Preparation method and application of laser-induced graphene without pinning effect

A laser-induced and pinning effect technology, which is applied in the preparation of test samples, material excitation analysis, Raman scattering, etc., can solve problems such as difficulty in implementation and complex process, and achieve good application prospects, simple preparation methods, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

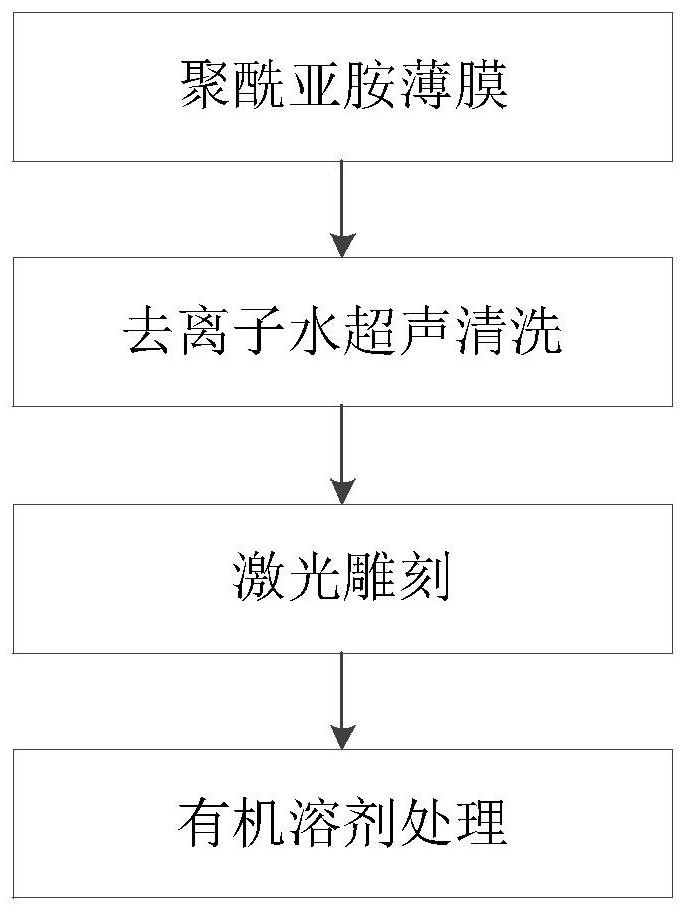

[0046]The invention provides a method for preparing laser-induced graphene without pinning effect, such as figure 1 shown, including the following steps:

[0047] (1) The polyimide film was ultrasonically cleaned with deionized water for 20 minutes;

[0048] (2) Design the graphene pattern that needs to be processed on the computer, and import the pattern into a laser engraving machine; the laser engraving machine is a semiconductor laser engraving machine with a wavelength of 460nm;

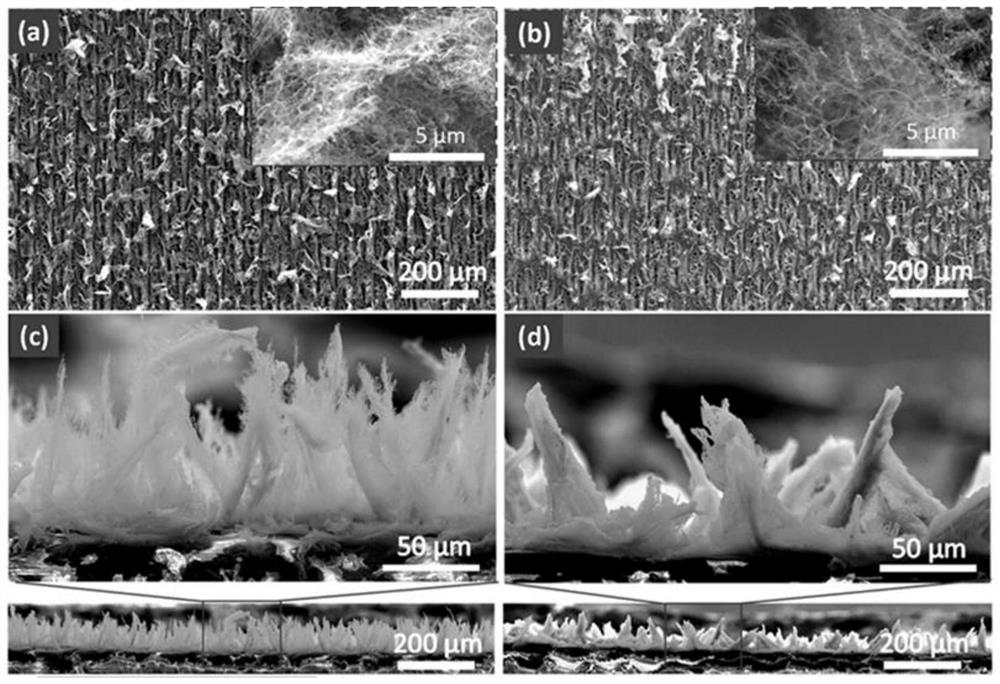

[0049] (3) the laser power of setting laser engraving machine is 10W, and engraving speed is 100mm / s, and polyimide film is carried out laser treatment, obtains LIG, and this graphene surface has fibrous graphene villi microstructure, as figure 2 as shown in (a) and (c);

[0050] (4) Add ethanol dropwise to the surface of graphene or soak graphene in ethanol for 5 minutes, and dry it at room temperature (ethanol evaporates cleanly) to obtain EtoH-LIG, and most of the fibrous graphene on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com