Internal Leakage Control and Venting for ABS Unit

a technology of internal leakage control and abs unit, which is applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of inability to form two mutually isolated sub-units (motor and pump) and vehicle accidents with such conventional brake system. , to achieve the effect of simple arrangement and machining of the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

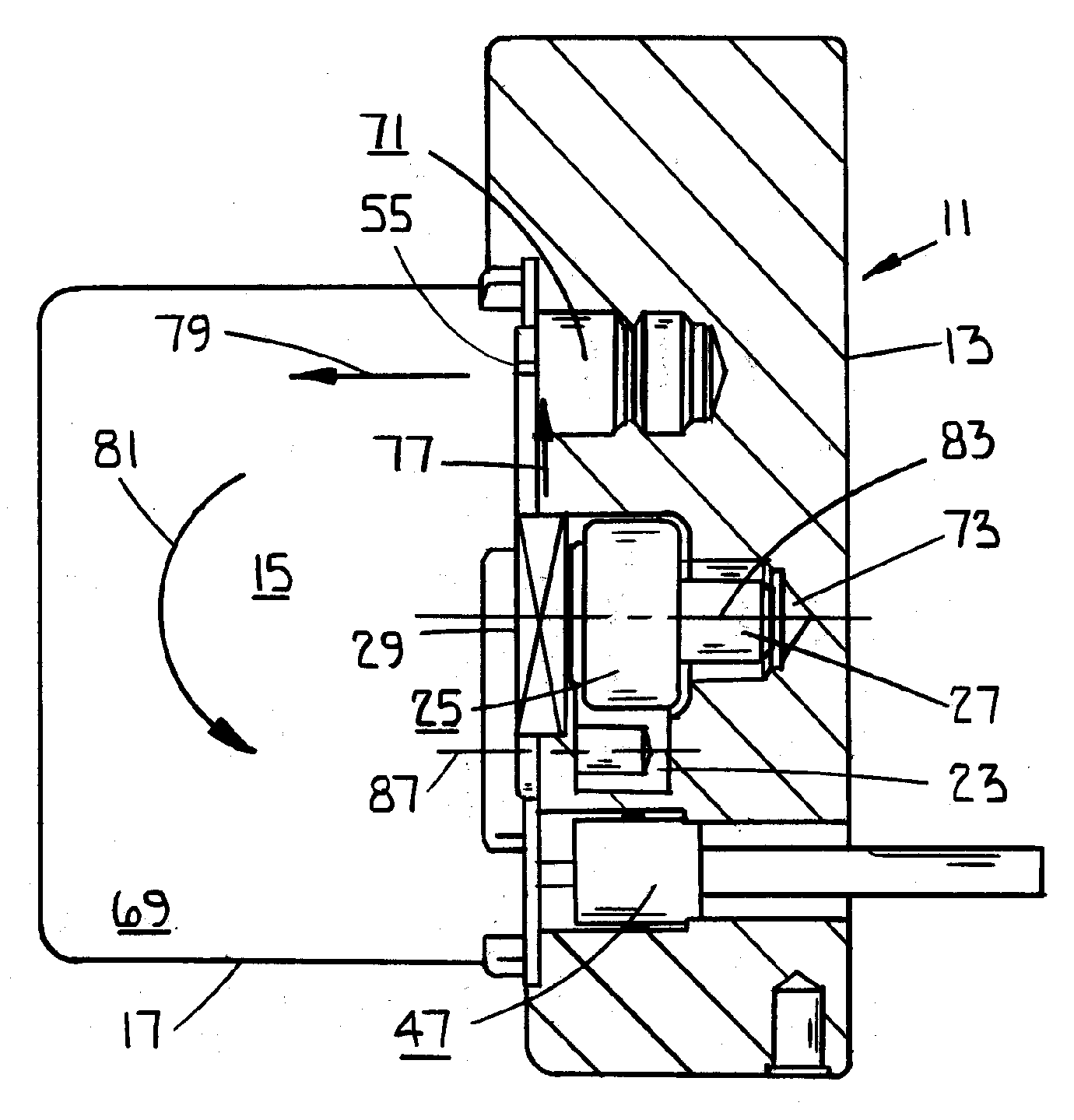

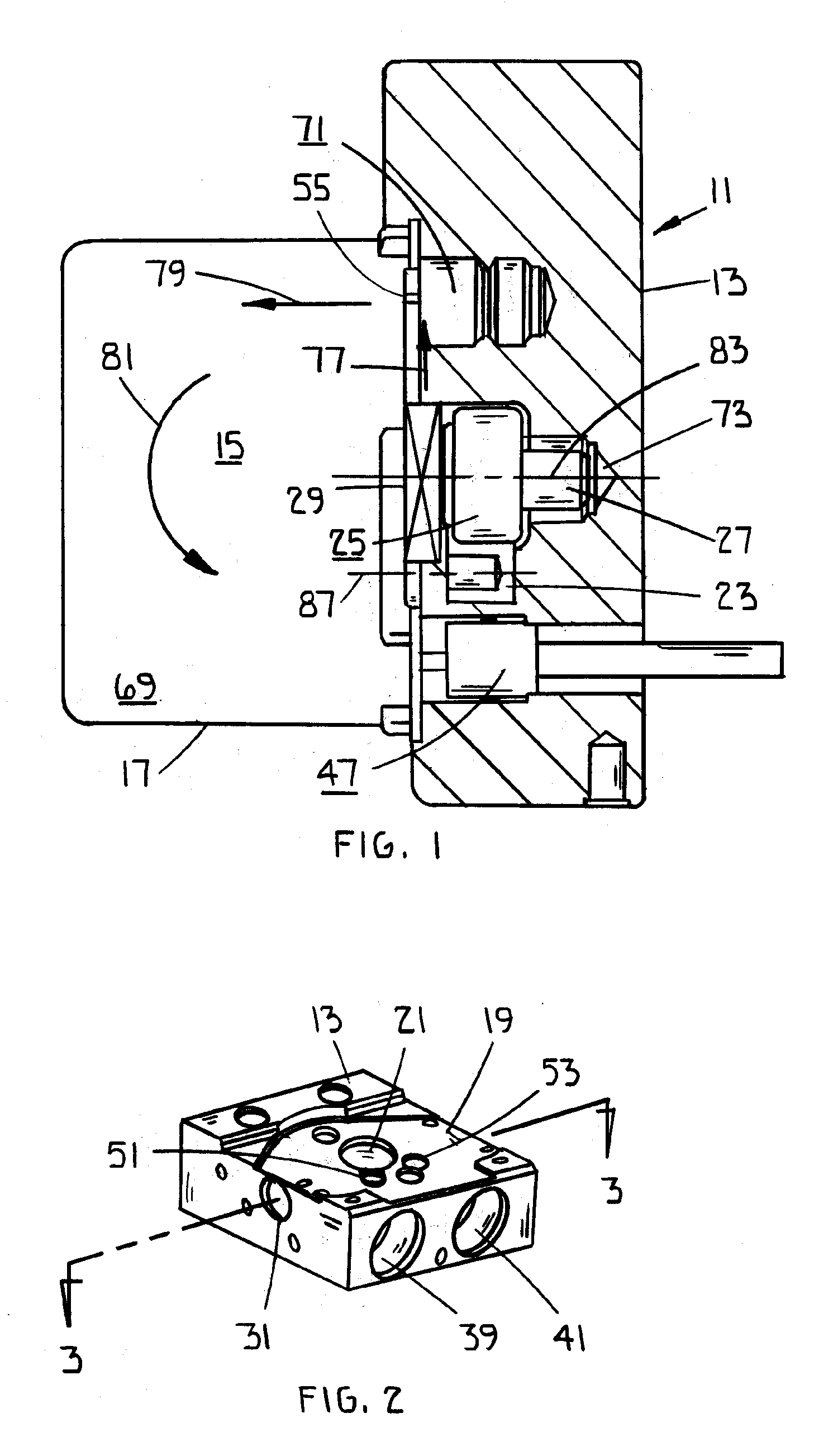

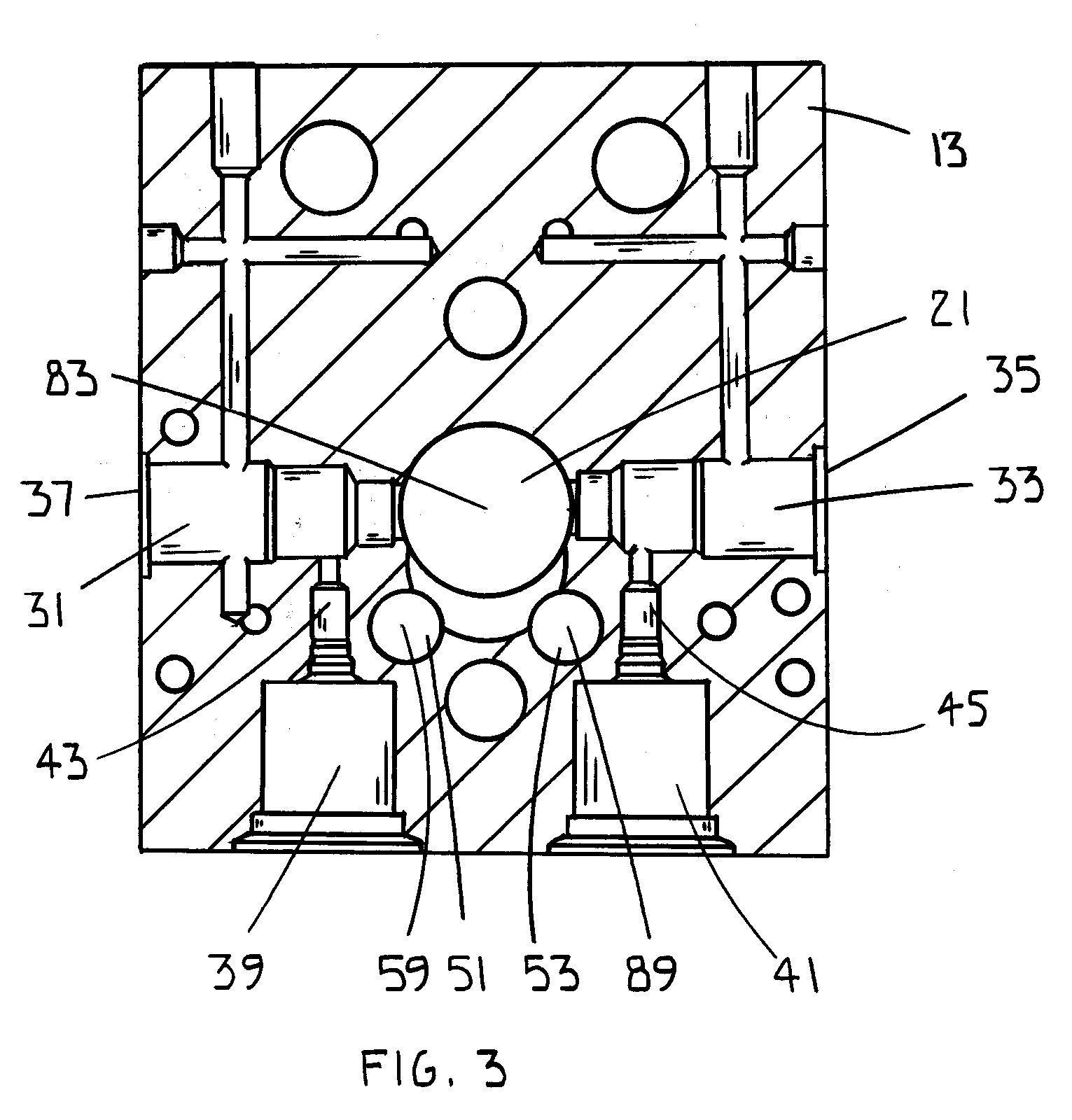

[0023] Referring now to the drawings and particularly to FIG. 1, there is shown a hydraulic unit 11 which includes a pump housing block 13 and, mounted against the housing block 13, a pump driving motor 15, having motor shaft 27 rotatable about axis 83. The motor is positioned within a motor enclosure or covering hood 17. The pump housing 13 has a generally planar securing face 19 for receiving the motor 15 shown in FIGS. 2, 4 and 6. Extending from this securing face 19 in the housing block 13 is a bore 21 communicating with an undercut region 23, which together define an eccentric chamber. An eccentric member 25 is fixed to the driving shaft 27 which shaft passes through a ball bearing 29 that is supported by the stepped bore 21. The eccentric member alternately actuates a pair of pump pistons (not shown) in cylinders 31 and 33. The eccentric member or element 25 may be a cam element, known swash plate, conventional crank shaft and connecting rod configuration, or other cam-like cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com