Patents

Literature

244 results about "Pressure equilibrium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The change of pressure can be observed on the reactions which involves gaseous substances. According to Le-Chateliers’s principle, increase of pressure on a system at equilibrium will shift the equilibrium in the direction in which pressure is reduce. By increase in pressure, the volume occupied by the system decreases.

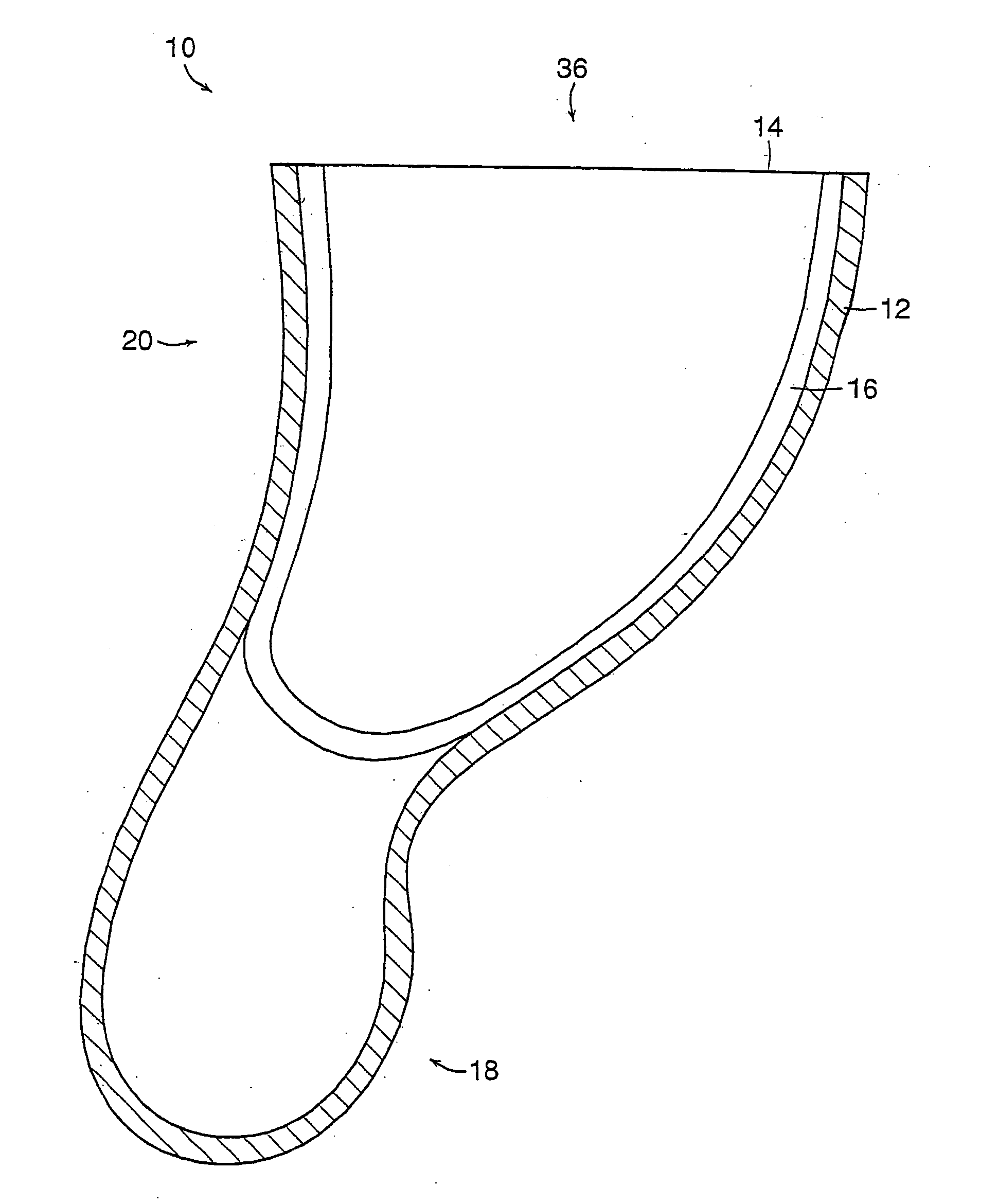

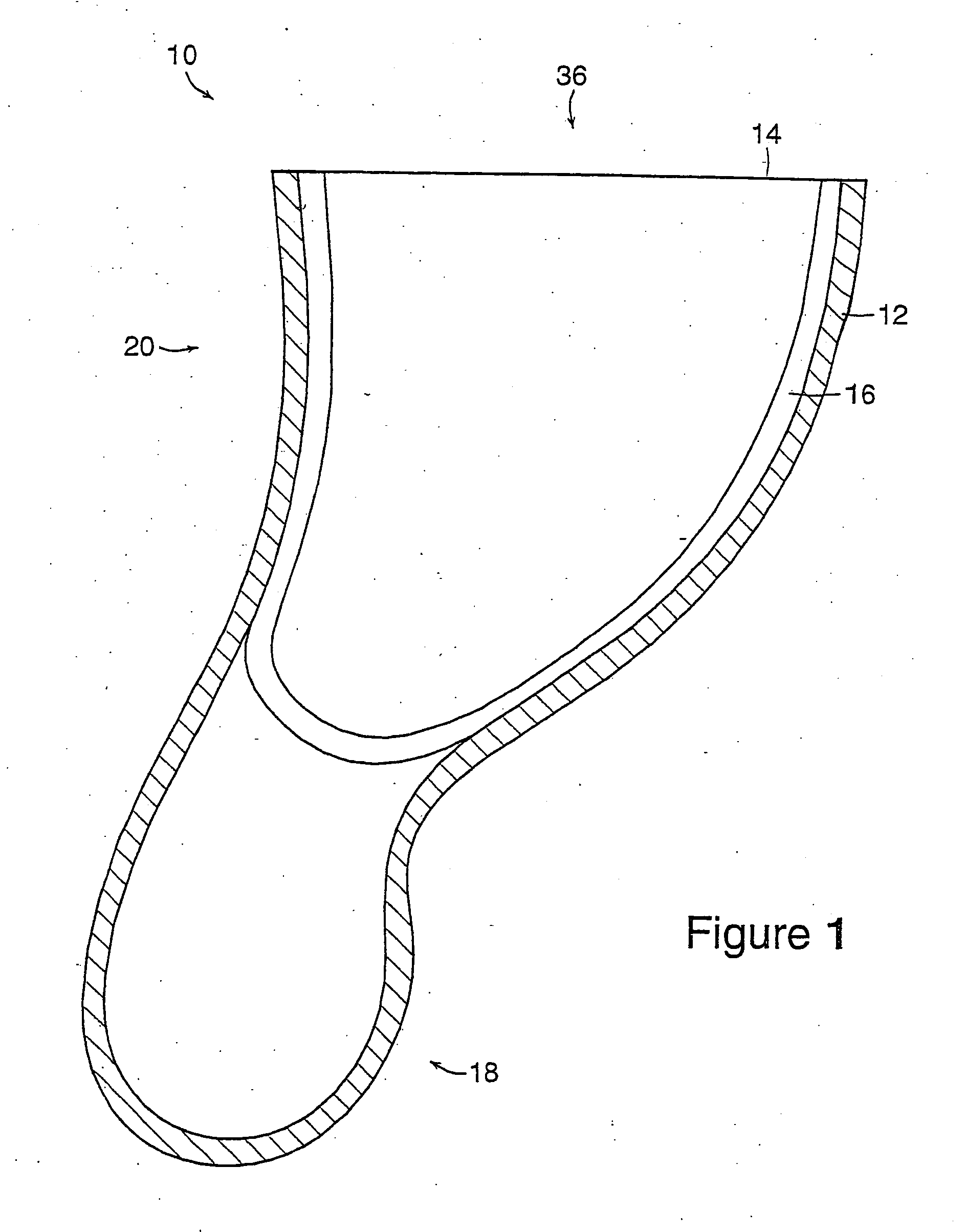

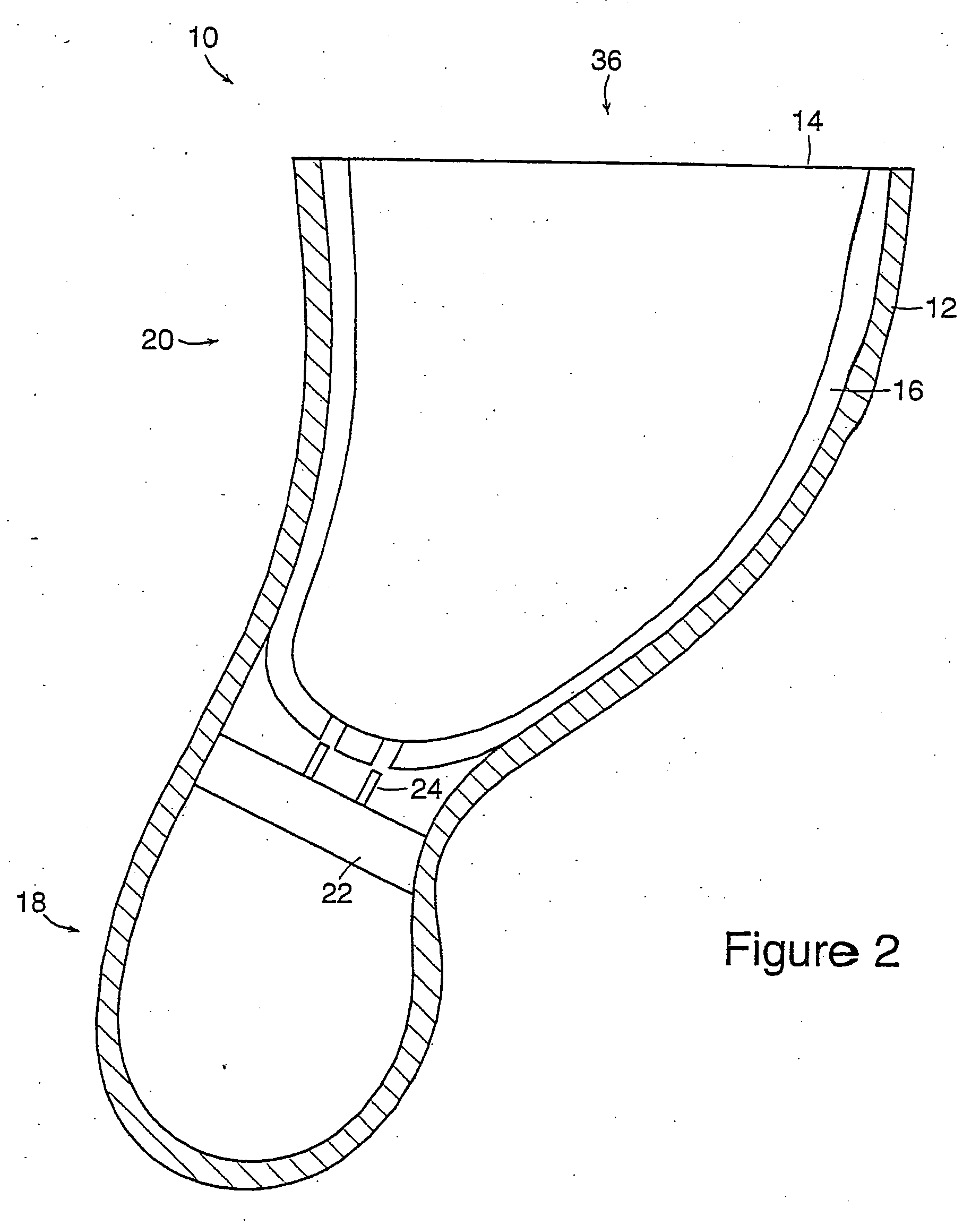

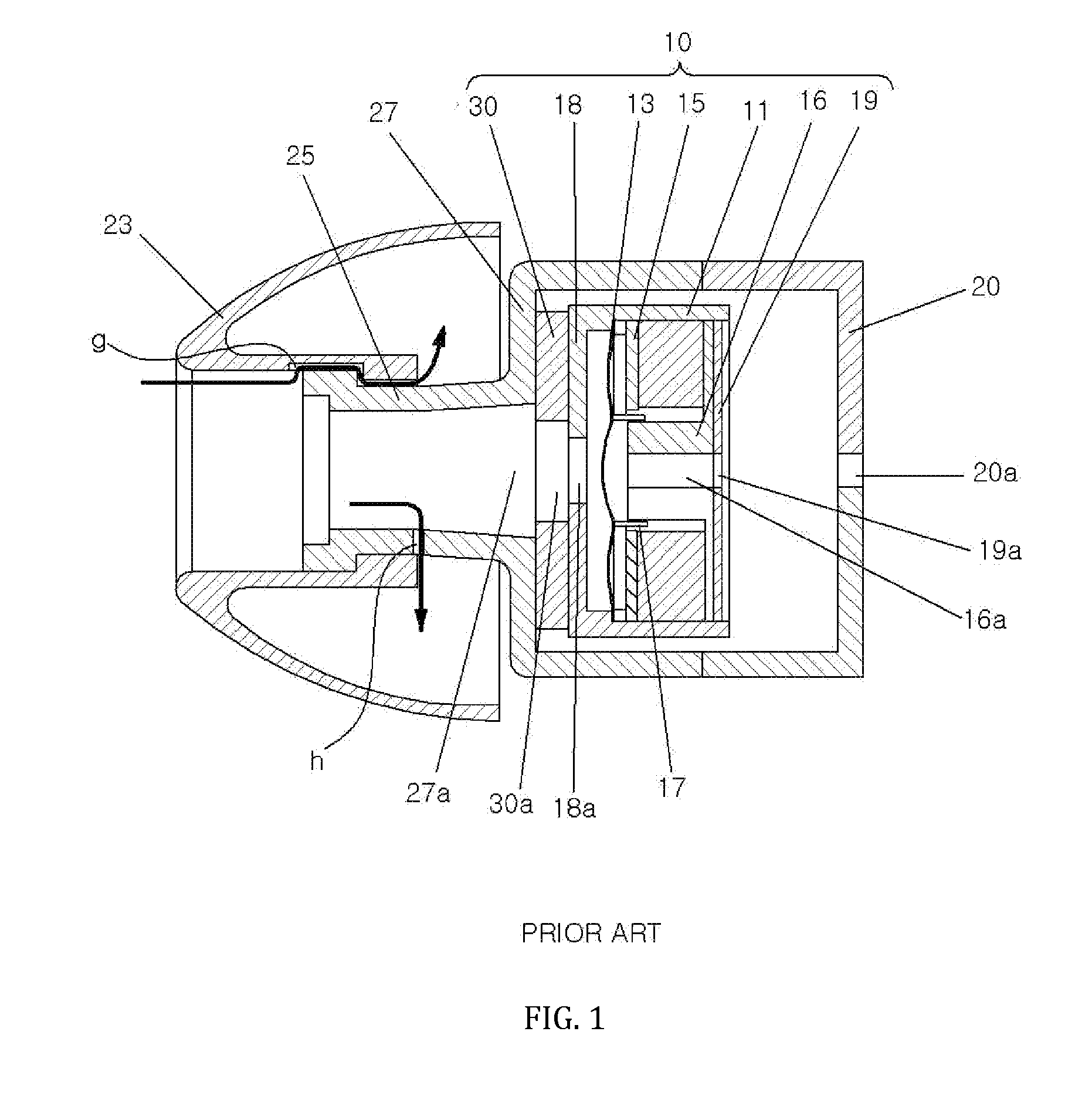

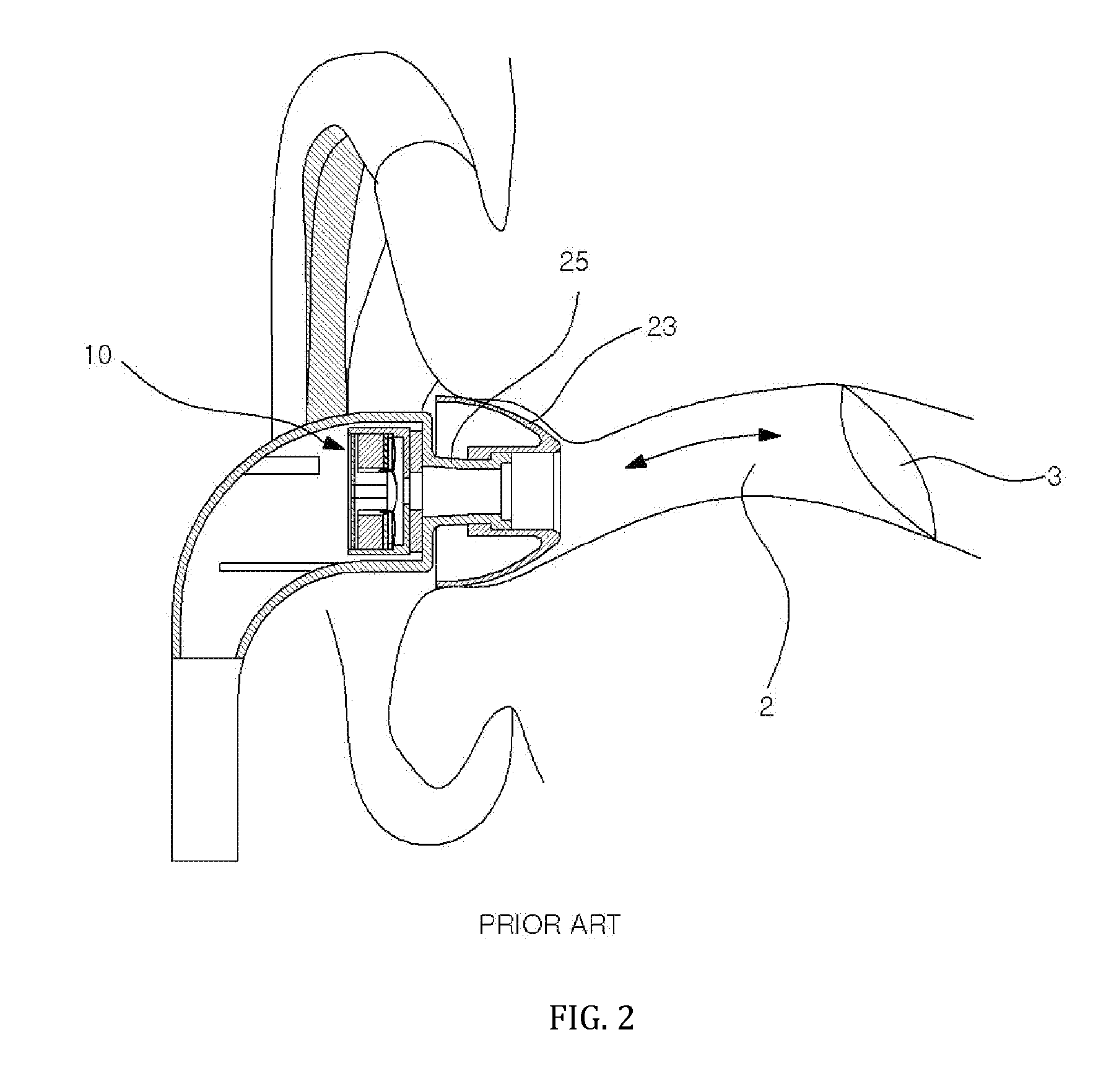

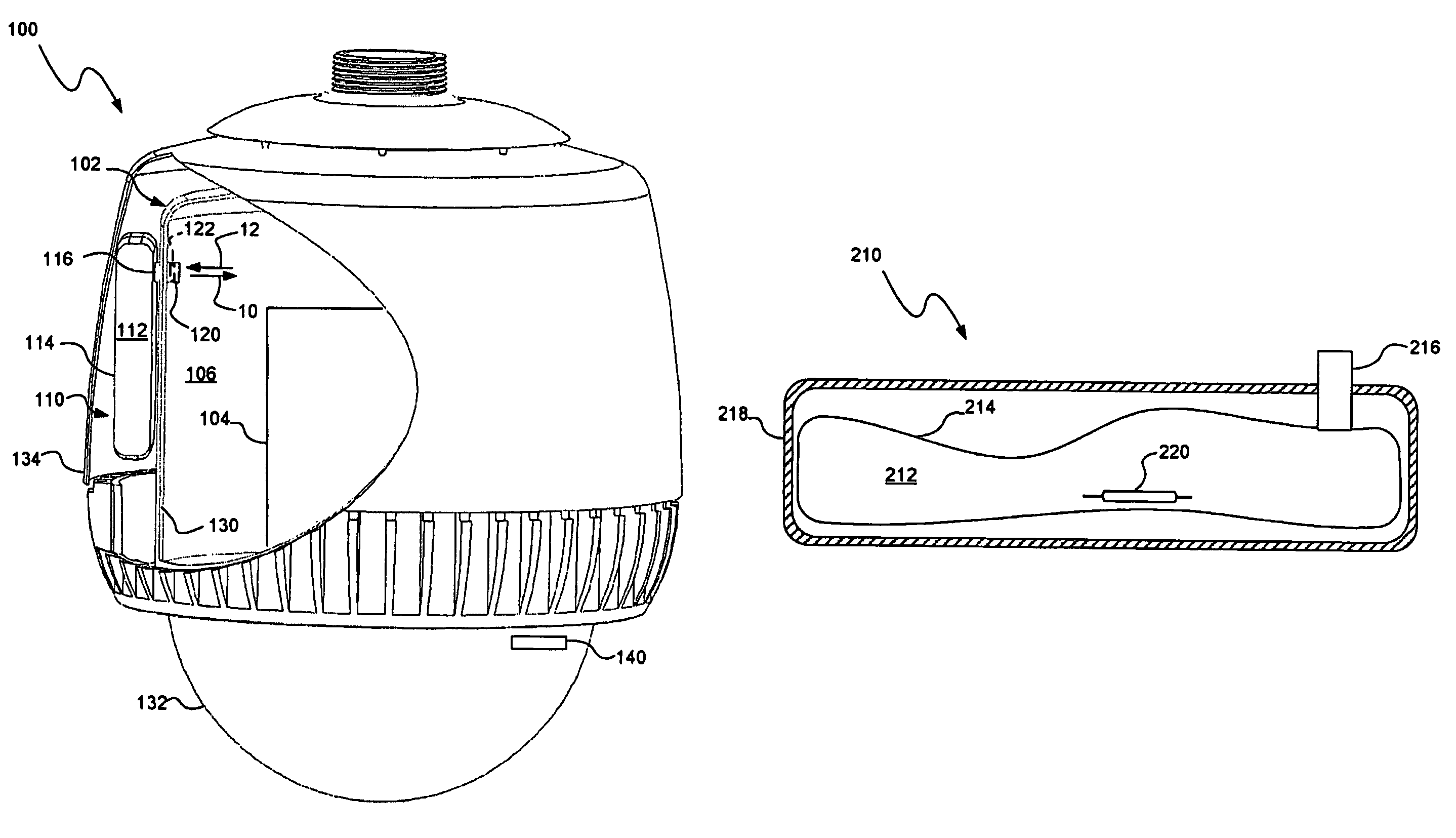

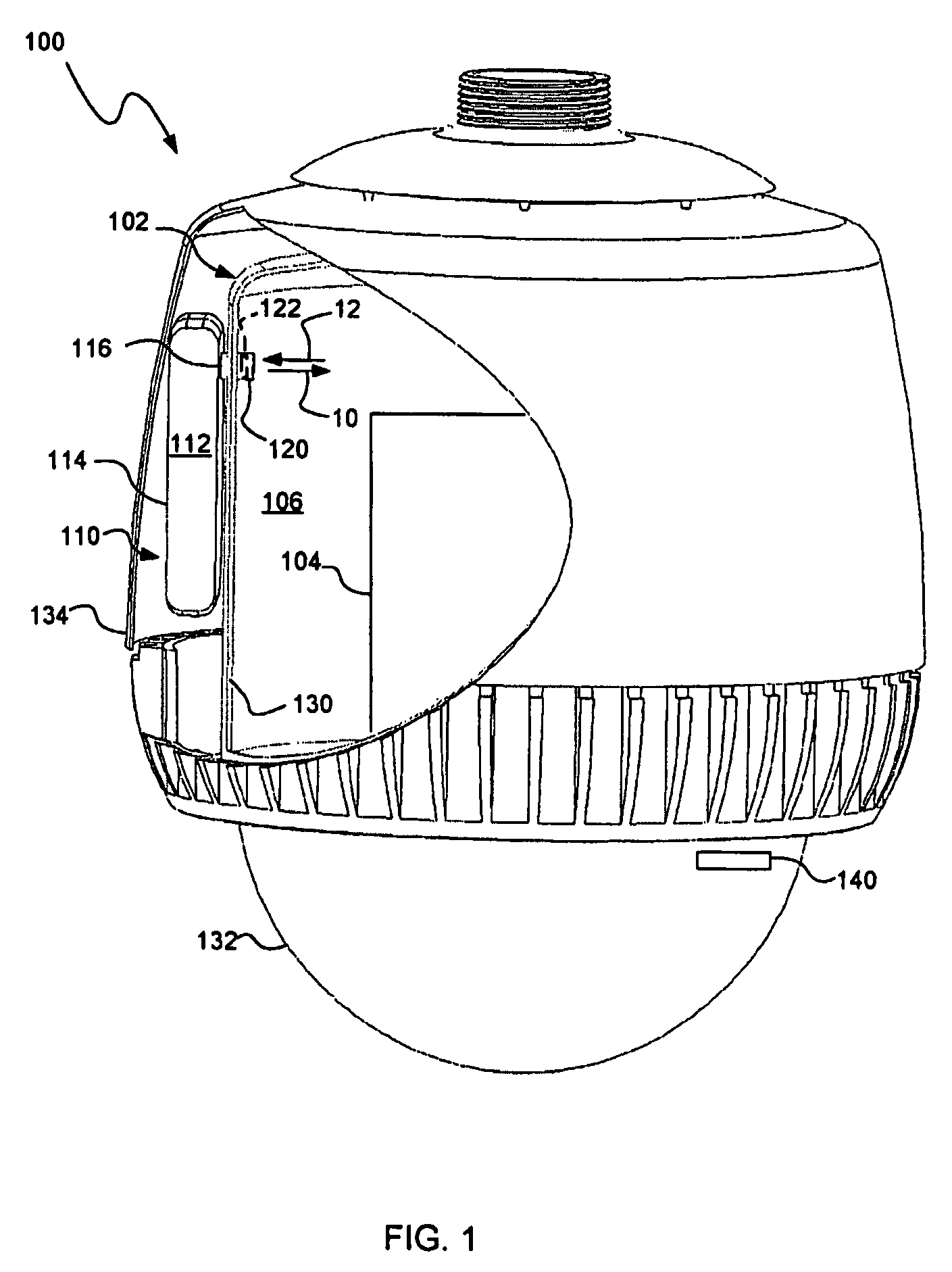

Disposable modular hearing aid

InactiveUS20070071265A1High degree of comfortImprove performanceCompletely in canal hearing aidsHearing aid ventsEngineeringHearing aid

A hearing aid includes a first half shell and a second shell attached to the first shell. A microphone, battery, electronics, a receiver and a flexible tip are mounted within a housing formed by the first half shell and the second half shell. A mechanical securing mechanism, located on the first half shell and the second half shell, attaches the first half shell to the second half shell. A flexible tip for a hearing aid includes a tip portion, a sound port attached to the tip portion and a vent formed in the flexible tip. The vent provides static pressure equilibrium between an ear canal and an ambient pressure.

