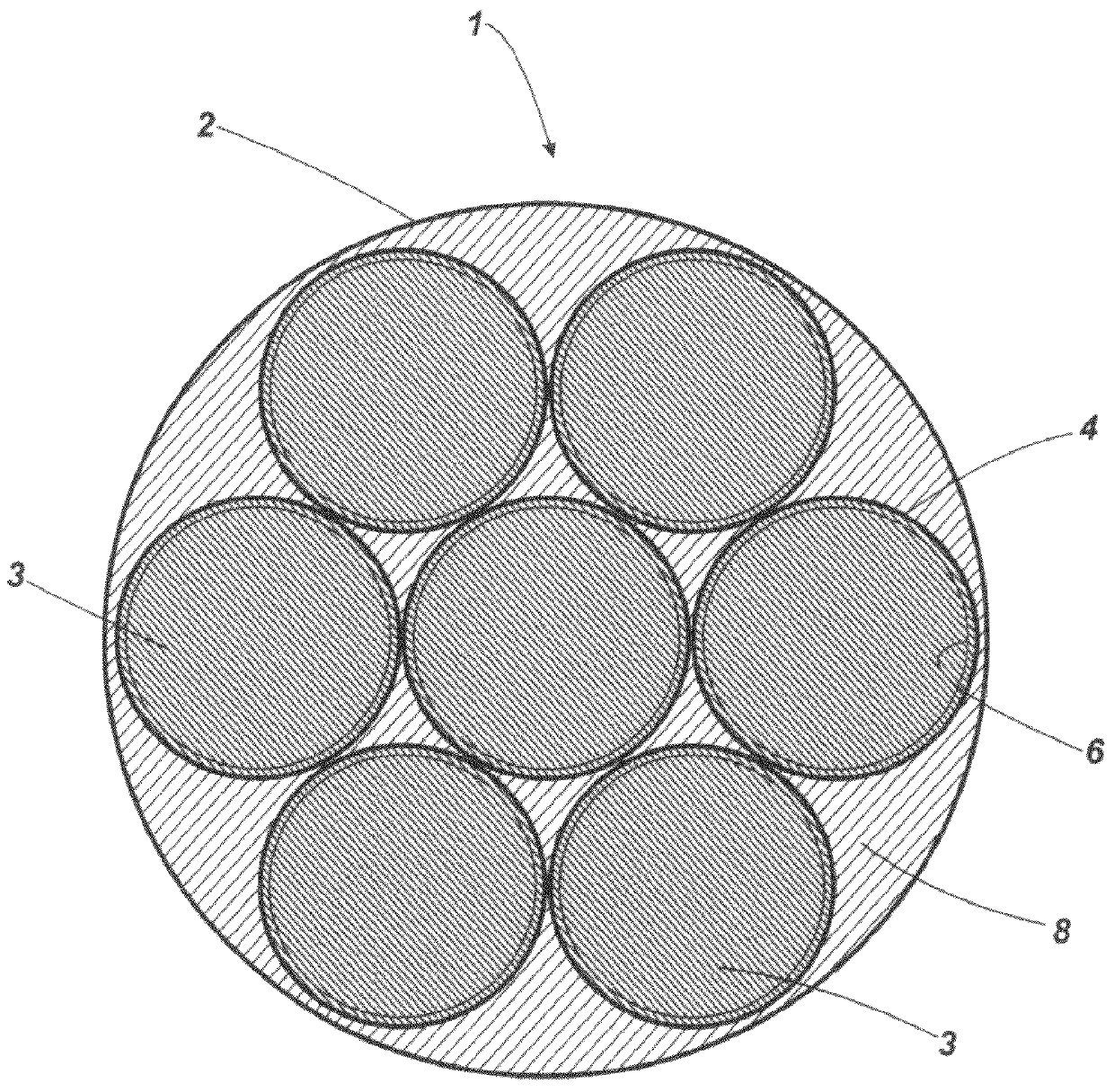

ActiveUS8256350B2Improve output performanceHigh materialAmmunition projectilesFuse ignition meansDetonationEngineering

This invention relates to a novel insensitive munition comprising one warhead and also munitions comprising one or more warheads. In particular, the invention lies in the field of insensitive munition warheads. There are further provided methods of preparing the warheads of the invention, methods of controllably detonating the warheads and a kit suitable for preparing such a warhead. The warhead comprises at least two portions of high explosive separated by a non-detonative material, wherein each portion has a cross section below its critical detonation cross section, and wherein the at least two portions are arranged such that the total cross section of the at least two portions exceeds the critical detonation cross section of said high explosive, such that in use only simultaneous detonation of the at least two high explosives causes detonation to occur.

Owner:QINETIQ LTD

Rocket motors with insensitive munitions systems

InactiveUS20030079464A1Increase available propellant volumeReduce overall inert weightRocket engine plantsSelf-propelled projectilesThermal dilatationThermodynamics

An embodiment of the rocket motor of this invention employs an insensitive munitions approach that, when subjected to elevated external temperatures, is activated by thermal expansion of the main propellant and gas generation from a secondary insensitive munitions charge. In a preferred embodiment, the rocket motor also includes a pressure equalizing system that accommodates changing temperature conditions during storage as well as varying gas pressure inherent in gun-launched systems in a manner that allows for thinner case cylinder design and increased propellant volume.

Owner:NORTHROP GRUMMAN SYST CORP

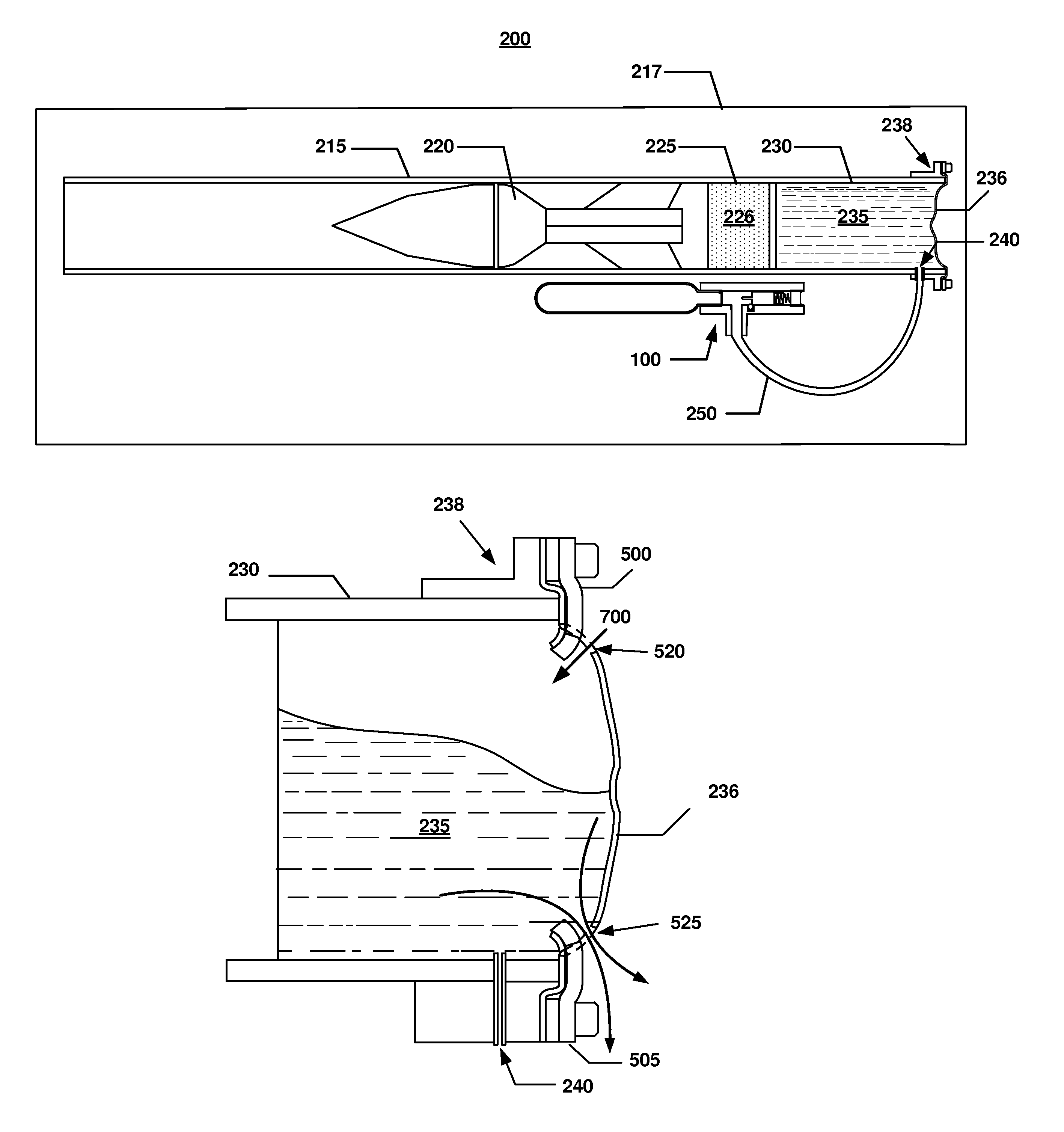

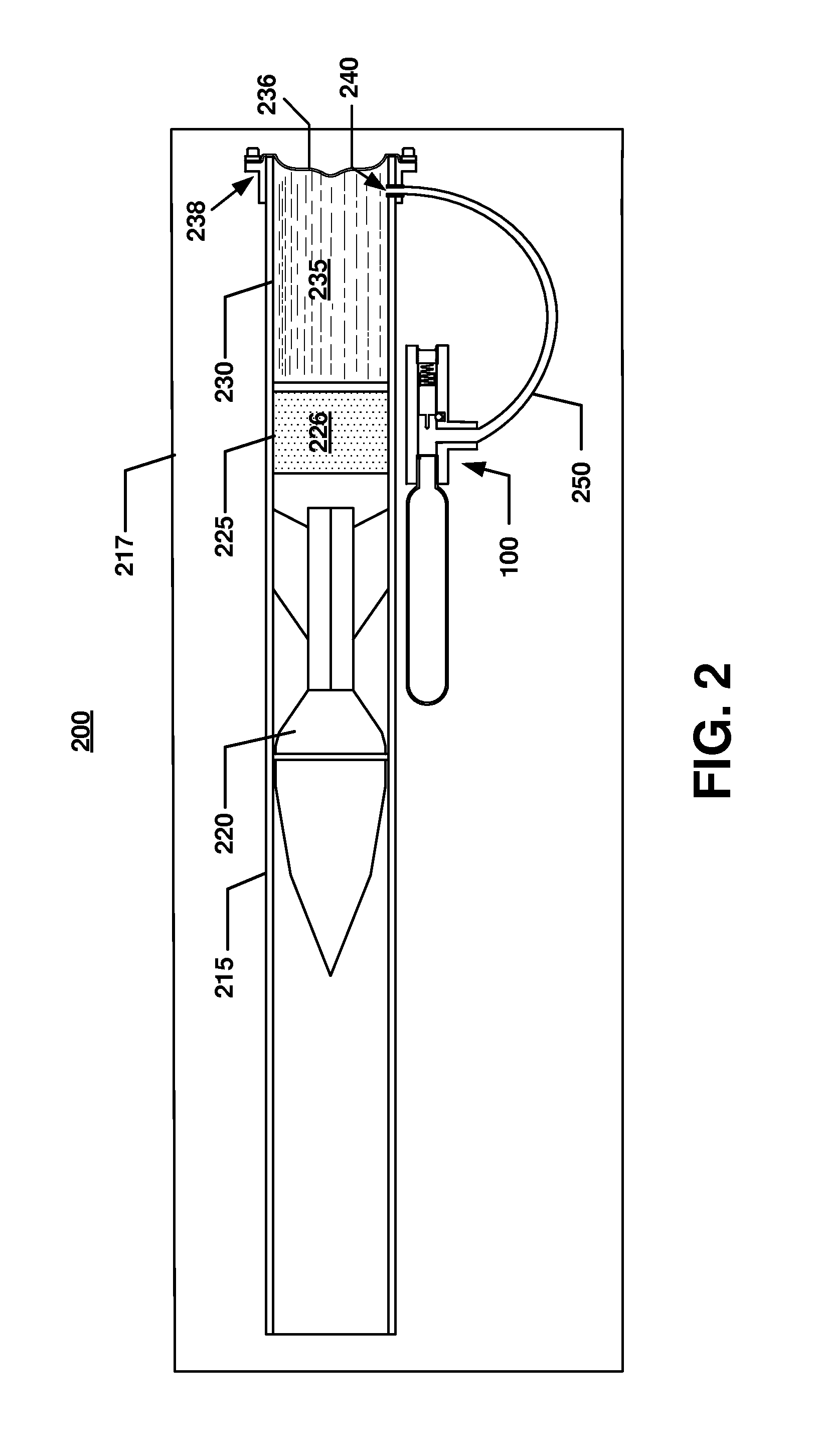

Bleeding mechanism for use in a propulsion system of a recoilless, insensitive munition

ActiveUS9441894B1Easily exposedGood insulatorMissile propulsionAmmunition storageLocking mechanismHeat sensitive

A bleeding mechanism for use in the propulsion system of a recoilless, insensitive munition utilizing a utilizing a fluidic countermass. The present bleeding mechanism utilizes a firing pin or a similar puncture or tear device. A heat sensitive material blocks the movement of the firing pin. A mechanical locking mechanism locks the firing pin in position until it is unlocked by the melting of the heat sensitive material. When the insensitive munition is exposed to heat, the reaction of the heat sensitive material within the bleeding mechanism allows the firing pin to be released and to rupture a cartridge seal. The cartridge may be filled with a compressed compound, which releases gas under pressure to the countermass container, causing a countermass cover to rupture, thereby emptying the countermass fluid.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Insensitive munition design for shrouded penetrators

A munition and method of making same comprising at least partially surrounding a warhead with a protective barrier comprising pumice and surrounding the protective barrier with a shroud.

Owner:LOCKHEED MARTIN CORP

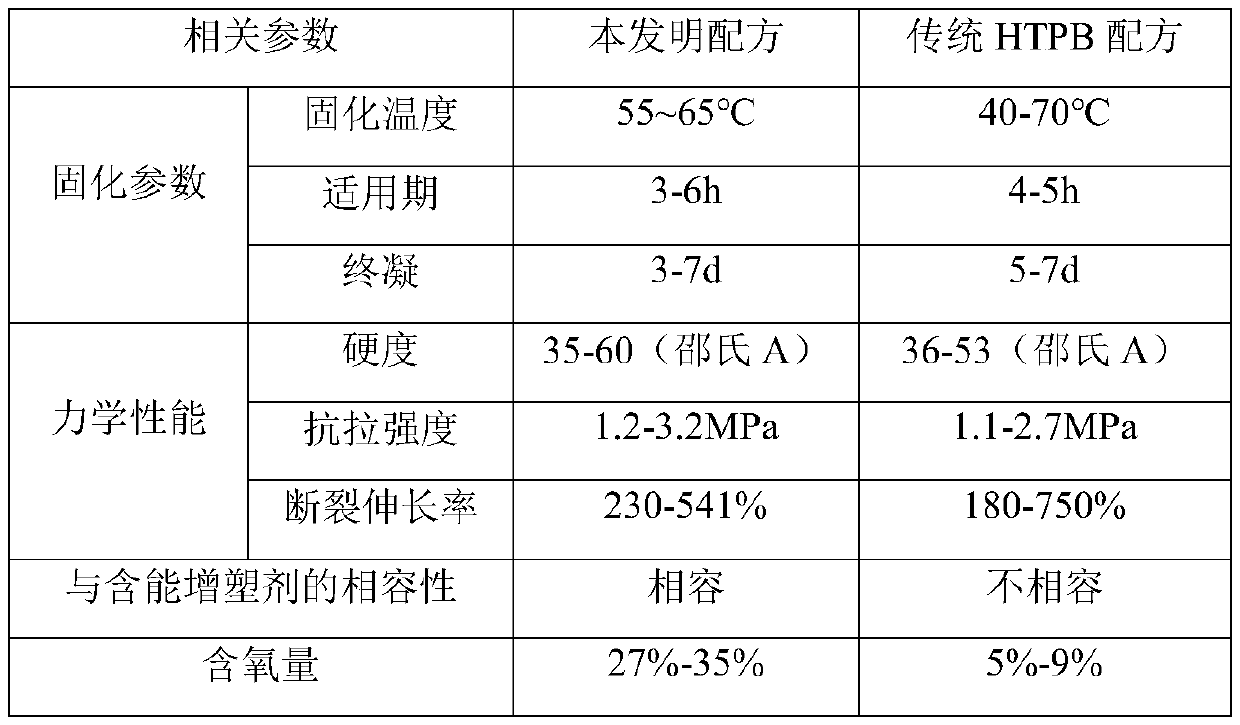

Adhesive system suitable for insensitive munitions and preparation method

InactiveCN110304977AIncrease oxygen contentReduce dosageNon-explosive fillers/gelling/thickening agentsPolyolPlasticizer

The invention provides an adhesive system suitable for insensitive munitions and a preparation method. The adhesive system is prepared by, by weight, 40-50 parts of polyol, 30-60 parts of energetic plasticizer, 5-10 parts of polyisocyanate, 0.0002-0.001 part of catalyst. During preparation, raw material preprocessing including the rotary evaporation dewatering of the polyol and the energetic plasticizer and raw material preheating is performed during preparation, the polyol and the energetic plasticizer are then premixed, and a curing agent is added finally and sufficient and uniform mixing isperformed to perform curing at 55-65 DEG C for 4-7 days. Compared with a traditional hydroxyl-terminated polybutadiene-based (HTPB-based) adhesive system, the adhesive system is high in oxygen content, good in compatibility with the energetic plasticizer, and capable of evidently increasing the energy output of an explosive system; the adhesive system is mild in reaction under a heat stimulationcondition and melts and expand when being heated to break through a munition shell, explosion possibility under the heat stimulation condition is lowered, and munition insensitivity is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Insensitive Munitions Warhead Explosive Venting System

A venting system for a casing containing an explosive material includes a base plug having one or more venting ports. A ring-shaped failure mechanism mounted to the base plug seals the venting ports. The failure mechanism has a selected melting temperature such that raising the temperature of the failure mechanism to its melting temperature causes the failure mechanism to unseal the venting port to allow controlled burning of the explosive material. An insert ring formed of a durable material to protect the failure mechanism from being damaged may be mounted on an outer surface of the failure mechanism. An adhesive may be used to seal gaps between the failure mechanism, the insert ring and the base plug. The failure mechanism may have a peripheral tab formed to fit within a corresponding groove in the base plug to mount the failure mechanism securely to the base plug.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

