Patents

Literature

69results about How to "Reduce heat output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature limited heaters with high power factors

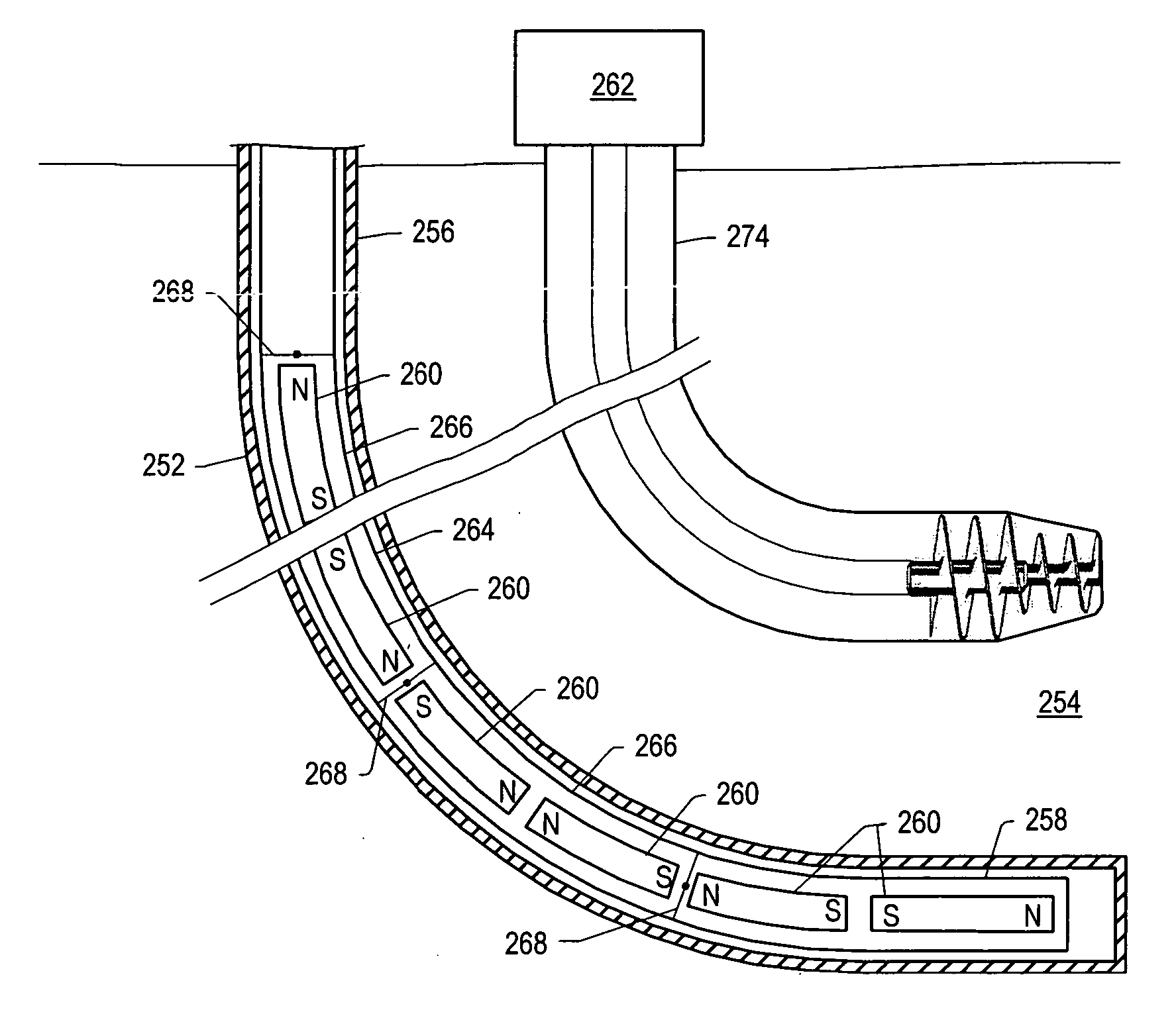

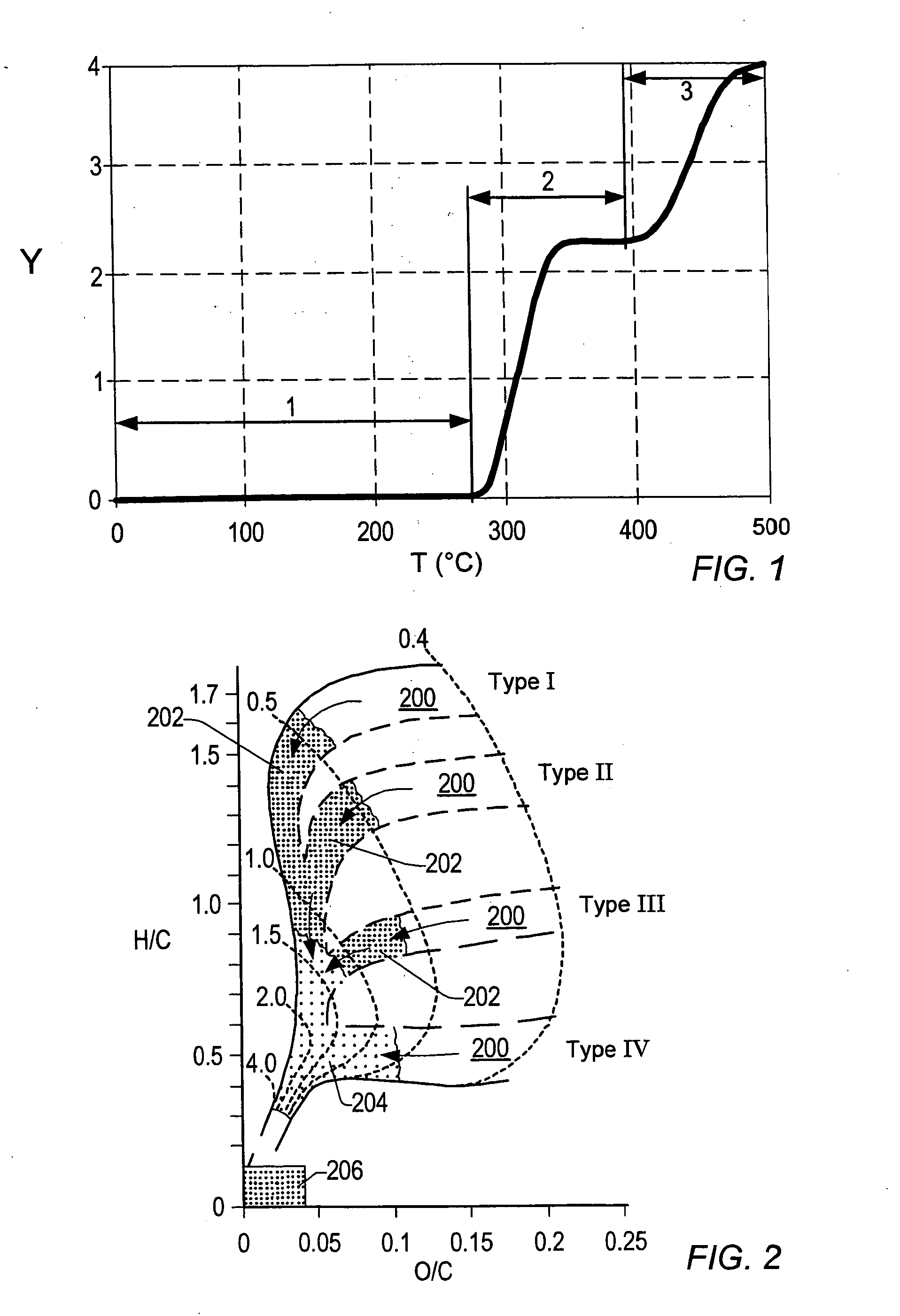

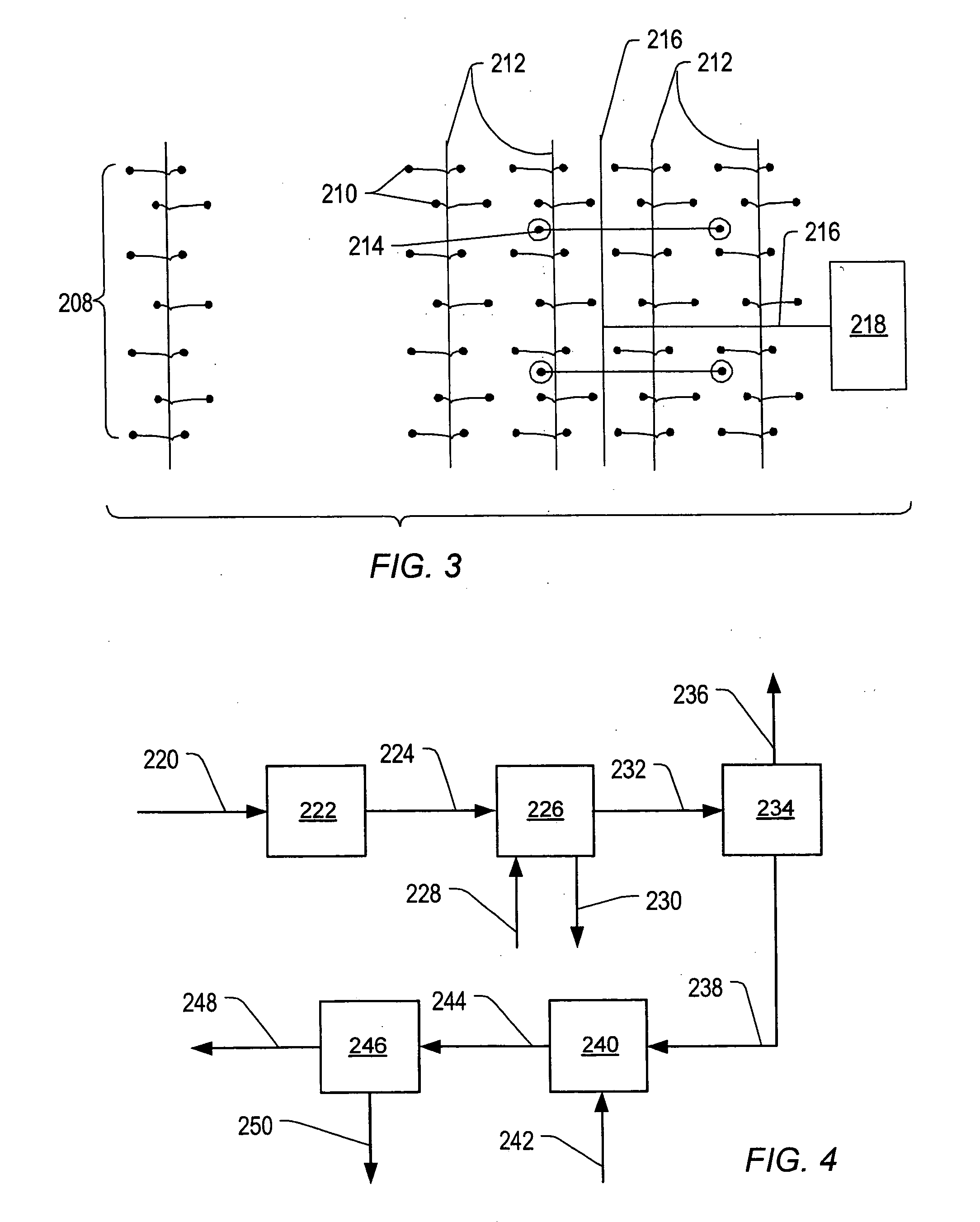

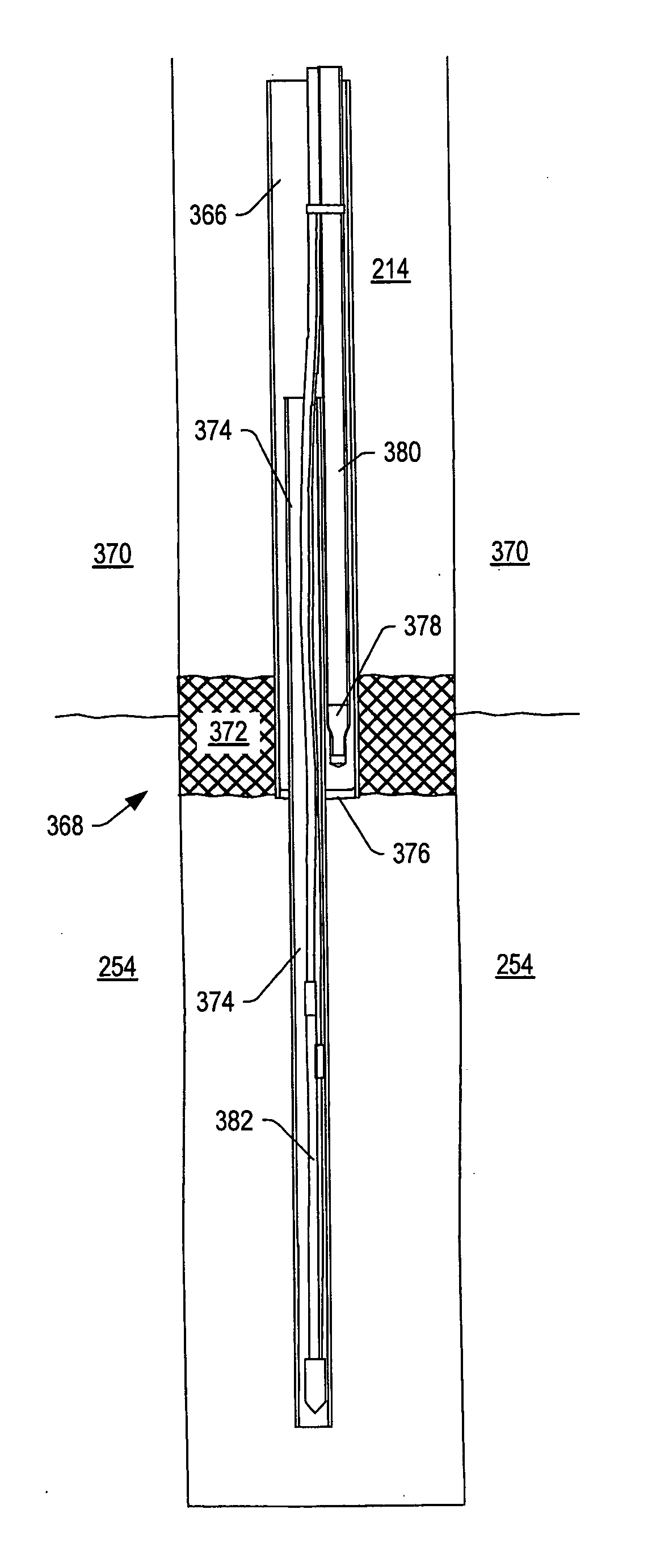

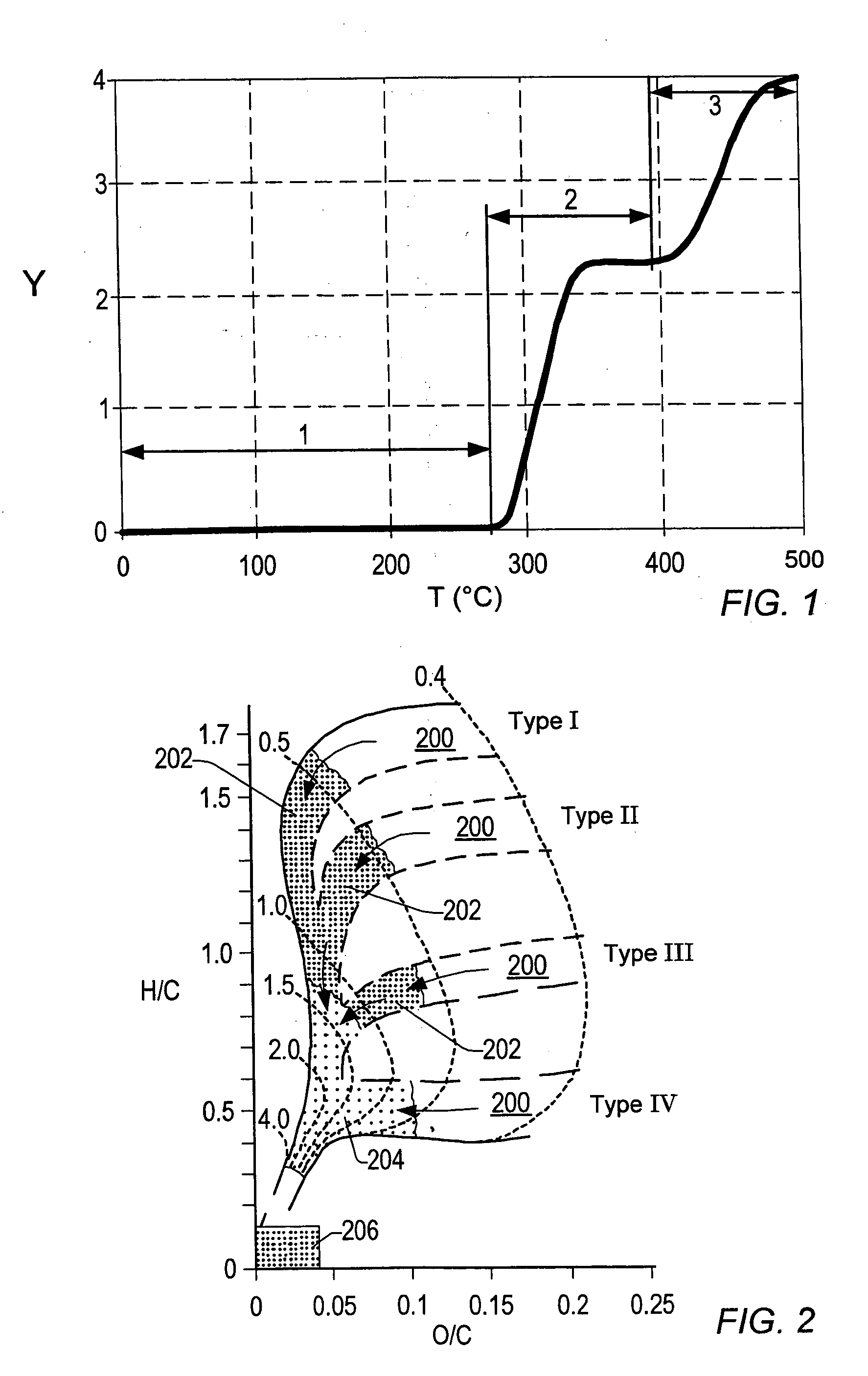

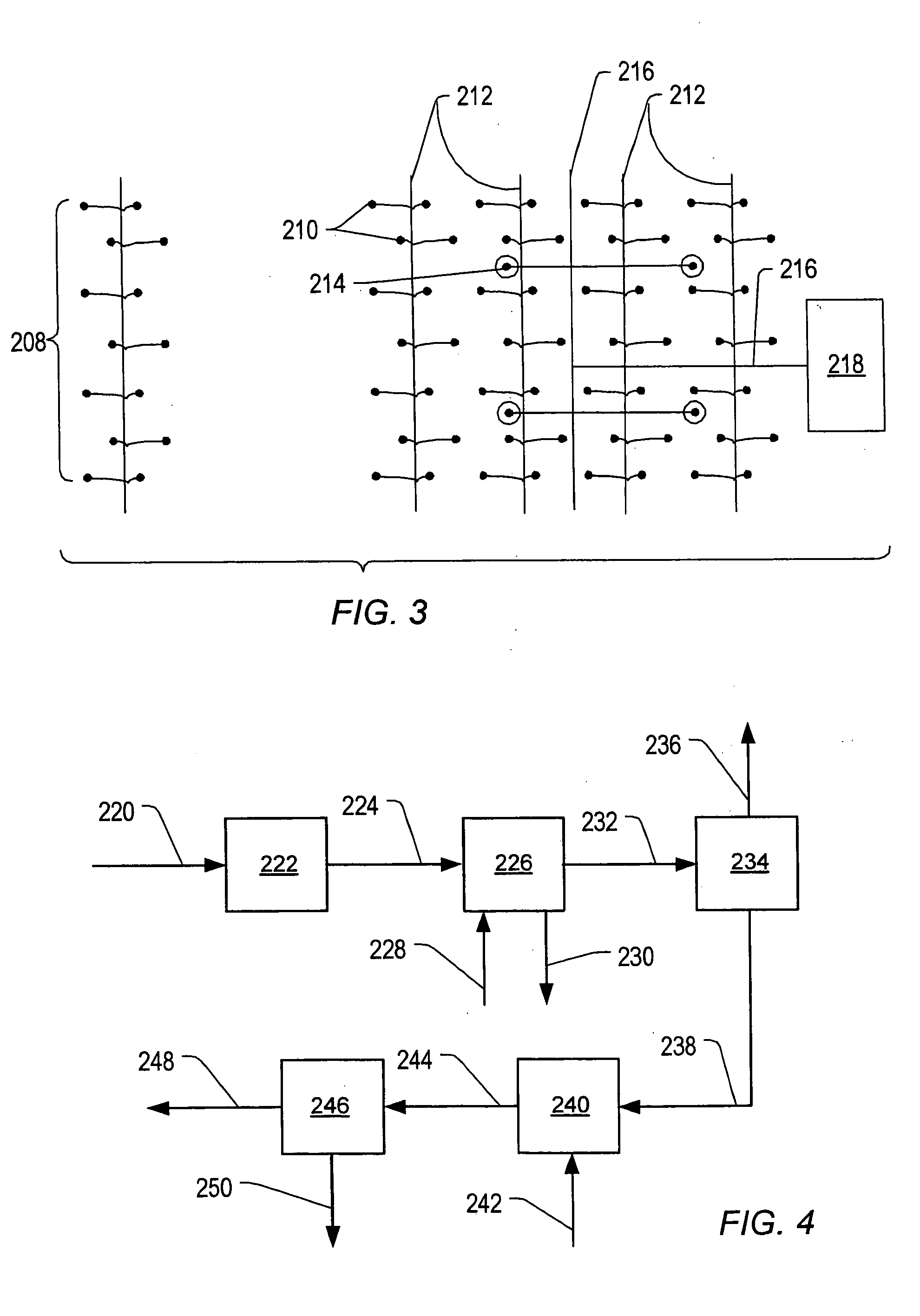

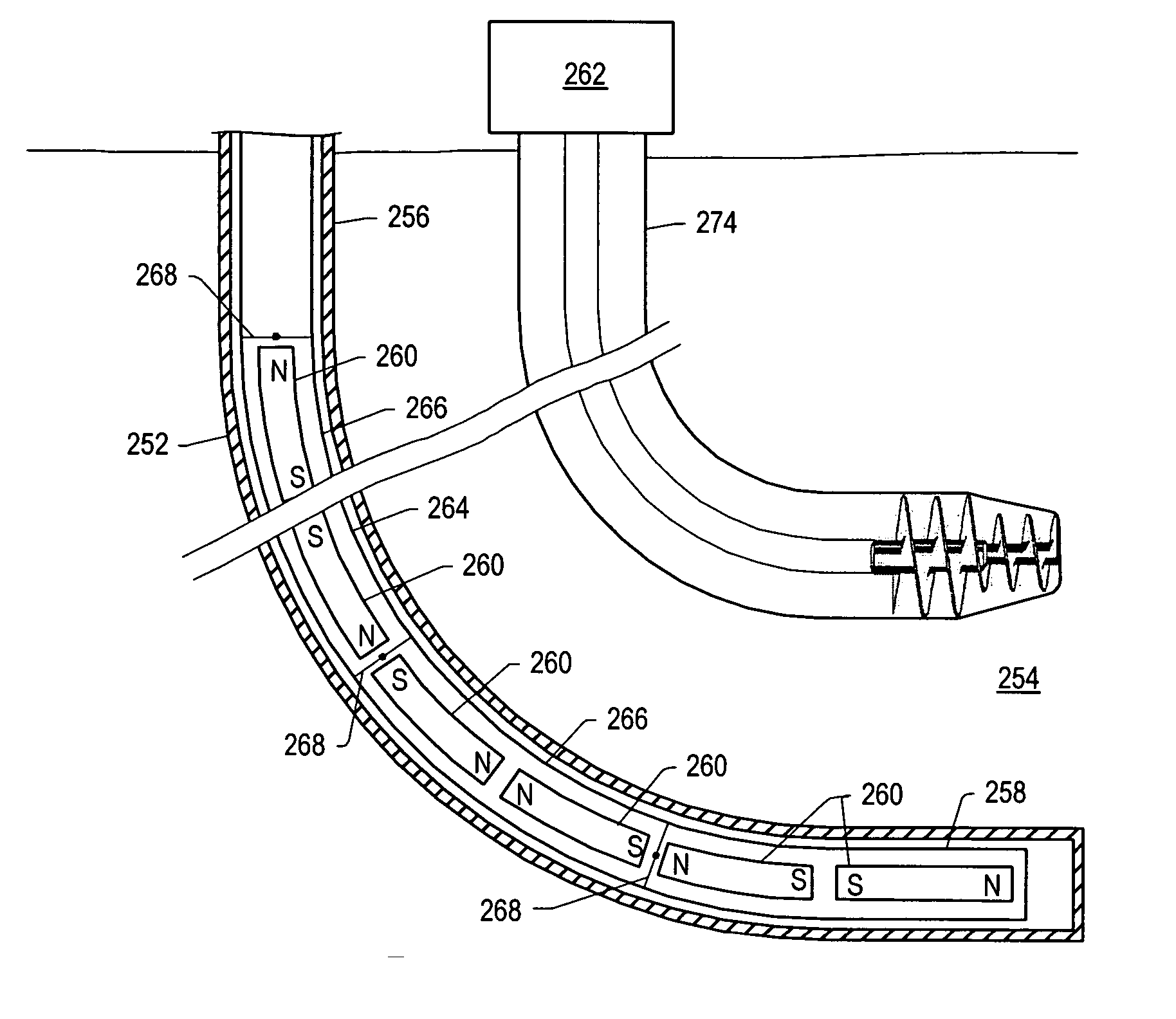

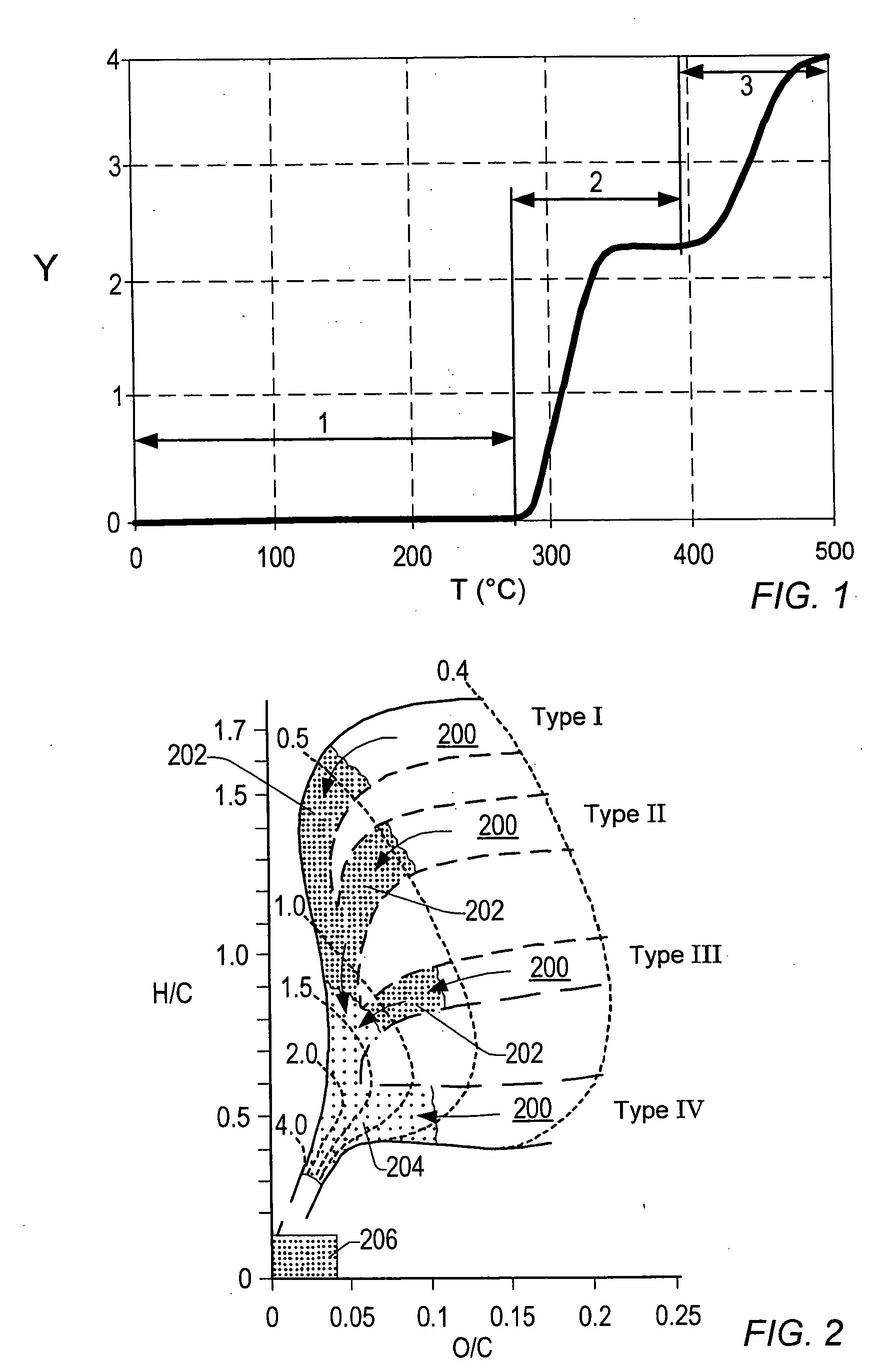

Certain embodiments provide a heater. The heater includes a ferromagnetic member. The heater also includes an electrical conductor electrically coupled to the ferromagnetic member. The electrical conductor is configured to conduct a majority of time-varying electrical current passing through the heater at about 25° C. The heater is configured to provide a first heat output below the Curie temperature of the ferromagnetic member. The heater is configured to automatically provide a second heat output approximately at and above the Curie temperature of the ferromagnetic member. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

Temperature limited heaters with relatively constant current

Owner:SHELL OIL CO

Variable frequency temperature limited heaters

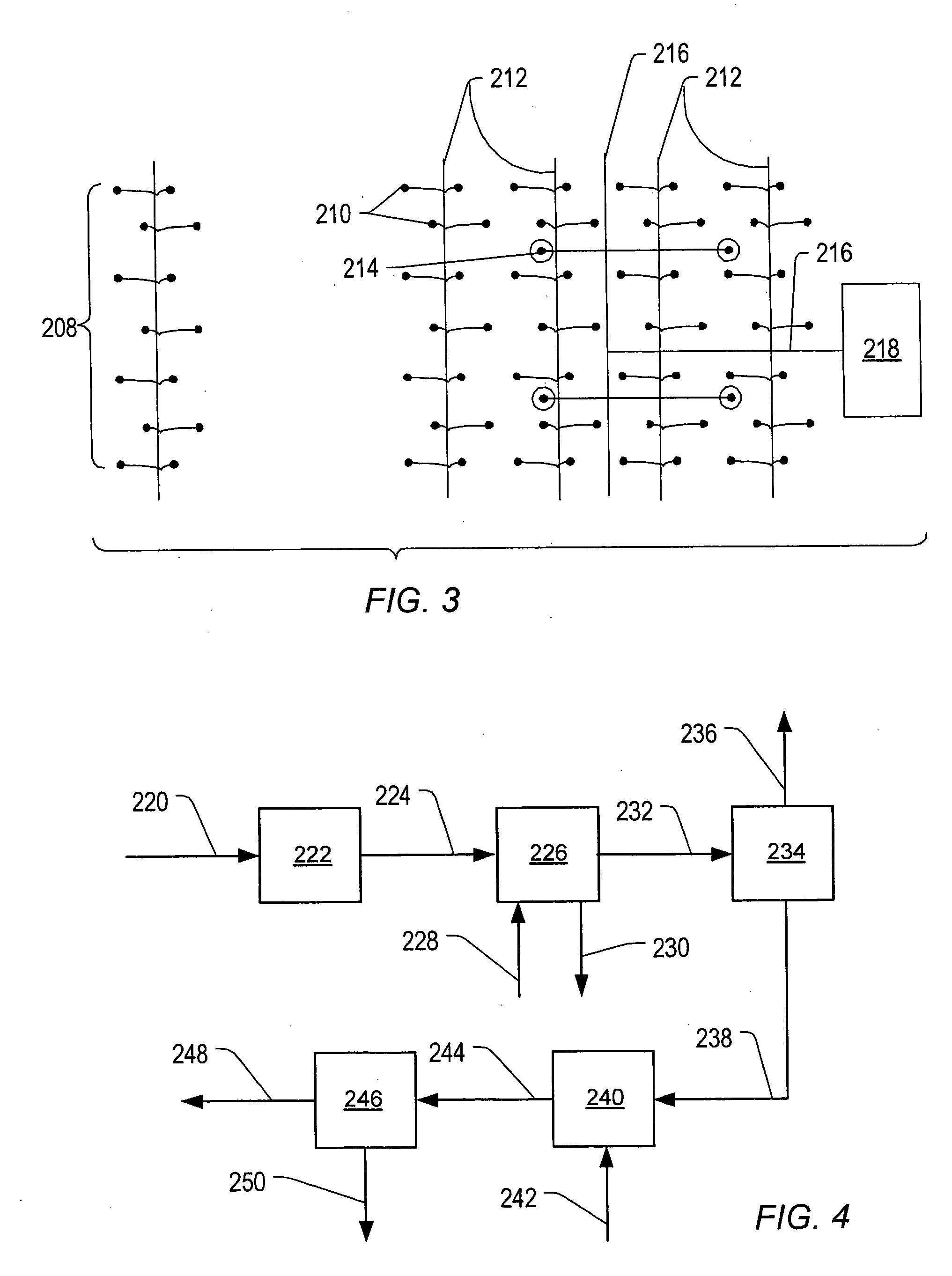

Certain embodiments provide a heating system configured to heat at least a part of a subsurface formation. The system includes an electrical power supply. A heater section includes one or more electrical conductors electrically coupled to the electrical power supply. The heater section is configured to be placed in an opening in the formation. At least one of the electrical conductors includes ferromagnetic material. The heater section provides a first heat output when time-varying electrical current is applied to the heater section below a selected temperature, and provides a second heat output approximately at and above the selected temperature during use. The second heat output is reduced compared to the first heat output. The system is configured to allow heat to transfer from the heater section to a part of the formation. The system is configured to allow a frequency of the applied time-varying electrical current to be varied.

Owner:SHELL OIL CO

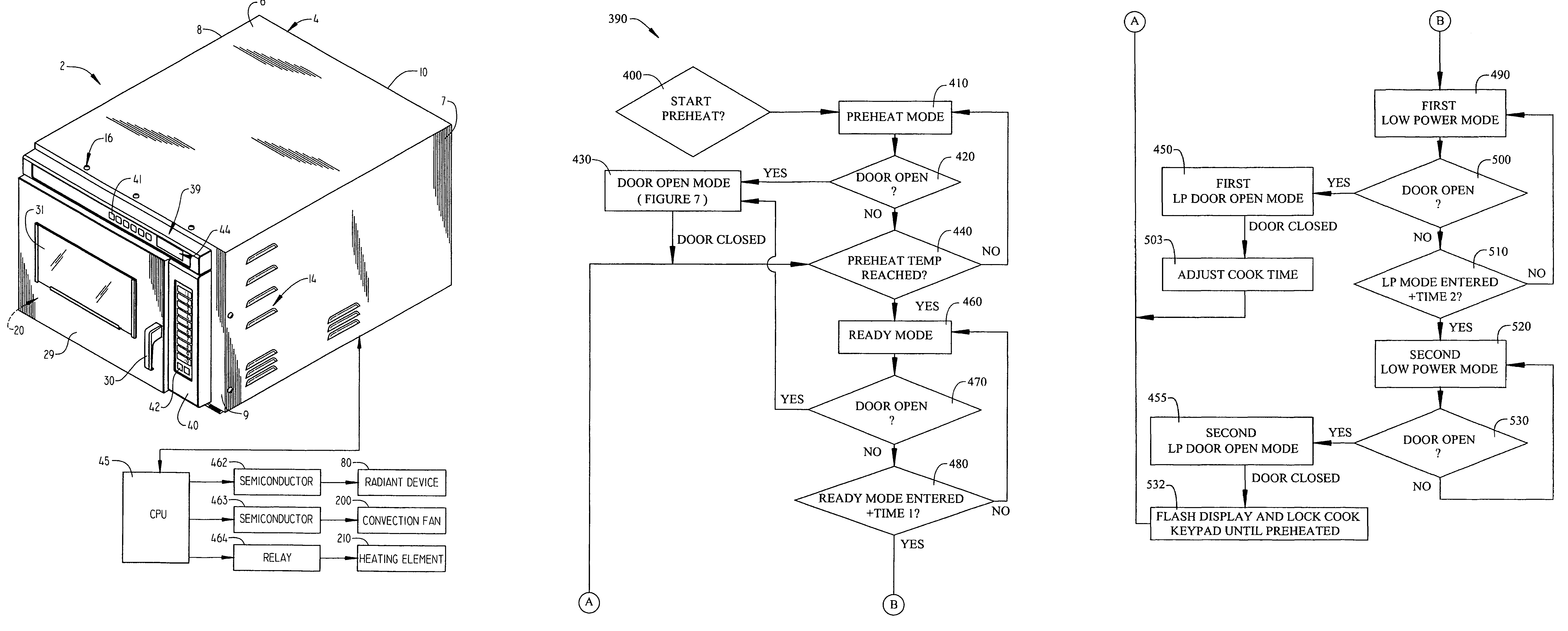

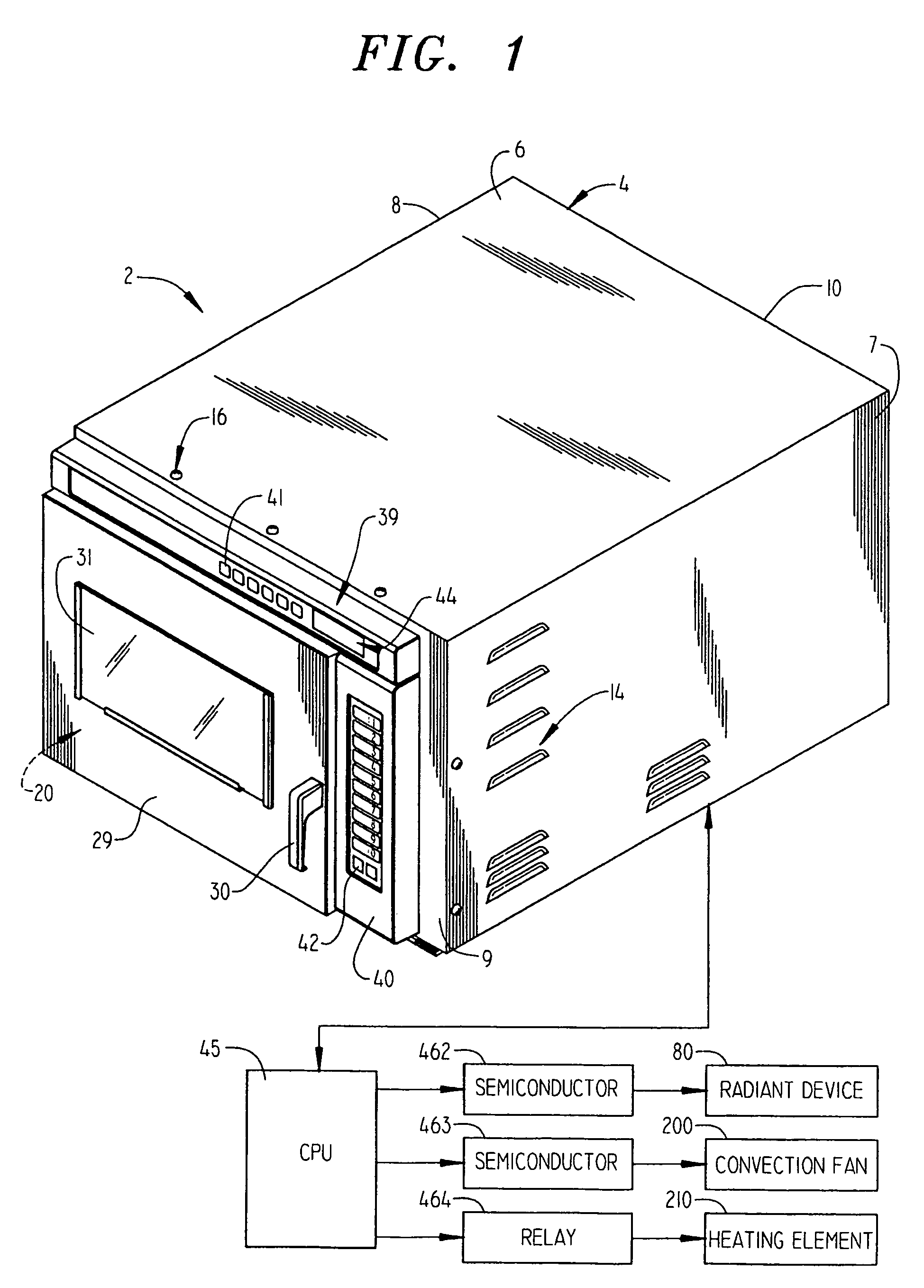

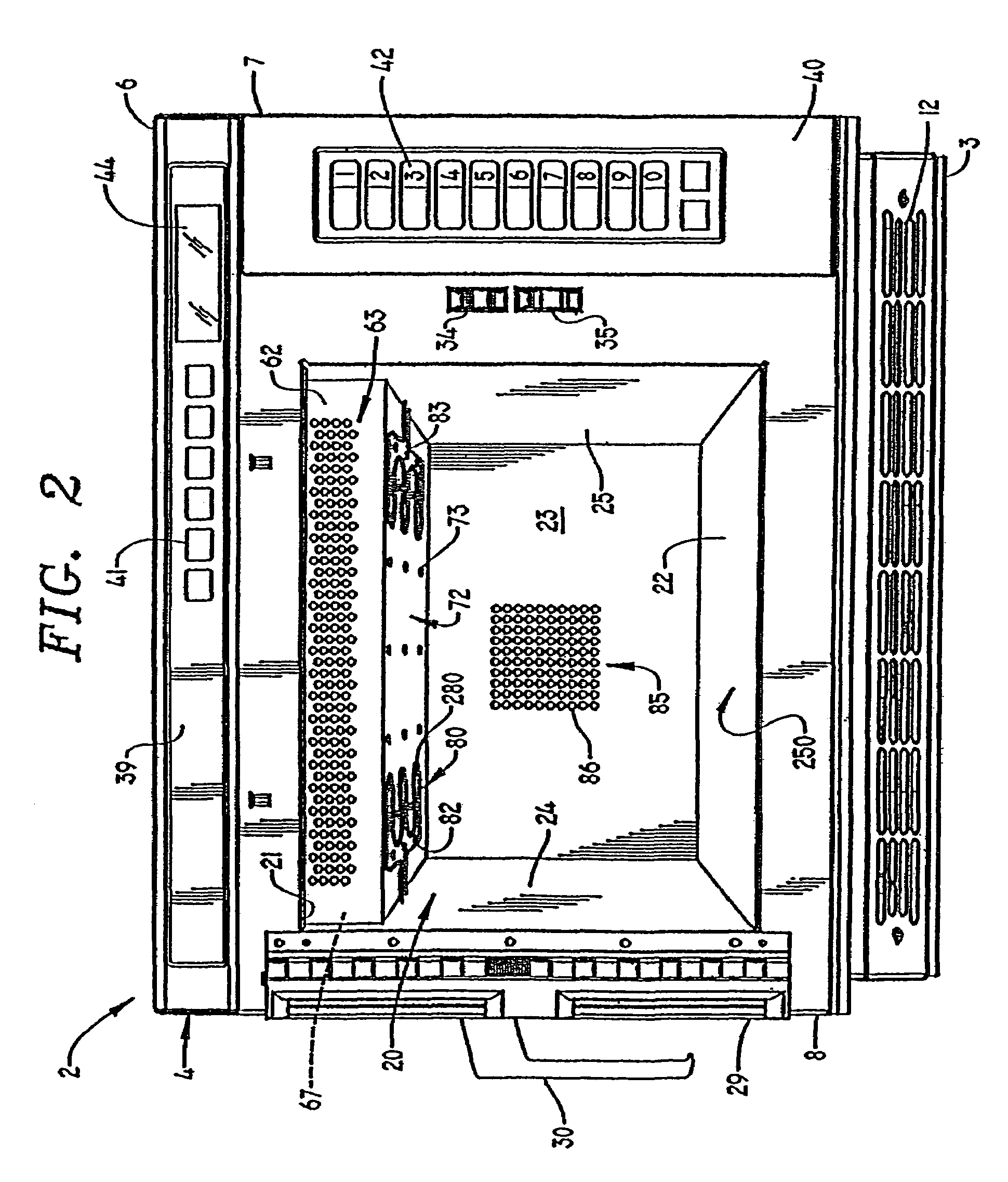

Operational modes for a cooking appliance employing combination cooking technology

A cooking appliance includes a controller for establishing a plurality of operating modes for heating an oven cavity. Specifically, the controller establishes one of a pre-heat mode, a ready mode, a first low power mode and a second low power mode for controlling a temperature of the oven cavity. Upon selecting a temperature for the oven cavity, the controller operates a radiant heating device, a convection fan and a convection heating device at full power to establish the selected temperature. After the selected temperature is achieved, the controller switches to a ready mode and reduces heat output of both the radiant heating device and the convection heating device, while also reducing fan speed. After respective periods of time in which a door of the appliance is not opened, the controller switches to first and second low power modes to conserve energy.

