Metal corrosion resistant insensitive ammunition and preparation method thereof

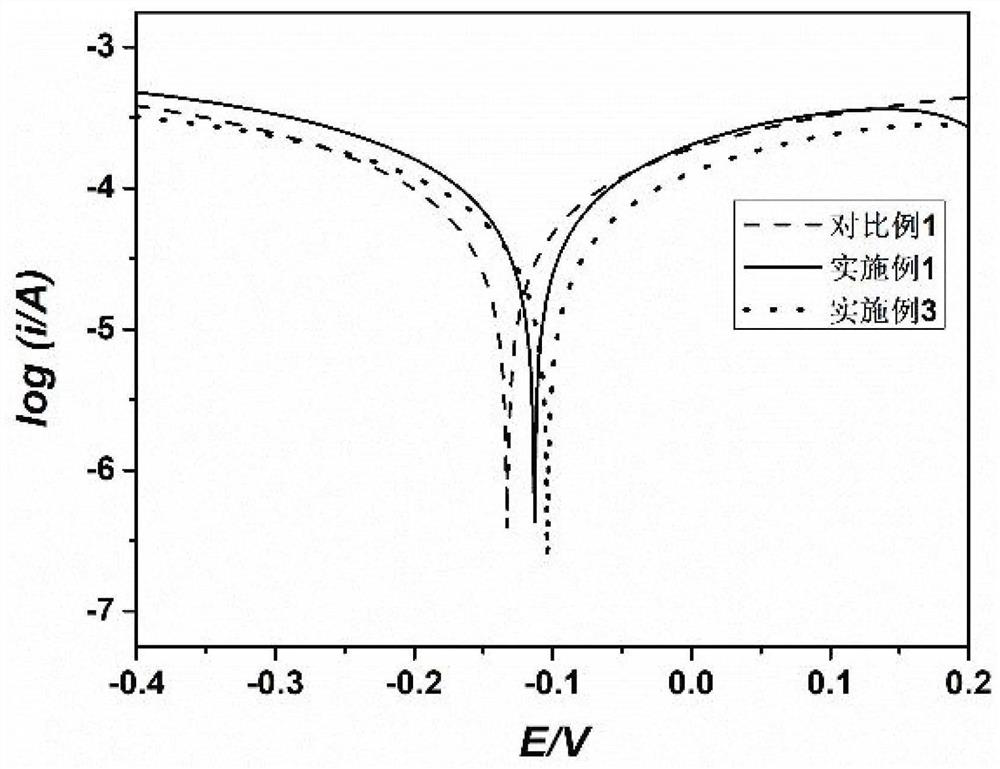

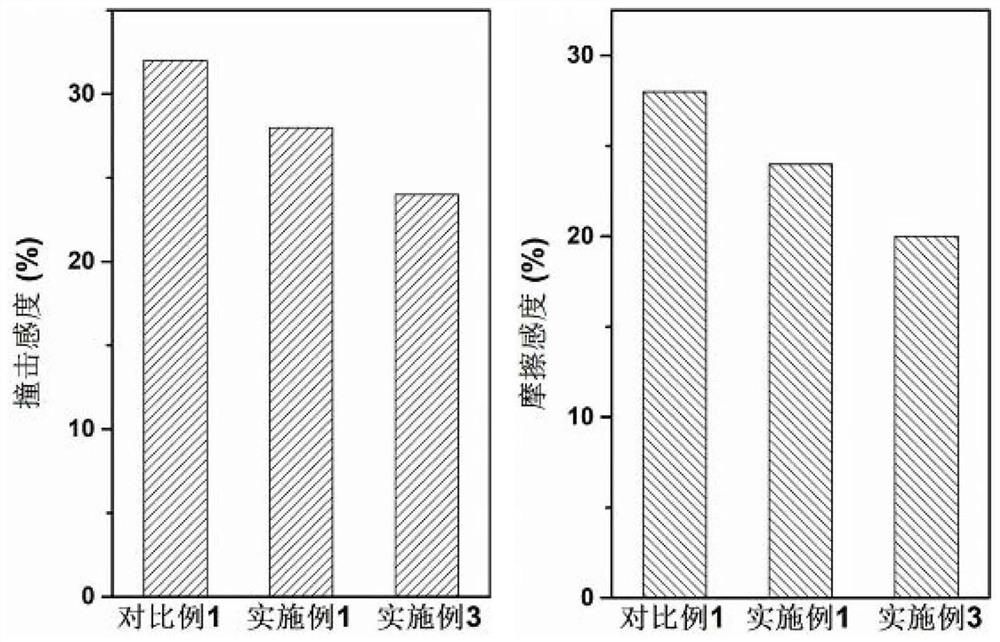

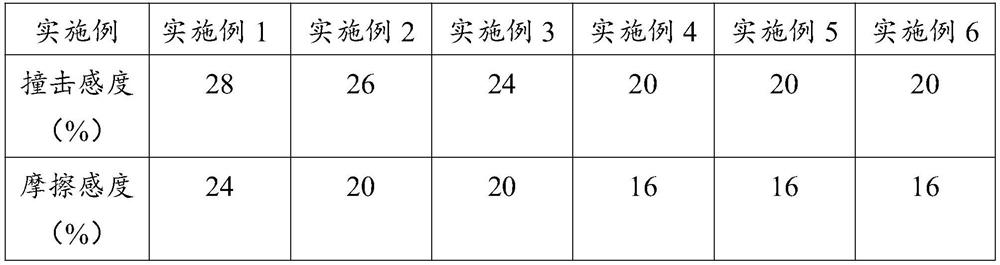

A corrosion-resistant, metal-resistant technology, applied in ammunition, separation methods, chemical instruments and methods, etc., can solve problems such as unfavorable weaponry application, NTO energy reduction, etc., and achieve improved metal corrosion resistance, electrical conductivity, and impact sensitivity The effect of reducing the frictional sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the above-mentioned anti-metal corrosion type insensitive ammunition, which specifically includes the following steps:

[0034] (1) Slowly add hydrofluoric acid solution with a mass fraction ≥ 40% to the MAX phase with a particle size ≤ 200 mesh, perform an etching reaction at 55-70°C for 24 hours, etch away the aluminum layer in the MAX phase, and then filter, Washing and drying to obtain layered MXene;

[0035] The mass volume ratio of the MAX phase to the hydrofluoric acid solution is 1g: 10mL;

[0036] (2) Dissolve the above-mentioned layered MXene and NTO raw materials with a purity of ≥98% in absolute ethanol, and obtain an anti-metal corrosion type insensitive ammunition through evaporation and crystallization under ultrasonic conditions. The mass percentage of MXene and NTO in absolute ethanol is 5 %~15%; ultrasonic power is 500W; evaporation crystallization temperature is 60~80℃. Wherein the mass volu...

Embodiment 1