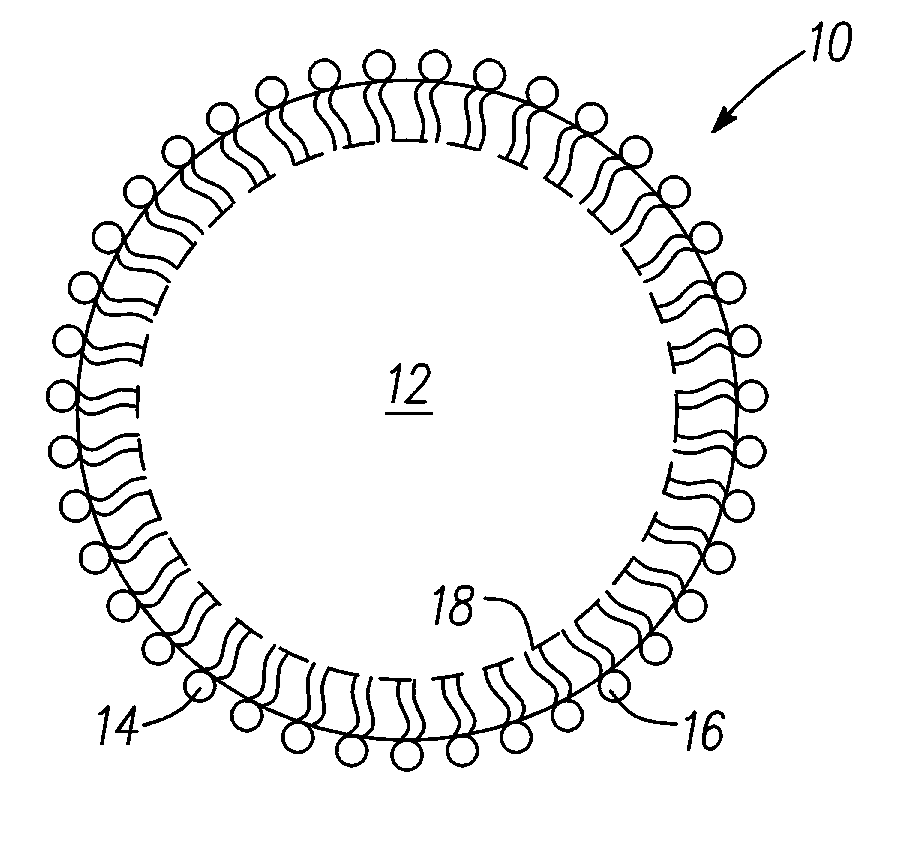

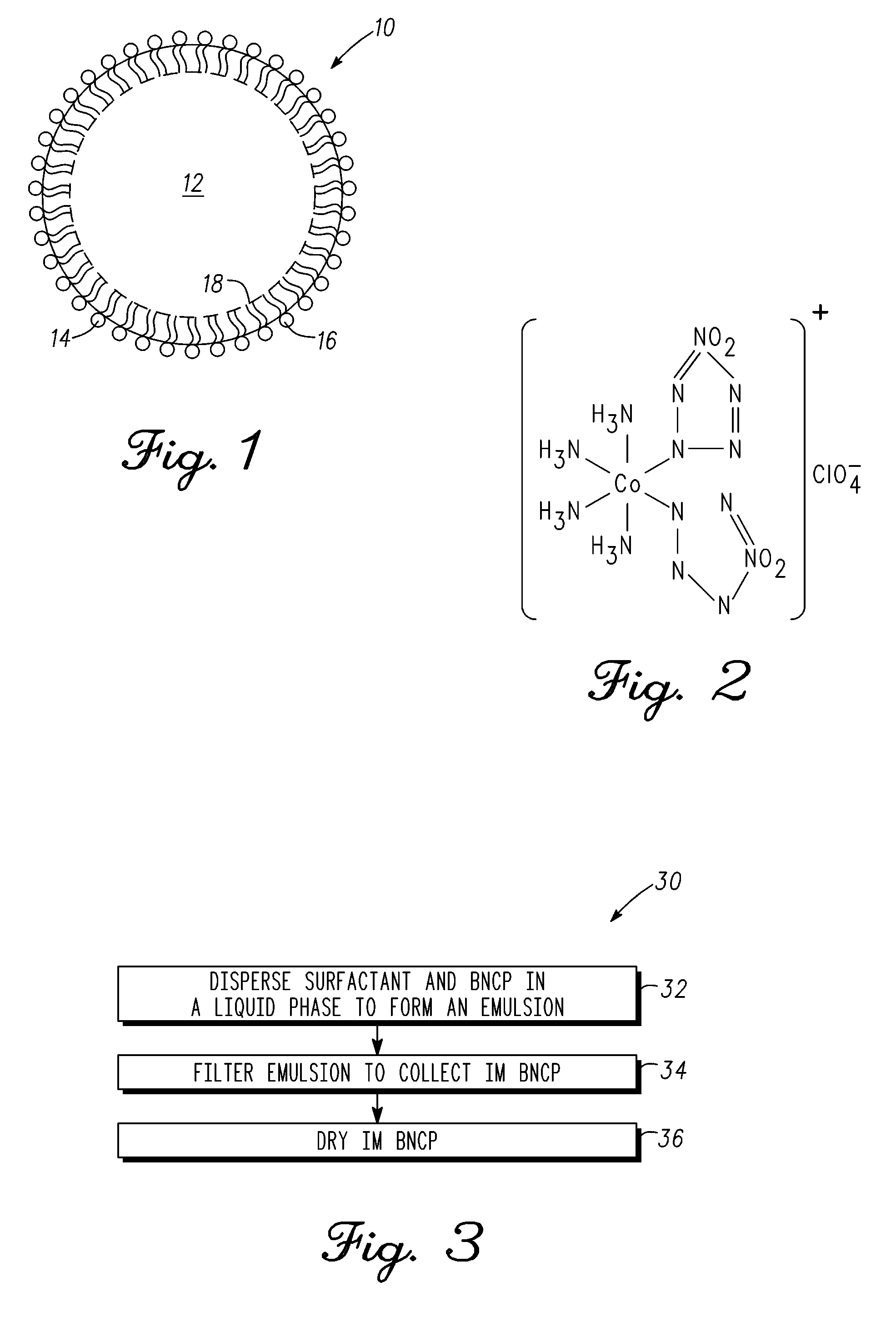

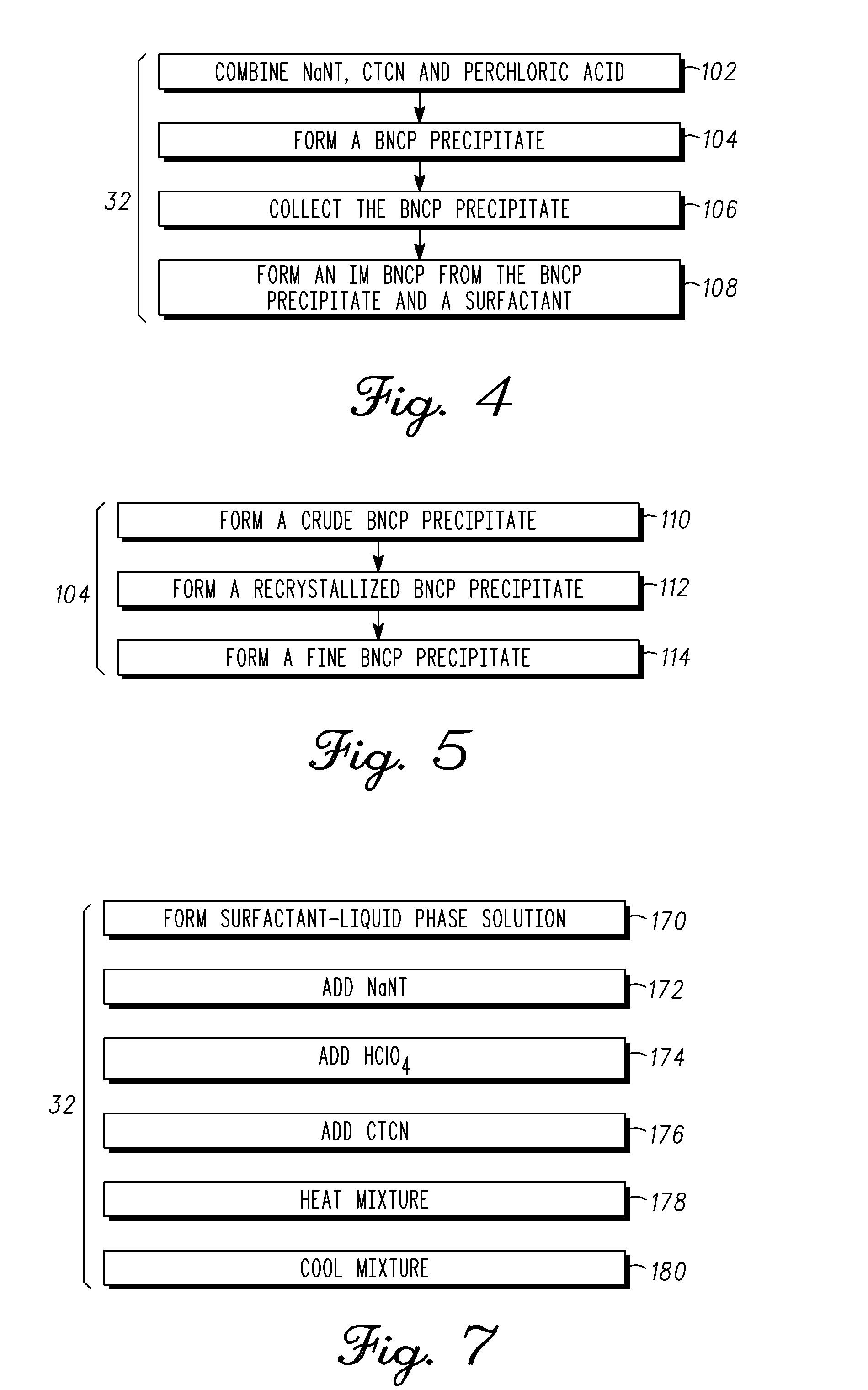

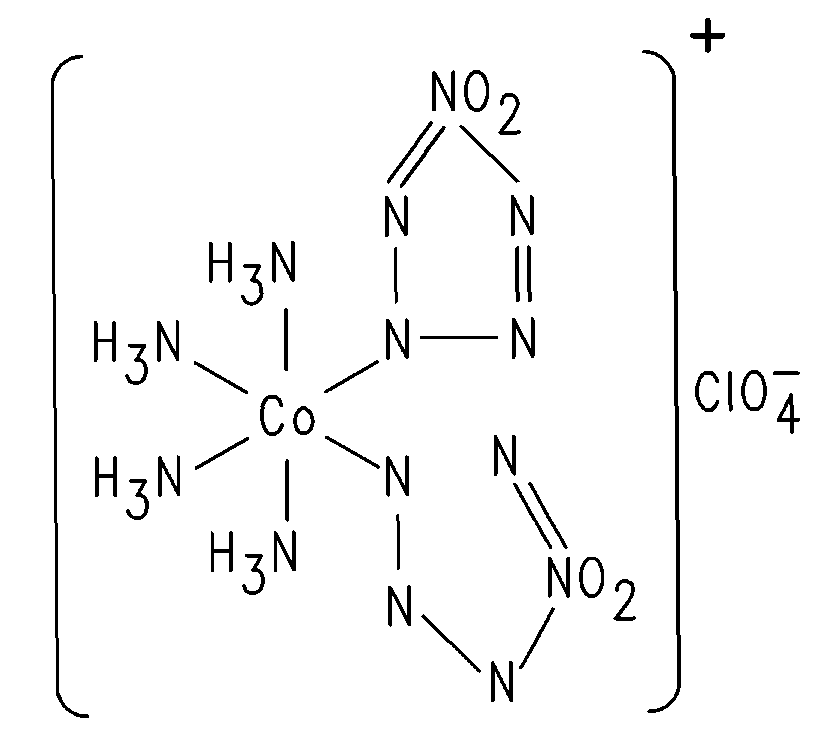

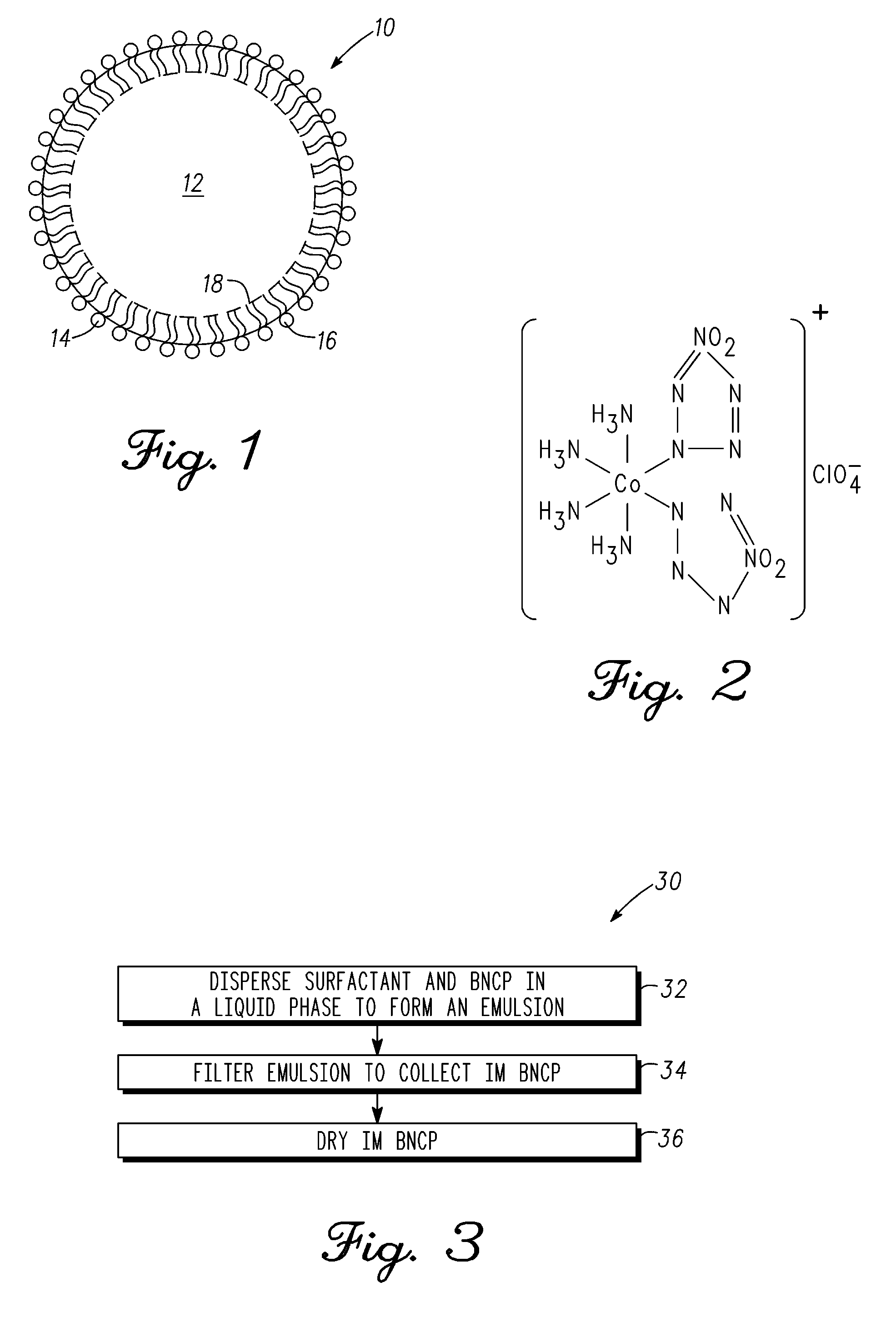

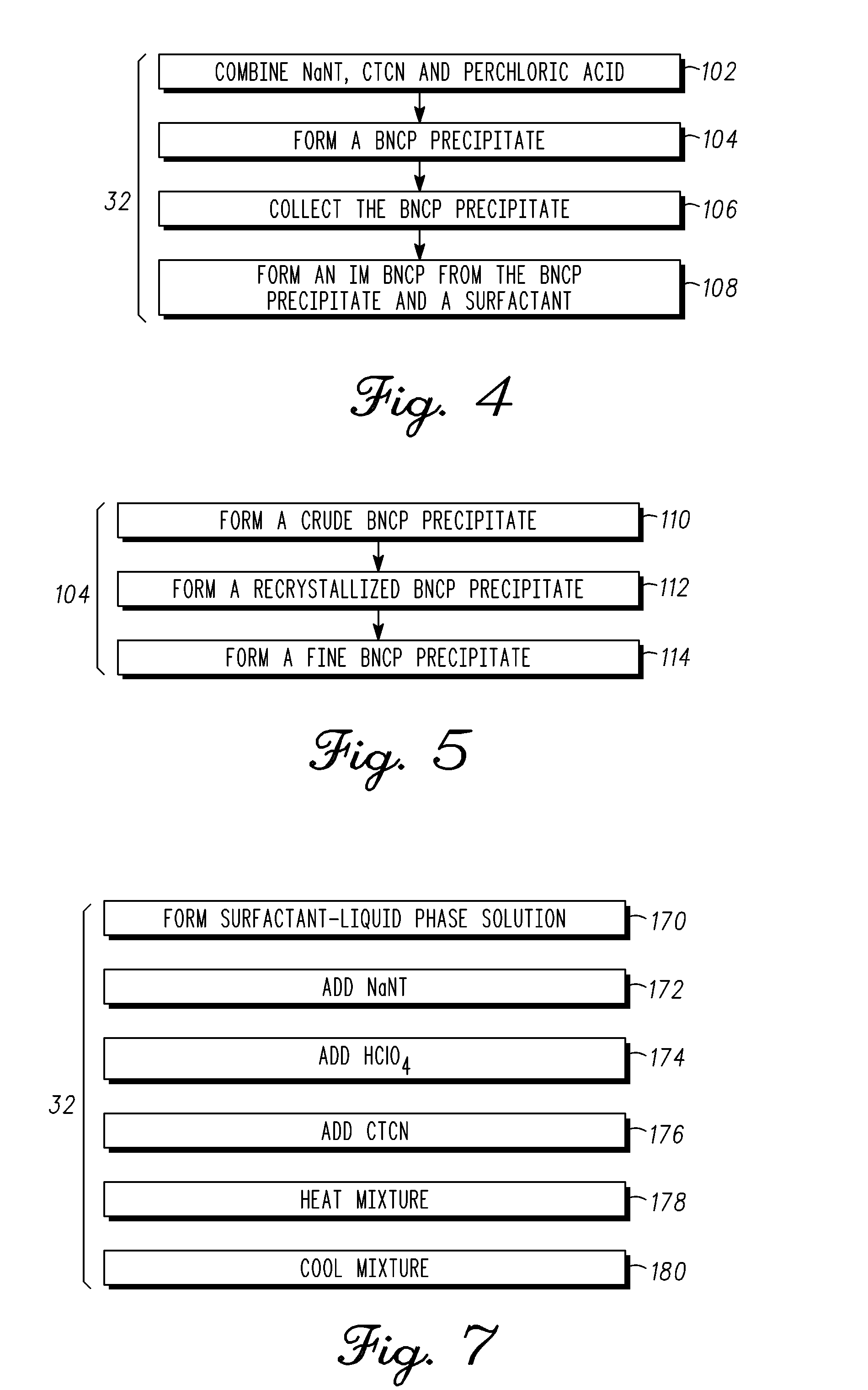

Insensitive munition-type bncp explosive material and methods for forming the same

Insensitive munition-type explosive material and methods for forming insensitive munition-type explosive material are provided. In an exemplary embodiment, an insensitive munition-type explosive material comprises a particle of BNCP and a surfactant-comprising shell that encapsulates the particle of BNCP.

Owner:RAYTHEON CO

Memory alloy type pressure relief structure of insensitive ammunition

The invention discloses a memory alloy type pressure relief structure of insensitive ammunition. The memory alloy type pressure relief structure of the insensitive ammunition comprises an ammunition bottom, memory alloy type springs, sealing plugs, an air guide plate and an air-permeable buffer piece; the air guide plate and the air-permeable buffer piece are sequentially arranged in the ammunition bottom from bottom to top; coaxial circular holes are formed in the centers of the air guide plate, the air-permeable buffer piece and the ammunition bottom; a plurality of grooves are evenly formedin the ammunition bottom in the radial direction, the grooves penetrate through the side wall of the ammunition bottom and form pressure relief holes; the sealing plugs are arranged on the pressure relief holes; the grooves do not communicate with the circular hole in the center of the ammunition bottom; the memory alloy type springs are arranged in the grooves, one ends of the memory alloy typesprings are fixedly connected with the ammunition bottom, and the other ends of the memory alloy type springs are fixedly connected with the sealing plugs; and a plurality of air guide holes are formed in the air guide plate, and the air guide holes communicate with the grooves. The memory alloy type pressure relief structure of the insensitive ammunition can achieve the effective pressure reliefwhen the ammunition is subjected to thermal stimulus.