Owner:ACP OF DELAWARE

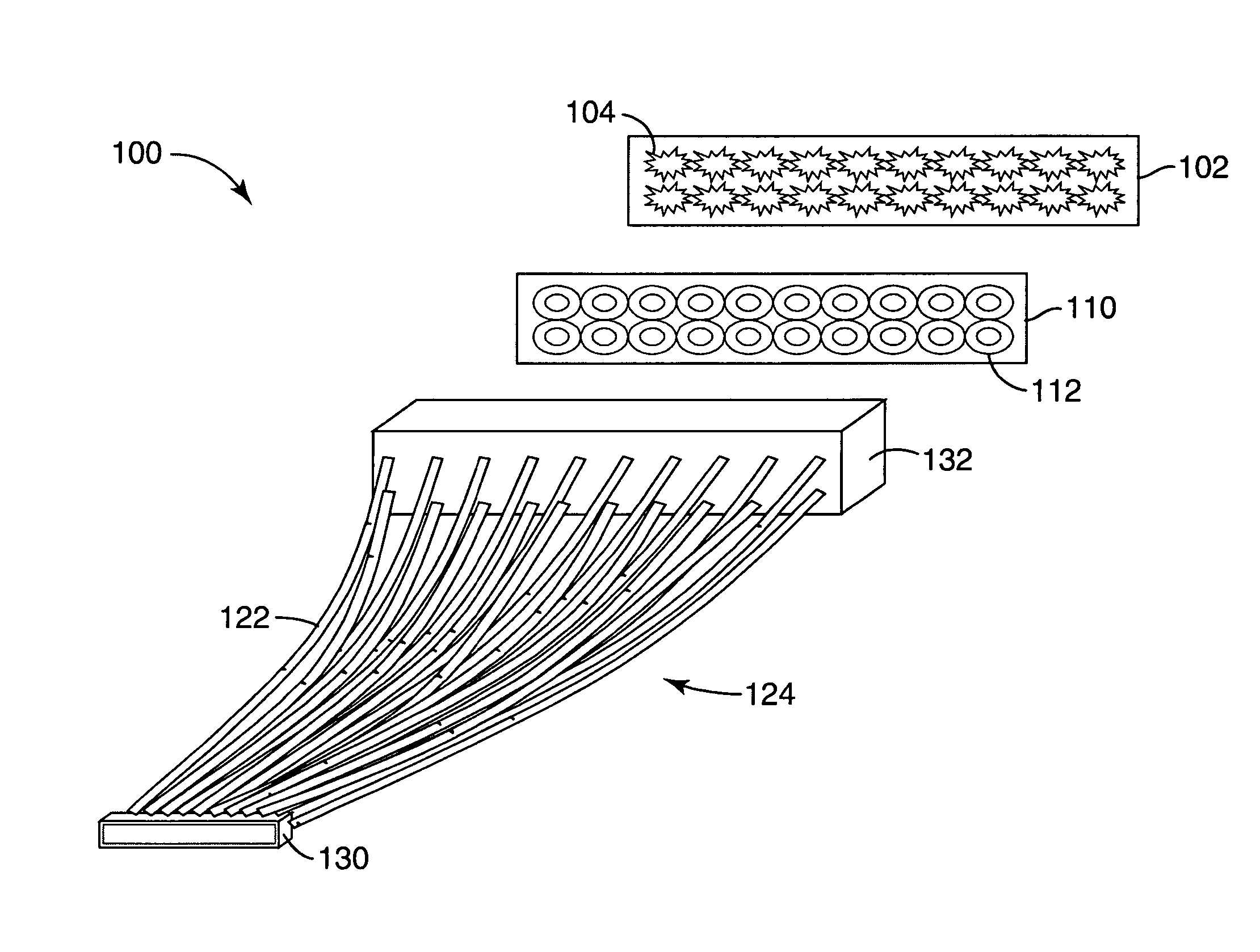

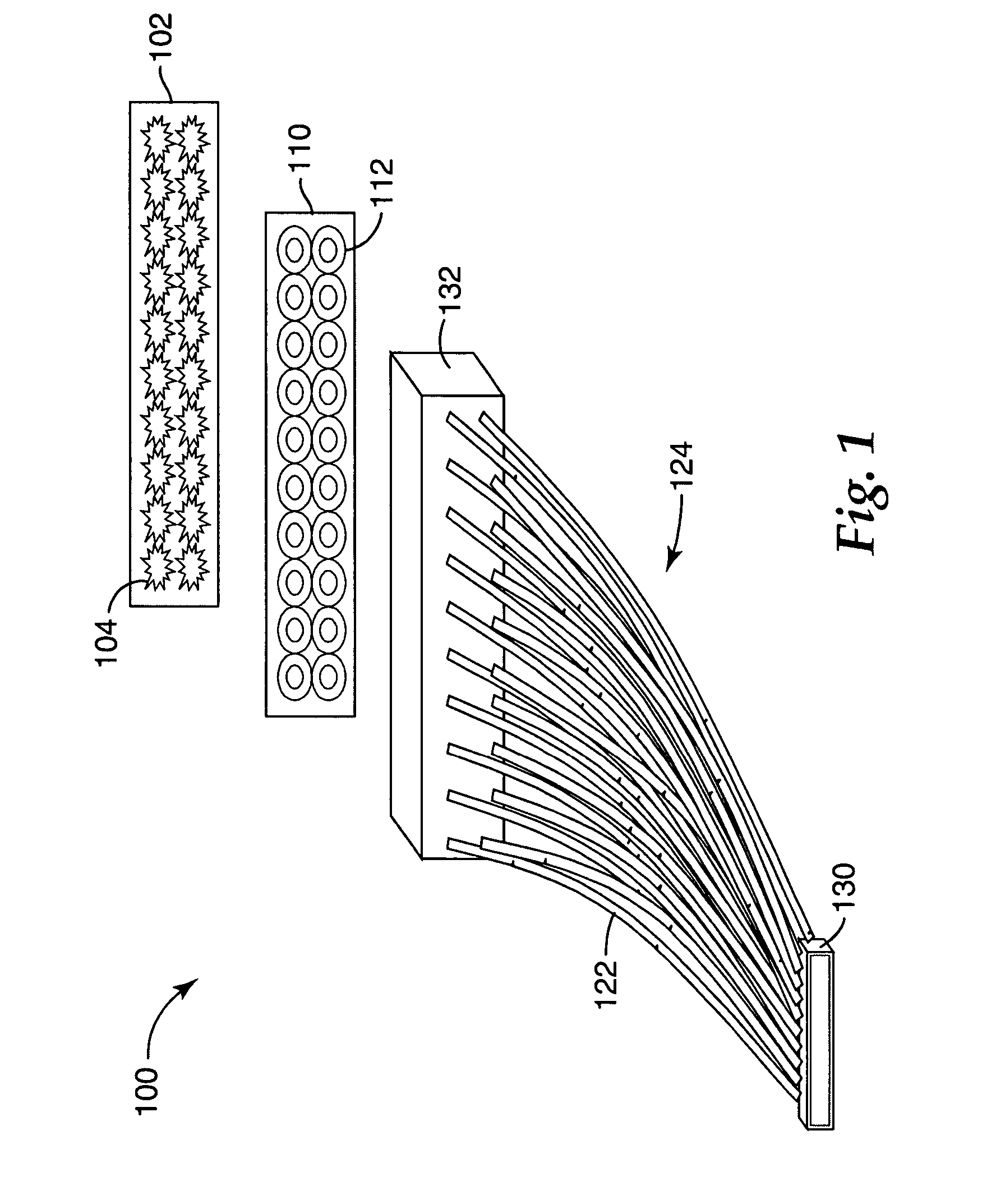

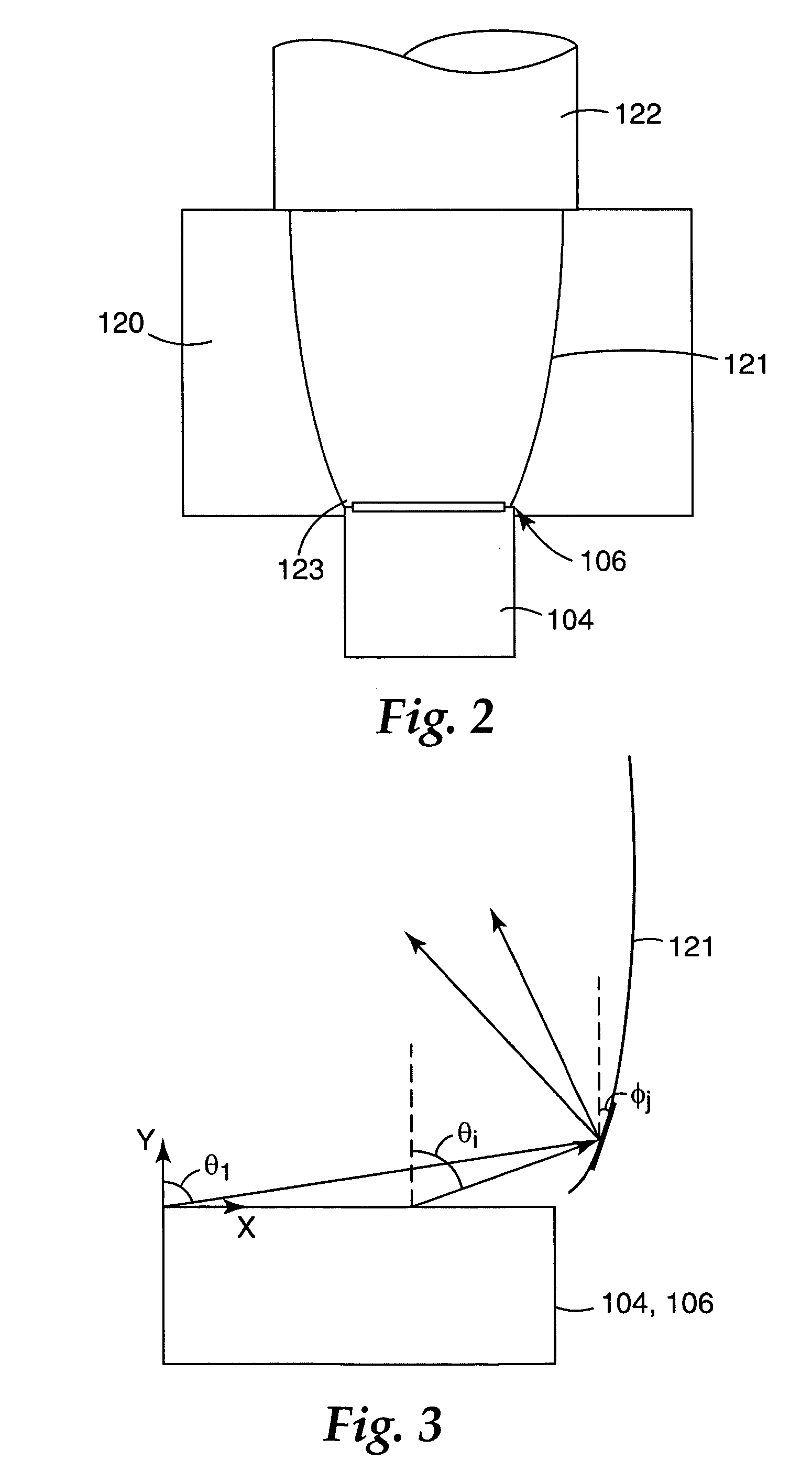

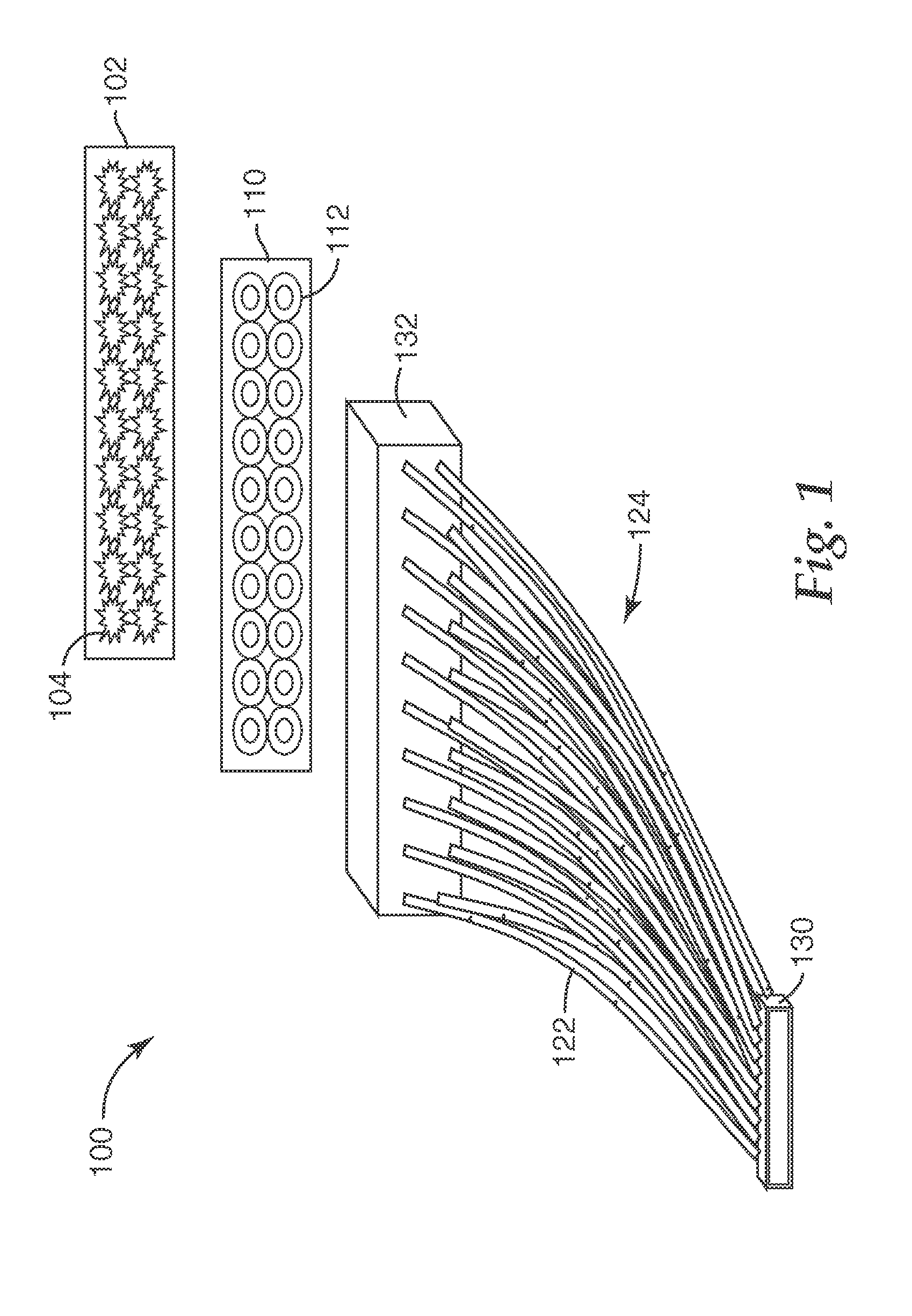

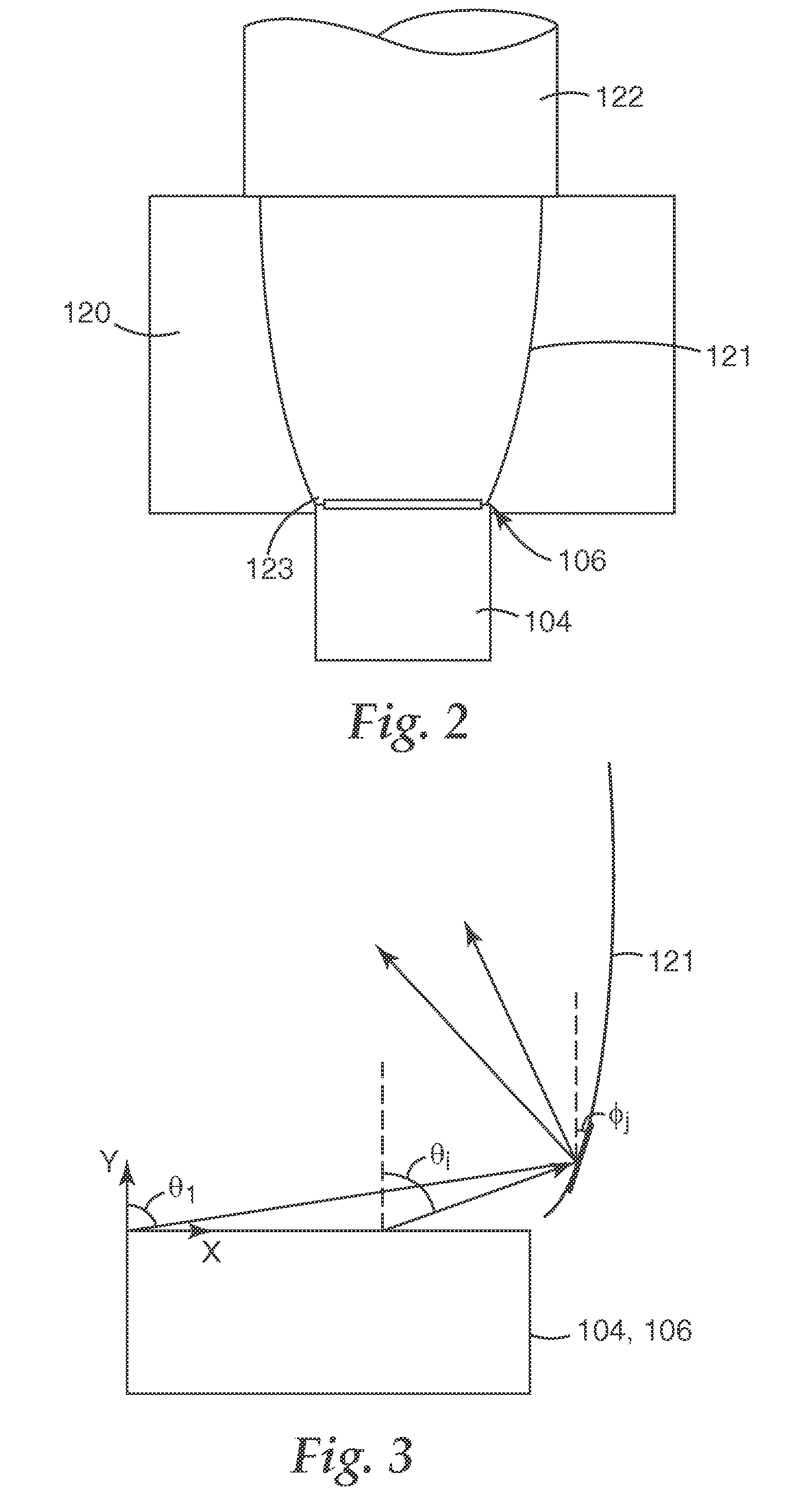

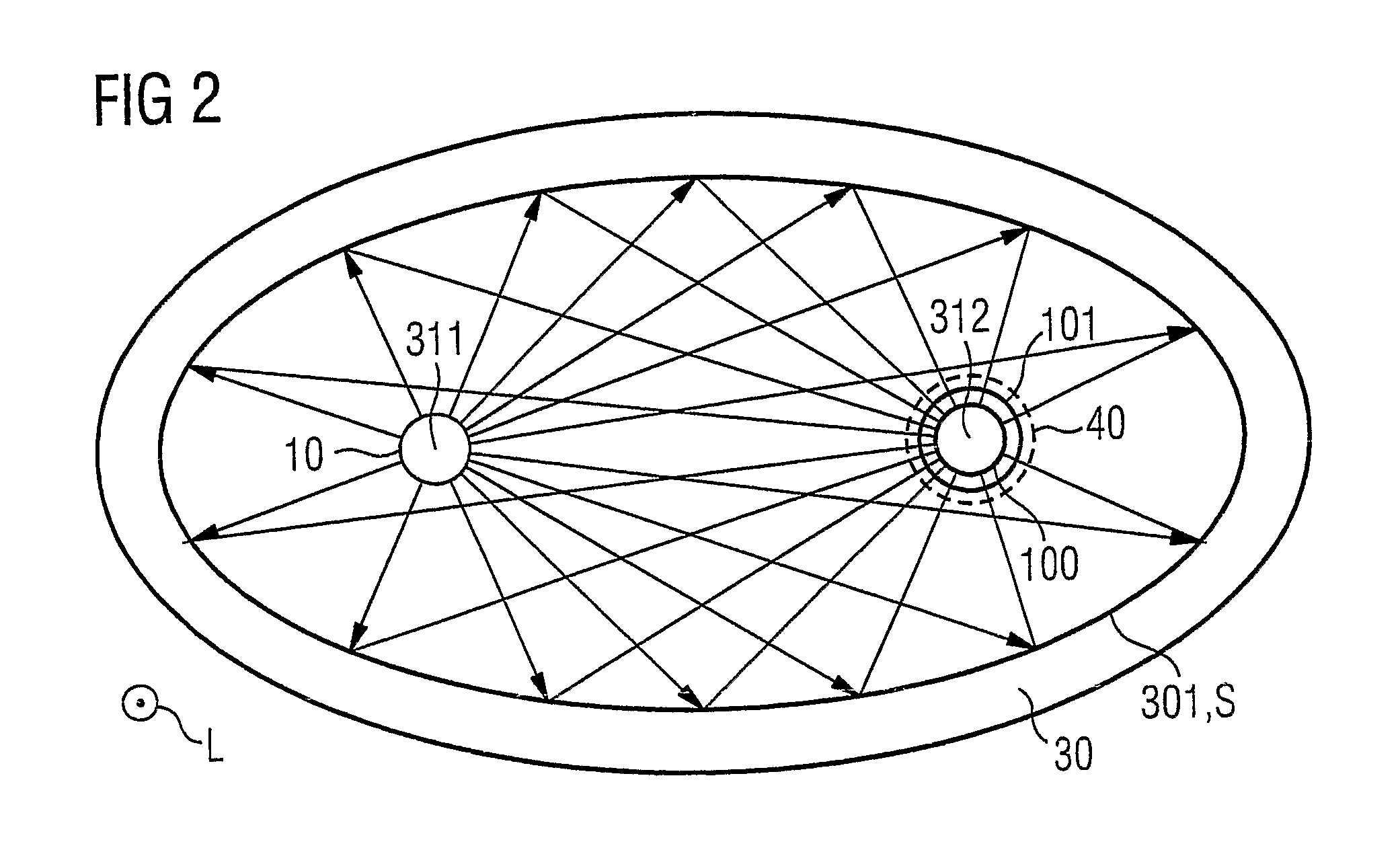

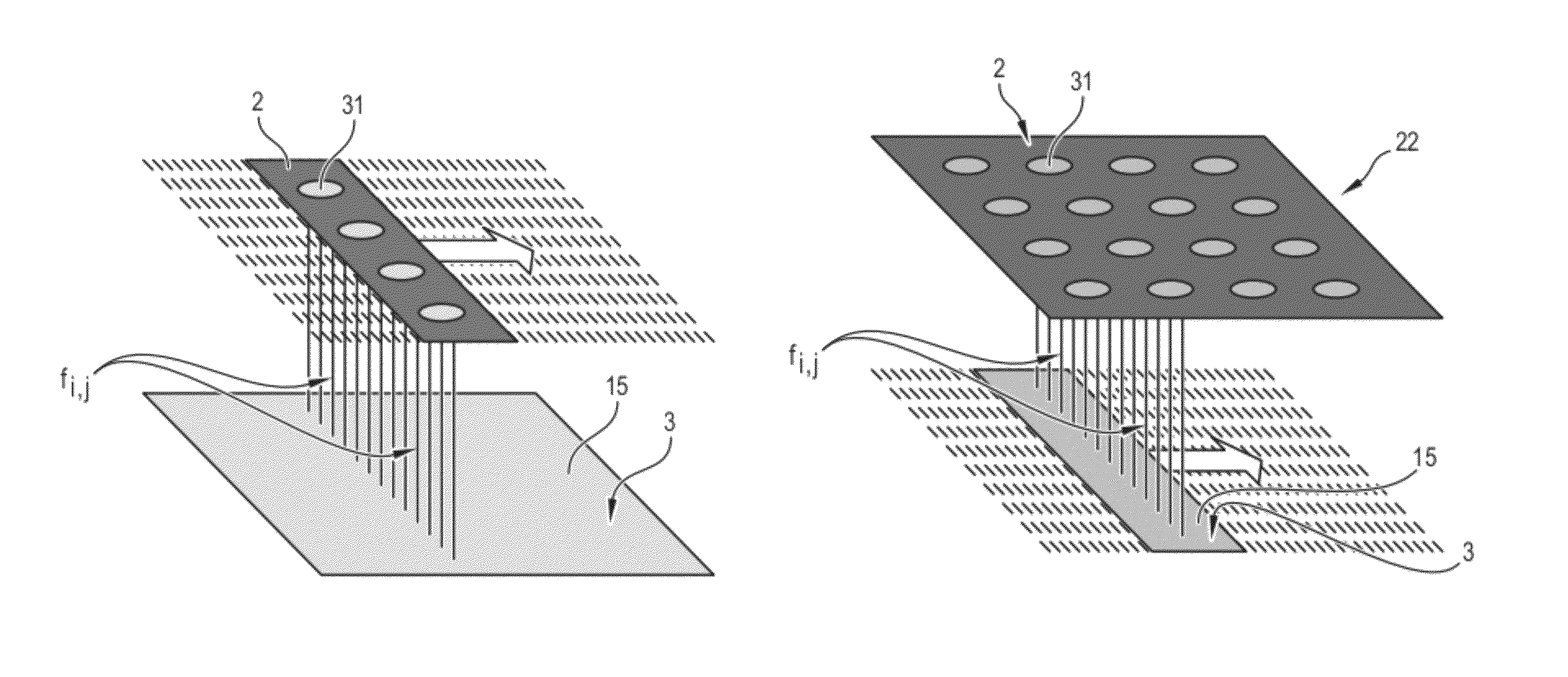

Illumination system using a plurality of light sources

InactiveUS7163327B2Reduce heat outputReduced life-timeMechanical apparatusPoint-like light sourceLighting systemOptical communication

An illumination system includes a plurality of radiation generating sources, such as LED dies. A corresponding plurality of optical waveguides is also provided, with each waveguide having a first and a second end, with each first end being in optical communication with the corresponding LED die. An array of corresponding passive optical elements is interposed between the plurality of LED dies and the corresponding first ends of the plurality of optical waveguides. The illumination system provides for substantially high light coupling efficiency and an incoherent light output that can appear to the human observer as arising from a single point of light. In addition, the light can be output remotely at one or more locations and in one or more directions.

Owner:3M INNOVATIVE PROPERTIES CO

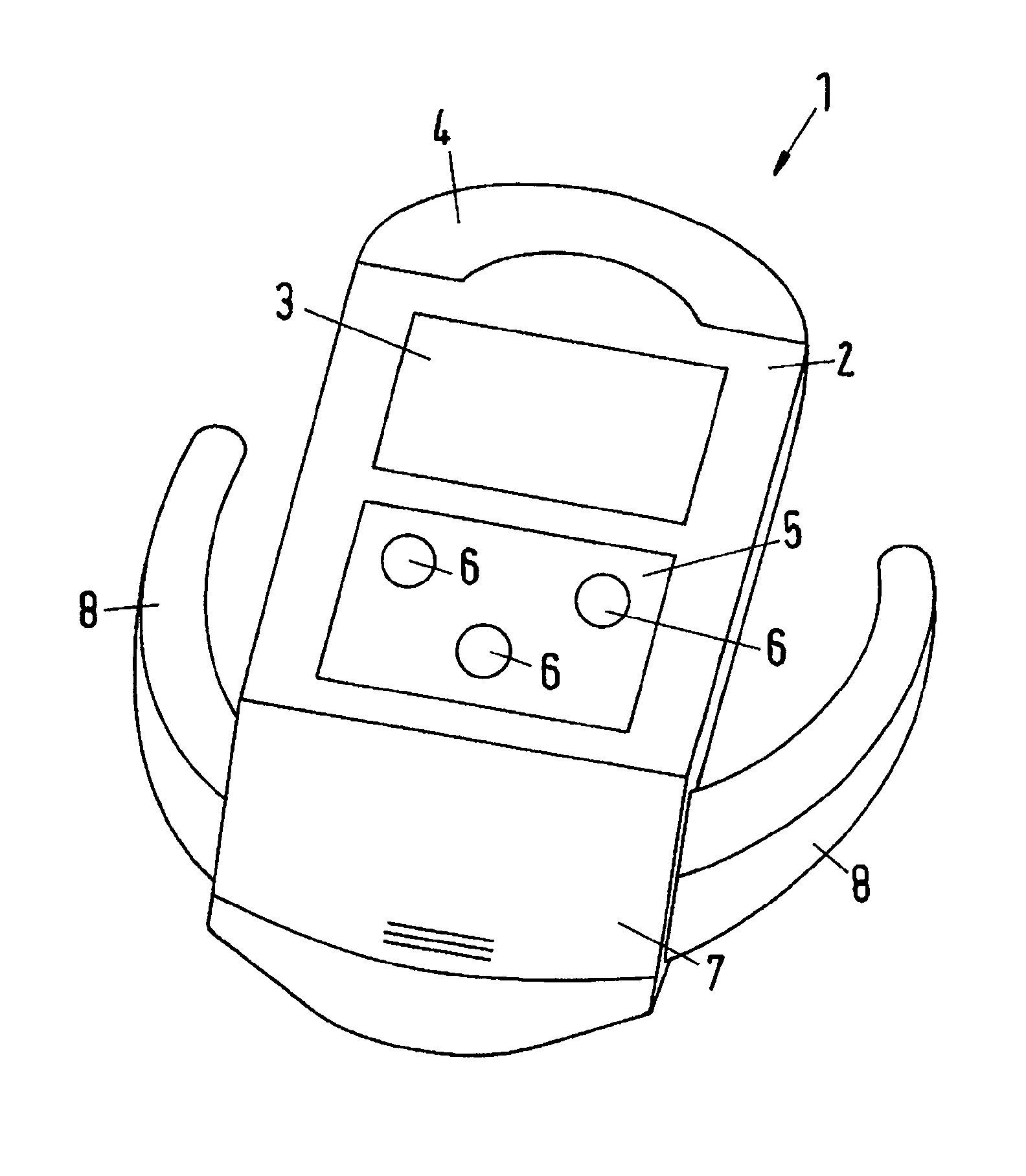

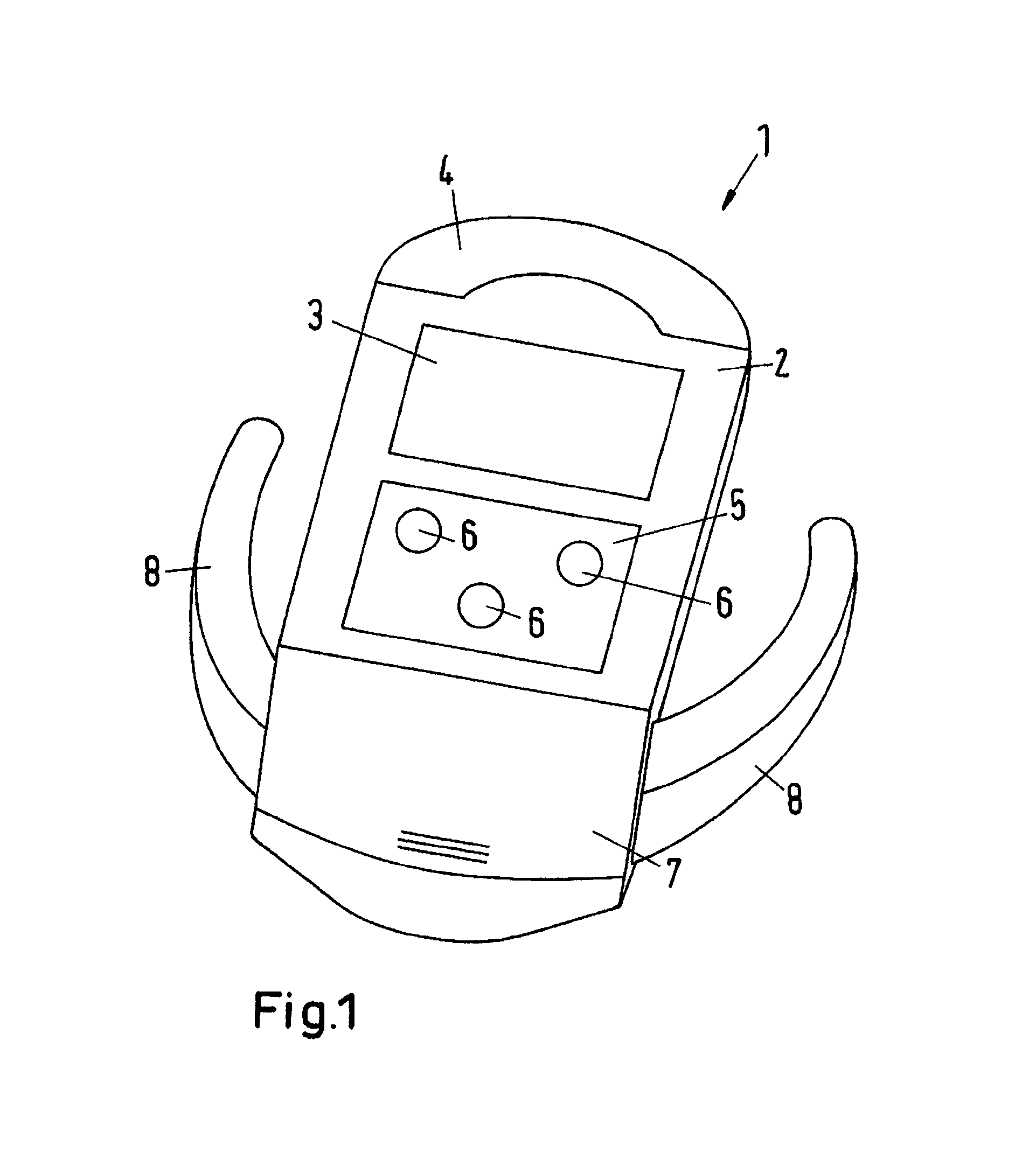

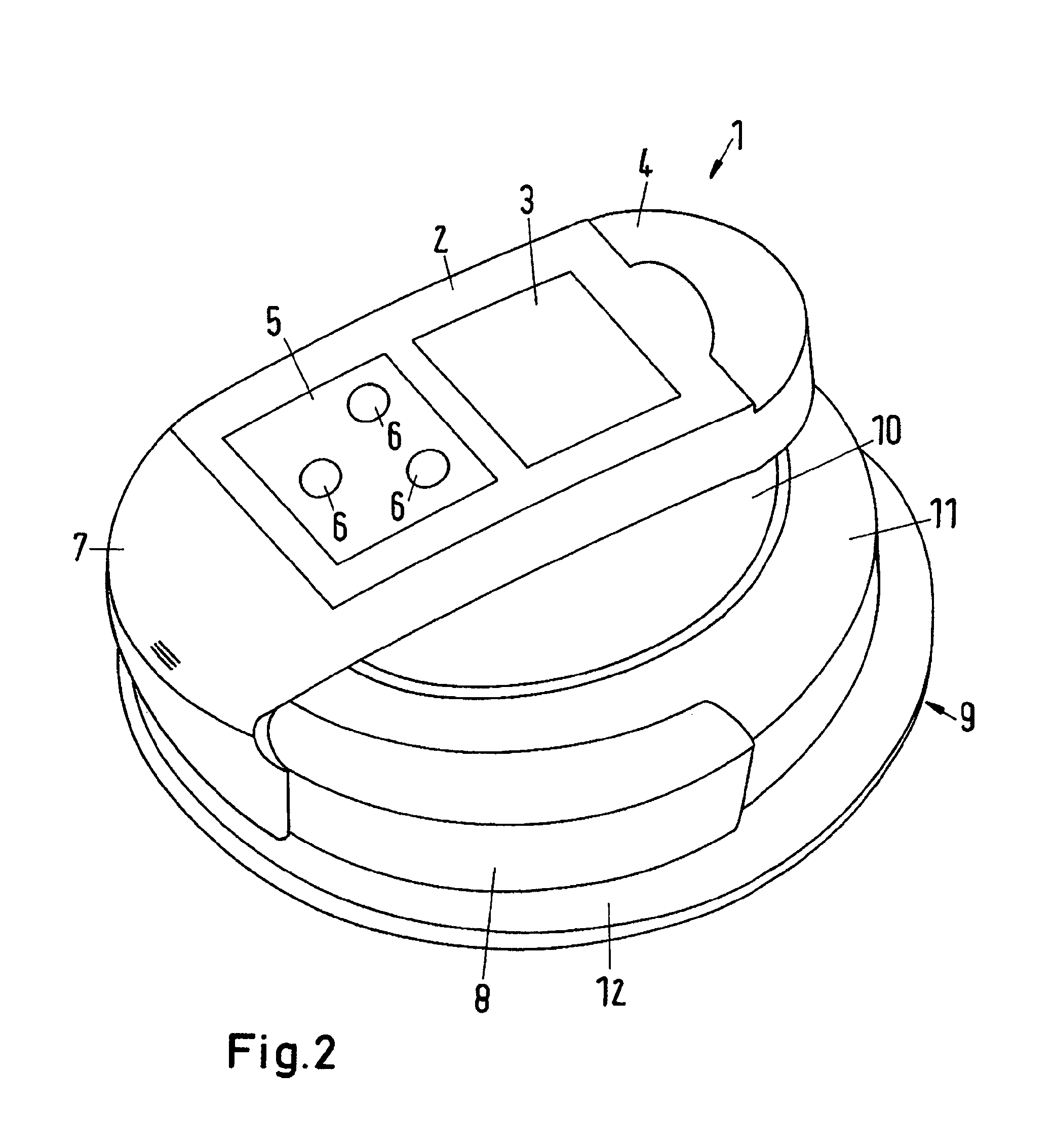

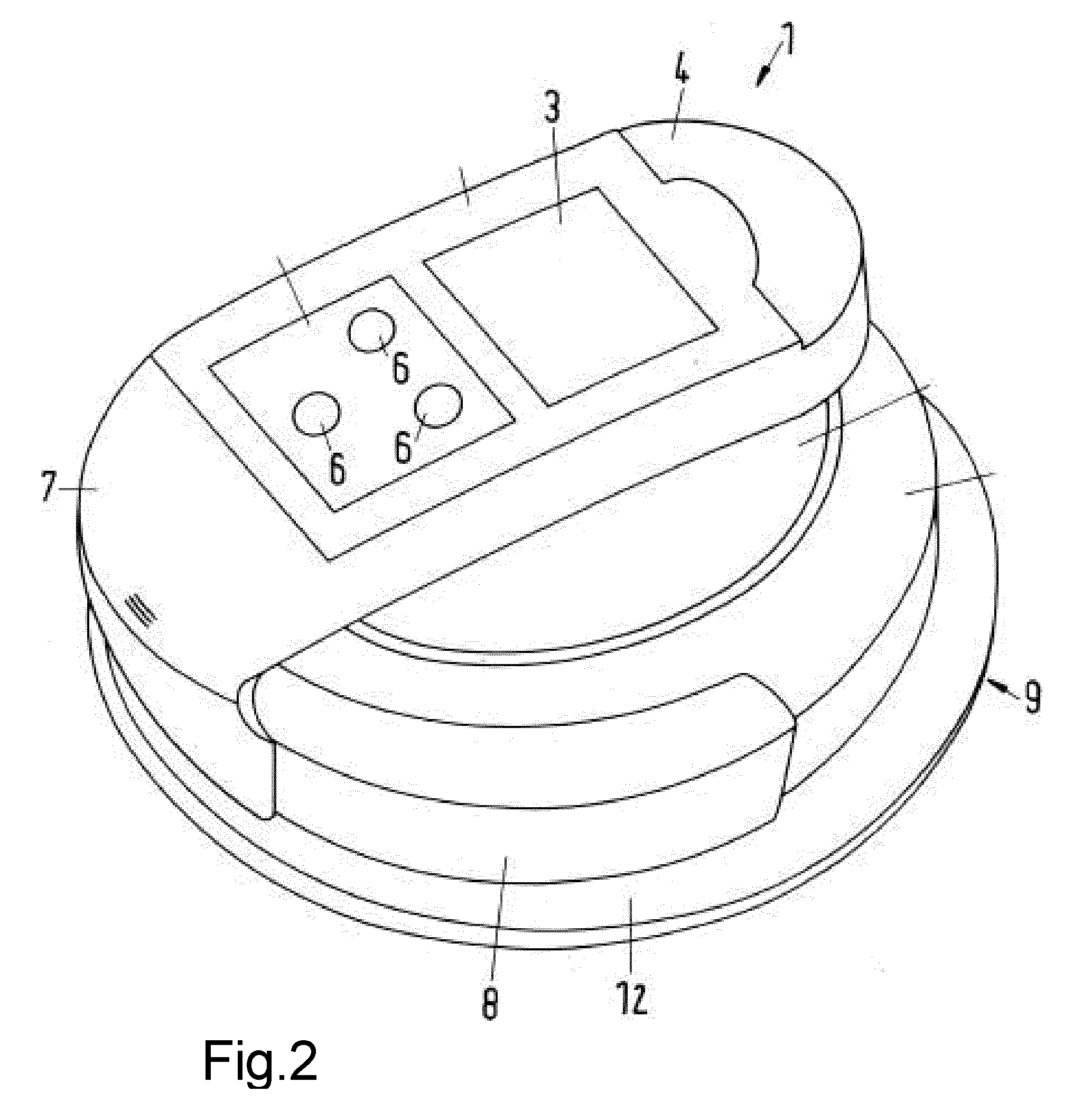

Pressure detection system for a pressure cooker indicating use-related wear

ActiveUS9177460B2Improve reliabilityReduce heat outputBoiling over preventionFluid pressure measurementDisplay deviceCooker

