Ammunition reaction intensity quantitative evaluation method based on reaction evolution model of combustion network

A quantitative evaluation and evolutionary model technology, applied in design optimization/simulation, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

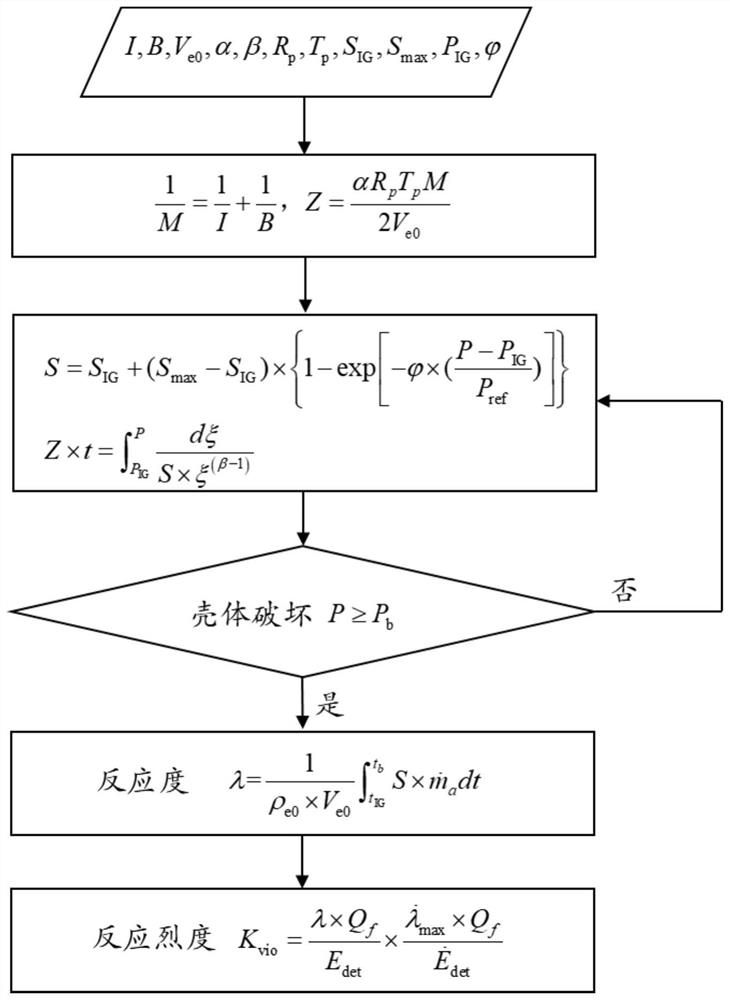

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

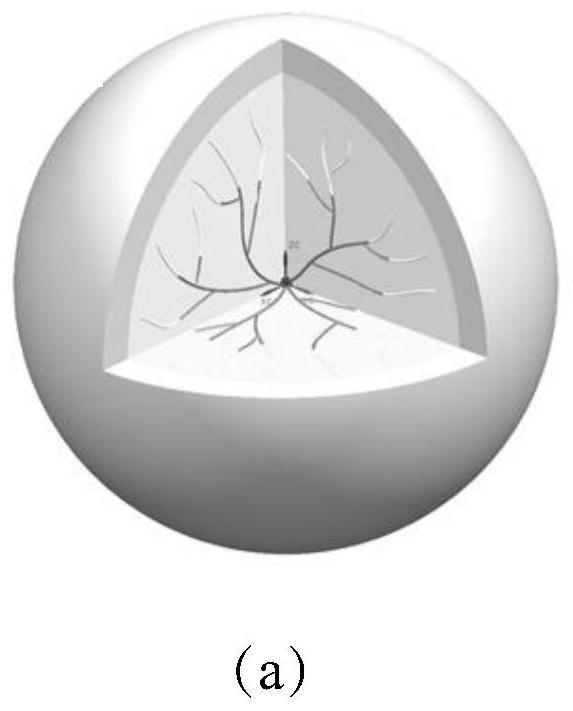

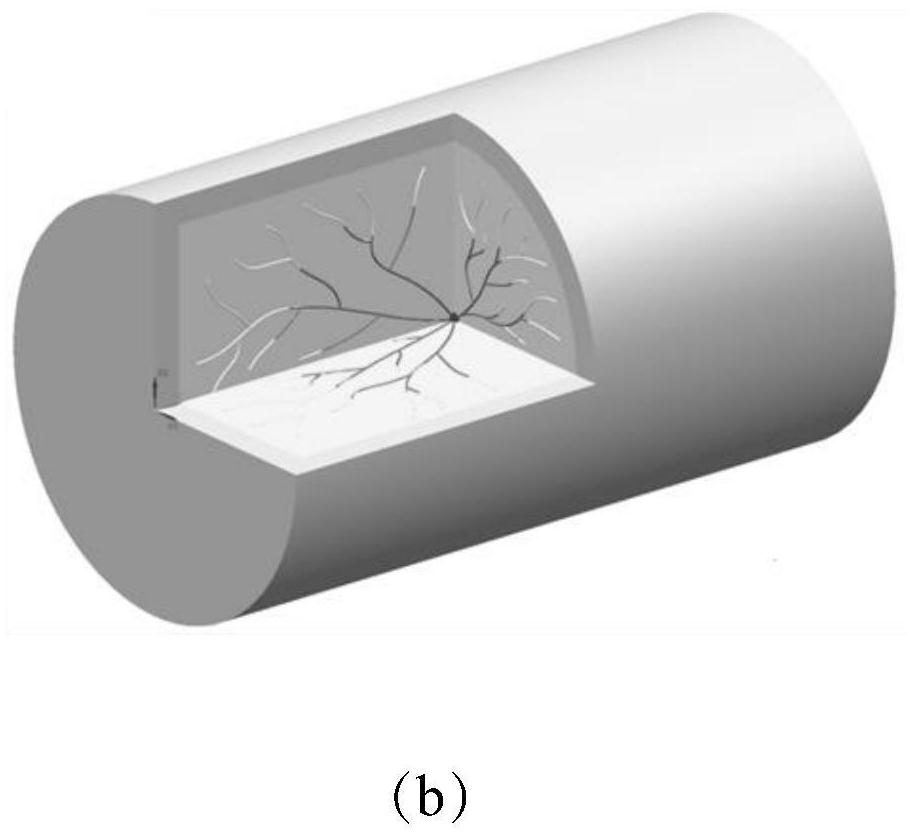

[0030] The present invention provides a quantitative evaluation method for ammunition response intensity based on a combustion network reaction evolution model, mainly constructing a combustion network for strongly constrained ammunition, and establishing a constrained explosive combustion crack network reaction evolution model. The structure of the ammunition targeted by the present invention is as follows: figure 2 , where (a) is a schematic diagram of the structure of ammunition constrained by a spherical shell; (b) is a schematic diagram of the structure of ammunition constrained by a cylindrical shell.

[0031] A certain intensity of ignition occurs in the center of the charge, and at the same time a local crack is generated, and the combustion spreads in the crack. Considering that the sound velocity of explosives is of the same order as that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com