Owner:NANJING UNIV OF SCI & TECH

Insensitive munitions swaged vent plug

Owner:NORTHROP GRUMMAN SYST CORP

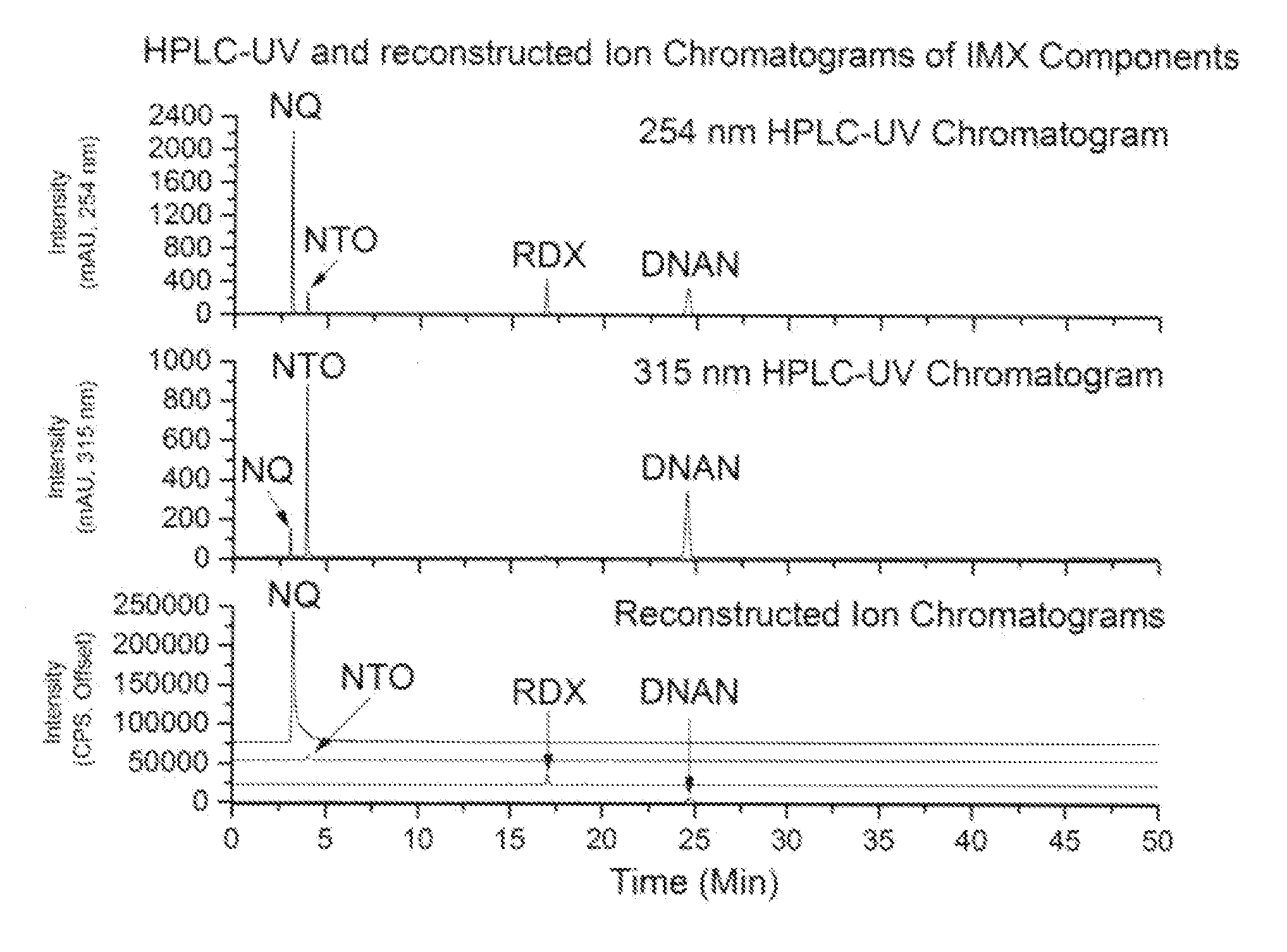

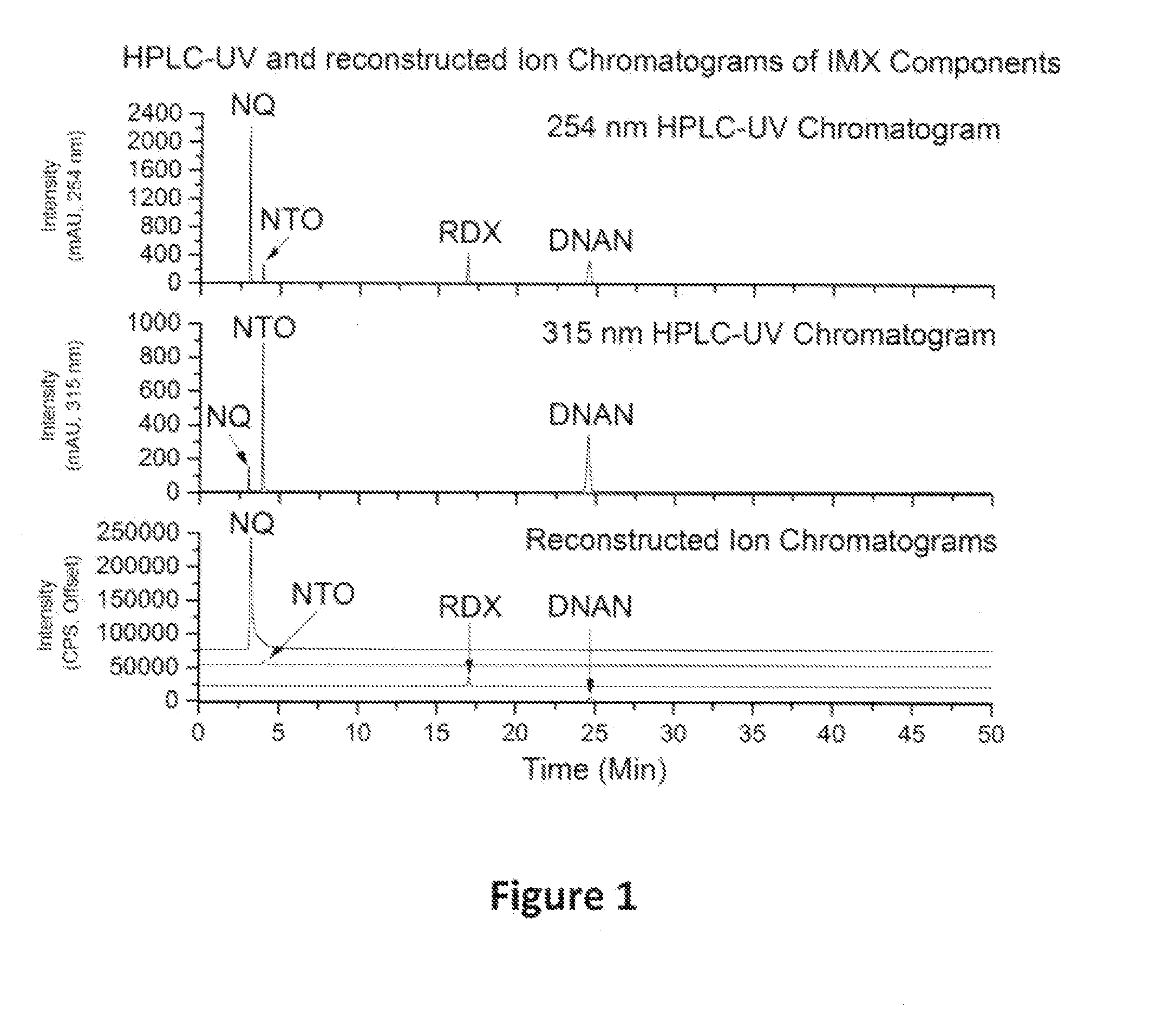

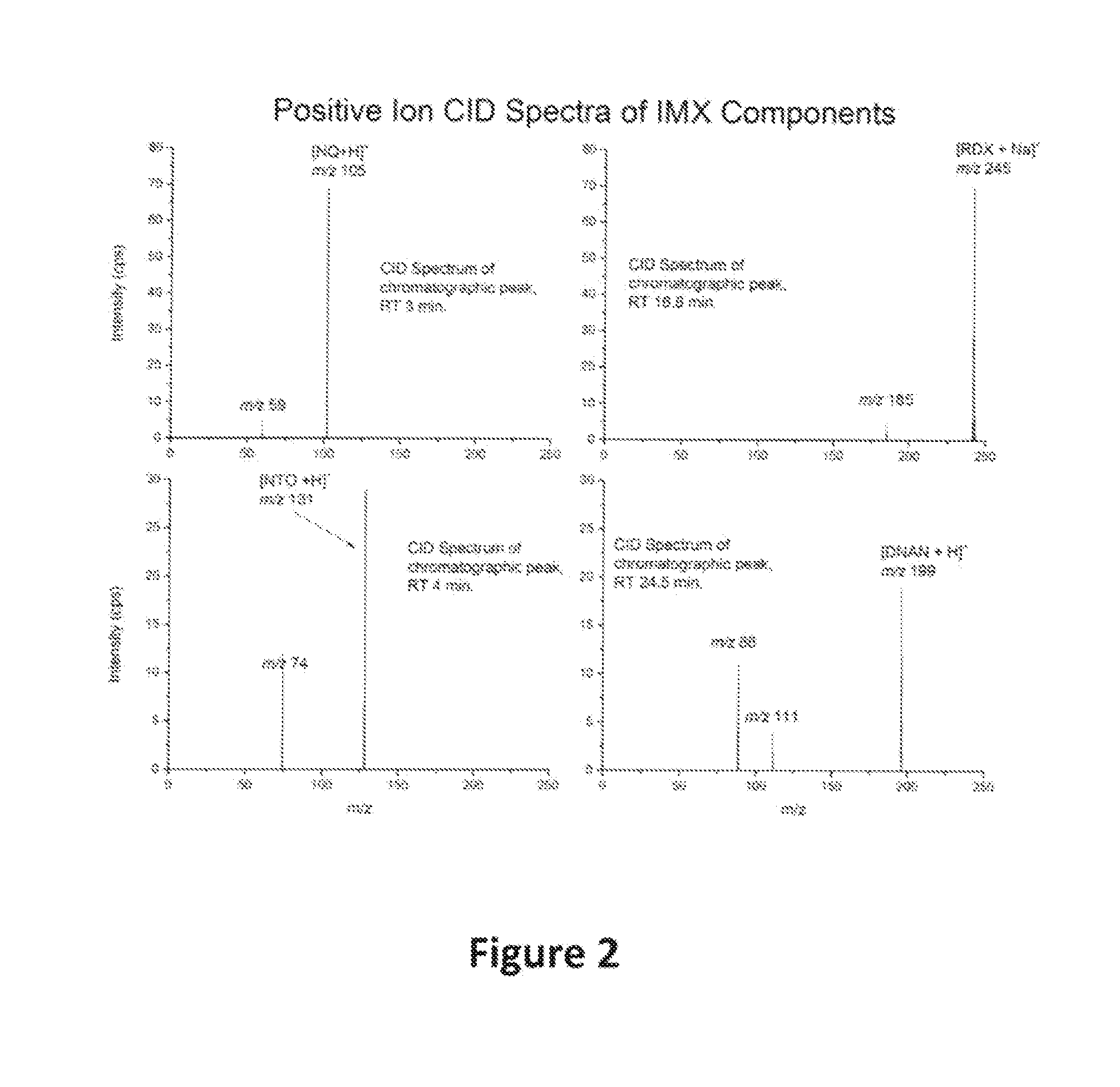

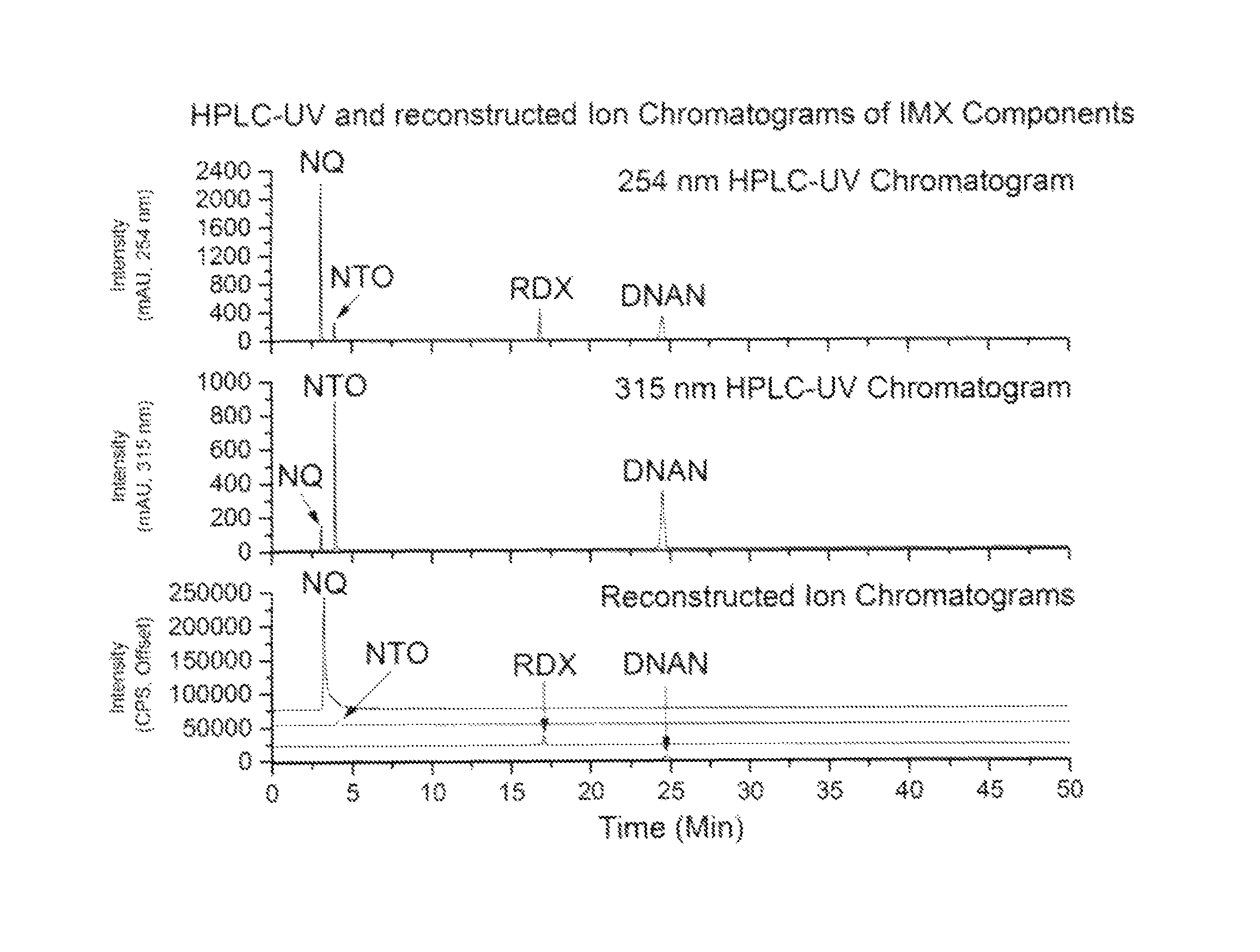

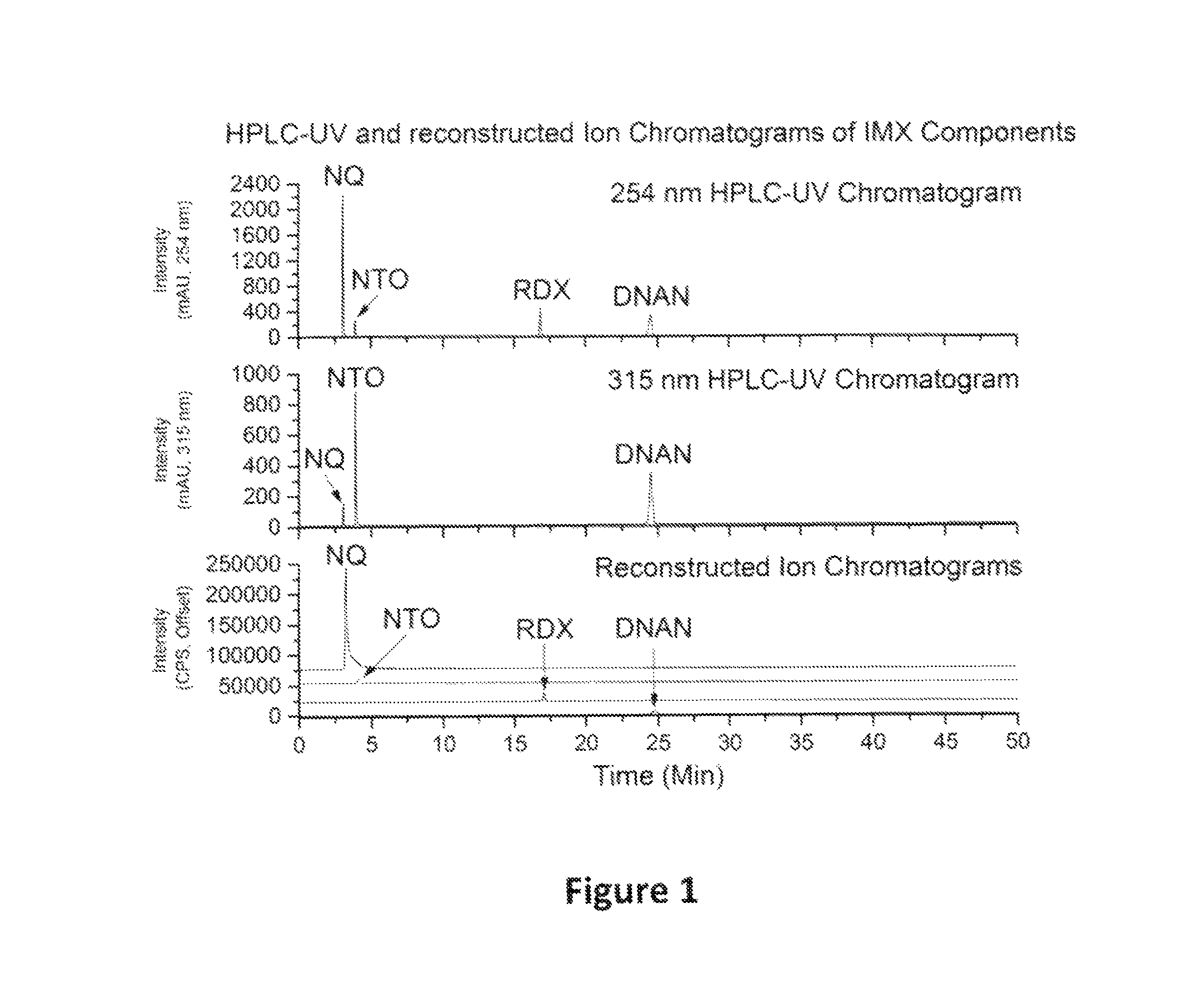

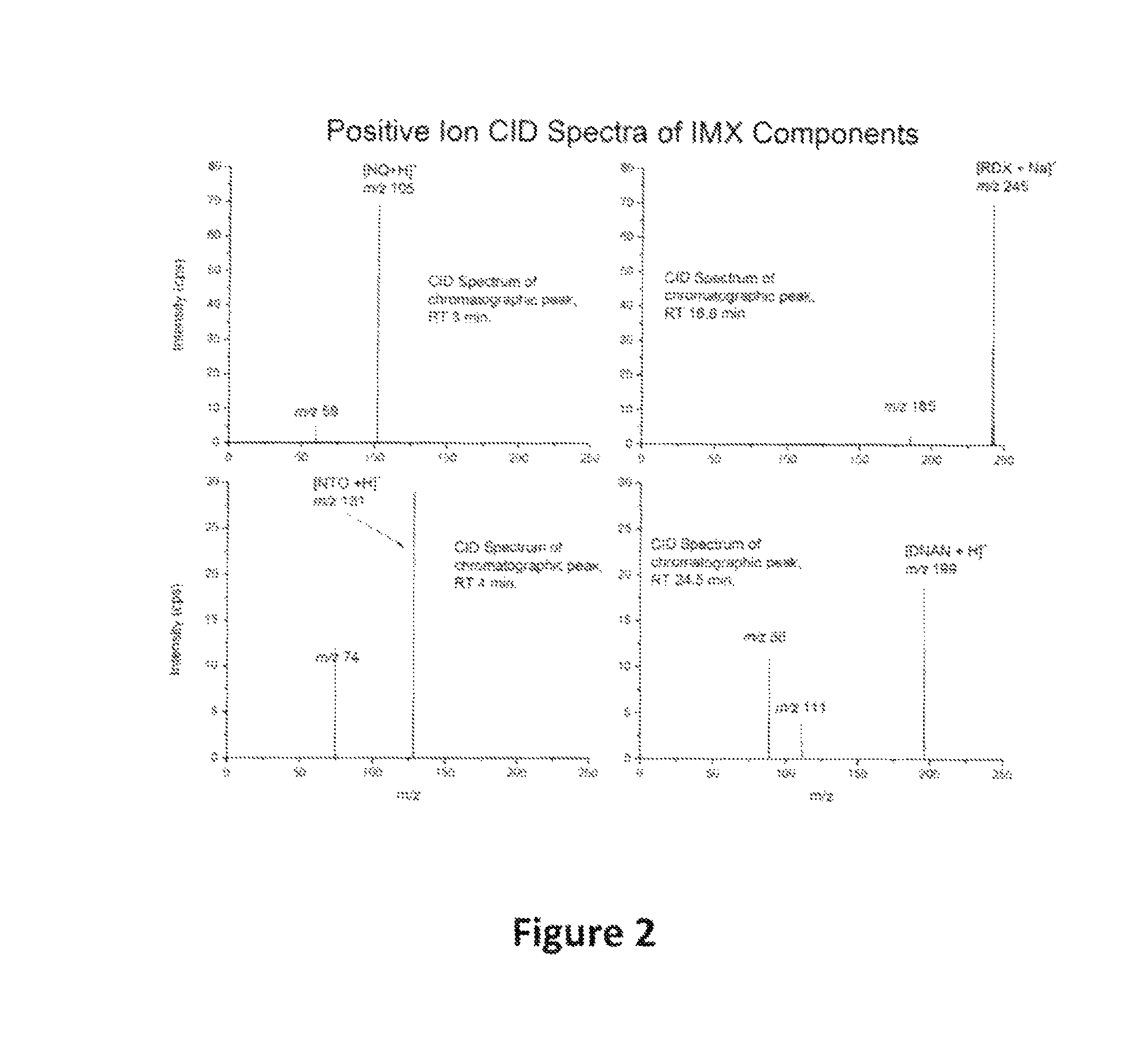

Methods of detecting and identifying munitions compounds

ActiveUS20160011154A1Shorten analysis timeReduce solvent useSamplingComponent separationHplc methodTissue sample

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Metal binders for insensitive munitions

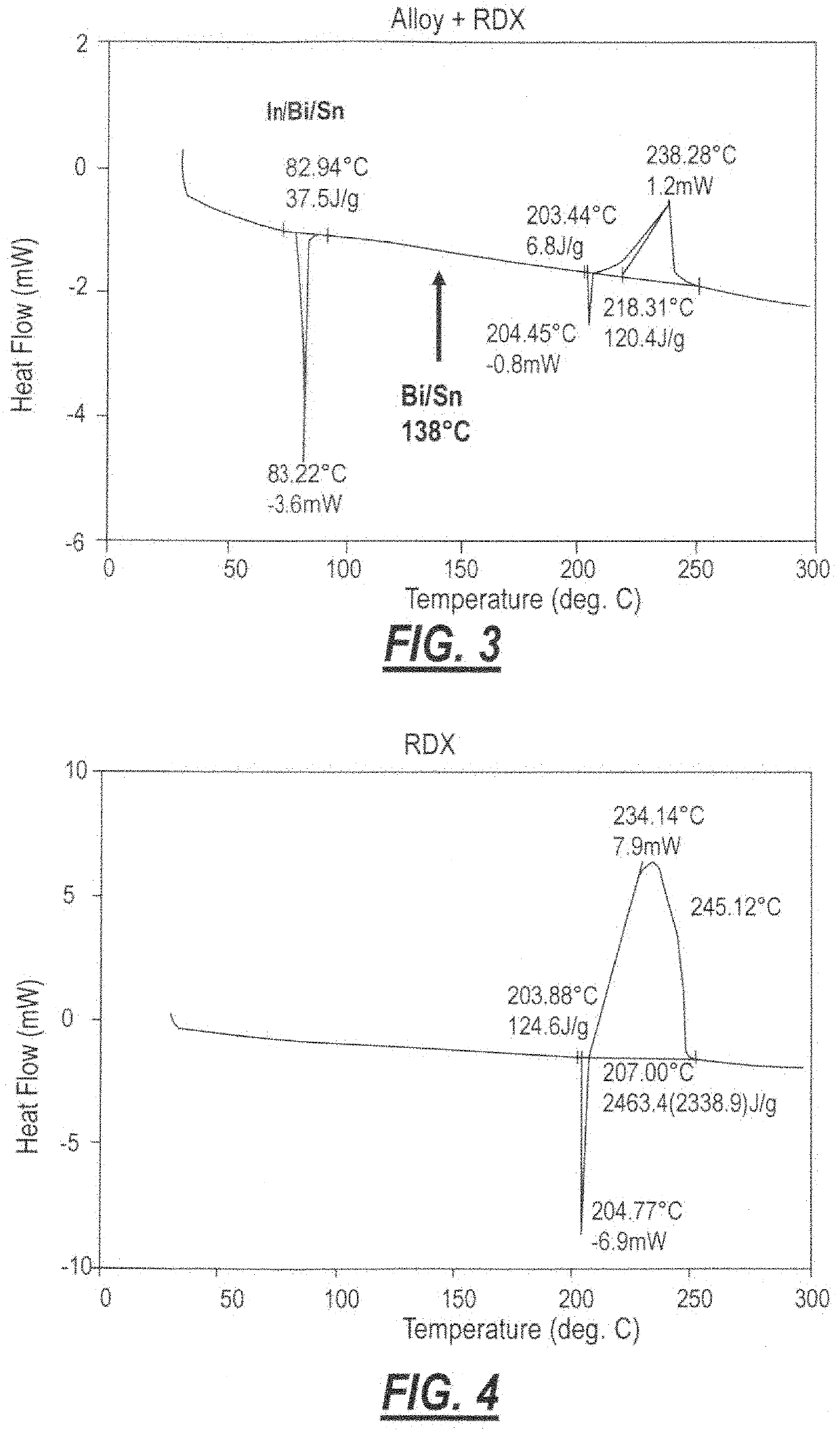

An explosive composition, an insensitive munition with a metal eutectic binder, and a method include using a metal eutectic binder with metal coated explosive particles. The metal eutectic binder concept represents novel melt-cast solid mixtures having explosives such as RDX (cyclonite) or HMX (octogen) distributed in an alloy including, for example, eutectic bismuth (Bi) / tin (Sn). Eutectic alloys are particularly considered to provide a melting point of the mixture below the exothermic point of the explosive so that vented munitions disarm by melting without exploding in the event of fire or other elevated heating. Particularly novel is the pre-coating of crystals of explosive (RDX / HMX) with a metal to promote wetting and bonding during melt fabrication of the final mixture. Copper, aluminum, and other metals are considered for use as coating.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Metal corrosion resistant insensitive ammunition and preparation method thereof