[0038] Embodiment 1 of the present invention provides a method for preparing metal corrosion-resistant insensitive ammunition, which specifically includes the following steps:

[0039] (1) Add 2g of Ti 3 AlC 2 Add to 20mL of 49% hydrofluoric acid solution and react at 60°C for 24h to etch away Ti 3 AlC 2 The aluminum layer in, obtained layered MXene through filtering, washing and drying;

[0040](2) Mix the obtained MXene with NTO at a mass ratio of 1:20 to obtain a mixture. Dissolve 10 g of the mixture in 100 mL of absolute ethanol at 55° C., then raise the temperature to 65° C. Under 500W), carry out evaporative crystallization, obtain MXene / NTO compound after the complete evaporation of absolute ethanol, be anti-metal corrosion type insensitive ammunition.

Embodiment 2

[0042] Embodiment 2 of the present invention provides a method for preparing metal corrosion-resistant insensitive ammunition, which specifically includes the following steps:

[0043] (1) Add 2g of Ti 3 AlC 2 Add to 20mL of 49% hydrofluoric acid solution and react at 60°C for 24h to etch away Ti 3 AlC 2 The aluminum layer in, obtained layered MXene through filtering, washing and drying;

[0044] (2) Mix the obtained MXene and NTO at a mass ratio of 1:15 to obtain a mixture. Dissolve 10 g of the mixture in 100 mL of absolute ethanol at 55° C., then raise the temperature to 65° C. Under 500W), carry out evaporative crystallization, obtain MXene / NTO compound after the complete evaporation of absolute ethanol, be anti-metal corrosion type insensitive ammunition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com