Owner:FISSLER

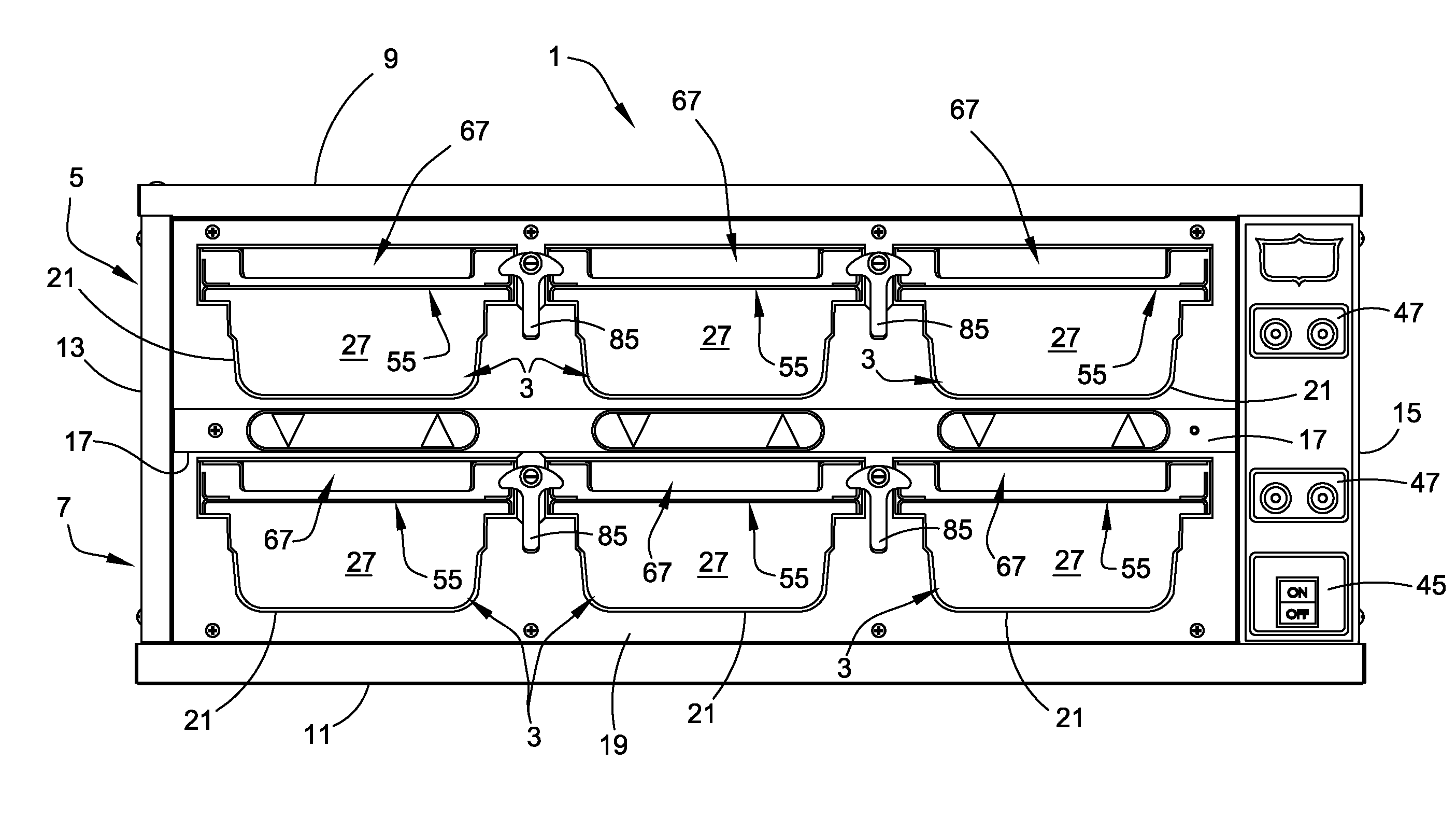

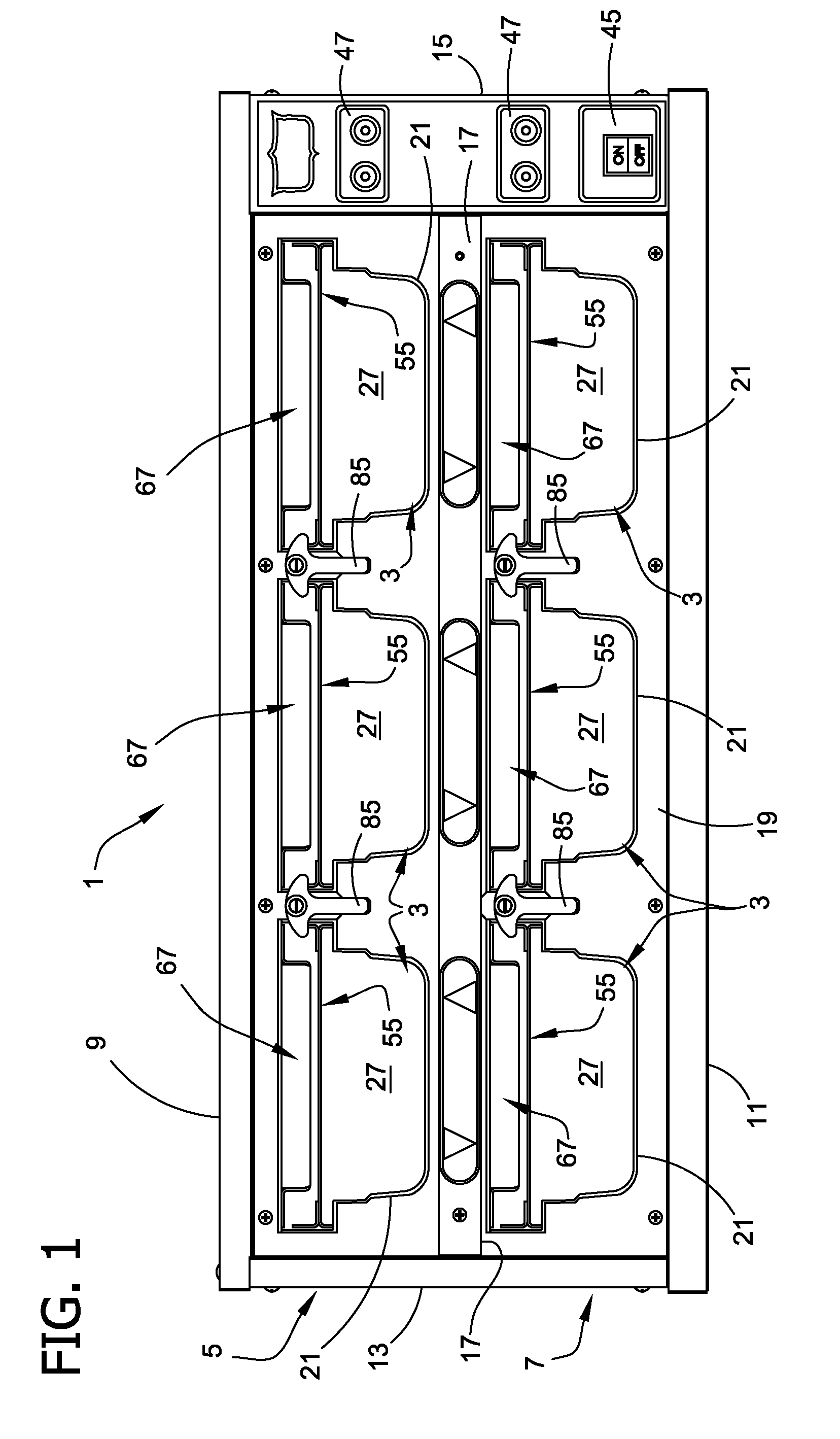

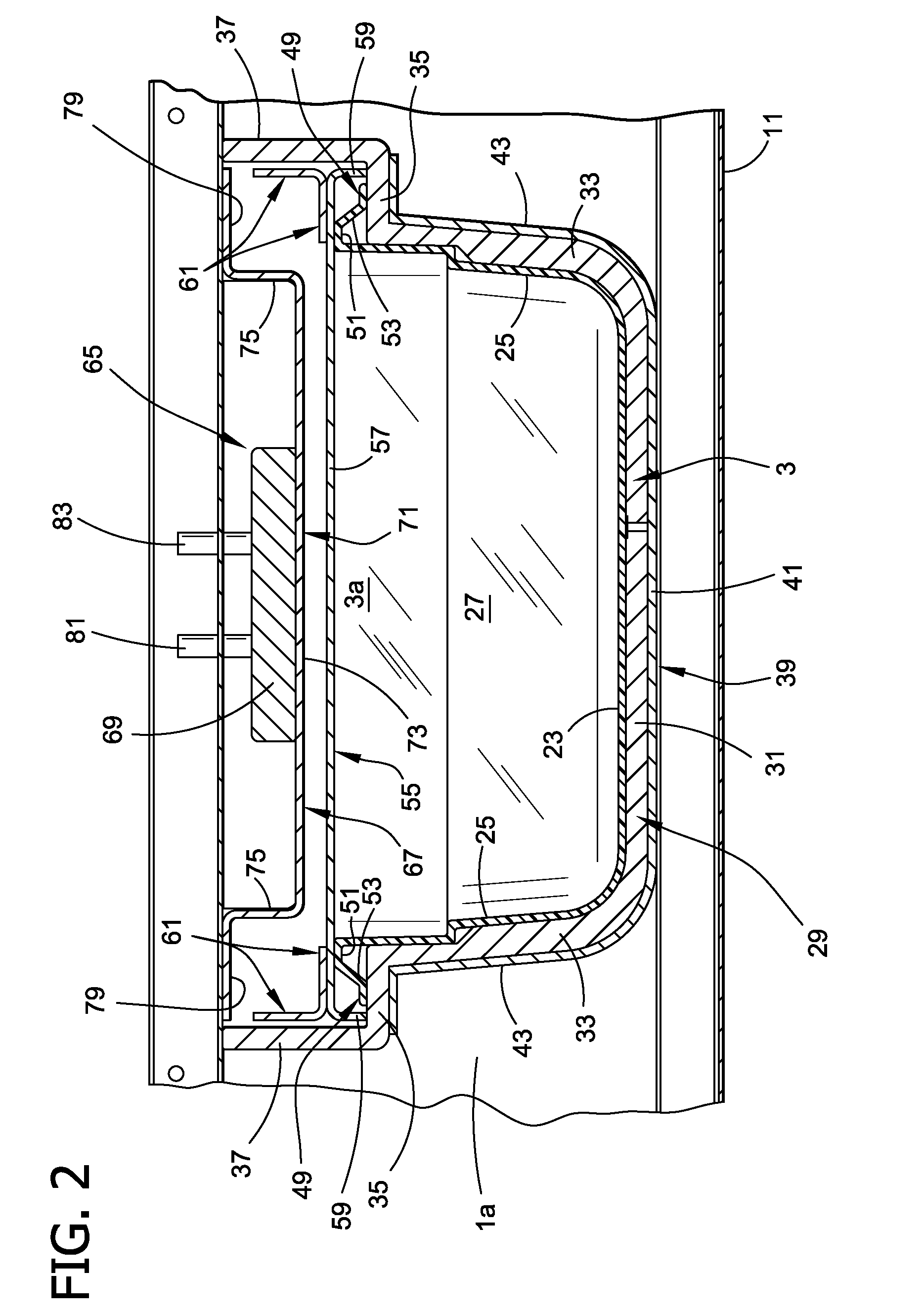

Food service apparatus and methods

InactiveUS20080023462A1Avoid overall overheatingLonger heldDomestic stoves or rangesElectrical heating fuelEngineeringIngested food

Owner:DUKE MANUFACTURING COMPANY

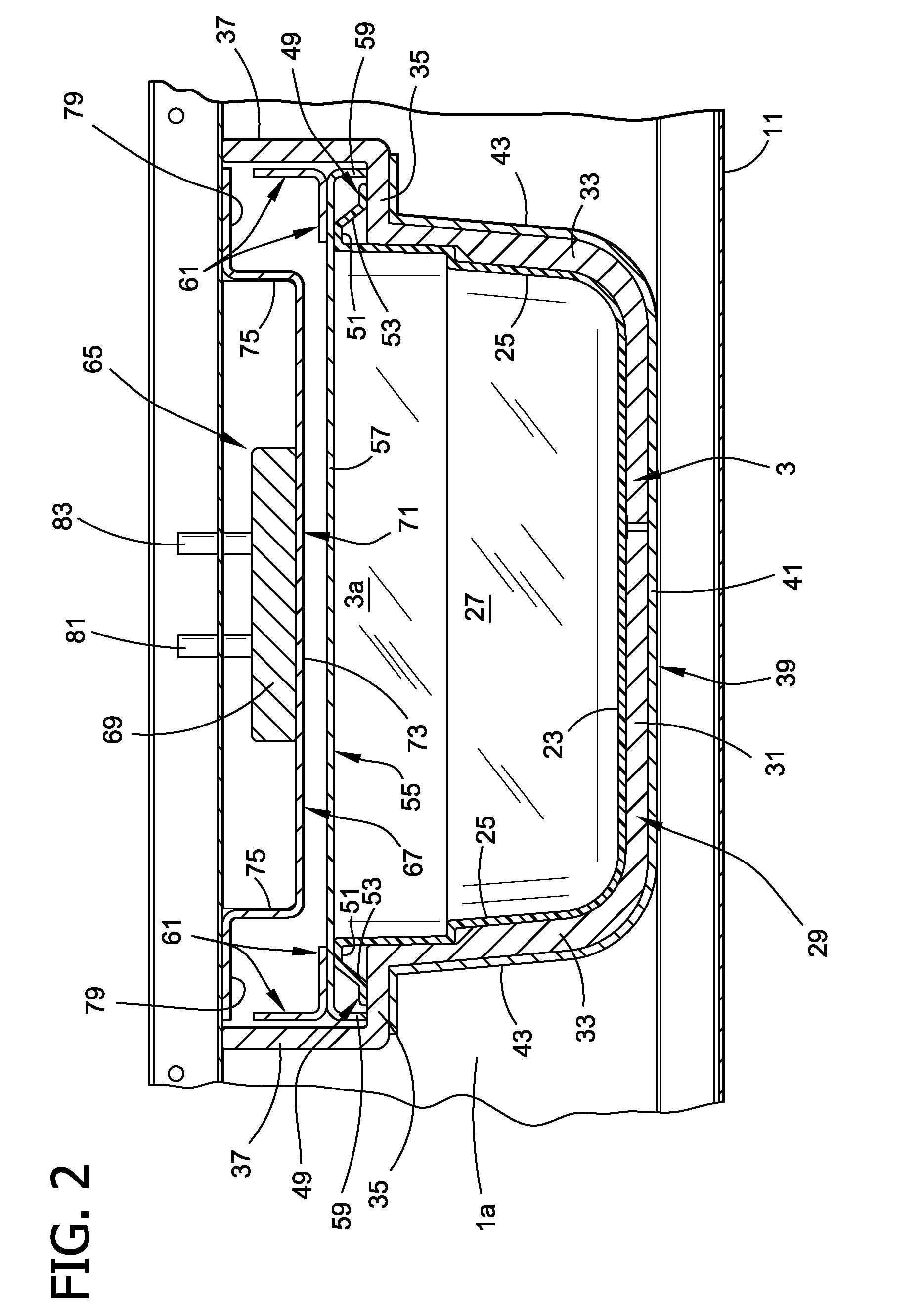

Food service apparatus and methods

InactiveUS7446282B2Avoid overall overheatingPrevent overheating of the foodAir-treating devicesDomestic stoves or rangesEngineeringFood products

Owner:DUKE MANUFACTURING COMPANY

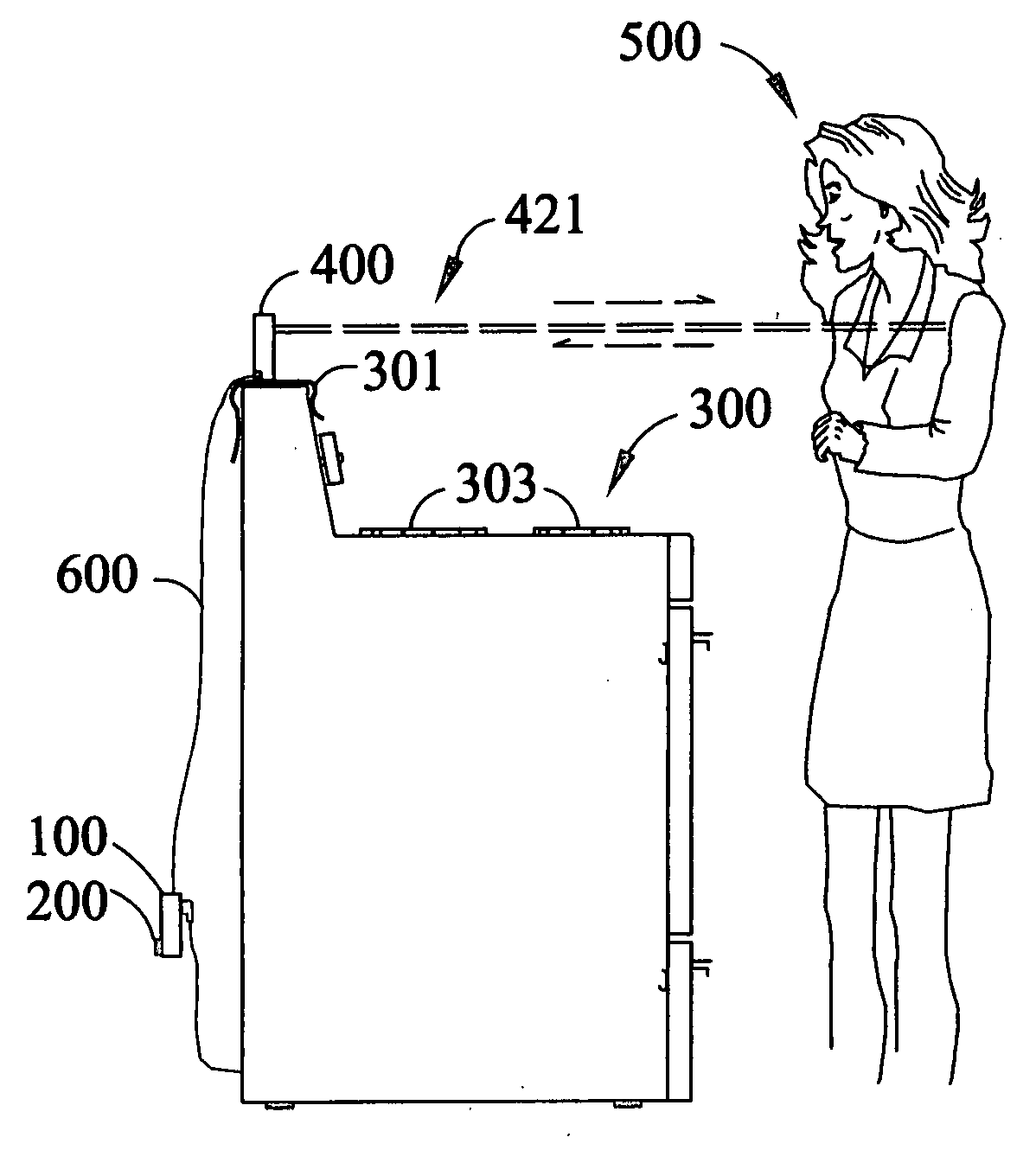

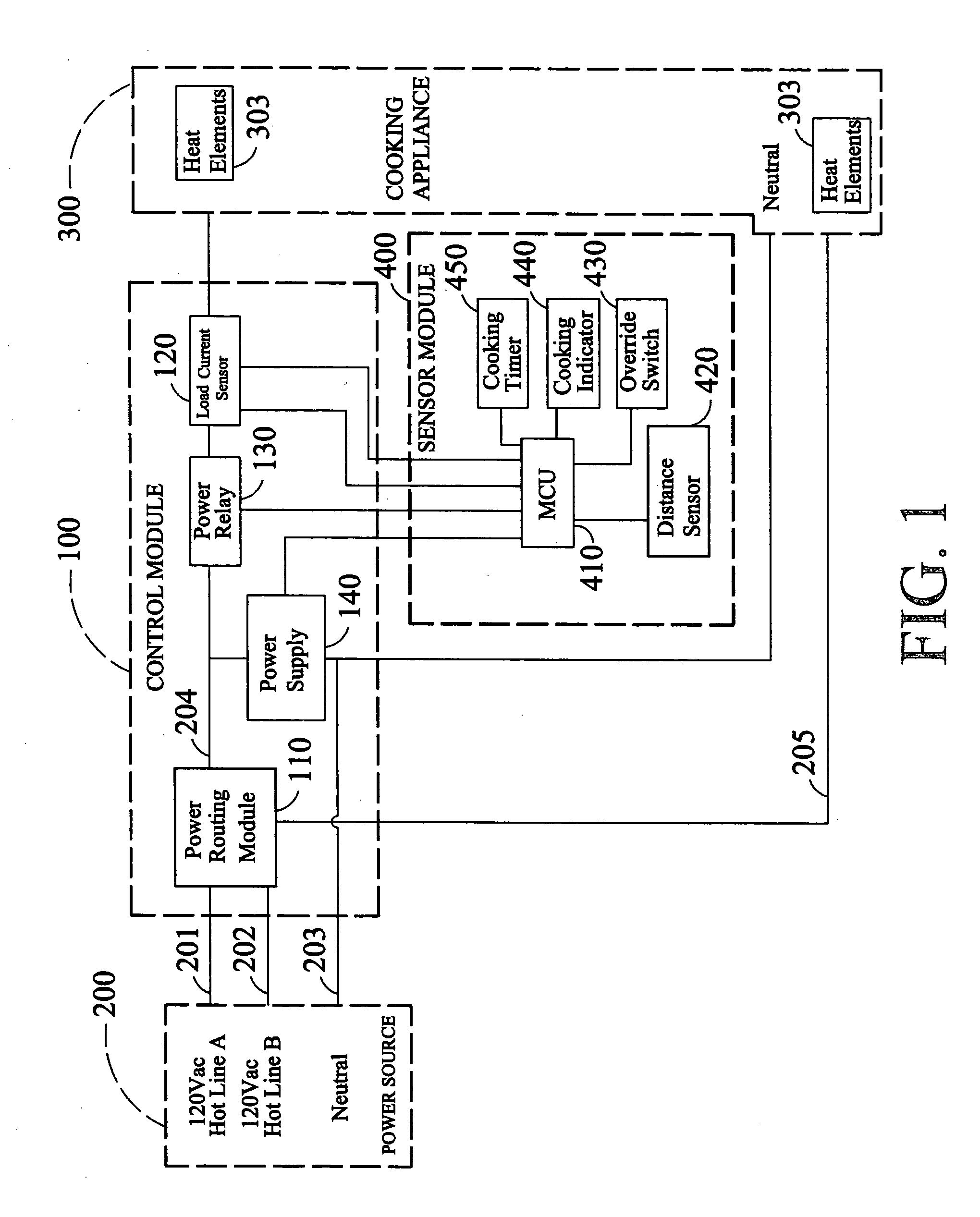

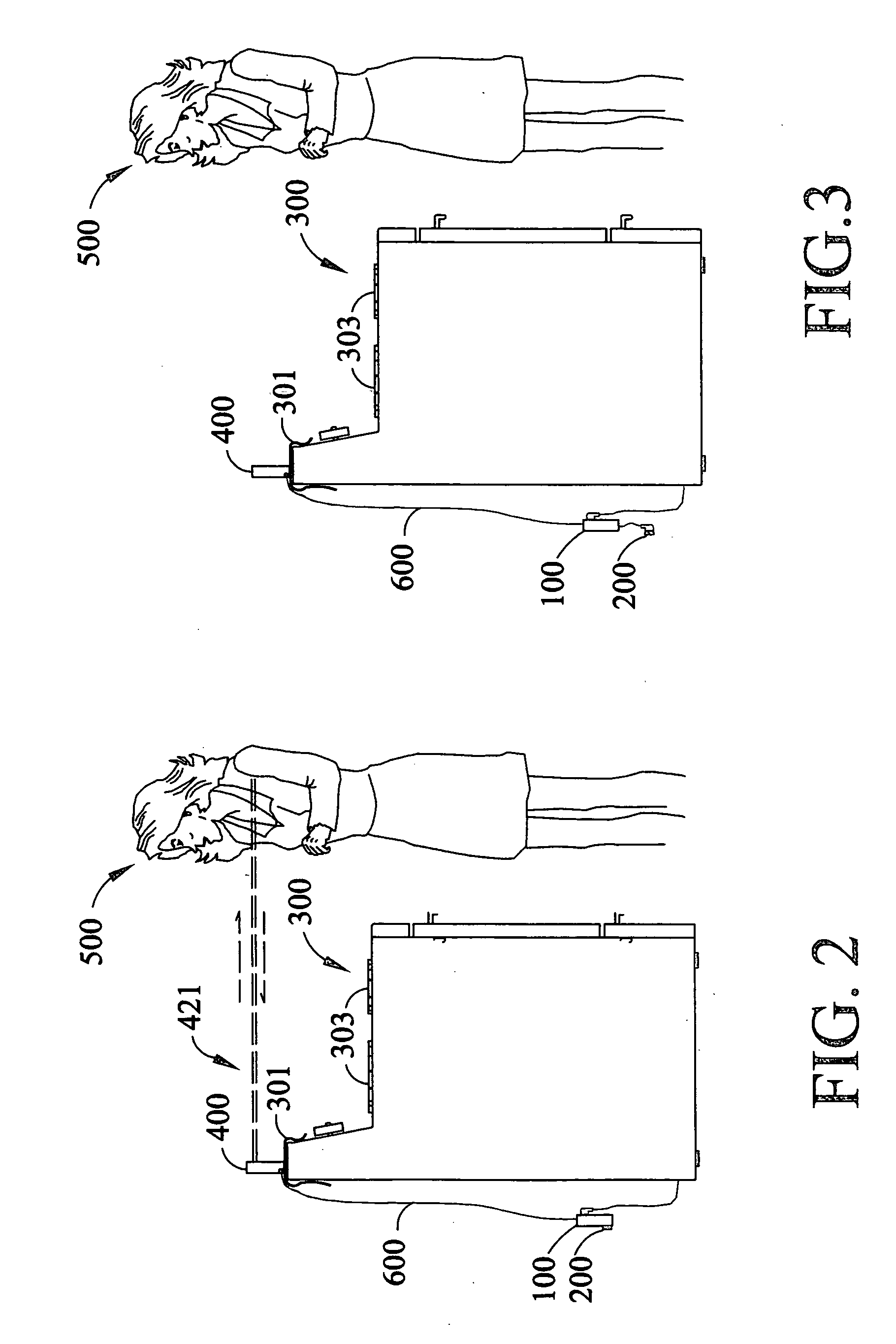

Safety device for regulating electrical power to a cooking appliance

InactiveUS20050109333A1Reduce heat outputReduce electric powerDomestic stoves or rangesLighting and heating apparatusEquipment OperatorEngineering

A safety device for regulating electrical power to a cooking appliance, comprising a control module having a power routing means, a power supply means, a load current sensing means for detecting a load current to the cooking appliance and a power relay means for controlling the electrical current to the cooking appliance, and a sensor module located adjacent to the cooking appliance for observation by an appliance operator and connected to the control module. The sensor module governs the production of the electrical current to the cooking appliance, and has a monitoring means, a distance sensing means, a timer means for showing elapsed cooking time, and a light emitting means. The monitoring means is responsive to outputs of the distance sensing means and includes a timer assembly programmed to a predetermined period of time for responding to the distance sensing means detecting the presence of the appliance operator.