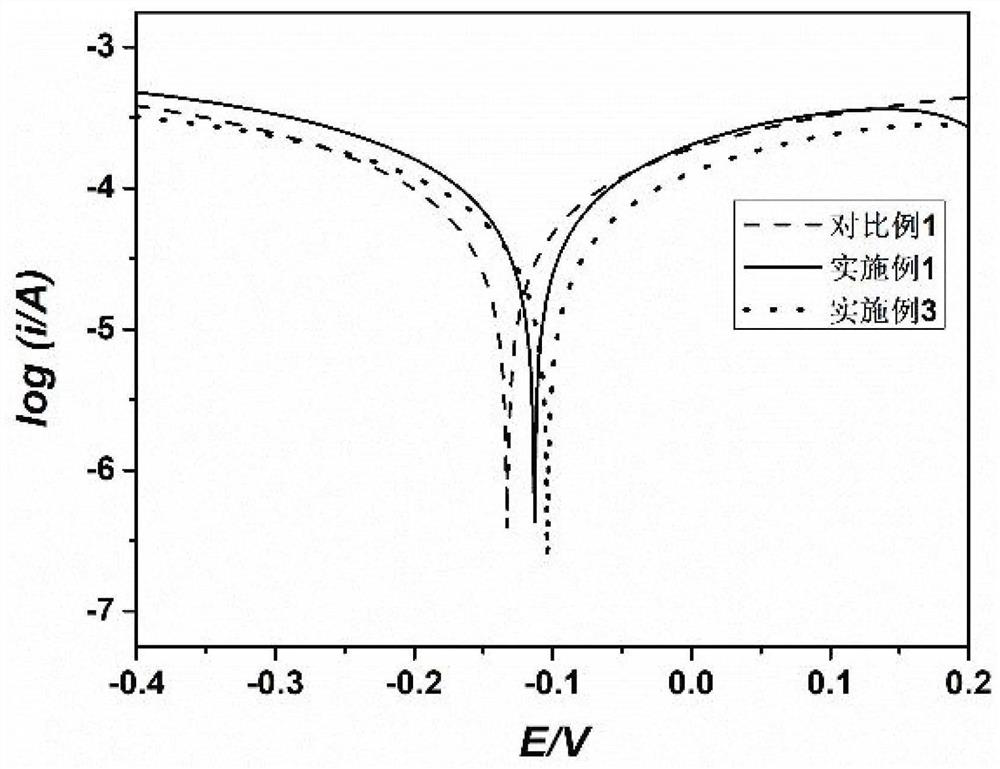

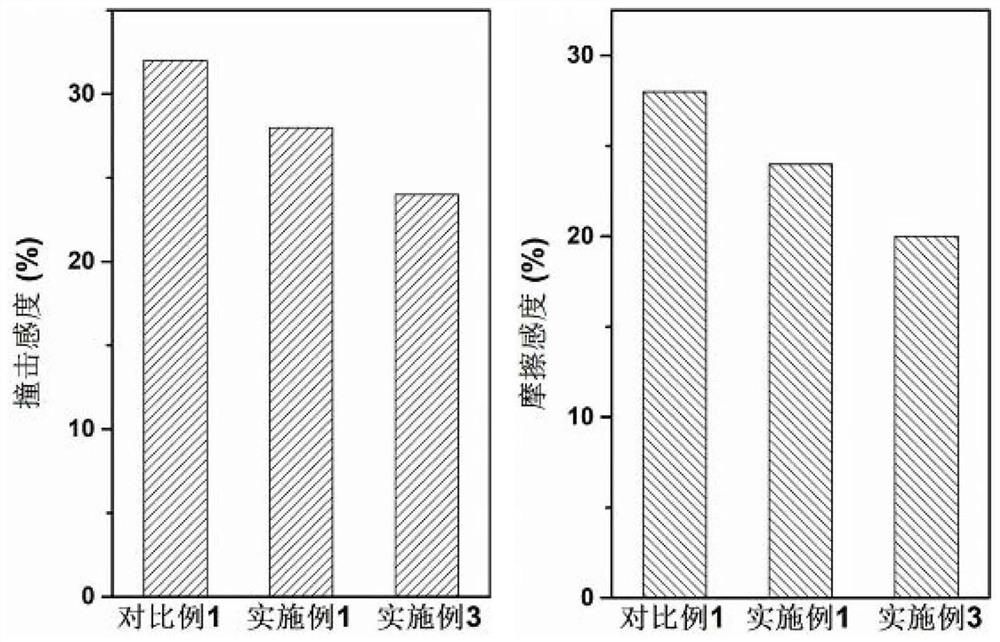

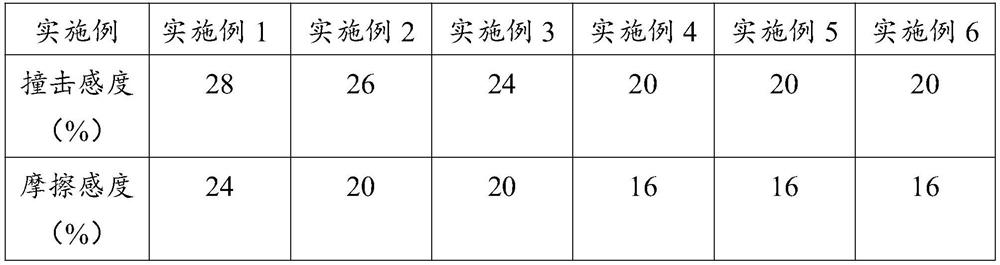

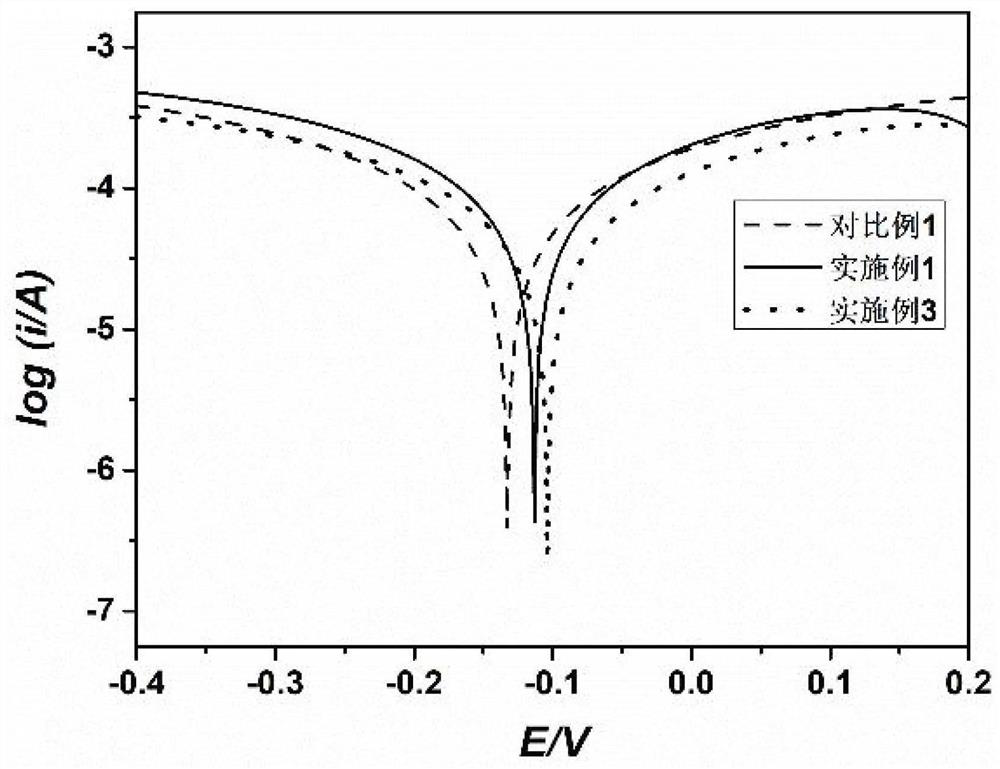

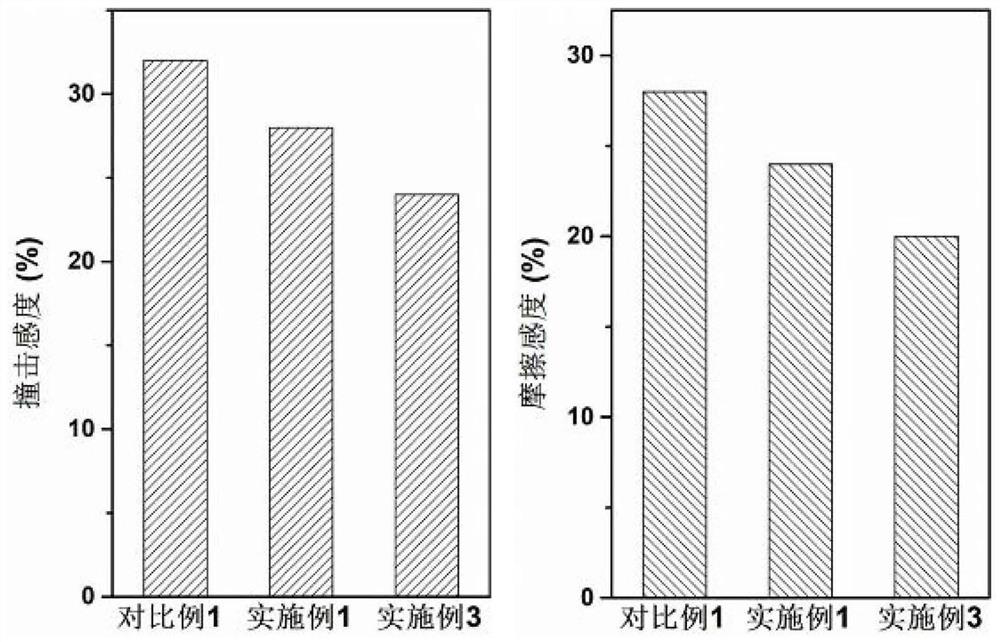

ActiveCN113916066AImprove conductivityImproves metal corrosion resistanceVibration crystallizationAmmunitionNitrotriazoloneInsensitive munition

The invention relates to the technical field of energetic materials, and particularly discloses a metal corrosion resistant insensitive ammunition and a preparation method thereof. The metal corrosion resistant insensitive ammunition is prepared from, by weight, 0-10% of layered MXene and 90-100% of 3-nitro-1, 2, 4-triazole-5-ketone. The preparation method comprises the following steps of firstly, etching an aluminum layer in an MAX phase with hydrofluoric acid to obtain layered MXene, dissolving the layered MXene and NTO raw materials in absolute ethyl alcohol in proportion, and finally, carrying out evaporative crystallization to obtain the metal corrosion resistant insensitive ammunition. According to the metal corrosion resistant insensitive ammunition, the metal corrosion resistance of NTO is enhanced, and the impact sensitivity and friction sensitivity of NTO are further reduced; and the preparation method is simple, the MAX phase is etched by hydrofluoric acid to obtain conductive MXenes, then the MXenes and NTO are prepared by a recrystallization method, and the preparation method has practical application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

A pressure relief structure of memory alloy insensitive ammunition

ActiveCN109631694BSmooth dischargeAvoid enteringAmmunition storageThermal stimulationMechanical engineering

The invention discloses a pressure relief structure for memory alloy type insensitive ammunition, which comprises a bullet bottom, memory alloy type spring, sealing plug, air guide plate, and breathable buffer sheet; the air guide plate and breathable buffer sheet are sequentially arranged from bottom to top It is arranged in the bottom of the bullet; the center of the air guide plate, the breathable buffer sheet and the bottom of the bullet is provided with a coaxial round hole; the bottom of the bullet is evenly arranged with a plurality of grooves along the radial direction, and the grooves pass through the bottom of the bullet The side wall forms a pressure relief hole; the sealing plug is arranged on the pressure relief hole; the groove is not connected to the center hole of the bottom of the bullet; the memory alloy spring is arranged in the groove, and one end is fixedly connected with the bottom of the bullet. The other end is fixedly connected with the sealing plug; the air guide plate is provided with a plurality of air guide holes, and the air guide holes communicate with the groove; the pressure relief structure of the present invention can realize the effective pressure relief of the ammunition under thermal stimulation.

Owner:NANJING UNIV OF SCI & TECH

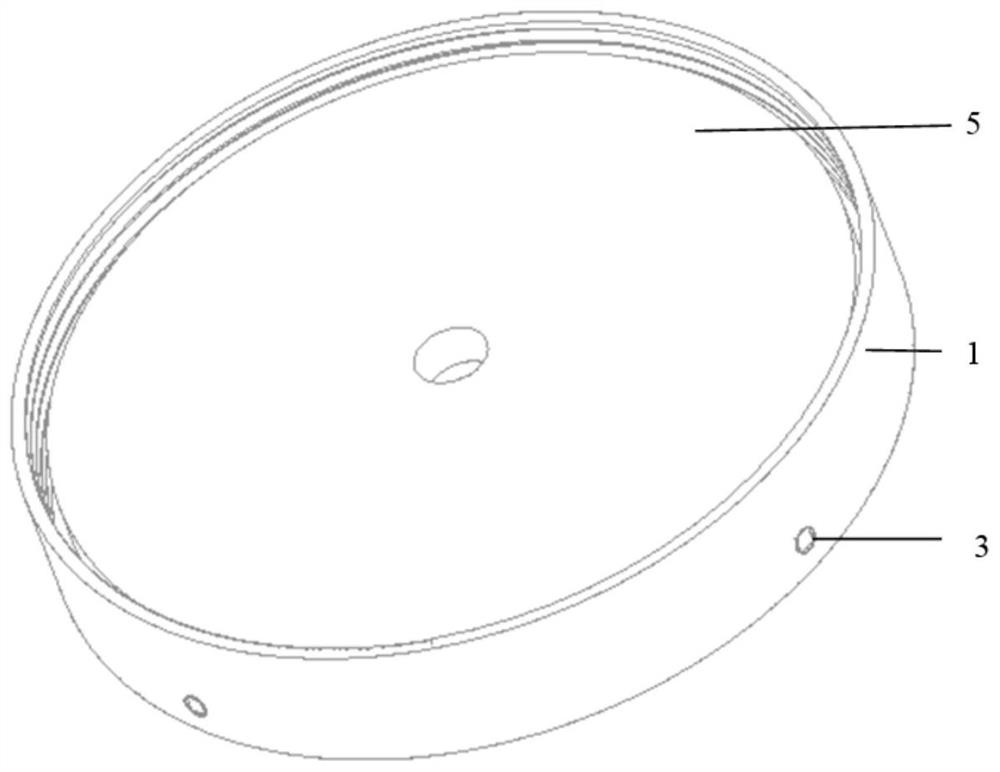

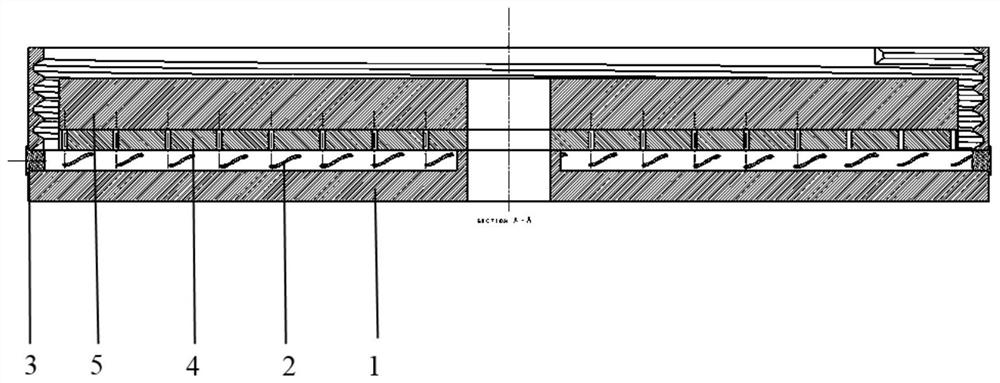

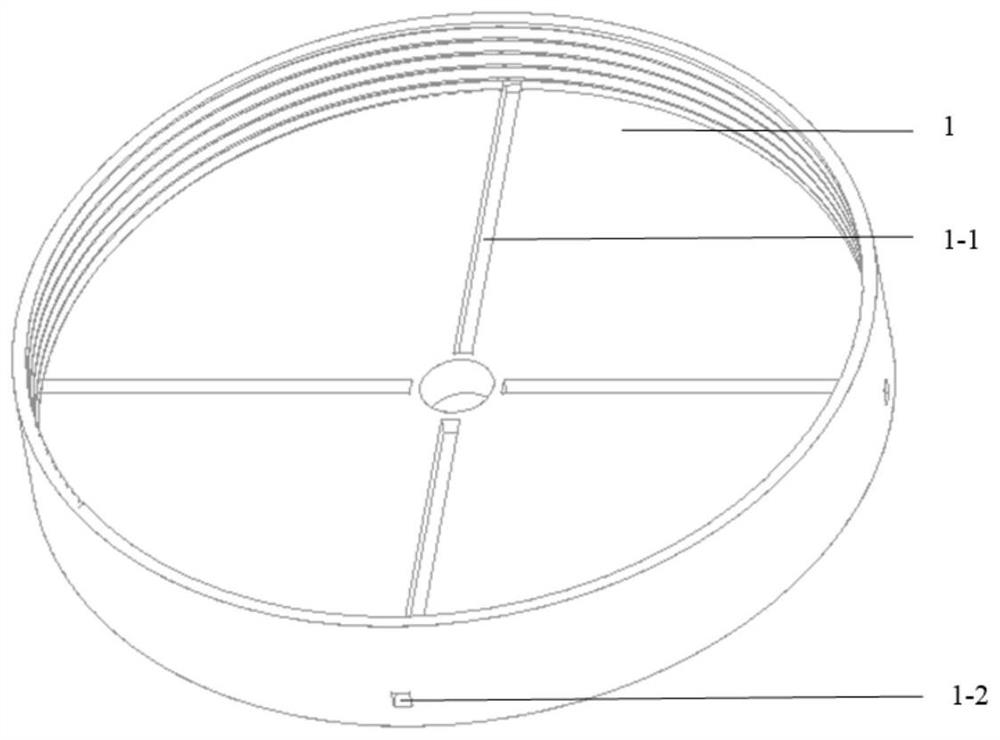

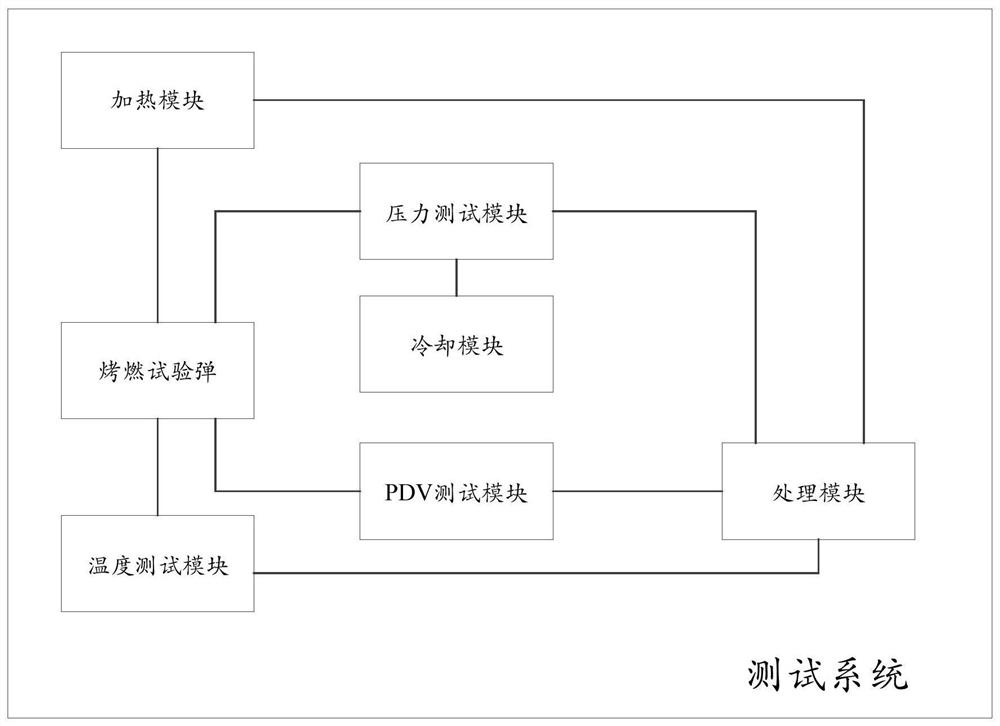

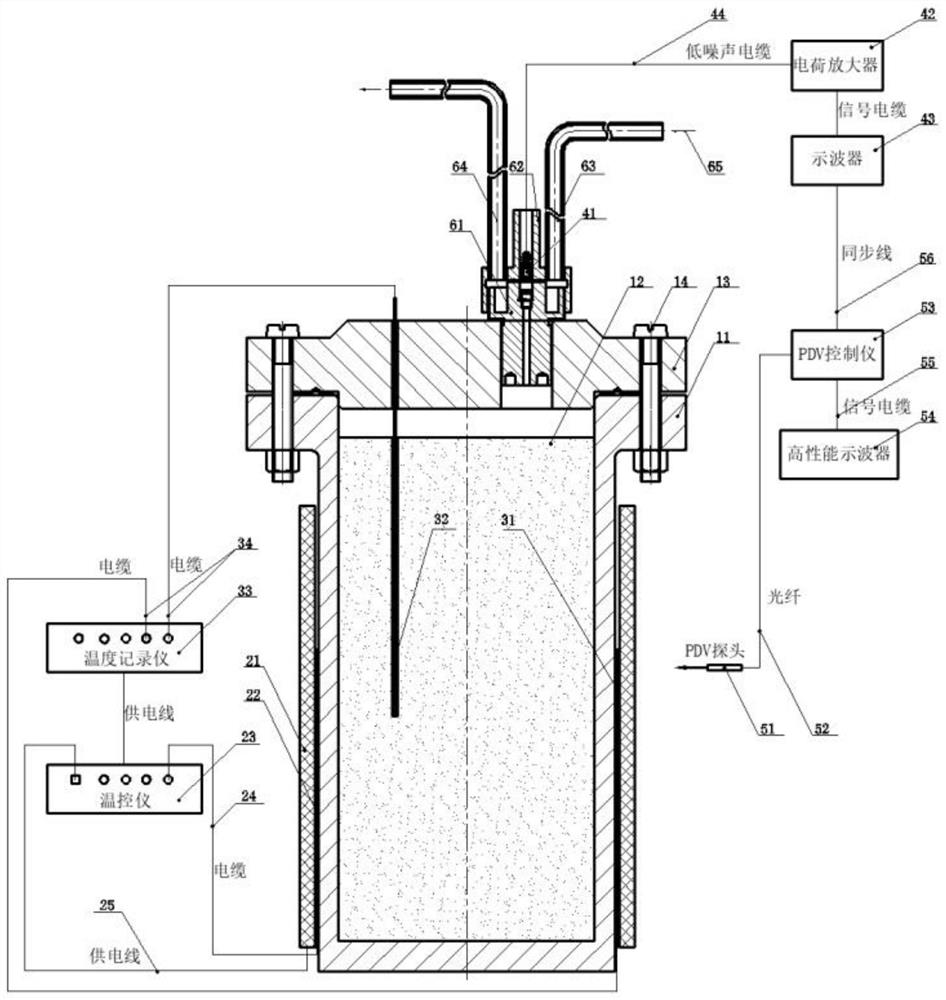

A test system for the whole process of heat-stimulated ammunition charge ignition and its reaction growth

ActiveCN111912303BPromote progressHigh measurement accuracyAmmunition testingThermal ignitionThermodynamics

