Automation welding system method of hollow stationary blades of steam turbine

A technology of automatic welding and hollow stator, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as unfavorable identification and adjustment, reduce welding deformation, and cannot be adjusted, so as to improve quality stability and reduce heat output. , The effect of reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

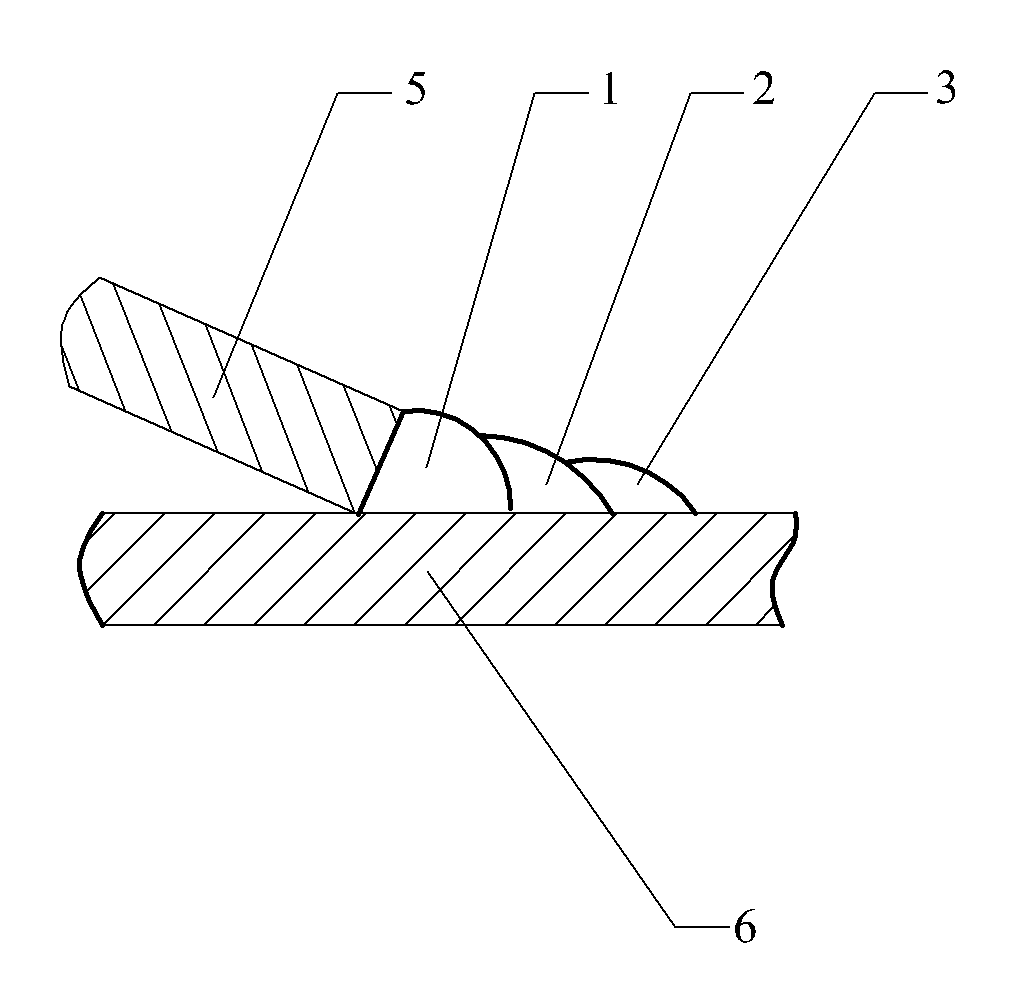

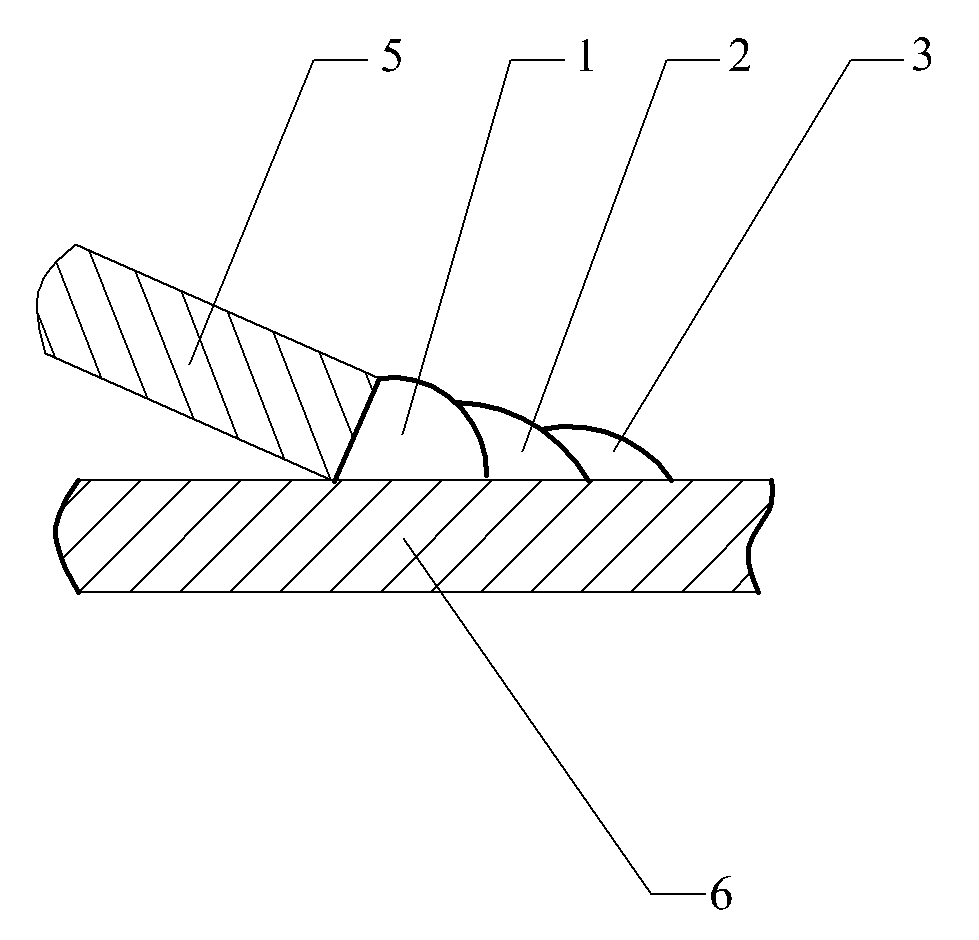

[0021] (1) Assemble and fix the two inner back arc plates of the hollow vane on the fixture;

[0022] (2) Manual tungsten argon arc welding electrode is used, and the welding wire matching the material of the inner back arc plate of the hollow stator is selected to fix and penetrate the inner back arc plate of the steam outlet side by spot welding, and the spot welding interval is 125mm ;

[0023] (3) Use the same type of welding wire as spot welding to repair the entire steam outlet edge with manual argon arc welding, in which the diameter of the welding wire is φ1.0mm, and the welding current is 130A, so that the steam outlet edge of the hollow stator is obtained A smooth and flat substrate weld, the fillet height of the substrate weld is 2mm;

Embodiment 2

[0025] (1) Assemble and fix the two inner back arc plates of the hollow vane on the fixture;

[0026] (2) Manual tungsten argon arc welding electrode is used, and the welding wire matching the material of the inner back arc plate of the hollow stator is selected to fix and penetrate the inner back arc plate of the steam outlet side by spot welding, and the spot welding interval is 200mm ;