Owner:THOMAS LOWELL RICHARD

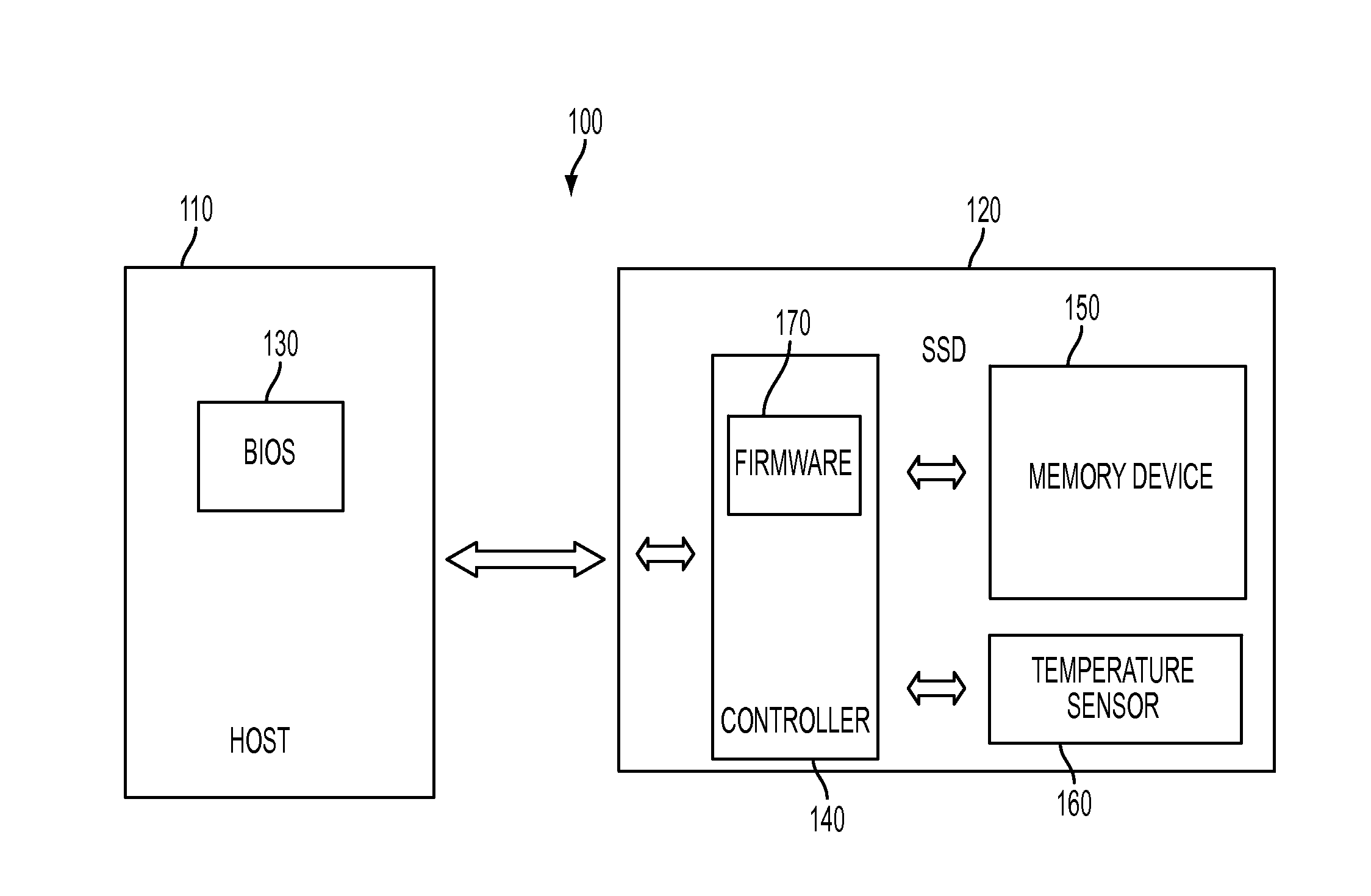

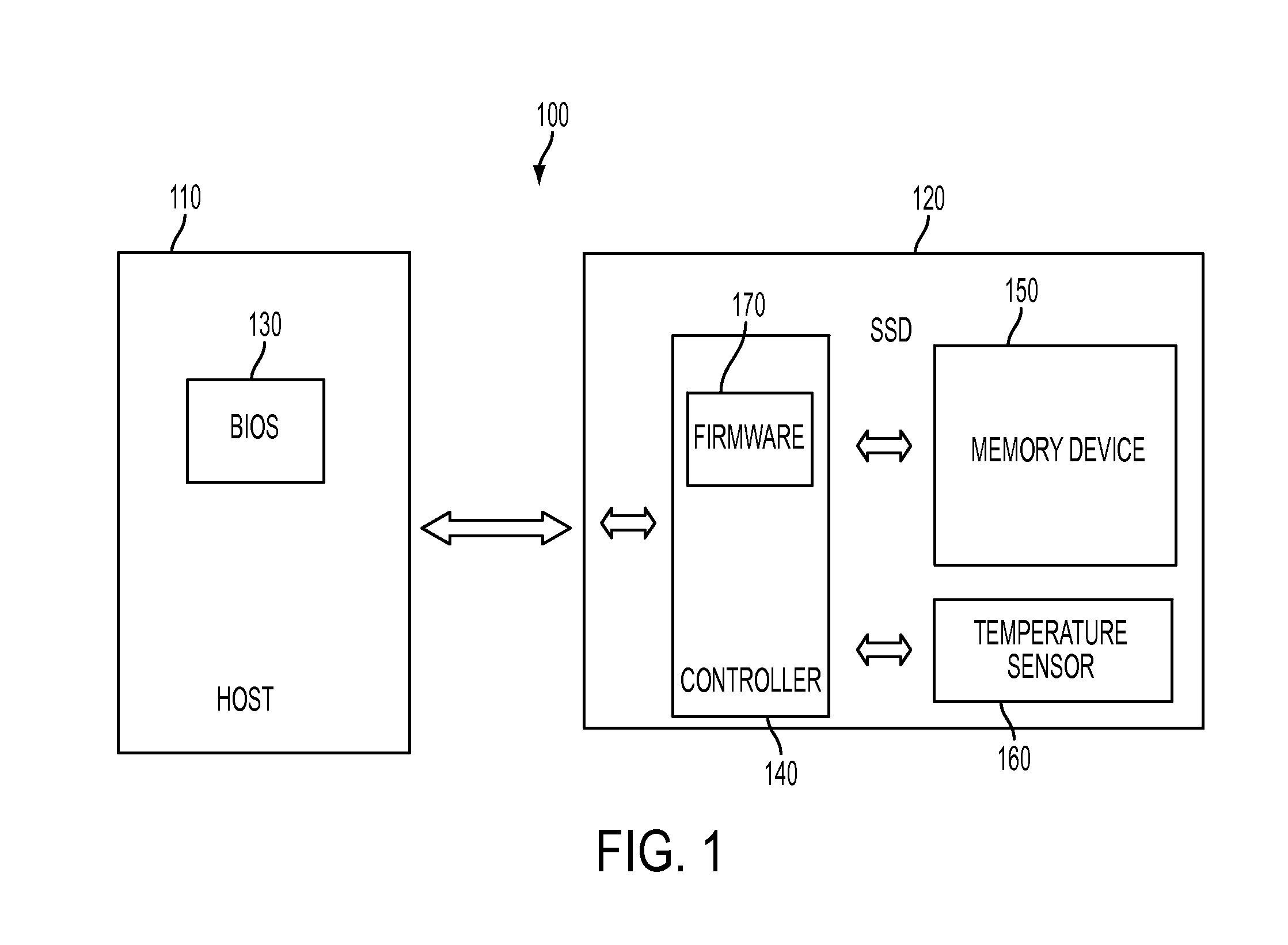

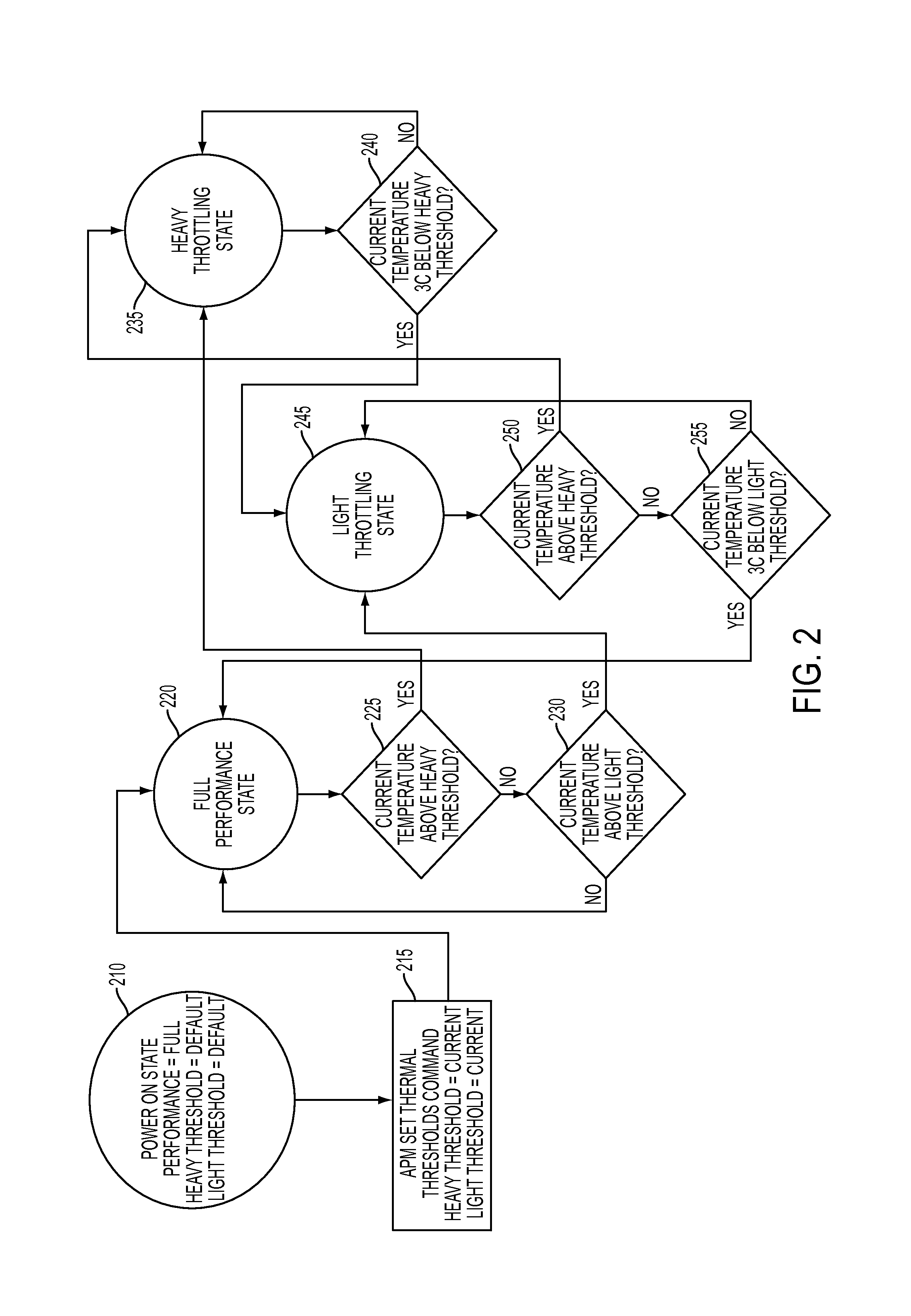

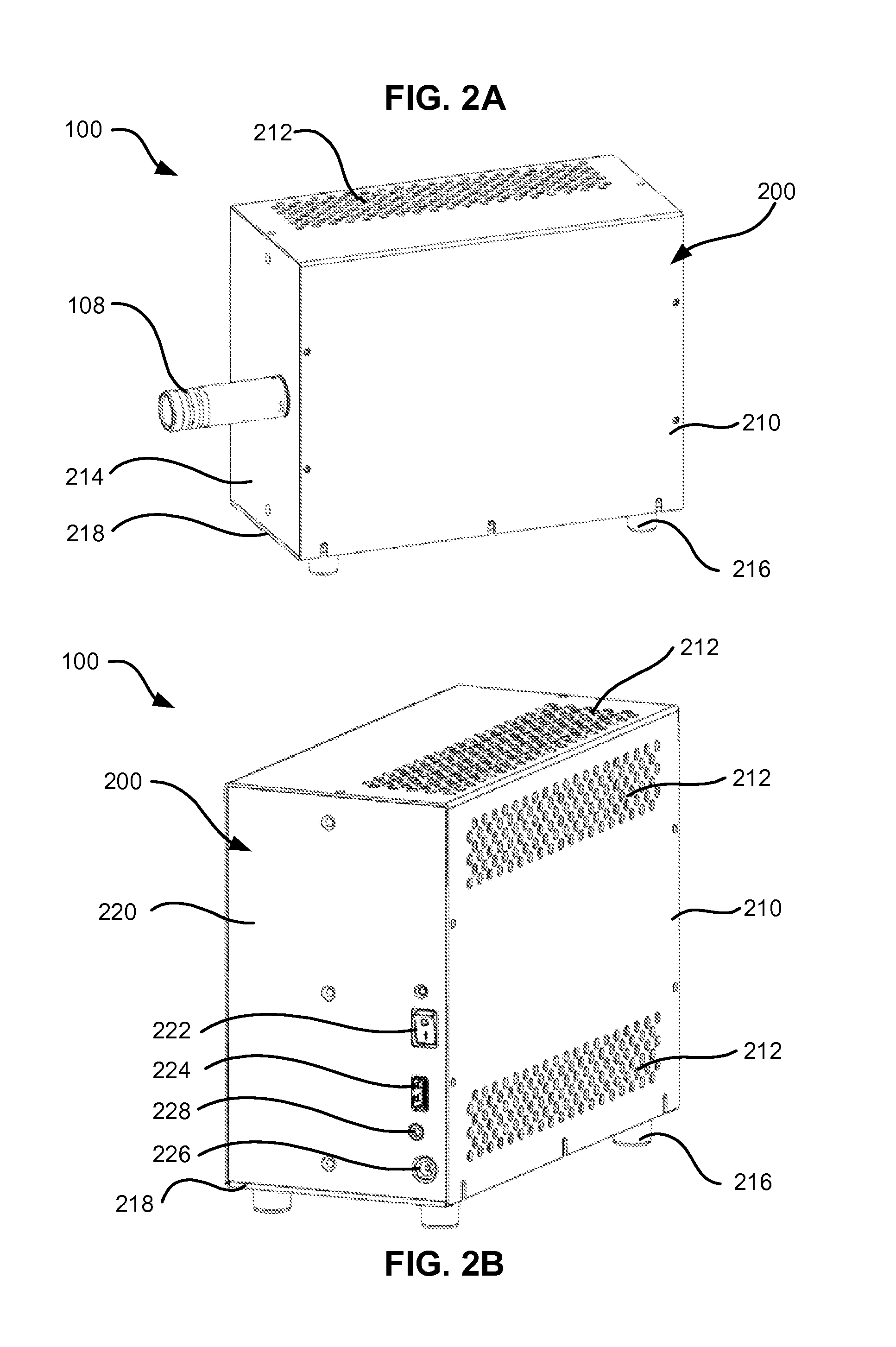

Device side initiated thermal throttling

InactiveUS20160062421A1Reduce heat outputComputer controlDigital data processing detailsOperating temperatureEmbedded system

Thermal throttling of a storage device may be provided independent of the host computing device according to the disclosed exemplary embodiments. The storage device may be connectable to more than one type and / or make of host computing devices whose thermal safety requirements may differ. Threshold temperature values for safely operating the storage device may be stored in the host computing device. A controller in the storage device may receive the threshold temperature value(s) from the host computing device and may throttle operating performance of the storage device based on a sensed operating temperature of the storage device compared relative to the stored threshold temperature value associated with the host computing device.

Owner:LENOVO (SINGAPORE) PTE LTD

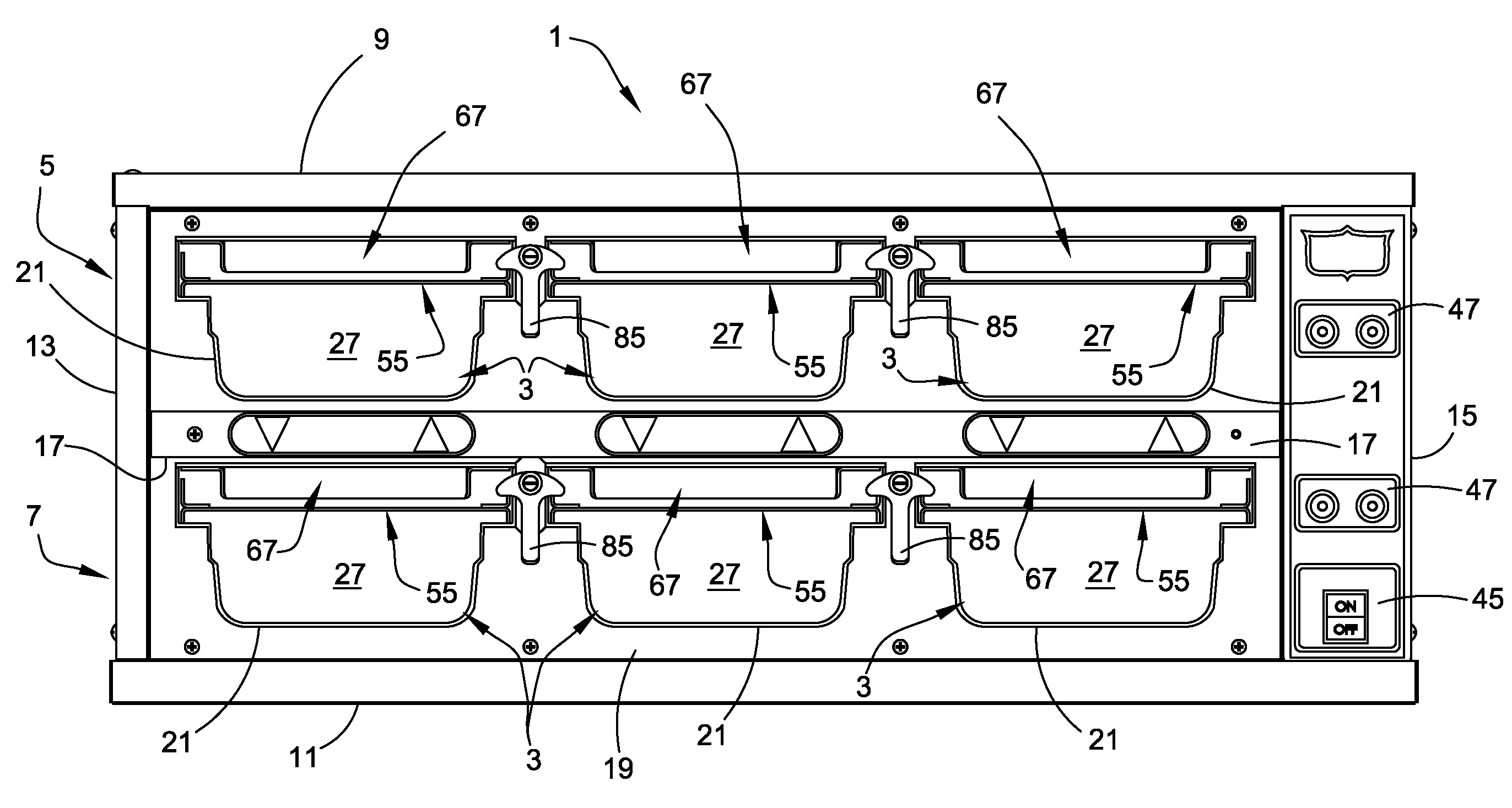

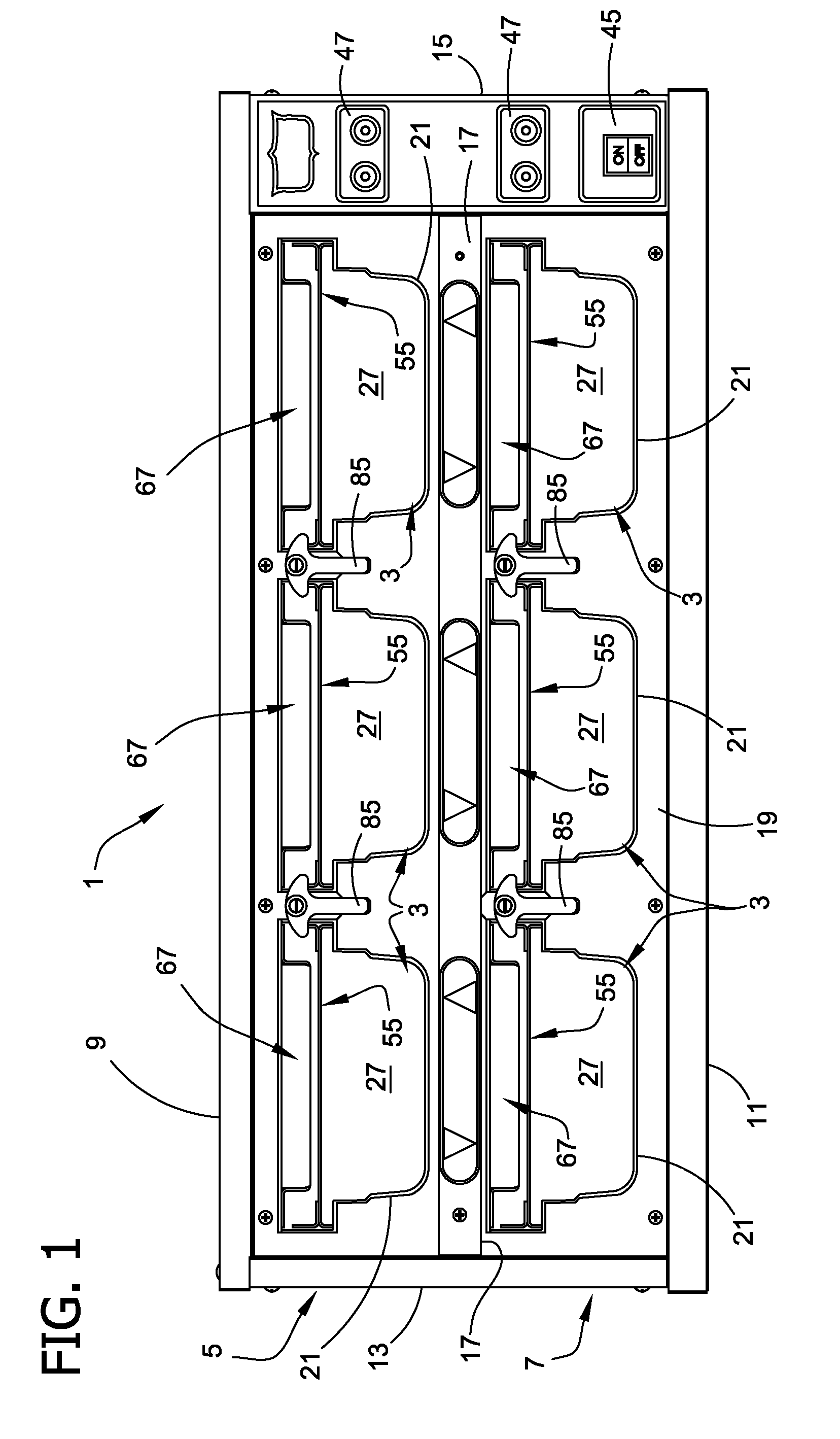

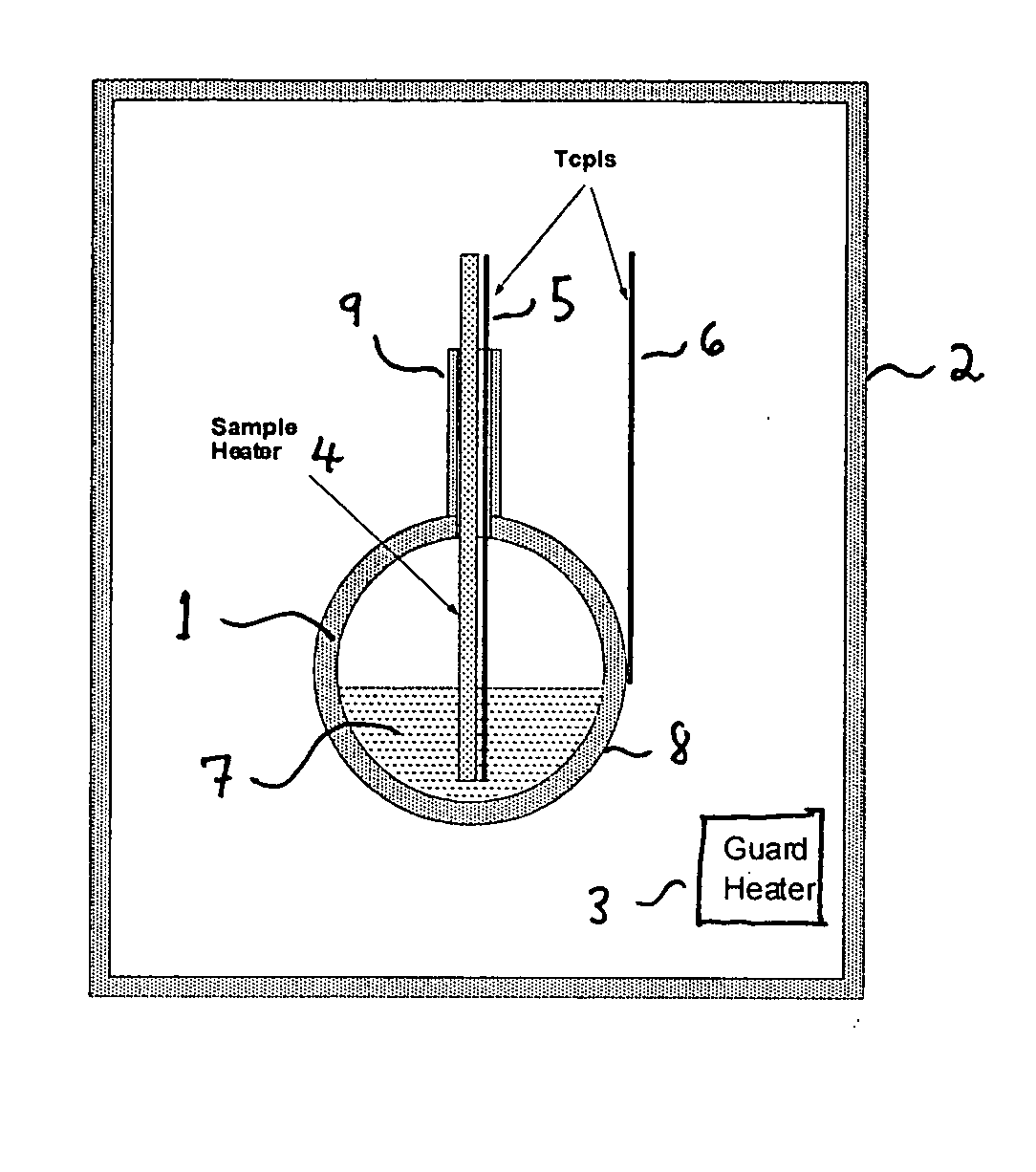

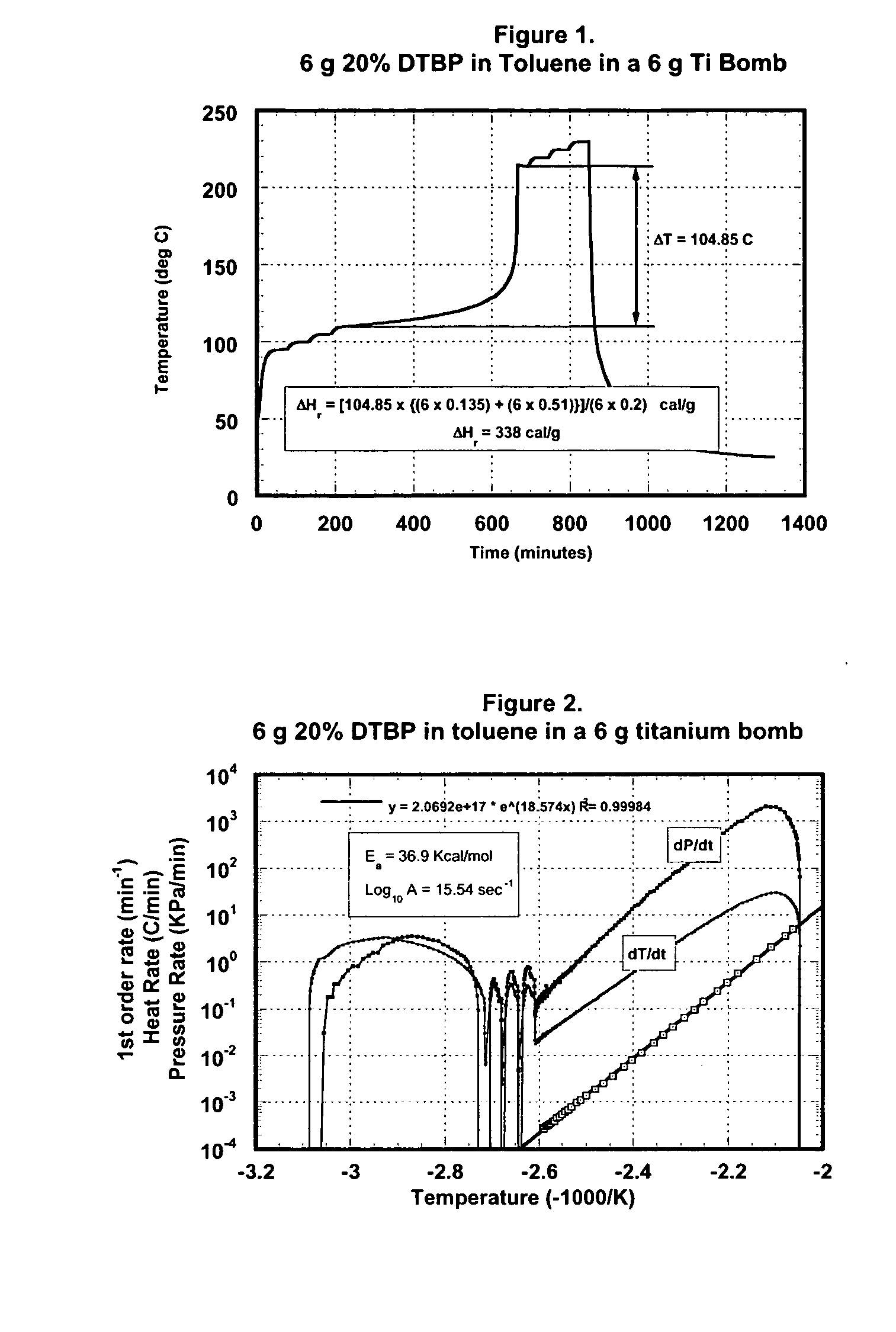

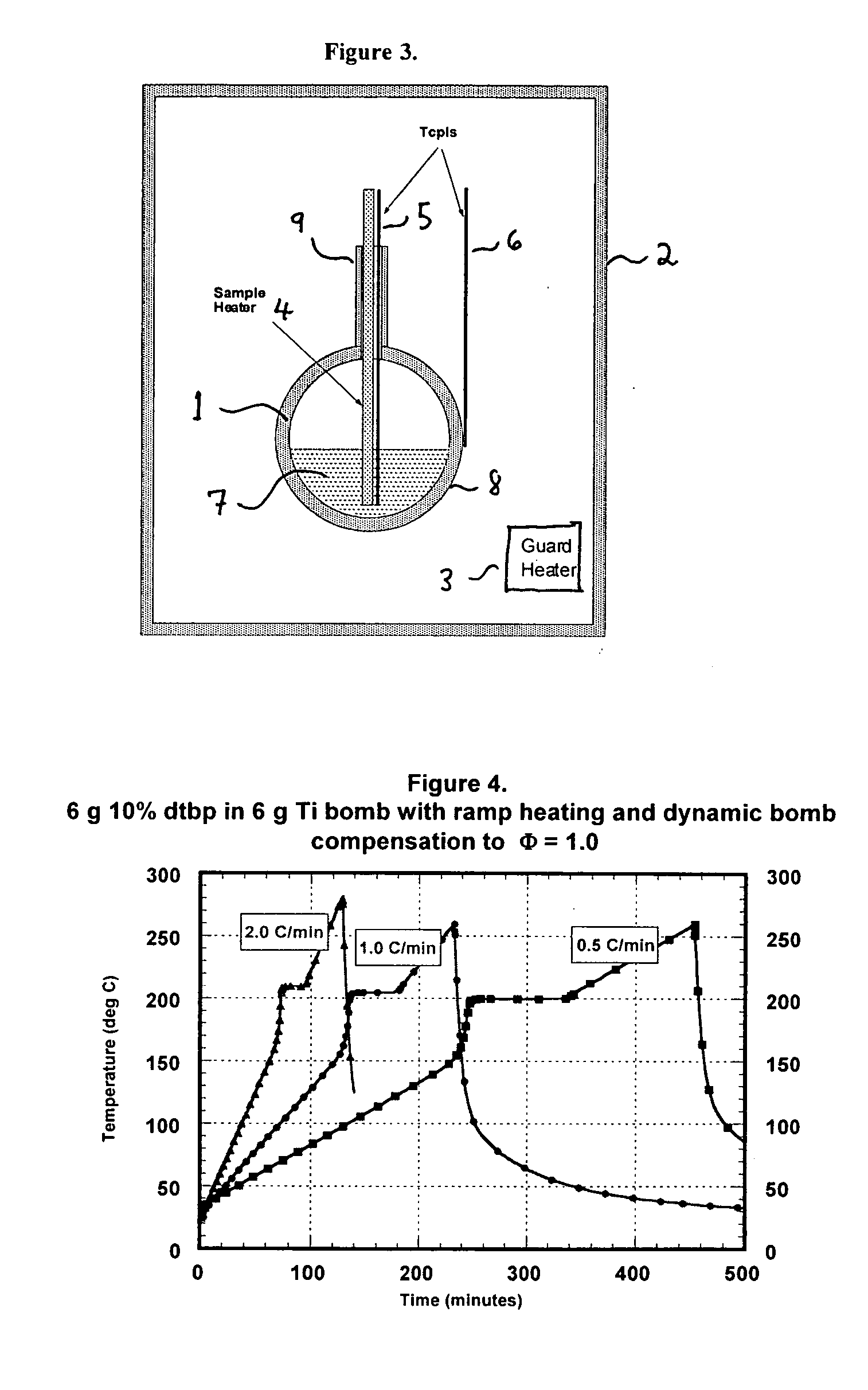

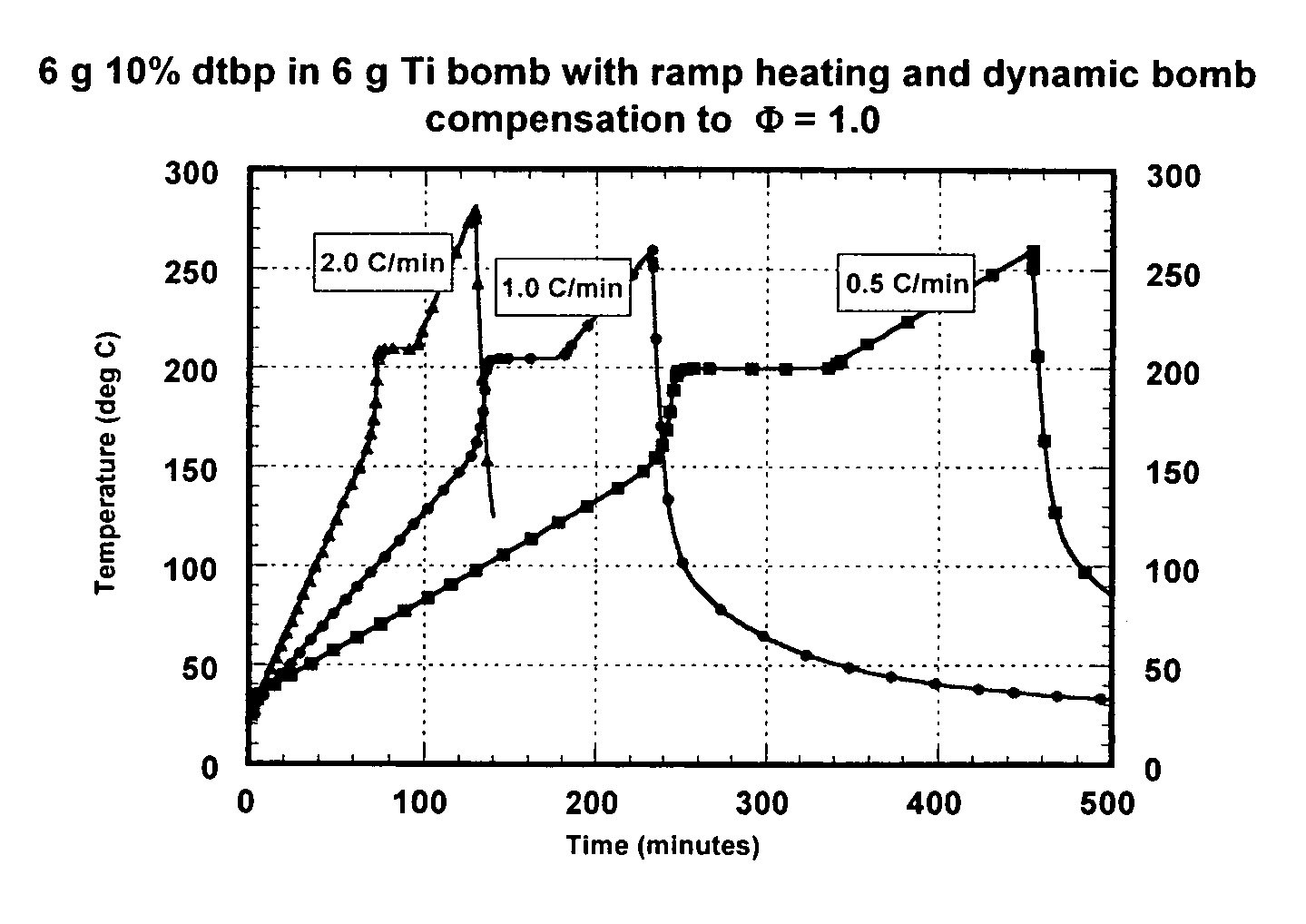

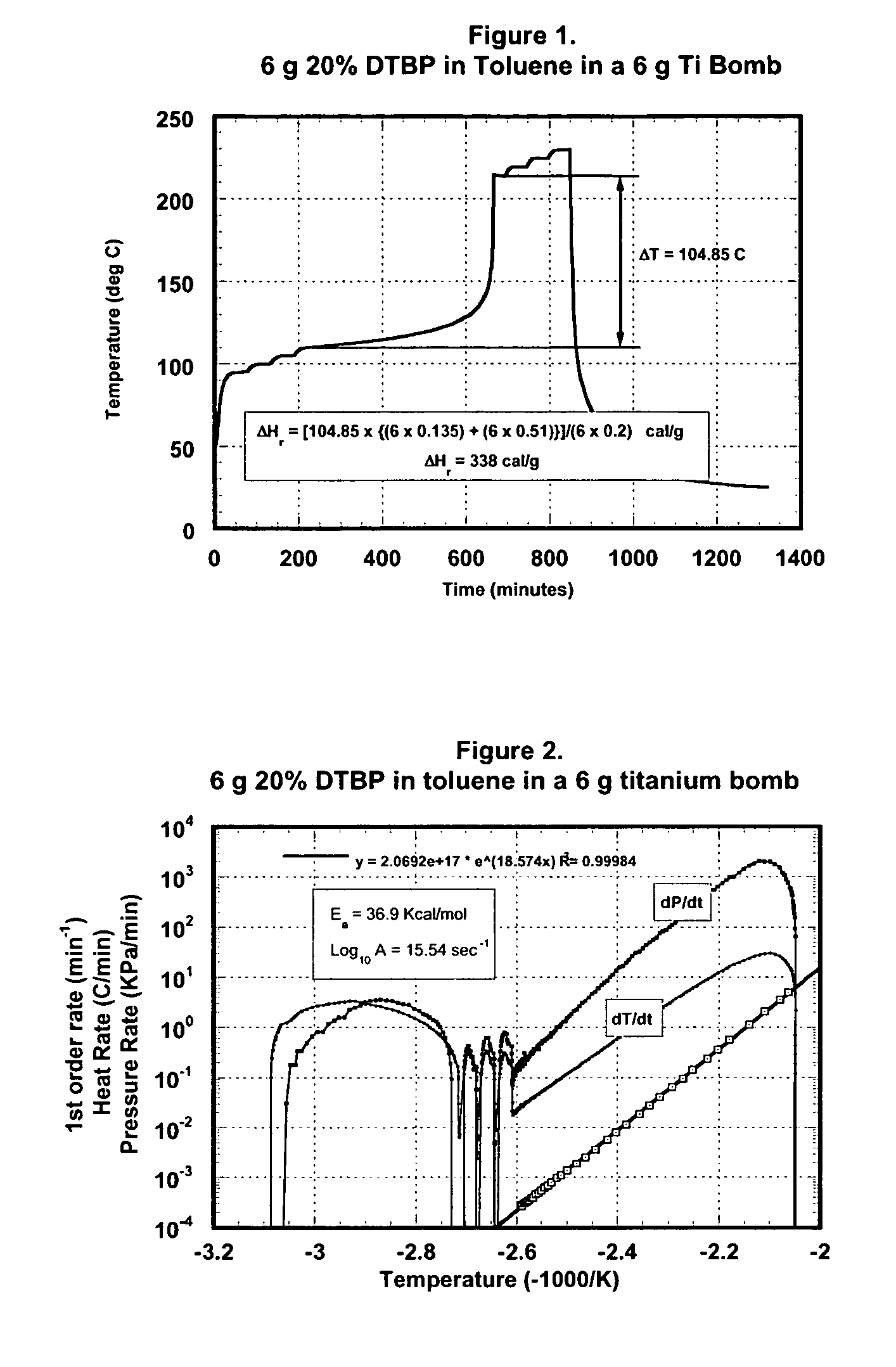

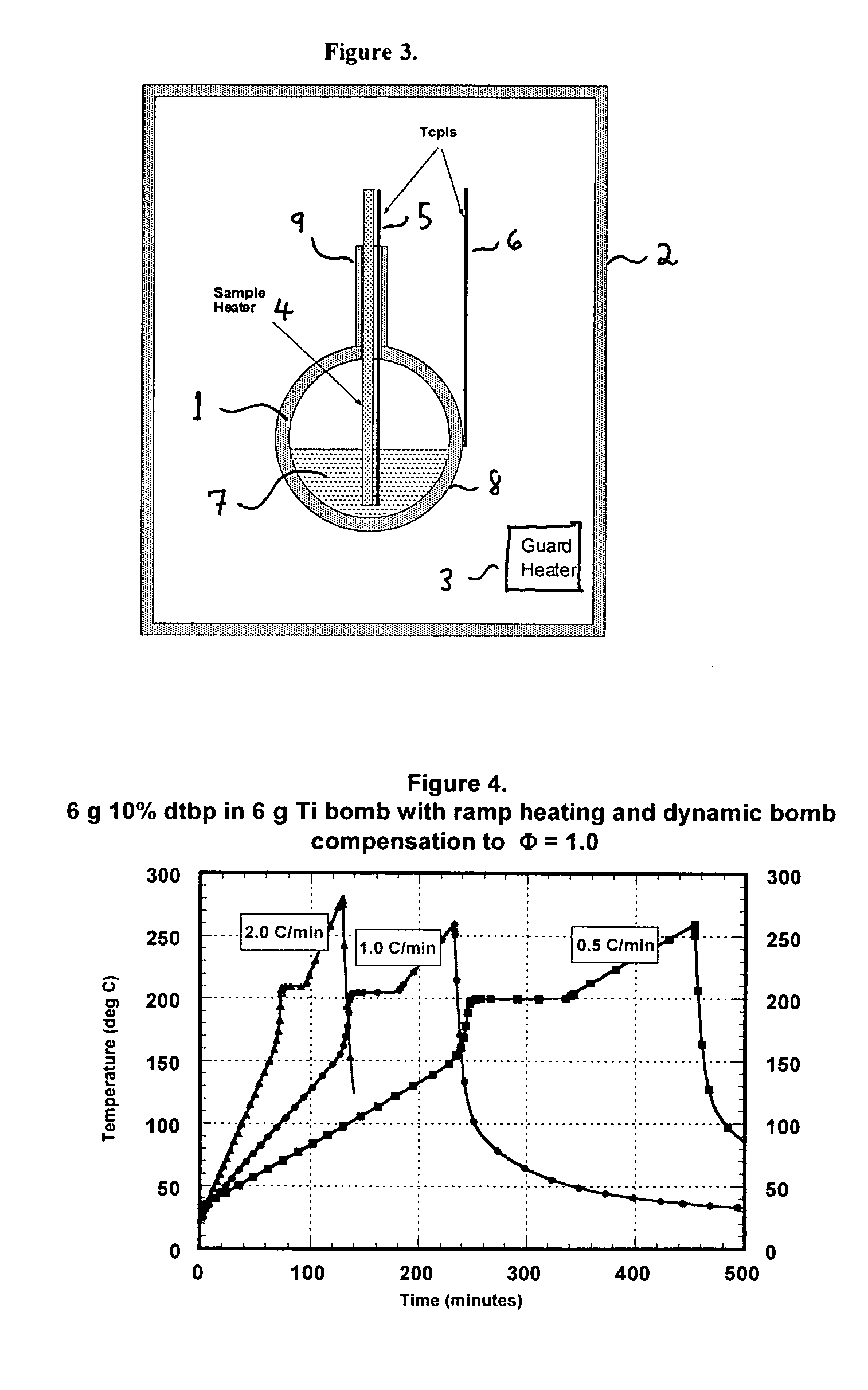

Low thermal inerta scanning adiabatic calorimeter

ActiveUS20050008063A1Prevent heat lossReduce heat outputMaterial heat developmentThermometers using electric/magnetic elementsContinuous measurementProduction rate

A new adiabatic scanning calorimeter allows the thermal mass of a high-pressure reaction vessel to be dynamically compensated during a test. This allows the effective Φ factor for the experiment to be reduced to 1.0 without the use of complex pressure balancing equipment. Endothermic events can be quantified and sample specific heats can be measured. The time required for test completion is much shorter than for conventional adiabatic calorimeters, thus considerably improving apparatus productivity. The sensitivity to exotherm detection is at least as good as existing adiabatic calorimeters employing the Heat-Wait-Search strategy, but does depend on the temperature-scanning rate. In addition, the heat of reaction is obtained without reference to the heat capacity of the sample, pressure is measured continuously, reactants may be injected into the test vessel and the sample can be mixed during the test.

