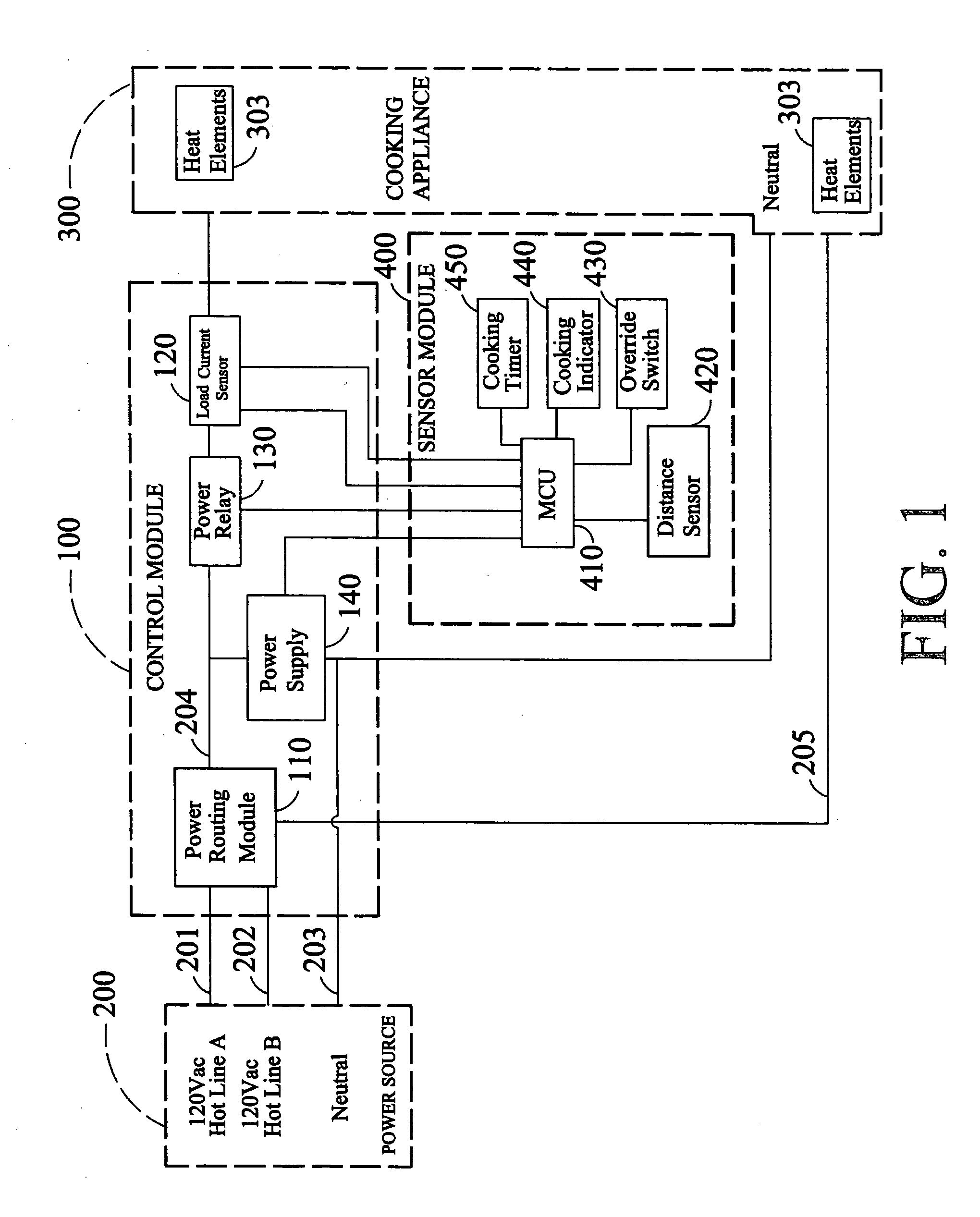

[0021] Safety devices utilizing an

infrared sensor adapted to sense the presence of a an appliance operator near an

electric stove are known in the related art. Ekblad patent '913, Graham patent '985, Vaillancourt patent '188, and Rak patent '413 all relate to electric stoves, and they all sense the presence of a person, the user or appliance operator, near the