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

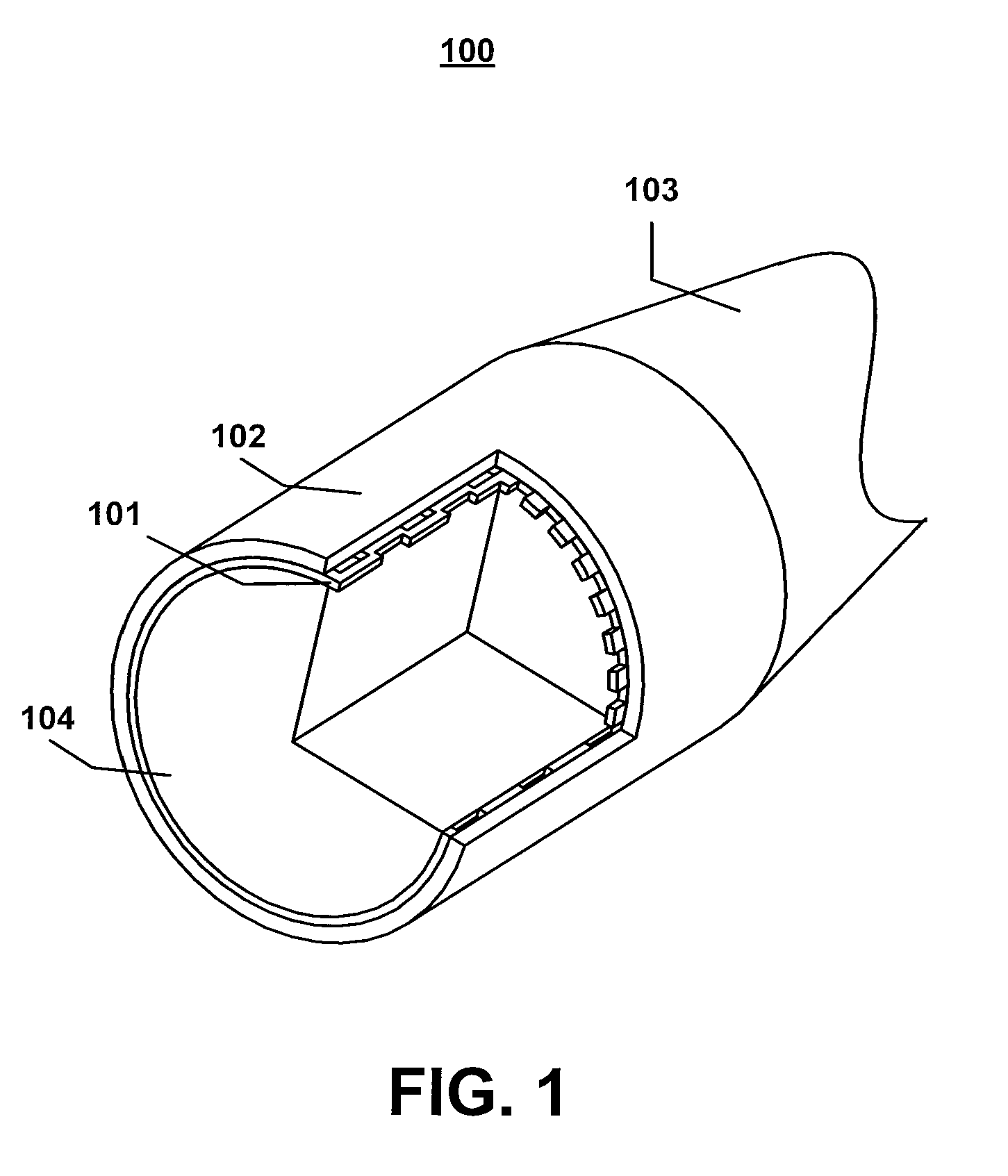

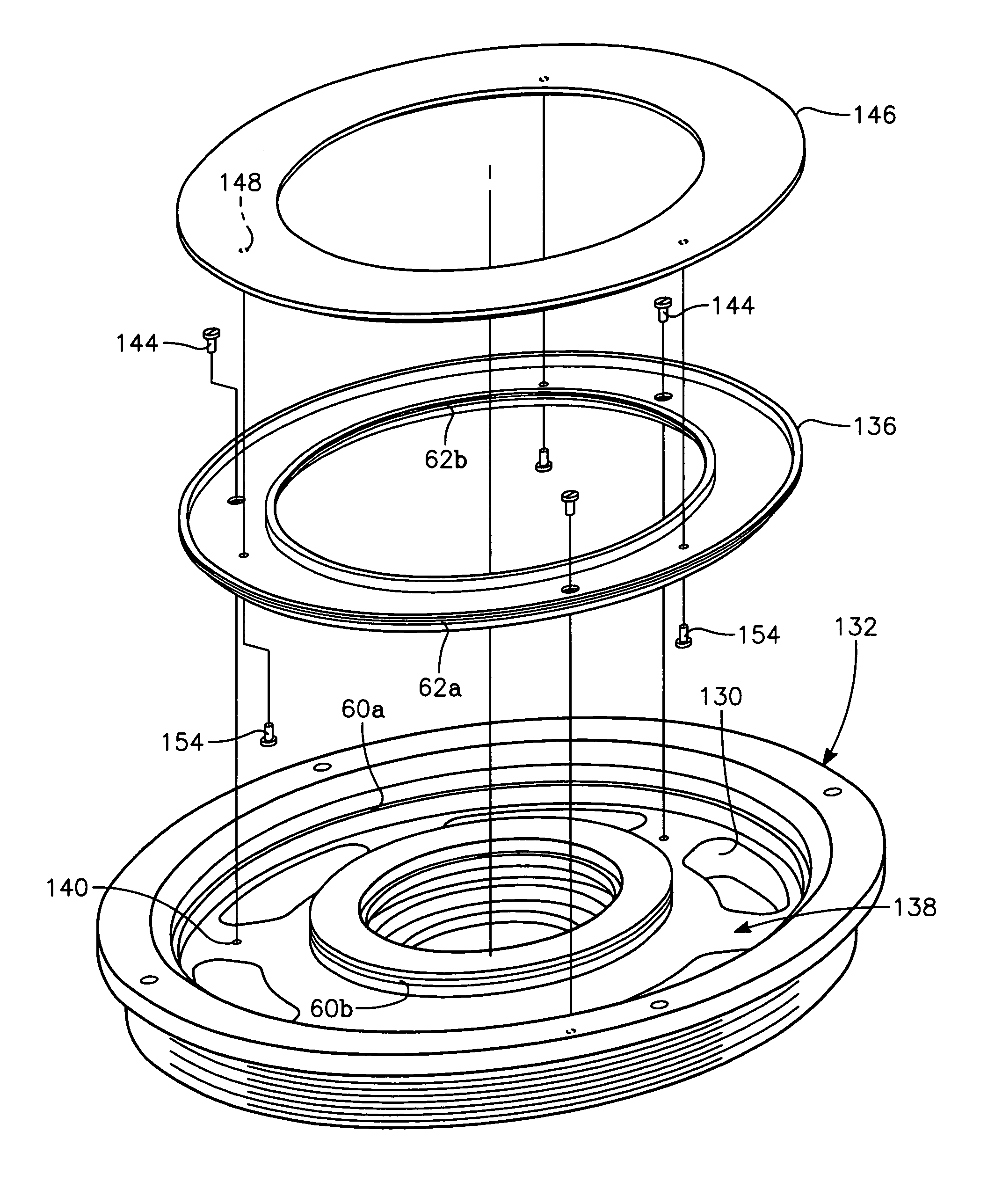

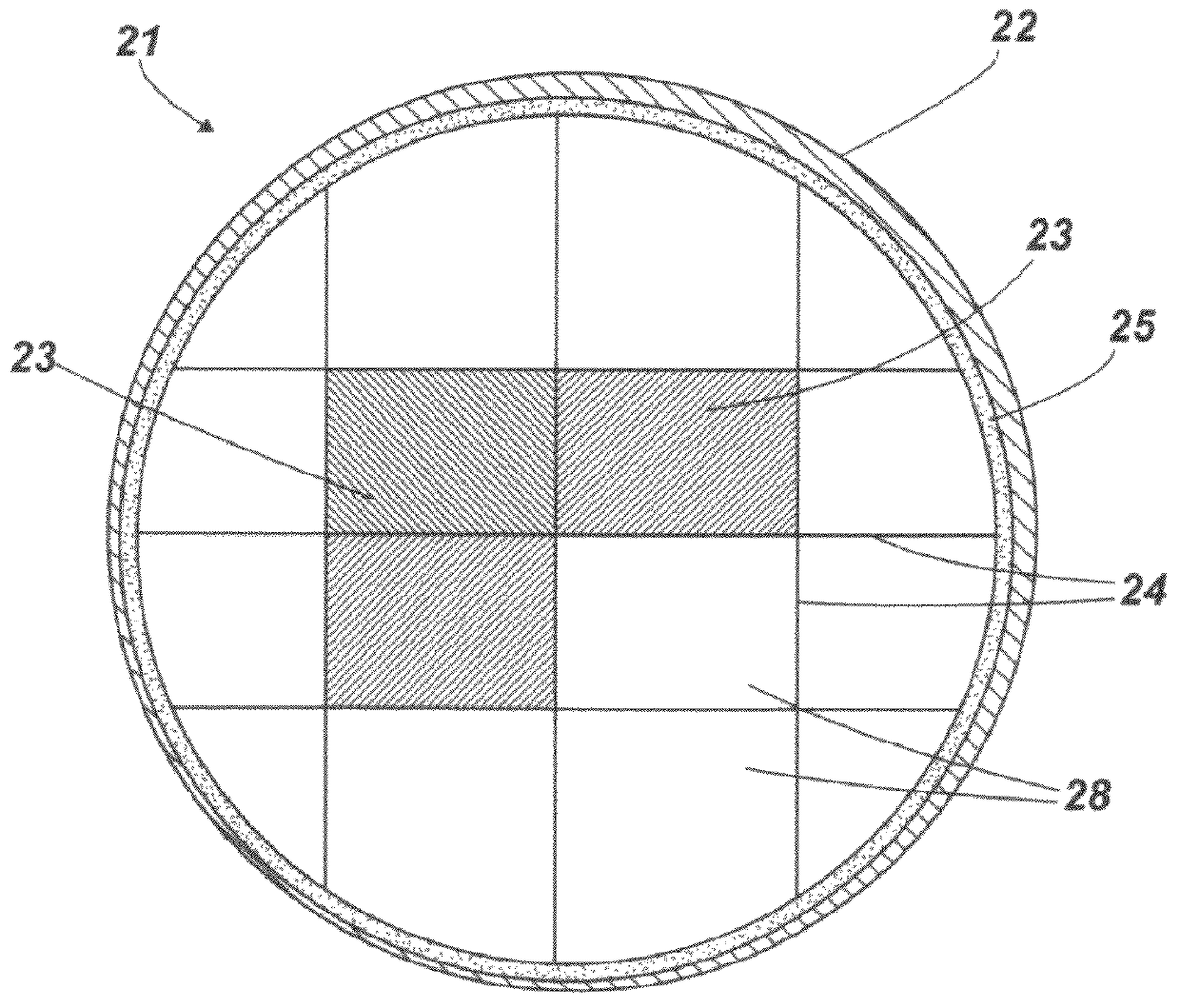

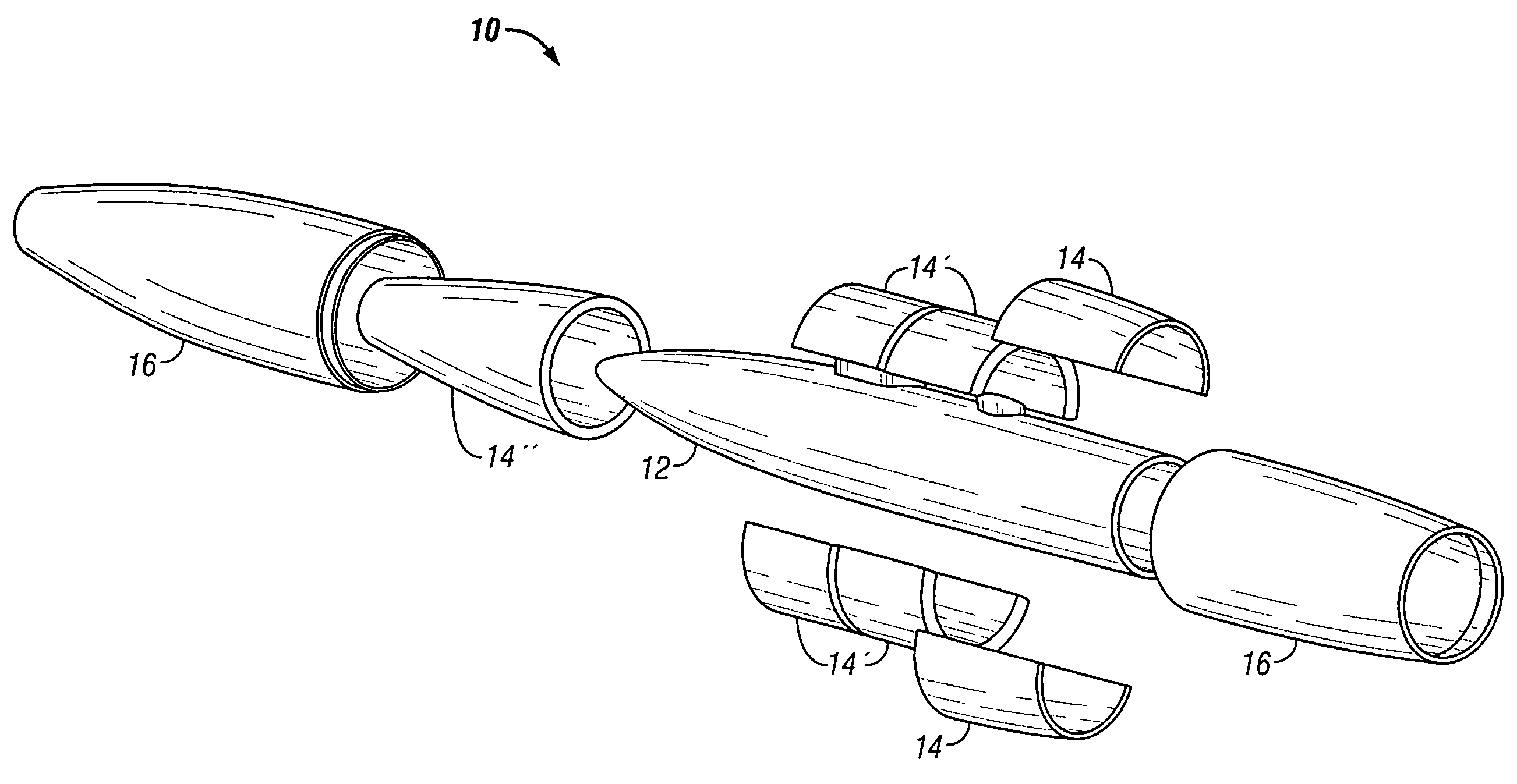

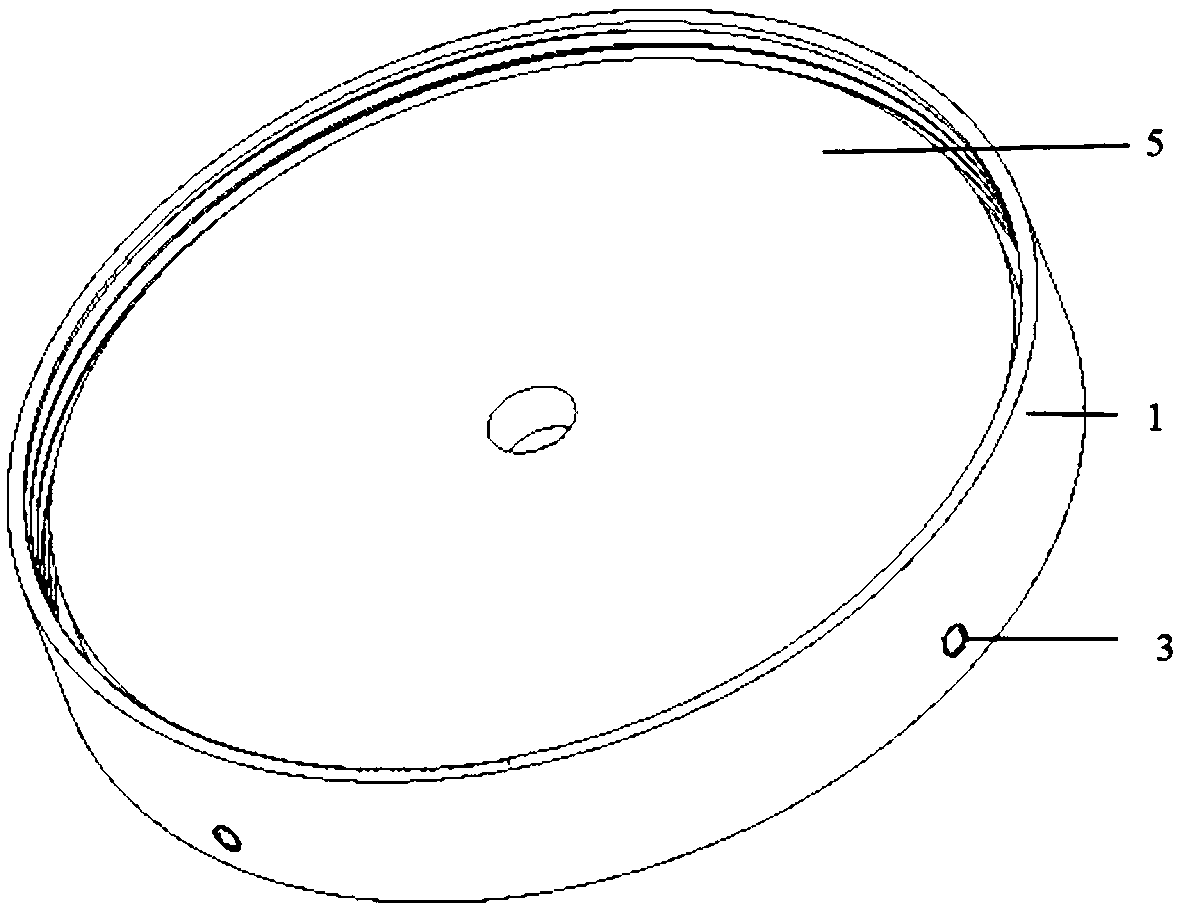

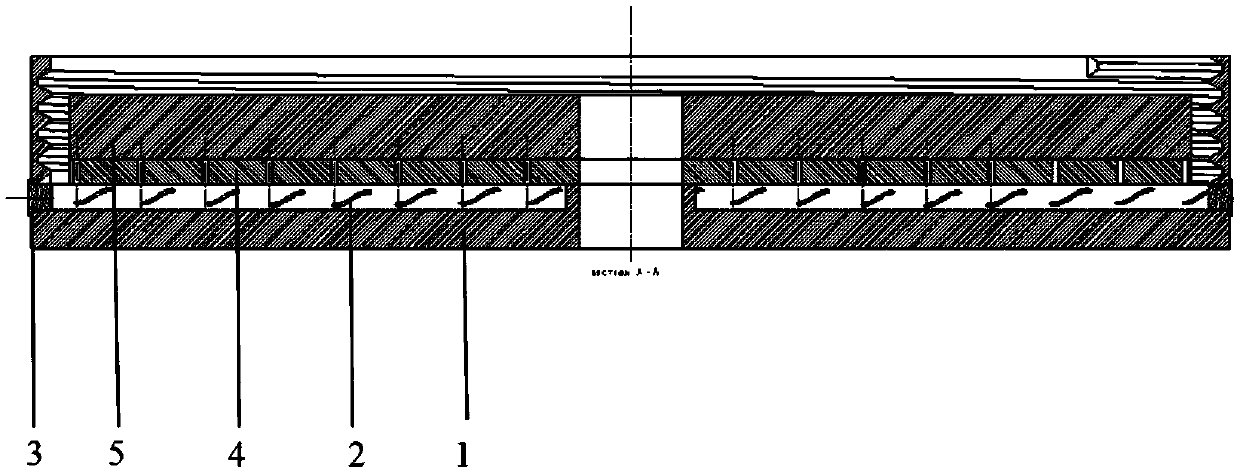

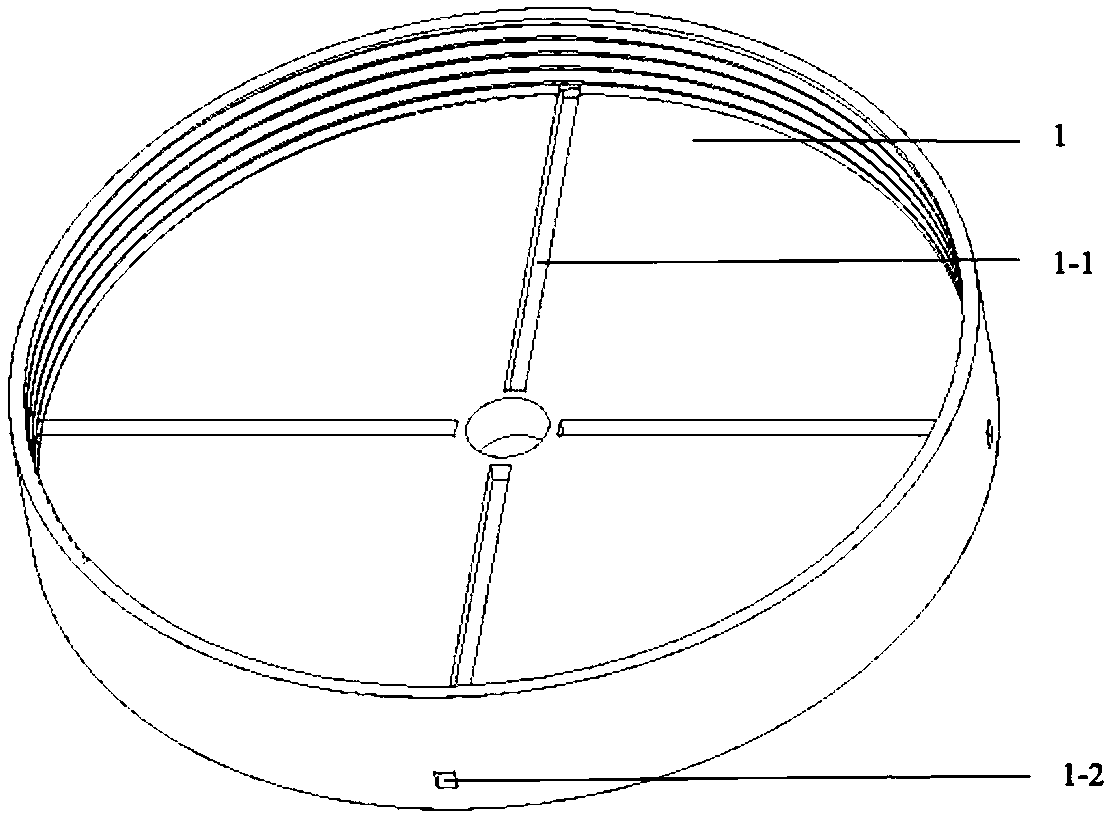

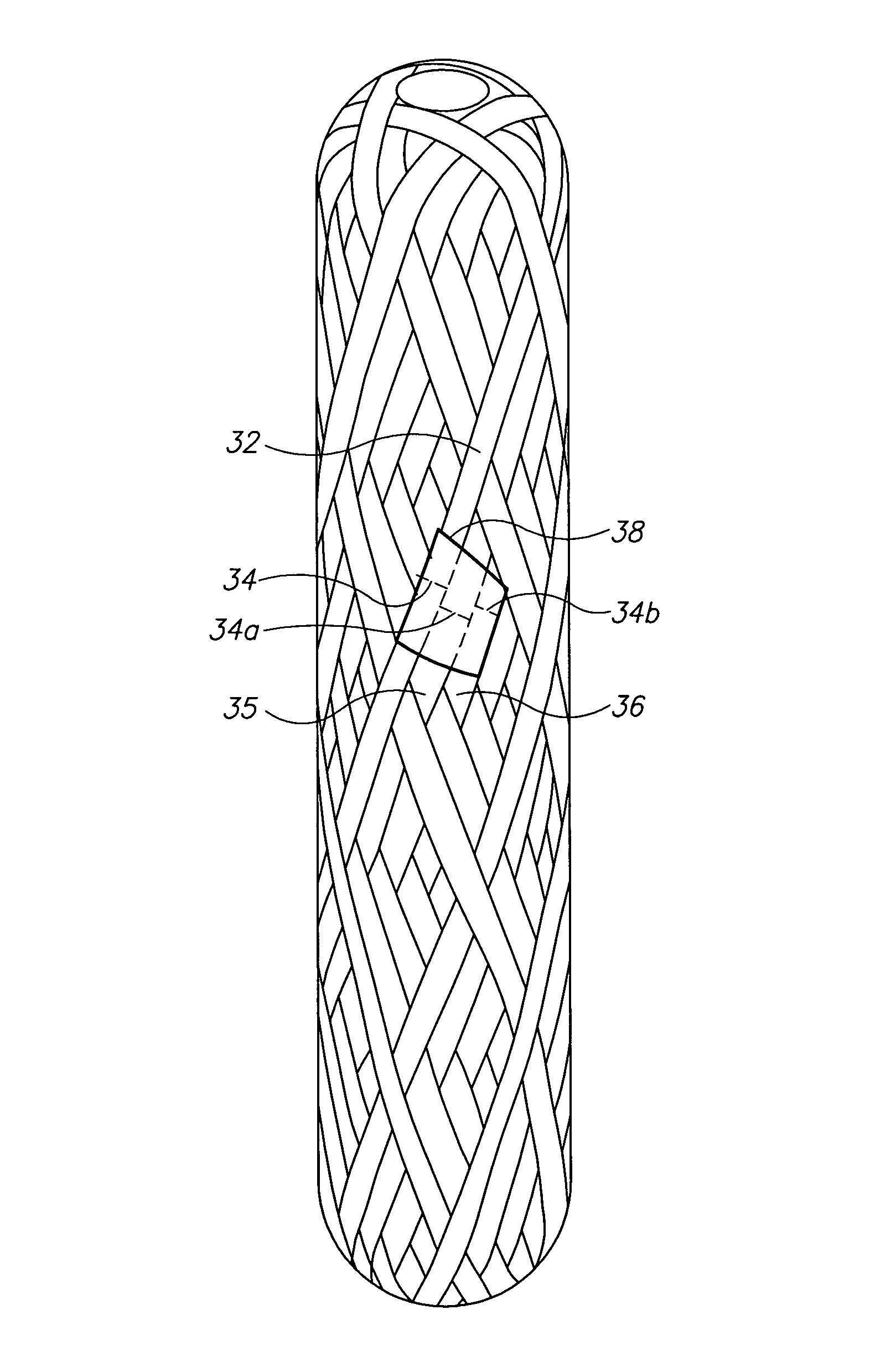

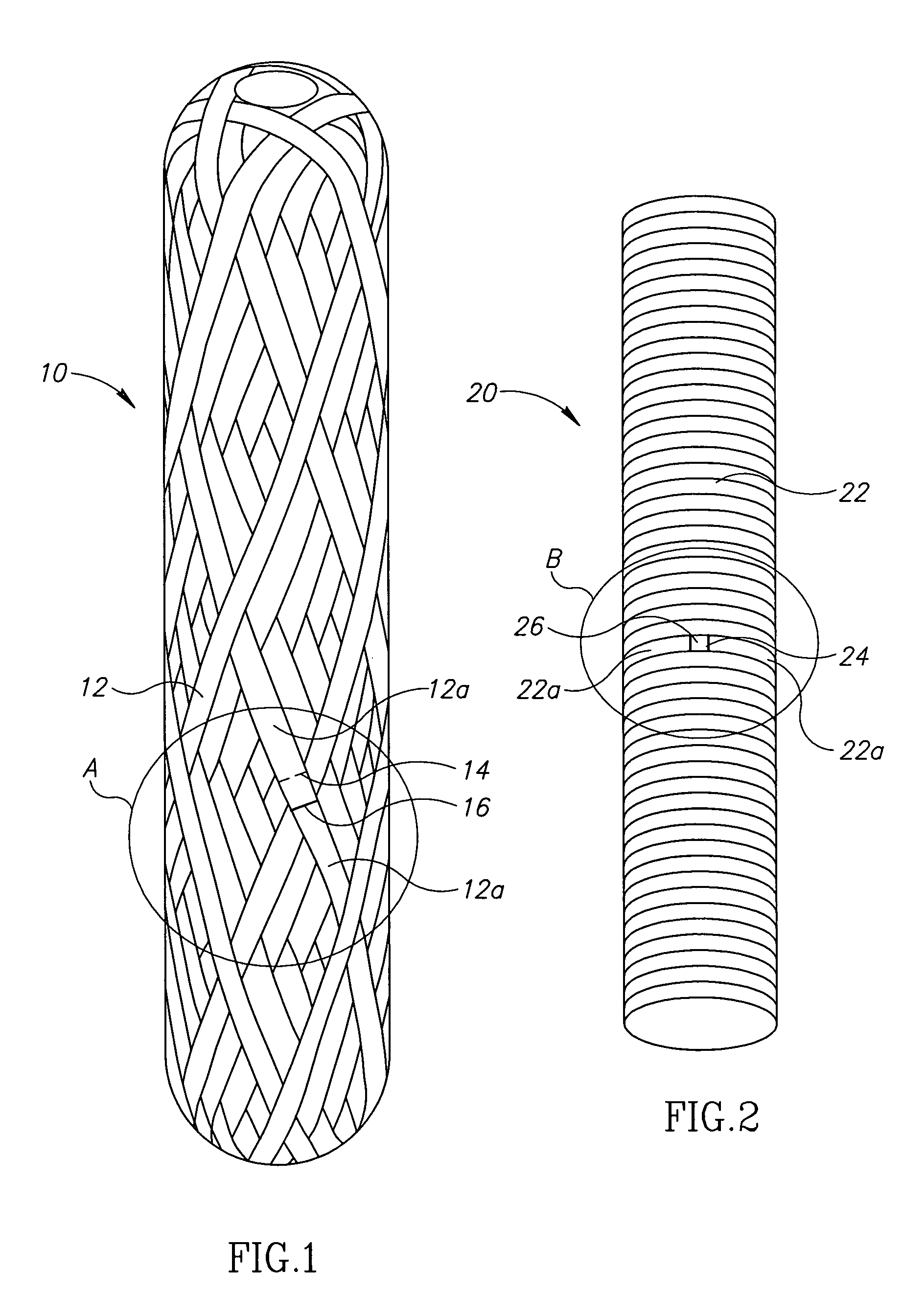

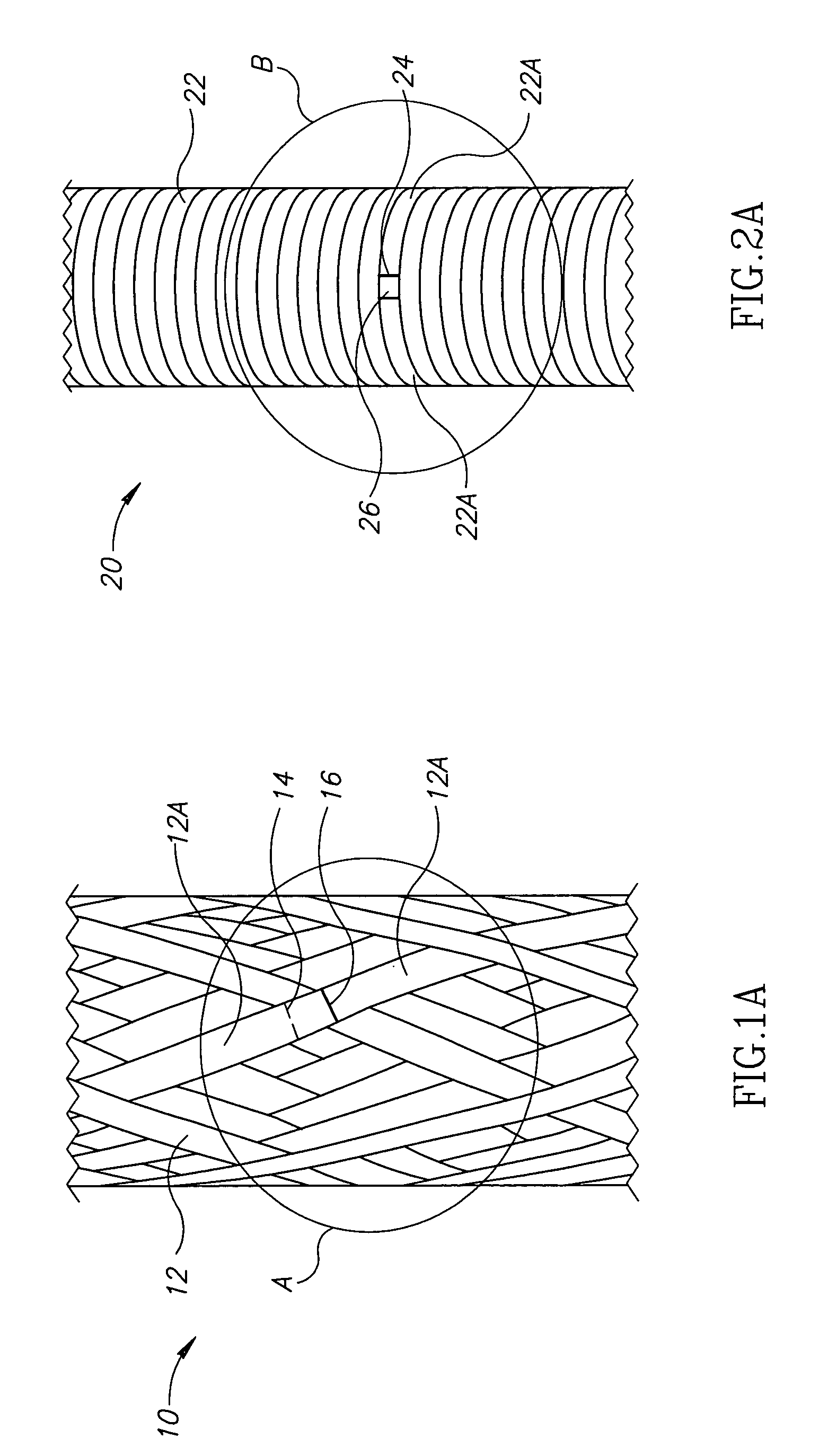

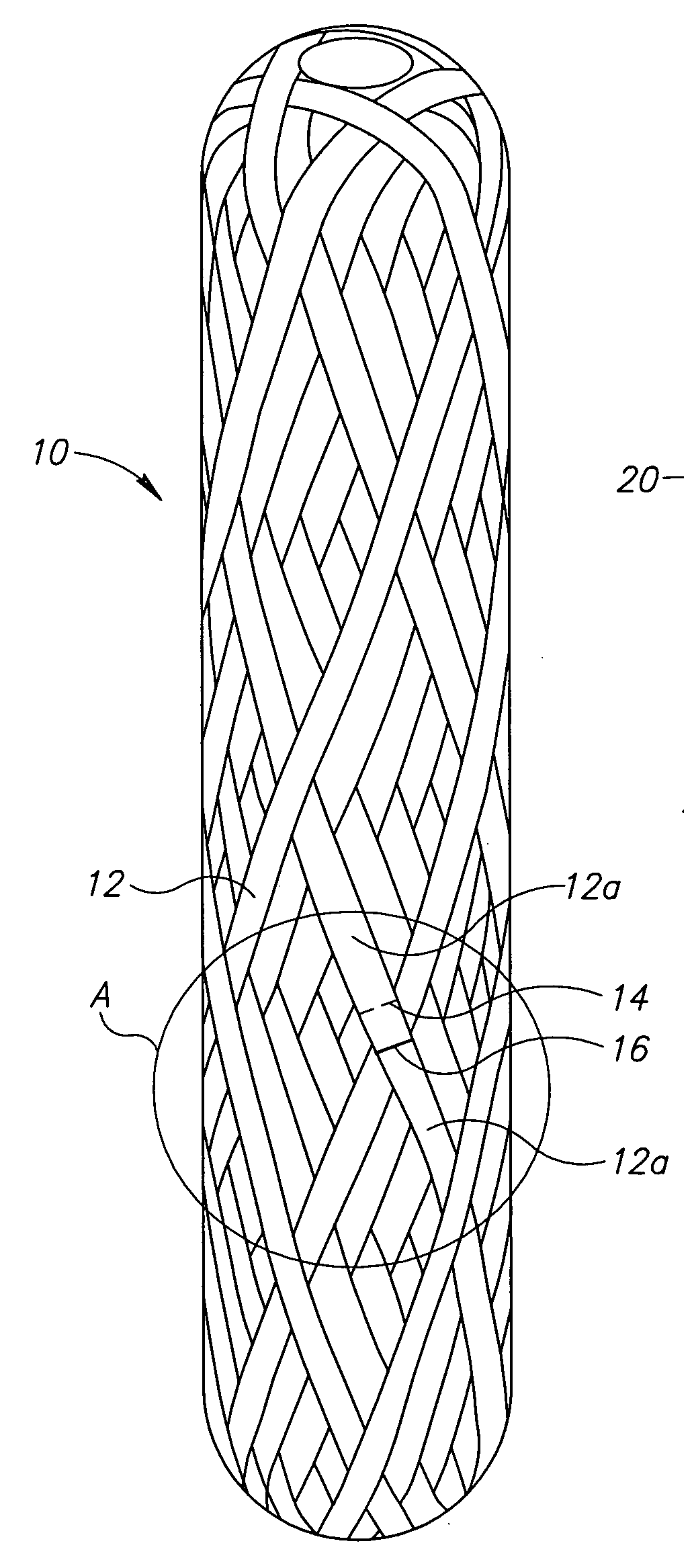

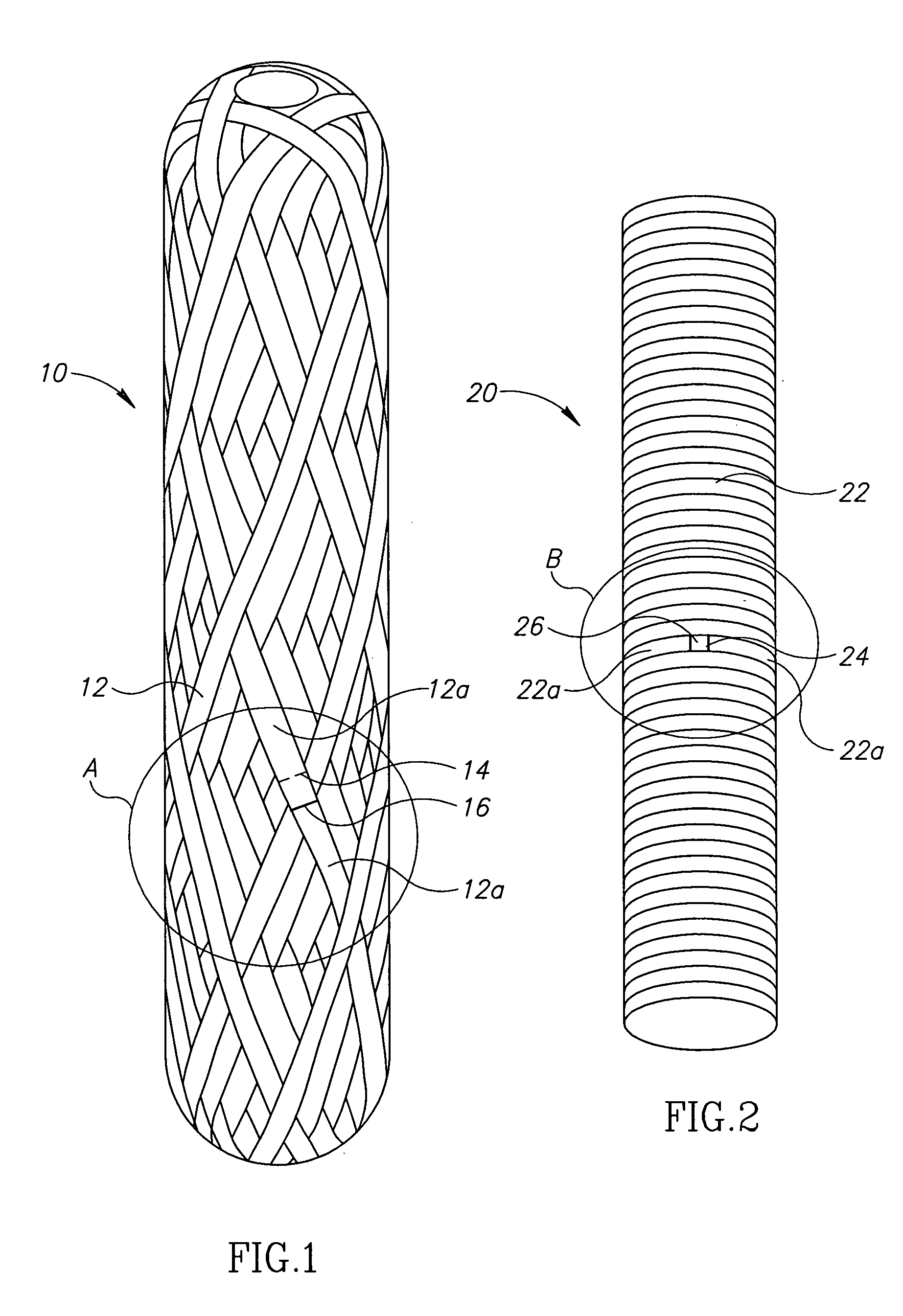

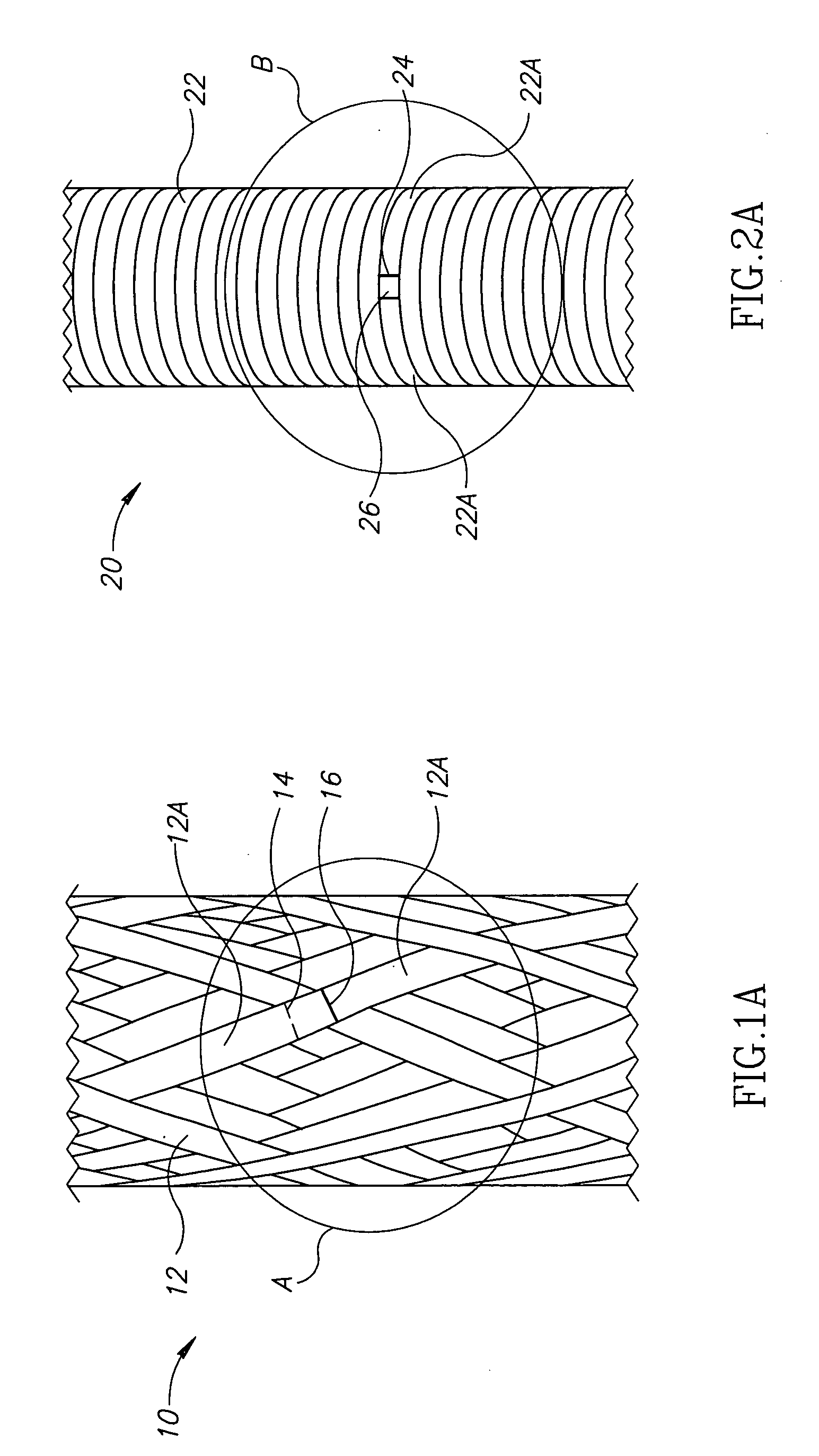

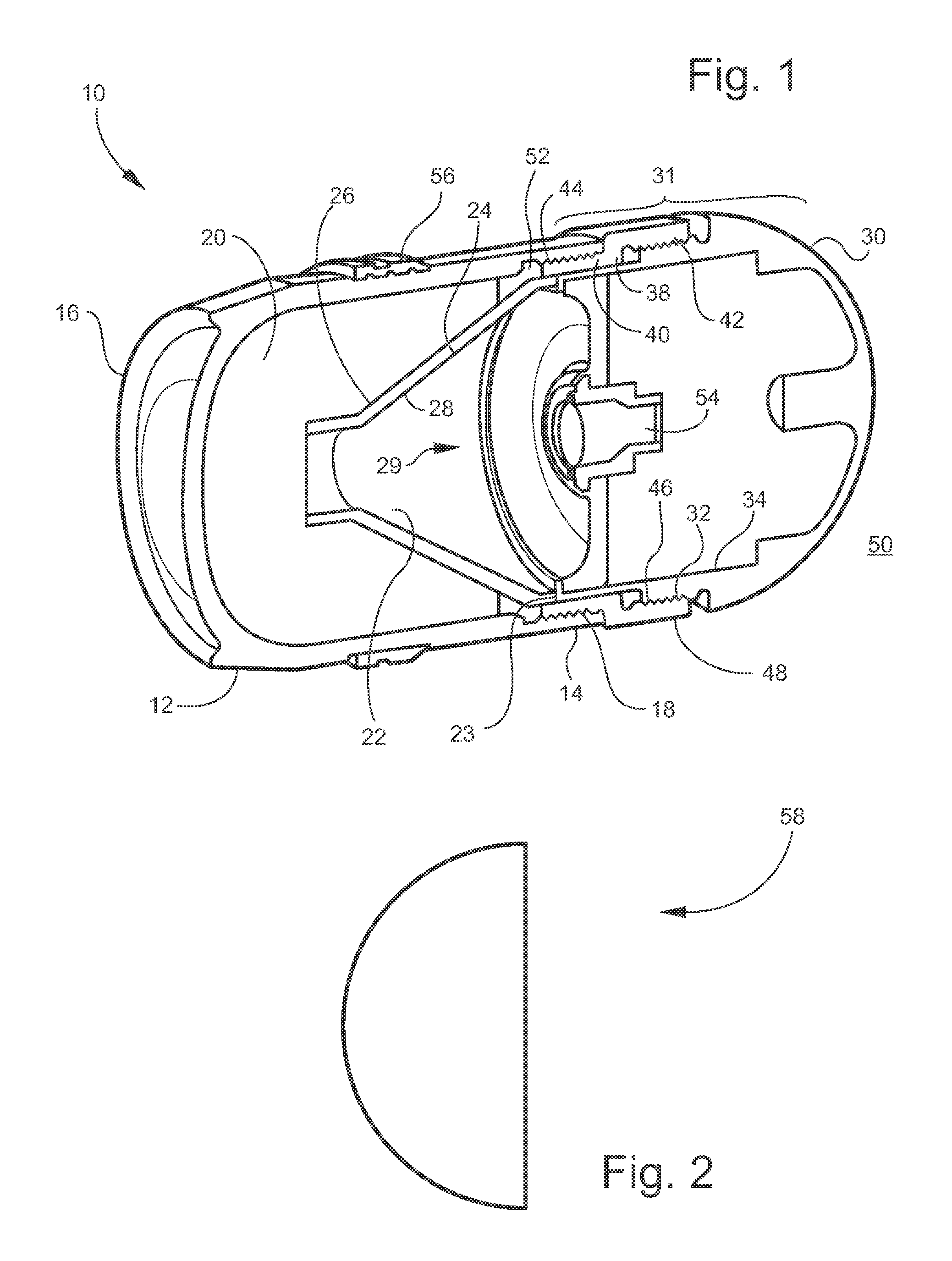

Casing for insensitive munitions and process for making same

An insensitive munitions casing, such as a motor case, for housing a propellant charge is disclosed. The casing is formed by winding, wrapping or rolling a fiber, tape or sheet of material such that the casing has a plurality of reinforcing layers. At least some of the reinforcing layers have discontinuous interfaces. Other reinforcing layers may overlap the discontinuous interfaces. The reinforcing layers are coated with adhesive bonding material for adhering the reinforcing layer to itself and bonding the discontinuous interfaces. The adhesive bonding material has a bond-strength breakdown temperature which is below the auto-ignition temperature of the propellant charge. Once the bond strength breakdown temperature of the adhesive is reached, the bond fails at the discontinuous interface, thereby enabling release of propellant charge pressurization.

Owner:IMI SYST LTD

A kind of metal corrosion resistant insensitive ammunition and preparation method thereof

ActiveCN113916066BImproves metal corrosion resistanceImprove conductivityVibration crystallizationAmmunitionNitrotriazoloneInsensitive munition

The invention relates to the technical field of energetic materials, and specifically discloses a metal corrosion resistant insensitive ammunition and a preparation method thereof, wherein the metal corrosion resistant insensitive ammunition comprises the following components by weight: 0-10% of layered MXene and 90-100% of 3-nitro-1,2,4-triazole-5-ketone; the preparation method firstly etches the aluminum layer in the MAX phase with hydrofluoric acid to obtain layered MXene, and then combines the layered MXene with NTO The raw materials are dissolved in anhydrous ethanol in proportion, and finally the metal corrosion-resistant insensitive ammunition is obtained through evaporative crystallization. In the invention, the anti-metal corrosion type insensitive ammunition not only enhances the anti-metal corrosion performance of NTO, but also further reduces