Owner:NETZSCH GERATEBAU GMBH

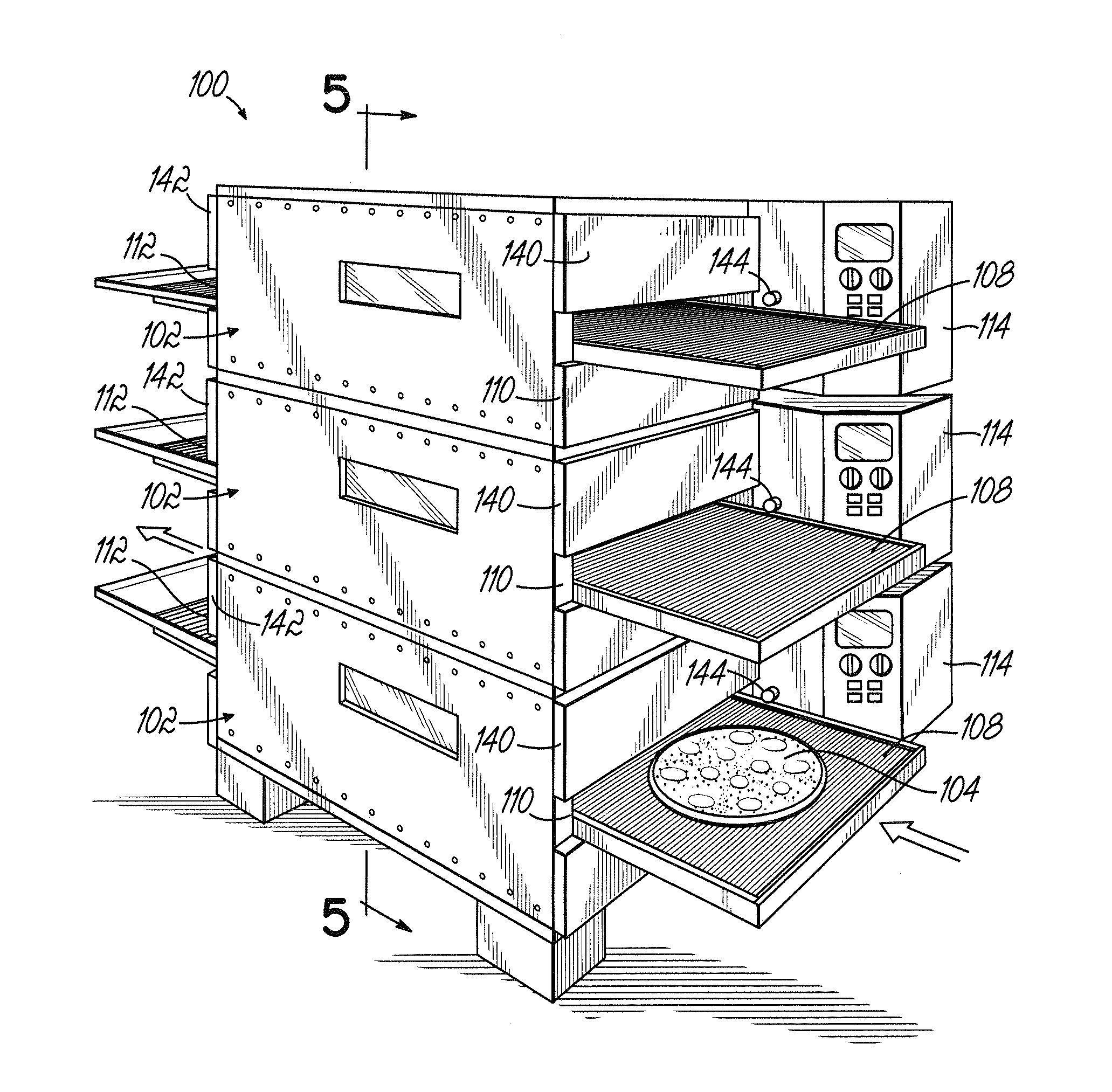

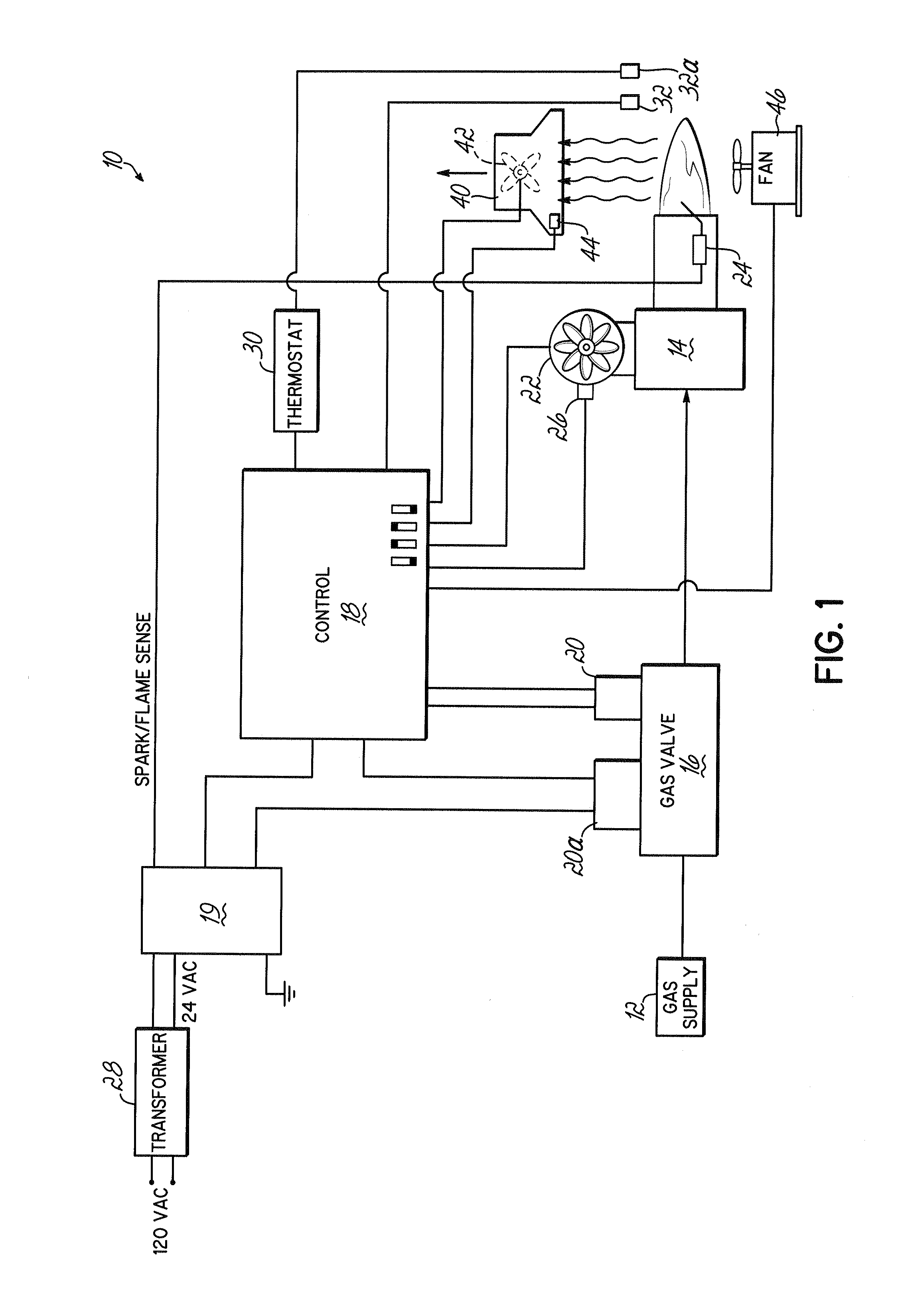

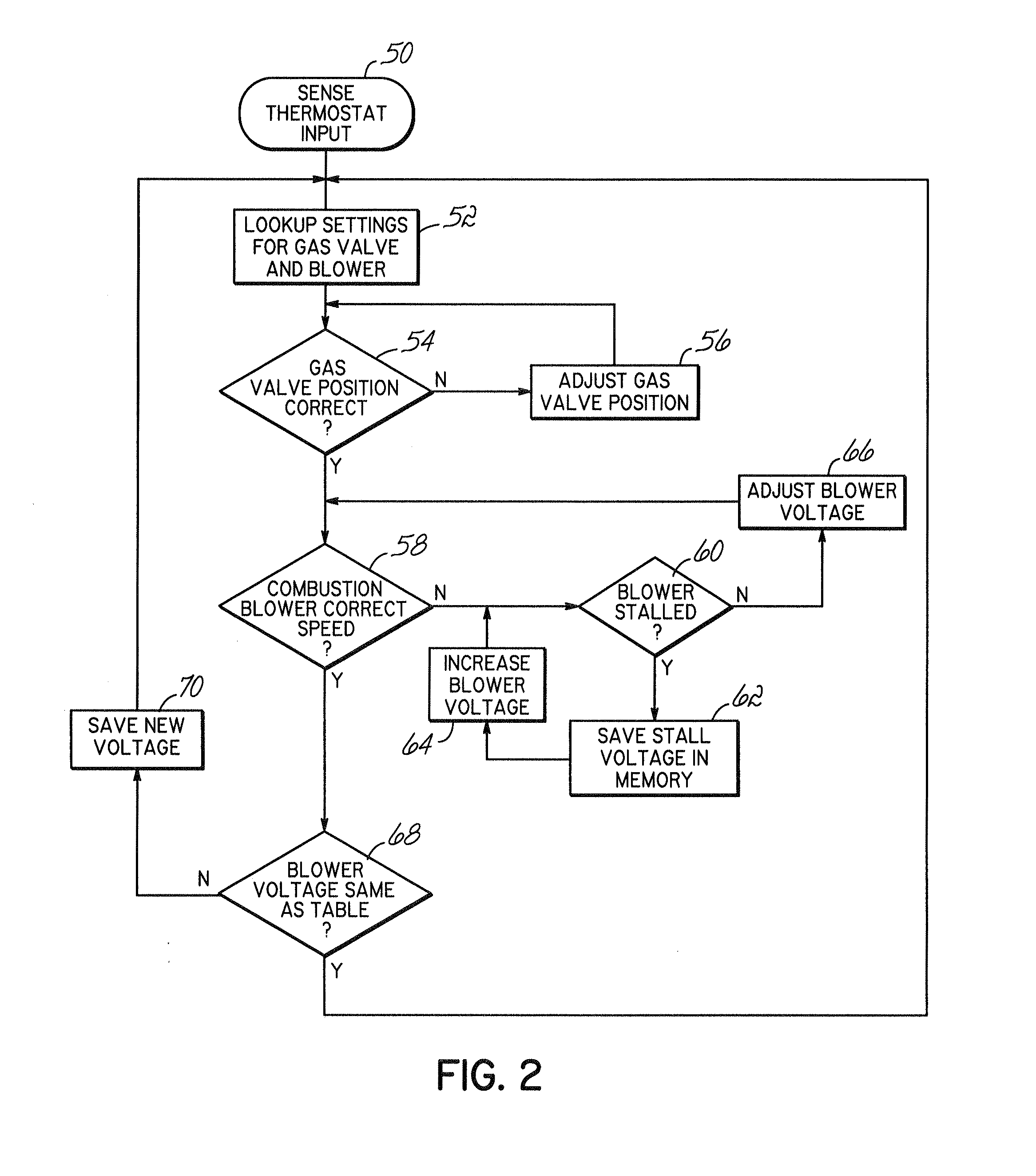

Modulated Power Burner System And Method

ActiveUS20100319551A1Maintenance conditionExcessive delayFuel supply regulationCombustion ventilatorsAir cycleCombustor

A power burner system for use with a heating appliance includes a burner tube, a gas valve for providing gas to the burner tube, and a variable speed combustion air blower for mixing air with the gas provided to the burner tube. The burner system further includes a control in communication with the gas valve and the combustion air blower. The control may also be in communication with various other devices of an appliance, such as a variable speed air-circulating fan, a variable speed exhaust fan, or various sensors associated with the heating appliance. The control modulates the gas valve and the combustion air blower to maintain substantially stoichiometric conditions of the gas and air provided to the burner tube and as a function of signals from at least one of the devices. In one embodiment, the burner system may be used in a conveyor oven.

Owner:WAYNESCOTT FETZER

Low thermal inertia scanning adiabatic calorimeter

ActiveUS7021820B2Prevent heat lossReduce heat outputMaterial heat developmentThermometers using electric/magnetic elementsProduction rateHigh pressure

A new adiabatic scanning calorimeter allows the thermal mass of a high-pressure reaction vessel to be dynamically compensated during a test. This allows the effective Φ factor for the experiment to be reduced to 1.0 without the use of complex pressure balancing equipment. Endothermic events can be quantified and sample specific heats can be measured. The time required for test completion is much shorter than for conventional adiabatic calorimeters, thus considerably improving apparatus productivity. The sensitivity to exotherm detection is at least as good as existing adiabatic calorimeters employing the Heat-Wait-Search strategy, but does depend on the temperature-scanning rate. In addition, the heat of reaction is obtained without reference to the heat capacity of the sample, pressure is measured continuously, reactants may be injected into the test vessel and the sample can be mixed during the test.

Owner:NETZSCH GERATEBAU GMBH

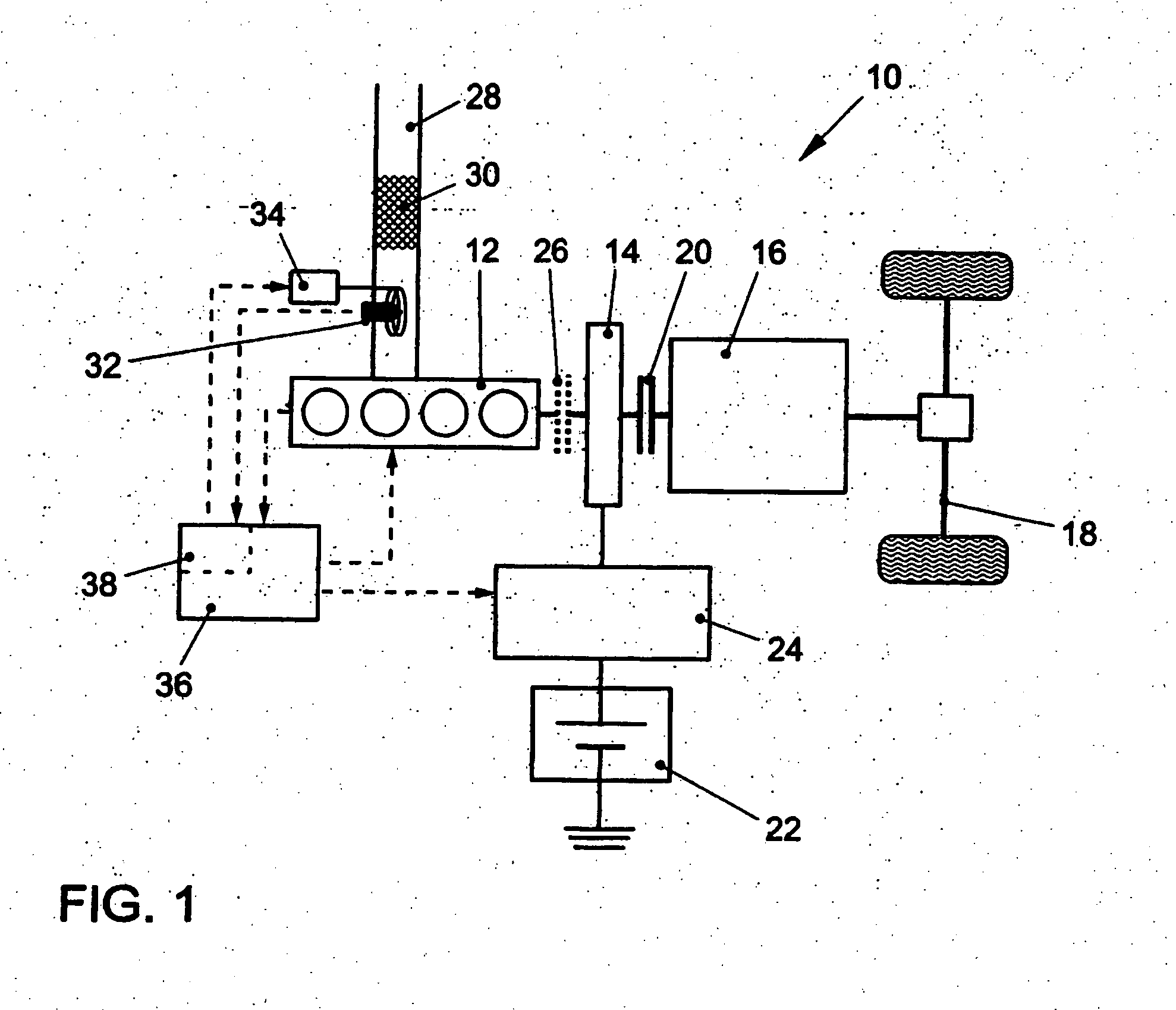

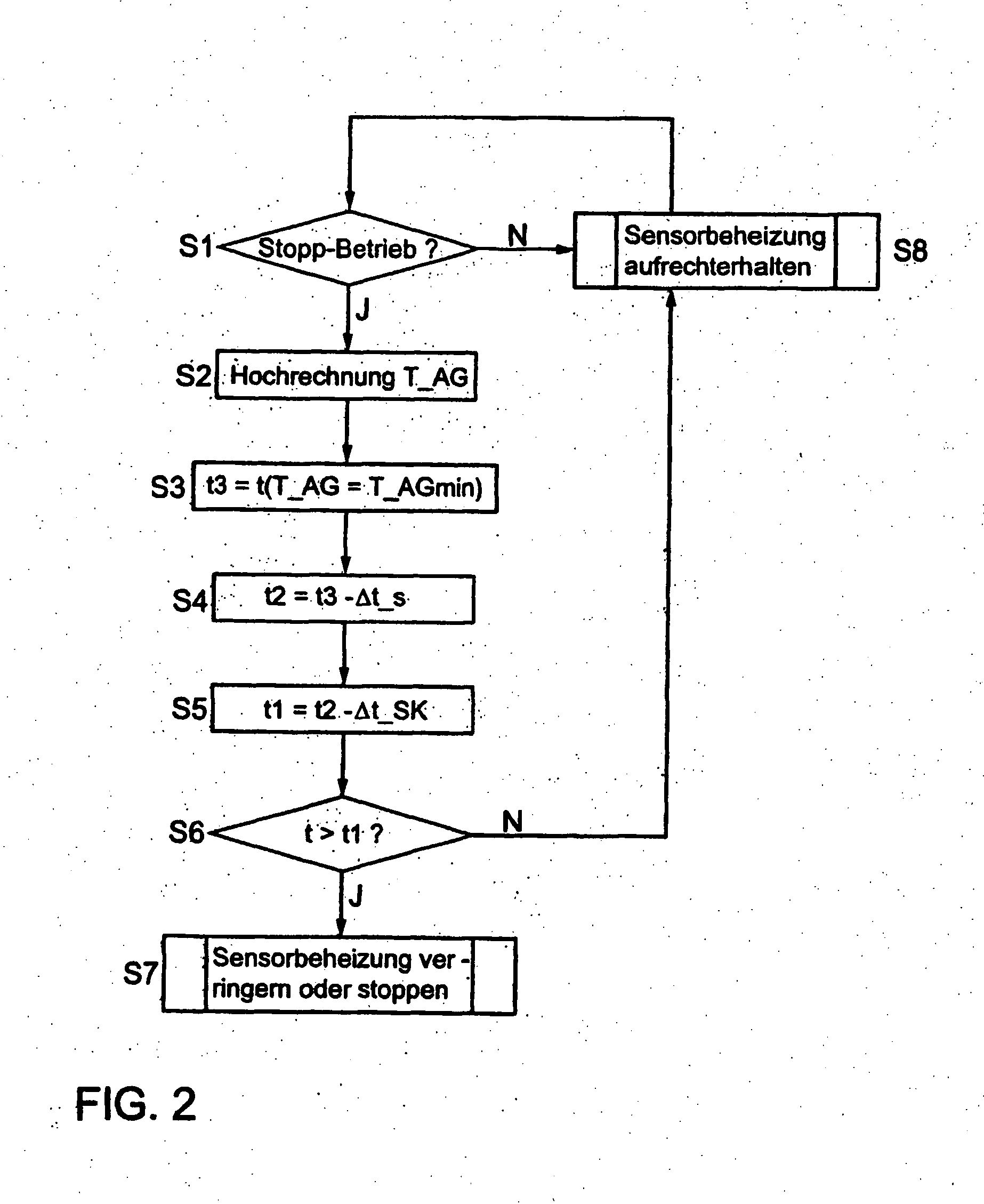

Method for Controlling an Operation of a Heatable Exhaust-Gas Sensor of a Motor Vehicle

InactiveUS20080209886A1Reduce heat outputImpair actionElectrical controlInternal combustion piston enginesHeat outputPrecipitation

A method is for controlling the operation of an exhaust-gas sensor disposed in an exhaust duct of a motor vehicle and equipped with an internal or external sensor heating device, the motor vehicle including a combustion engine and an automatic switchoff, which causes an automatic switching off of the combustion engine when at least one stop condition is present. It is provided that: (a) following an automatic switching off of the combustion engine by the automatic switchoff, a first future instant is determined at which the exhaust-gas temperature in the exhaust duct will drop below a condensation temperature below which condensate precipitation from the exhaust gas may occur; (b) a second instant is determined at which a heat output of the sensor heating device must be interrupted or reduced so that a sensor temperature of the exhaust-gas sensor will have dropped to a maximally allowed sensor temperature no later than the first future instant; and the heat output of the sensor heating device is interrupted or reduced when the second instant is attained.

Owner:VOLKSWAGEN AG +1

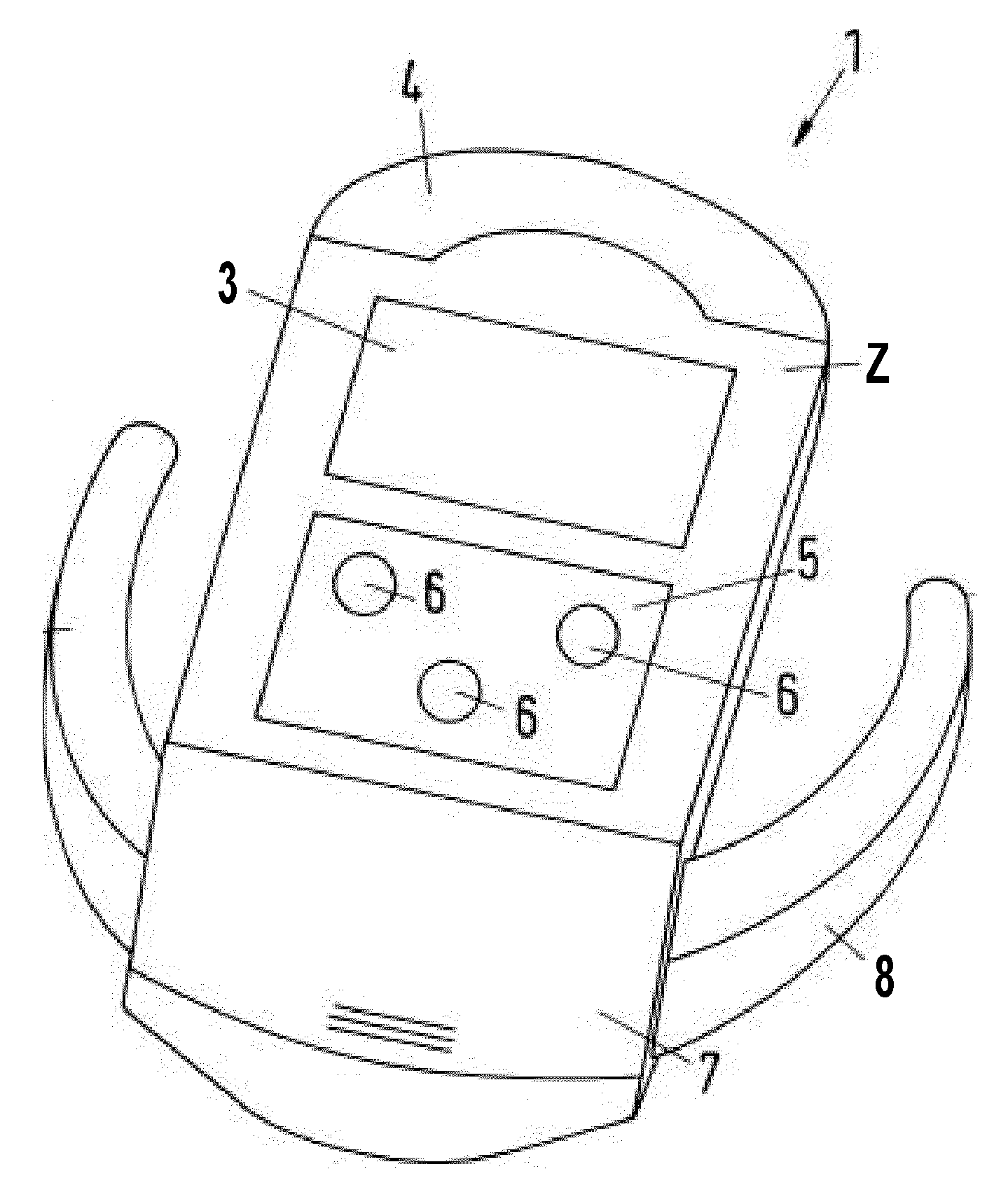

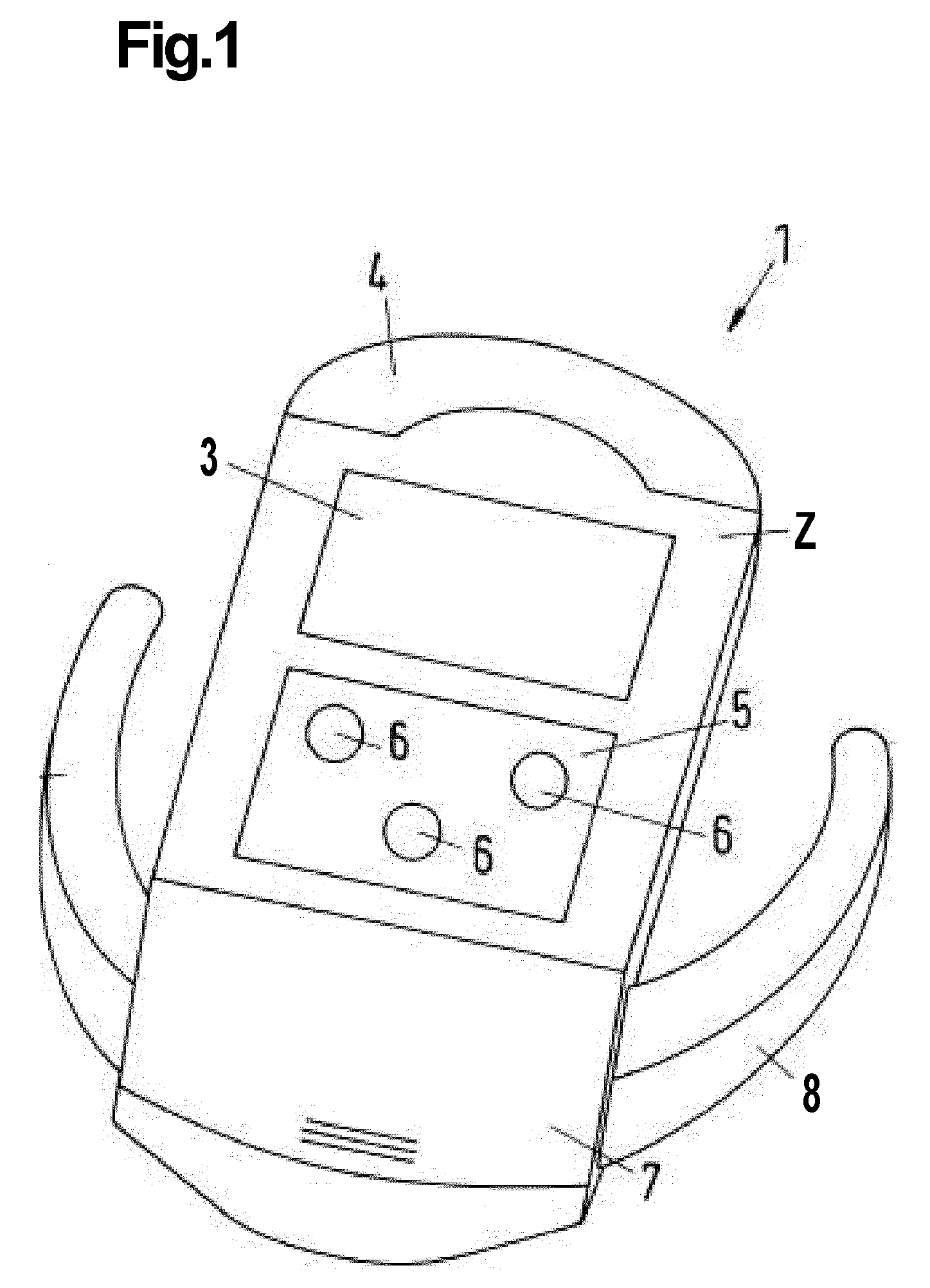

Pressure detection system for a pressure cooker

ActiveUS20130249698A1Improve reliabilityReduce heat outputBoiling over preventionFluid pressure measurementDisplay deviceEngineering

The invention describes a pressure detection system for a pressure cooker, having a sensor (17) for detecting a pressure prevailing inside the pressure cooker by means of measured values, a computer unit (16) connected to the sensor (17), and a display (3, 4), wherein the computer unit (16) is designed to evaluate the measured values supplied by the sensor (17) and to establish whether at least one first threshold value (S1) has been reached. In order to indicate use-related wear, the computer unit (16) is further designed to continue a counter when the measured value reaches the first threshold value (S1) and to output a notification on the display (3, 4) when a predefined value of the counter is reached.