Owner:LEEDOM MARVIN A +8

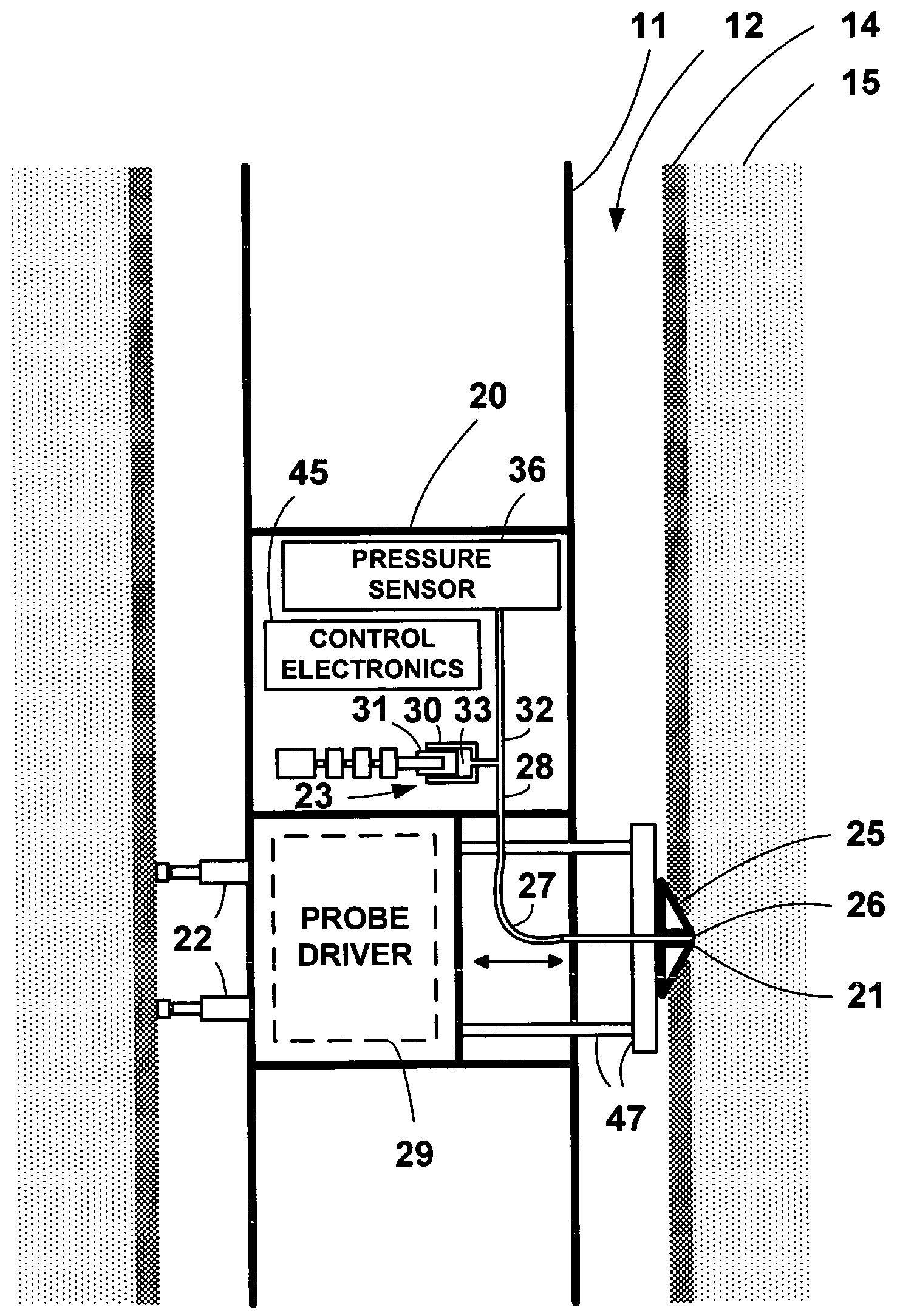

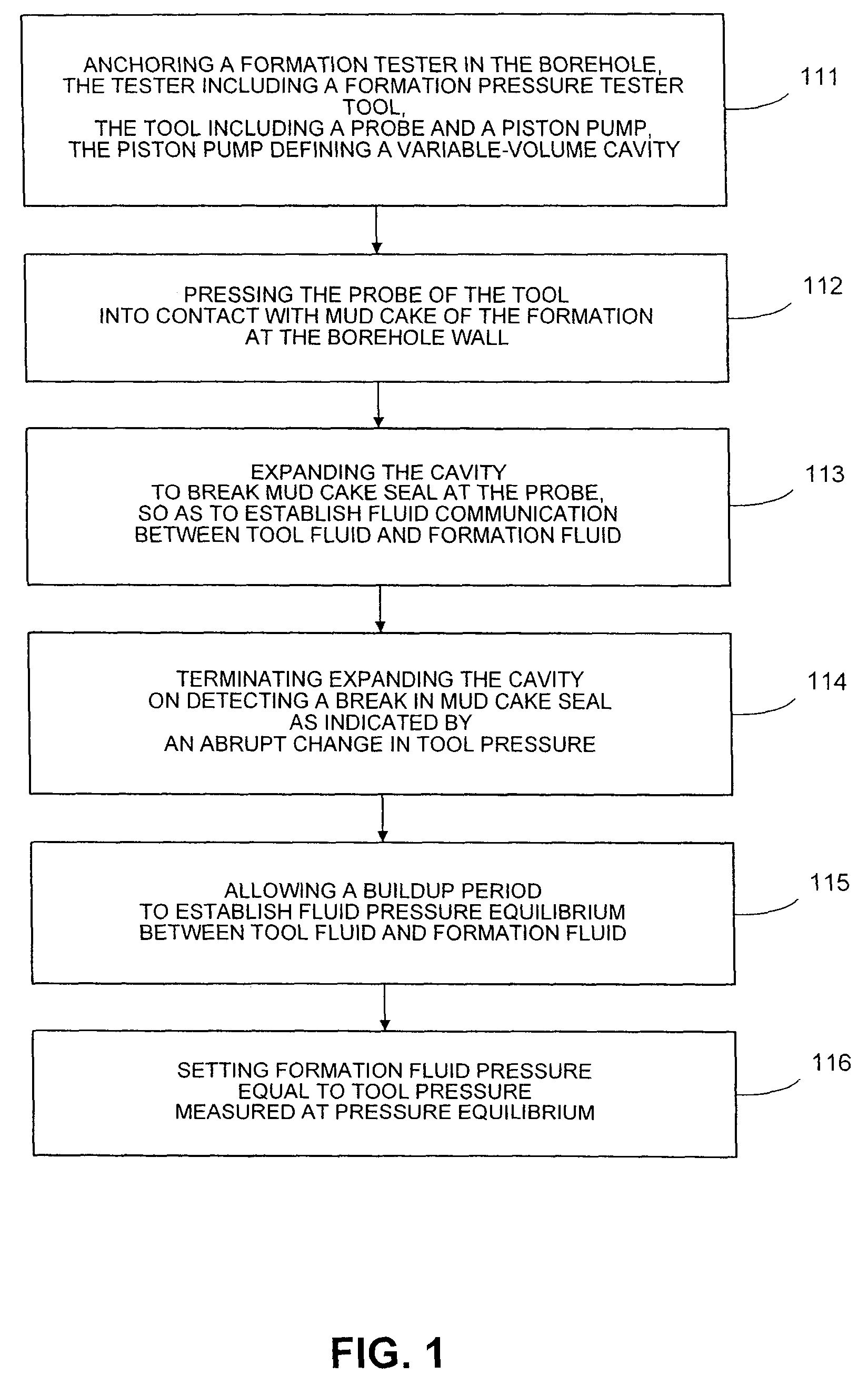

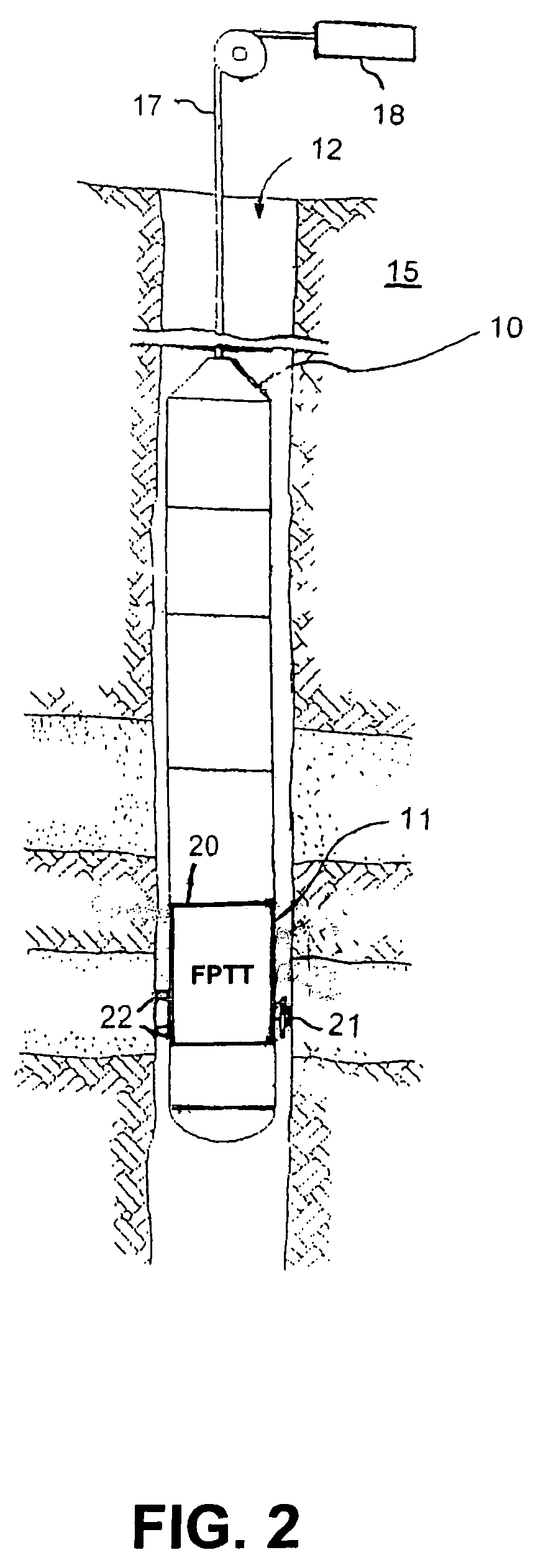

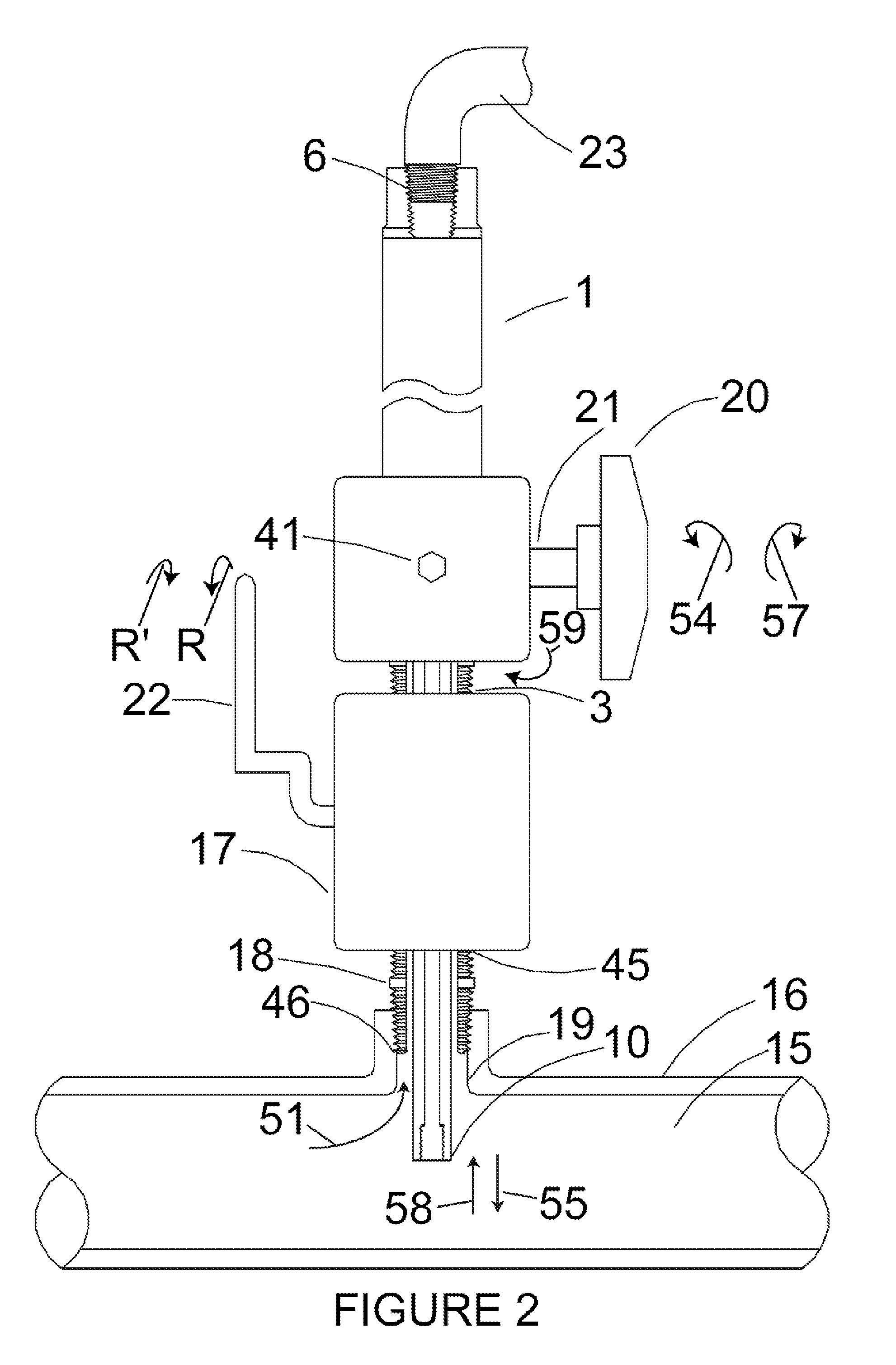

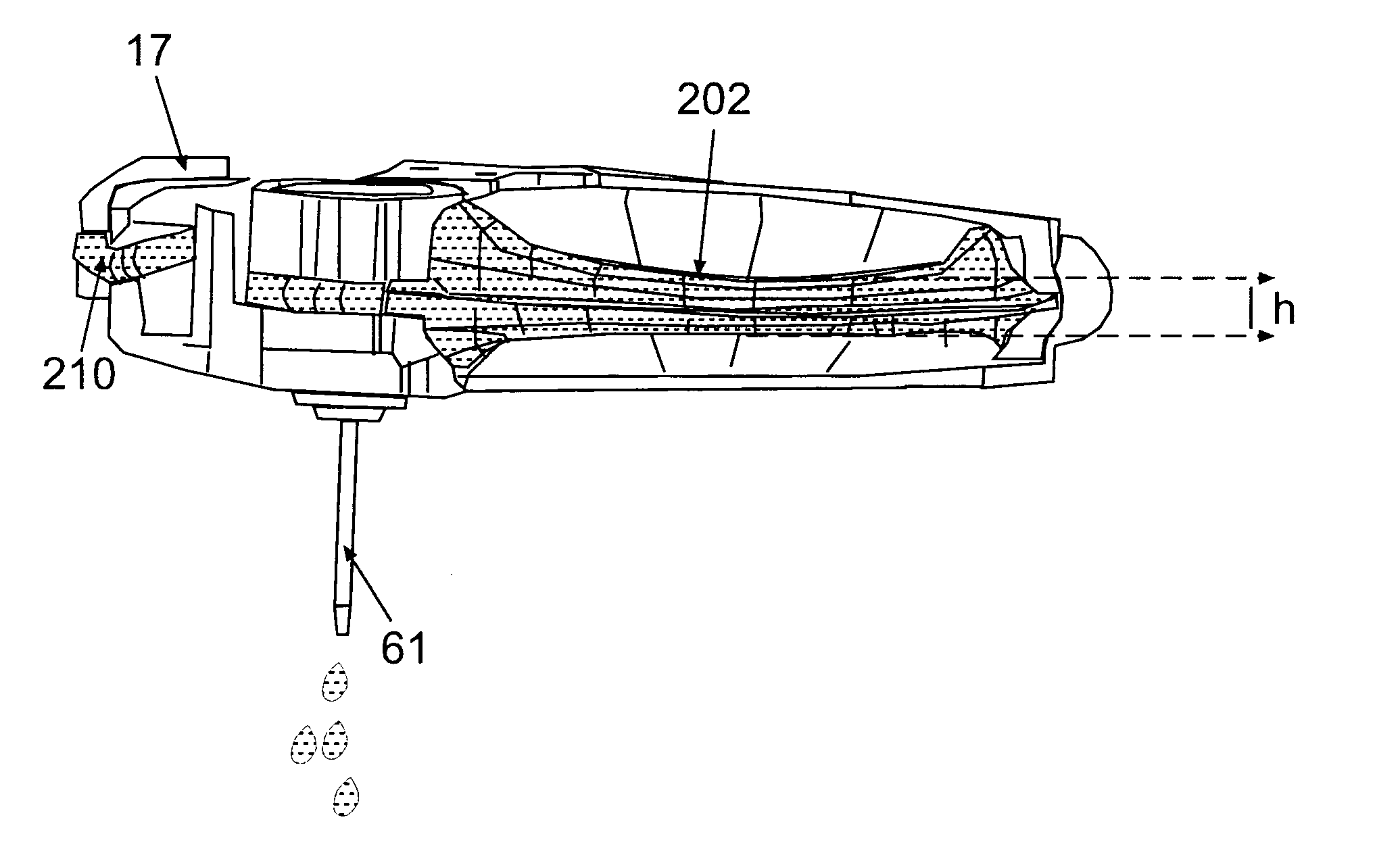

Determining the pressure of formation fluid in earth formations surrounding a borehole

A method for determining formation fluid pressure in earth formation surrounding a borehole wall uses a downhole probe coupled to a variable-volume cavity. The probe is driven into contact with formation at the borehole wall. The method includes expanding the volume of the cavity during a first period of time to establish fluid communication between tool fluid and formation fluid, by withdrawing a minimal amount of fluid from the formation. During a second period of time the tool pressure is allowed to equilibrate to formation pressure. When pressure equilibrium is established, formation fluid pressure is set equal to tool pressure. A preferred embodiment includes terminating expanding the volume of the cavity on detecting a break in the mud cake seal. An associated formation pressure tester tool includes an elongated body; a probe defining a formation fluid inflow aperture, an electromechanical assembly defining a variable-volume cavity, a pretest flow line coupling the aperture to the cavity, a pressure sensor coupled to the cavity; and downhole electronic means for controlling the expansion of the volume of the cavity.

Owner:SCHLUMBERGER TECH CORP

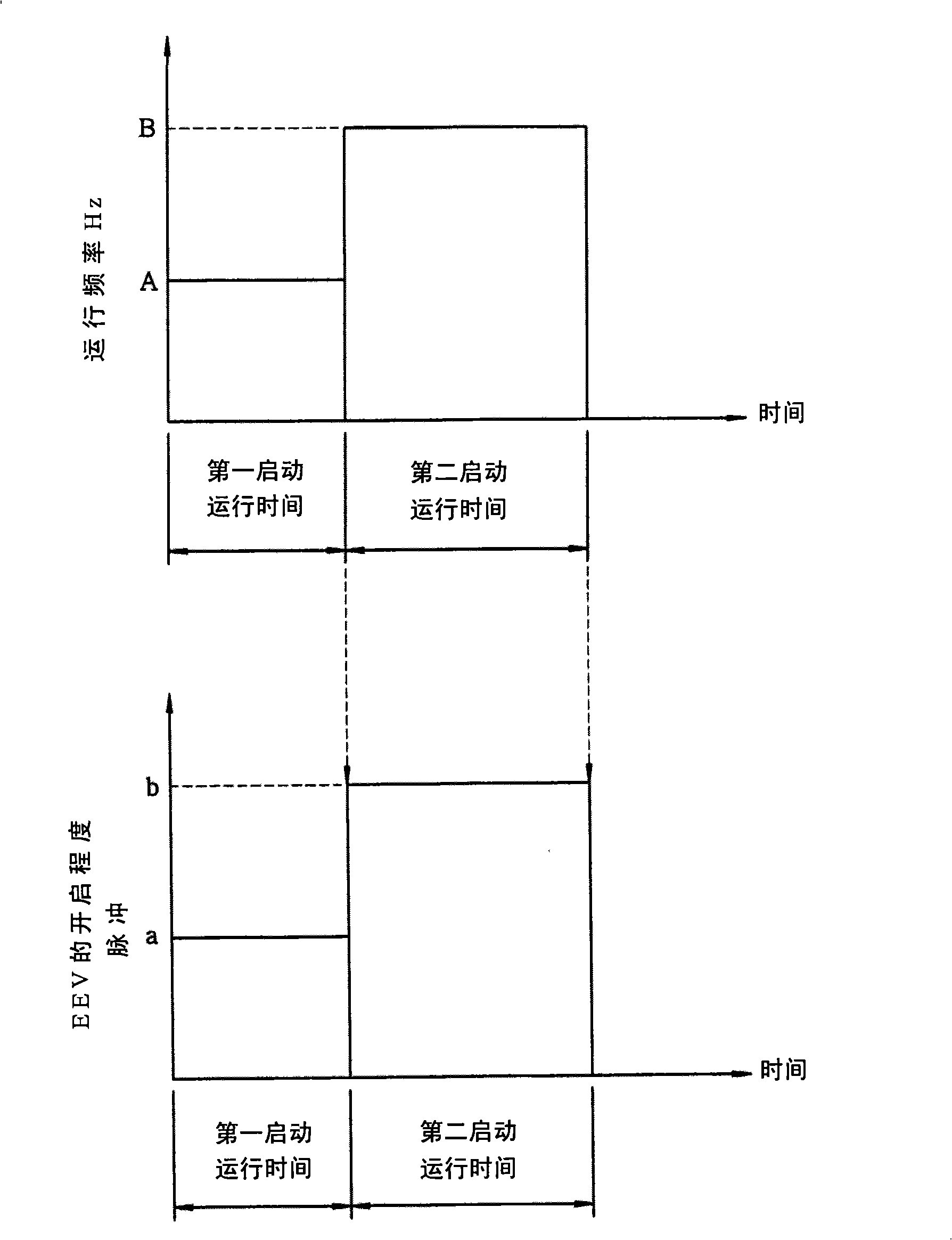

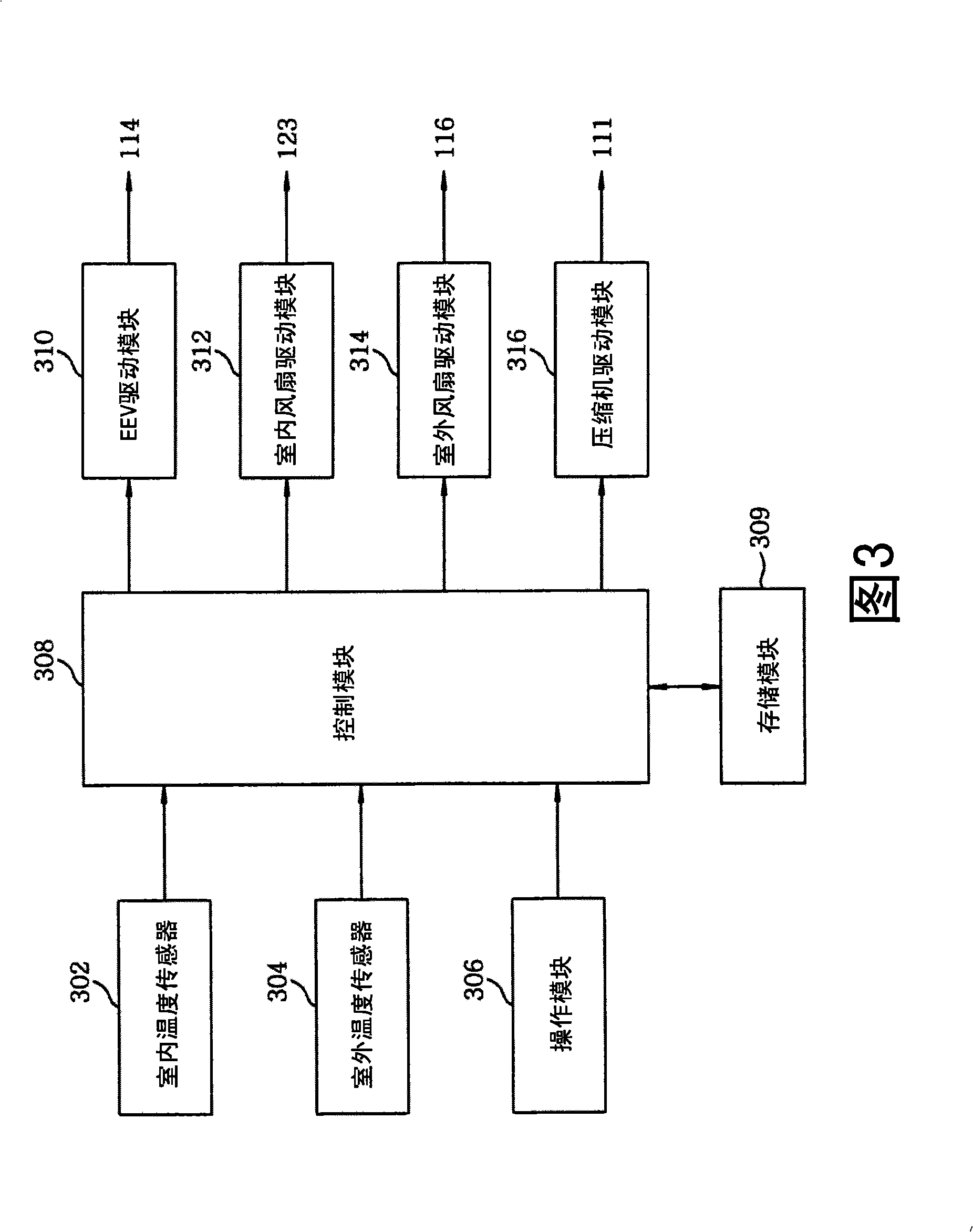

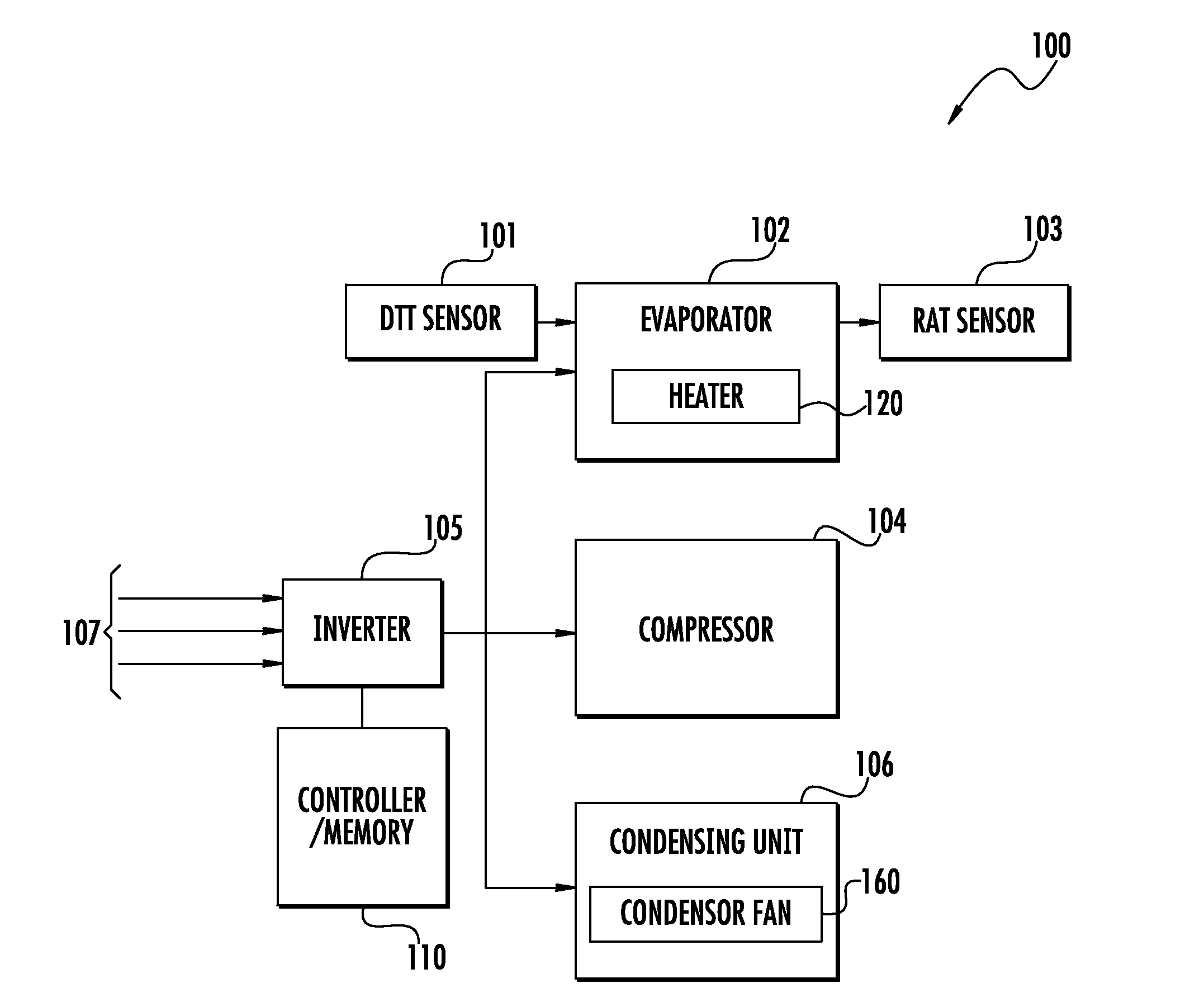

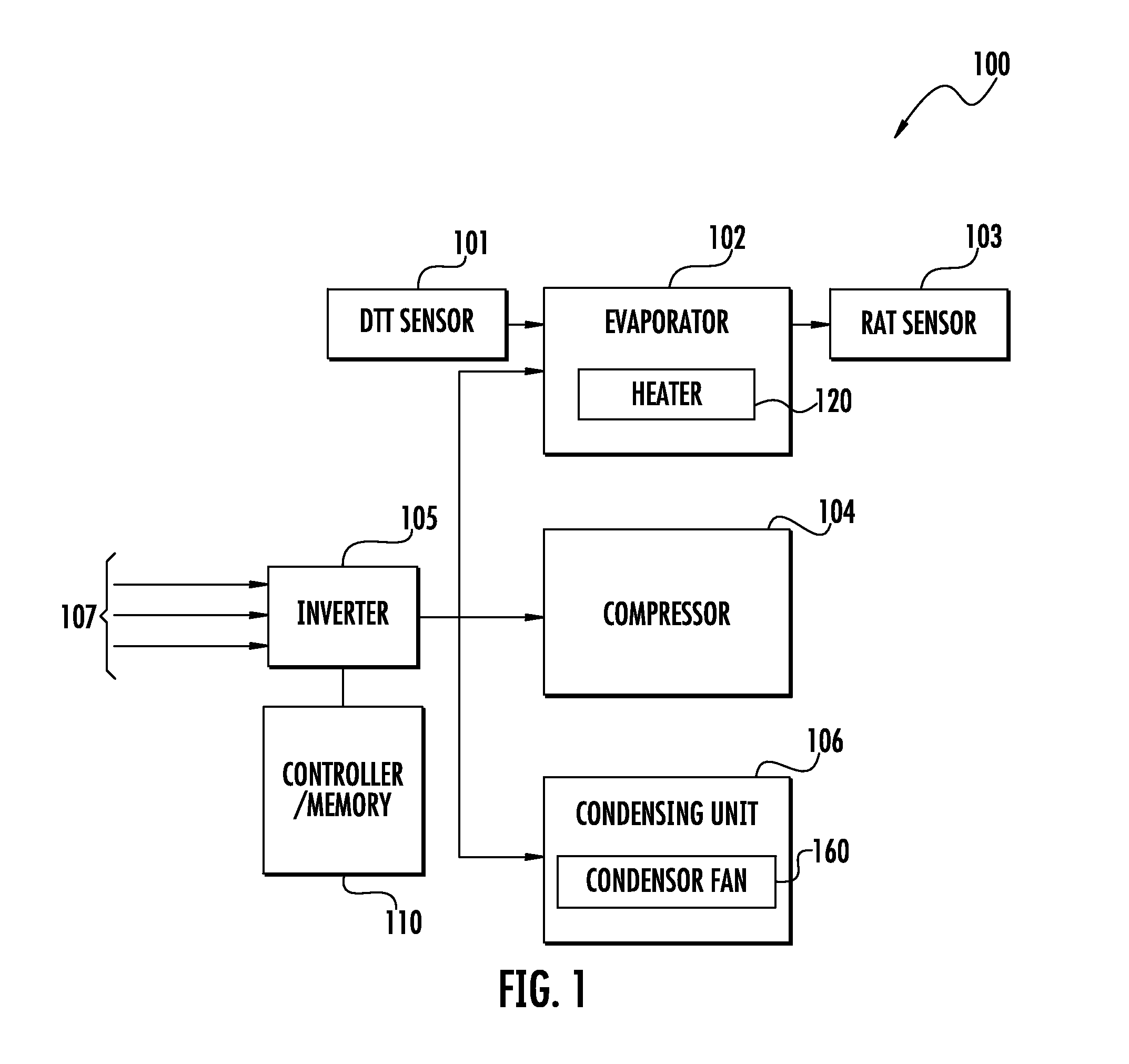

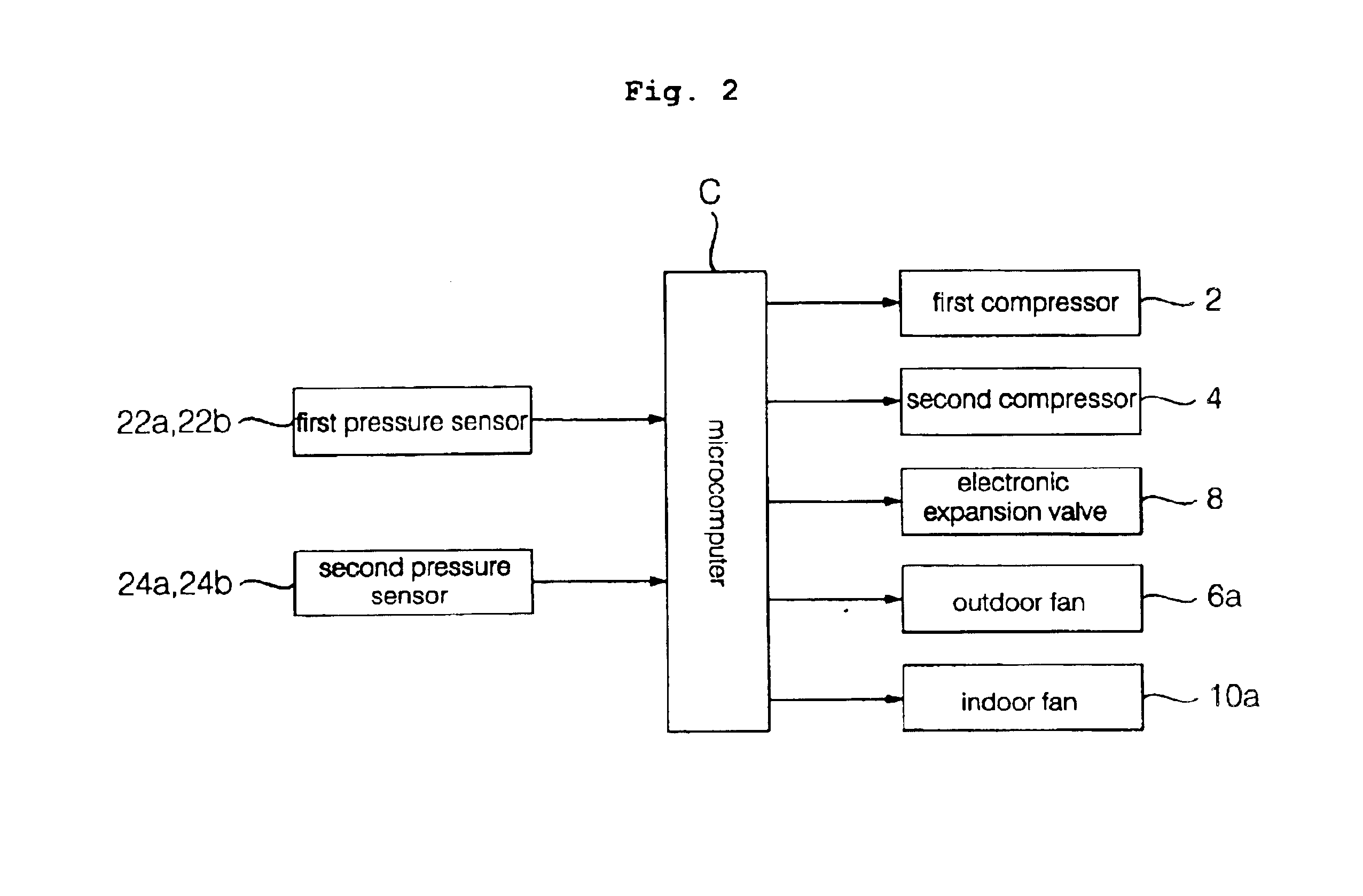

Method for controlling operating of air conditioner

InactiveCN101495815AIncrease operating frequencyImprove operating conditionsMechanical apparatusSpace heating and ventilation safety systemsEngineeringOperating frequency

A method for controlling a start-up operation of an air conditioner having a compressor and an indoor and an outdoor fan includes the steps of: (a) calculating indoor cooling / heating load; (b) calculating a reference operating frequency of the compressor; (c) driving the indoor and the outdoor fan during a first time period to thereby adjust pressure equilibrium between an indoor and an outdoor pressure; (d) driving the compressor during a preset time period while increasing an operating frequency of the compressor; and (e) setting the operating frequency of the compressor to the reference operating frequency and driving the compressor. The operating frequency of the compressor is increased in a stepwise manner during the preset time period and kept to be lower than the reference operation frequency throughout the preset time period.

Owner:DAEWOO ELECTRONICS CO LTD

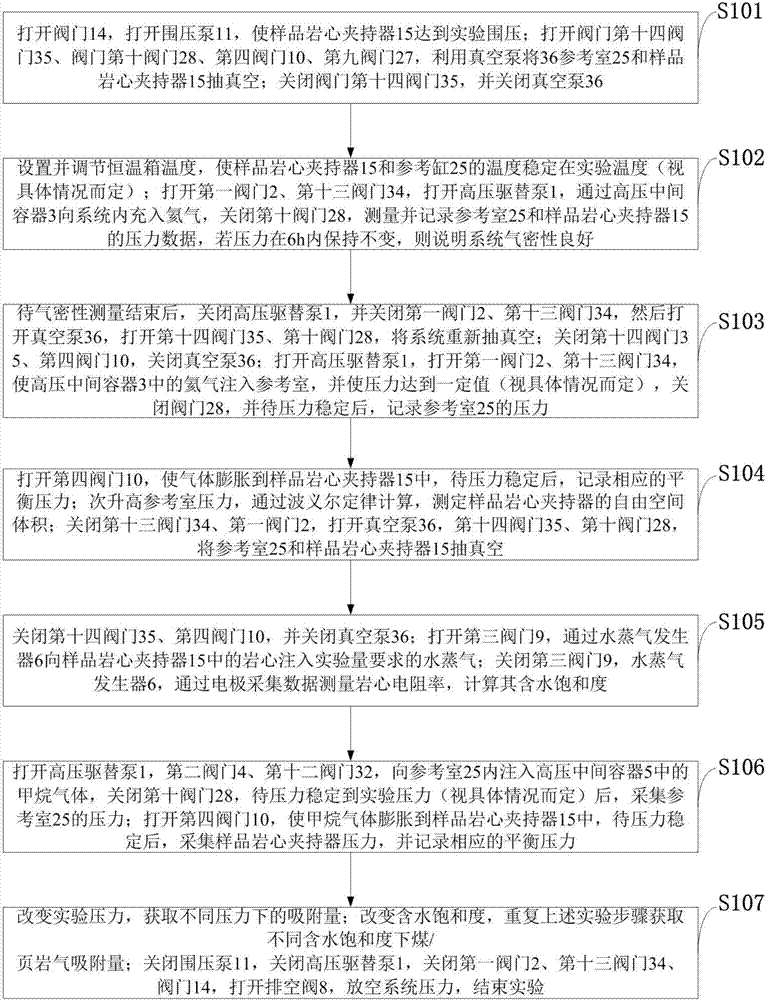

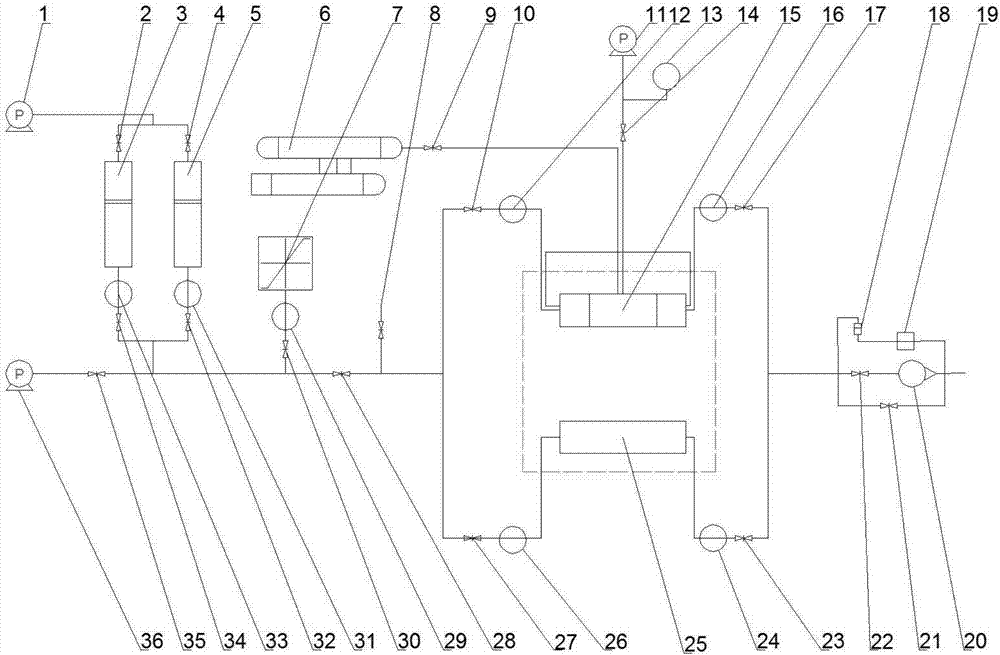

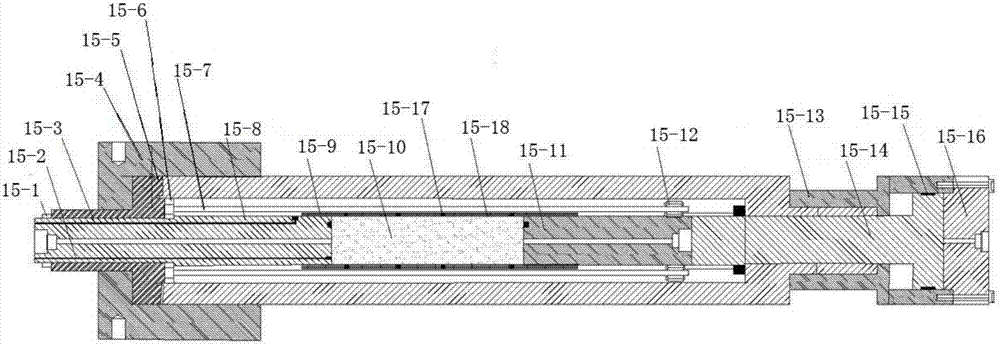

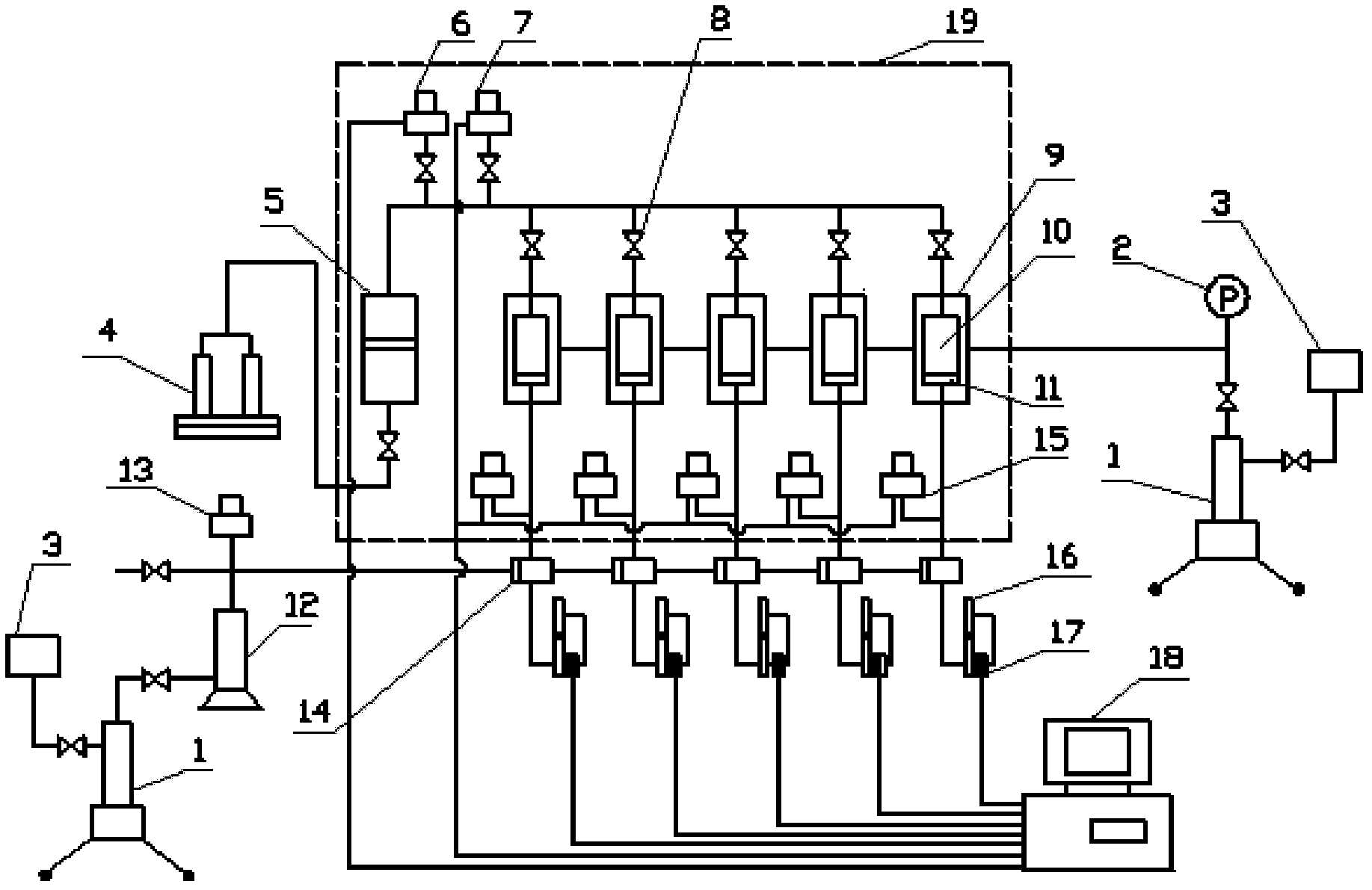

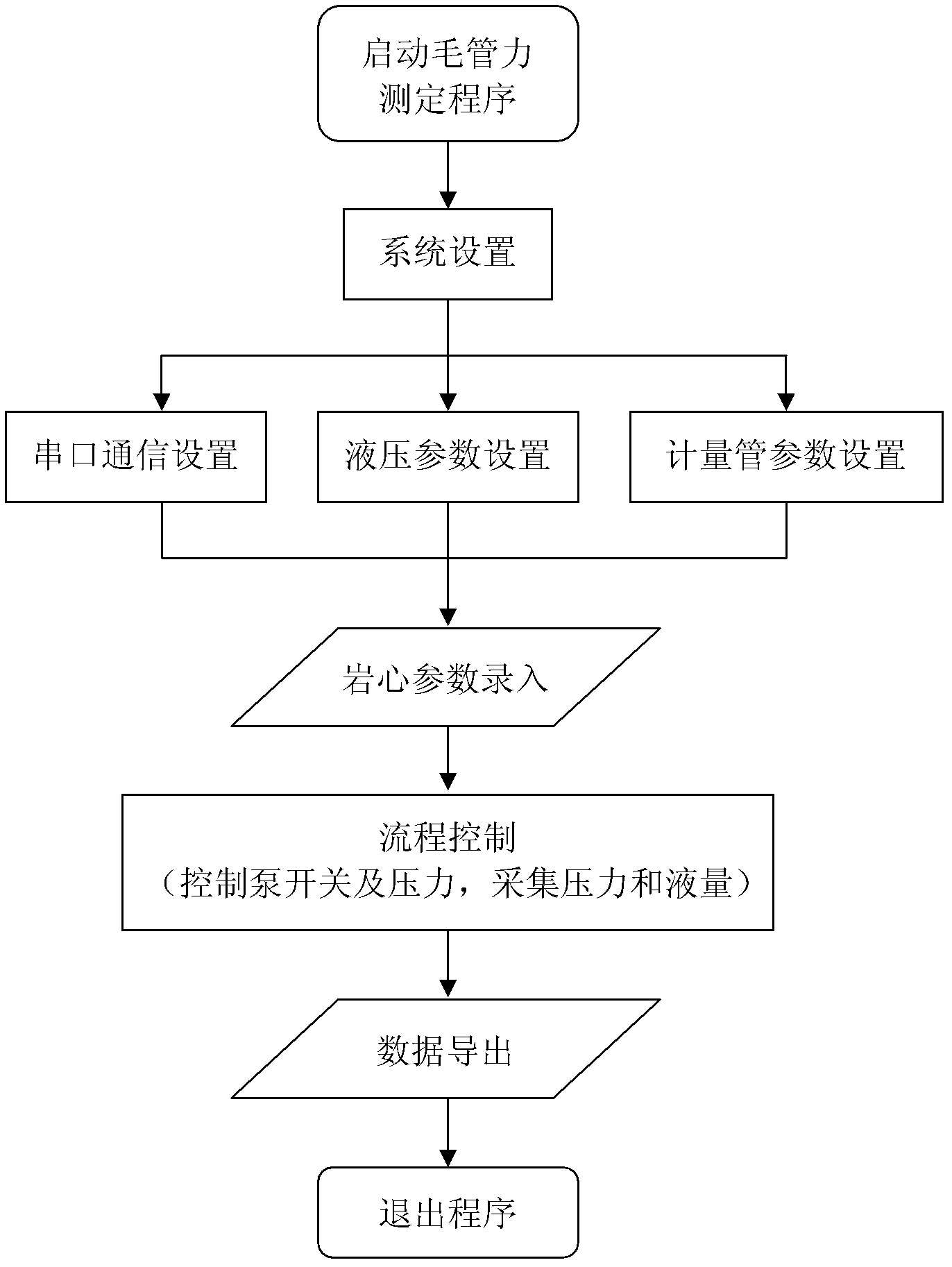

Method for evaluating shale gas adsorption through coal/shale ultrahigh pressure gas absorption and seepage experiment

The invention discloses a method for evaluating shale gas adsorption through a coal / shale ultrahigh pressure gas absorption and seepage experiment. The method comprises the steps that a core is selected and put in a sample cylinder, a confining pressure pump is started to make the sample cylinder reach an experimental confining pressure, and vacuumizing is performed; the temperatures of the sample cylinder and a reference cylinder are stabilized at experimental temperature; helium gas is injected into the reference cylinder, and the pressure of the reference cylinder is measured; after the reference cylinder and the sample cylinder are balanced in pressure, the pressure of the sample cylinder is measured; the pressure of the reference cylinder is increased sequentially, and free space volume measurement of the sample cylinder is completed; systematic vacuumizing is performed; water steam is injected into the sample cylinder; methane having set pressure is injected into the reference cylinder, and the pressure of the reference cylinder is acquired; a balancing valve is turned on, and the pressure of the sample cylinder is acquired; the pressure of the reference cylinder is increased sequentially, and the shale gas adsorption experiment is completed under certain water saturation. By adopting the method, the porosity, the permeability, the adsorbing capacity and gas-water seepage of the experimental core, electrical resistivity change of the core in the experimental process and the influence of different water saturations on absorption and desorption amounts can be respectively measured.