the impact sensitivity and friction sensitivity of NTO; the preparation method is simple, and the MAX phase is etched with hydrofluoric acid to obtain conductive MXenes, and then The MXenes and NTO were prepared by recrystallization method, which has practical application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Insensitive munition-type BNCP explosive material and methods for forming the same

Insensitive munition-type explosive material and methods for forming insensitive munition-type explosive material are provided. In an exemplary embodiment, an insensitive munition-type explosive material comprises a particle of BNCP and a surfactant-comprising shell that encapsulates the particle of BNCP.

Owner:RAYTHEON CO

Exoskeleton cartridge case design for LW 30MM ammunition

ActiveUS10775141B1Relieve fratricidal explosionsAmmunition projectilesAmmunition storageNitrocelluloseMetal foil

An insensitive munition (IM) feature for a lightweight LW 30 MM ammunition projectile utilizing combustible vent plugs for the projectile, which plugs feature an exclusively nitrocellulose material sheet fused to a metal foil sheet, to plug vent holes in the projectile.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Fuse small shaped charge output detonator adopting single charge

The invention discloses a small-sized fuze shaped charge output detonator adopting single charge. The small-sized fuze shaped charge output detonator comprises a detonator shell, the single charge and a shaped charge cover, the single charge is a coprecipitation initiating explosive with lead azide as a main component, and the lead azide and tetraazene coprecipitation initiating explosive with high needling sensitivity and the lead azide and trinitroresorcinol lead coprecipitation initiating explosive with high flame sensitivity are used for the needling energy-gathered output detonator and the flame energy-gathered output detonator respectively. And meanwhile, power output charging is also achieved. The explosive loading structure of the detonator is simplified, the height size of the detonator is reduced, the explosive loading amount of the detonator is reduced, so that the explosive-proof safety of the fuze is facilitated, axial long-distance and large-power accurate output is realized by an energy gathering effect, and the explosive loading device is particularly suitable for the detonator with the diameter and the height being less than 4 mm and is used for detonating insensitive low-vulnerability explosive-conducting and booster explosive in an insensitive ammunition fuze.

Owner:NANJING UNIV OF SCI & TECH

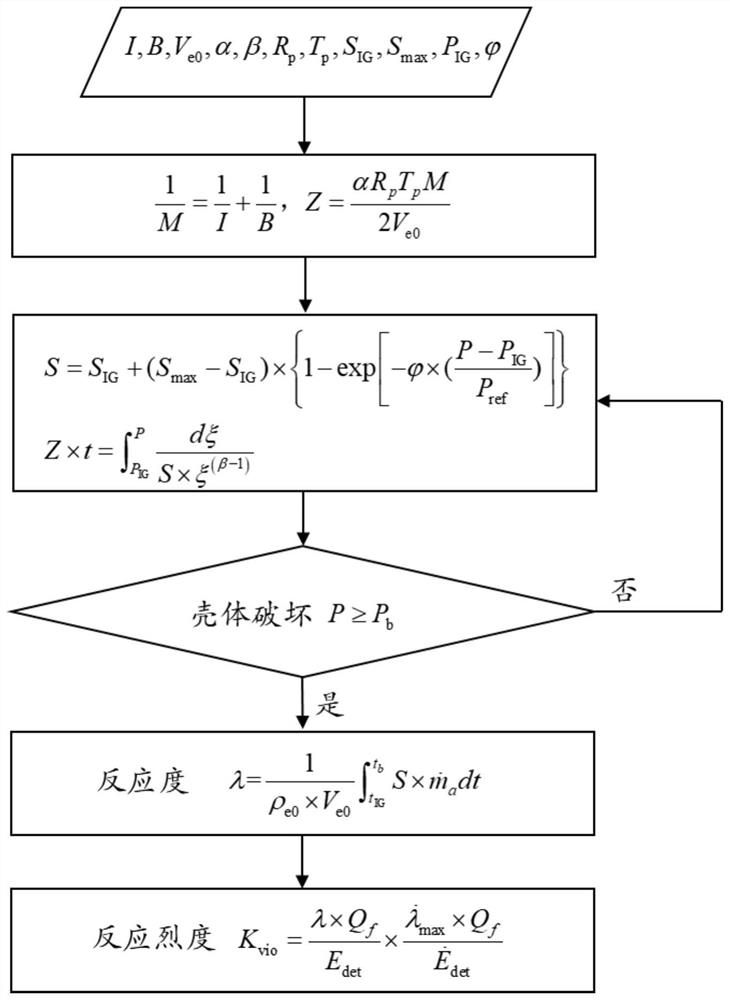

