Reservoir capillary pressure curve determinator under high temperature and pressure

A capillary pressure curve, high temperature and high pressure technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of calculation error, interfacial tension and rock wetting angle cannot be accurately measured, and achieve the effect of solving large errors and maintaining stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

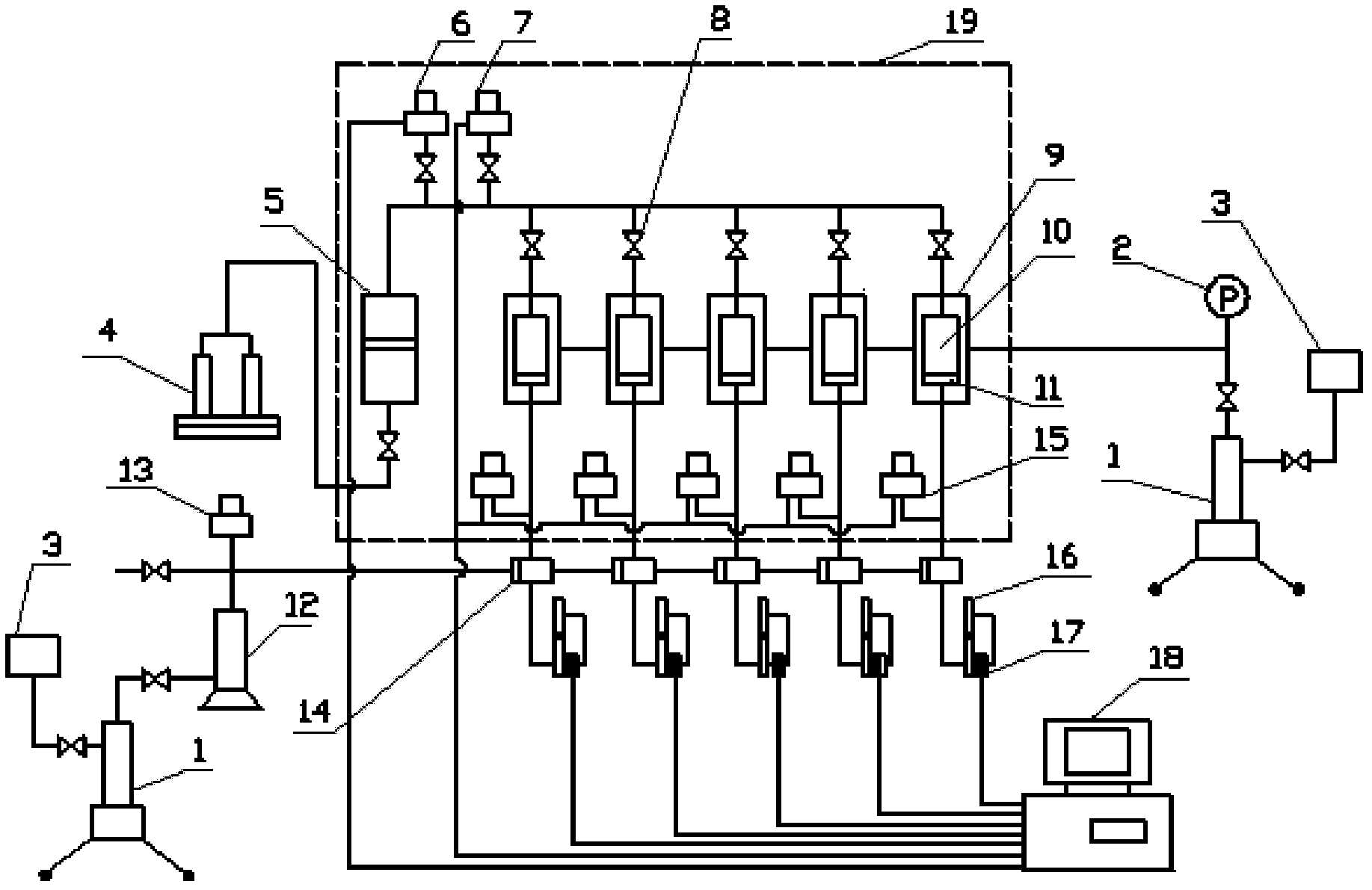

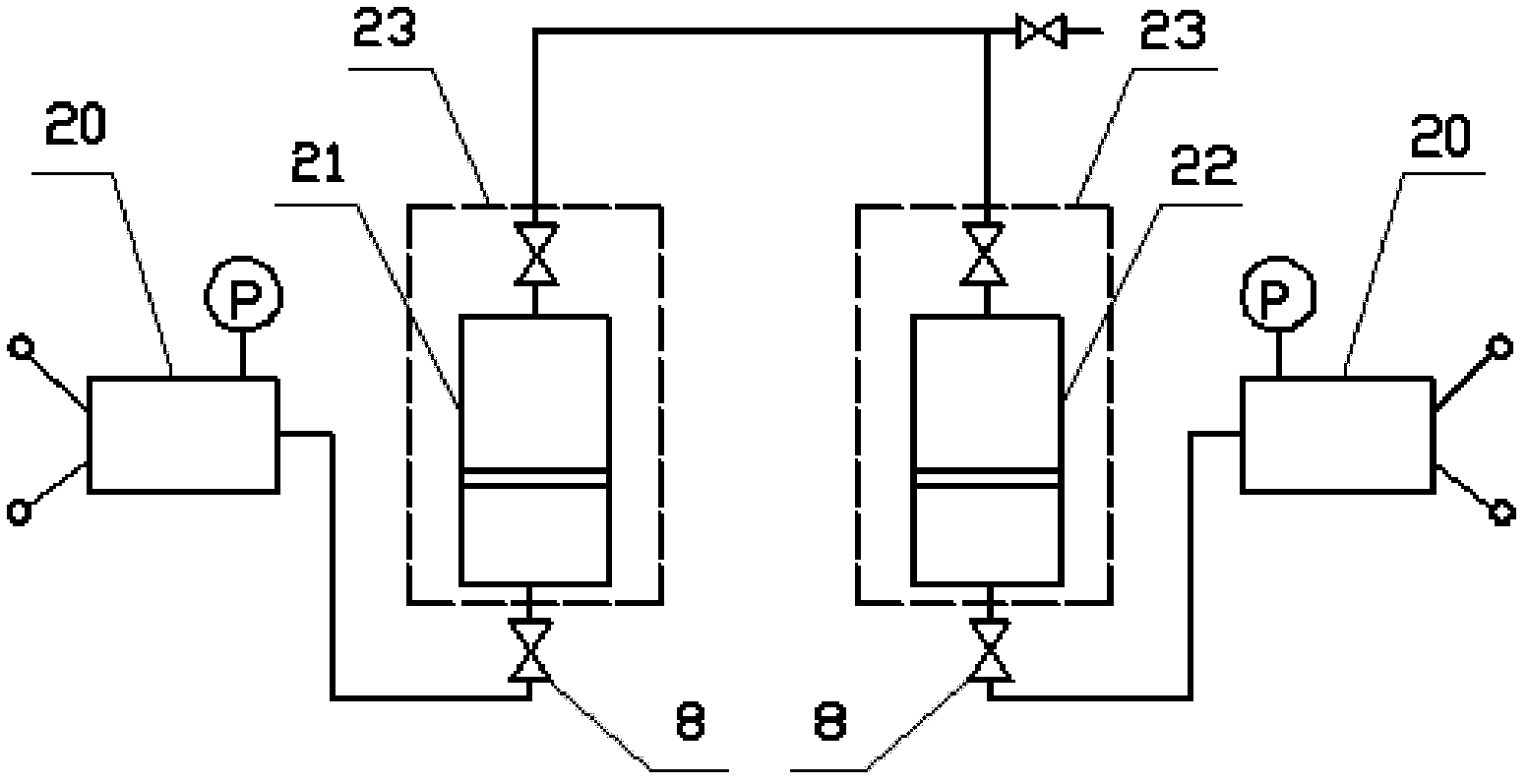