Owner:FISSLER

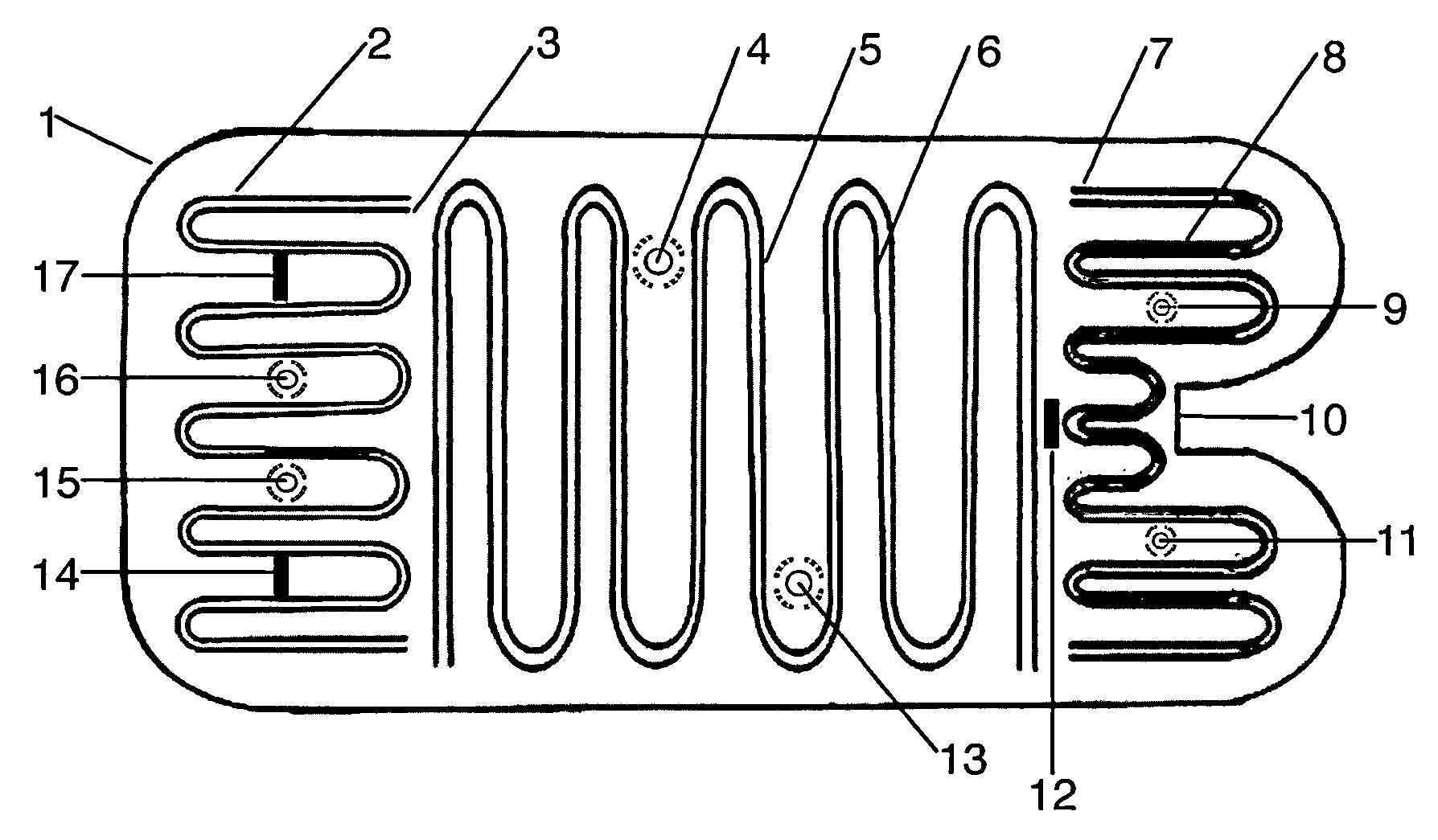

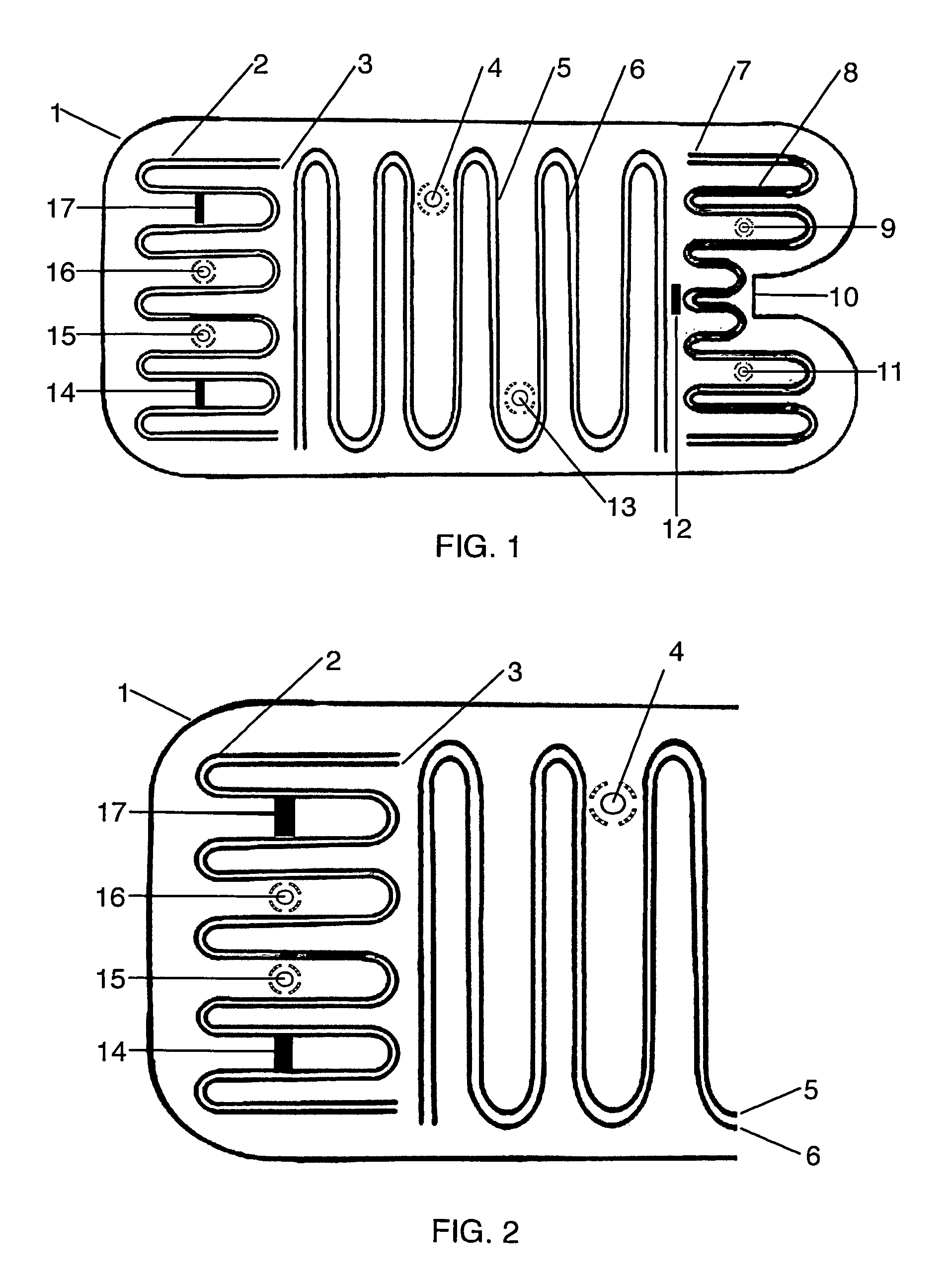

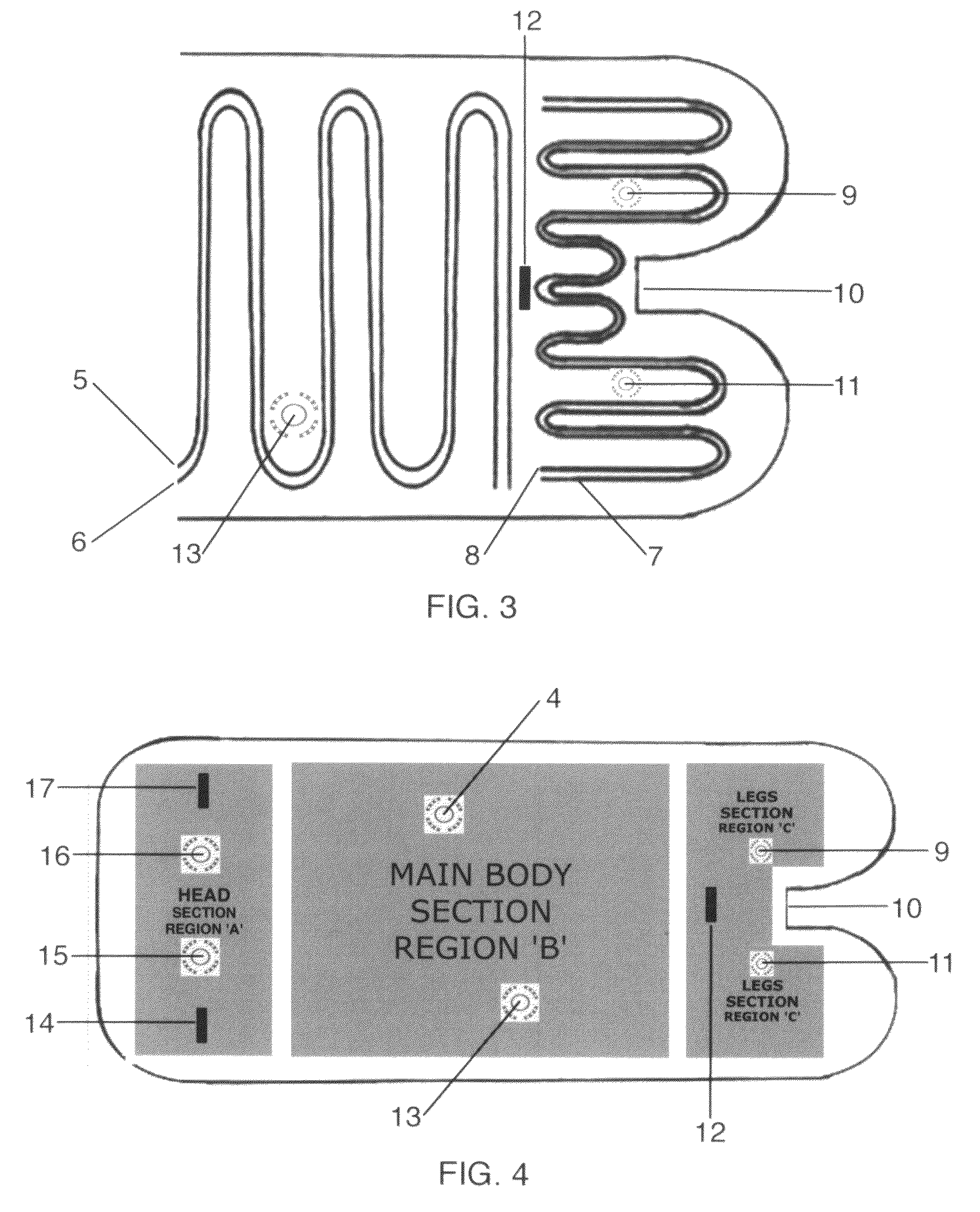

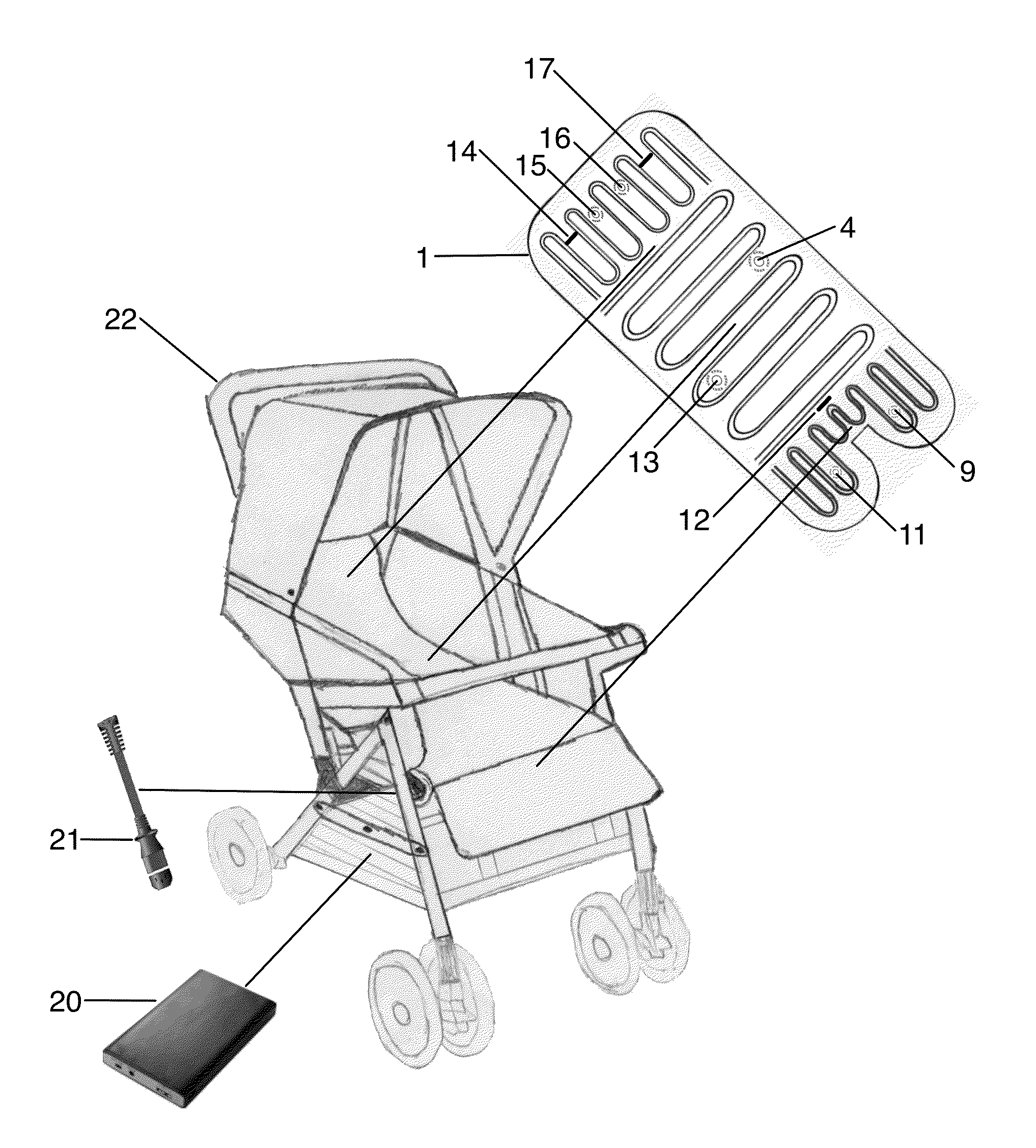

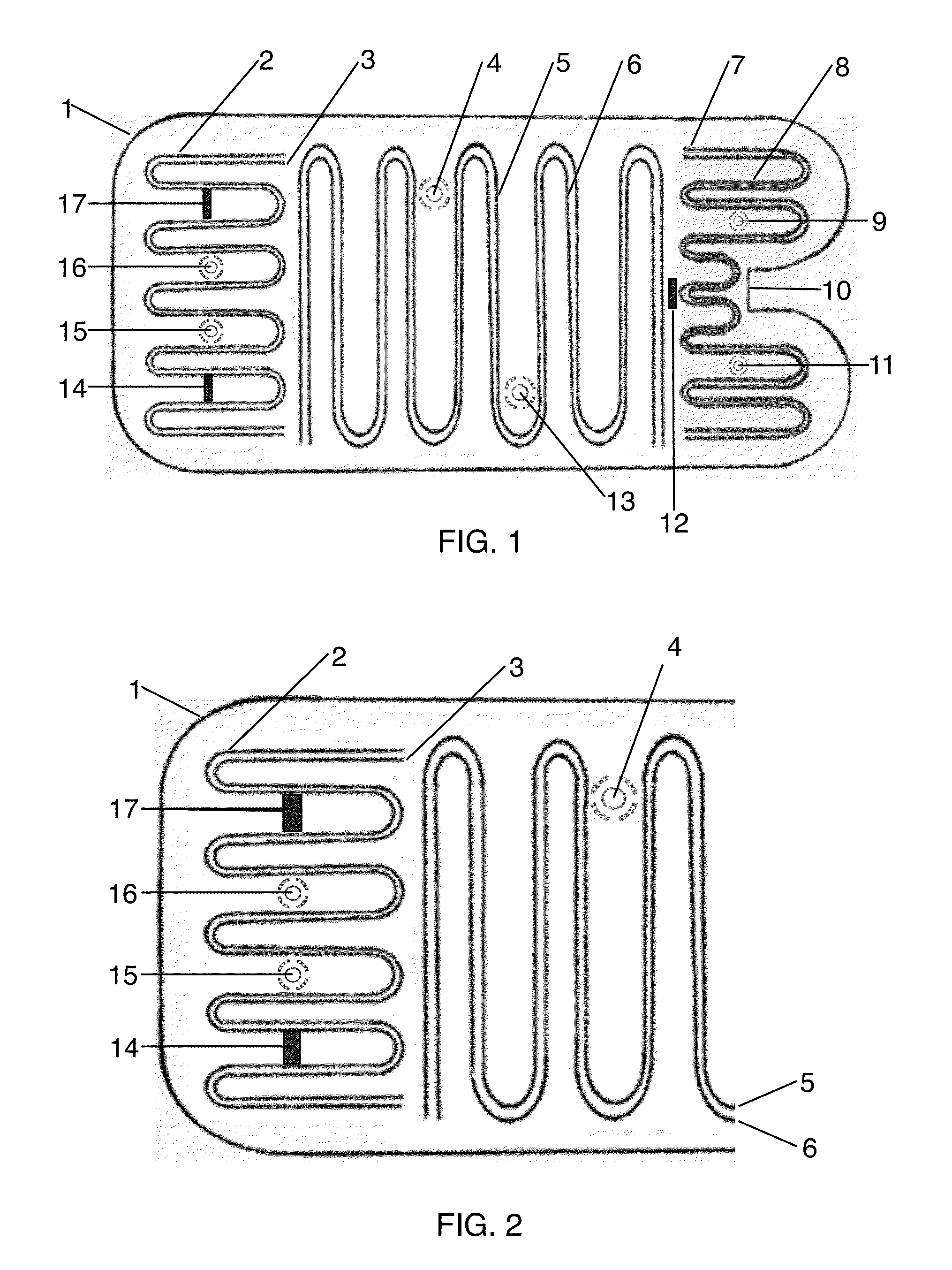

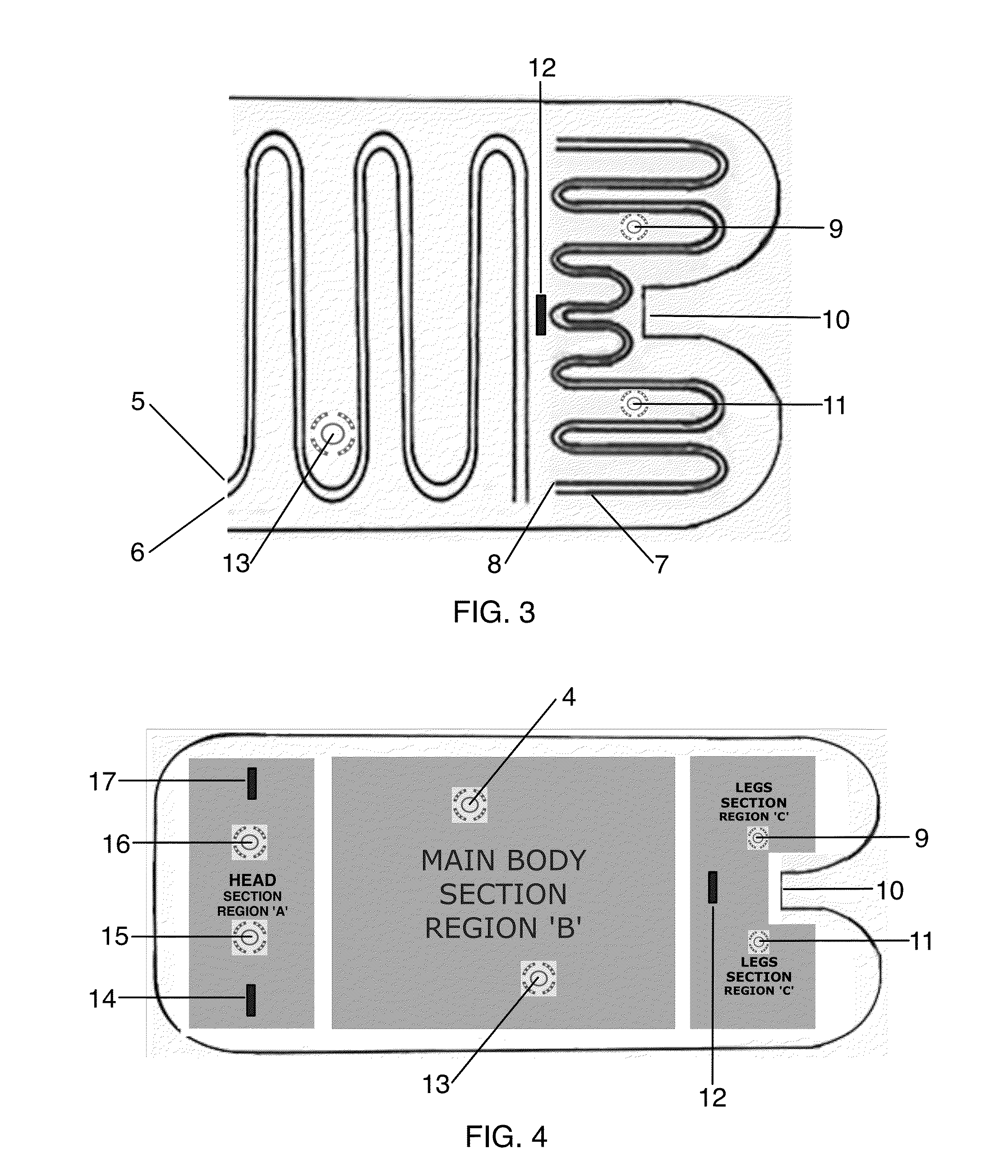

Autonomous rechargeable heated child's mat

ActiveUS9044867B2Quickly and safely be warmedEasy to operateCarriage/perambulator accessoriesDc network circuit arrangementsEngineeringMobile device

The Autonomous Rechargeable Heated Child's Mat is totally portable and forms an integrated yet detachable part of the child's pushchair, buggy or pram (or similar conveyance). Rechargeable embedded power cells power the system for over 4 hours at a full heat output. The system is fully controllable from the parent or operator's mobile telephone or tablet device via bidirectional wireless communication. Simply seat or lay the child in the pushchair, buggy or pram (or similar conveyance) as normal. Using a dedicated application on the mobile device the child will quickly and safely be warmed to a controlled temperature as set by the parent or operator. The longest of excursions can now be made with the child in complete comfort and warmth. A powerful, intelligent and safe mobile heating system that is simple to operate and control wirelessly with simplicity.

Owner:ROTHSCHILD MICHAEL BENN

Autonomous Rechargeable Heated Child's Mat

ActiveUS20140231410A1Quickly and safely be warmedReduce heat outputPrimary cell to battery groupingBatteries circuit arrangementsHeat outputHeating system

The Autonomous Rechargeable Heated Child's Mat is totally portable and forms an integrated yet detachable part of the child's pushchair, buggy or pram (or similar conveyance). Rechargeable embedded power cells power the system for over 4 hours at a full heat output. The system is fully controllable from the parent or operator's mobile telephone or tablet device via bidirectional wireless communication. Simply seat or lay the child in the pushchair, buggy or pram (or similar conveyance) as normal. Using a dedicated application on the mobile device the child will quickly and safely be warmed to a controlled temperature as set by the parent or operator. The longest of excursions can now be made with the child in complete comfort and warmth. A powerful, intelligent and safe mobile heating system that is simple to operate and control wirelessly with simplicity.

Owner:ROTHSCHILD MICHAEL BENN

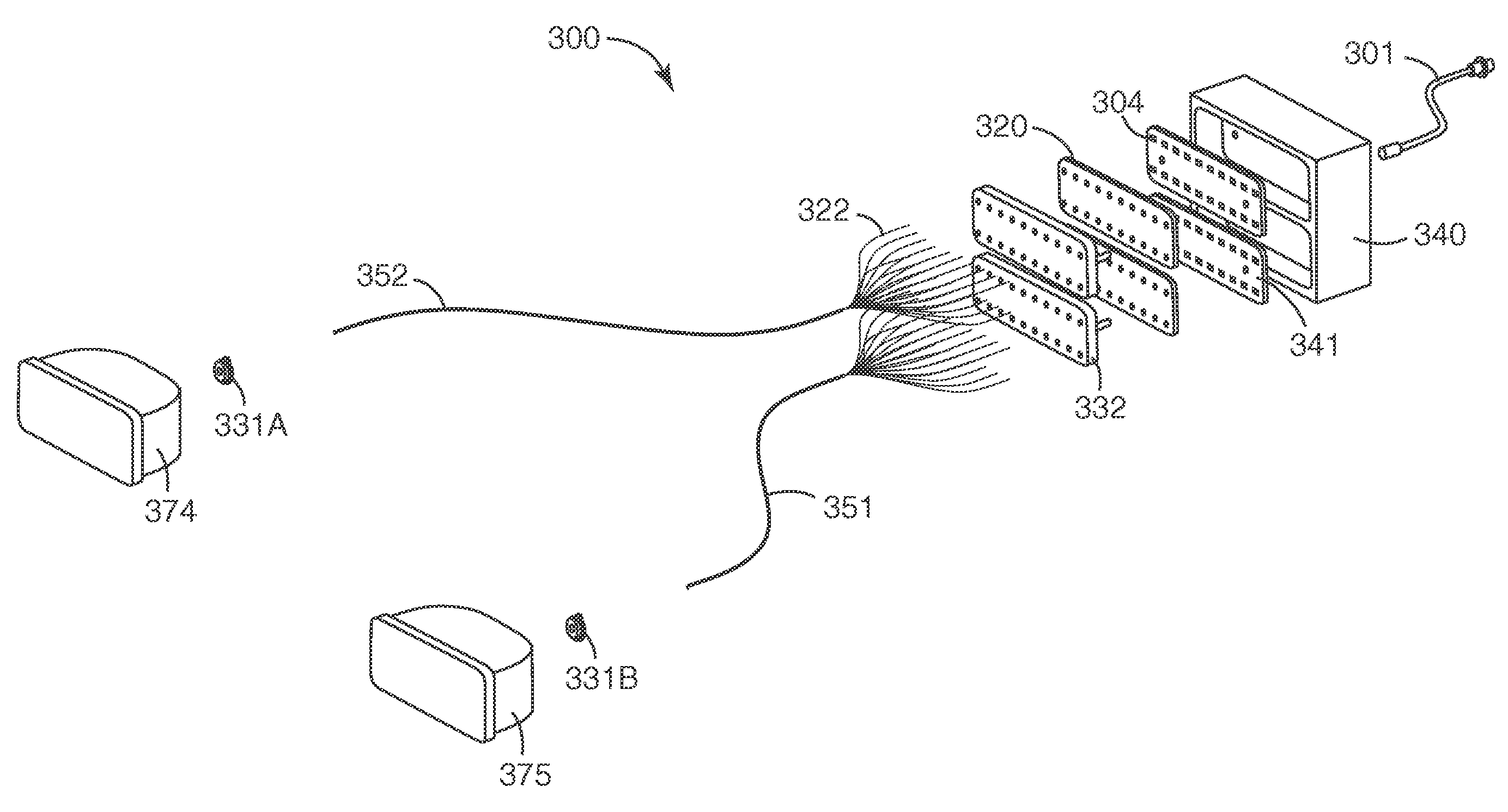

Illumination system using a plurality of light sources

InactiveUS20070103925A1Reduce heat outputReduced life-timeMechanical apparatusPoint-like light sourceOptical communicationLight source

An illumination system includes a plurality of radiation generating sources, such as LED dies. A corresponding plurality of optical waveguides is also provided, with each waveguide having a first and a second end, with each first end being in optical communication with the corresponding LED die. An array of corresponding passive optical elements is interposed between the plurality of LED dies and the corresponding first ends of the plurality of optical waveguides. The illumination system provides for substantially high light coupling efficiency and an incoherent light output that can appear to the human observer as arising from a single point of light. In addition, the light can be output remotely at one or more locations and in one or more directions.

Owner:3M INNOVATIVE PROPERTIES CO

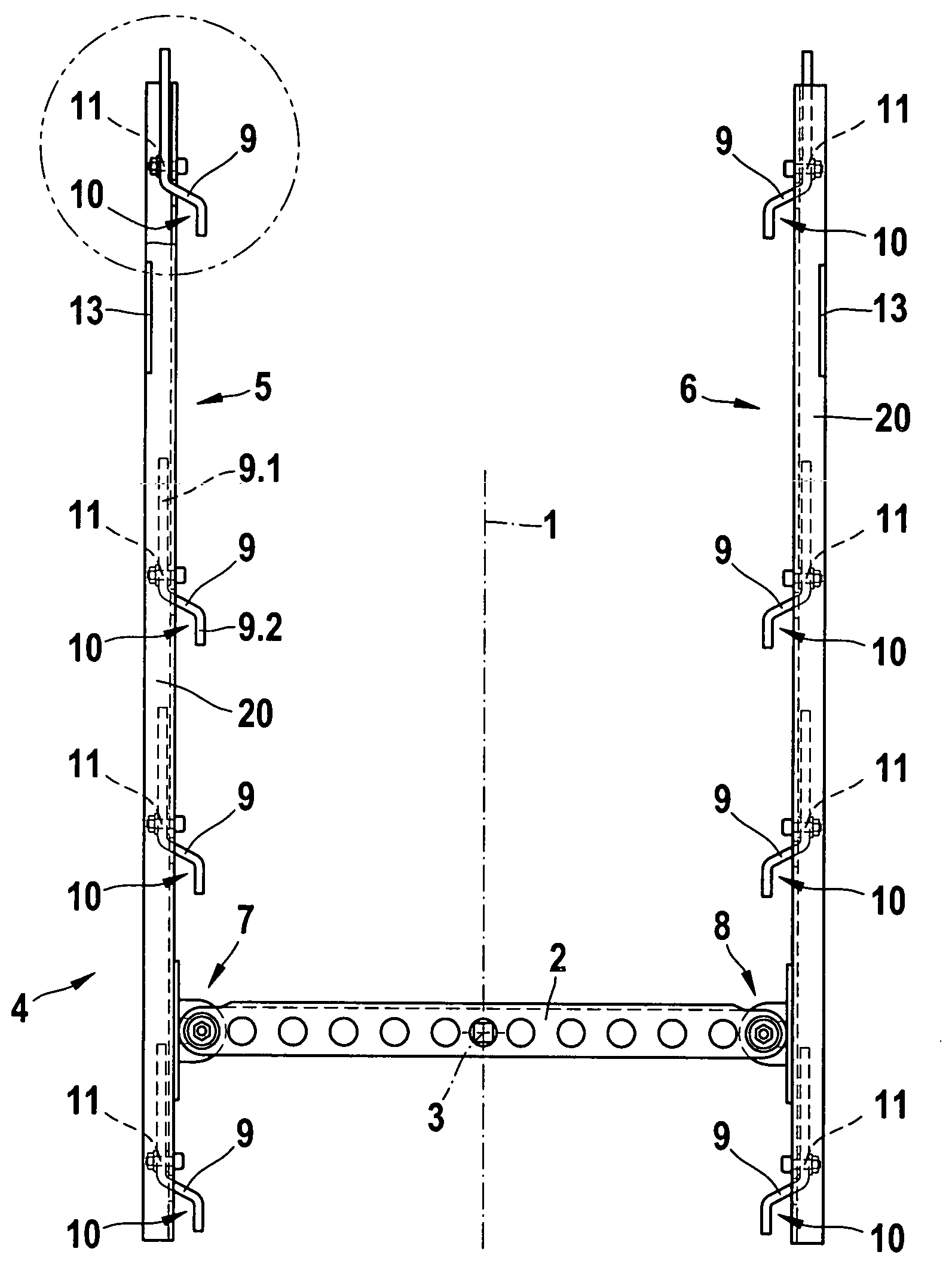

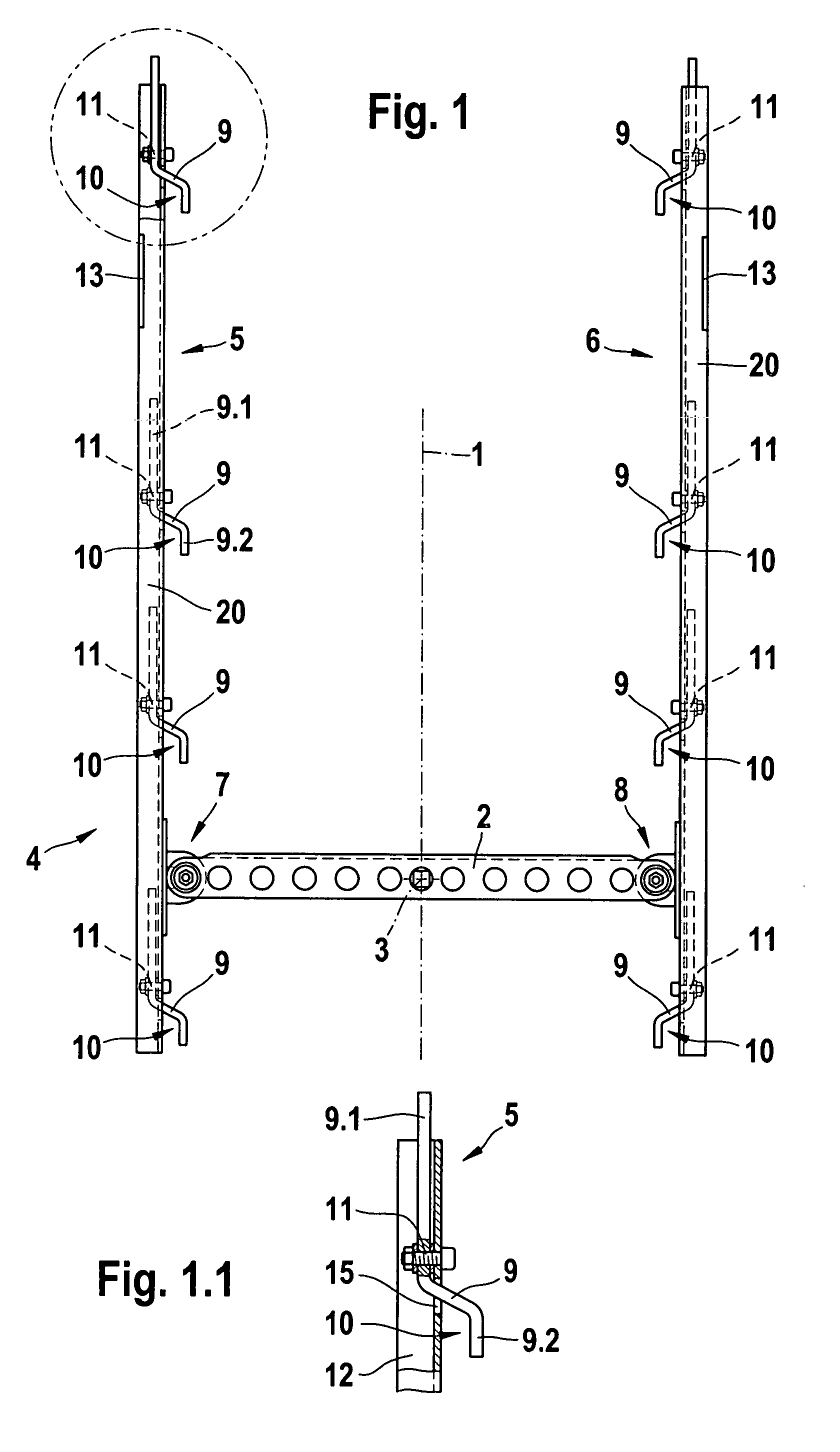

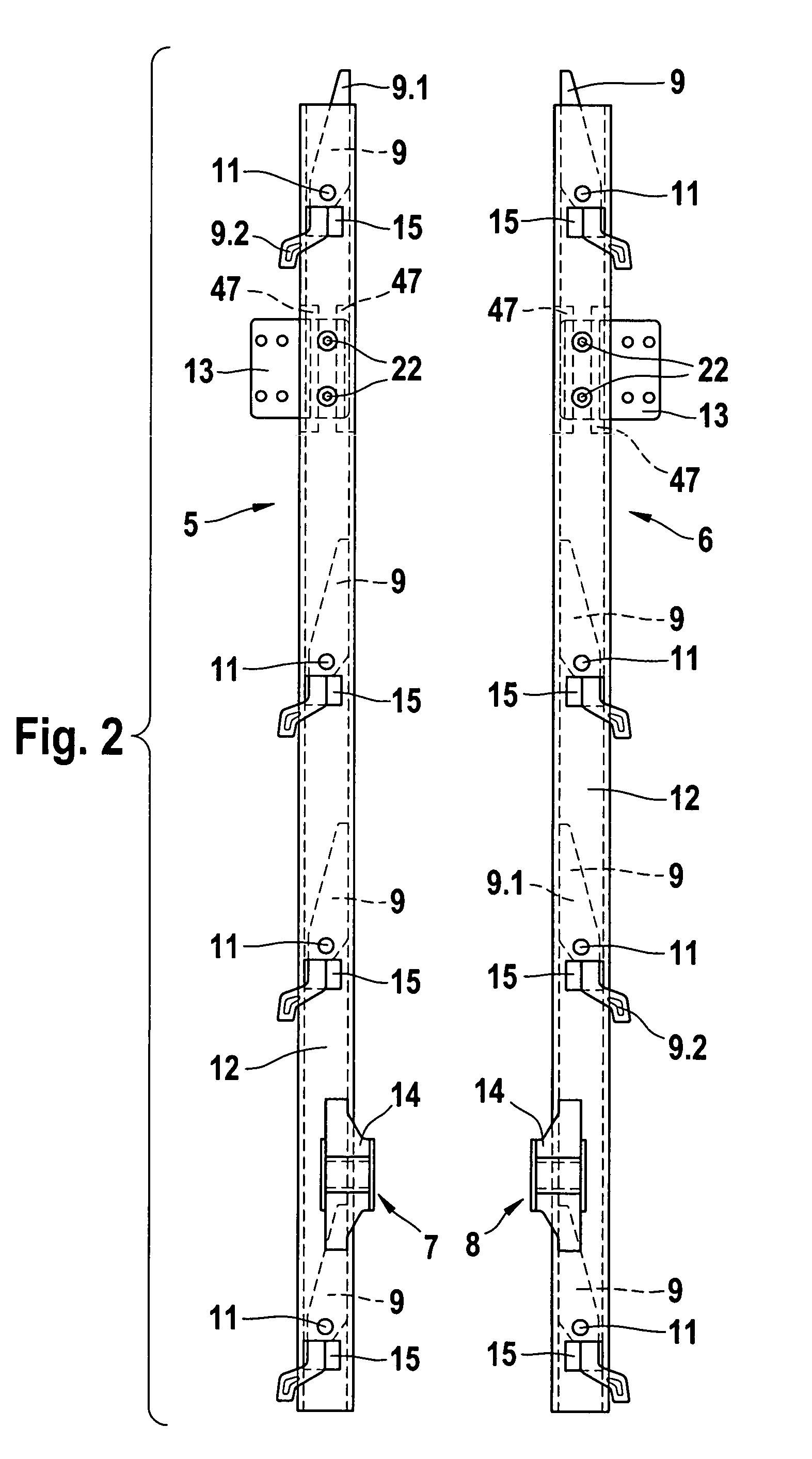

Straight-through dishwasher with a carriage which is driven in opposite directions

InactiveUS6955179B2Improve washabilityIncreased efficiency and cost-effectivenessPlatesTableware washing/rinsing machinesMotor driveEngineering

A motor drive with devices for translating the rotary movement of an output shaft (44) into a reciprocating linear movement, preferably for driving a reciprocating transporting device (4; 5, 6). The latter comprises catches (9; 9.1, 9.2), which engage in one direction and not in the other direction, in order to transport a receptacle (16) for items for washing. The transporting device comprises an articulated transporting frame (4), of which the transporting rails (5, 6) can be moved in opposite directions to one another.

Owner:MEIKO MASCHENBAU

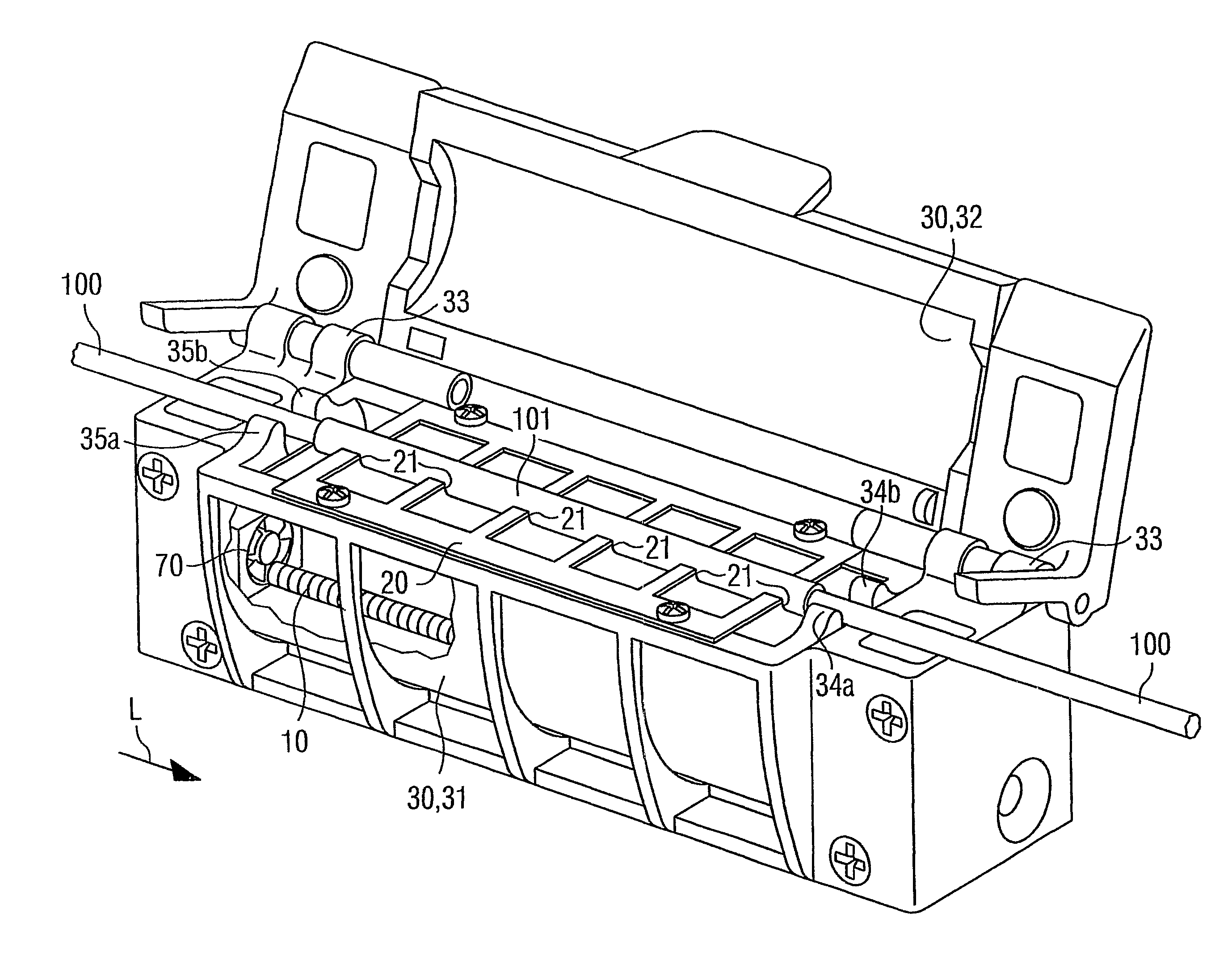

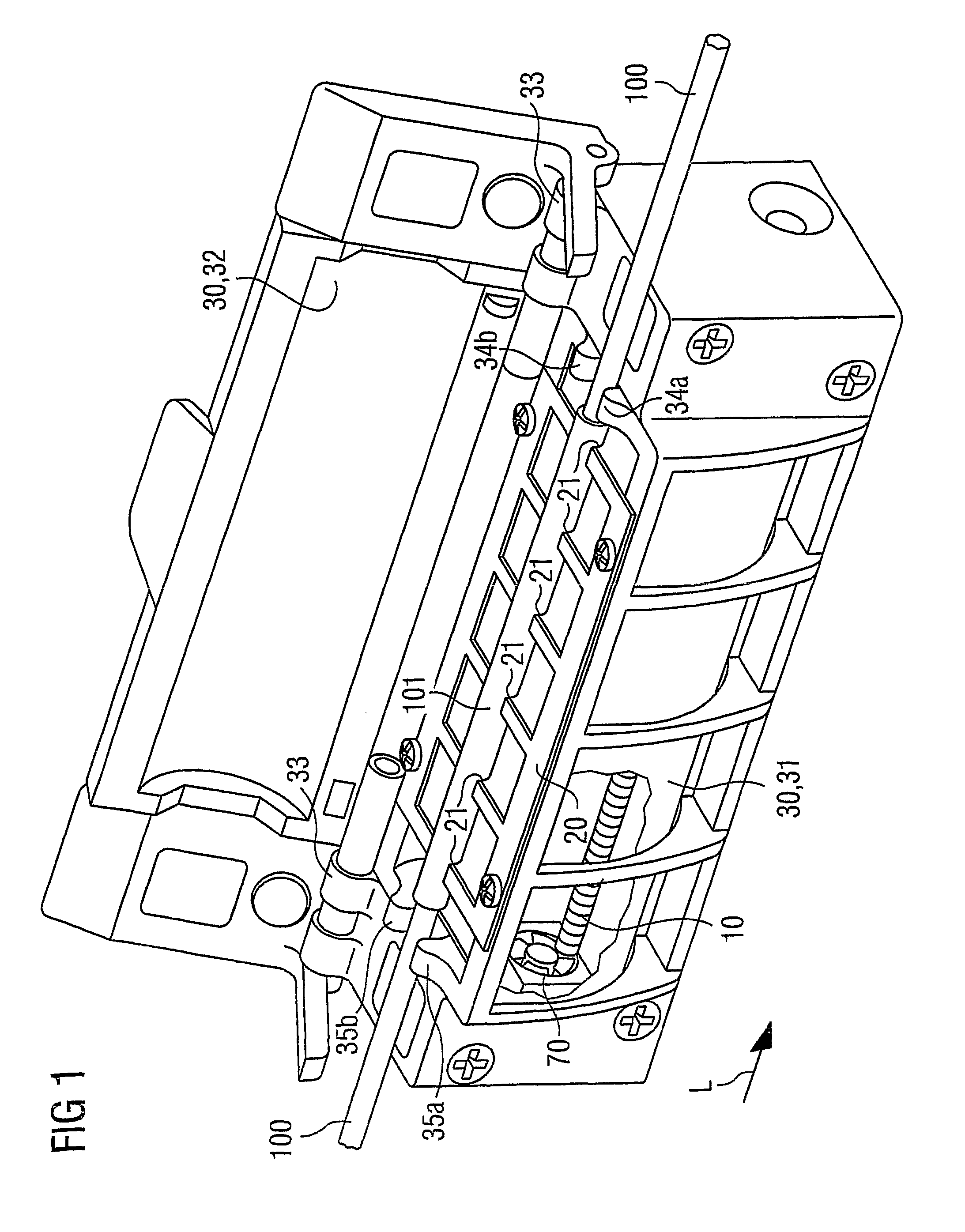

Apparatus and method for applying a protective element on an optical waveguide

ActiveUS8866051B2Short supplyPower Loss MinimizationDomestic stoves or rangesDrying solid materials with heatEngineeringThermal radiation