Owner:SOUTHWEST PETROLEUM UNIV

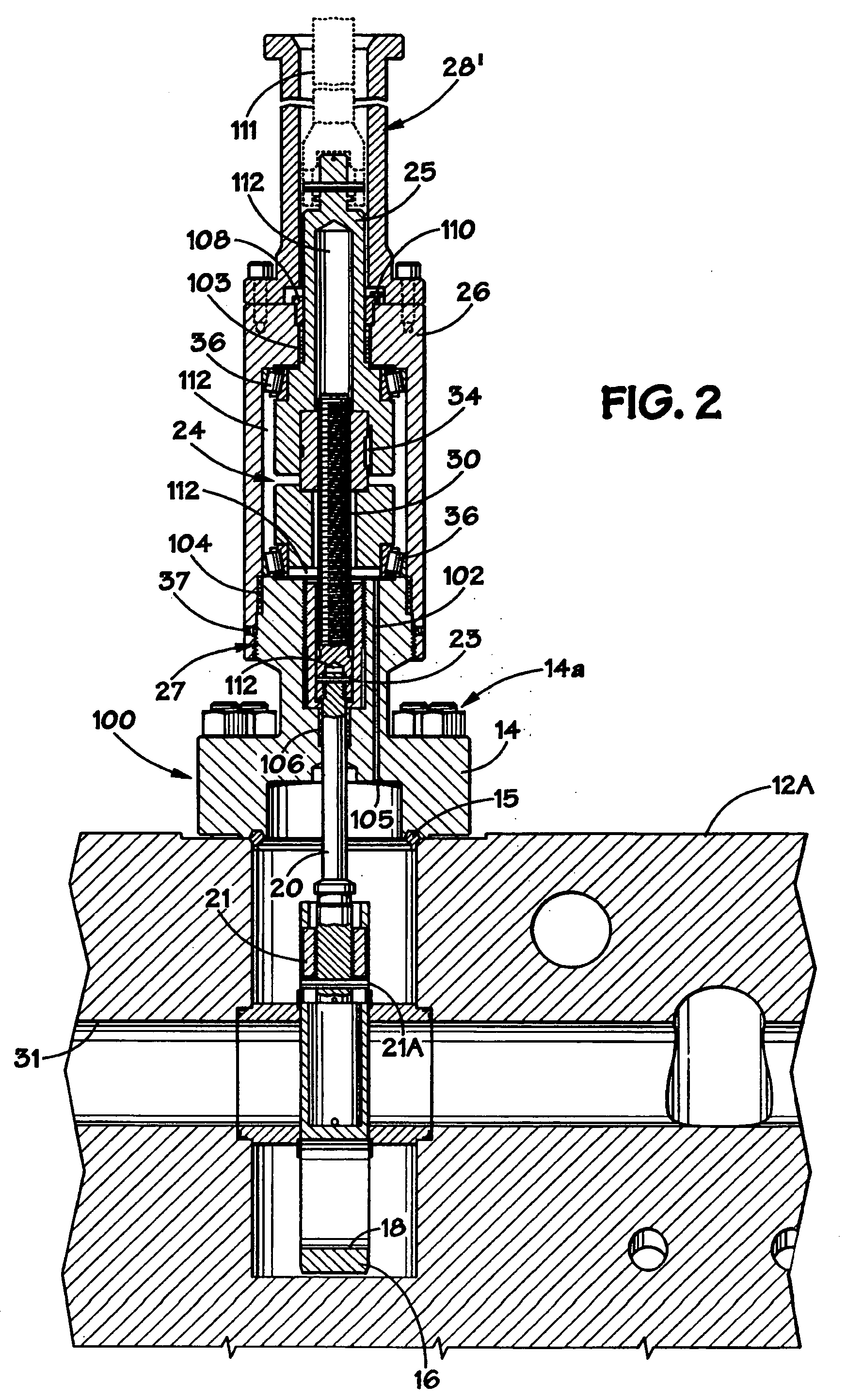

Test apparatus for direct measurement of expansion and shrinkage of oil well cements

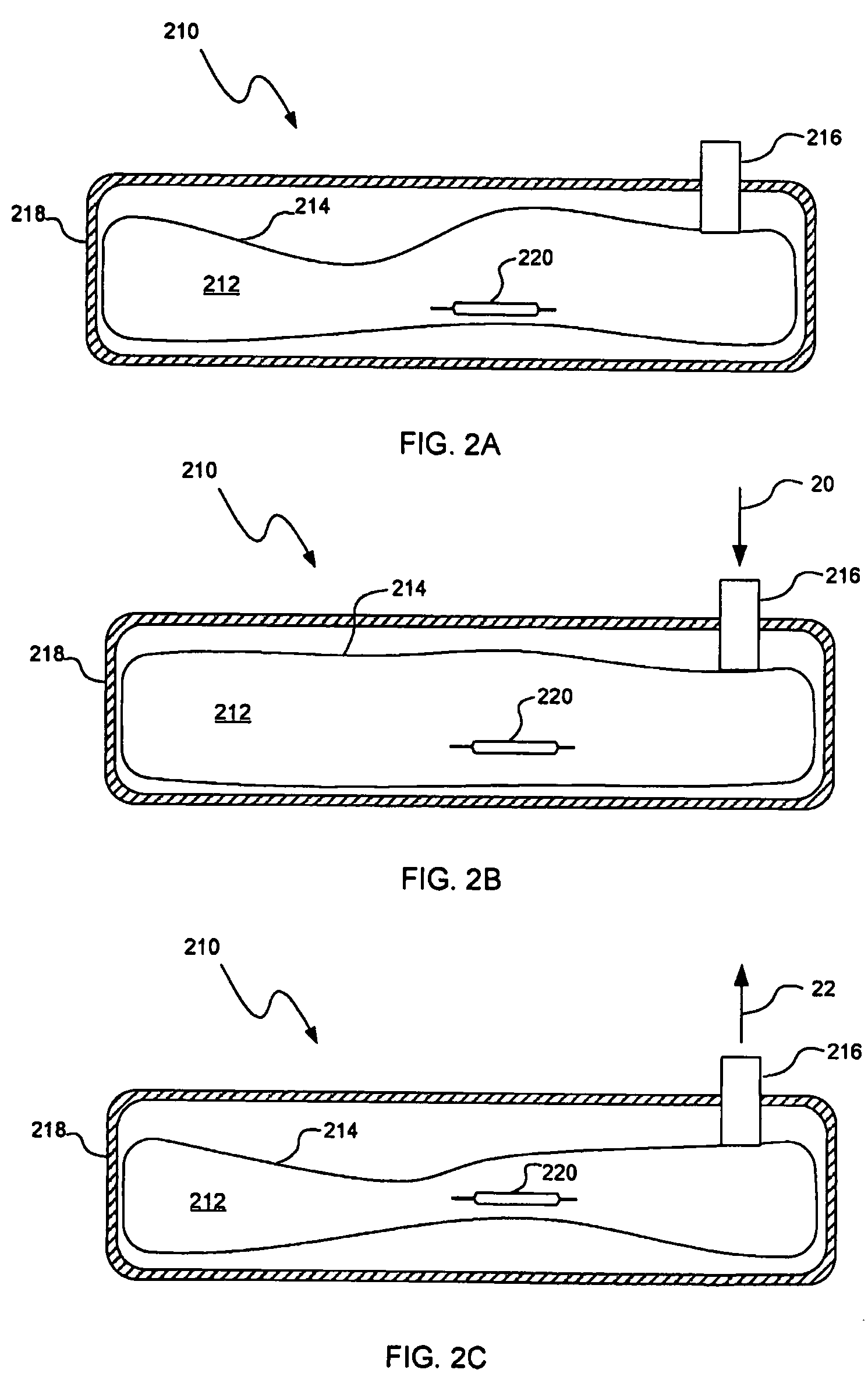

InactiveUS7240545B1Weather/light/corrosion resistanceMaterial strength using tensile/compressive forcesTest sampleEngineering

A test apparatus for the measurement of expansion and / or shrinkage of a cement test sample during curing under pressure and temperature conditions that simulate downhole oil well conditions isolates the test sample from a first fixed volume of incompressible pressurized liquid using a flexible barrier that forms a wall of a first chamber in a pressure vessel assembly. The first chamber is sealed by a movable piston. A second pressurizing medium is contained in a second chamber on the opposite side of the piston, and is in fluid communication with a pump, whereby the piston is pressure-balanced between the first and the second medium. The piston moves in a bore of the vessel assembly in response to changes in the volume of the test sample during curing and the amount of linear movement of the piston is detected by a sensor system that measures, correlates and transmits any change in the position of the piston as a change in the sample volume for display and recording.

Owner:SAUDI ARABIAN OIL CO

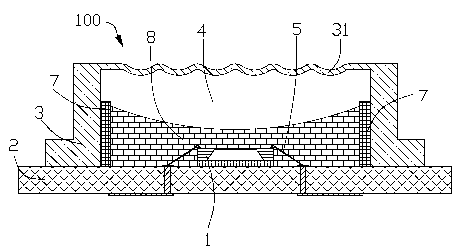

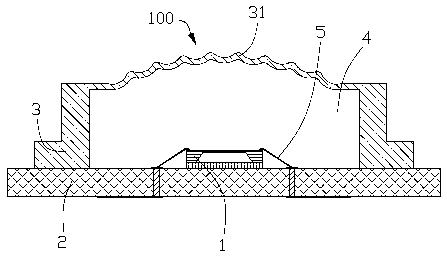

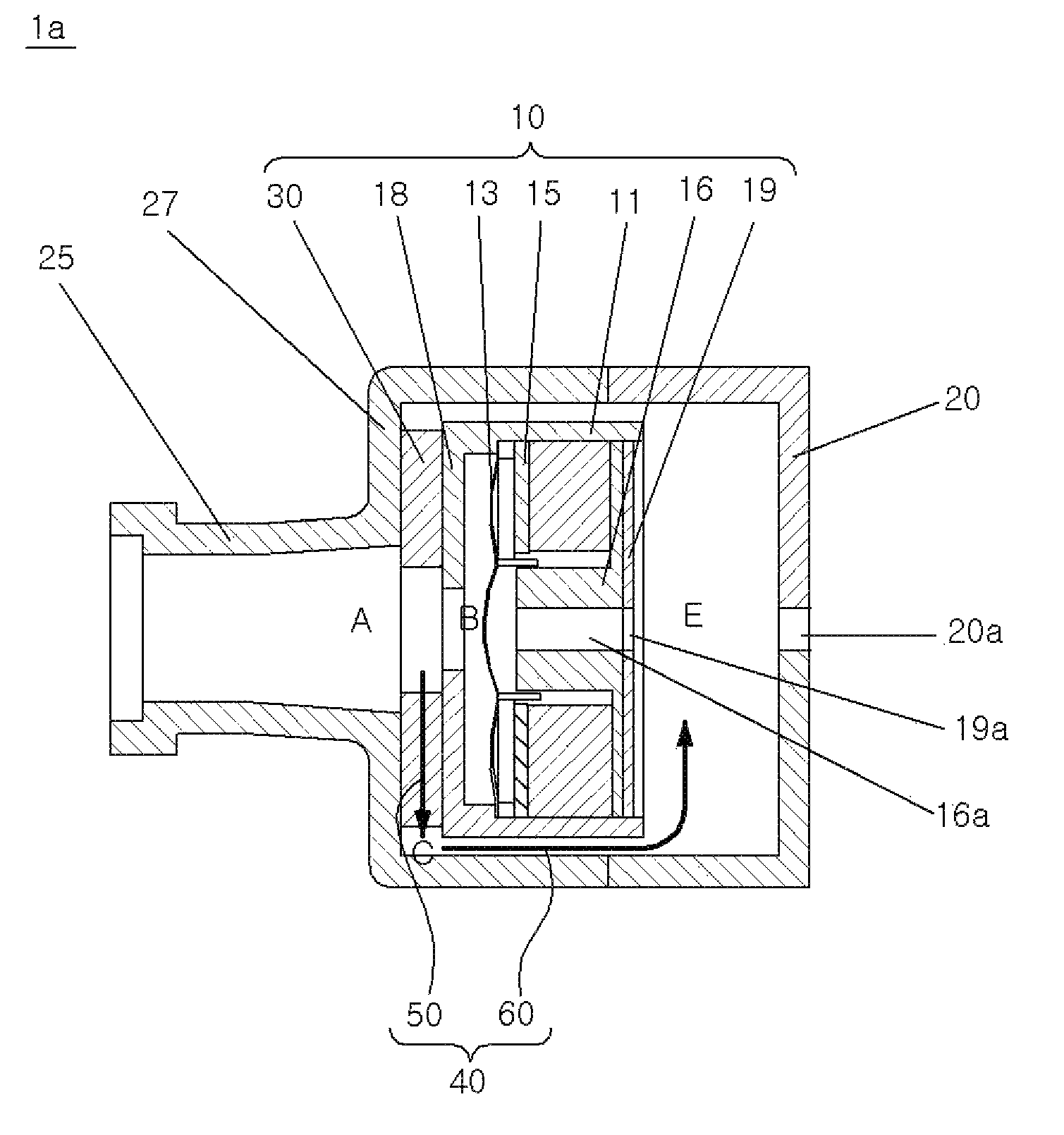

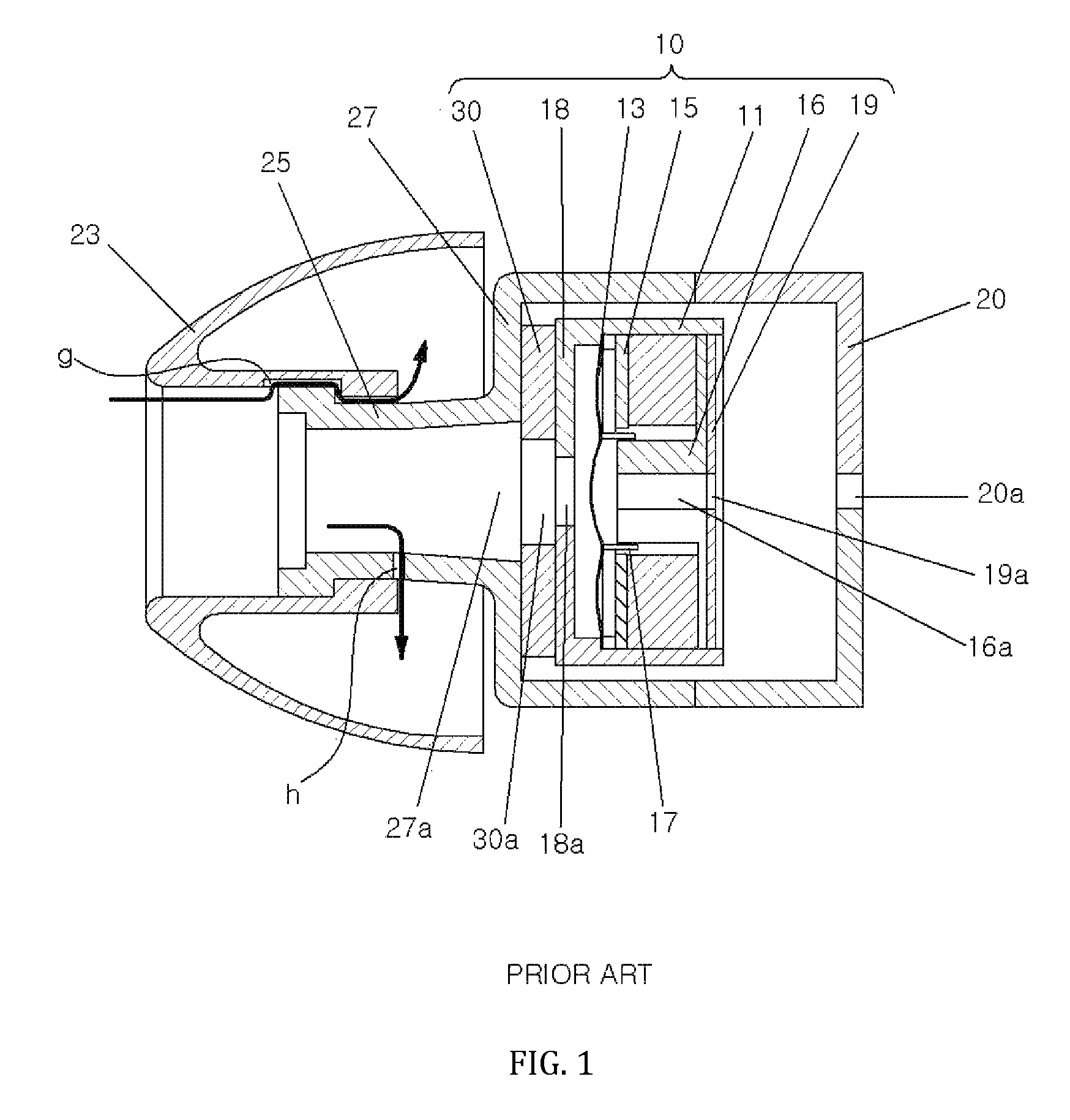

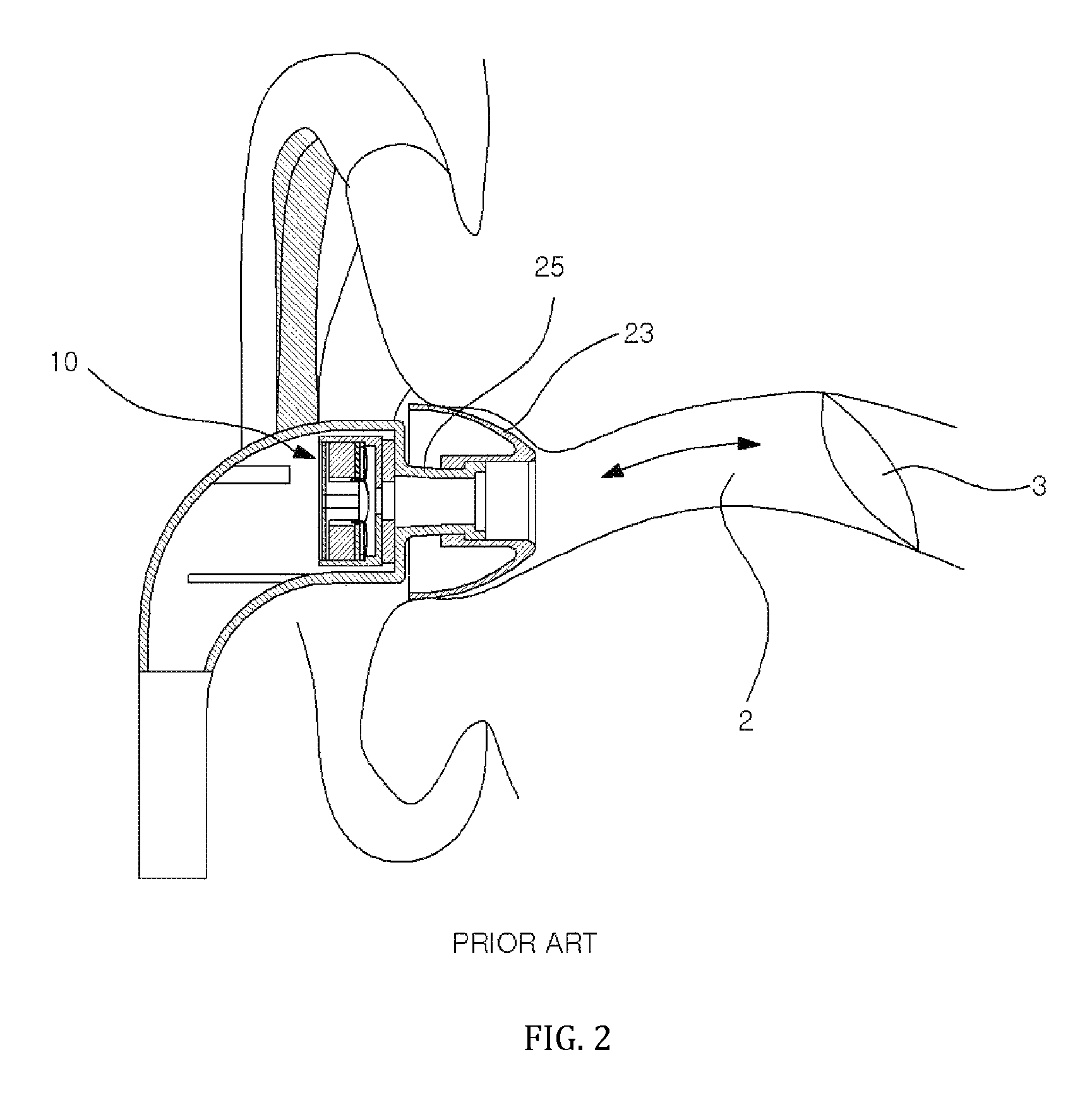

Canal Type Earphone with Pressure Equilibrium Means

ActiveUS20140348372A1Avoid damageMinimize changesHearing aid ventsIntra aural earpiecesEngineeringHeadphones

Disclosed herein is a canal type earphone with a pressure equilibrium means, capable of eliminating a pressure difference between a user's external auditory meatus and an outside during wearing of the canal type earphone. A pressure equilibrium means includes a side air passage through which air within a tube or air within a speaker unit in the canal type earphone is discharged to a side surface of a gasket or a side surface of the speaker unit, and a rear air passage through which air in the side surface of the speaker unit is discharged to the rear of the speaker unit.

Owner:BUJEON

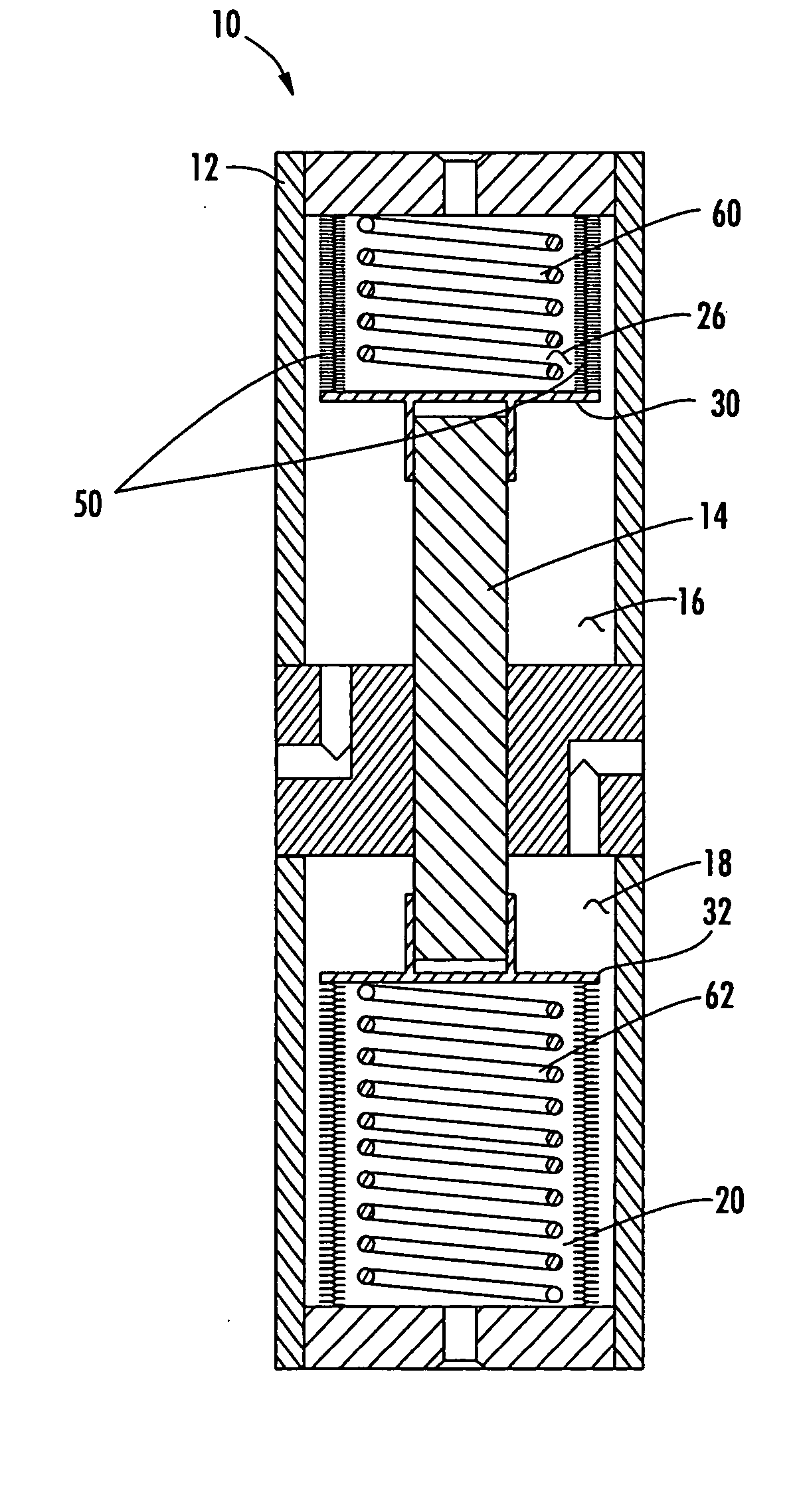

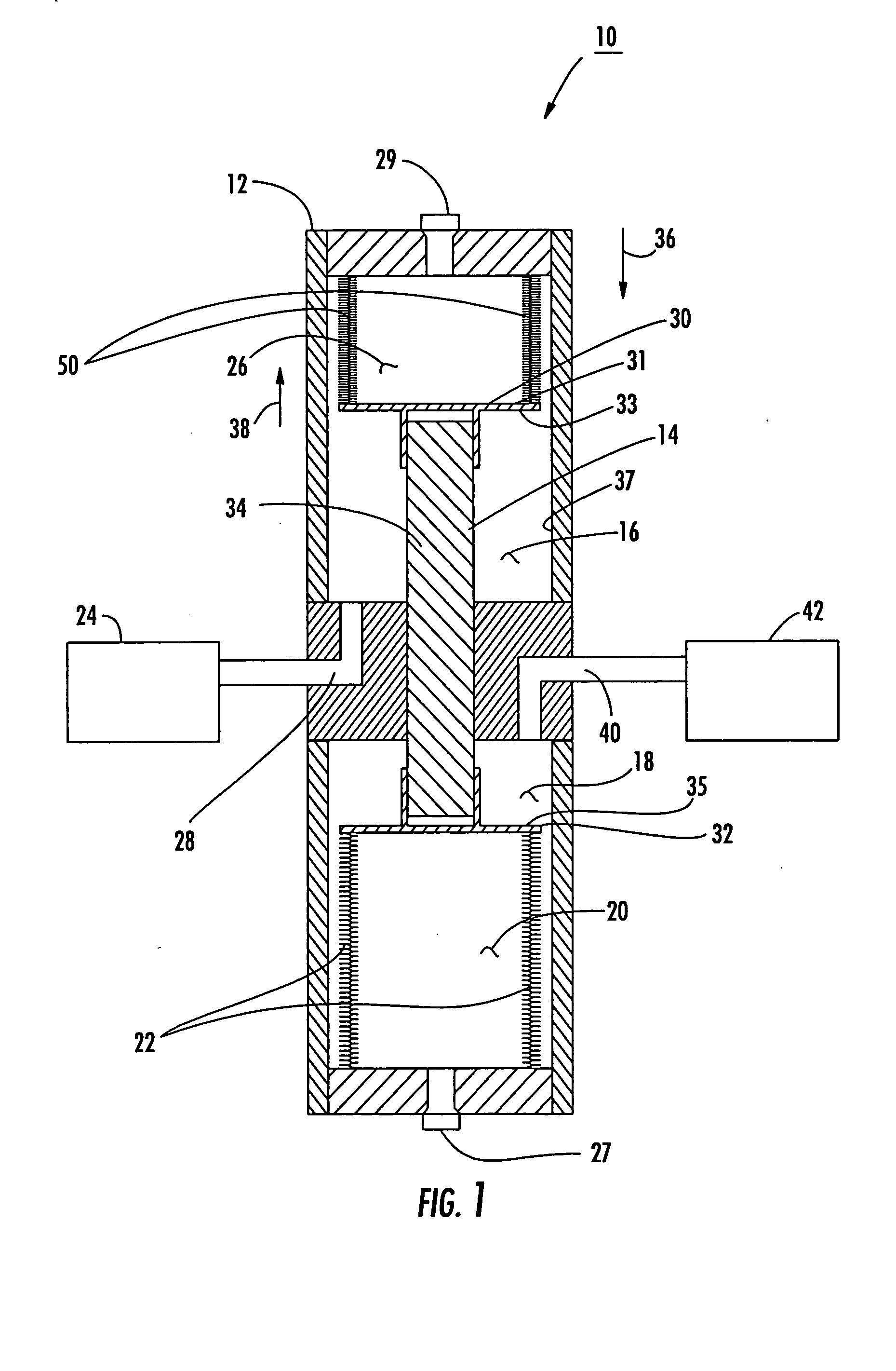

Hermetically sealed pressure balanced accumulator

InactiveUS20050155658A1Improve sealingPrevent leakagePipe elementsDifferential pressureHermetic seal

A hermetically sealed pressure-balanced accumulator includes a housing and a moveable divider mechanism for separating the housing into at least an accumulator chamber at a pre-selected accumulator pressure. A first balancing chamber is responsive to changes in ambient pressure for adjusting said pre-selected accumulator pressure with respect to ambient pressure. A second balancing chamber is responsive to the first balancing chamber, and the first and second balancing chambers maintain a predetermined pressure differential between the pre-selected accumulator pressure and ambient pressure. The hermetically sealed pressure-balanced accumulator further includes a hermetic sealing device for sealing the first balancing chamber from at least one of the accumulator chamber and the second balancing chamber.