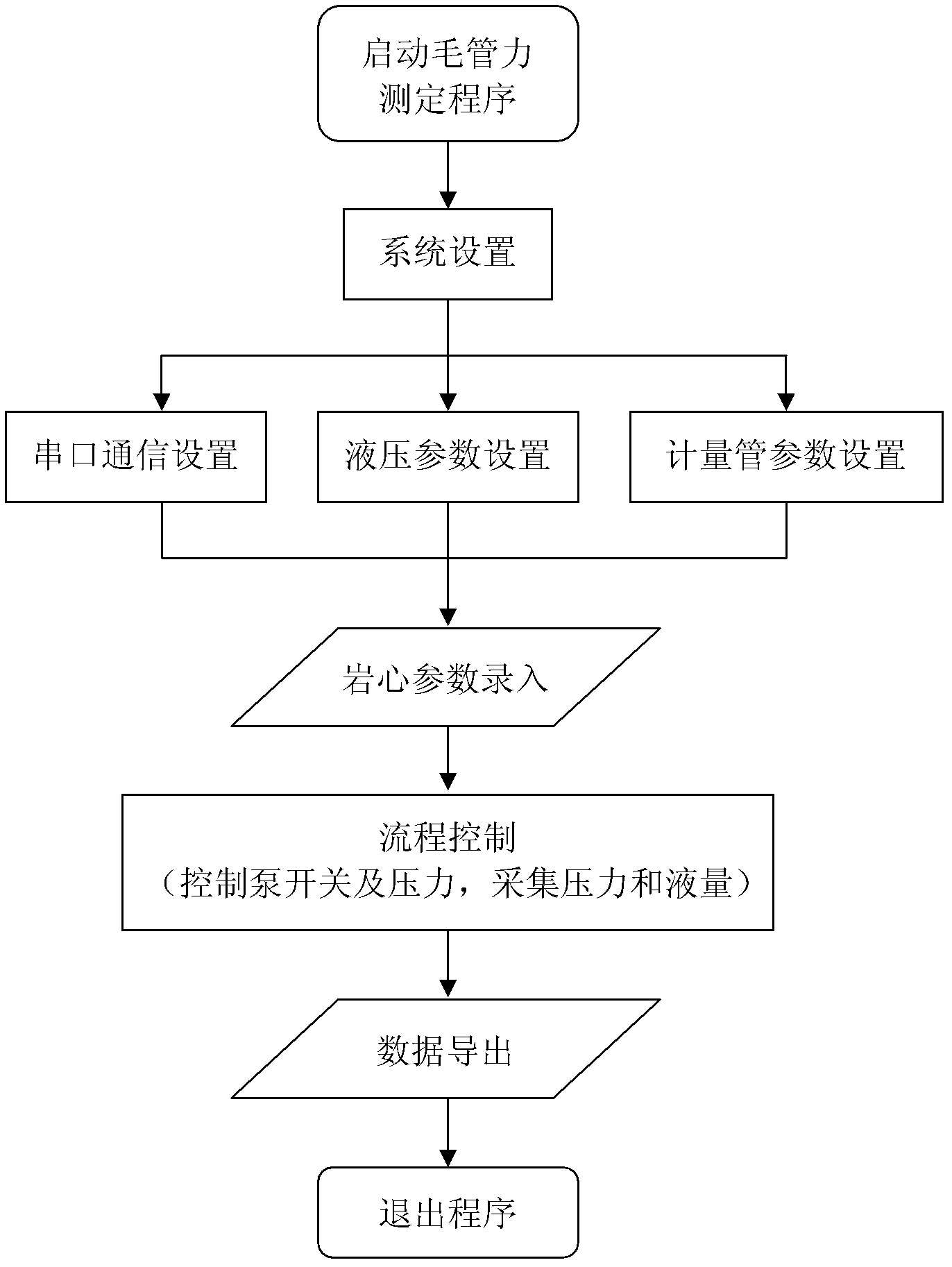

[0021] Such as figure 1 As shown, the present invention is composed of an annular pressure system, an injection system, a core clamping system, a semi-permeable partition, a back pressure system, a metering system, an automatic data collection and processing system and a constant temperature box connected by pipelines.

[0022] 1. Ring pressure system: mainly composed of manual pump 1, pressure gauge 2 (including gauge seat) and liquid supply cup 3, each component is connected by a high-pressure pipeline with a pressure resistance of 80MPa, and the liquid supply cup 3 is connected to the liquid of manual pump 1 At the inlet, the outlet of the manual pump 1 is connected with the pressure gauge 2, the ring pressure and axial pressure inlets of the core holder. Rotate the handle (hand wheel) of the manual pump to compress the liquid in the pump, apply axial and circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com