Owner:CCS TECH INC

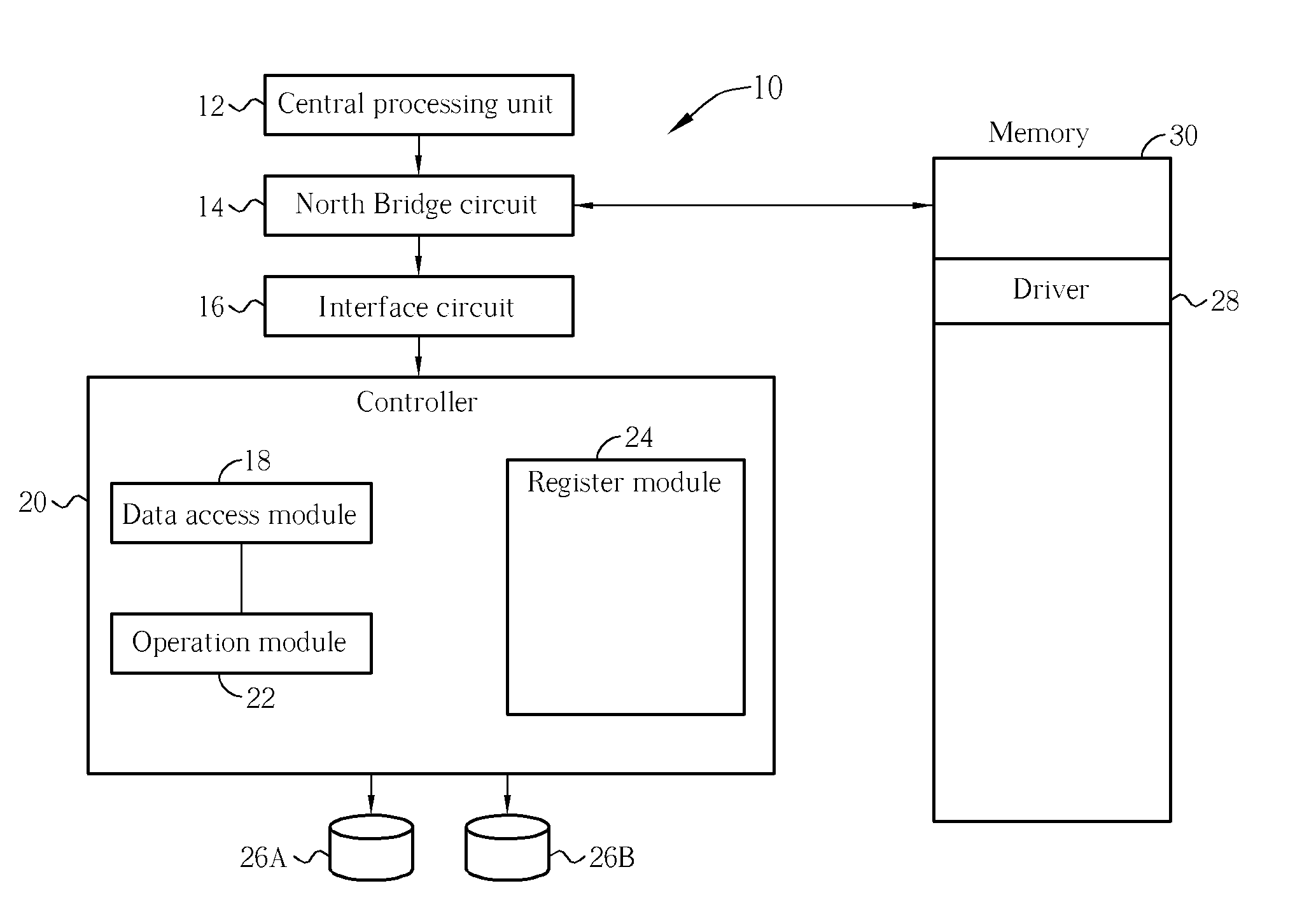

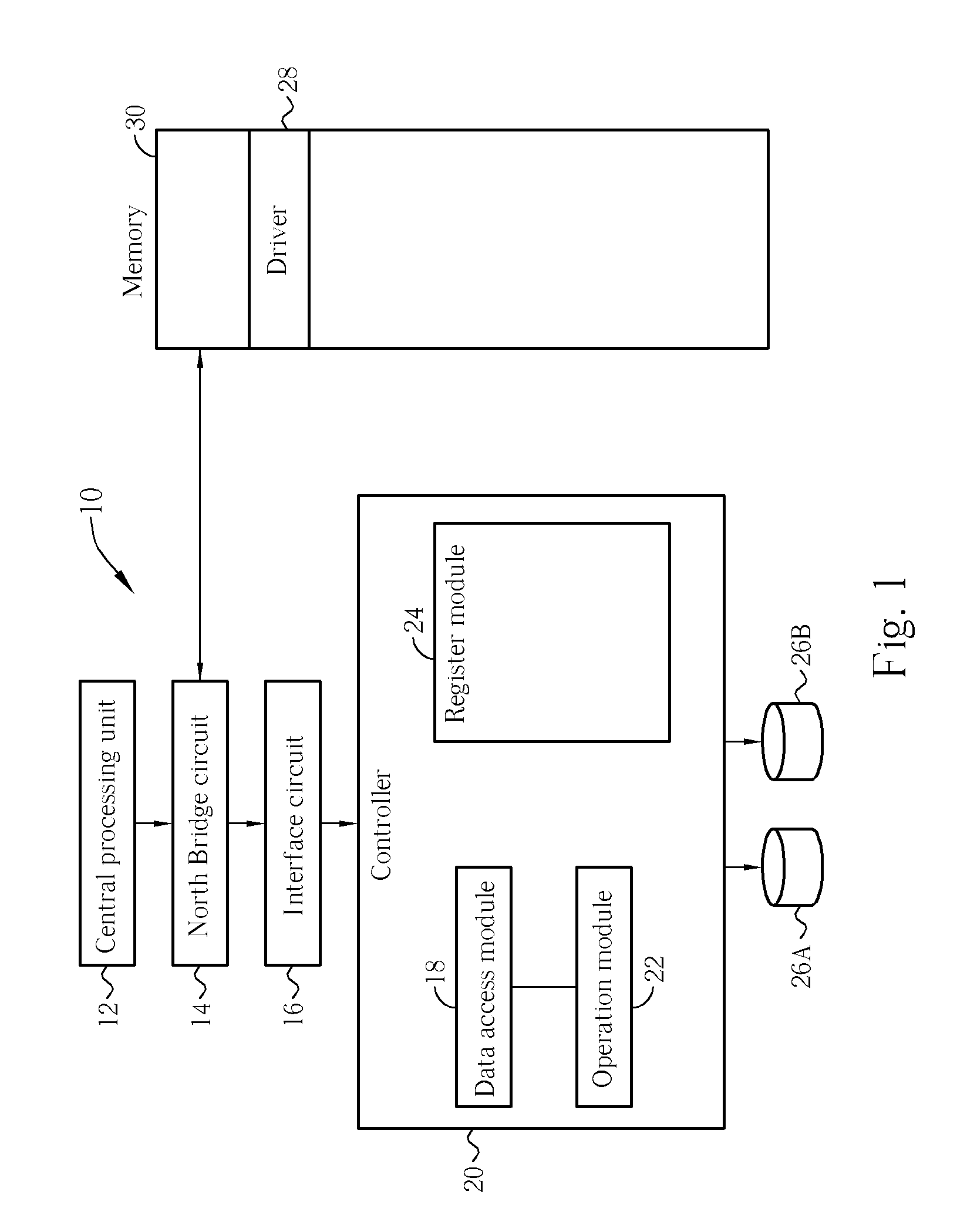

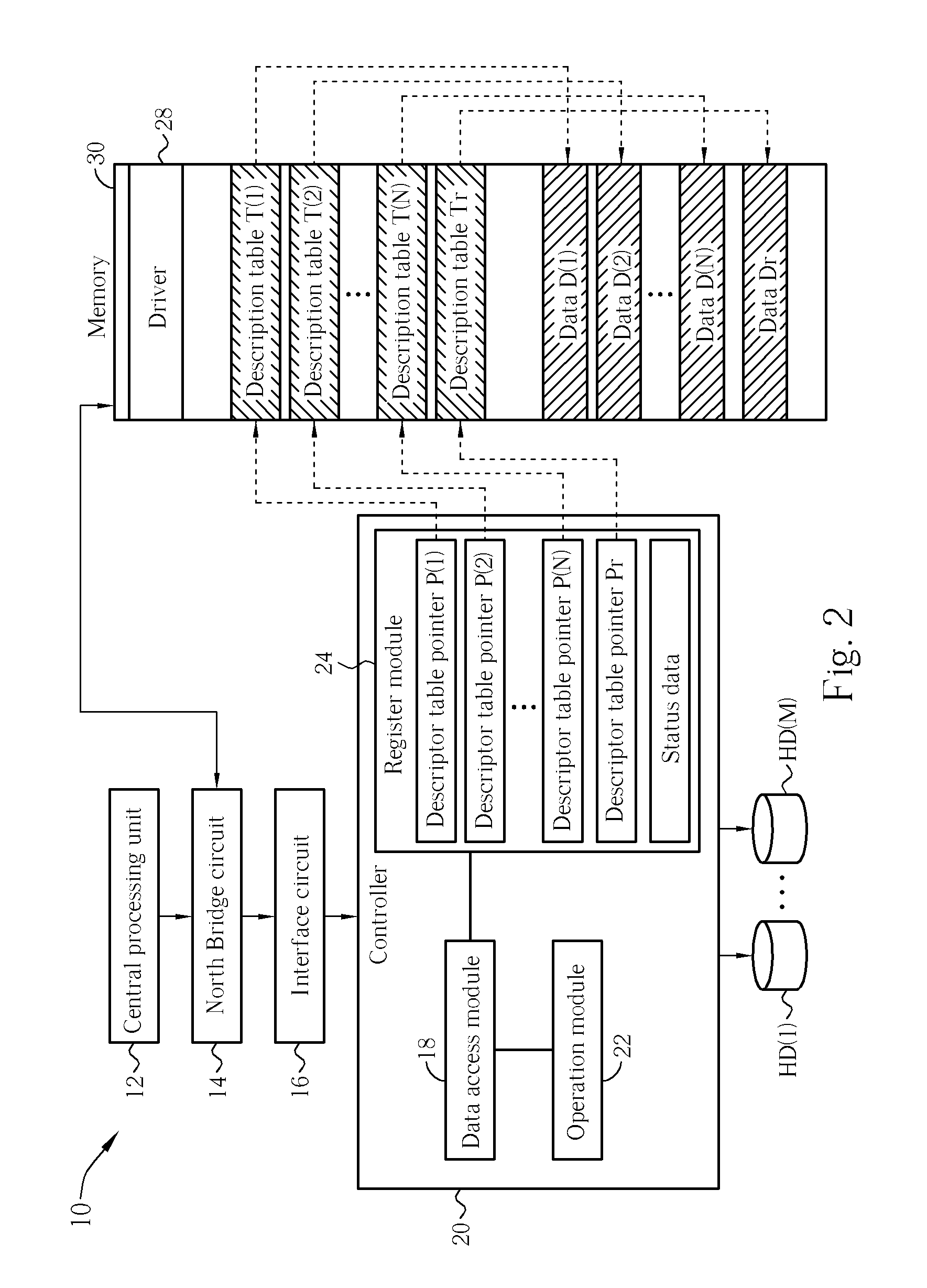

Apparatus And Related Method For Calculating Parity of Redundant Array Of Disks

InactiveUS20060026328A1Fast and efficient hardware parity calculationLow costElectric digital data processingRAIDDirect memory access

For error tolerance in a redundant array disks (RAID), a parity data is calculated according to plurality of data respectively accessed in disks of the RAID. A hardware calculation module for parity calculation can be implemented in a RAID controller. With direct memory access (DMA) capability of the RAID controller, the calculation module performs parity calculation by directly accessing a system memory for the plurality of data and the parity data. Thus, memory resources of the parity calculation can be supported by the system memory, and a central processing unit (CPU) can be offloaded during parity calculation.

Owner:VIA TECH INC

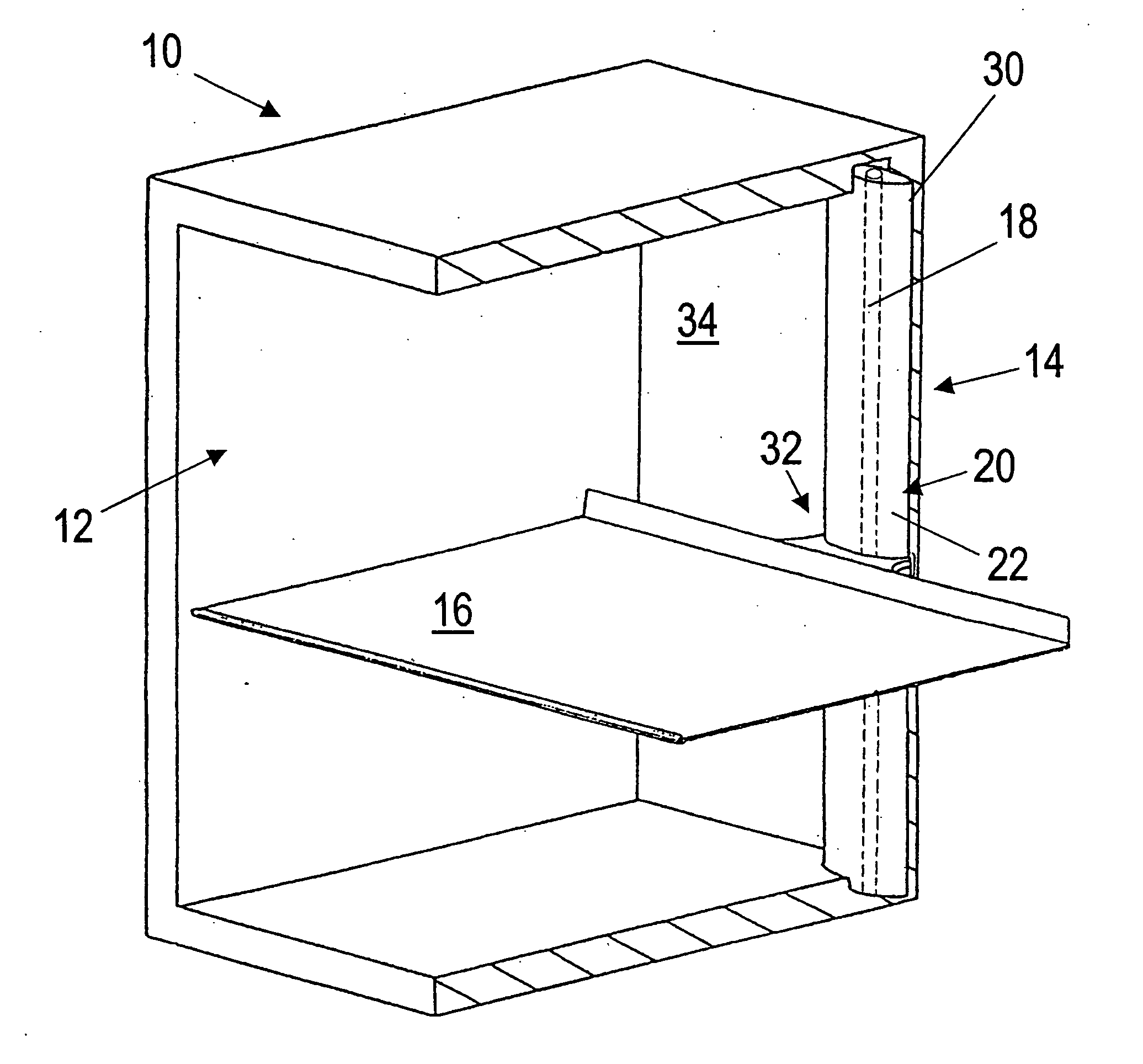

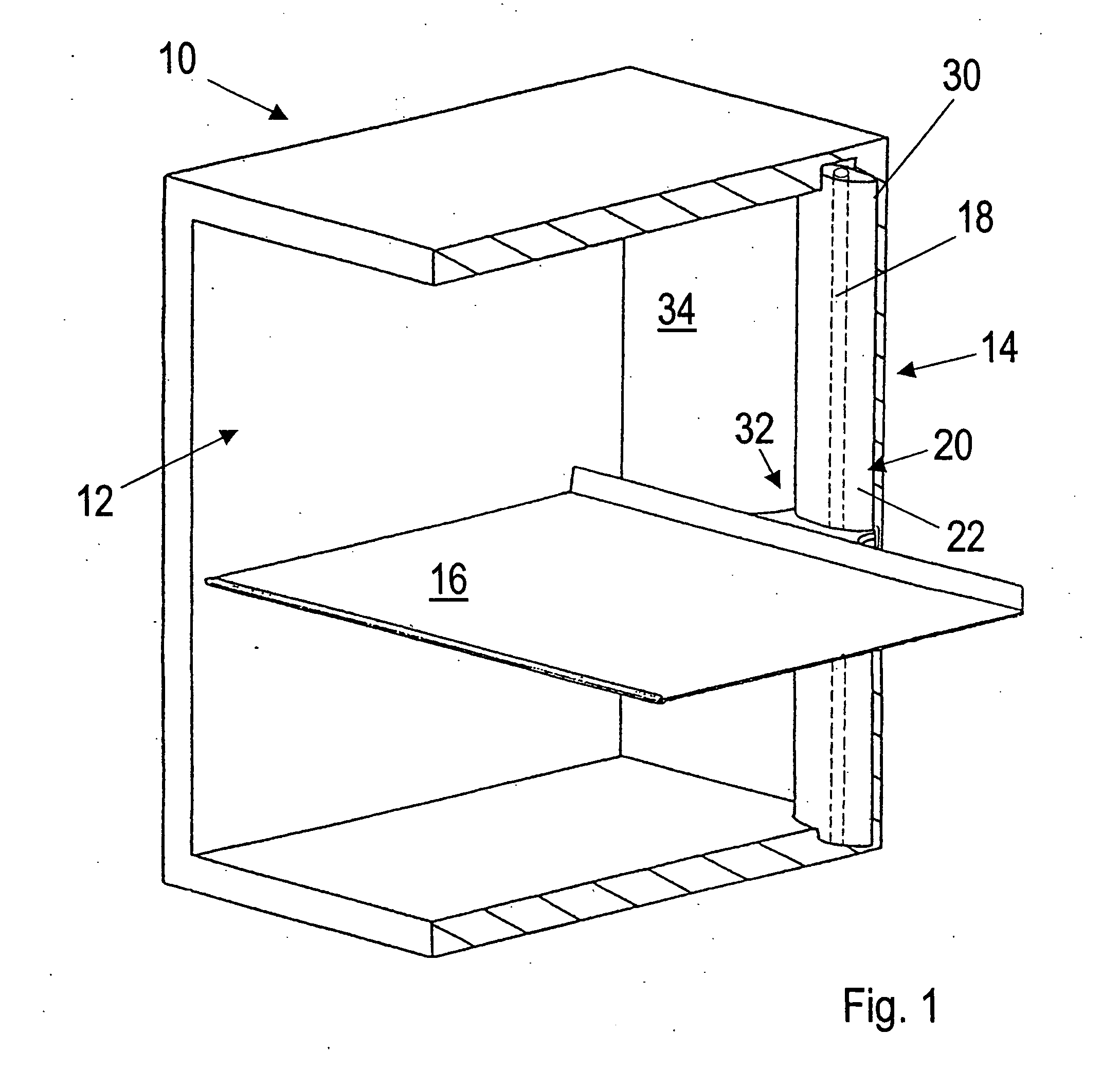

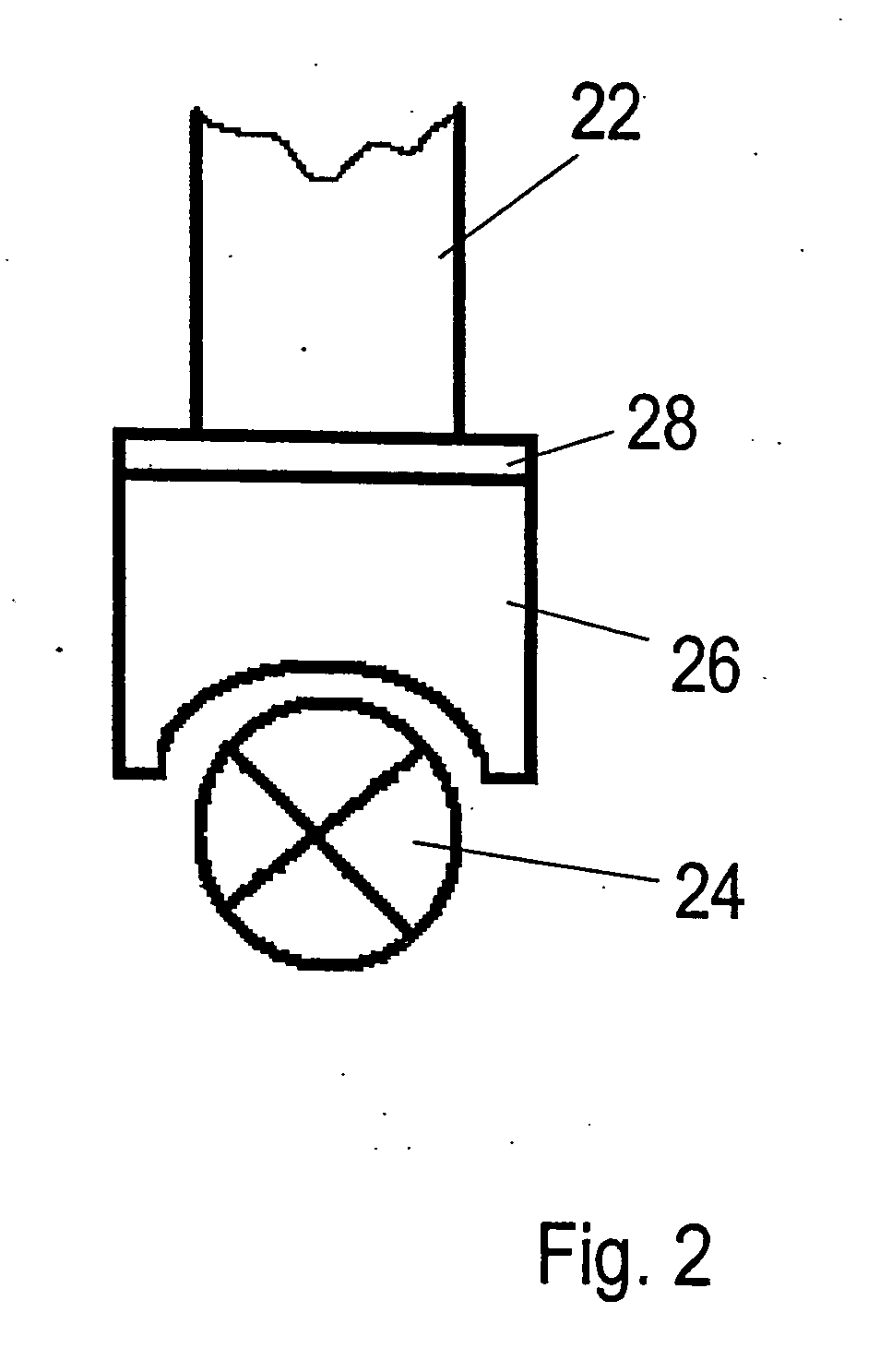

Lighting installation for household appliances

InactiveUS20040246716A1Easy to useReduce energy consumptionMechanical apparatusPoint-like light sourceLight waveLight source

A lighting installation for household appliances having an interior in which a bracket for receiving support shelves is arranged. The lighting arrangement includes an illuminating device integrated into at least a partial area of the bracket or entirely into the bracket. The illuminating device can include a fluorescent tube or an arrangement of a plurality of light-emitting diodes. Alternatively, at least a partial area of the bracket can be embodied as an optical waveguide, into which the light from a light source not arranged in the interior can be introduced.

Owner:SCHOTT AG +1

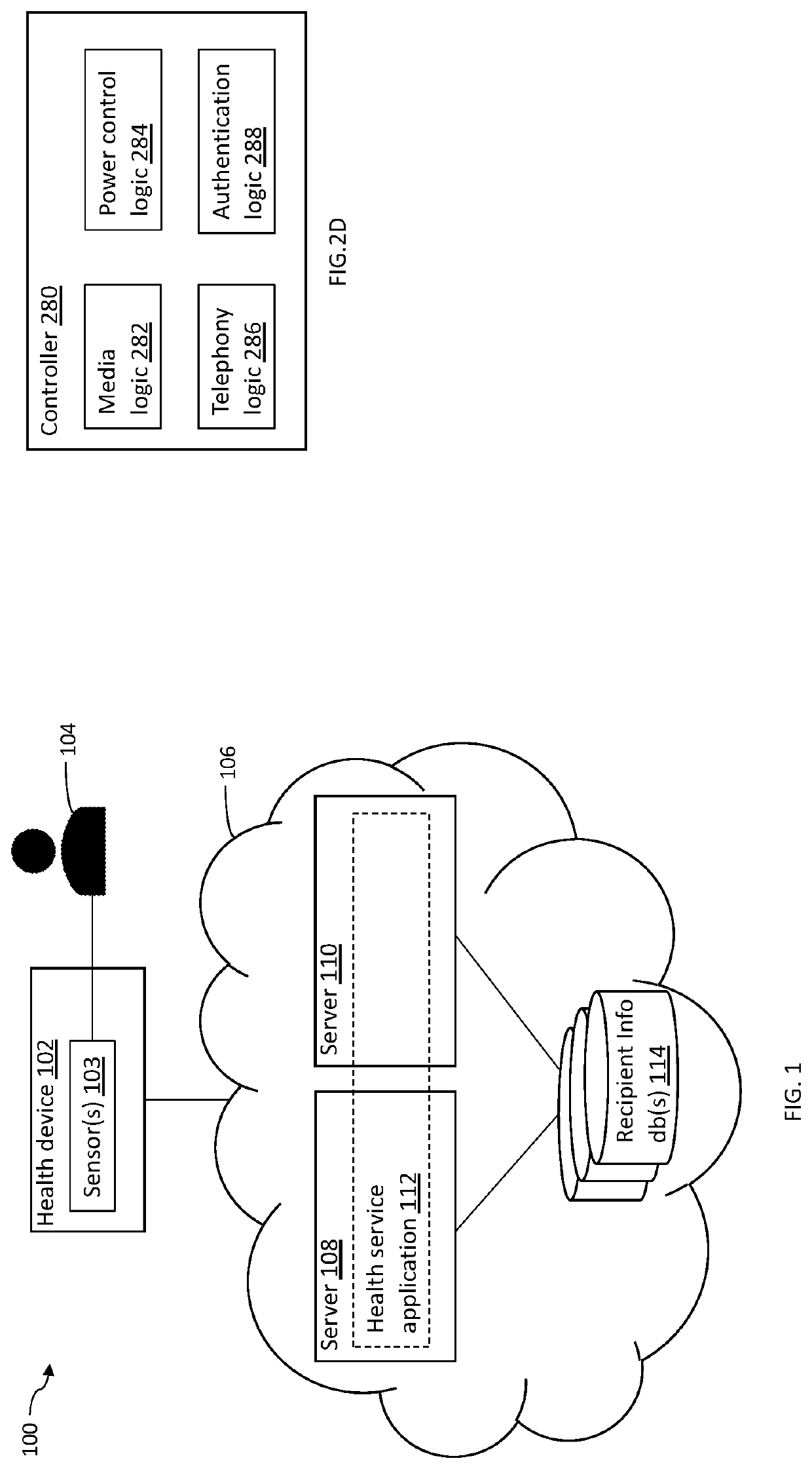

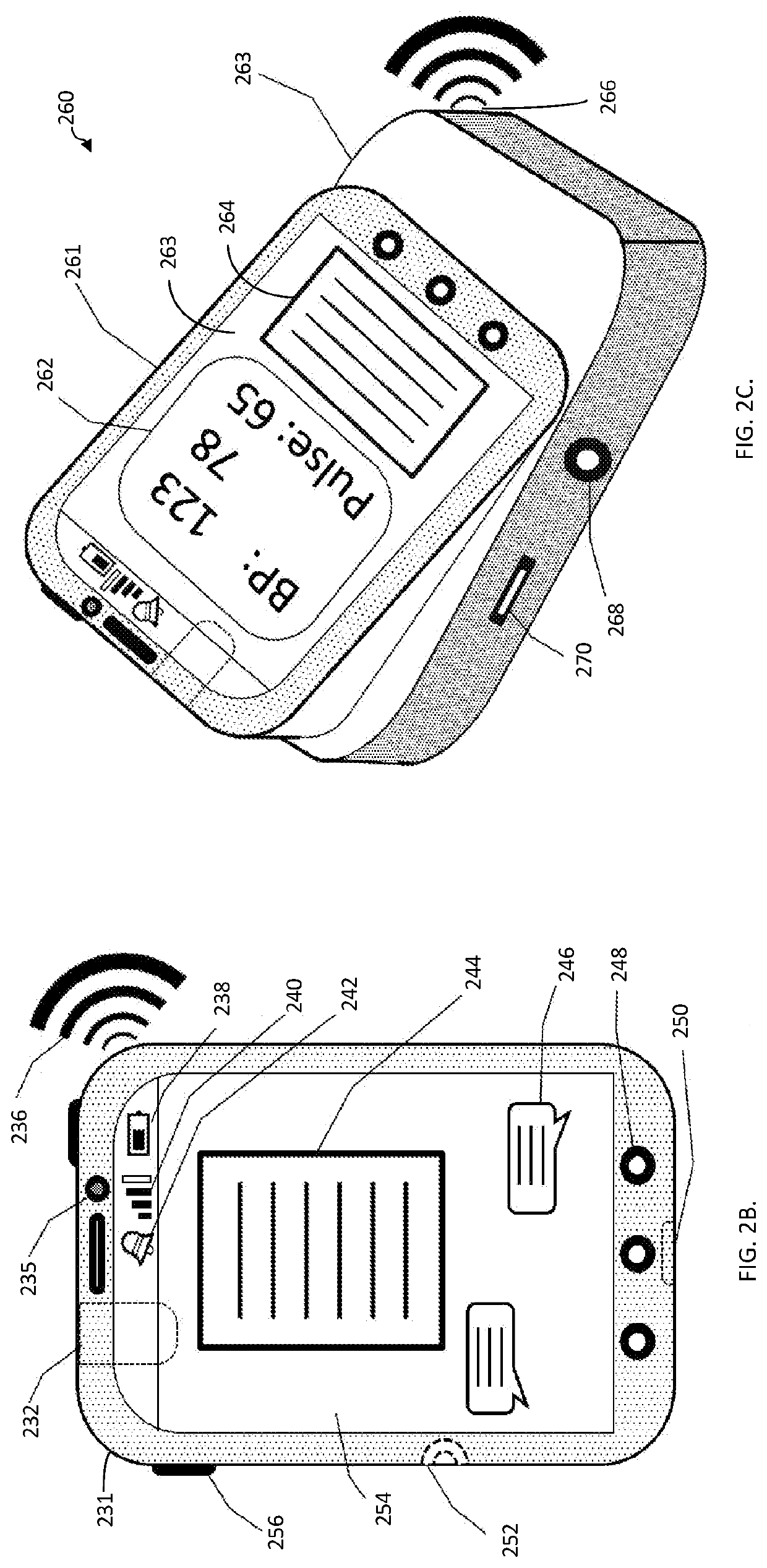

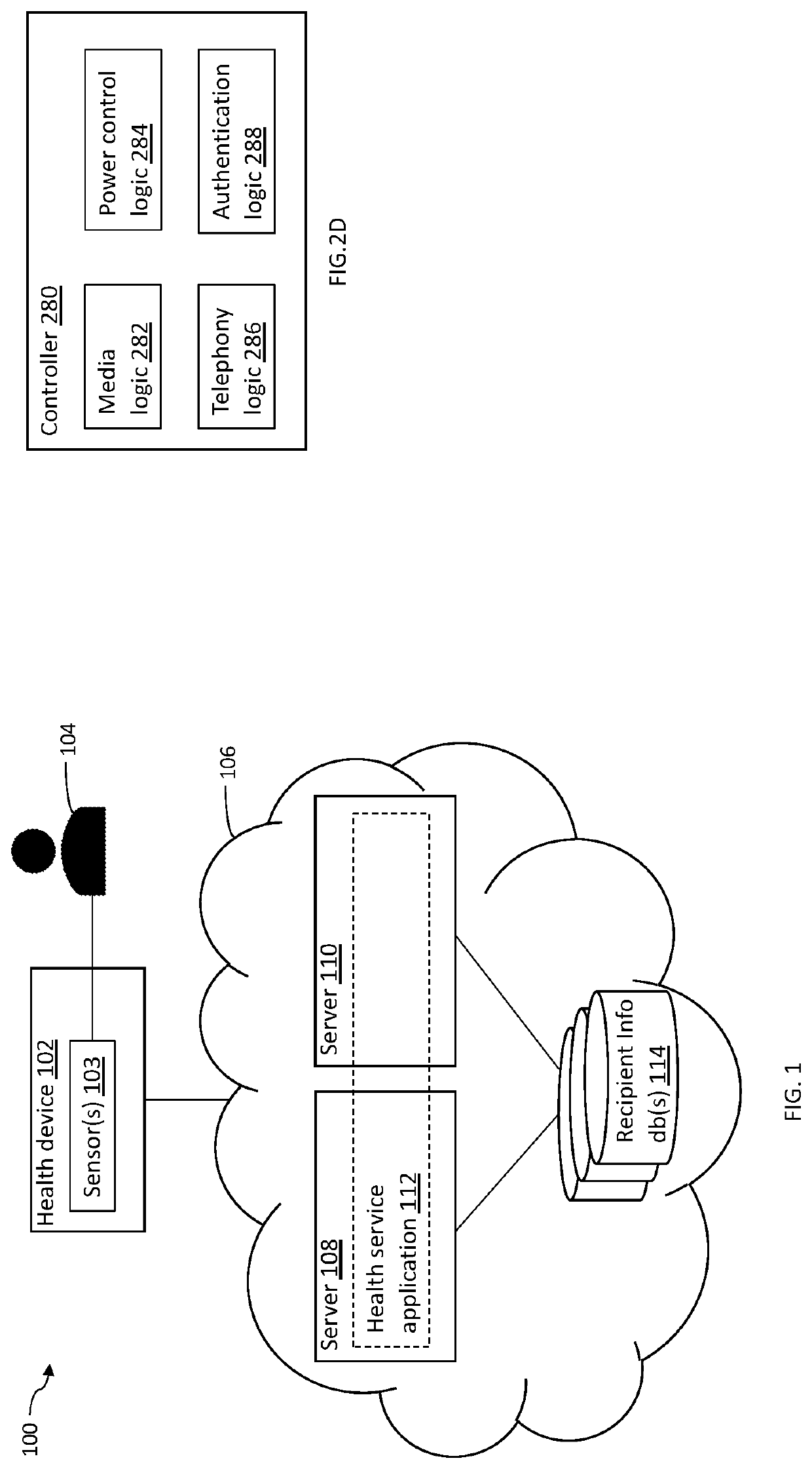

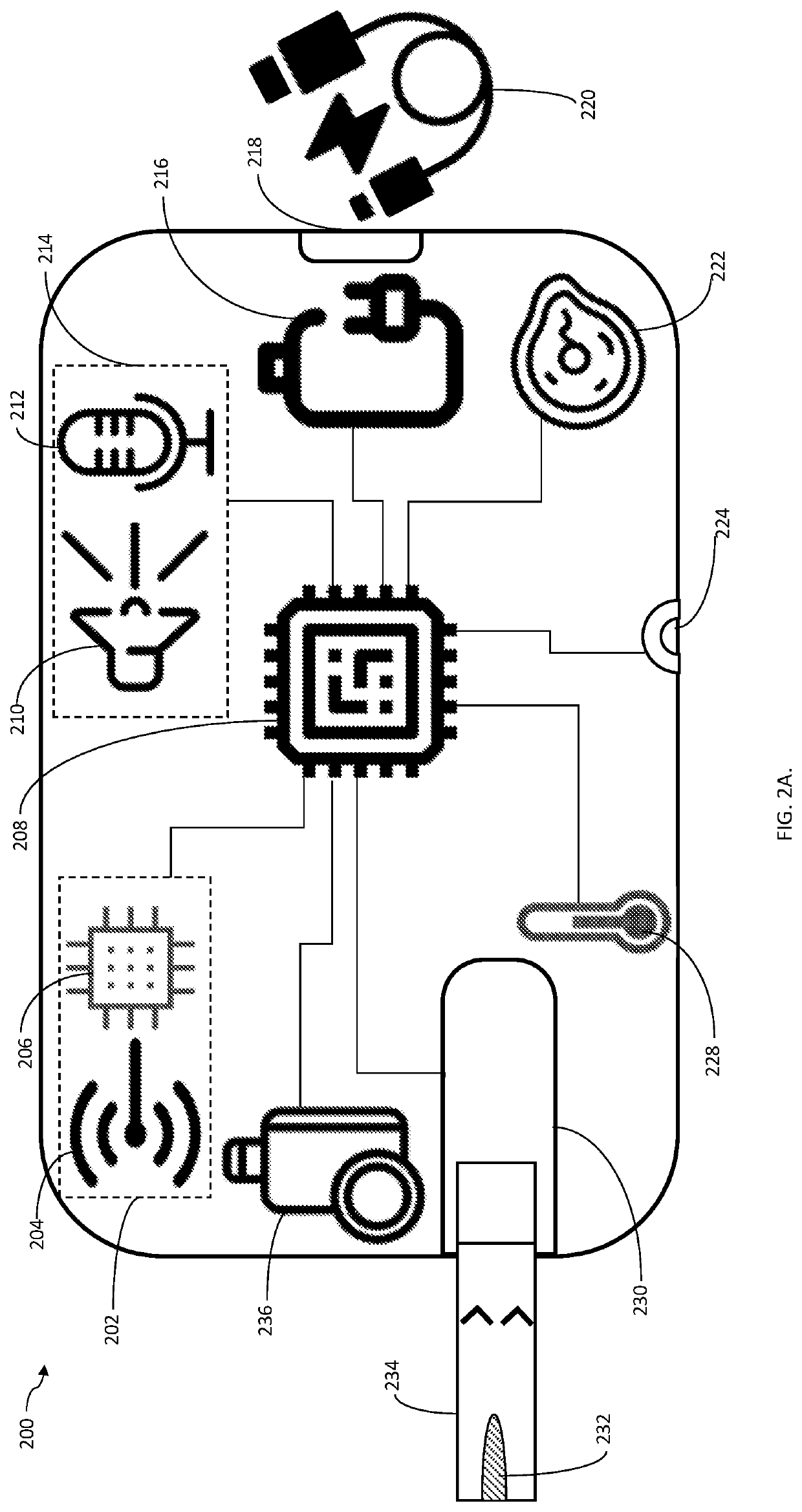

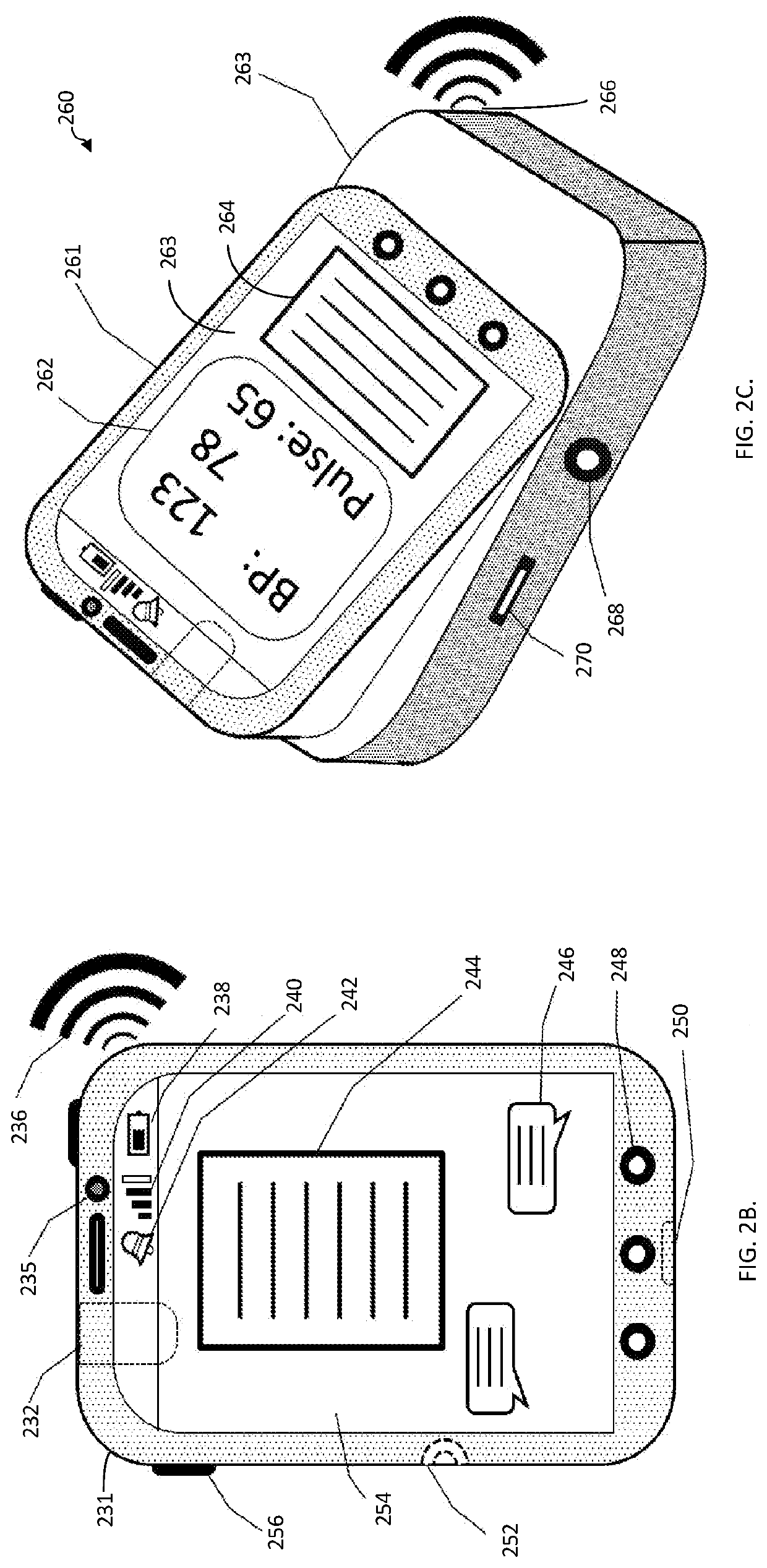

Determining interventions for remote health services

InactiveUS20200388393A1Reduce heat outputReduce frequencyImage enhancementImage analysisRemote monitoring and controlMedical emergency

Remote health services may be provided, for example, in real time, based on values of health metrics monitored remotely, and in some embodiments, continuously, for a recipient. The system may include a mobile health device configured to continually monitor or intermittently detect values of one or more health metrics. A mobile health device may be locally coupled to a recipient, and may include a health sensor that detects values of one or more health metrics of the recipient. Servers may be remotely coupled to the mobile health device and provide one or more health services based at least in part on health metric values detected by the health device. Providing the services may include determining health communication characteristics, and sending health communications from one or more servers to the mobile health device according to determined health communication characteristics.

Owner:TELADOC HEALTH INC

Managing health metric irregularities when providing health services

InactiveUS20200383648A1Reduce heat outputReduce frequencyImage enhancementImage analysisMedical emergencyFamily medicine

Providing to a person a health service for a health condition includes receiving, from a health sensor of a mobile health device over an initial period, a plurality of initial values of health metrics of the person associated with performance of the health service, determining, based on the initial values, baseline values of the health metrics for the person, receiving, from the health sensor at a time after the initial period, an additional value corresponding to at least one of the health metrics, and determining whether the additional value represents an irregularity with respect to the baseline values for the person. Providing to a person a health service for a health condition may also include, if it is determined that the additional value represents an irregularity with respect to the baseline values, communicating the irregularity to a provider of the health service.