Owner:EATON CORP

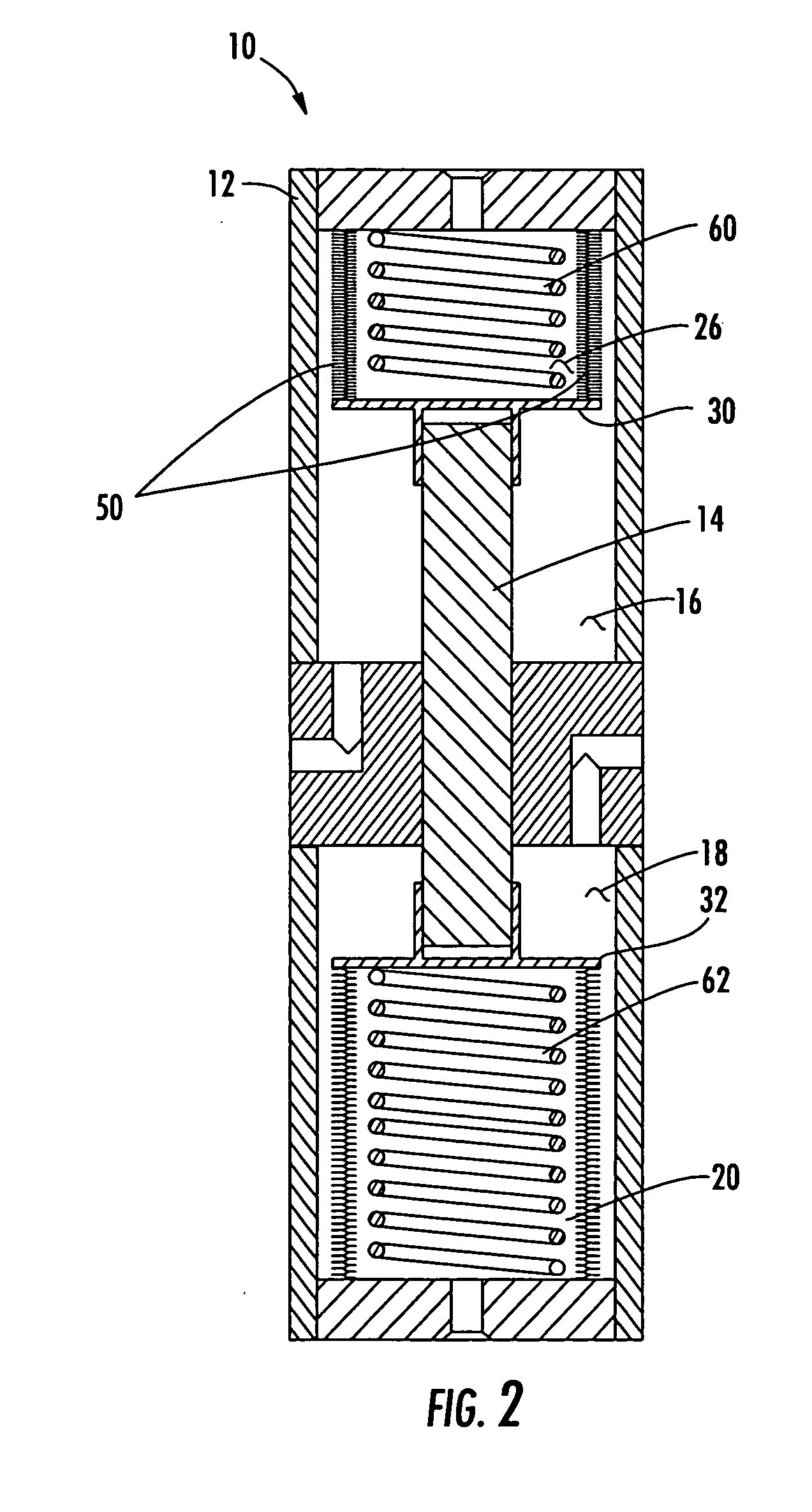

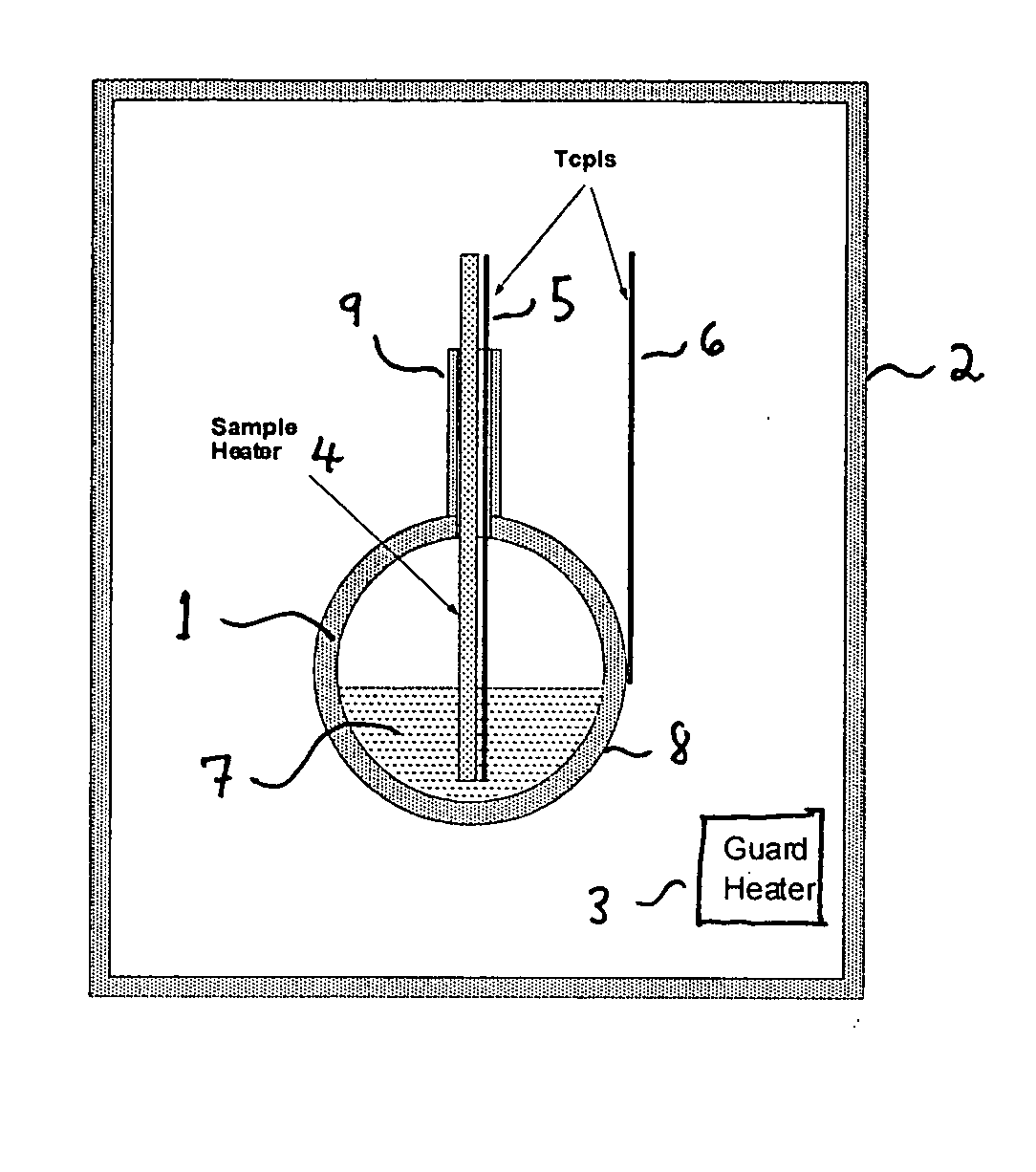

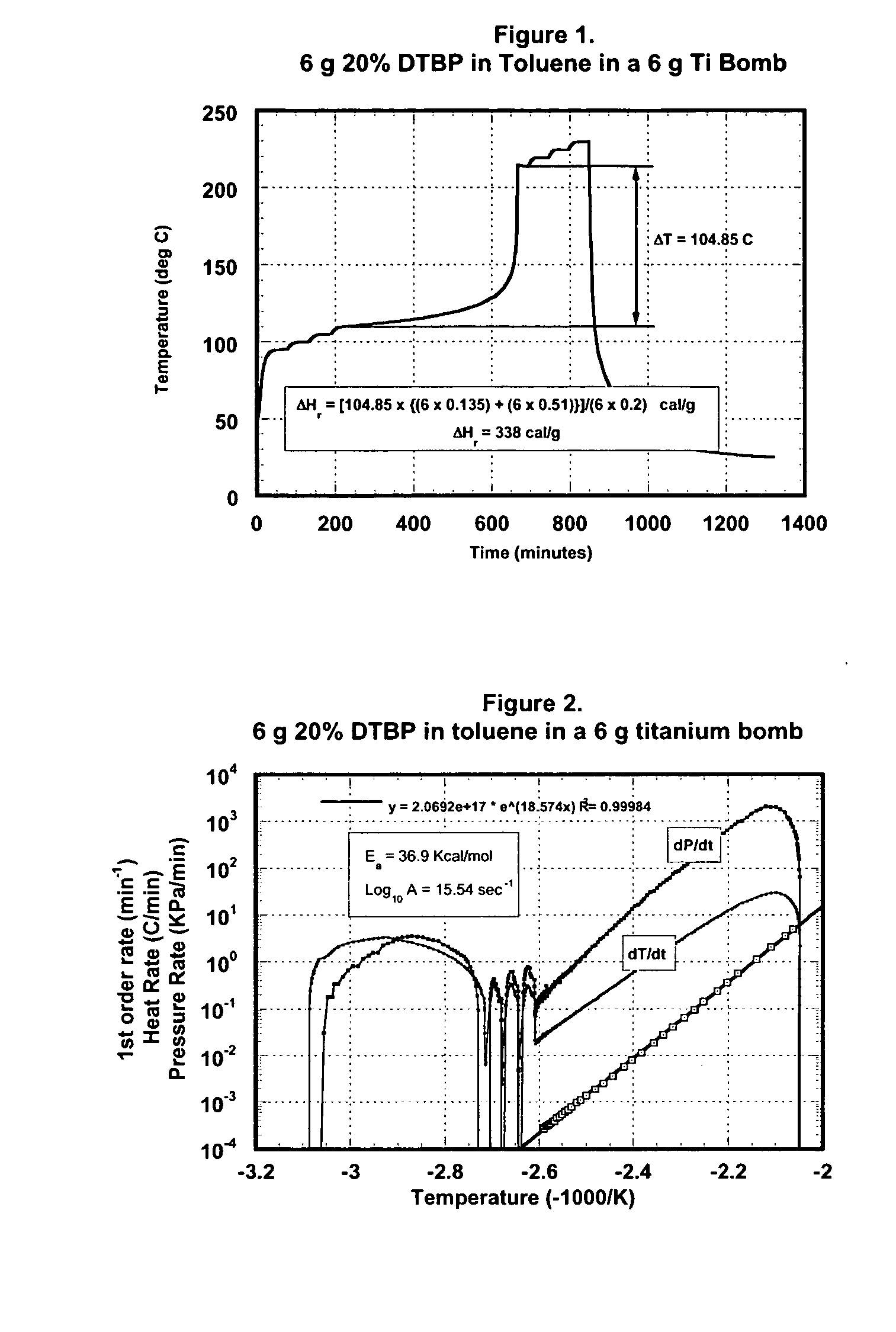

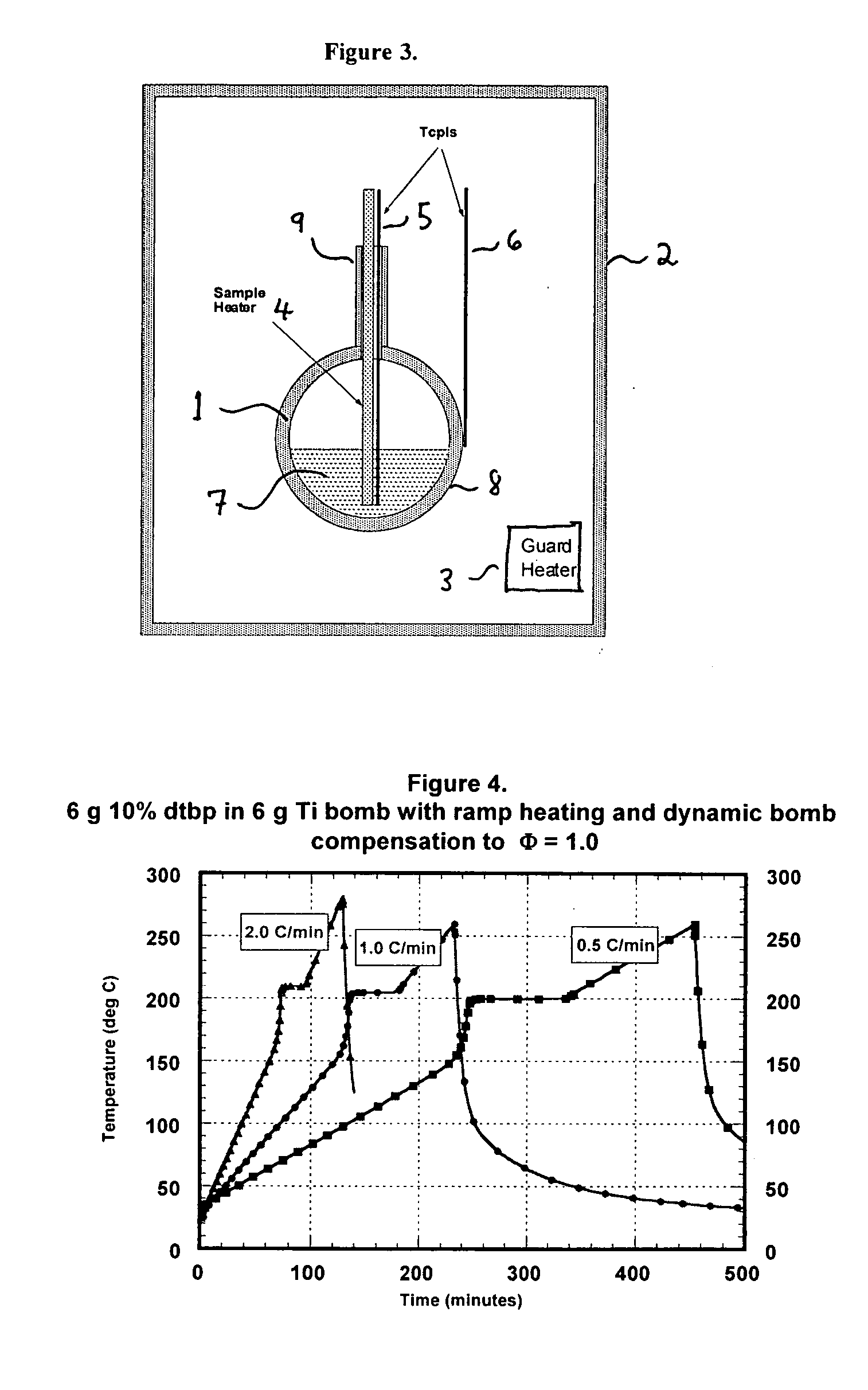

Low thermal inerta scanning adiabatic calorimeter

ActiveUS20050008063A1Prevent heat lossReduce heat outputMaterial heat developmentThermometers using electric/magnetic elementsContinuous measurementProduction rate

A new adiabatic scanning calorimeter allows the thermal mass of a high-pressure reaction vessel to be dynamically compensated during a test. This allows the effective Φ factor for the experiment to be reduced to 1.0 without the use of complex pressure balancing equipment. Endothermic events can be quantified and sample specific heats can be measured. The time required for test completion is much shorter than for conventional adiabatic calorimeters, thus considerably improving apparatus productivity. The sensitivity to exotherm detection is at least as good as existing adiabatic calorimeters employing the Heat-Wait-Search strategy, but does depend on the temperature-scanning rate. In addition, the heat of reaction is obtained without reference to the heat capacity of the sample, pressure is measured continuously, reactants may be injected into the test vessel and the sample can be mixed during the test.

Owner:NETZSCH GERATEBAU GMBH

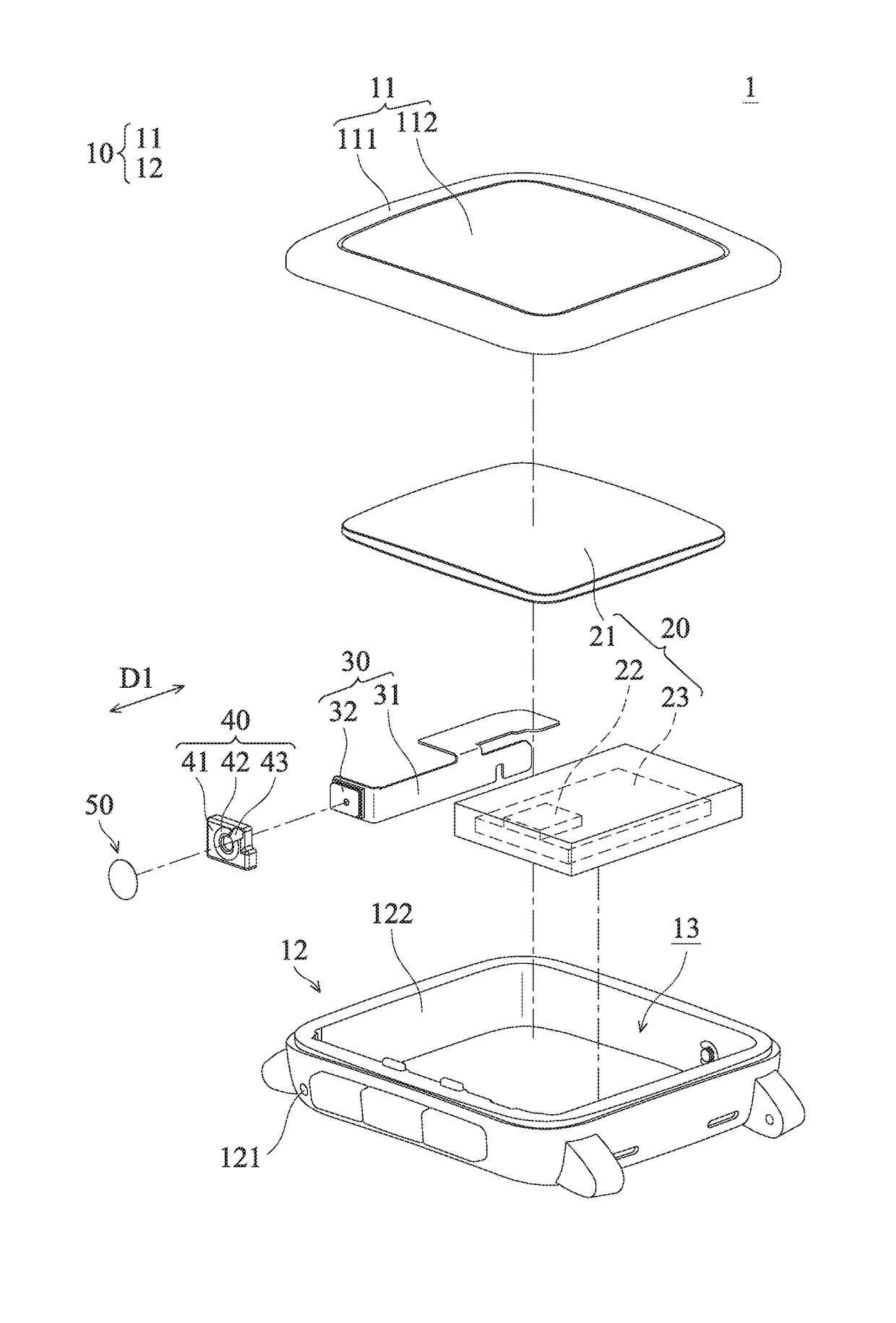

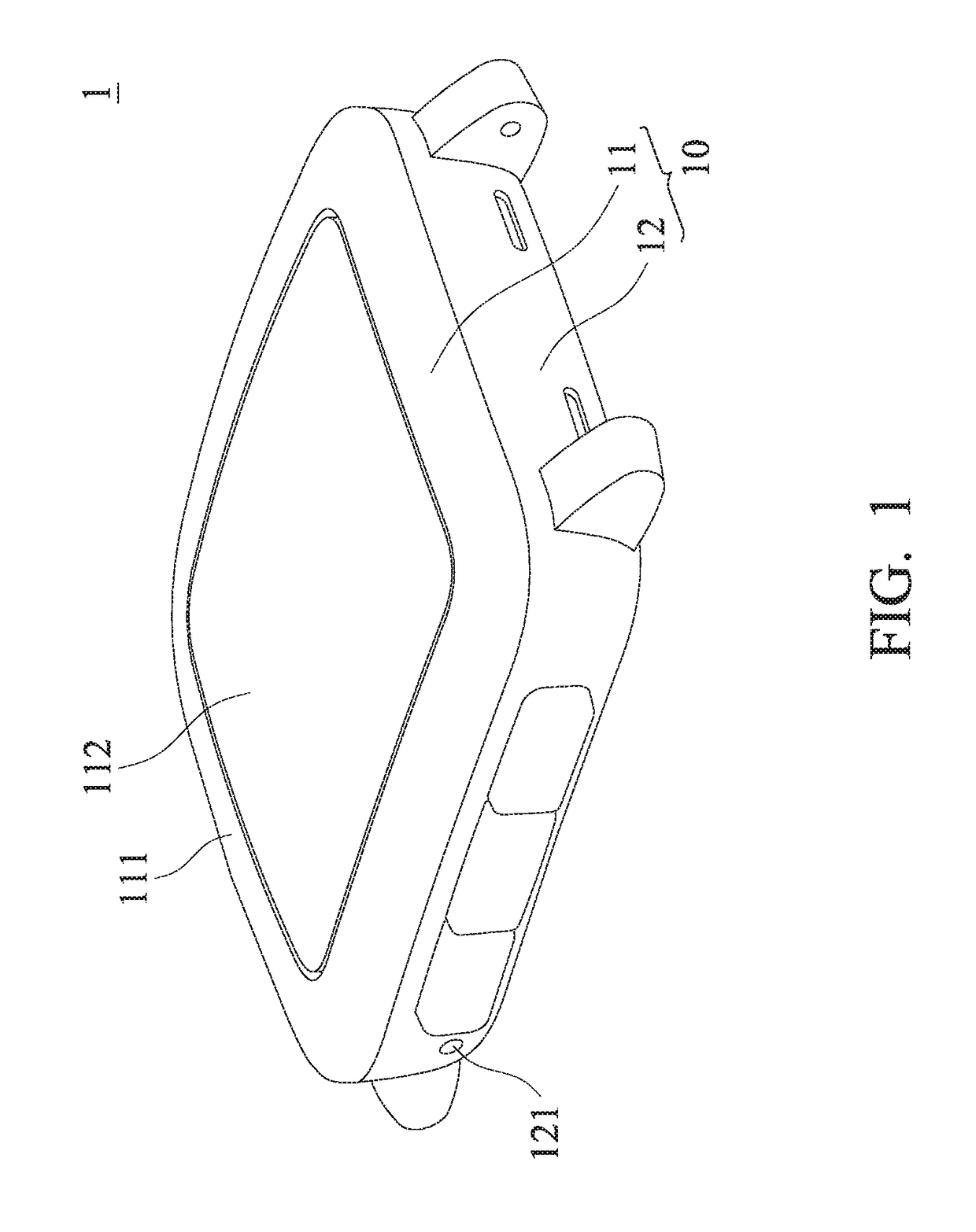

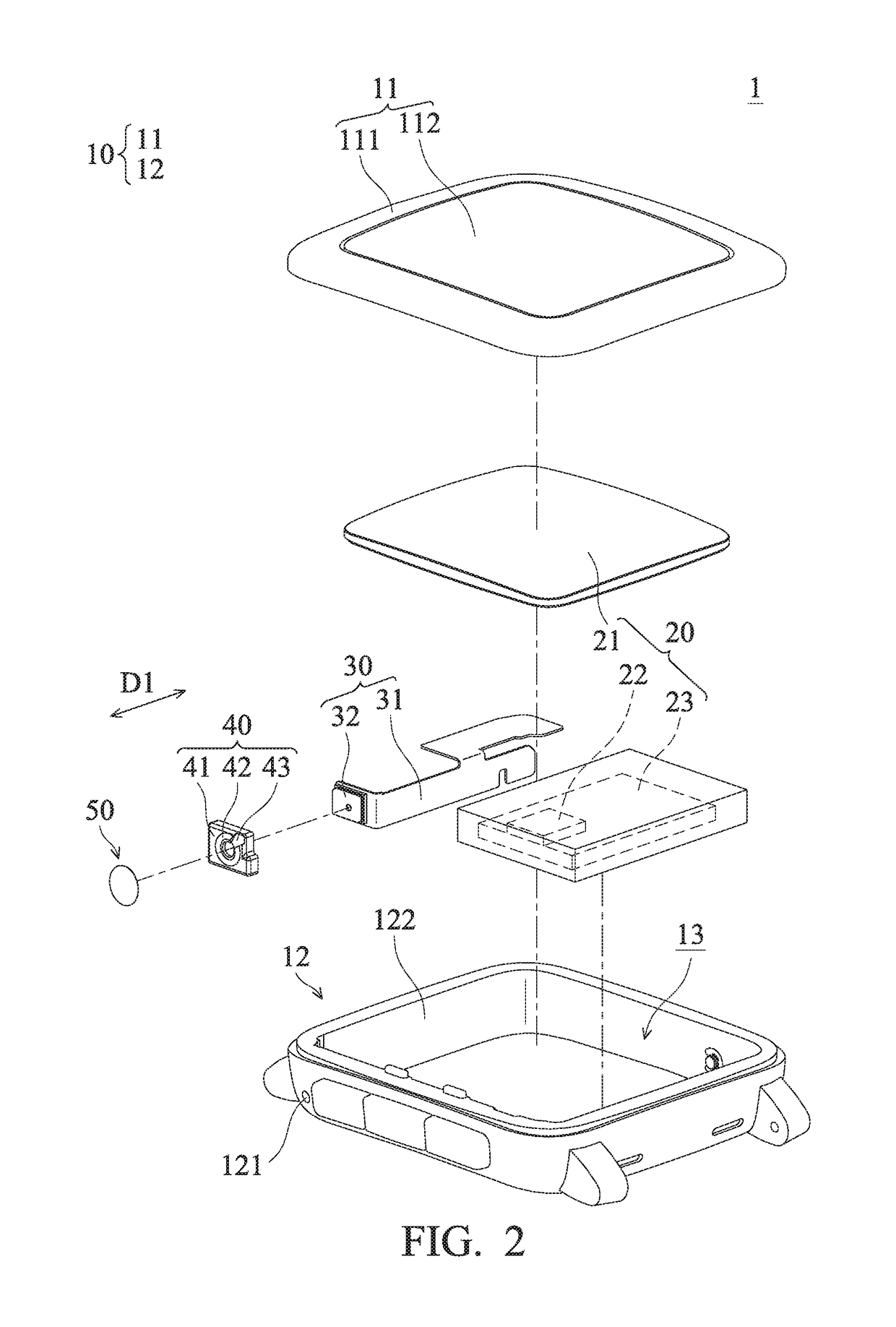

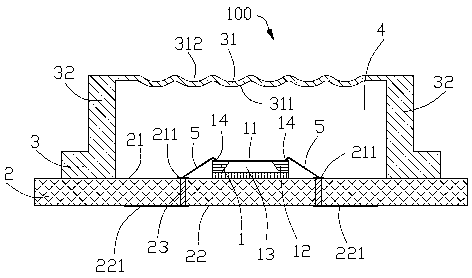

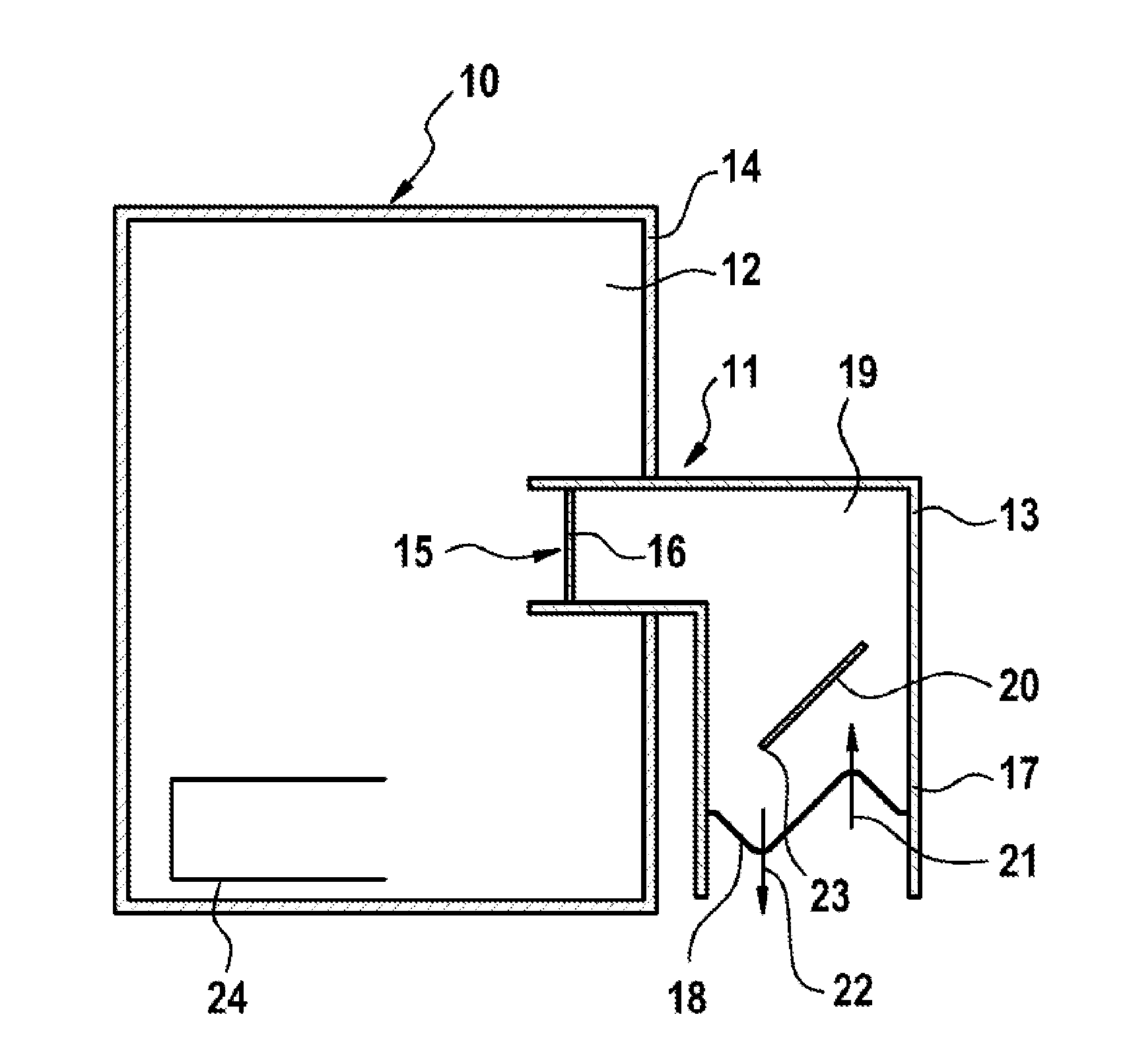

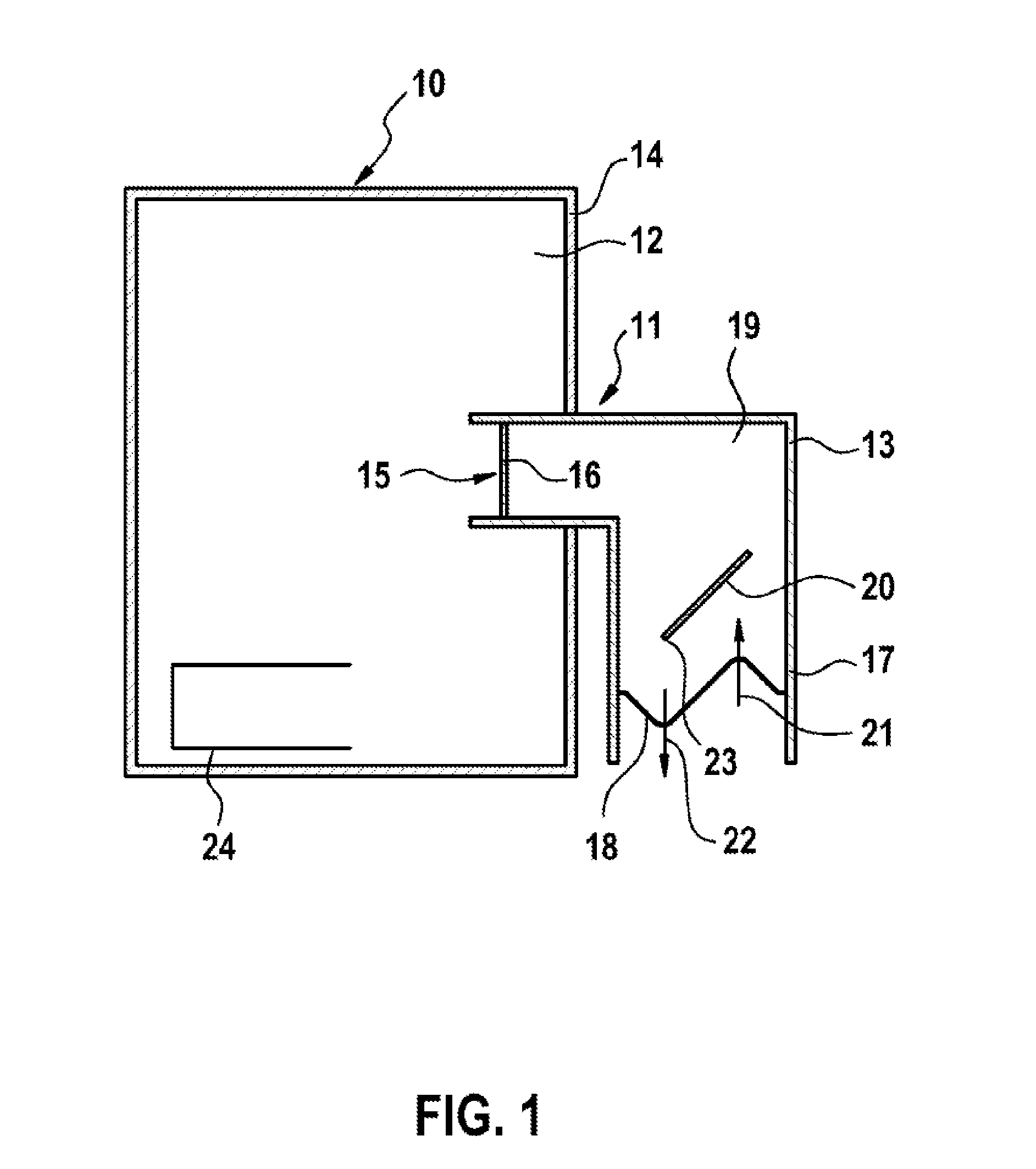

Waterproof electronic device with pressure-equilibrium functions

InactiveUS20170180850A1Not deformTransducers for subaqueous useTransducer casings/cabinets/supportsEngineeringPressure equilibrium

A waterproof electronic device that is waterproof and has pressure-equilibrium functions is provided. The waterproof electronic device includes a housing, a microphone, an elastic element, and a waterproof element. The housing has a chamber and an acoustic hole communicating with the chamber. The microphone is disposed in the chamber. The elastic element is disposed on the microphone. The elastic element includes a through hole facing the microphone, and a ventilation groove communicating with the through hole. The waterproof element is connected to the elastic element and the housing, and is configured to block liquid. The waterproof element includes pores communicating with the acoustic hole and the through hole.