electric stove. They all have a

timer that is set by the user of the stove and begins to run when that person is not sensed in the presence of the

electric stove. All of these patented inventions turn off the

electric power to the stove when the operator has not been sensed near the stove for a predetermined period of time. However, these patents utilize the more widely used passive

infrared (PIR) motion sensor, which does not actively emit any

signal. Vaillancourt patent '188 implies that it uses an

active infrared sensor but does not disclose how it works to detect a person. The present invention in its preferred embodiment uses a Sharp brand GP2Y0A02YK sensor which is an active sensor, a

detector /

transmitter, emitting an

infrared beam of light detected as it reflects off of an object. The PIR sensor, attempting to detect long wavelengths of radiated heat from a

human body, is easily saturated by radiated heat of similar

wavelength from a cooking appliance, such as a stove, which then masks, and defeats, its ability to detect appliance operator. An additional

advantage of the present invention utilizing the active sensor is that it is narrowly focused above and perpendicular to the cooking appliance's

radiation direction in the preferred embodiment, and therefore less likely to receive

radiation from a stove than a PIR sensor, which typically has a broader detection angle.

[0022] Another crucial

disadvantage in Ekblad patent '913, Graham patent '985, Vaillancourt patent '188, and Rak patent '413 is that the predetermined period of time to detect the presence of the appliance operator is set and reset for each one of these devices by the appliance operator or by various appliance operators for the same appliance. Therefore, in each of these cases the predetermined period of time could be different each time the stove, or another cooking appliance, is subsequently used, thus creating a hazardous situation if the timer isn't set properly or consistently. For instance, if the appliance operator inadvertently turns the appliance on (for example, by returning to the kitchen and briefly moving past the stove), after having left the stove's operation understanding that the sensor would turn the stove off, the stove, or other cooking appliance would begin to cook again. In the case of the Rak '413 patent, an intervening operator could reset the appliance for a time period unexpected by a later operator.

[0023] Ekblad patent '913 proposes a device for use in conjunction with a stove which enables operation of a stove when an appliance operator is in the area of the stove, and temporarily disables the stove for a predetermined time after the appliance operator leaves the area of the stove. Operation is automatically re-enabled when the appliance operator returns a first time; however, thereafter the appliance operator must reset the device upon his or her return to the stove. The operation of this patent has the

disadvantage in that it creates a hazardous situation whereby the stove might inadvertently return to “on” state before cooled to a safe temperature or unbeknownst to the user.

Human error causes the hazardous situations to occur, such as leaving the stove unattended, forgetting to set the timer, or forgetting to turn the device on or off.

[0024] Graham patent '985 also proposes a

detector device built into a stove by a manufacturer to perform generally similar function of disabling the stove when it is left unattended for more than a given period. However, installation of this element is cost prohibitive and can interfere with the operation of the stove. Graham patent '985 cuts off power to the entire operation of the cooking appliance. As well, the current manufacturing situation leaves those stoves already manufactured and installed in homes without a safety shutoff device. The Rak '413 patented invention weighs an inconvenient seven pounds.

[0025] Canadian

Patent Application No. 2,152,015 to Vaillancourt discloses a safety device, which may be either incorporated into or used in conjunction with a stove for detecting the absence of an operator and some other condition such as excessive heat, or the activation of a

heating element, and in response,

cutting power to the stove. The specification suggests that

heat output from the stove may be reduced rather than

cut off, but Canadian Vaillancourt '015 application does not disclose a means of achieving such a result.

[0026] Japanese Patent Publication, No. 02279925, also discloses a device that detects both the presence of a user and heat from the stove, and controls a stove operation accordingly. Again, this device has the same

disadvantage of other inventions, a sensor that is limited to

motion detection and its attendant problems and being susceptible to the

radiant heat of a stove; which sensors are built into the cooking appliance by the manufacturer as set forth above. Additionally, the Japan '925 patent, does not disclose how it reduces the electrical power to a stove; it merely measures the number of amperes drawn from the appliance.

Login to View More

Login to View More  Login to View More

Login to View More