Owner:TELADOC HEALTH INC

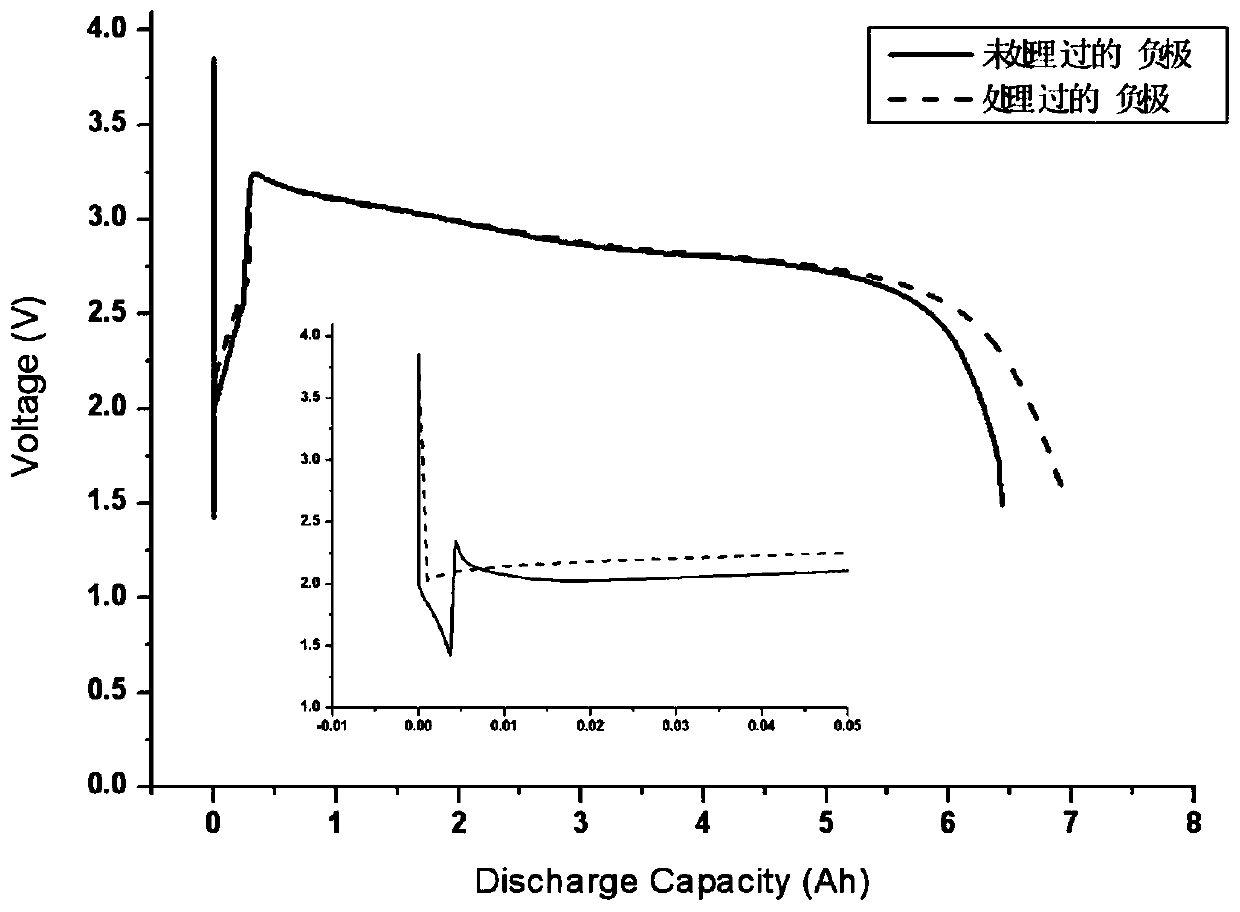

Preparation method of ultrathin lithium metal negative electrode

ActiveCN109817893AImprove bindingReduce contact resistanceElectrode manufacturing processesBristleLithium metal

The invention discloses a preparation method of an ultrathin lithium metal negative electrode, and belongs to the technical field of lithium primary batteries. The thickness of ultrathin lithium metalis less than 100[mu]m; and the preparation method of the ultrathin lithium metal negative electrode is characterized by comprising the following steps: step 1, cutting an ultrathin lithium strip intoultrathin lithium sheets according to requirements; step 2, cutting a copper foil into tabs according to requirements; step 3, lithium sheet treatment: brushing a lithium sheet and tab bonding area with at least one of natural bristles, horse hairs, sisal hemp, soft plastic fibers, nylon, polypropylene, polyethylene and PBT to remove a lithium sheet passivation layer in the tab area; and step 4,negative electrode piece pressing: adhering a current collecting tab to the treated lithium sheet area, adopting plane pressing equipment and setting equipment pressure; wrapping the upper part and the lower part of the prepared negative electrode piece with polypropylene films respectively; and placing the negative electrode piece between an upper plate and a lower plate of a flat plate pressingmachine, and pressing to obtain the tightly combined negative electrode piece.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

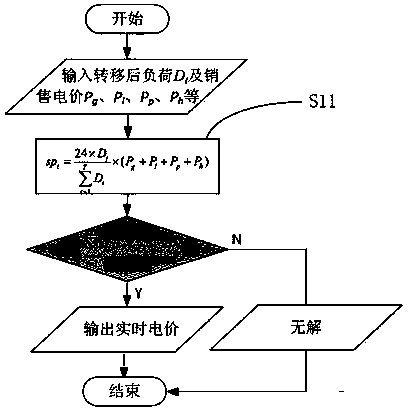

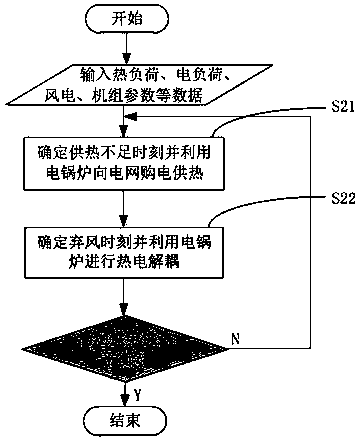

Wind power dissipation scheduling method of cogeneration system based on electricity price-load linkage response

ActiveCN109687470ARealize dynamic transfer across time periodsImprove wind power absorption capacitySteam generation heating methodsPower network operation systems integrationElectricity priceCogeneration

The invention relates to a wind power dissipation scheduling method of cogeneration system based on electricity price-load linkage response. According to the method, a real-time electricity price mechanism is introduced, a new real-time electricity price is generated according to load change, the new real-time electricity price guides a power user to respond, load and real-time electricity price linkage response is achieved so as to guide the market behaviors among the main bodies of the power market and transfer the load across time periods. An electric boiler is installed in a heat load center so as to decouple the restraint of determining the electricity by heat, thereby reducing the heat energy loss in the transmission process. In the process of target optimization, the optimal coordination control of the daily load integral dynamic transfer across time periods and the thermal electrolytic coupling is achieved, so that the difference between the network cost and the auxiliary service cost of the abandoned wind is absorbed to the greatest extent, the wind energy is absorbed to the greatest extent, and meanwhile, the load peak-valley difference is reduced.

Owner:CHINA THREE GORGES UNIV

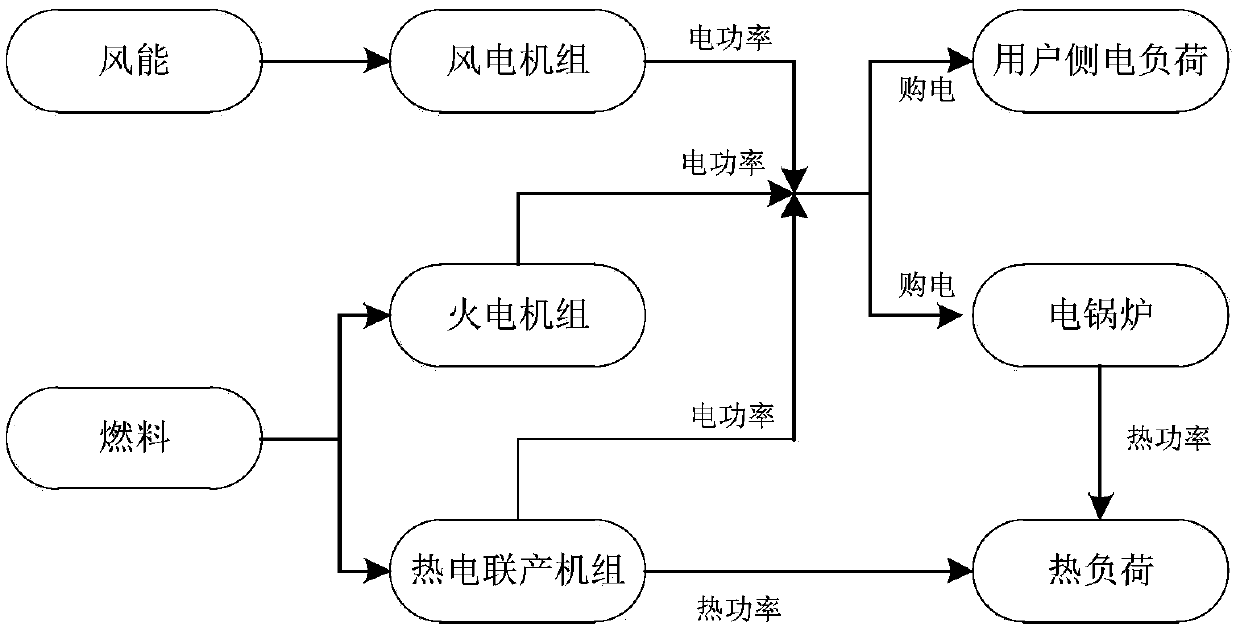

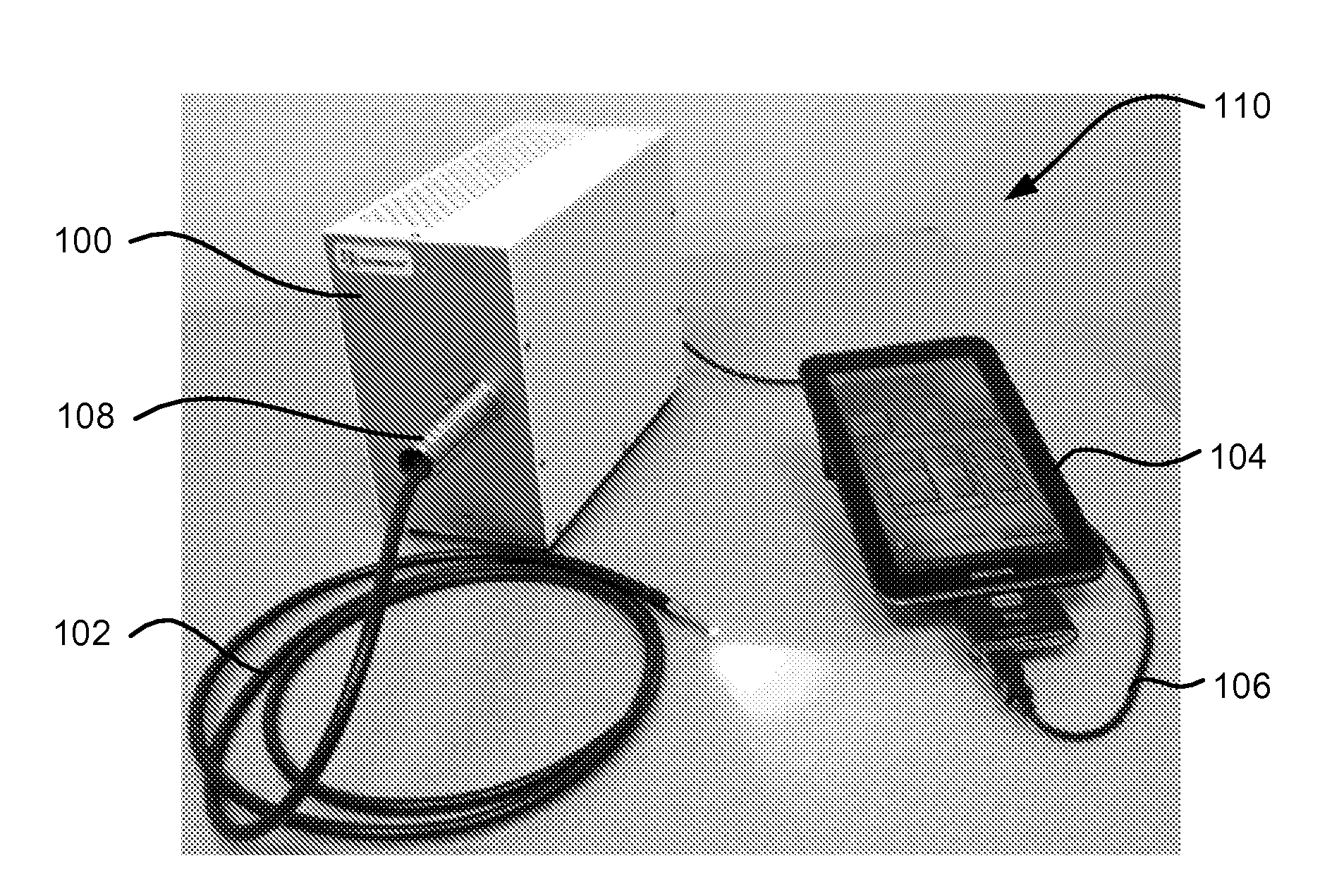

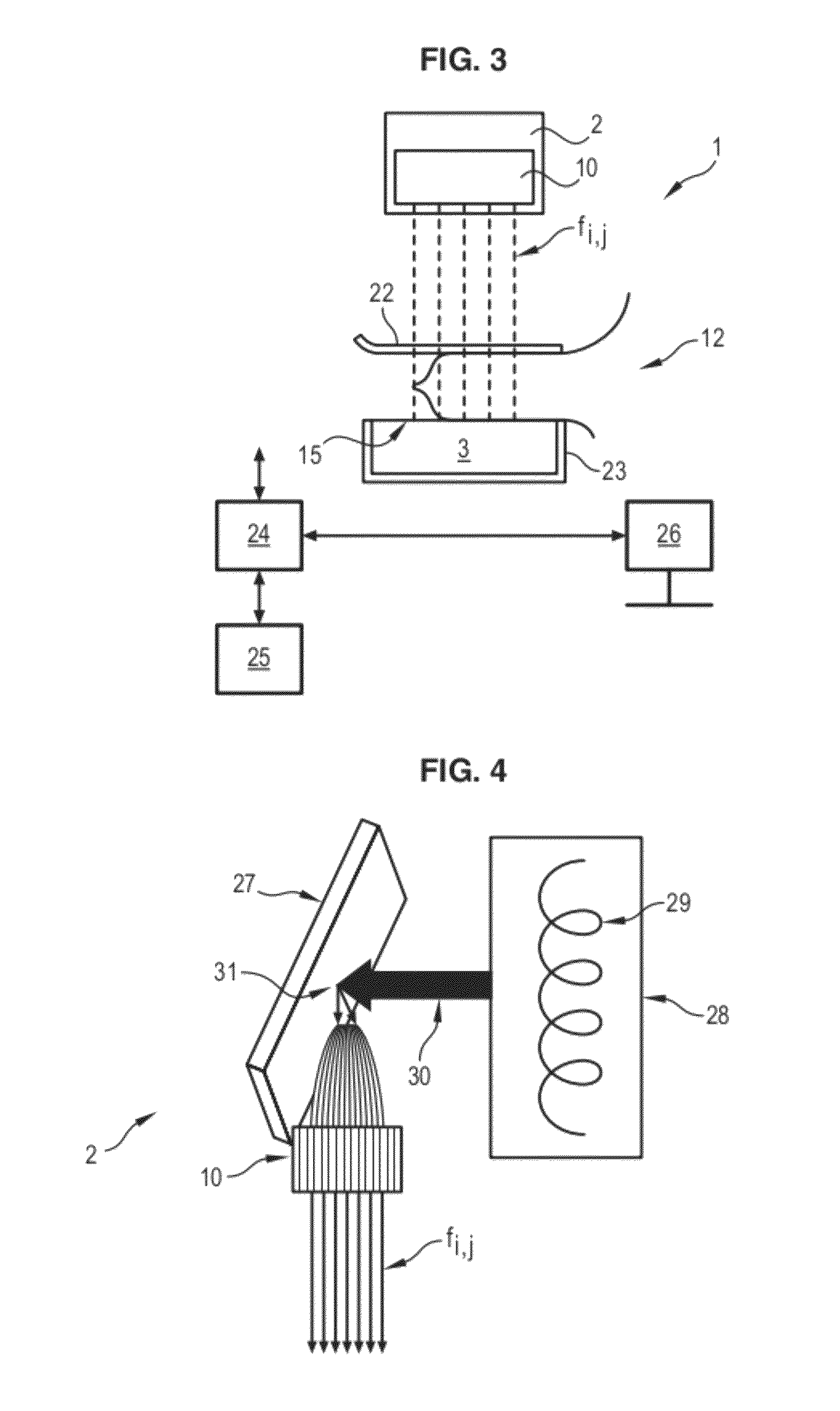

Solid state light source for photocuring

ActiveUS20130335992A1Small footprintReduce heat outputMechanical apparatusDrying solid materials with heatTouchscreenPhotoinitiator

A compact passively-cooled solid state illumination system is provided as a replacement for conventional arc light, metal halide and Xenon white-light sources for photocuring applications. The solid state illumination system utilizes LED modules to generate high intensity light output suitable for photocuring. The light output is continuous in the visible spectrum from 380 nm to 530 nm and is suitable for photocuring using a wide range of photoinitiators. A touchscreen interface allows programming of spectral output, intensity and duration. Output can be initiated using the touchscreen interface and / or a foot pedal.

Owner:LUMENCOR

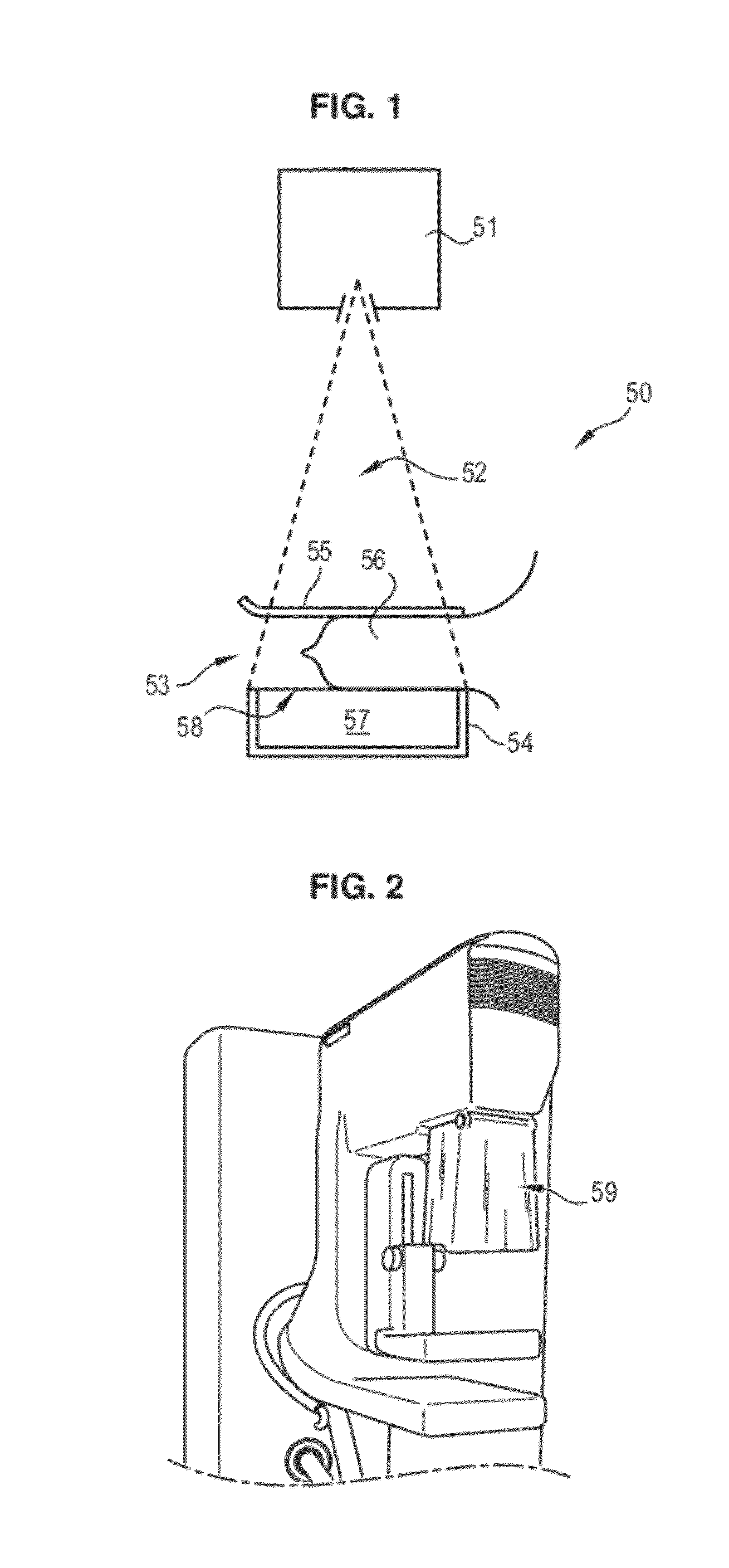

Compact mammograph and associated mammography process

ActiveUS9364190B2Reduced risk of collisionReduce heat outputX-ray tube electrodesNanoinformaticsX-rayMammography

A mammograph is provided. The mammograph includes a source of X-rays; a detector of X-rays, the source being configured to emit at least one beam of X-rays to the detector; and an optic control device configured to control the direction of X-rays emitted by the source such that the X-rays emitted by the source are substantially parallel to one another.

Owner:GENERAL ELECTRIC CO

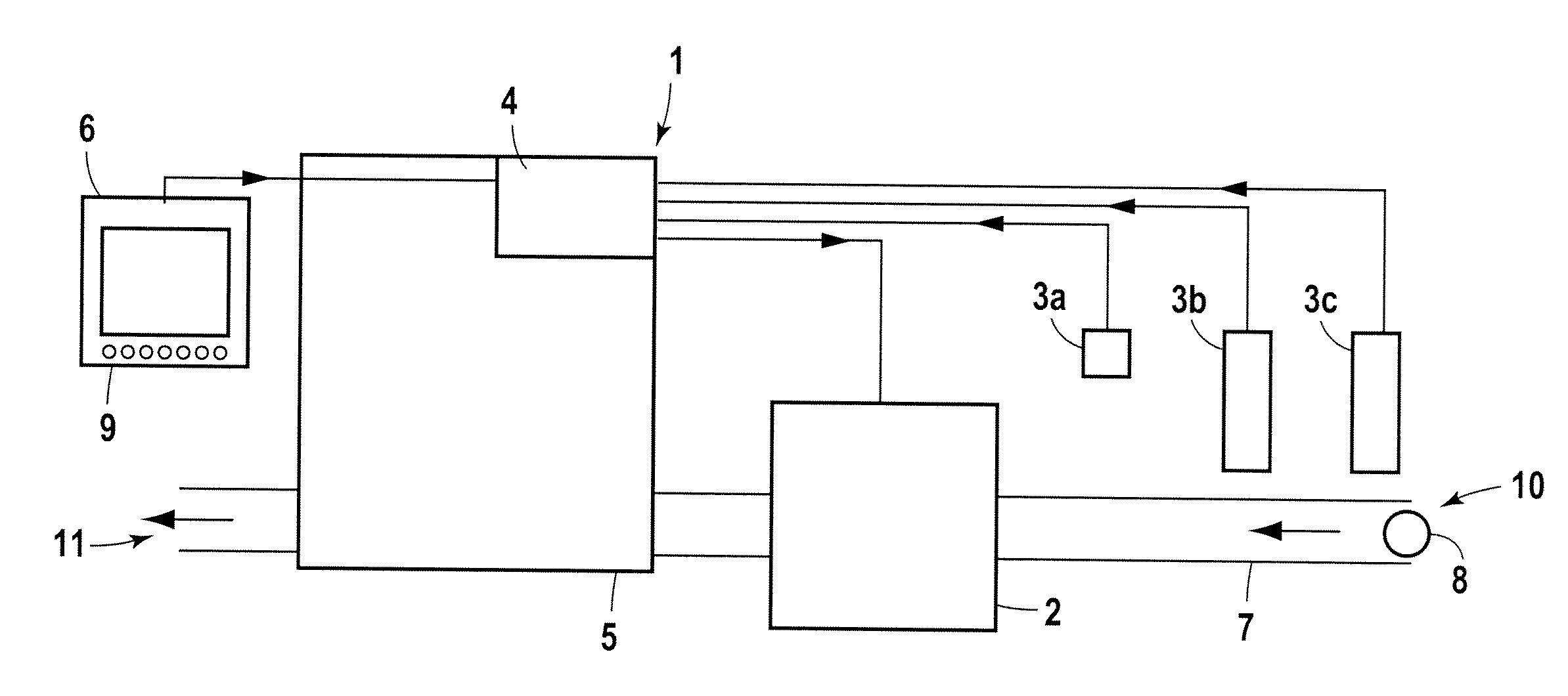

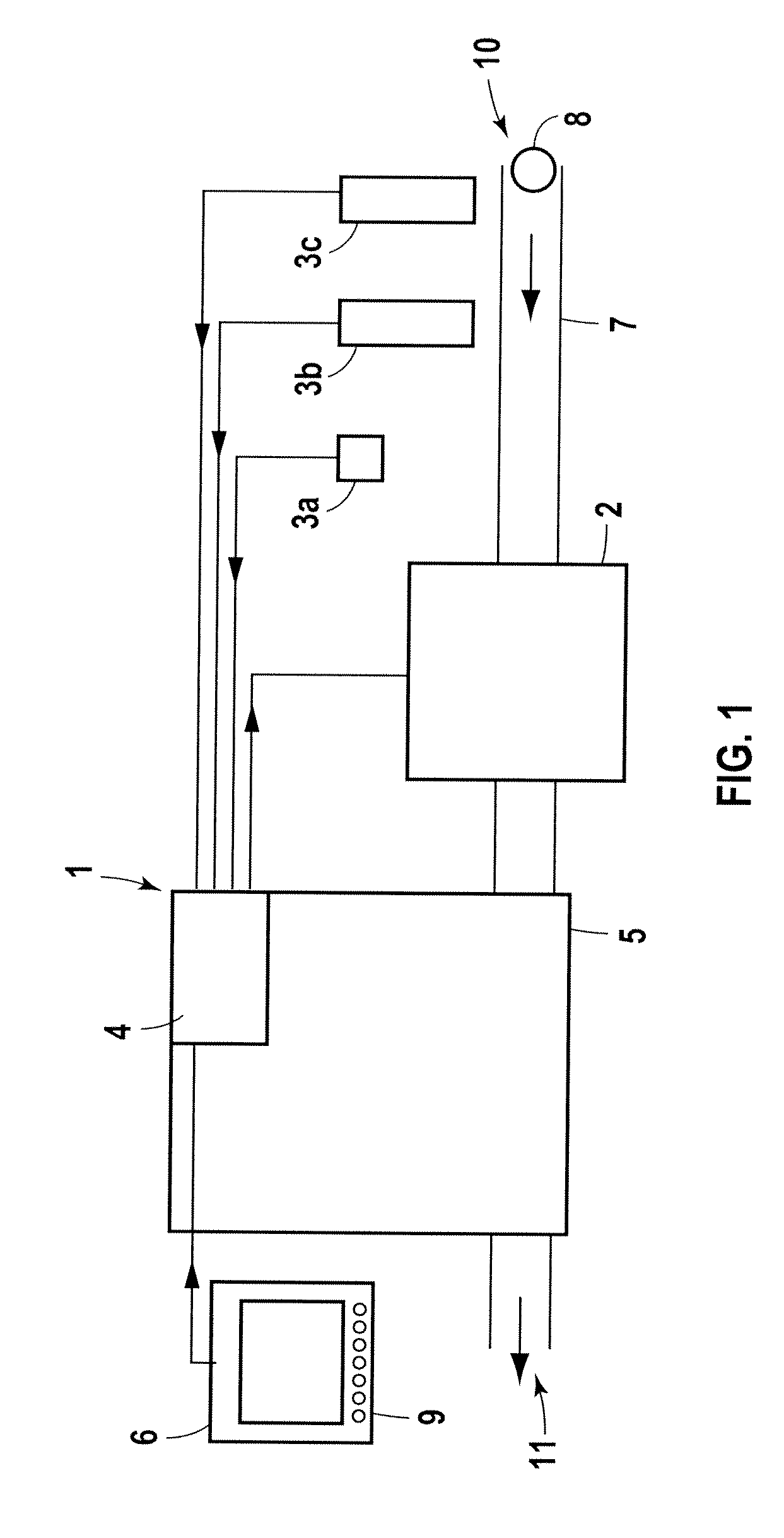

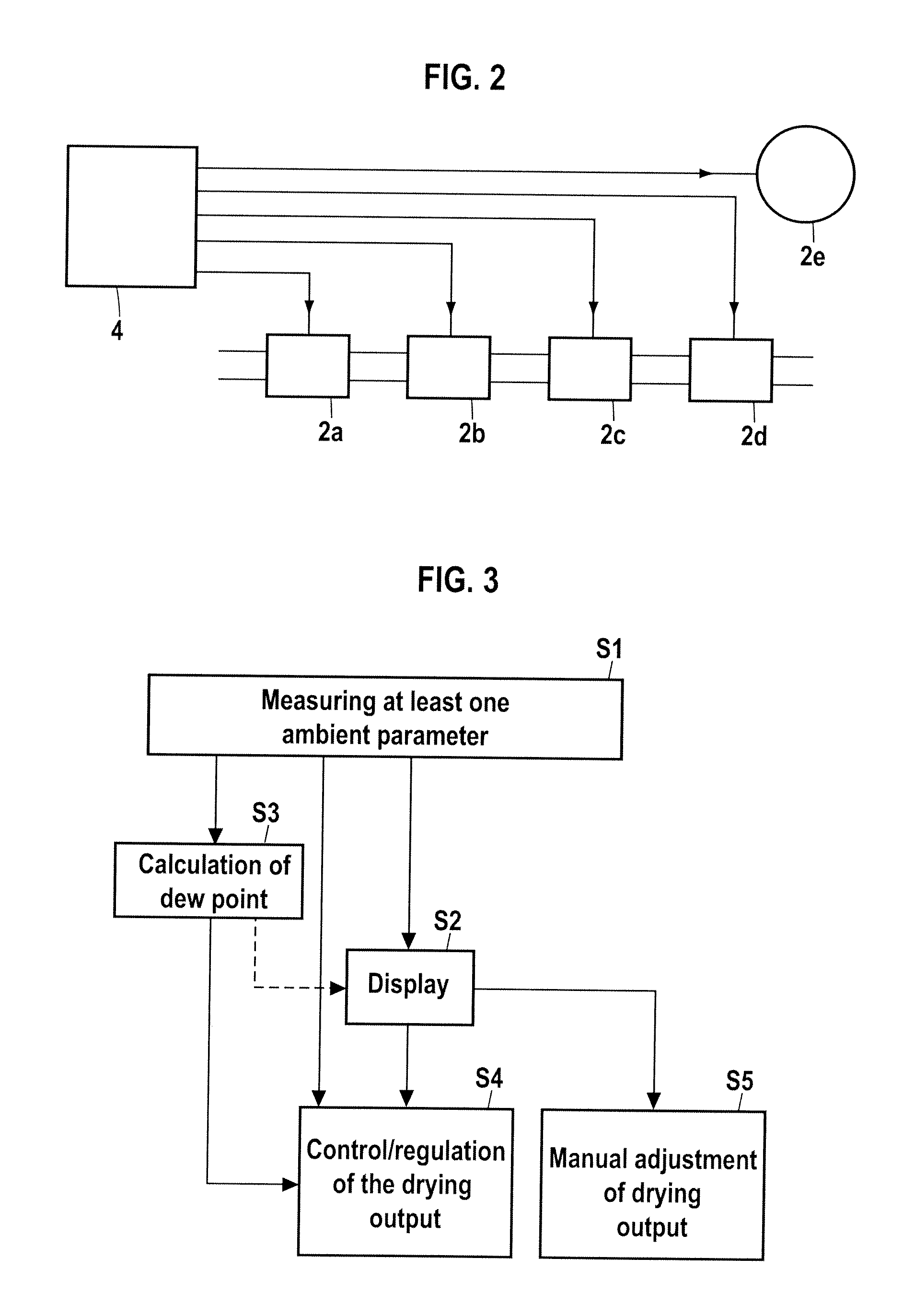

Device and method for drying containers

InactiveUS20080222912A1Dry performance be regulateEnergy saveDrying using combination processesDrying gas arrangementsEngineeringControl unit

A device and method for drying containers, in particular bottles, having a drying unit for removing water on the container surface. The drying process saves energy and is adapted to ambient conditions, so that labels, for example, can be applied reliably in a downstream labeling machine. The device includes at least one measuring unit for measuring ambient parameters. In addition, a control unit designed so that the drying performance of the drying unit can be regulated as a function of at least one measured ambient parameter is provided. The device and method makes it possible to prevent the condensation of water on the container surface or to keep it below a certain minimum.

Owner:KRONES AG

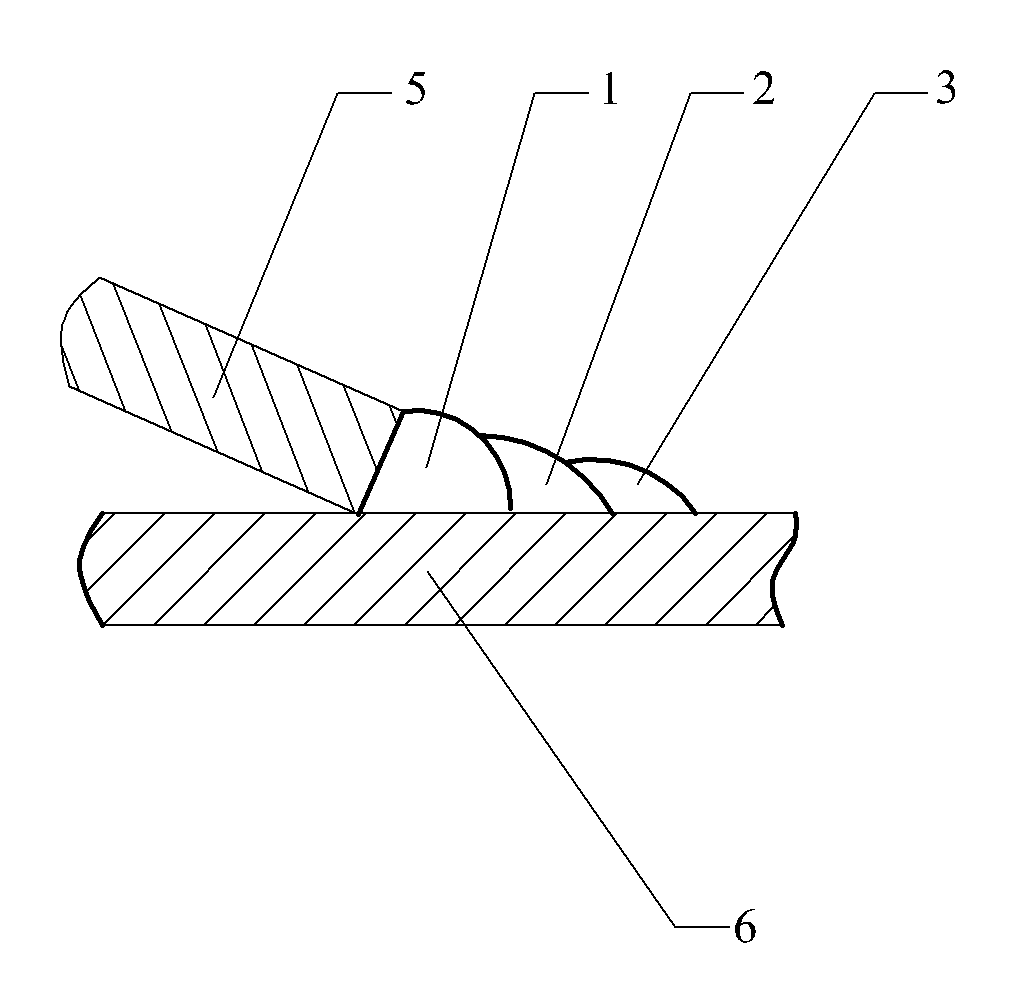

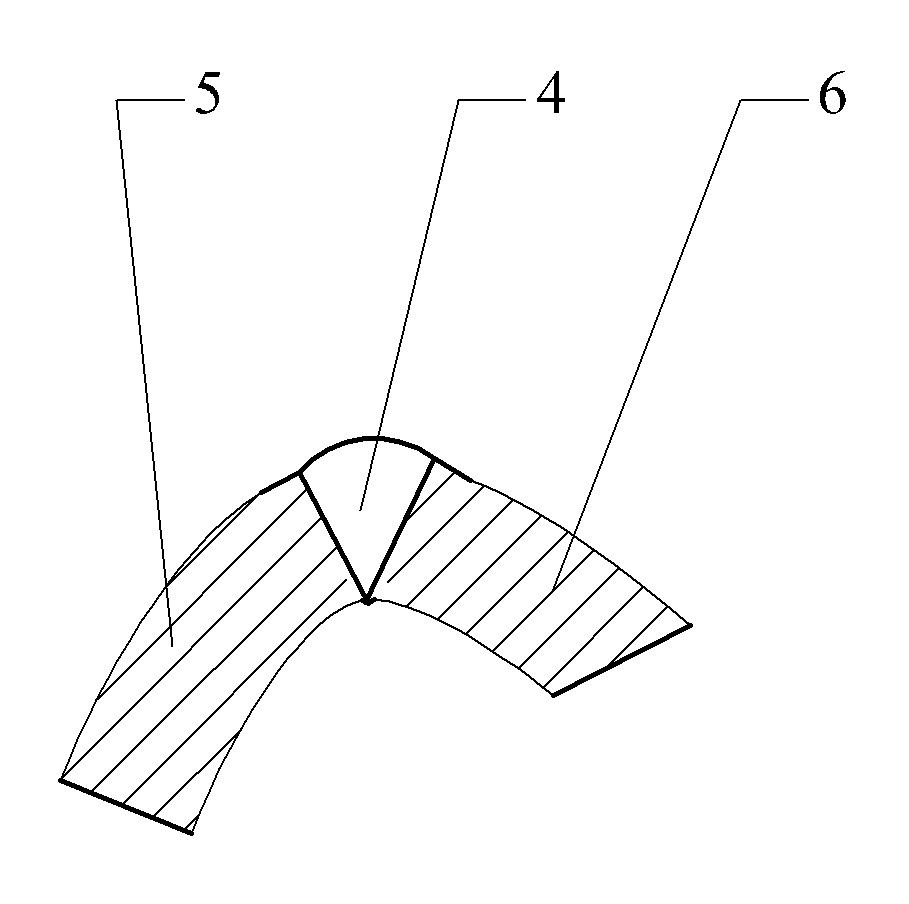

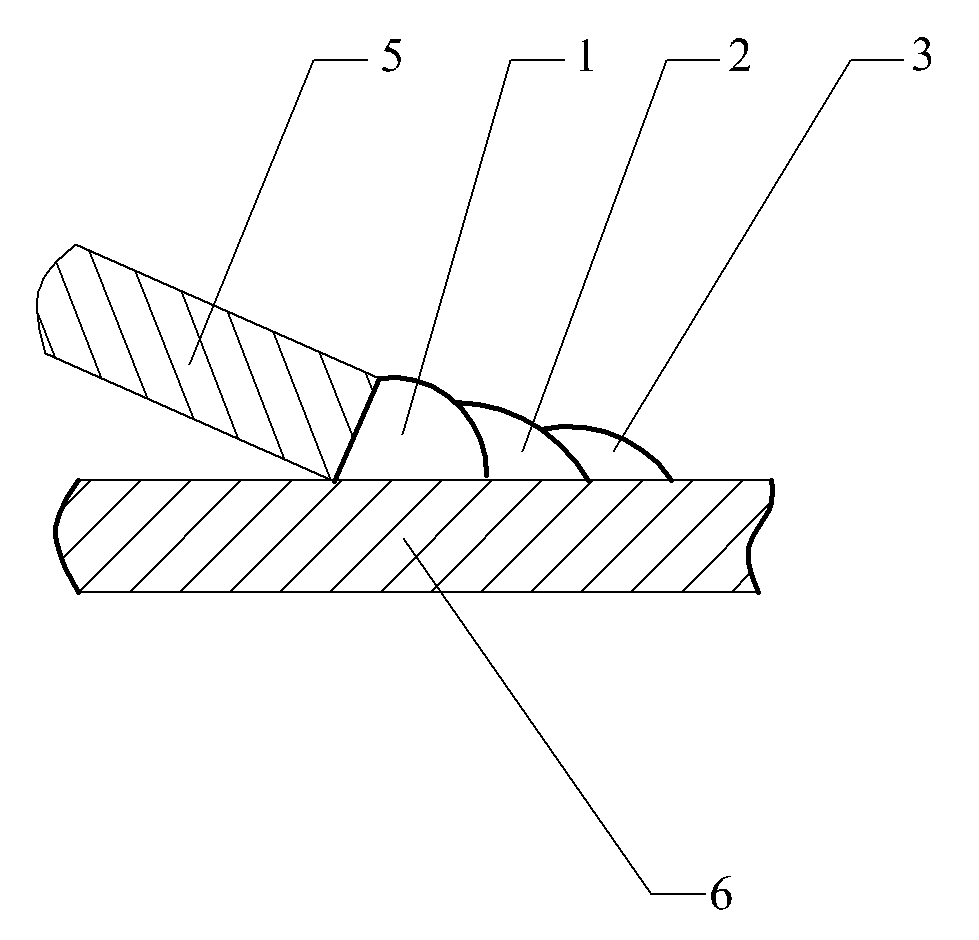

Automation welding system method of hollow stationary blades of steam turbine

ActiveCN102179604AGuarantee welding qualityReduce labor intensityArc welding apparatusEngineeringLaser tracker

The invention provides an automation welding system method of hollow stationary blades of a steam turbine. By adopting the method, the existing manual welding method is replaced, the labor intensity of workers is reduced, the working efficiency is improved, the difficulty that welding equipment is hard to recognize and adjust a welding position owning to consistency difference before groove welding of an inner arc sheet and a back arc sheet of the hollow stationary blade is overcome, the problem that common automatic welding equipment can not adjust the welding position in real time accordingto the features of a groove of a workpiece is effectively solved, the process flow of the existing manual welding is improved, the number of welding seams is reduced and welding deformation is reduced. The inner arc sheet and the back arc sheet of the hollow stationary blade of the steam turbine are assembled on a fixture and fixed. The automation welding system method is characterized in that preprocessing is carried out to a groove of a steam outlet edge of the hollow stationary blade firstly, then balance arc process welding is carried out to the steam outlet edge and a steam inlet edge ofthe hollow stationary blade of the steam turbine by adopting a welding robot system with arms and gas shielded arc welding equipment with a consumable electrode, a laser tracker with a scanning function is arranged in front of a welding gun of the arm of a welding robot, and in welding, the laser tracker is utilized to scan the groove corner lines of the hollow stationary blade with thin sheets, and the position of the welding gun can be automatically adjusted according to the change of the features of the groove so as to finish the welding operation finally.

Owner:WUXI TURBINE BLADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com