Owner:QUANTA COMPUTER INC

Pressure sensor dielectric medium isolation packaging structure and packaging method of same

ActiveCN103257007AReduce manufacturing costFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsDielectricEngineering

The invention discloses a pressure sensor dielectric medium isolation packaging structure and a packaging method of the pressure sensor dielectric medium isolation packaging structure. The pressure sensor dielectric medium isolation packaging structure comprises a substrate, a cover body made of soft low-elasticity-modulus materials and a pressure sensor chip. The cover body and the substrate form an airtight cavity body together in order to accommodate the pressure sensor chip. When the pressure of a dielectric medium to be measured is acted on the cover body, the cover body deforms and accordingly compresses gas in the airtight cavity body to achieve balanced internal and external pressure. In the process, the dielectric medium to be measured is transmitted to a pressure sensitive membrane of the pressure sensor chip and accordingly the purpose that the pressure of pressure sensor chip and the pressure of the dielectric medium to be measured are separated is achieved. According to the pressure sensor dielectric medium isolation packaging structure and the packaging method of the pressure sensor dielectric medium isolation packaging structure, the pressure is transmitted by compressing the gas, and accordingly complex silicone oil filling procedures in a traditional silicone oil filling stainless steel packaging technology are avoided and manufacturing cost is greatly reduced.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

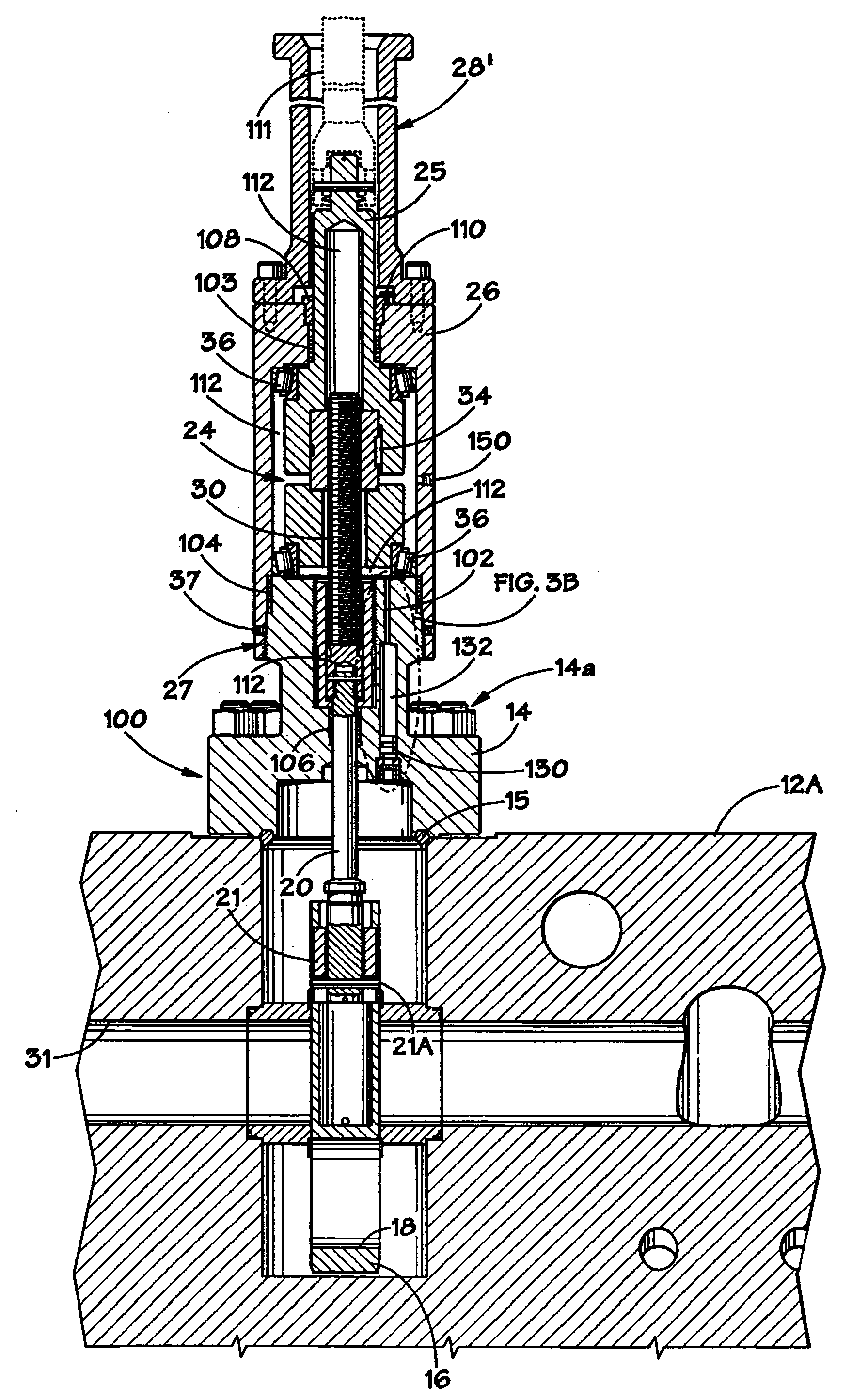

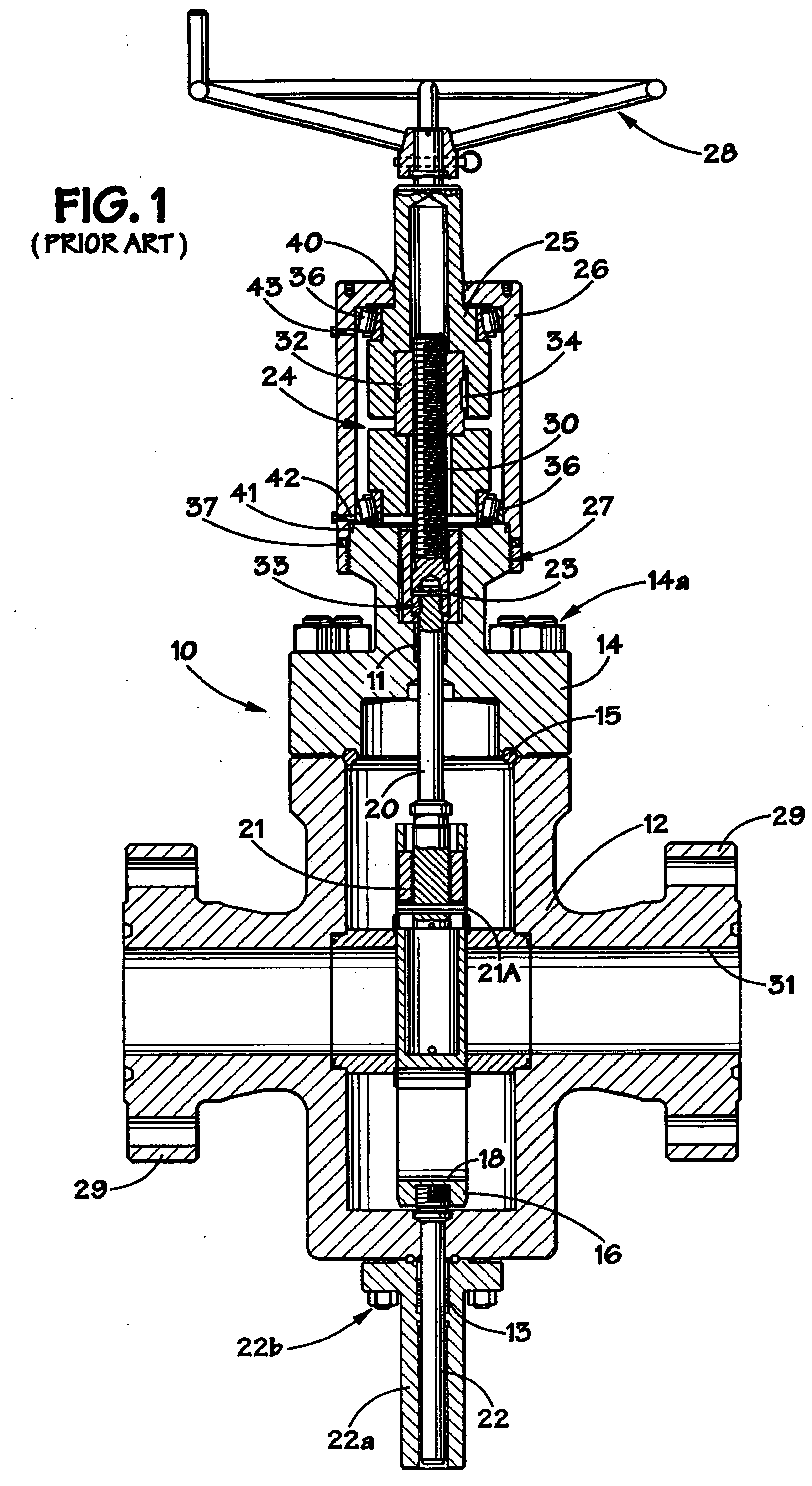

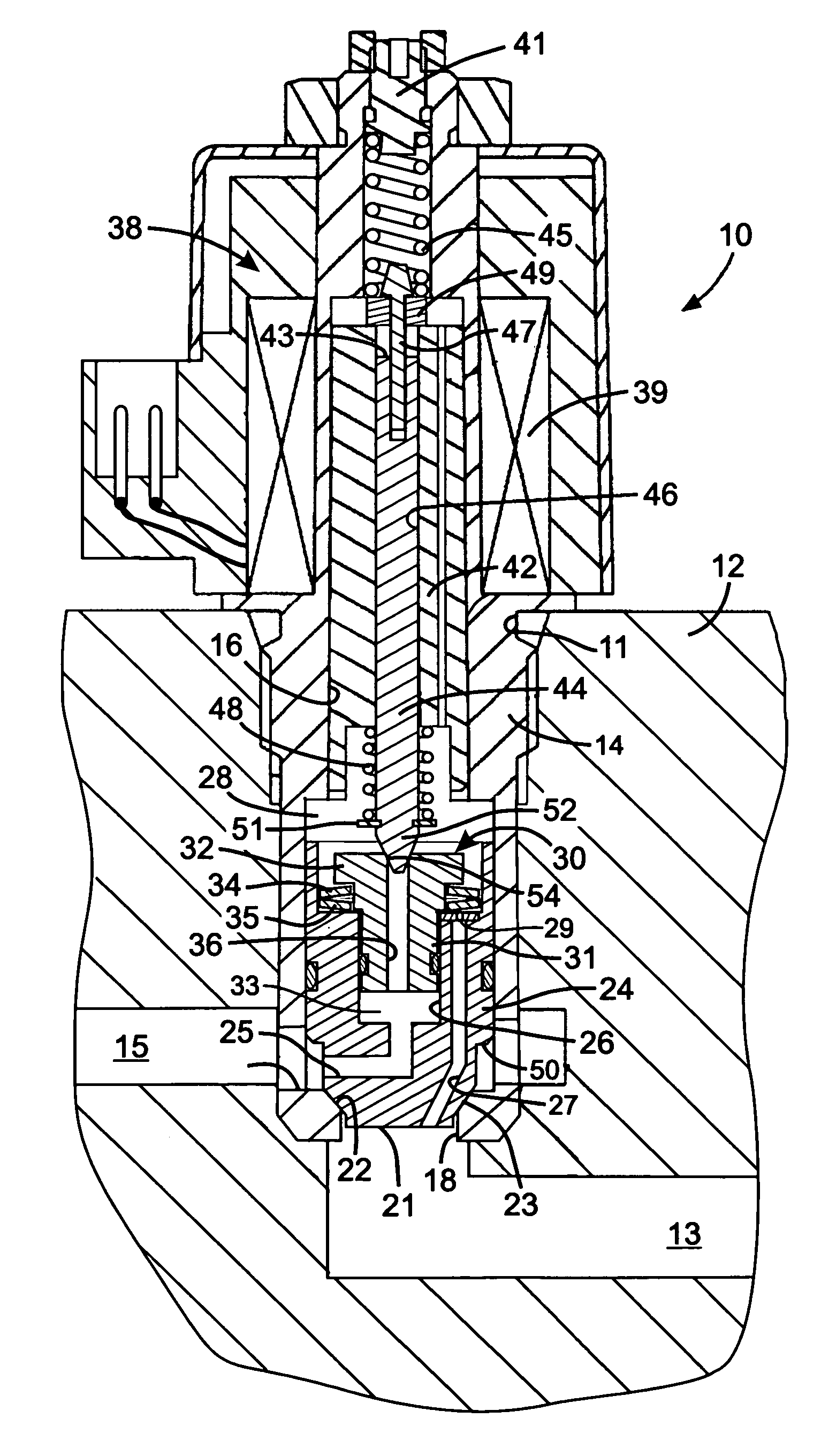

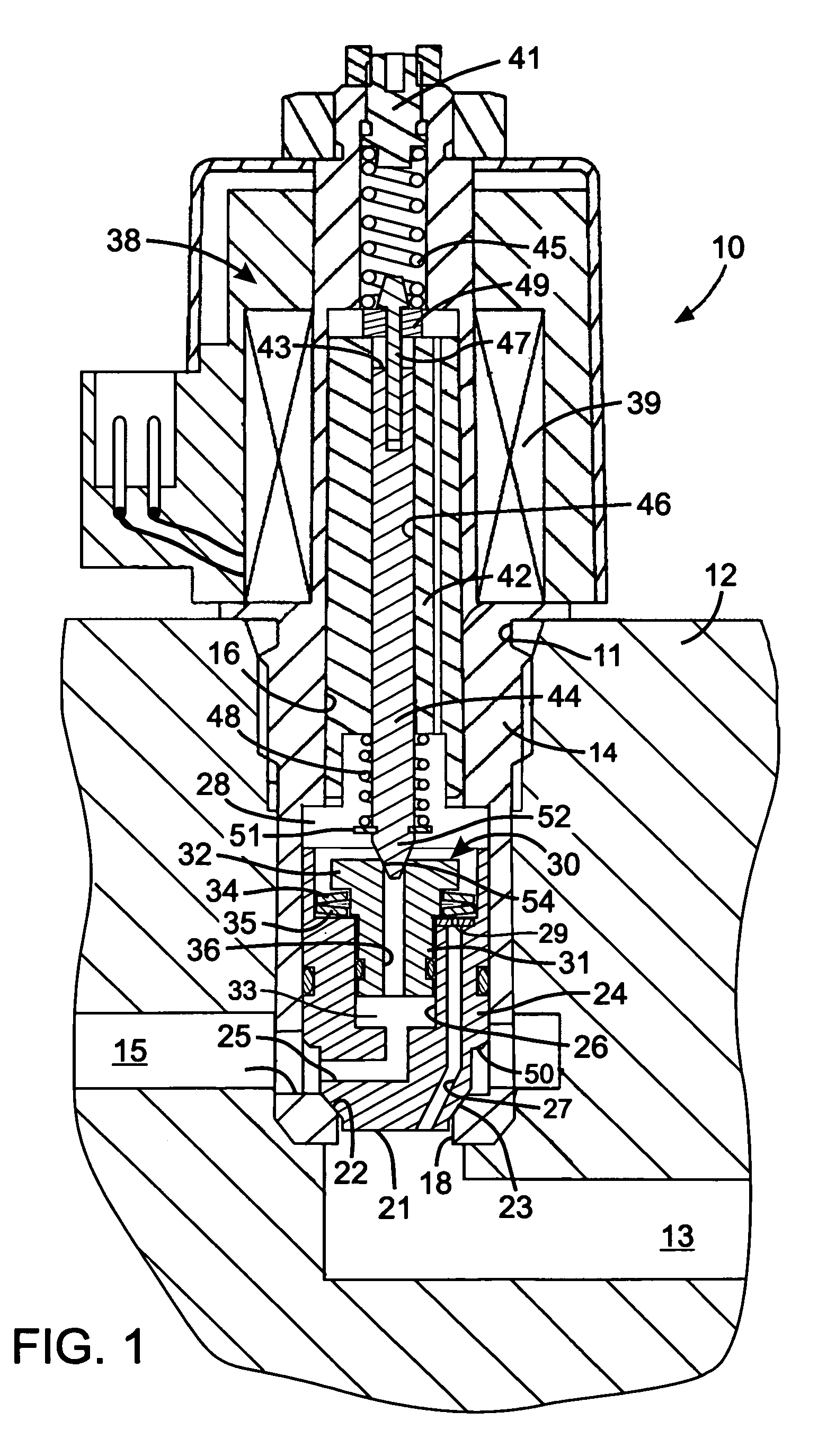

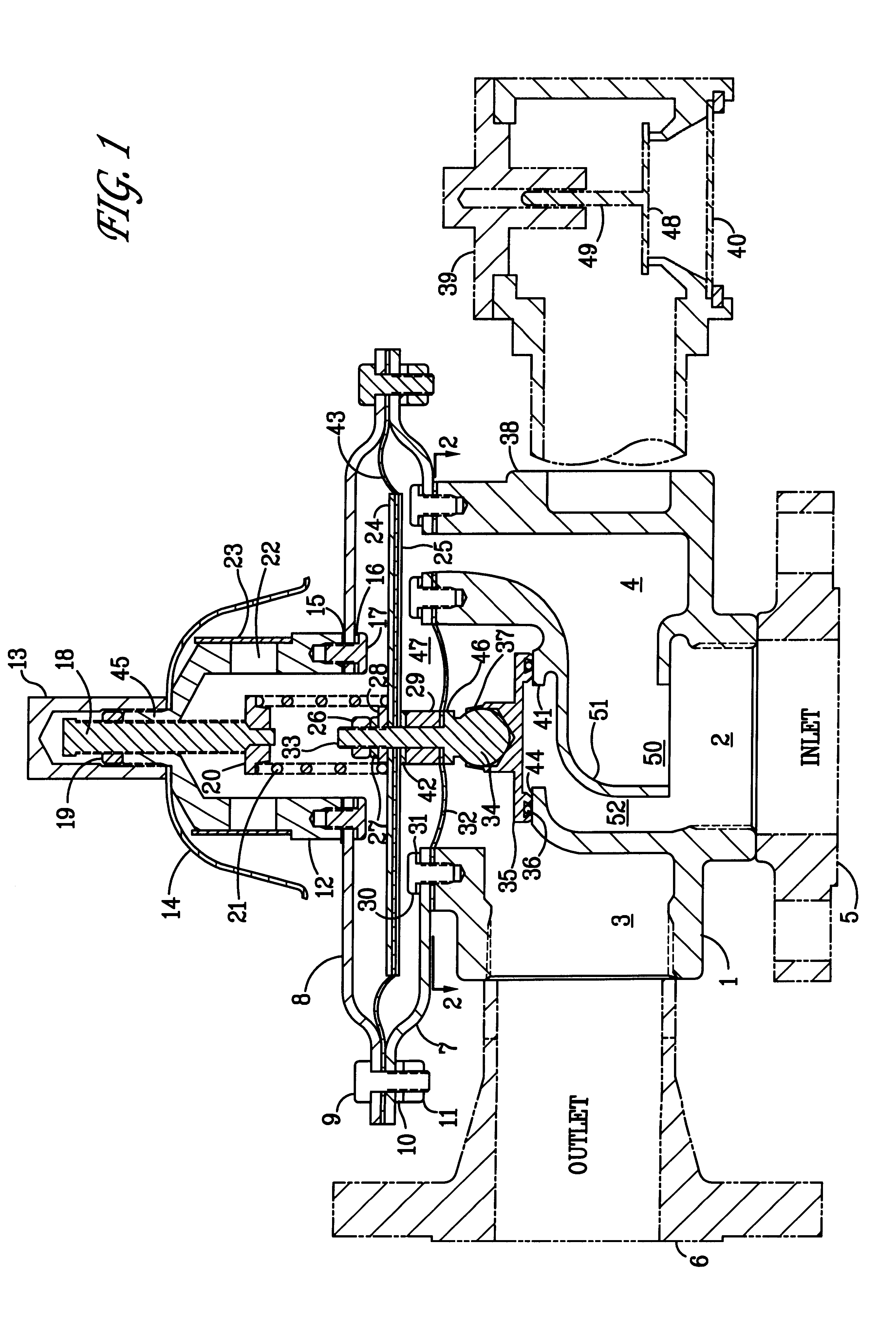

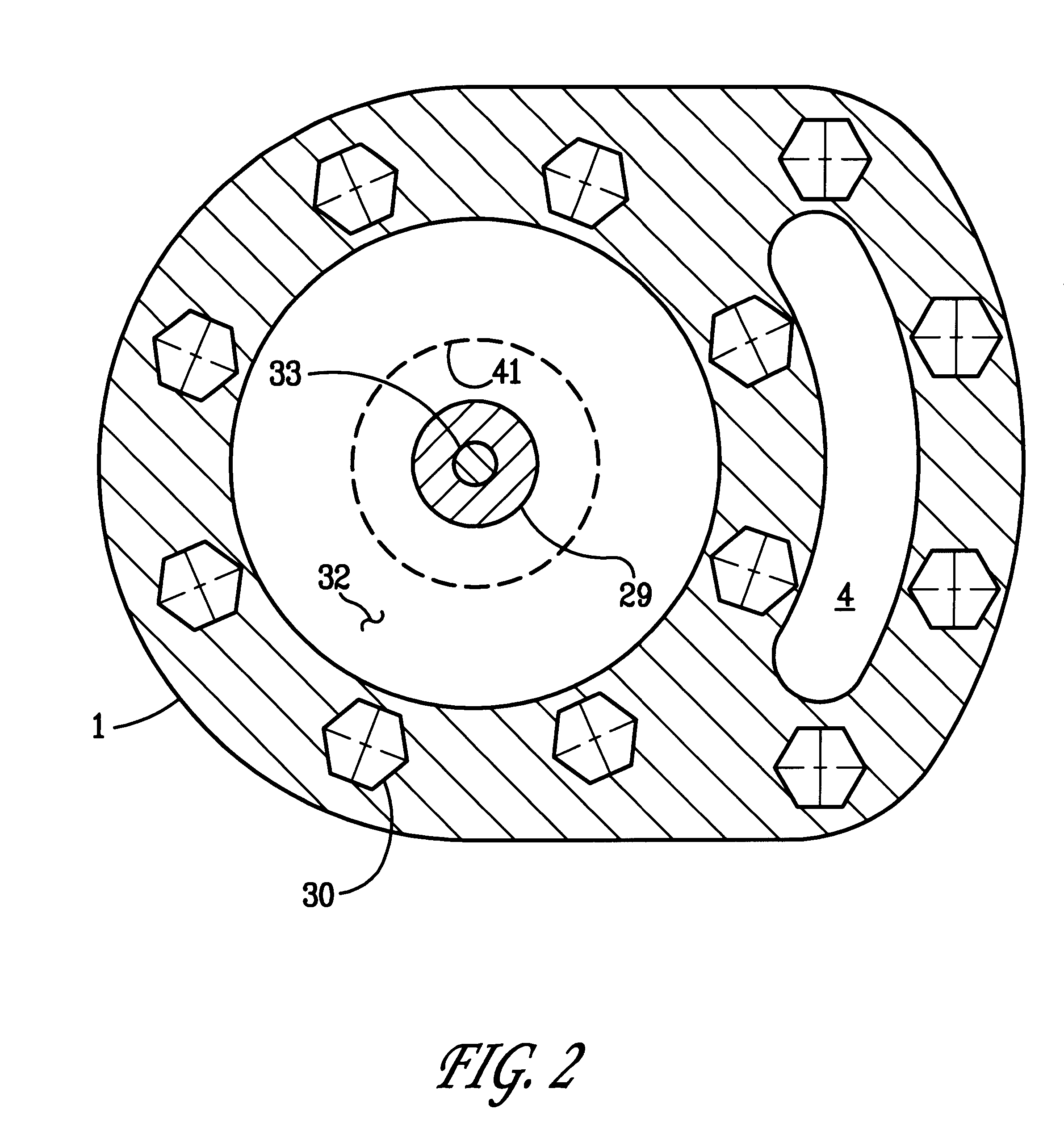

Pressure balanced fluid control device

ActiveUS20050173667A1Avoid enteringOperating means/releasing devices for valvesPressure relieving devices on sealing facesWorking fluidFluid control

The present invention is directed to a pressure balanced fluid control device. In one illustrative embodiment, the device comprises a body, a bonnet coupled to the body, a valve stem operatively coupled to a gate positioned in the body, a valve stem seal positioned between the valve stem and the bonnet, wherein a sealed cavity exists above the valve stem seal, and an opening through the bonnet that is adapted to allow a pressure of a working fluid flowing through the valve to be exerted in the sealed cavity above the valve stem seal. In another illustrative embodiment, the device comprises a body, a bonnet coupled to the body, a valve stem operatively coupled to a gate positioned in the body, a valve stem seal positioned between the valve stem and the bonnet, wherein a sealed cavity exists above the valve stem seal, and an opening through the bonnet, the opening being in fluid communication with the sealed cavity and an interior region of the body. In a further illustrative embodiment, the device comprises a body, a bonnet coupled to the body, a valve stem operatively coupled to a gate positioned in the body, a valve stem seal positioned between the valve stem and the bonnet, wherein a sealed cavity exists above the valve stem seal, a piston chamber formed in the bonnet, the piston chamber being in fluid communication with the sealed cavity and an interior region of the body, and a piston positioned in the piston chamber.

Owner:FMC TECH INC

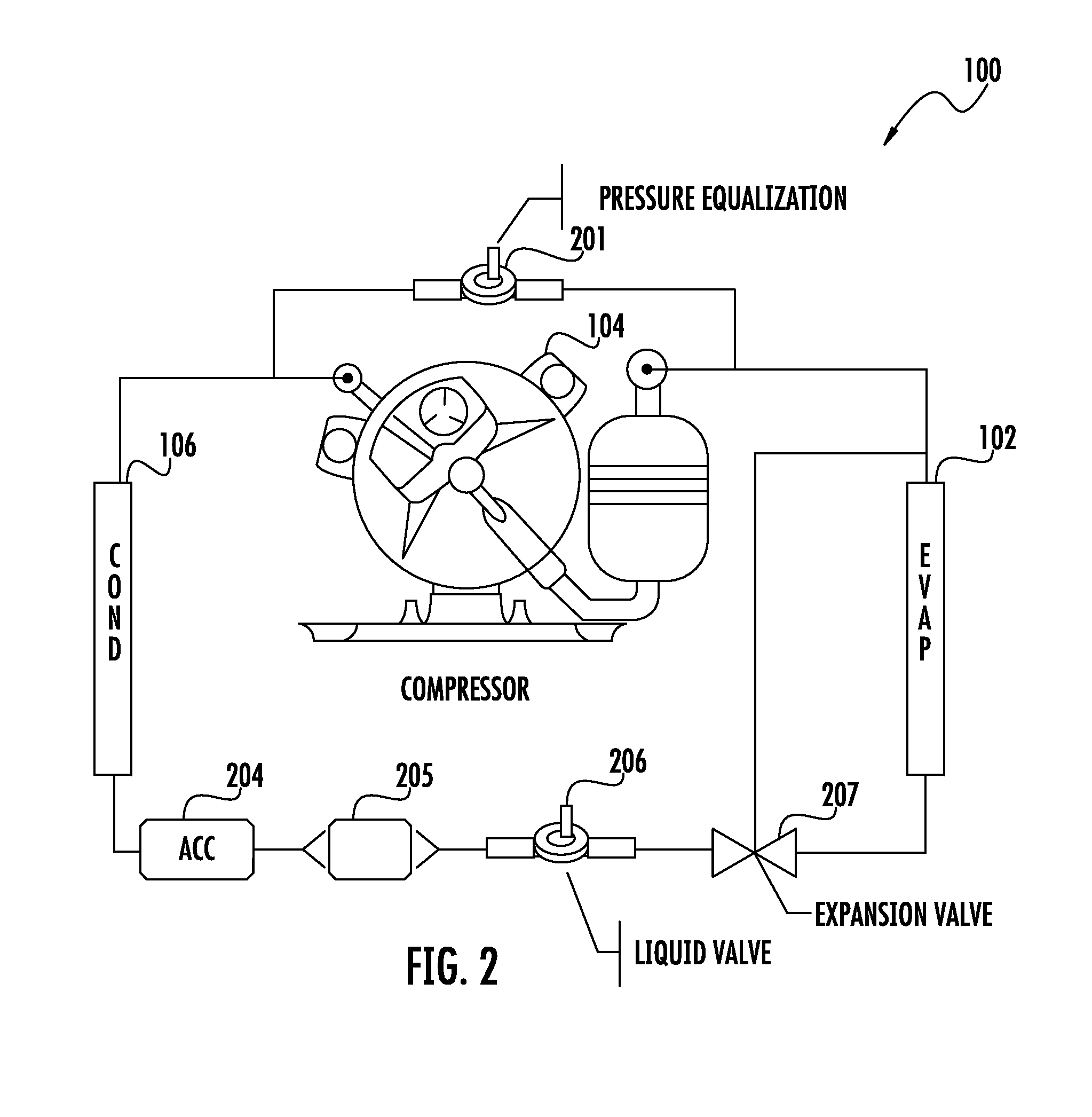

Method And System For Transport Container Refrigeration Control

ActiveUS20140137580A1Reduce processing stepsMechanical apparatusCorrosion preventionEqualizationRefrigeration

A method of refrigeration control through a refrigeration system of a refrigerated transport container includes performing a defrost cycle on the refrigeration system by activating a heat source; and restarting the refrigeration system after the defrost cycle has completed, wherein restarting the refrigeration system includes performing a liquid slugging avoidance process including: initiating a compressor of the refrigeration system at a speed; opening a pressure equalization valve in parallel with the compressor in response to the initiating; opening a liquid valve in series between a condenser and an evaporator after opening of the pressure equalization valve; and closing the pressure equalization valve after a period of time.

Owner:CARRIER CORP

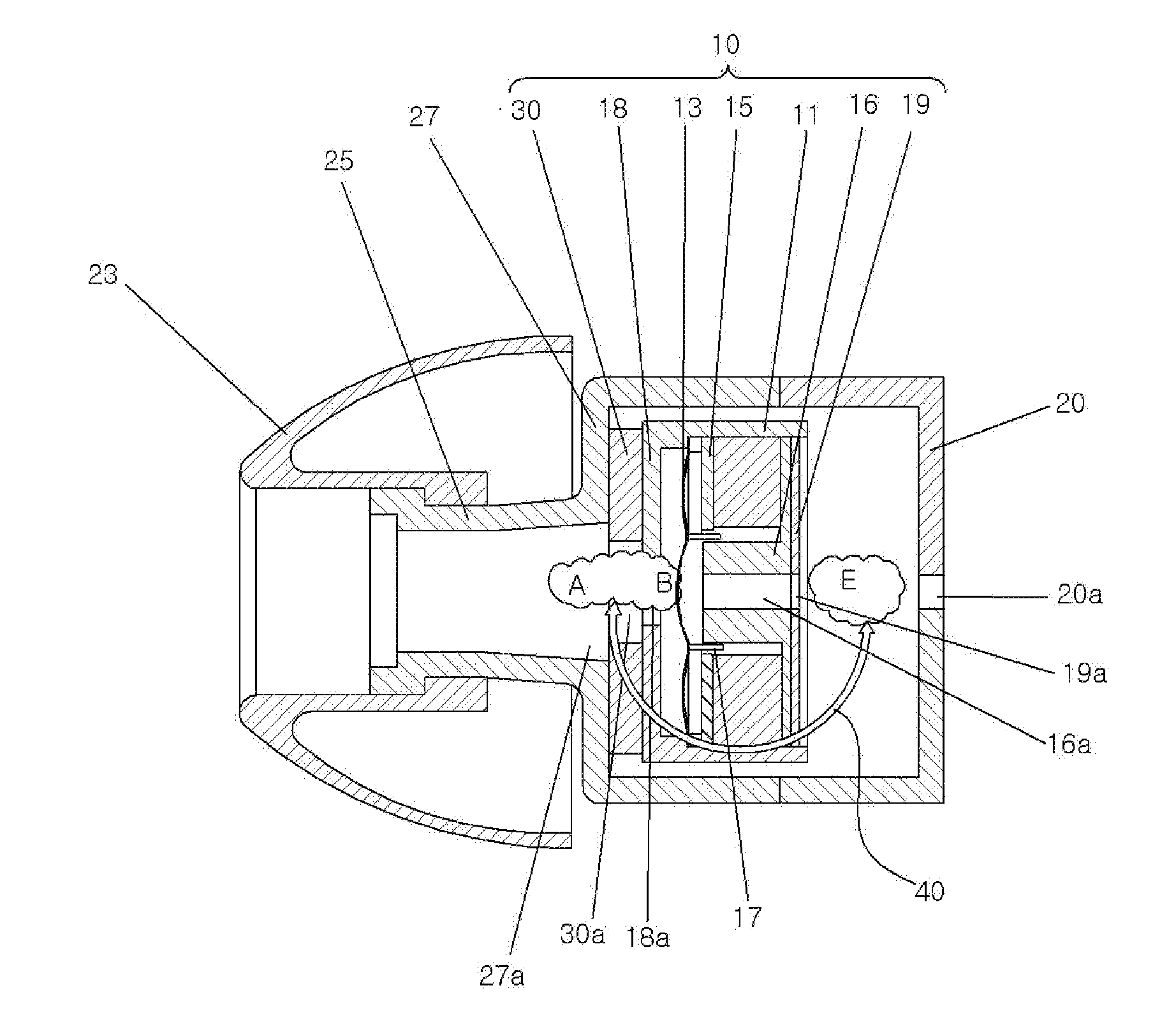

Canal type earphone with pressure equilibrium means

ActiveUS9237394B2Avoid damageMinimize changesHearing aid ventsIntra aural earpiecesEngineeringHeadphones

Disclosed herein is a canal type earphone with a pressure equilibrium means, capable of eliminating a pressure difference between a user's external auditory meatus and an outside during wearing of the canal type earphone. A pressure equilibrium means includes a side air passage through which air within a tube or air within a speaker unit in the canal type earphone is discharged to a side surface of a gasket or a side surface of the speaker unit, and a rear air passage through which air in the side surface of the speaker unit is discharged to the rear of the speaker unit.

