Method for removing gas well accumulated liquid by means of oil jacket pressure balancing method

A balance method and gas removal technology, which is applied in earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of poor practicability and achieve the effects of strong practicability, reduced consumption, and wide range of well conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is a specific description of the present invention through the embodiments, it is necessary to point out that the present embodiment is only a preferred embodiment of the present invention, and the present invention is not limited in any way. Any simple modifications, changes and equivalent structural changes still fall within the protection scope of the technical solution of the present invention.

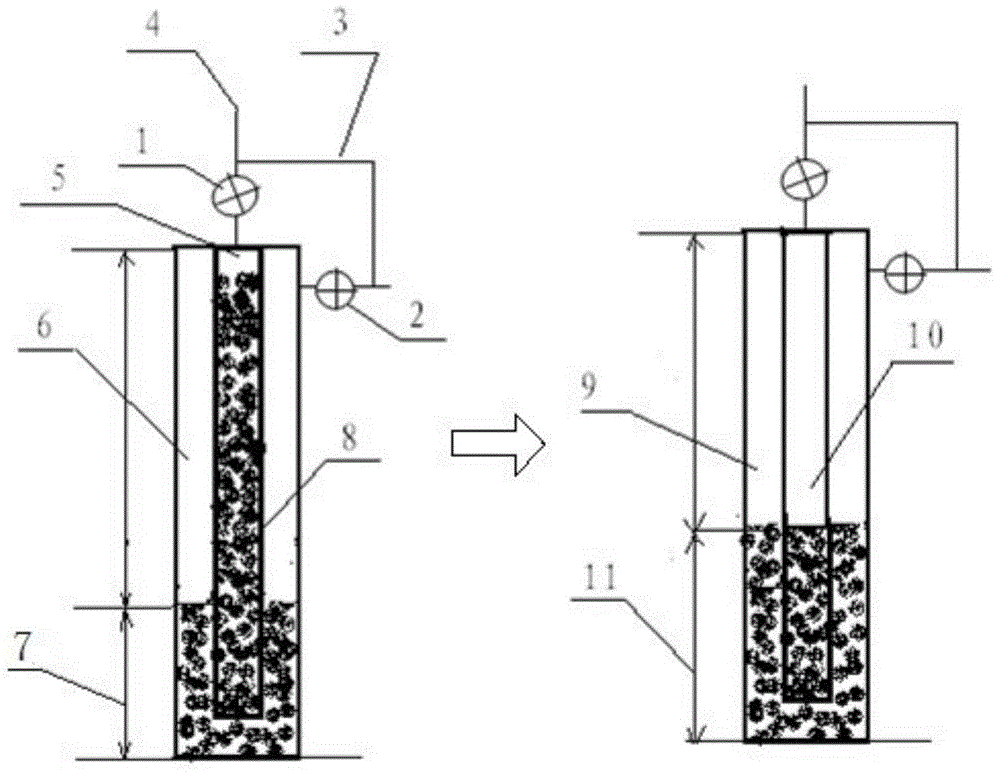

[0037] The method of the present invention is a method for removing liquid accumulation in a gas well by using the oil casing pressure balance method, which includes the following main steps:

[0038] 1) Diagnosis of fluid accumulation in the well:

[0039] Diagnose the bottom hole liquid level by steel wire detection liquid level or ultrasonic liquid level detection technology, and determine the height H of the liquid accumulation in the oil and casing 套 and H 油 , and then calculate the ratio N of the section of the oil jacket annulus to the inner section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com