Reaction intensity evaluation method for ammunition with pressure relief structure based on reaction evolution model

A pressure relief structure and evolution model technology, applied in design optimization/simulation, special data processing applications, chemical process analysis/design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

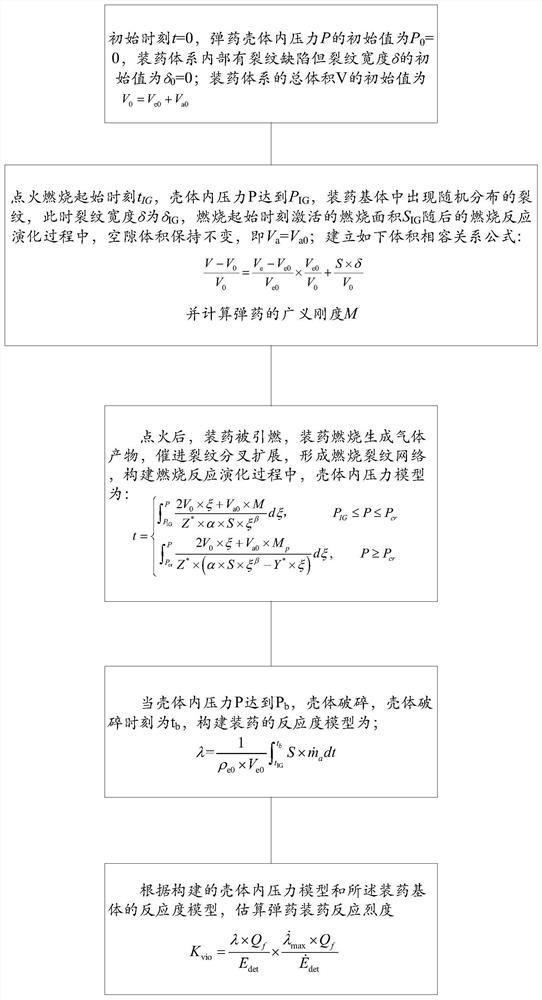

[0034] The invention provides a reaction intensity evaluation method for ammunition with a pressure relief structure based on a combustion network reaction evolution model. The process is as follows: figure 1 shown.

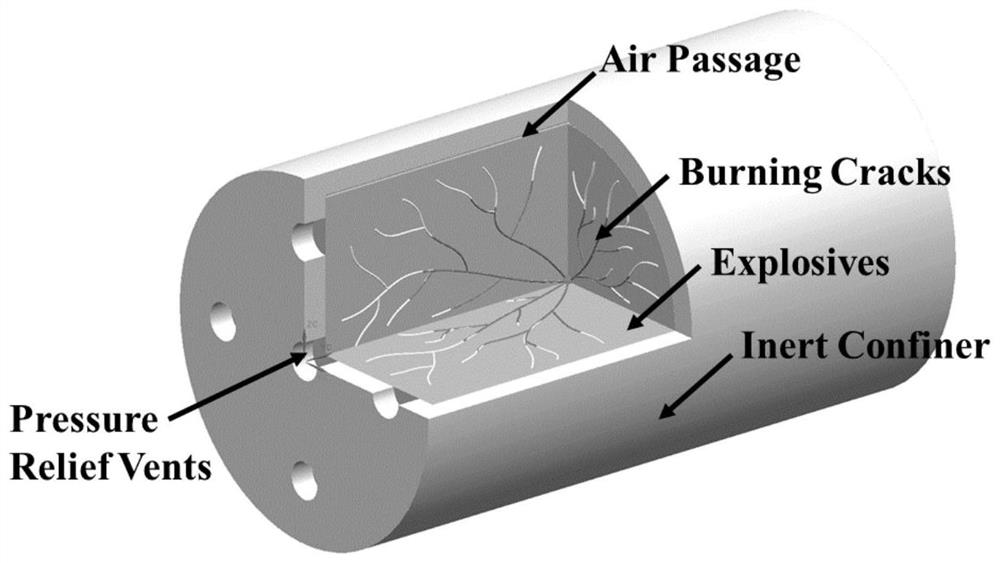

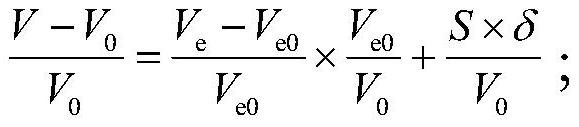

[0035] In the design of insensitive ammunition, in order to ensure reliable pressure relief of the charge, an exhaust channel is usually reserved between the charge and the shell, such as figure 2 As shown, and in order to prolong the ignition induction time in engineering, an air gap is often preset between the shell and the explosive charge, which can be collectively referred to as the pressure relief channel volume. Although this part of the volume accounts for a small proportion, it has a significant effect on the induction phase of the explosive charge reaction growth.

[0036]The ammunition with pressure relief channel and pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com