Owner:BUJEON

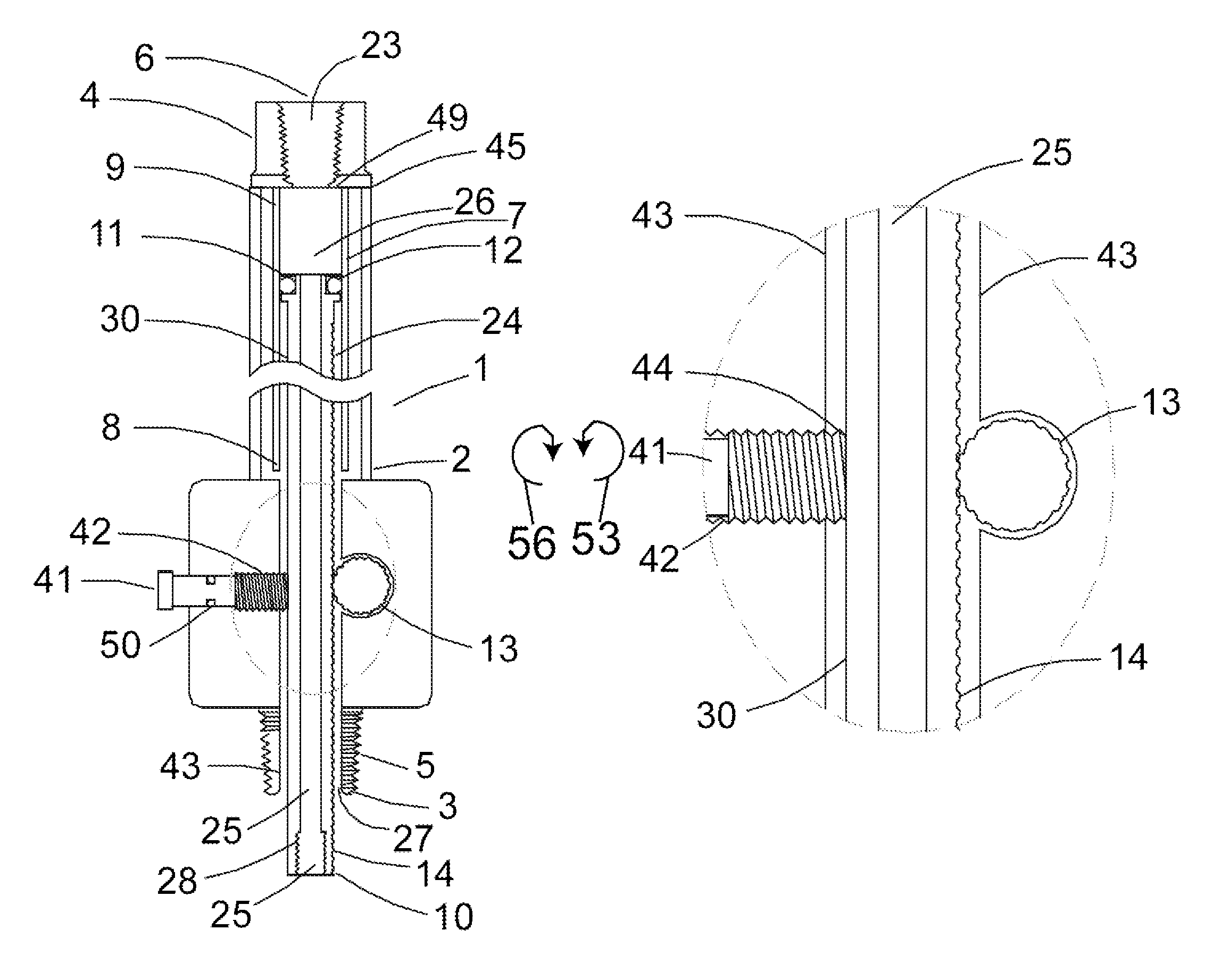

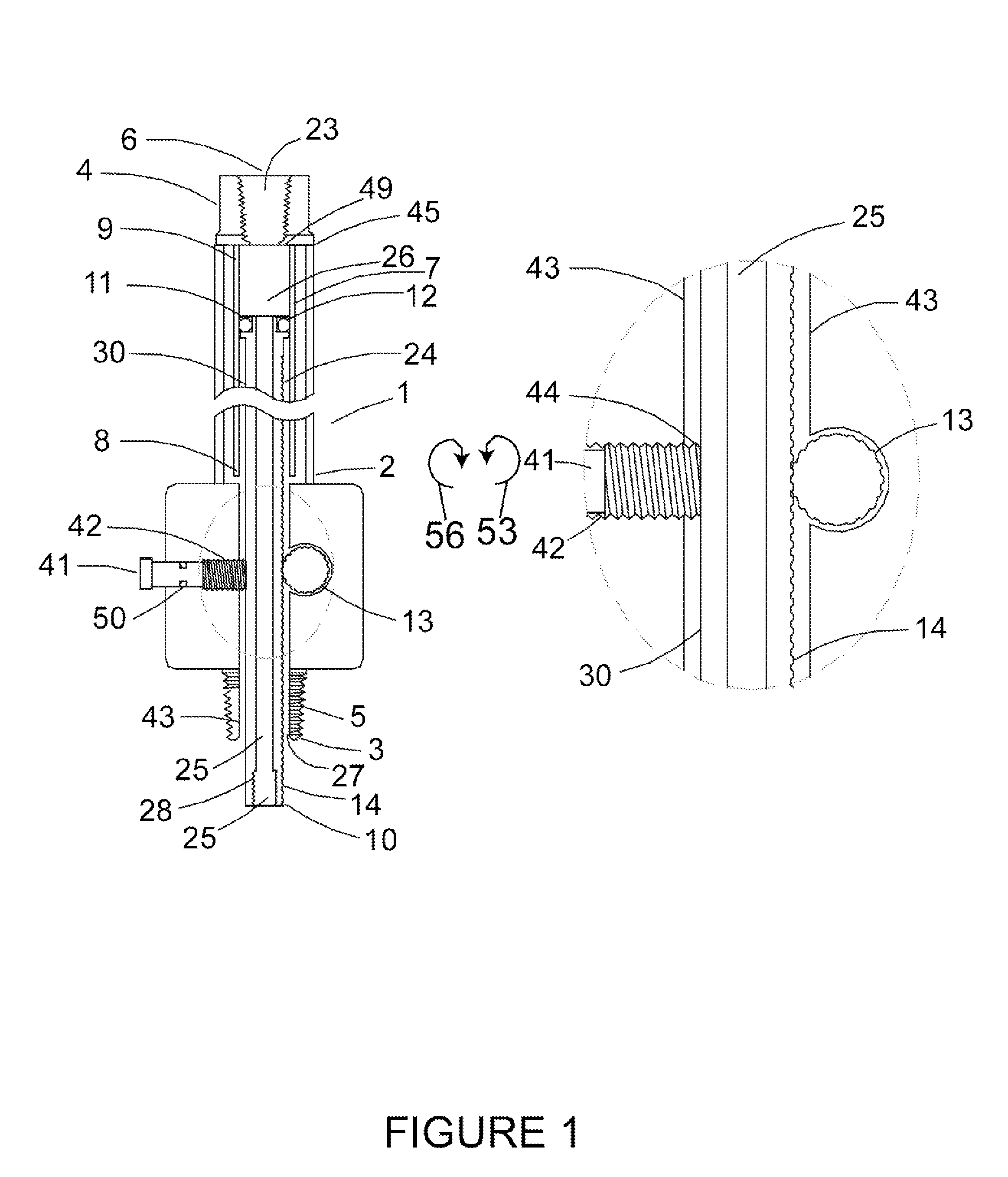

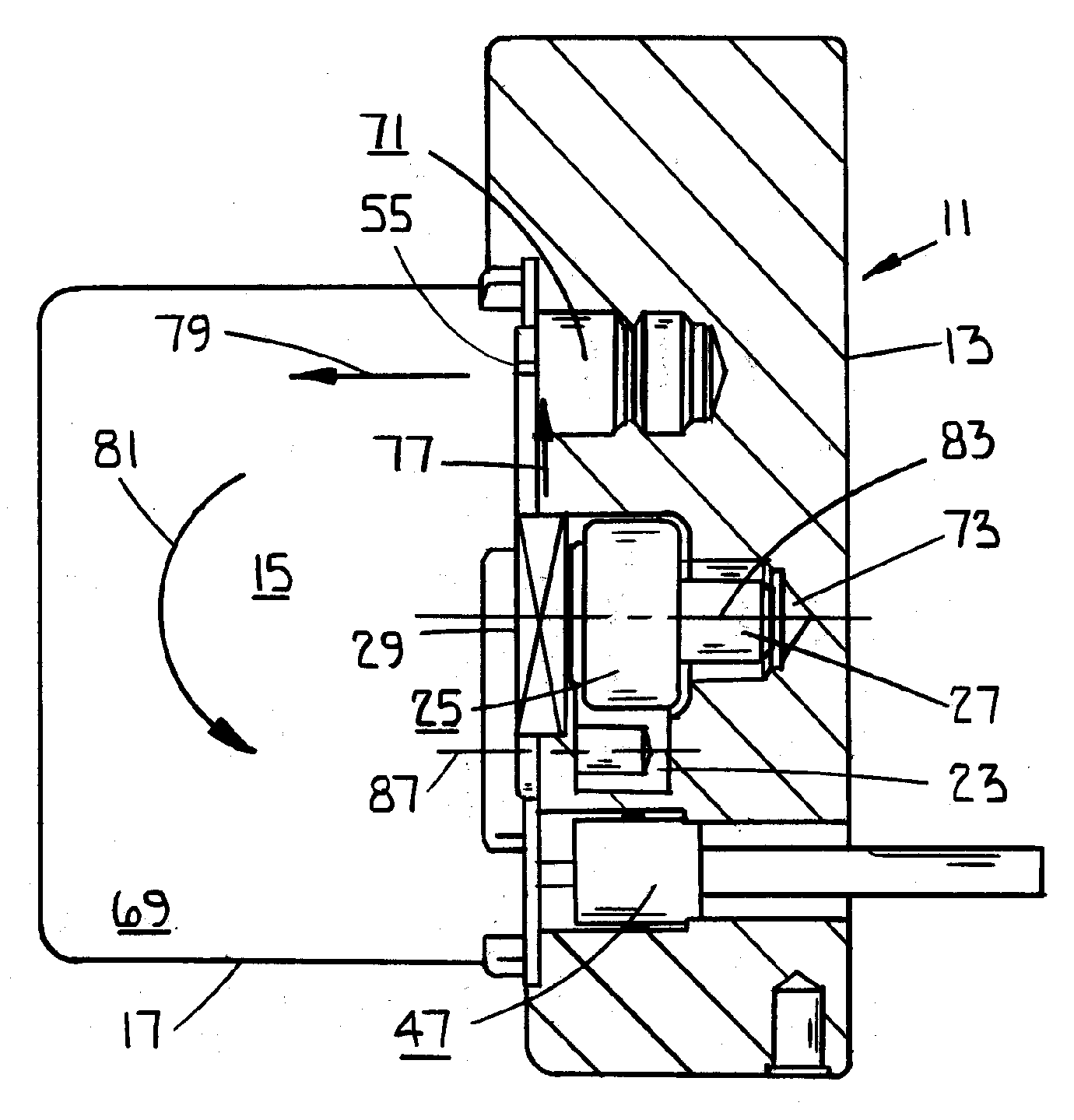

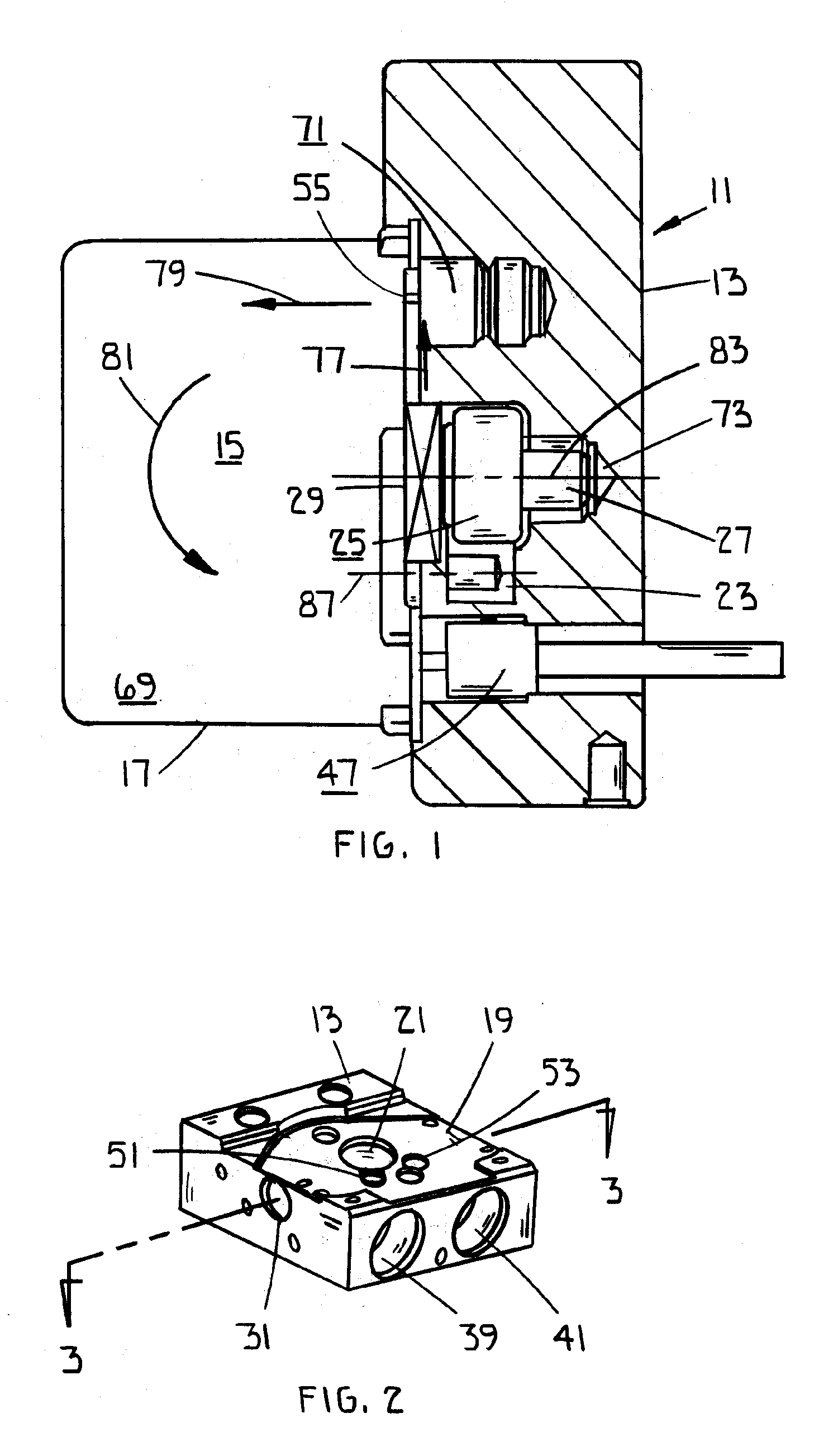

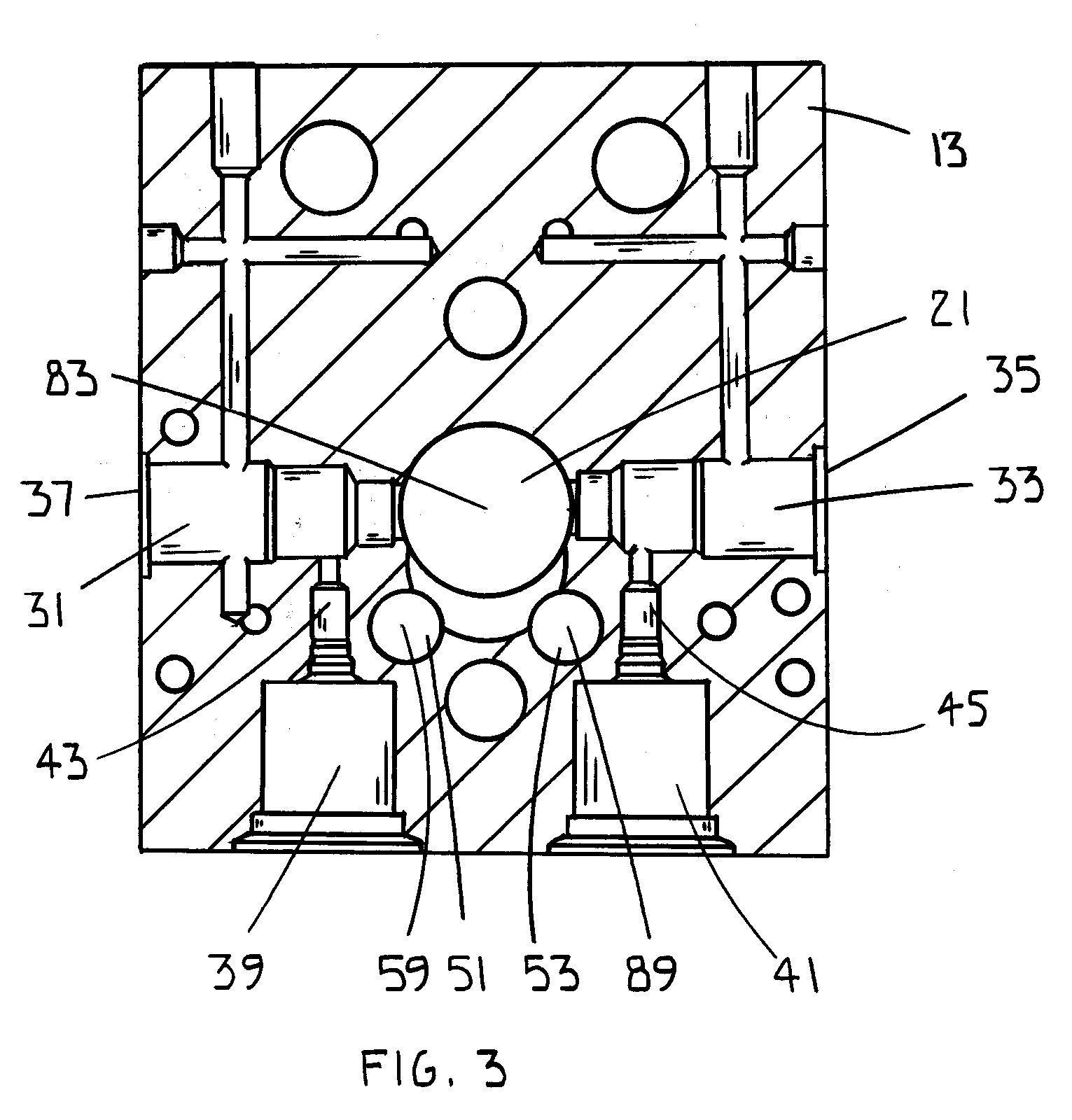

Portable insertable probe assembly

InactiveUS7472615B2Improve securitySimple meansThermometer detailsWeather/light/corrosion resistanceDifferential pressureCatheter

An assembly for insertion and retraction of probe or probe-like device which does not require a seal or packing gland, instead utilizing pressure equalization between pressurized process fluids and the housing containing a probe, so as to negate the use of a dynamic seal. The preferred embodiment of the present invention contemplates an inserting / retraction mechanism for raising and lowering the probe into and from the pressurized fluid, respectively. A housing having a valve is configured to allow fluid communication between the pressurized fluid source, and the interior of the housing assembly. A conduit engages the housing assembly, and is formed to slidingly receive the outer diameter of the probe therethrough, such that a sliding seal maintains a fluid seal between the outer wall of the probe and the inner wall of the conduit, as the probe is telescoped therethrough during insertion and retraction of the probe into / from the pressurized process. Fluid flow will occur until the pressure of the housing assembly and the fluid source are equal to each other. The probe is then lowered through an opening in the first end of the housing assembly without having to overcome the force exerted by the differential pressure across a dynamic seal. An example of the insertion / retraction mechanism of the present invention utilizes a rack and pinion system.

Owner:MAYEAUX HLDG

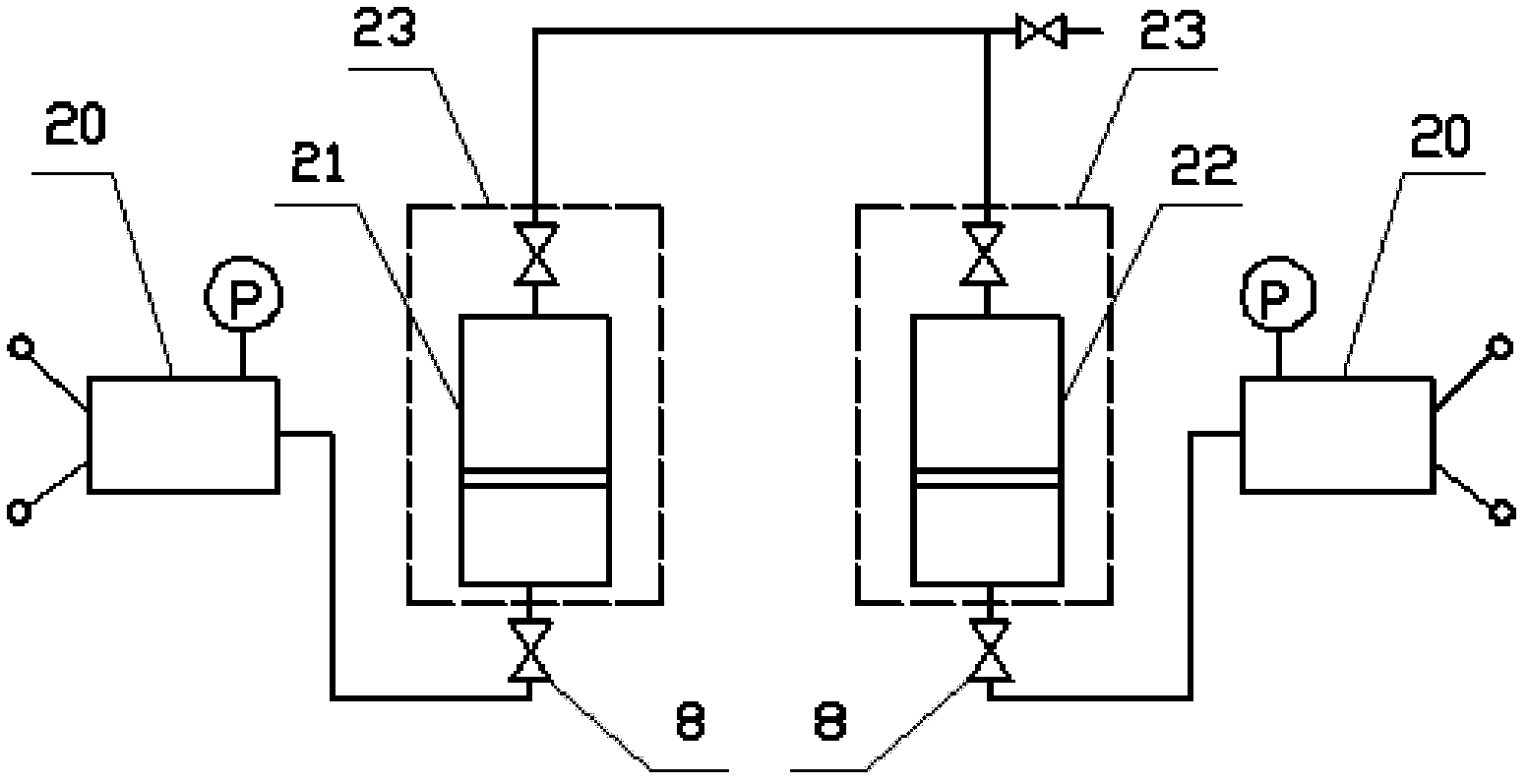

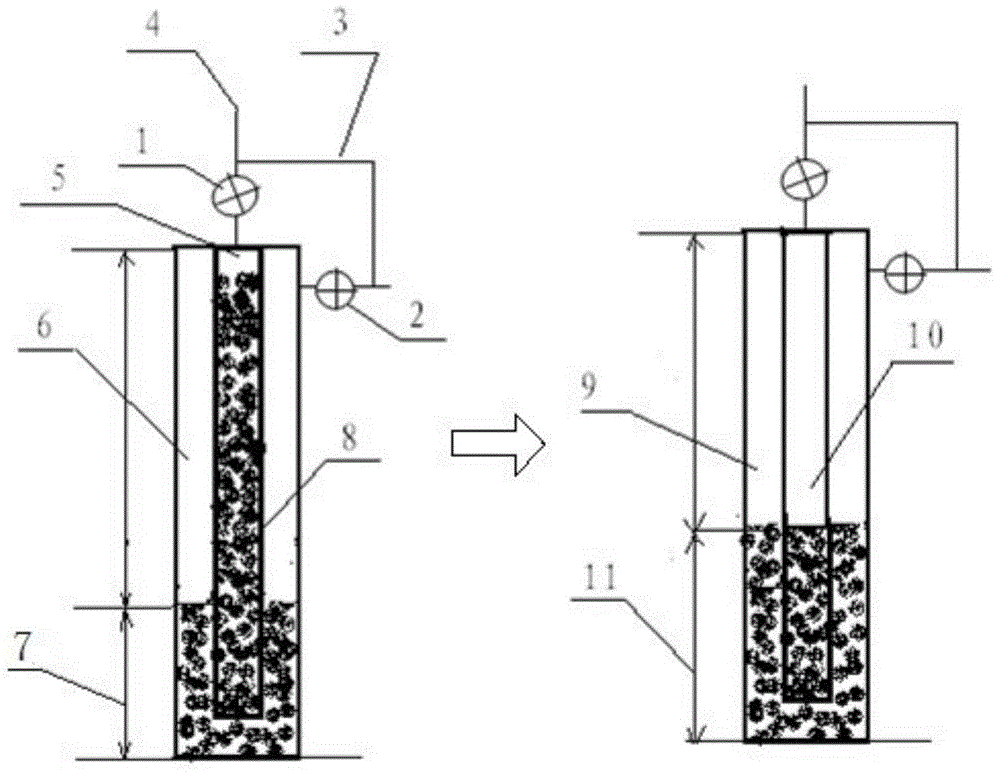

Coal/shale isothermal adsorption experiment method

InactiveCN103994960AReduce the number of gas injectionsShorten adsorption experiment timePermeability/surface area analysisAdsorption equilibriumConservation principle

The invention provides a coal / shale isothermal adsorption experiment method. The method is carried out by a reference kettle, a sample kettle and a middle region of an experiment device; a sample to be detected is placed in the sample kettle and an experiment temperature is set to be constant according to actual stratum conditions; the sample kettle is calibrated to obtain a free space volume of the sample kettle; the reference kettle and the sample kettle are vacuumized to obtain the initial pressure of the sample kettle; the middle region is communicated with the reference kettle and the middle region is separated from the sample kettle; enough amount of adsorbate gas is injected into the reference kettle one time; after the pressure in the middle region is balanced with the pressure in the reference kettle, the initial pressure of the reference kettle is obtained; an adsorption experiment is carried out to obtain the pressure of the reference kettle and the pressure of the sample kettle after adsorption is balanced; according to a mass conservation principle before and after each time of adsorption, the adsorption amounts under different sample kettle pressures after a plurality of times of adsorption balance are obtained by using the initial pressure of the sample kettle, the initial pressure of the reference kettle, the free space volume of the sample kettle and the pressure of the reference kettle and the pressure of the sample kettle in an adsorption process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Vented dispensing device and method

ActiveUS20100198187A1Avoid enteringFacilitate controlled deliveryMedical devicesPharmaceutical delivery mechanismEngineeringAmbient air

Disclosed is a fluid dispensing device that includes at least one reservoir to hold the therapeutic fluid, at least one other unit requiring communication with ambient air, at least partly, to operate, and at least one housing defining an interior to retain the at least one reservoir and the at least one other unit. The at least one housing has at least one vent port formed on one or more of its walls. The at least one vent port is adapted to direct or communicate air to maintain pressure equilibrium between the air pressure in the interior of the at least one housing and the ambient air pressure outside the at least one housing, and provide communication with the ambient air to the at least one other unit requiring air to enable operation of the at least one other unit.

Owner:ROCHE DIABETES CARE INC

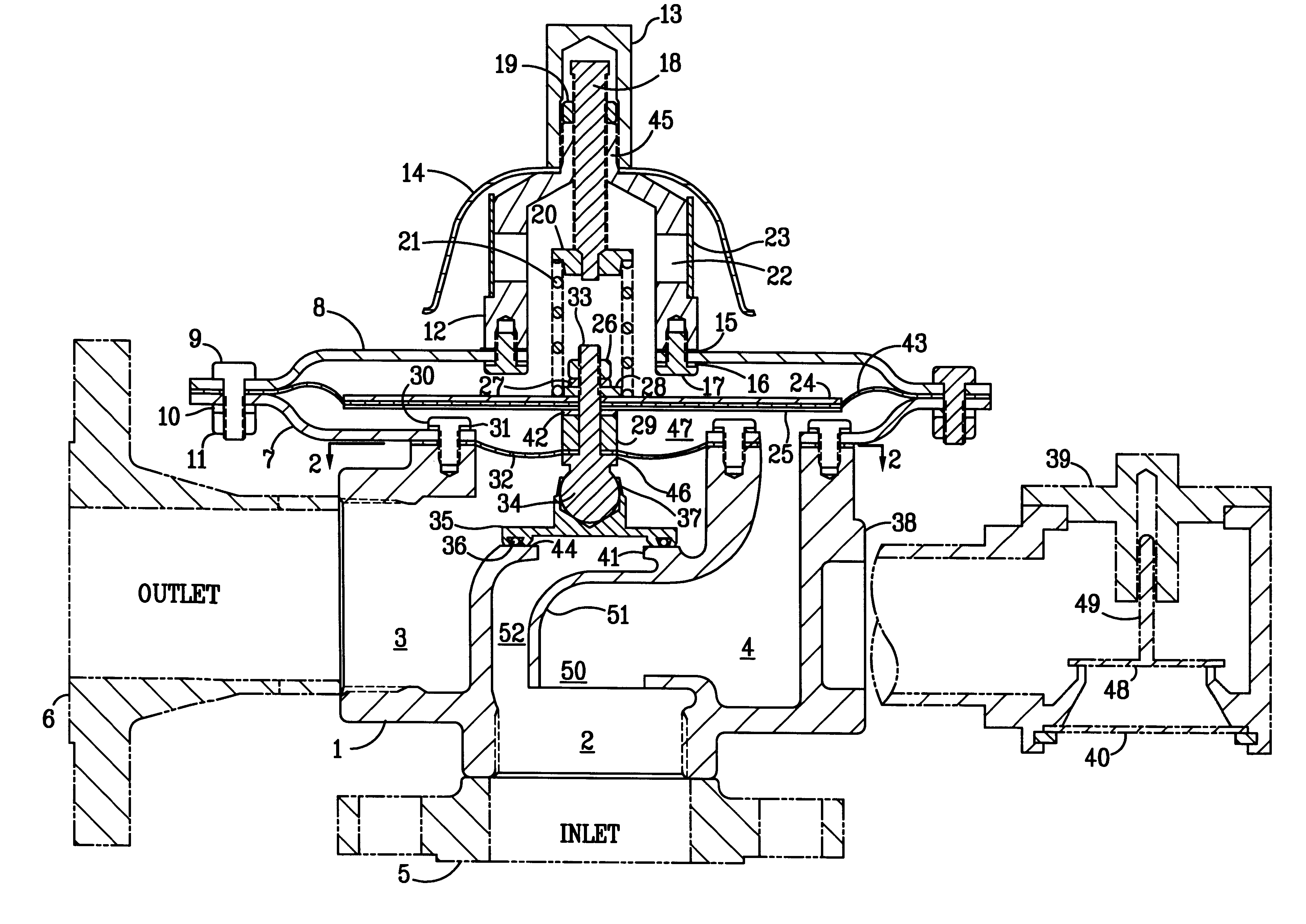

Pilot operated valve with a pressure balanced poppet

ActiveUS7341236B2Effect valve operationOperating means/releasing devices for valvesFluid pressure controlEngineeringControl room

A pilot operated valve has a main poppet that selectively controls flow of fluid between first and second ports in response to pressure in a control chamber on one side of the main poppet. The main poppet has an aperture extending between the control chamber and the first port. A pilot piston slides within the aperture and has the pilot passage with a pilot orifice and a first disk spring biases the pilot piston with respect to the main poppet. A pilot valve element selectively engages the pilot orifice to open and close the pilot passage and thereby controls motion of the main poppet. Forces from the first disk spring and a pressure differential between control and pilot chambers alter a position of the pilot valve seat with respect to the main poppet. The change in position compensates for effects on valve operation due to variation of the pressure at the two ports.

Owner:HUSCO INT INC

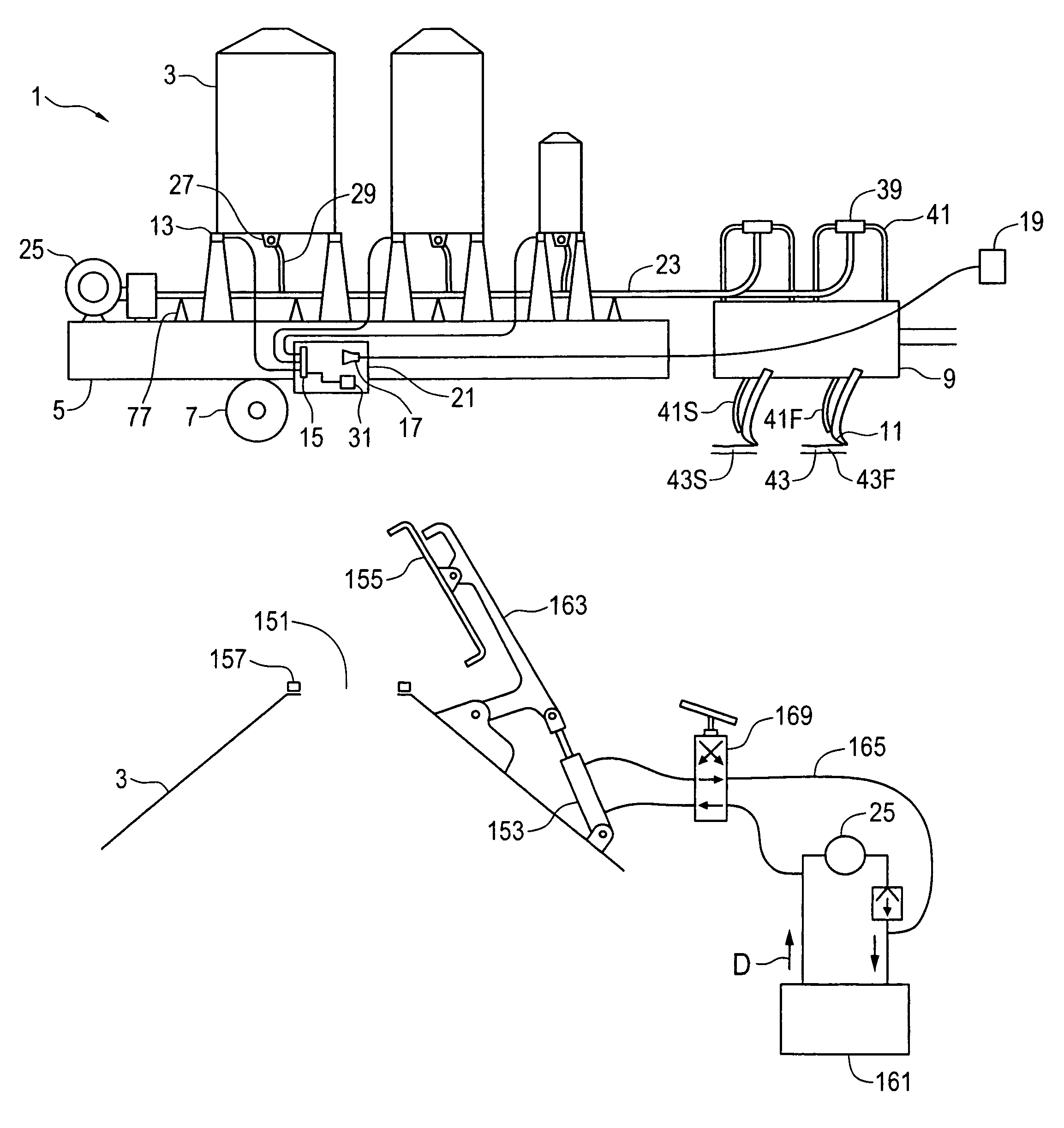

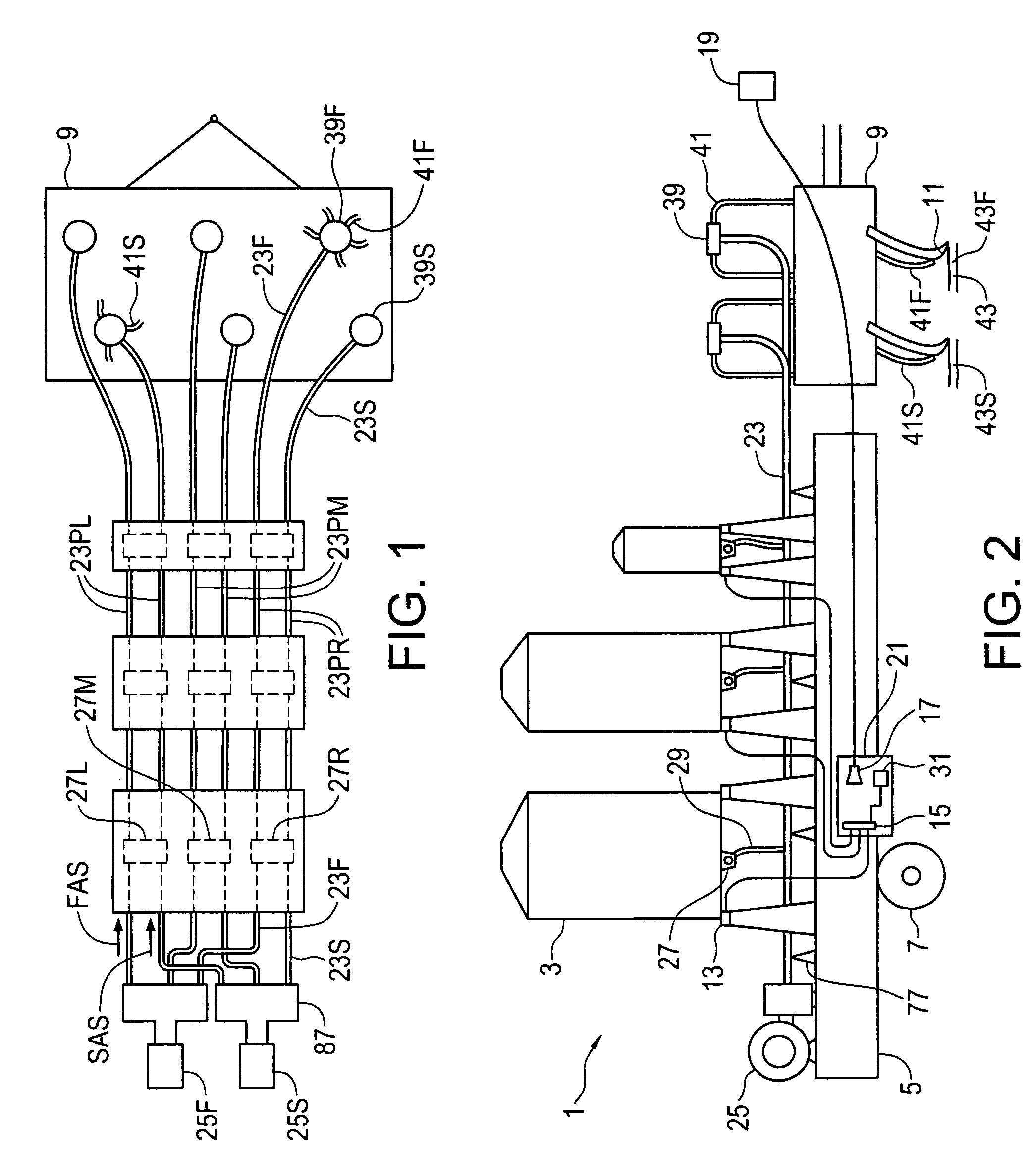

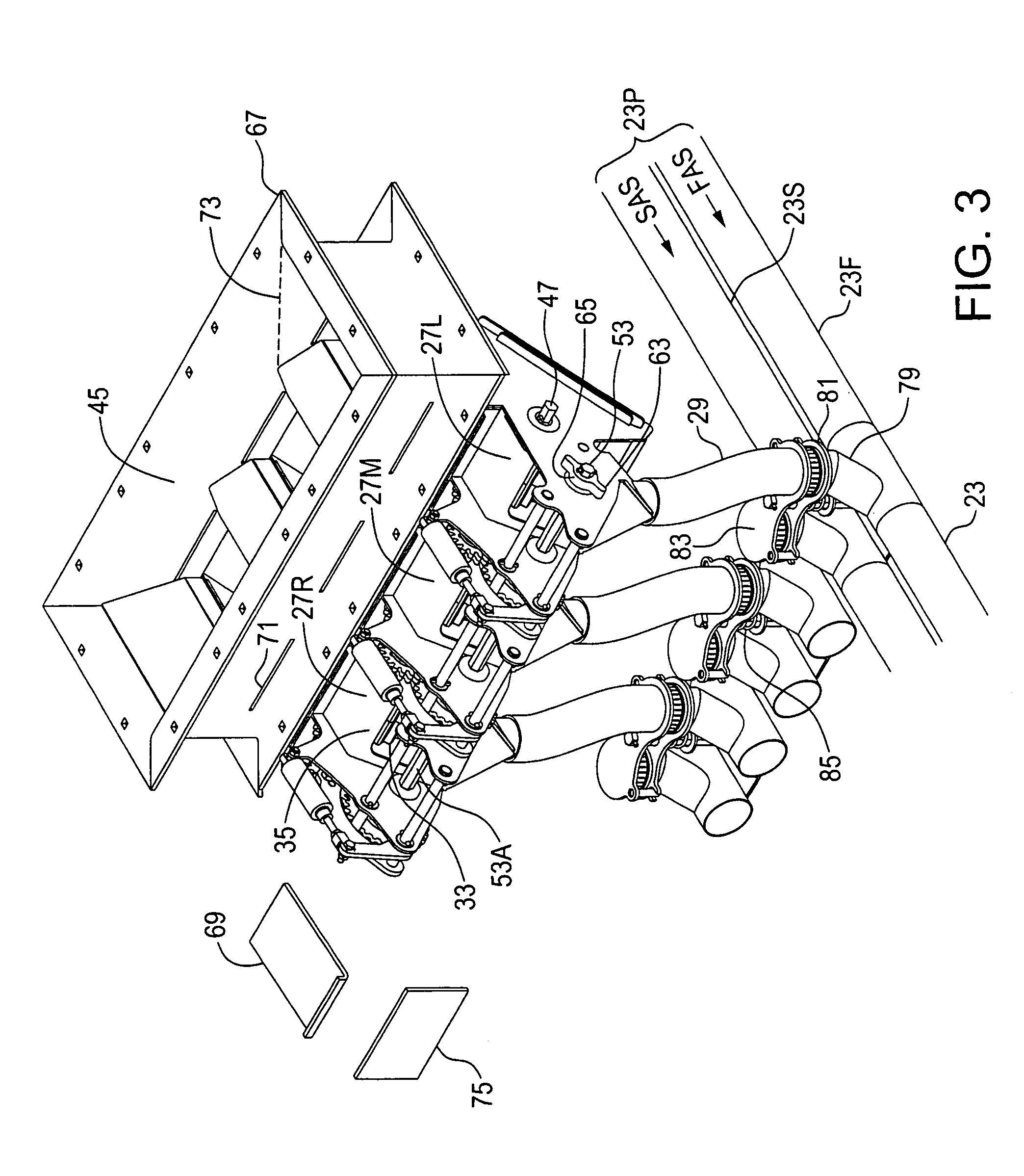

Air seeder tank and distribution apparatus

ActiveUS8733257B2Different pressureDifferent speedFertiliser distributersAgriculture and animal husbandary industryInternal pressureSeeder

