TCO thin film and preparation method thereof

A thin film and zinc oxide thin film technology, applied in the field of transparent conductive oxide thin film (TCO thin film) and its preparation, can solve the problems of reducing the optical transmittance of the TCO film layer, increasing the production cost, and narrowing the process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

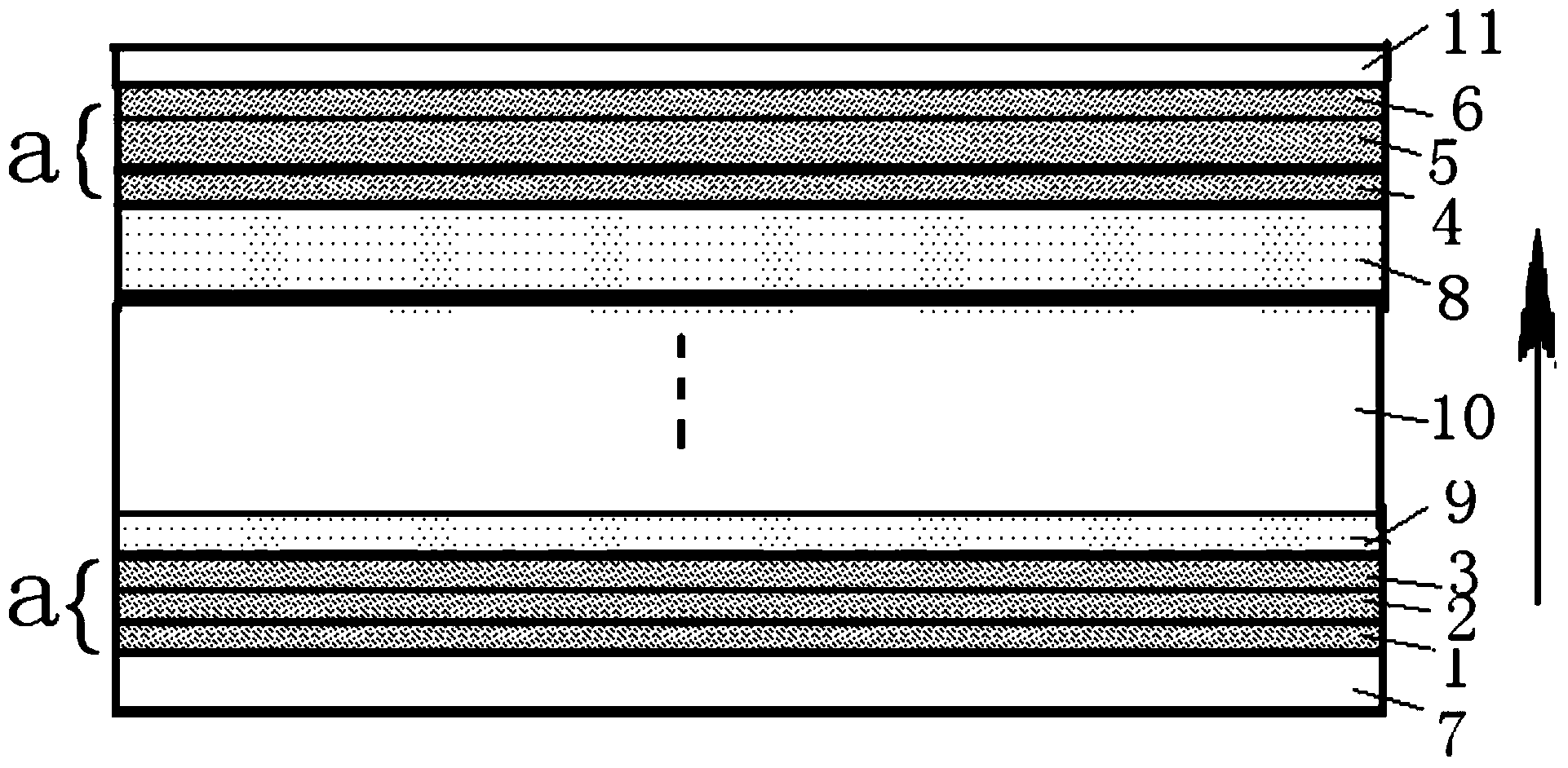

[0036] A preparation process for a textured transparent conductive oxide film of a multi-junction multi-stacked silicon-based thin-film solar cell. The specific implementation steps include: cleaning the substrate, and depositing a three-layer doped film on the substrate by applying low-pressure chemical vapor deposition technology. ZnO composite film, in which each layer of ZnO has different doping concentrations according to its position. The substrate is a stainless steel substrate, a glass substrate, a polymer substrate or a semi-finished substrate to be plated with a back electrode.

[0037] The above-mentioned front electrode composite TCO thin film is composed of three layers of ZnO thin films deposited on the substrate in sequence, the doping concentrations are n1: 0.35-0.50, n2: 0.01-0.10, n3: 0.35-0.50, and the doping substances are One or more of B, Al, Ga (n represents the atomic ratio of doping gas to diethyl zinc gas). Before depositing the absorber layer, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com