Ammunition reaction intensity quantitative evaluation method based on reaction evolution model of combustion network

ActiveCN111898261ASolve the calculation problem of combustion reaction growth evolutionDesign optimisation/simulationSpecial data processing applicationsMechanical engineeringMechanics

The invention discloses an ammunition reaction intensity quantitative evaluation method based on a combustion network reaction evolution model and relates to the technical field of insensitive ammunition and can solve the problem of combustion reaction growth evolution calculation after accidental ignition of strong-constraint ammunition charging, and solves the problems of reaction intensity control and quantitative evaluation of ammunition under accidental stimulation of high temperature, fire and the like. The projectile charging safety evaluation method based on a combustion network reaction evolution model. Modeling is carried out on the combustion reaction growth evolution process after the strong-constraint ammunition is charged and ignited; the growth history of the internal pressure, the reactivity and the like of the projectile body close to the actual state is quantitatively given; the pressure model in the shell and the reactivity model of the charging matrix are obtained,the reaction intensity of the ammunition is finally obtained, objective description of the reaction growth evolution behavior after ammunition charging ignition is achieved, and a theoretical basis isprovided for strong-constraint insensitive ammunition design and reaction intensity control and quantitative evaluation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Methods of detecting and identifying munitions compounds

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Casing for insensitive munitions and process for making same

An insensitive munitions casing, such as a motor case, for housing a propellant charge is disclosed. The casing is formed by winding, wrapping or rolling a fiber, tape or sheet of material such that the casing has a plurality of reinforcing layers. At least some of the reinforcing layers have discontinuous interfaces. Other reinforcing layers may overlap the discontinuous interfaces. The reinforcing layers are coated with adhesive bonding material for adhering the reinforcing layer to itself and bonding the discontinuous interfaces. The adhesive bonding material has a bond-strength breakdown temperature which is below the auto-ignition temperature of the propellant charge. Once the bond strength breakdown temperature of the adhesive is reached, the bond fails at the discontinuous interface, thereby enabling release of propellant charge pressurization.