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

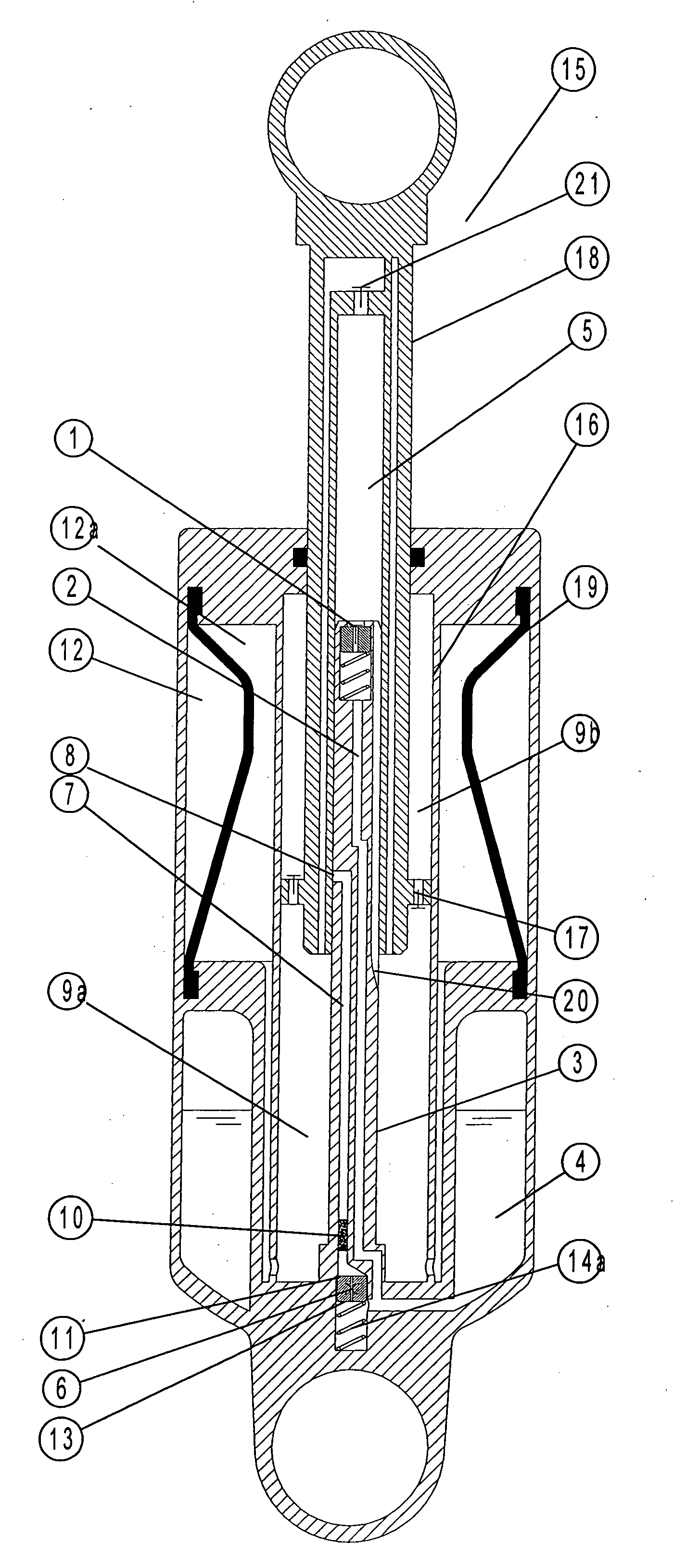

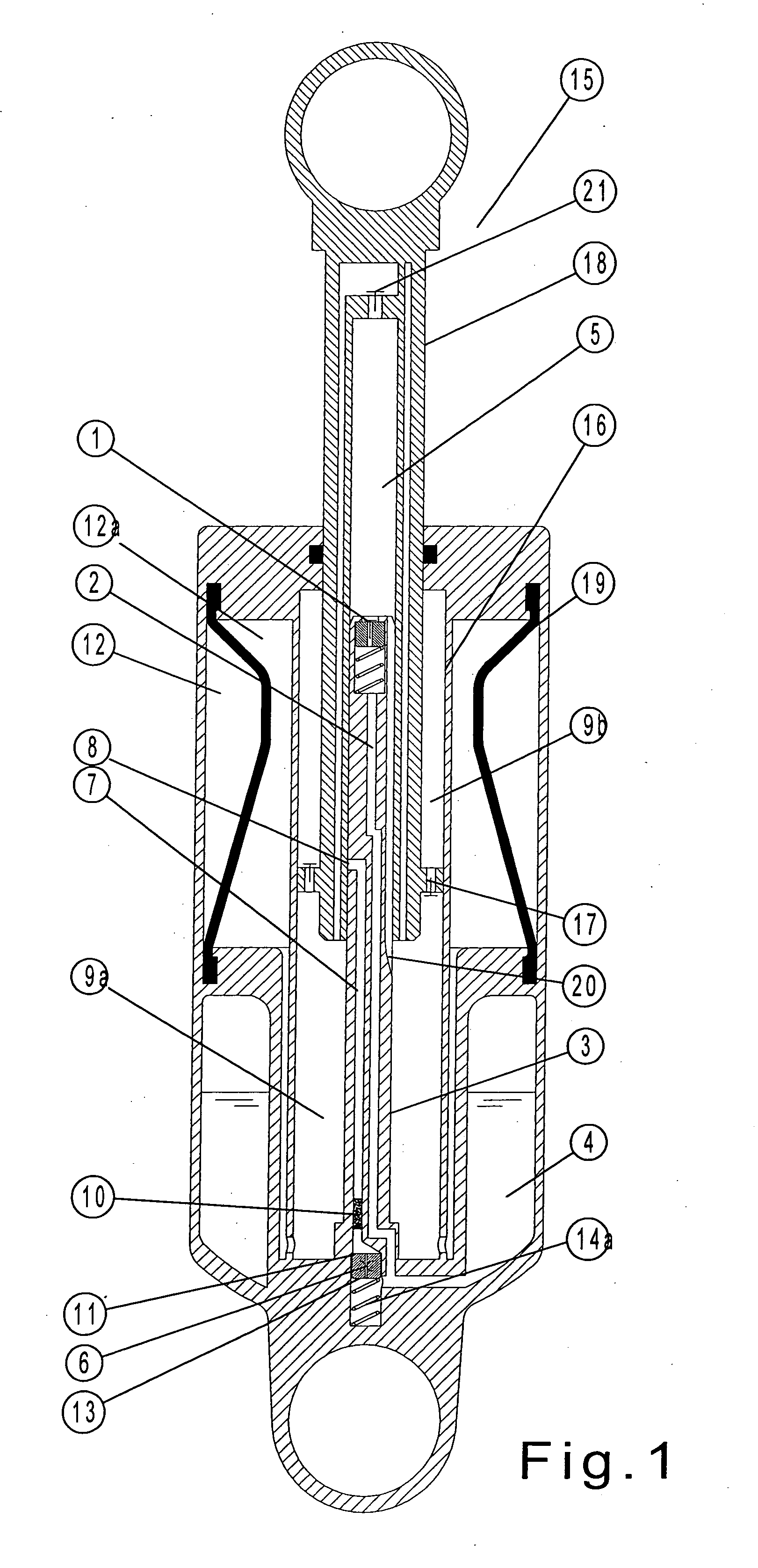

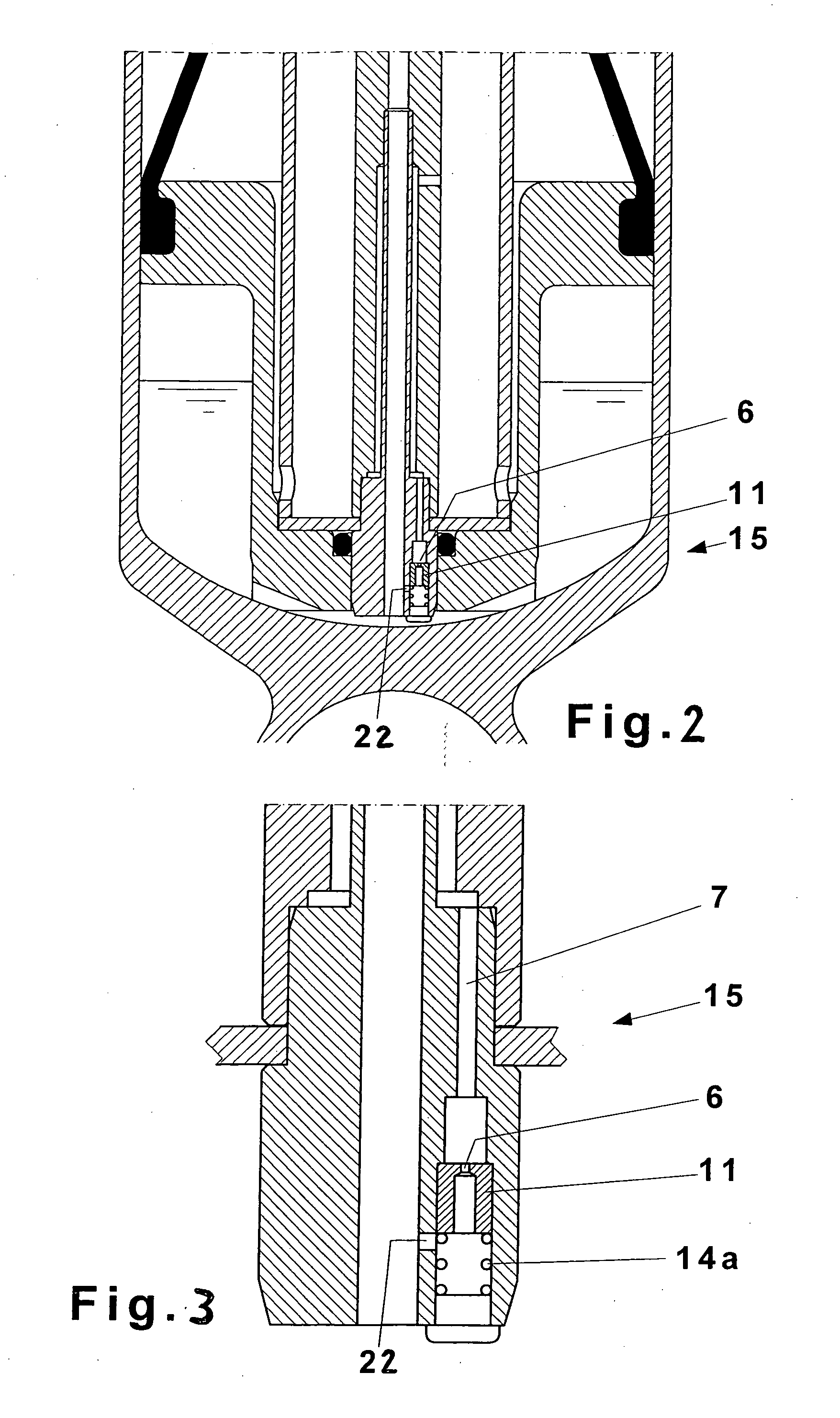

Self-pumping hydropneumatic spring-damper unit

A self-pumping hydropneumatic spring-damper unit with internal leveling control is provided. The spring-damper unit has an oil-filled work cylinder under pressure by gas cushions. A damping piston is displaceable in the work cylinder and arranged at the end of a hollow piston rod whose hollow space serves to receive a pump by means of a pump rod fastened to the work cylinder. Damping medium is sucked out of a reservoir space when the piston rod moves outward and is conveyed into the work space when the piston rod moves inward. The pump rod has a control opening and, at a distance therefrom, an outlet bore for pressure equilibrium between work spaces in the work cylinder. At least one pressure-dependent throttle point is provided in the pump space between the high-pressure and low-pressure gas cushions. A first flow connection in the pump rod provided with at least one check valve connects the low-pressure gas cushion to the pump space. A second flow connection having the throttle point is connected to the work space by the outlet bore.

Owner:ZF FRIEDRICHSHAFEN AG

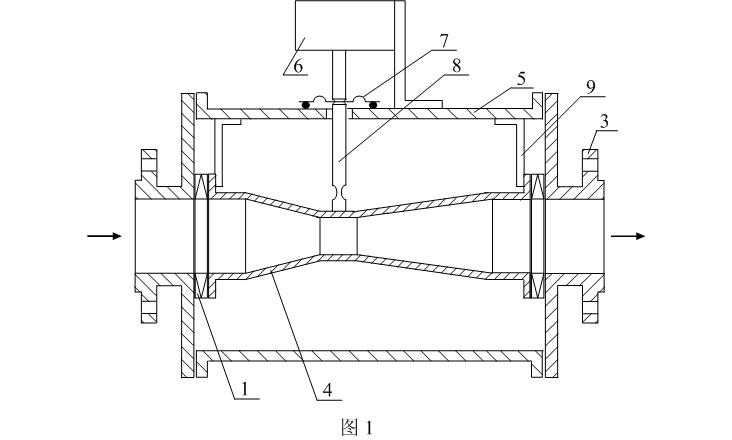

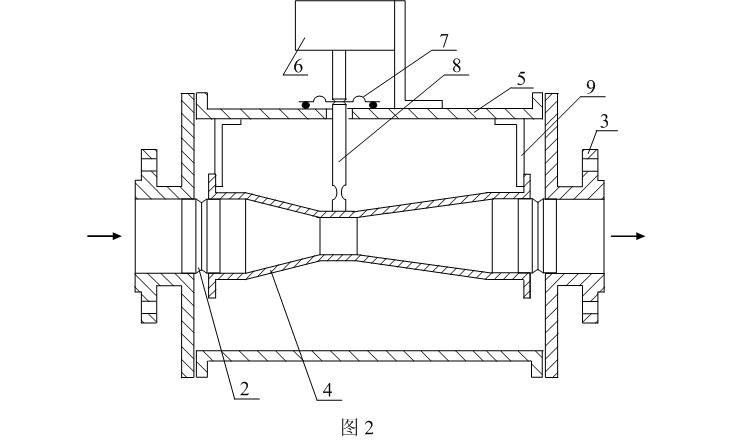

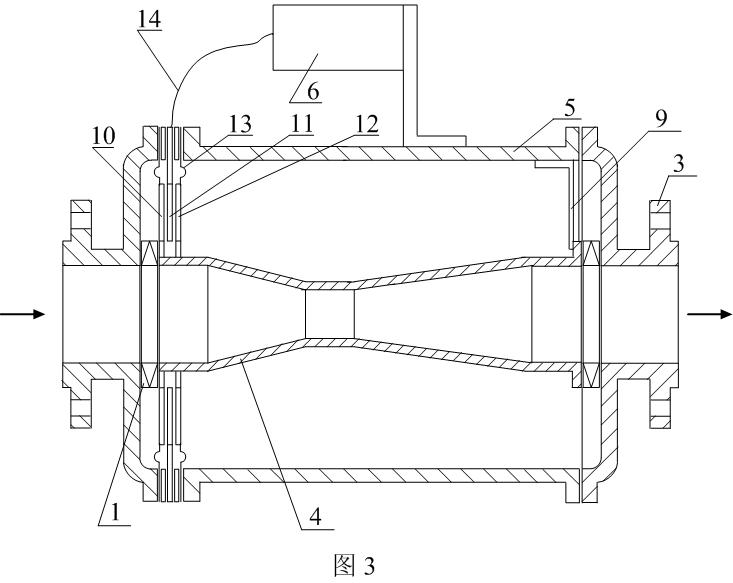

In-built middle through-hole dynamic throttling element flow meter

ActiveCN102620776ALittle flow resistance lossEasy to useVolume/mass flow by differential pressureFlow resistivityDifferential pressure

The invention discloses an in-built middle through-hole dynamic throttling element flow meter, belonging to the technical field of automatic detection of a throttling flow meter. The flow meter is characterized in that an in-built middle through-hole dynamic throttling element is adopted; the internal and external pressures of the dynamic throttling element are balanced; the measured fluid pressure is born by a flow meter pressure hull, thus, a thin wall thick dynamic throttling element can be used; the main boy of an anti-blocking mechanism is a flexible filter medium or a filter membrane with a simple structure; compared with the used pore plates of a differential pressure flow meter, the flow meter provided by the invention mainly uses a dynamic venturi tube; the venturi tube has the advantages of small flowing resistance loss, long service life, high precision, and the tube is hard to block and the like. The flow meter provided by the invention is simple in structure, easiness in manufacturing, high in performance cost ratio, less in energy consumption for measurement, thus, the flow meter can be used for measuring the flow of small pipe diameter and dirty fluid, and has a development prospect for replacing differential pressure flow meters and partial small pipe diameter ultrasonic flow meters.

Owner:YANGZHOU HONGWEI MASCH EQUIP CO LTD

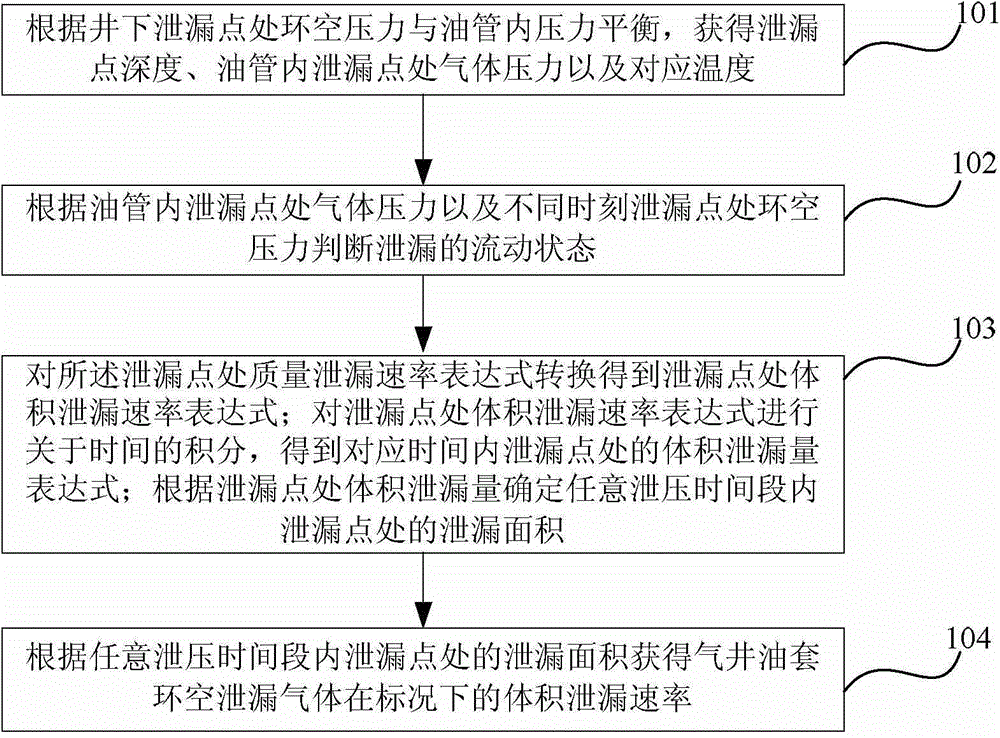

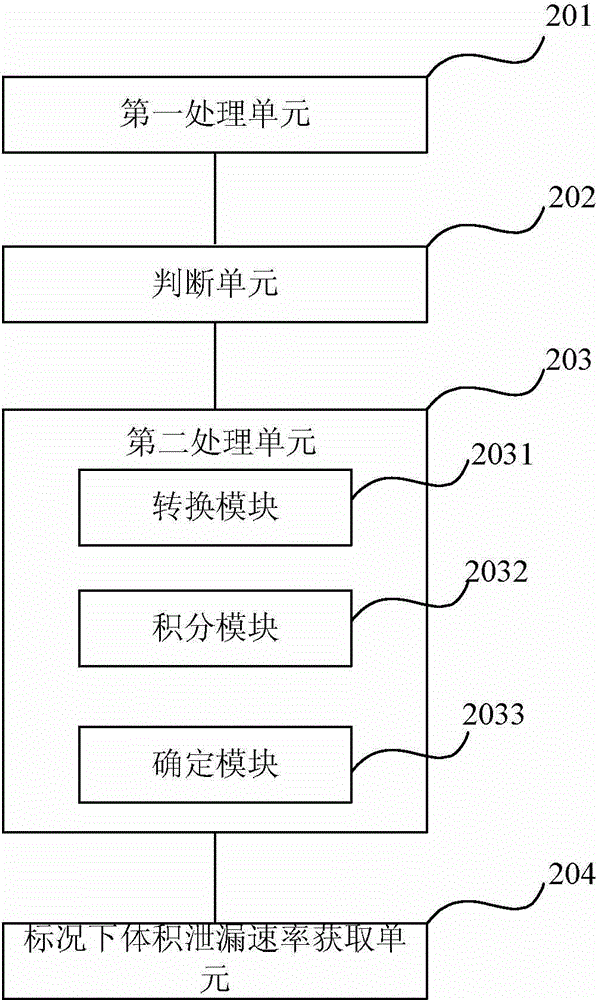

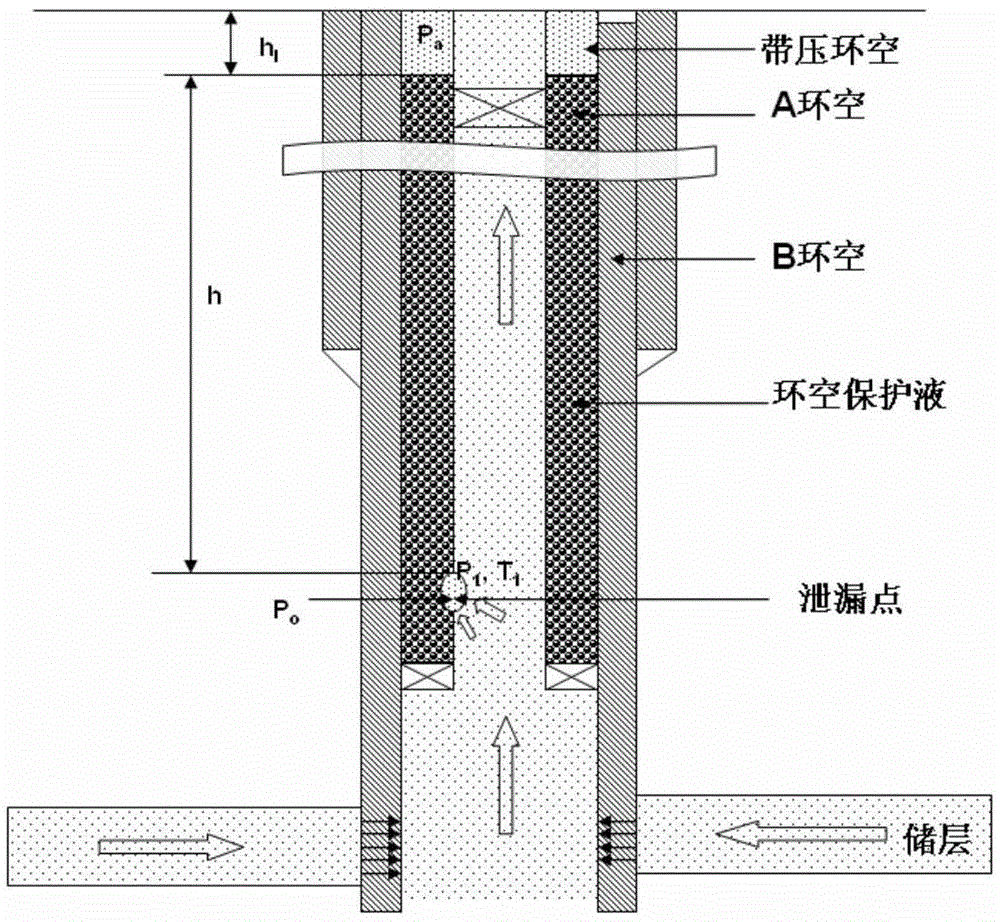

Method and device for obtaining volume leakage speed under standard condition of gas well

The invention relates to a method and a device for obtaining the volume leakage speed under the standard condition of a gas well, wherein the method comprises the following steps that: the depth of a leakage point, the gas pressure at the leakage point in an oil pipe and the corresponding temperature are obtained according to a condition that the annular pressure in the position of the leakage point under the well is balanced with the pressure in the oil pipe; the flowing state of the leakage is judged according to the gas pressure at the leakage point in the oil pipe and the annular pressure in the position of the leakage point in different moments; a mass leakage speed expression in the position of the leakage point is converted to obtain a volume leakage speed expression in the position of the leakage point; the volume leakage speed expression in the position of the leakage point is subjected to time integration to obtain a volume leakage speed expression in the position of the leakage point in the corresponding time; the leakage area of the position of the leakage point in the corresponding time is obtained; the leakage area of the position of the leakage point in any pressure relief time period is determined according to the volume leakage speed in the position of the leakage point; and the volume leakage speed of the gas well oil jacket annular leakage gas under the standard condition is obtained according to the leakage area of the position of the leakage point in any pressure relief time.

Owner:PETROCHINA CO LTD

Pressure equalizing equipment housing

A pressure equalizing housing may be used to house equipment (e.g., one or more mechanical and / or electronic devices). The pressure equalizing housing may include a pressure equalization device to provide pressure equalization between an internal pressure inside of the housing and an ambient pressure outside of the housing. The pressure equalization prevents relatively humid air outside of the housing from passing into the housing and thus prevents or substantially minimizes condensation inside of the housing.