[0027] (3) Use the same type of welding wire as spot welding to repair the entire steam outlet edge with manual argon arc welding, in which the diameter of the wire is φ1.5mm, and the welding current is 90A, so that the steam outlet edge of the hollow vane is obtained A smooth and flat substrate weld, the fillet height of the substrate weld is 3mm;

Embodiment 3

[0029] (1) Assemble and fix the two inner back arc plates of the hollow vane on the fixture;

[0030] (2) Manual tungsten argon arc welding electrode is used, and the welding wire matching the material of the inner back arc plate of the hollow stator is selected to fix and penetrate the inner back arc plate of the steam outlet side by spot welding, and the spot welding interval is 50mm ;

[0031] (3) Use the same type of welding wire as spot welding to repair the entire steam outlet edge with manual argon arc welding, in which the diameter of the wire is φ2.0mm, and the welding current is 110A, so that the steam outlet edge of the hollow vane is obtained A smooth and flat substrate weld, the fillet height of the substrate weld is 4mm.

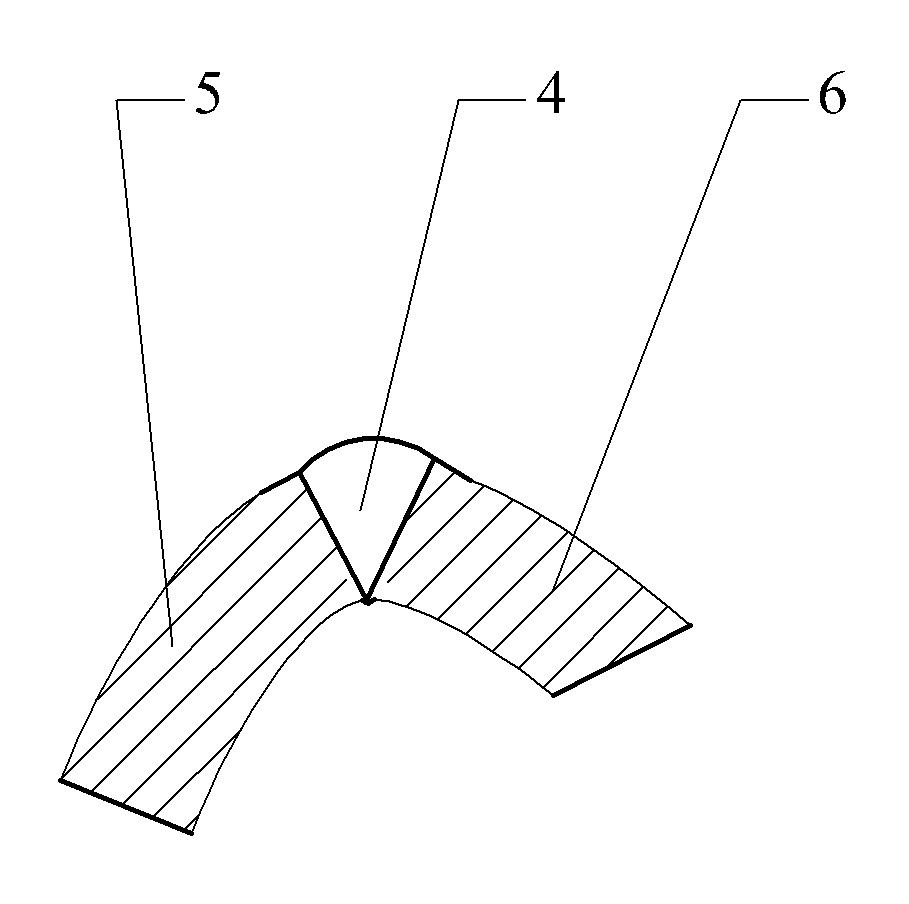

[0032] 3. Use the welding robot system with arms combined with the gas shielded arc welding equipment (Fronius CMT welding equipment) to perform swing arc welding on the steam outlet side and the steam inlet side of the hollow stationary blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com