Owner:IMI SYST LTD

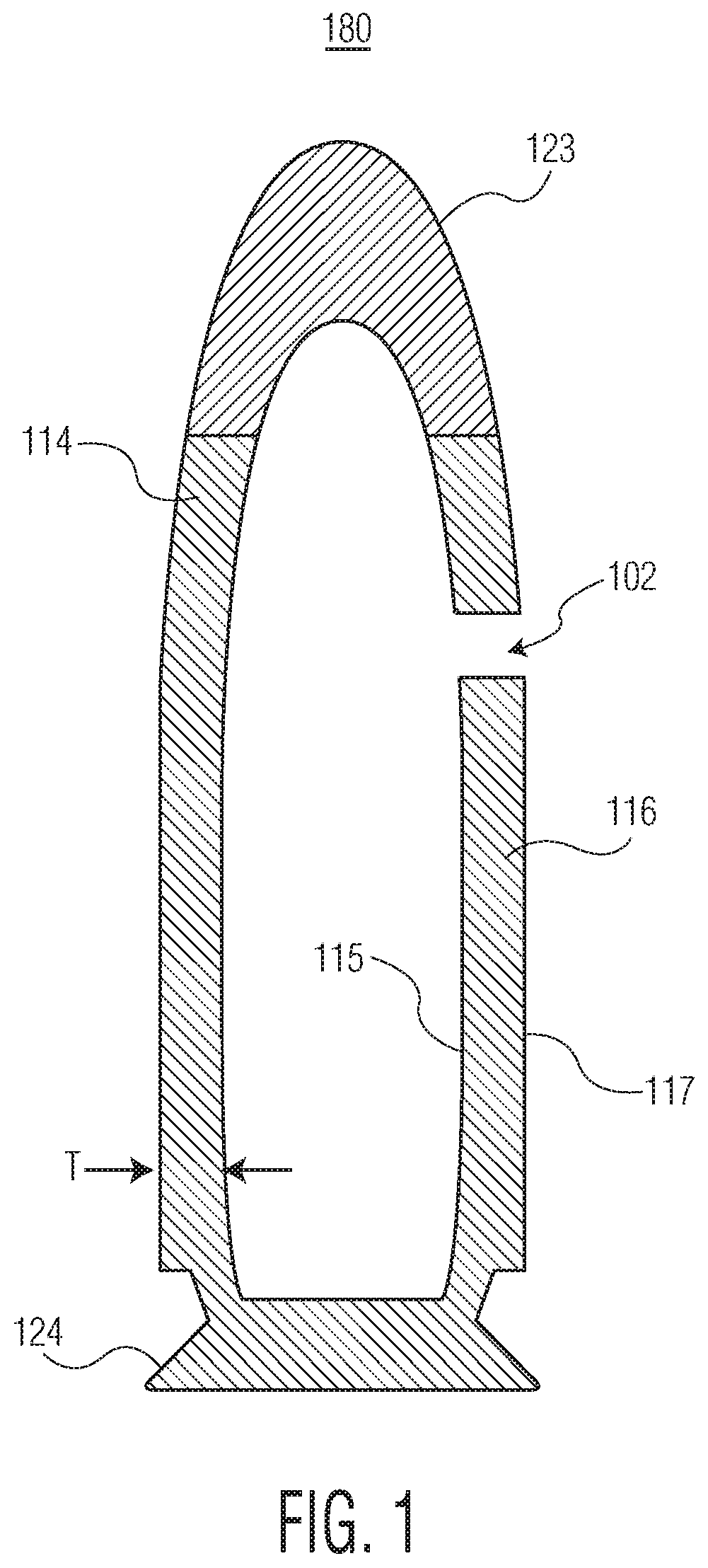

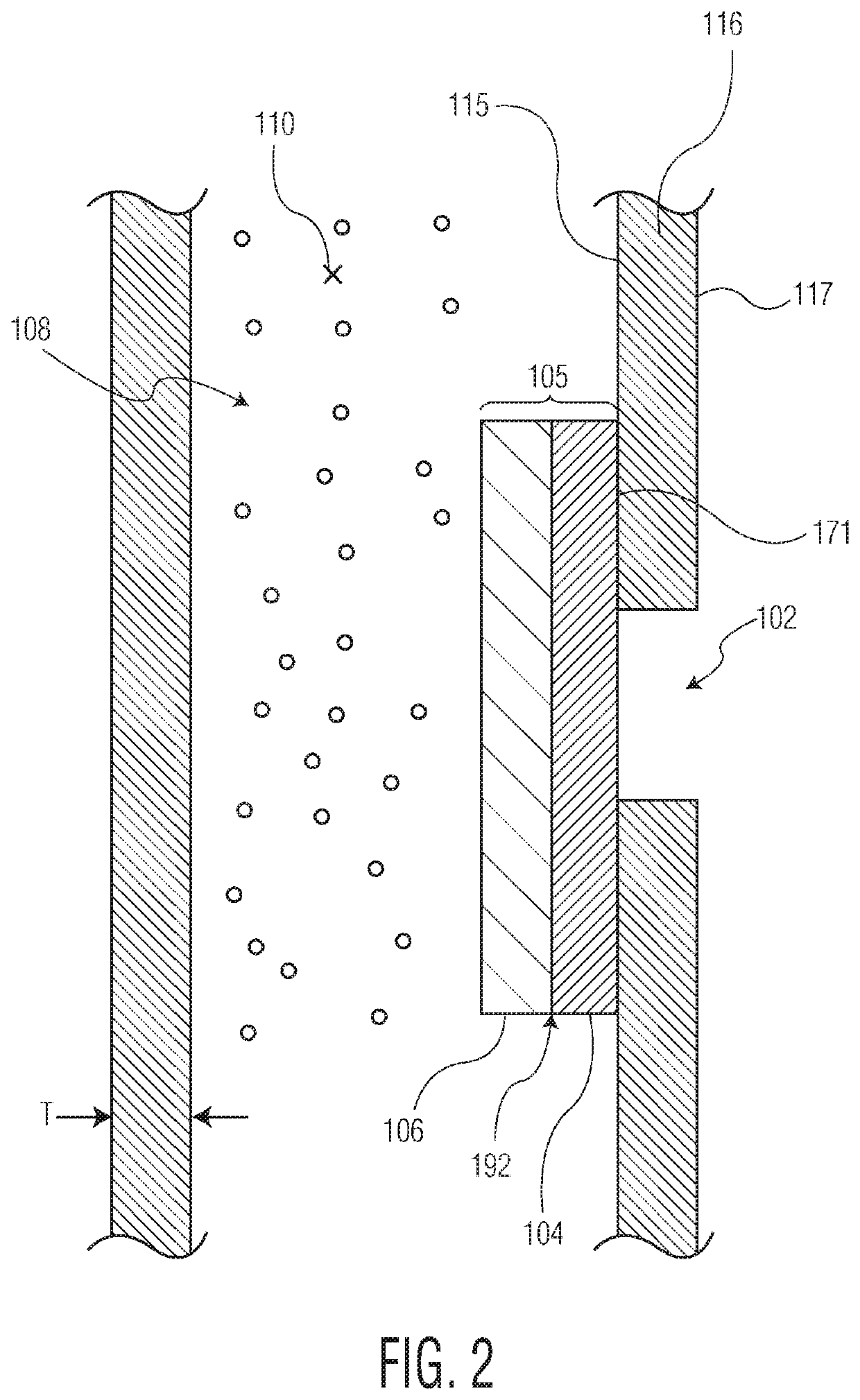

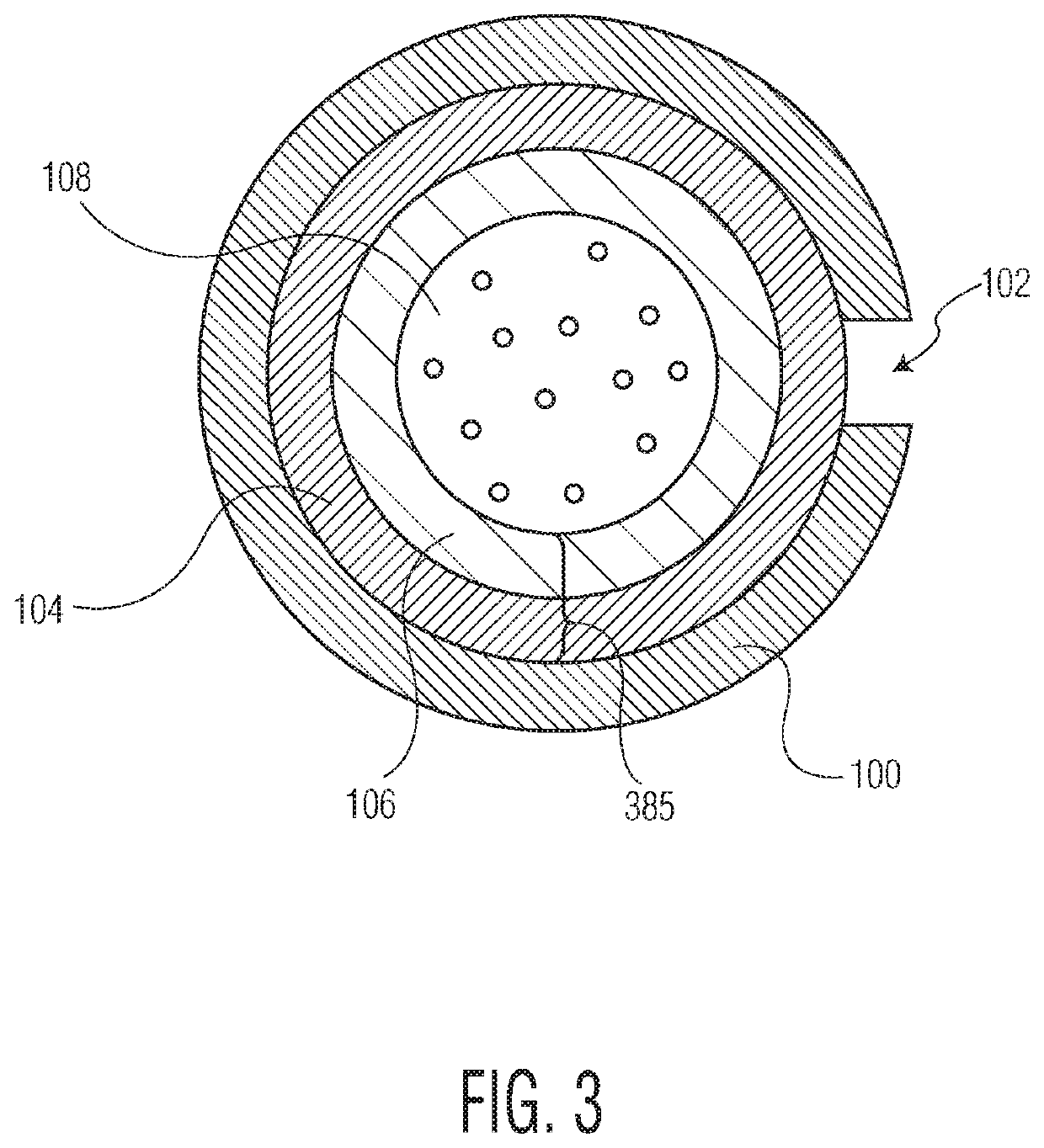

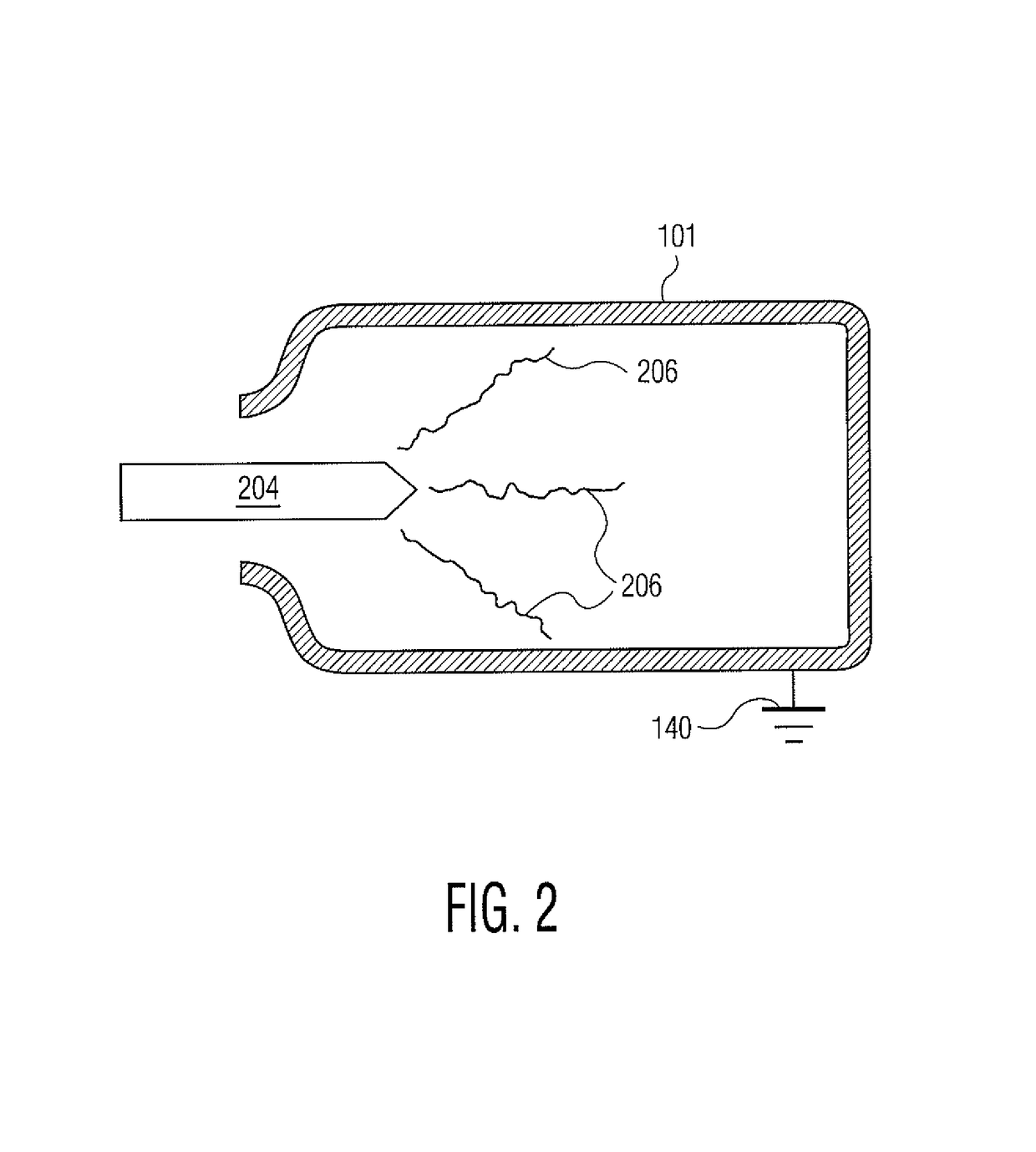

Insensitive munitions liner

A munition is rendered less sensitive to inadvertent initiations by providing a polymer liner on the entire inside surface of the munition. A thermoplastic liner may be fabricated totally within an empty inert munition casing by spraying a layer of electrostatically charged low melt thermoplastic material particles over substantially the entire inside surfaces of the munition casing, which casing is first electrically grounded. After thickening the particle layer through heat, further such layers may be then applied there over, until a desired cumulative thickness liner is fabricated.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

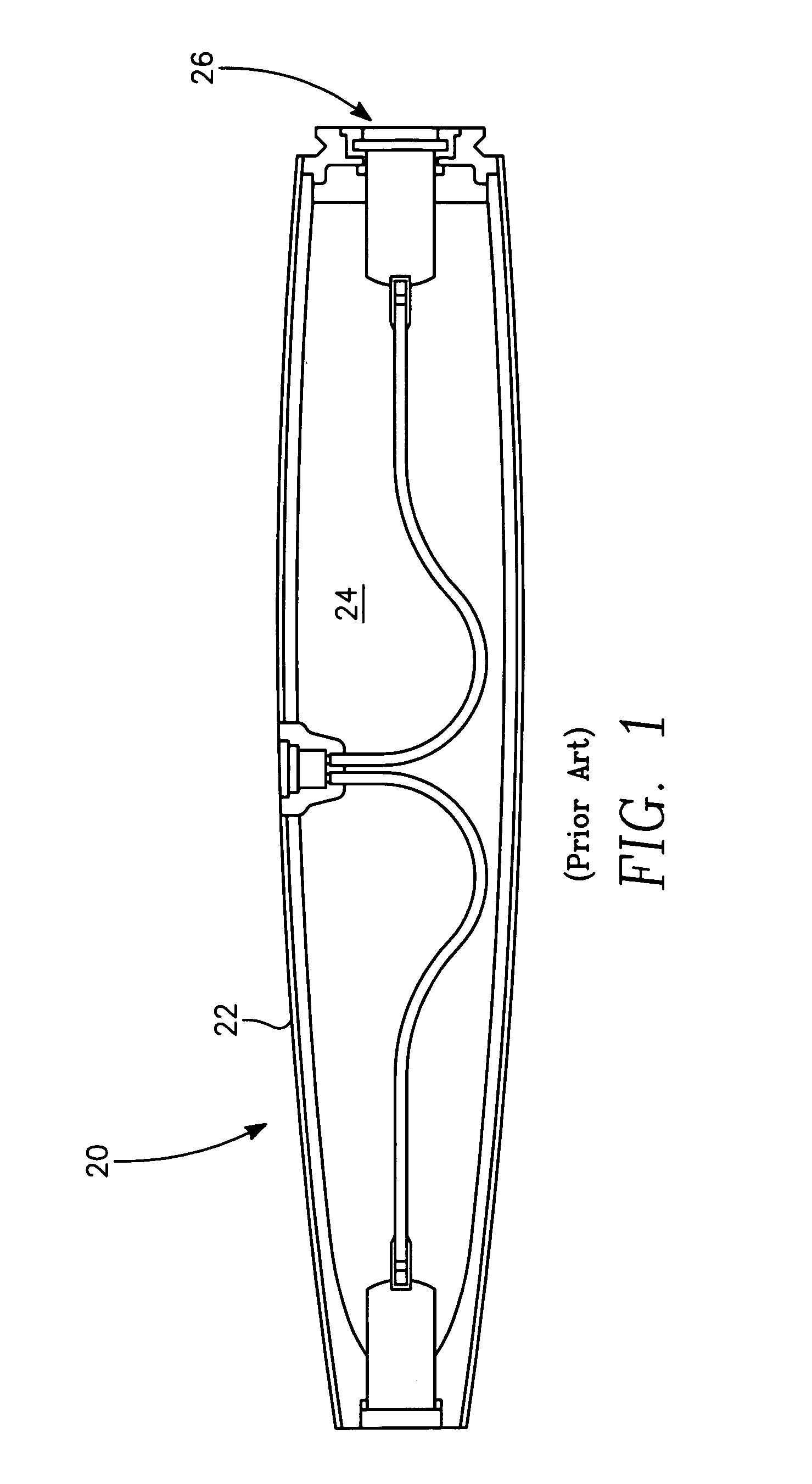

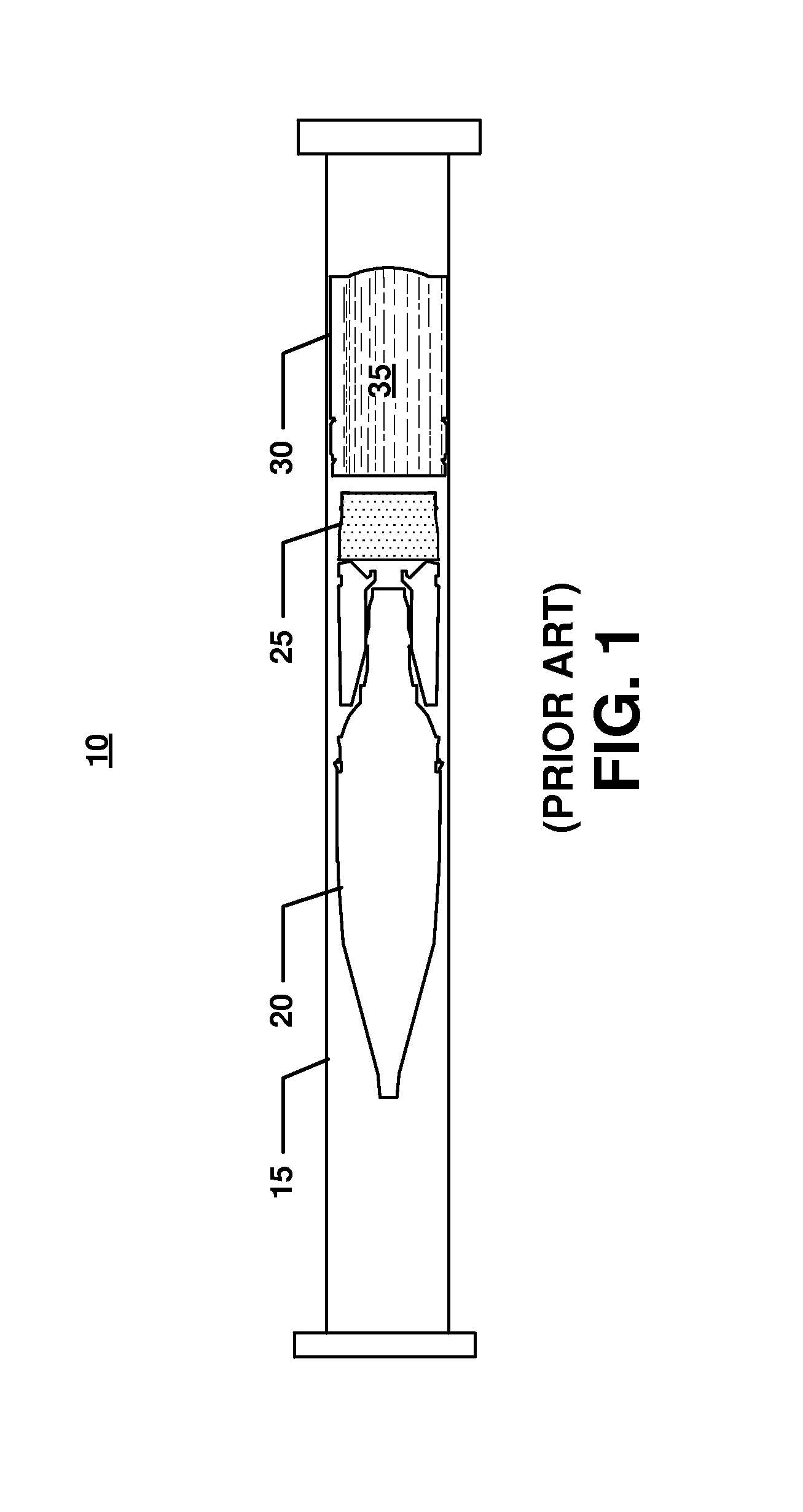

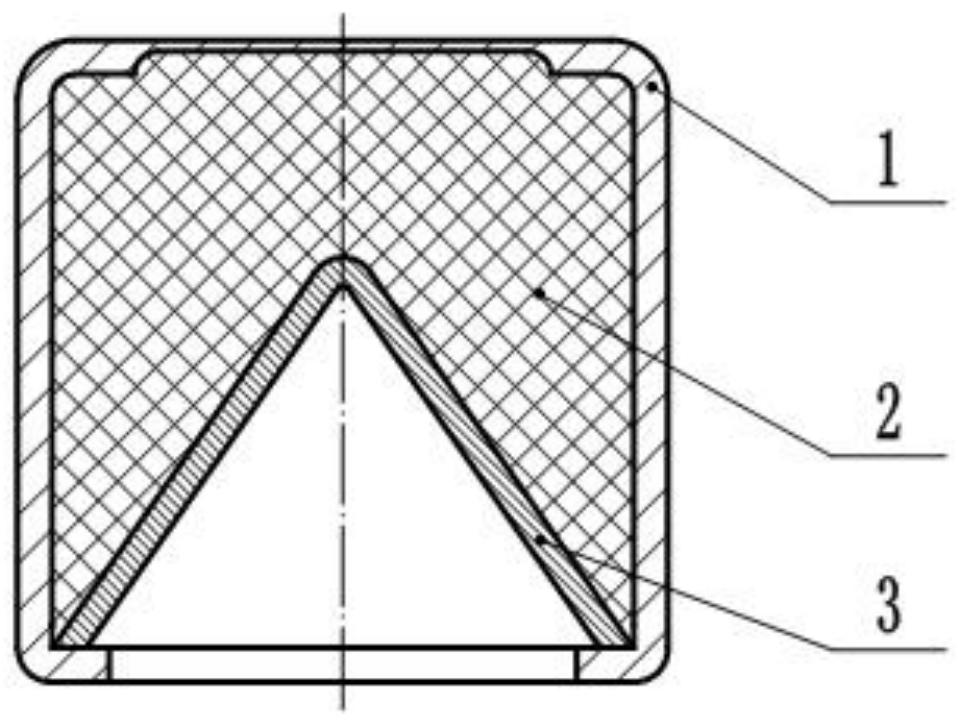

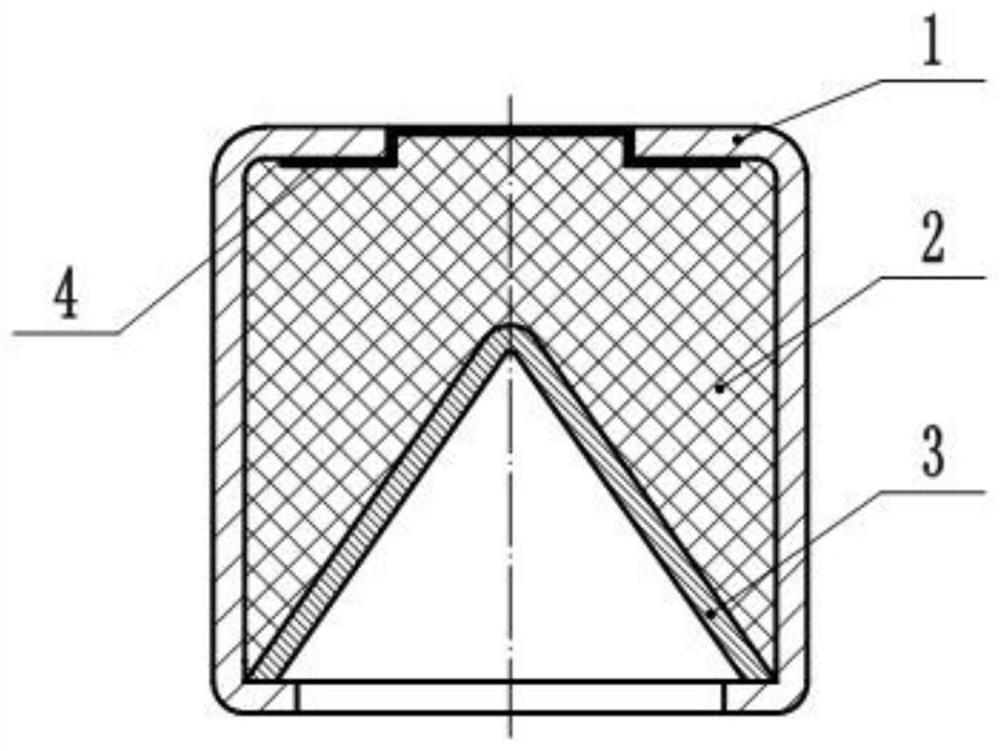

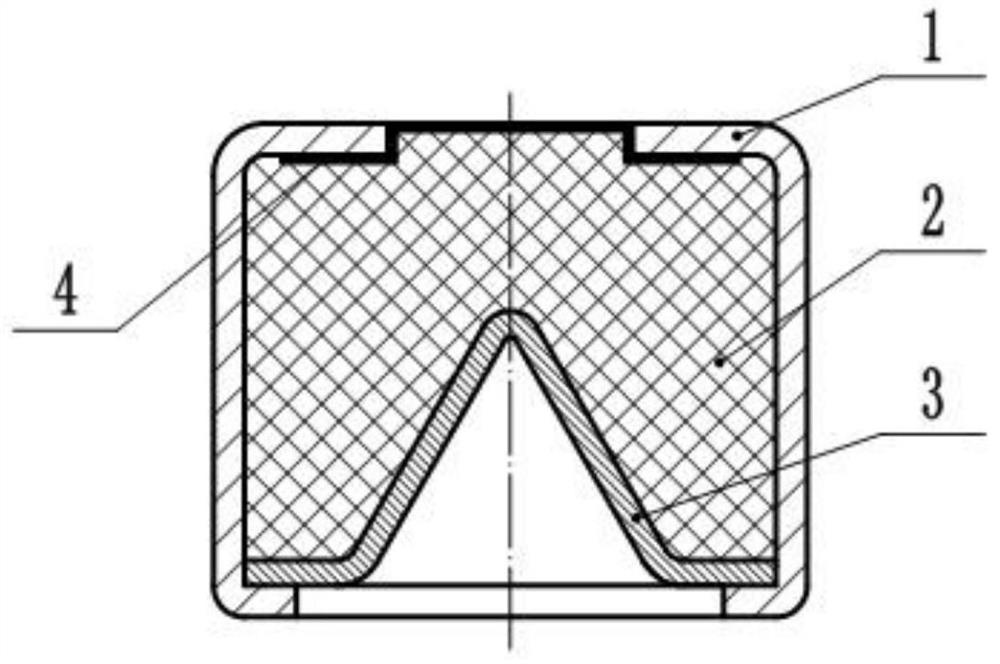

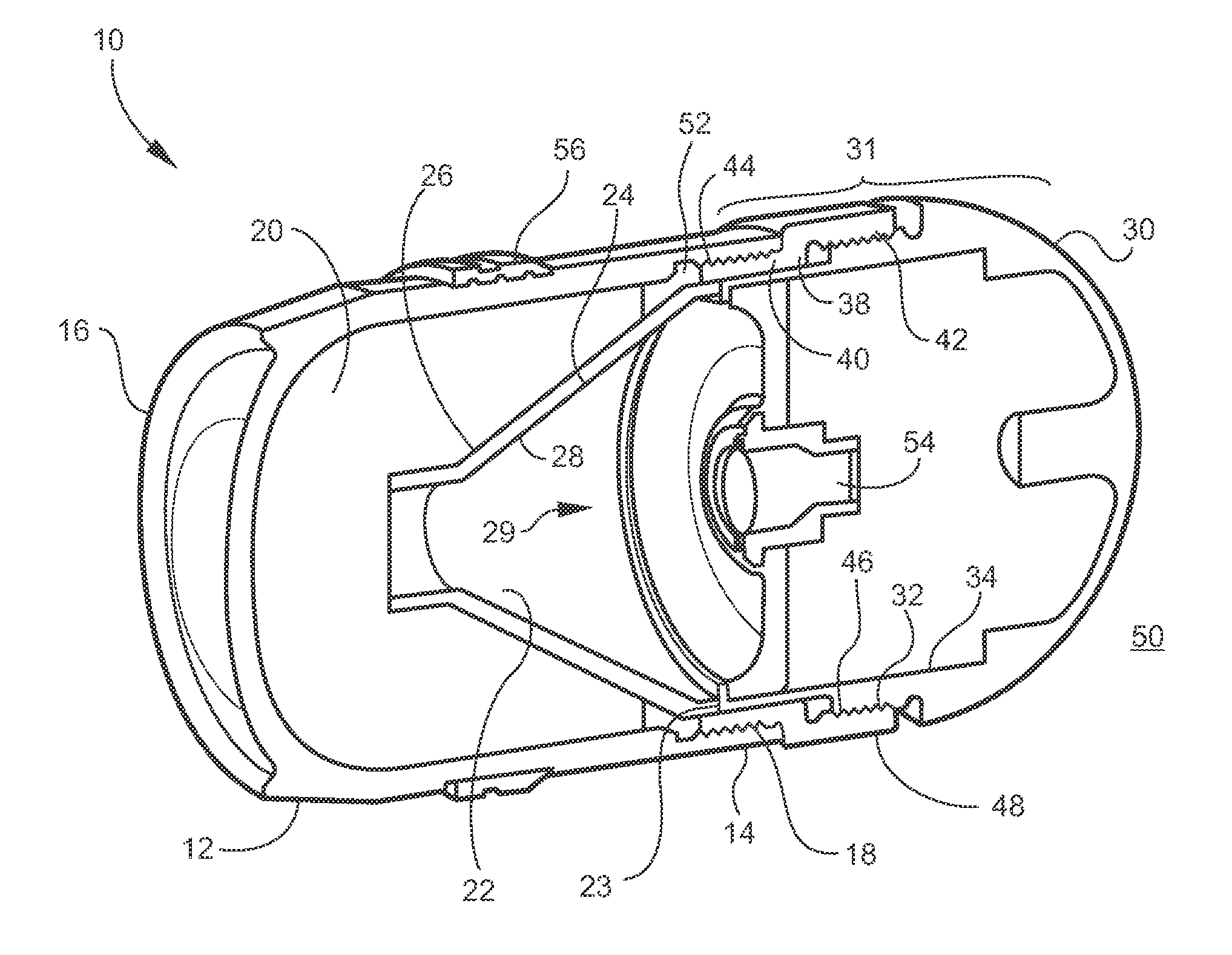

Liner release mechanism for anti-armor munitions

InactiveUS8943972B1Reduce generationAmmunition projectilesAmmunition storageHeat deflection temperatureEngineering

An Insensitive Munitions safety device mitigates the occurrence of a violent response of an anti-armor munition subjected to elevated temperatures. The anti-armor munition includes a projectile body having fore and aft ends, an explosive charge disposed in the projectile body, and a projectile-forming or jet-forming liner disposed in the projectile body. The liner includes an aft surface contiguous with the explosive charge and a fore surface that defines a void. A liner restraint abuts a fore end of the liner and restrains movement of the liner. A portion of the liner restraint comprises a material having a heat deflection temperature less than the critical temperature of the explosive charge in the munition.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com