Owner:SENSORMATIC ELECTRONICS CORP

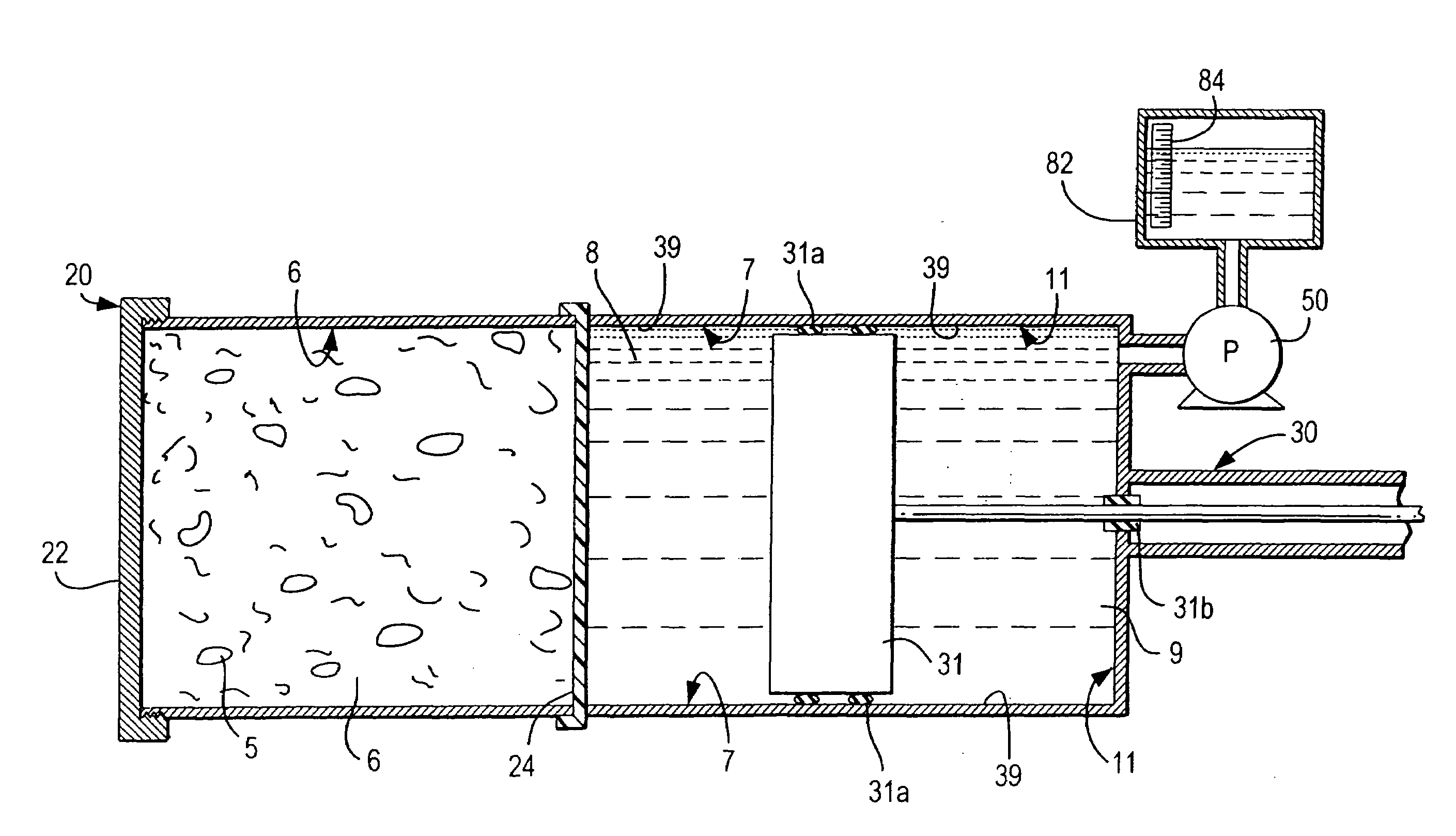

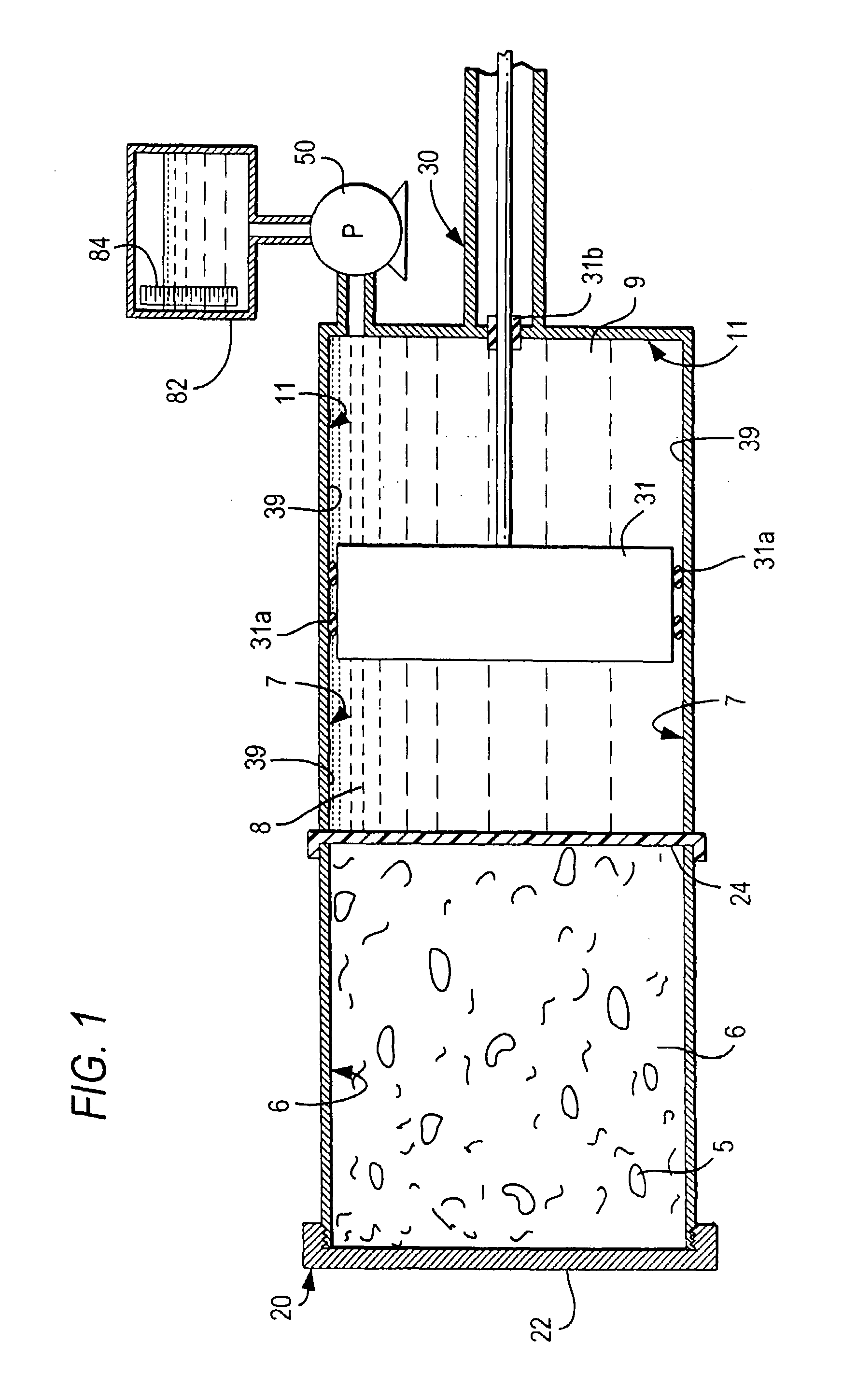

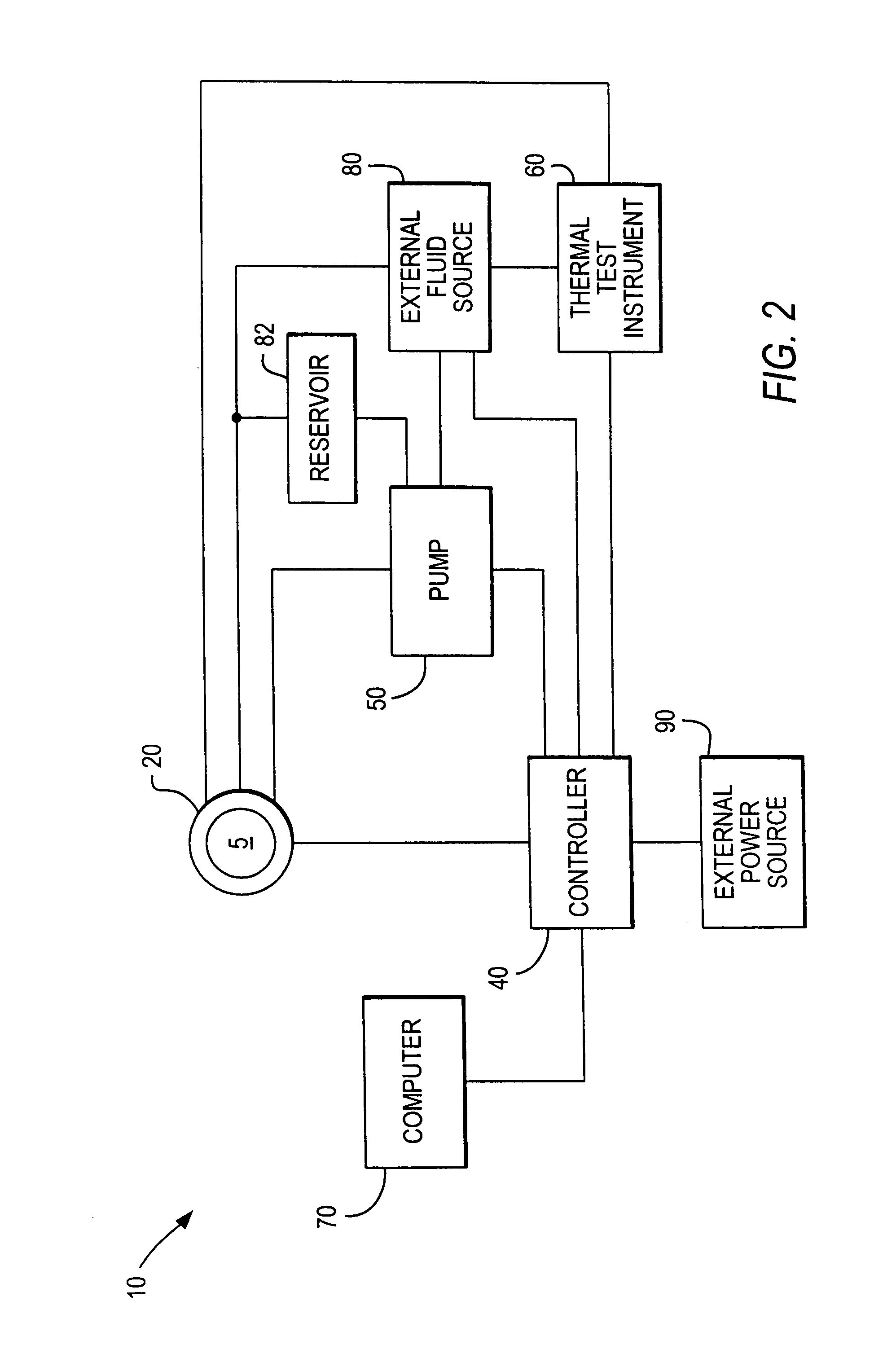

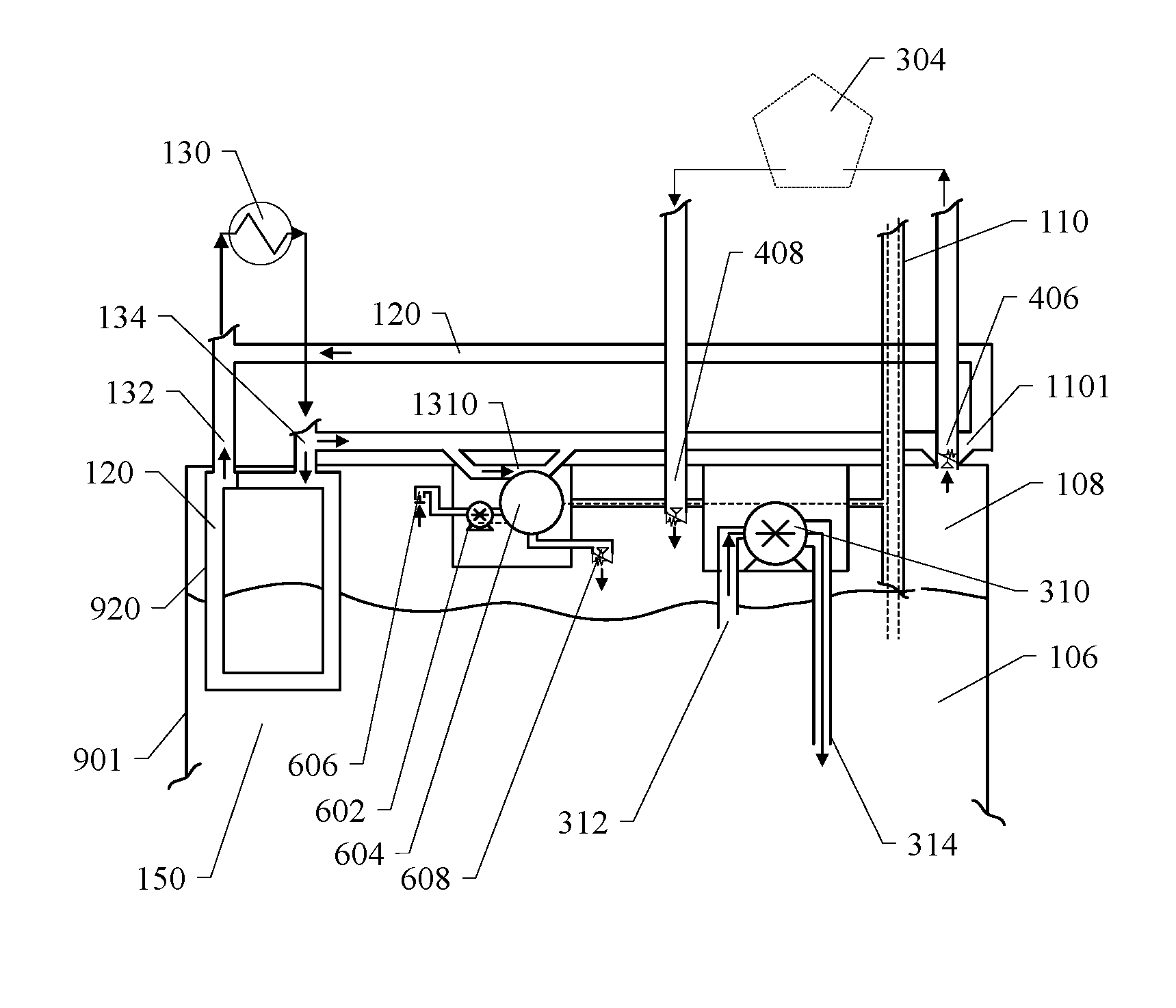

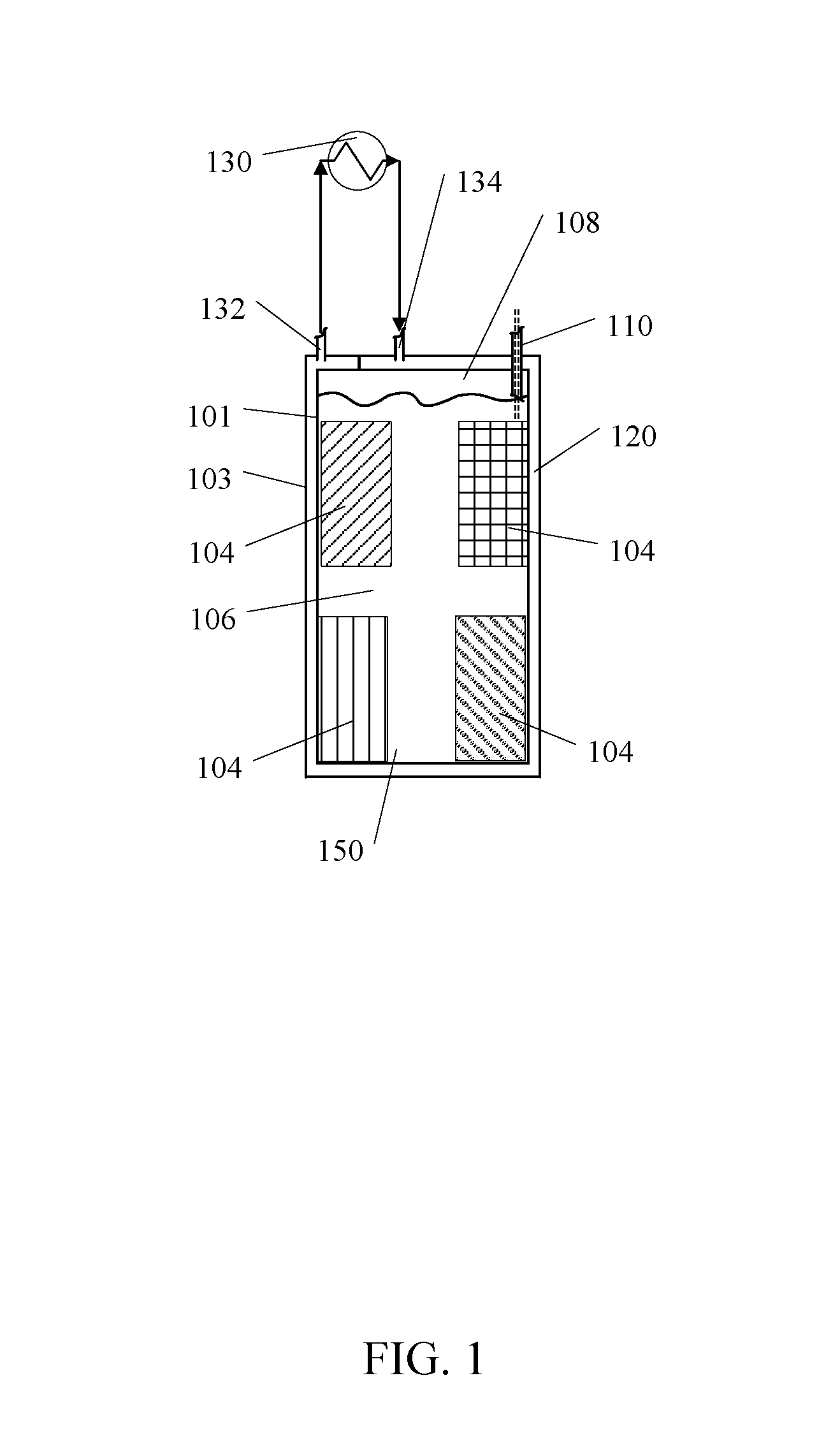

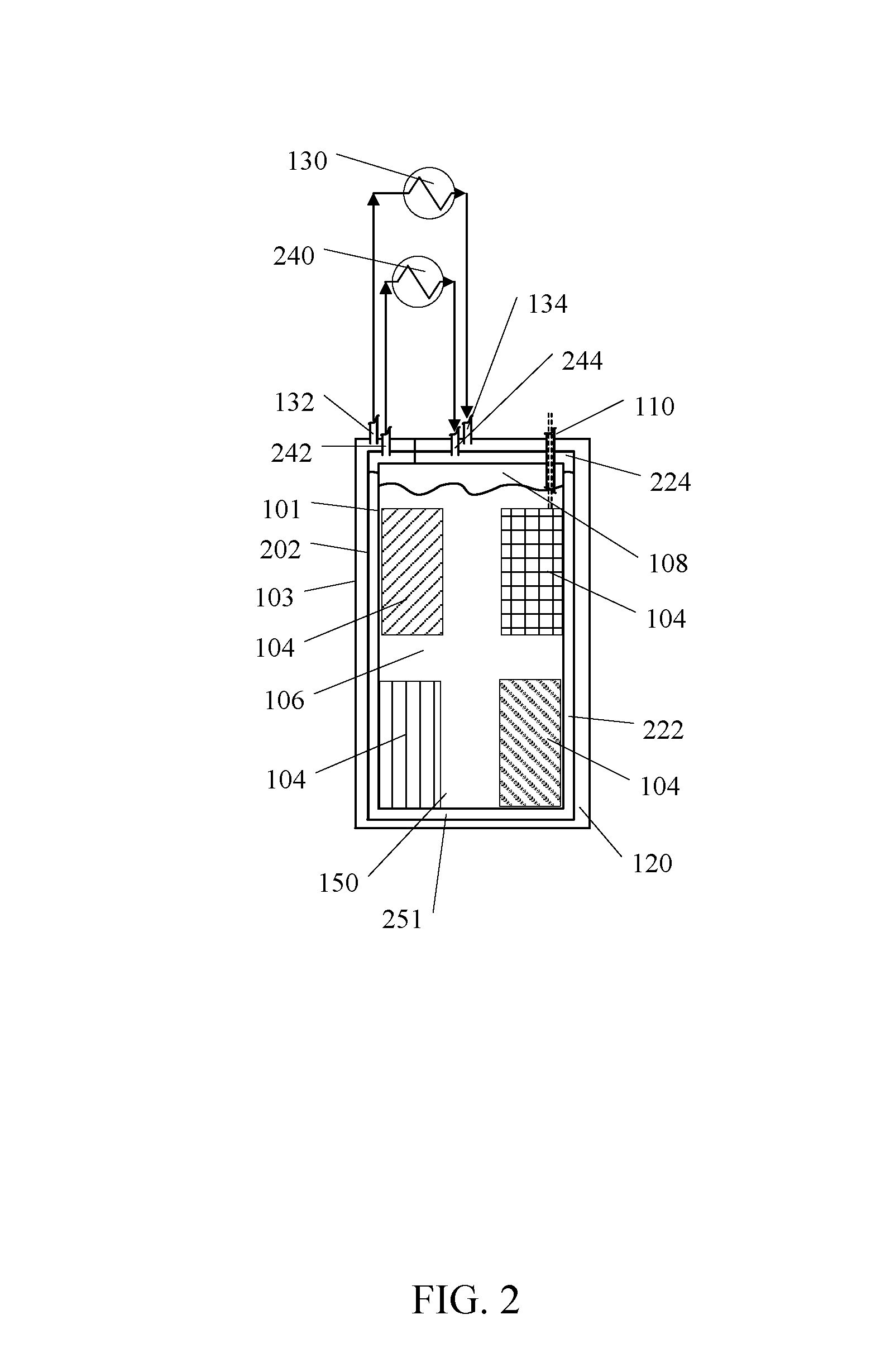

System and method for fluid cooling of electronic devices installed in a sealed enclosure

ActiveUS9408332B2Effective and efficient directHigh degreeDigital data processing detailsCooling/ventilation/heating modificationsPropellerMulti phase

Owner:SMITH DAVID LANE

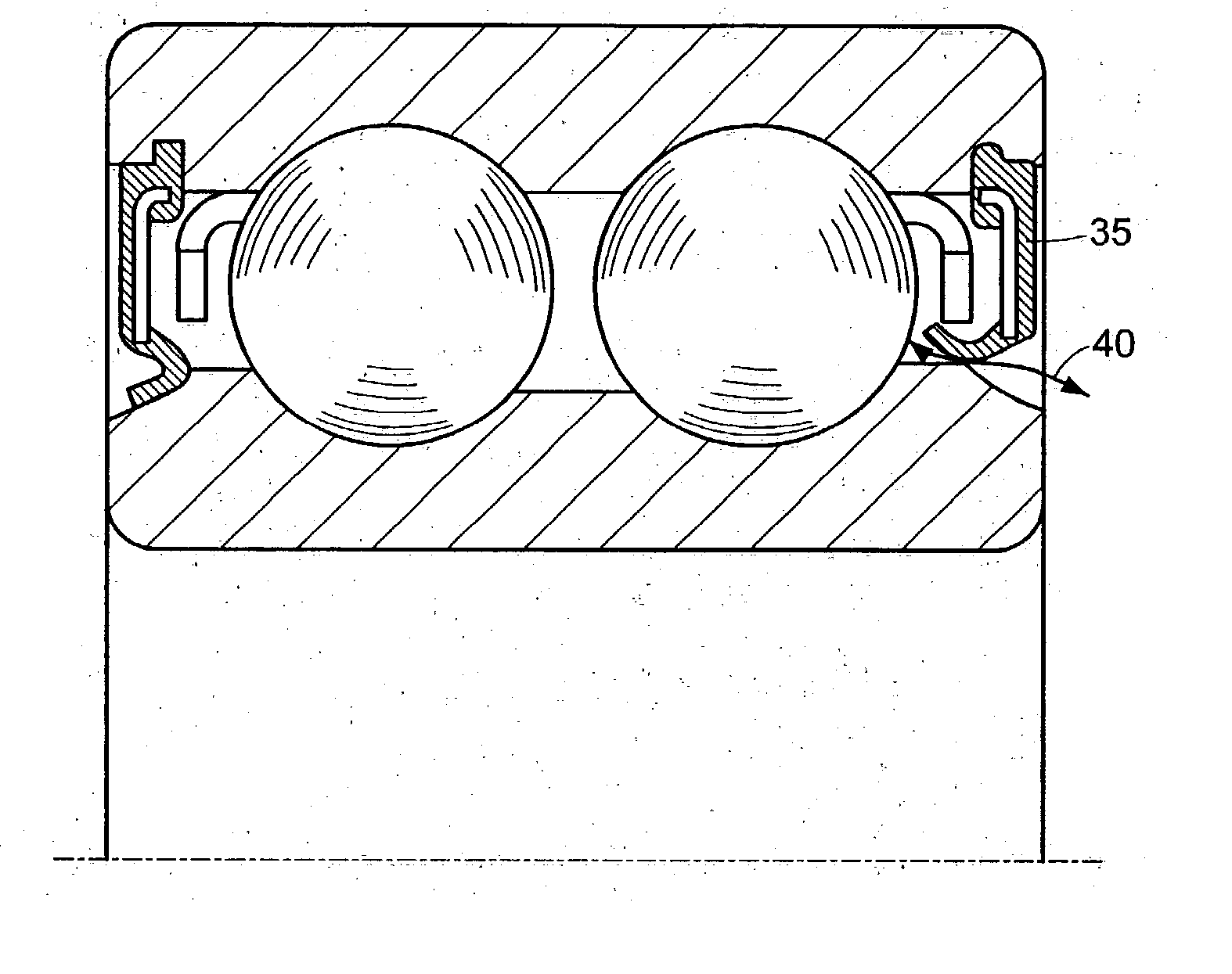

Internal Leakage Control and Venting for ABS Unit

InactiveUS20060099090A1Convenient ArrangementSimple machiningPositive displacement pump componentsPiston pumpsMotor driveEngineering

A housing block for a hydraulic unit of a vehicle brake system that retaining a piston pump and an eccentric element that rotates the piston. A motor drives the eccentric element within an eccentric chamber. The block has a cylindrical cavity within a hydraulic leakage reservoir and a fluid leakage path that begins near a lower most portion of the eccentric element chamber and extends to a cylindrical cavity by way of a passage defined by an intersection of the eccentric chamber and cylindrical cavity. A pressure equalization path extends from the eccentric chamber upwardly to a point intermediate the housing block and motor enclosure and into the motor enclosure to a location that is substantially above the eccentric chamber. A seal intermediate the motor enclosure and housing block is formed as a closed curve of mastic material encircling the motor shaft, eccentric chamber, hydraulic leakage reservoir hydraulic fluid leakage path, and pressure equalization path.

Owner:ROBERT BOSCH CORP

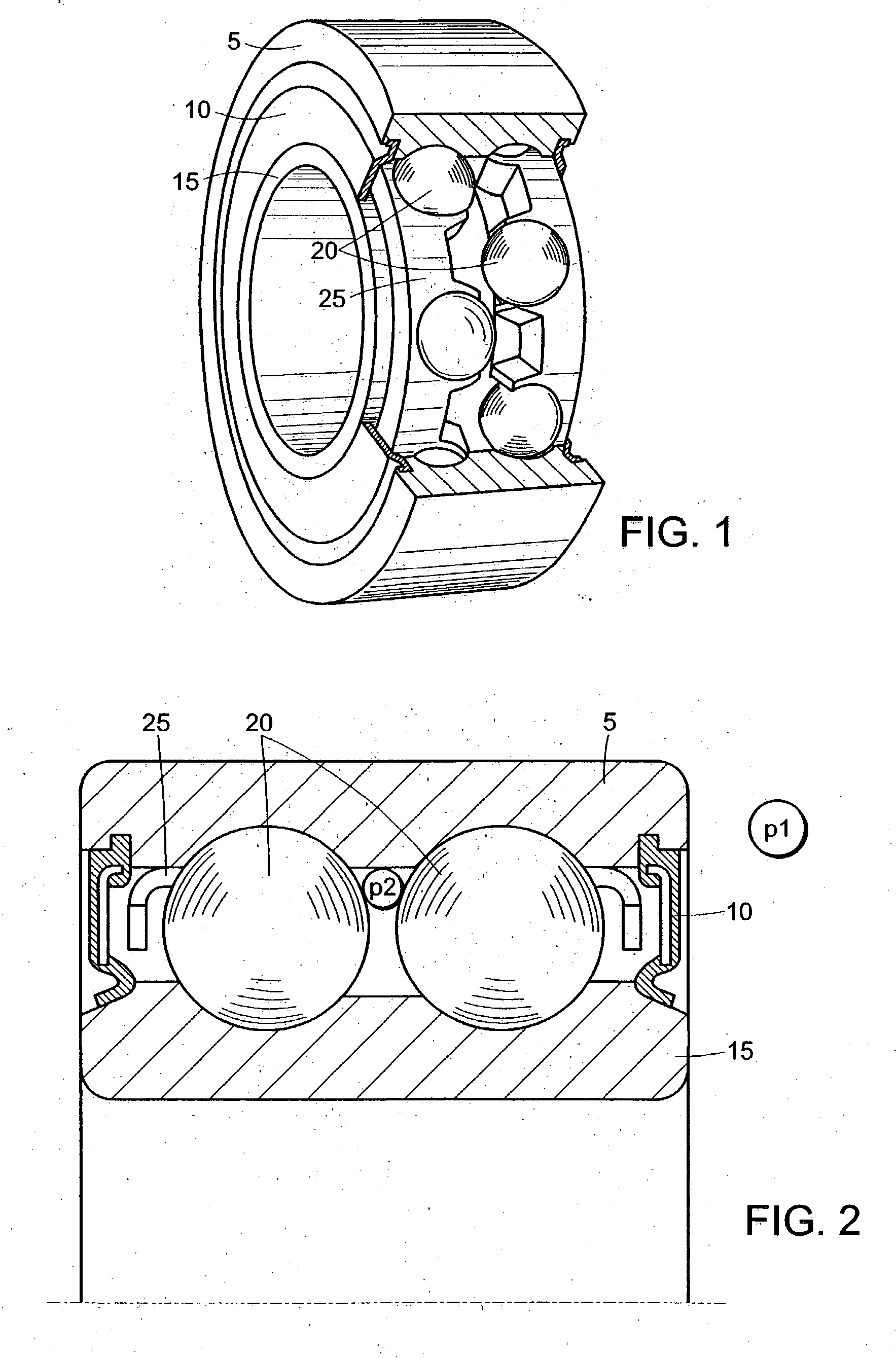

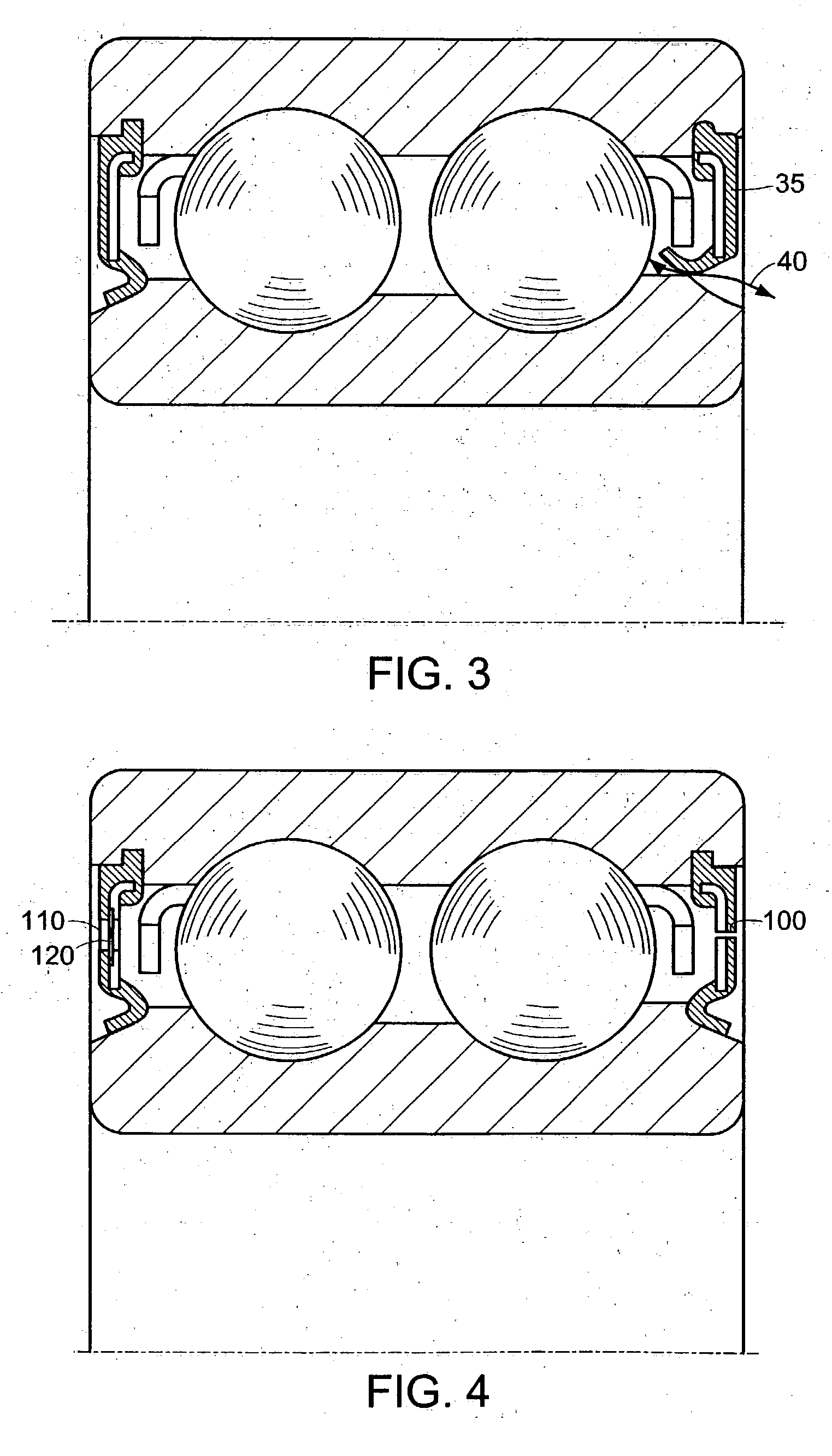

Method and device for bearing seal pressure relief

InactiveUS20050008272A1Equalize more quicklyPressurized more rapidlyBall bearingsBearing componentsEngineeringViscosity

An improvement to a sealed bearing allowing the pressure between the interior and exterior of a sealed bearing in a pressurized vessel, such as a Stirling engine, to equalize quickly. The device includes a small pressure relief hole in the bearing seal. The relief hole allows the pressure to equalize as the engine is pressurized, avoiding damage to the seal. The hole is sized so that the viscosity of the lubricant prevents leakage through the hole. Alternatively, the device may include lip seals that deform to allow the pressure to equalize.

Owner:NEW POWER CONCEPTS

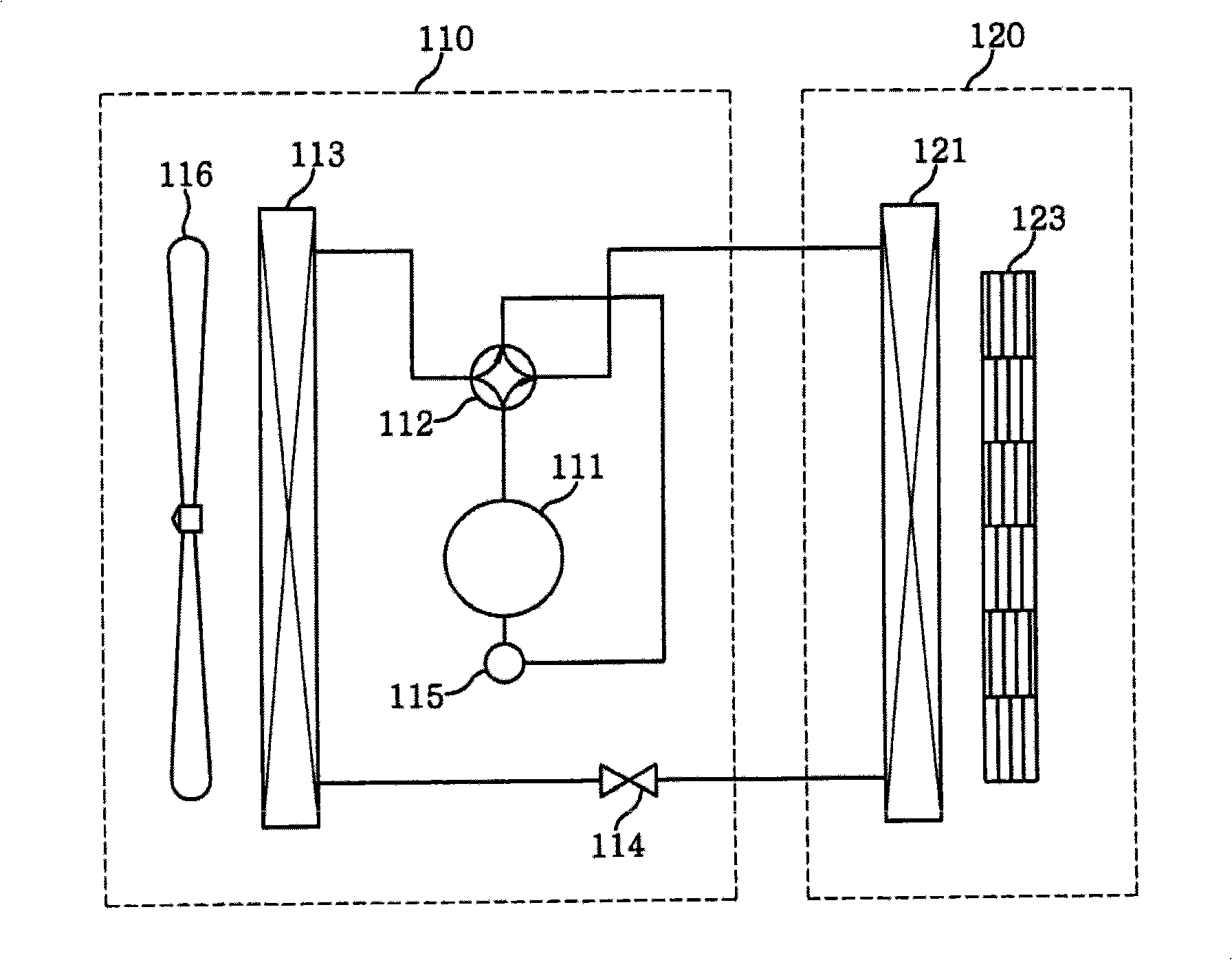

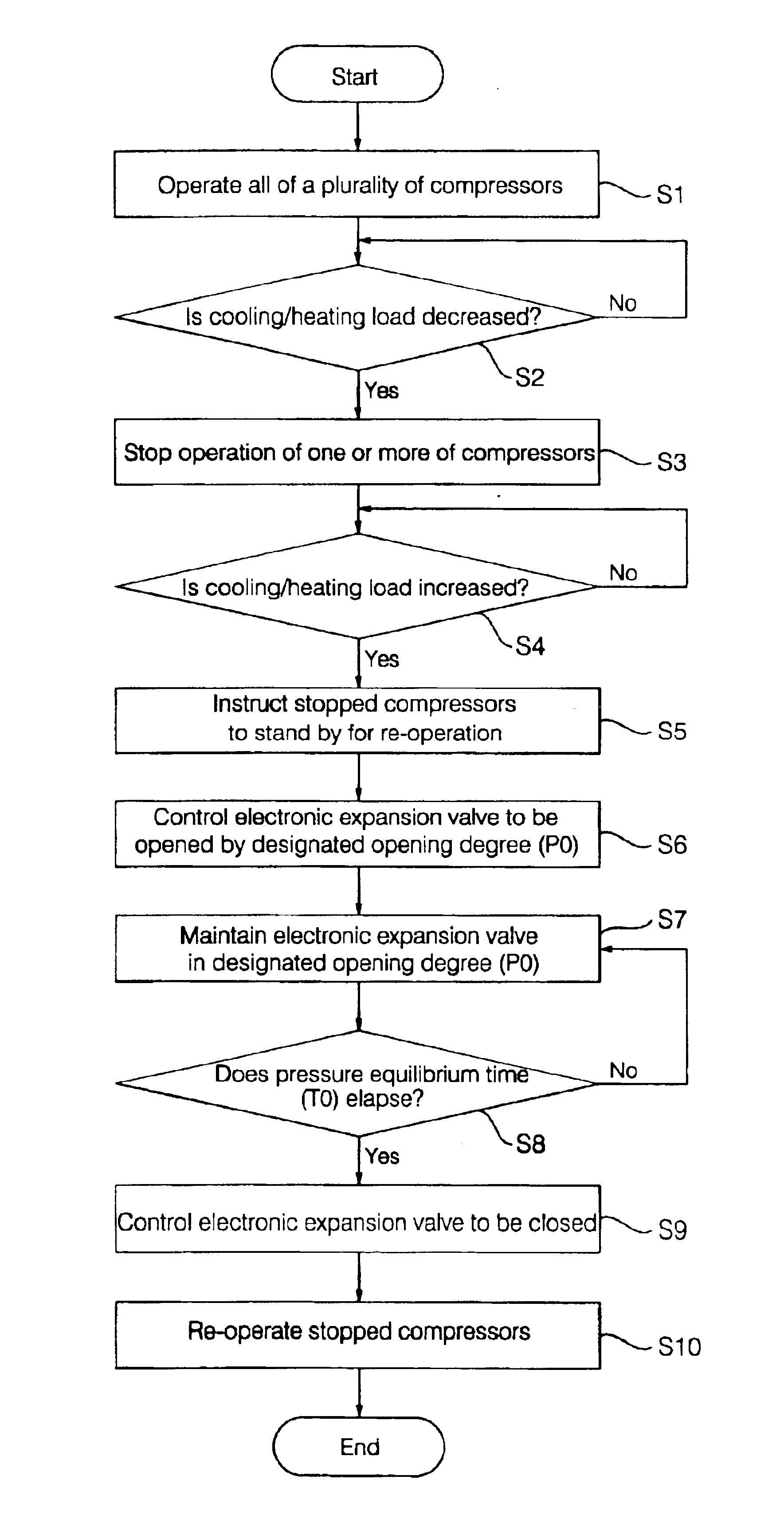

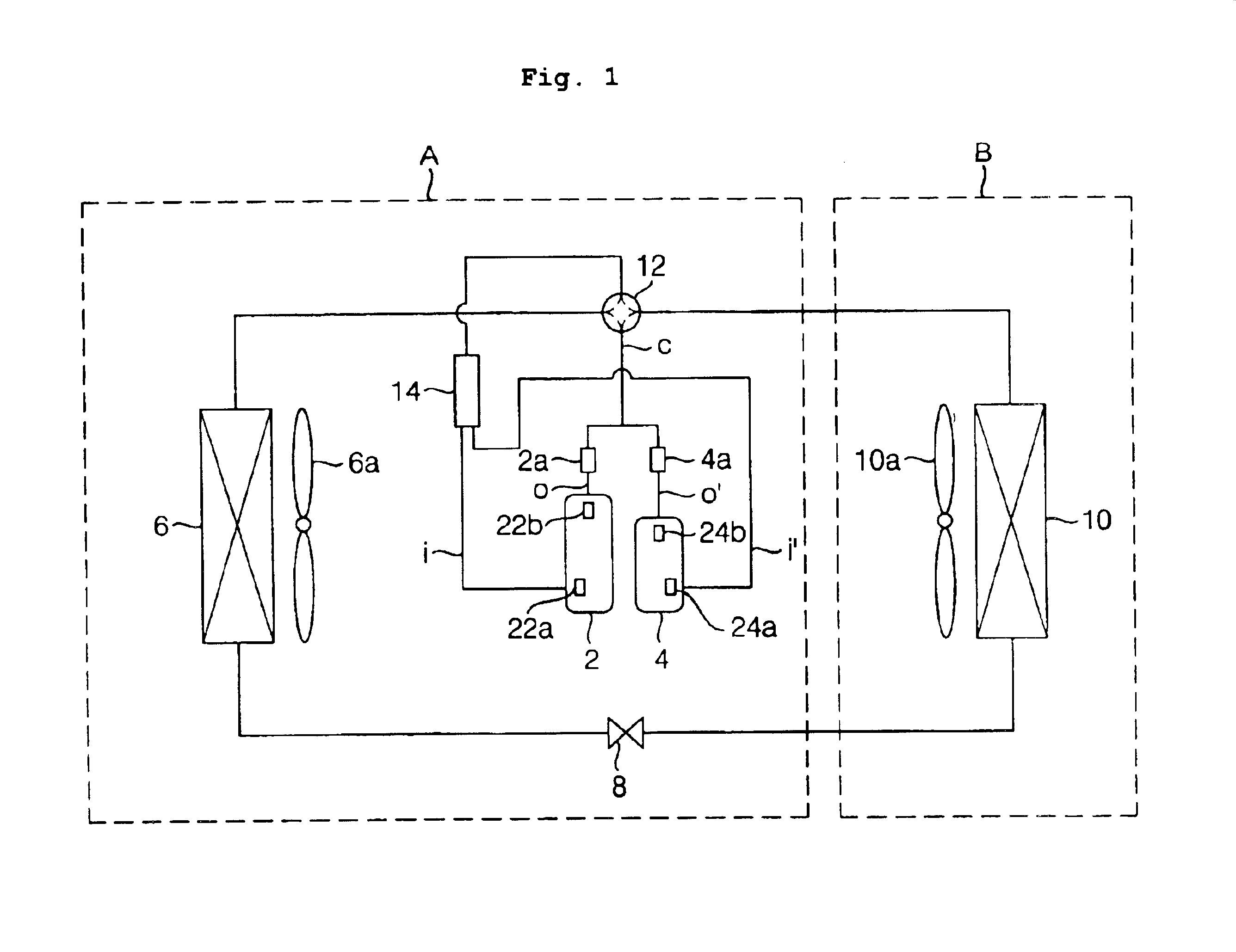

Air conditioner and method for controlling electronic expansion valve of air conditioner

ActiveUS6843067B2Reduce time spentReduce noiseMechanical apparatusHeat pumpsEngineeringPressure equilibrium

Disclosed are an air conditioner for cooling or heating air in a room by compressing, condensing, expanding and evaporating a refrigerant, and a method for controlling an electronic expansion valve of the air conditioner. The air conditioner includes a plurality of compressors, for compressing a refrigerant, of which one or more are operated so that refrigerant compression capacity is variably changed according to the variation of a cooling / heating load; and an electronic expansion valve adapted to control the refrigerant compression capacity. The electronic expansion valve controls the flow rate of the refrigerant after one or more of the compressors are stopped, thereby rapidly achieving the pressure equilibrium at inlet and outlet pipes of the stopped compressor(s), shortening a time taken to allow the stopped compressor(s) to be re-operated, and improving reliability in operating the compressors.

Owner:LG ELECTRONICS INC

Reservoir capillary pressure curve determinator under high temperature and pressure

InactiveCN102621034AStable pressureSolve the problem of large errorsMaterial analysisPressure curveFluid saturation

The invention provides a reservoir capillary pressure curve determinator under a high temperature and a pressure. The determinator comprises a ring pressure system, an injection system, a core clamping system, a semi-permeable baffle plate, a back pressure system, a measuring system, a data automatically collecting and processing system, and a thermostat which are connected through pipelines. A semi-permeable baffle plate method is adopted to measure capillary pressure curves under a stratum condition, and the basic rationale is that a principle of balance between an impressed pressure and the capillary pressure is used to measure the capillary pressure curves under the high temperature and the pressure. Core saturated wetting phase fluid displaces a wetting phase with a nonwetting phase under a certain displacement pressure. When the impressed pressure overcomes the capillary pressure of a certain capillary in the core, the wetting phase fluid in the capillary is discharged gradually, and the wetting phase fluid saturation in the core is reduced. Pressure is increased stepwise, accumulated discharged quantity of the wetting phase fluid when the wetting phase fluid is no longer discharged and an injection pressure are measured, and the capillary pressure curves can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pressure equalization element, housing comprising a pressure equalization element, lithium ion accumulator and motor vehicle

ActiveUS20140079964A1Avoid enteringReduce pressureCell seperators/membranes/diaphragms/spacersBattery isolationLithiumEngineering

A pressure equalization element for a housing includes a water-impermeable membrane. The membrane is combined with either a pressure relief valve acting in two directions or with a corresponding combination of two pressure relief valves such that a volume of air exchange is reduced. An amount of moisture transported into the housing is thus also reduced.

Owner:ROBERT BOSCH GMBH +1

Method for removing gas well accumulated liquid by means of oil jacket pressure balancing method

InactiveCN104790916AReduce dosageThe technology is applicable to a wide range of well conditionsConstructionsFluid removalLiquid ratioFoaming agent

The invention belongs to the technical field of water drainage and gas recovery of a gas well, and particularly provides a method for removing gas well accumulated liquid by means of the oil jacket pressure balancing method. The method mainly comprises the steps of bottom hole accumulated liquid diagnosis, formation pressure prediction, flow inducing with the oil jacket balancing method, foam drainage and the like. The feasibility of the technique is determined through accumulated liquid diagnosis and formation pressure prediction. Liquid in a well and foaming agents can be well mixed through accumulated liquid flowing caused by the oil jacket balancing method, and liquid drainage effect is promoted cooperatively. The method is suitable for wells with certain stratum energy and reduced productivity due to liquid accumulation or dead wells. The method is not limited by well deflection, gas-liquid ratio, ground environment and the like and has the advantages of being simple, economical and practical.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Diaphragm actuated pressure relief valve with pressure balanced outlet and fail-safe operation

InactiveUS6173736B1Operating means/releasing devices for valvesValve members for absorbing fluid energySafe operationFail-safe

A diaphragm / spring operated pressure relief valve having a sensing passage of substantially the same flow area as the outlet orifice of the valve whereby failure of either diaphragm results in "fail open" configuration with the addition of a sensing inlet shroud located to capture the total pressure at the inlet and channel it to the sensing chamber to allow the valve to relieve full rated capacity in the event the sensing diaphragm is ruptured.

Owner:LIGH J YEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com