Compound forward osmosis membrane with separation function and preparation method thereof

A forward osmosis membrane and functional technology, applied in the field of forward osmosis membrane and preparation, to achieve the effect of good separation effect, high water flux and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

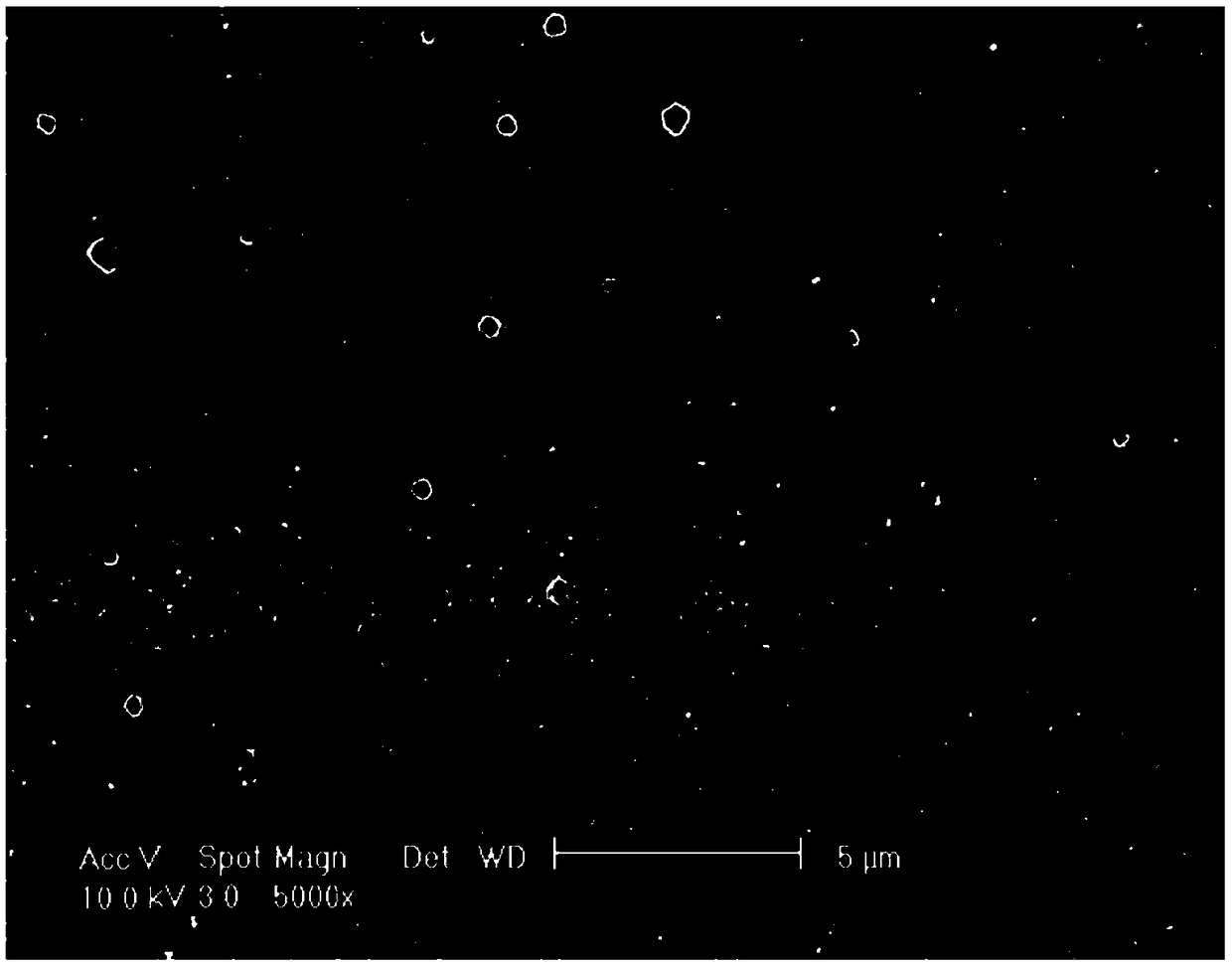

Image

Examples

preparation example Construction

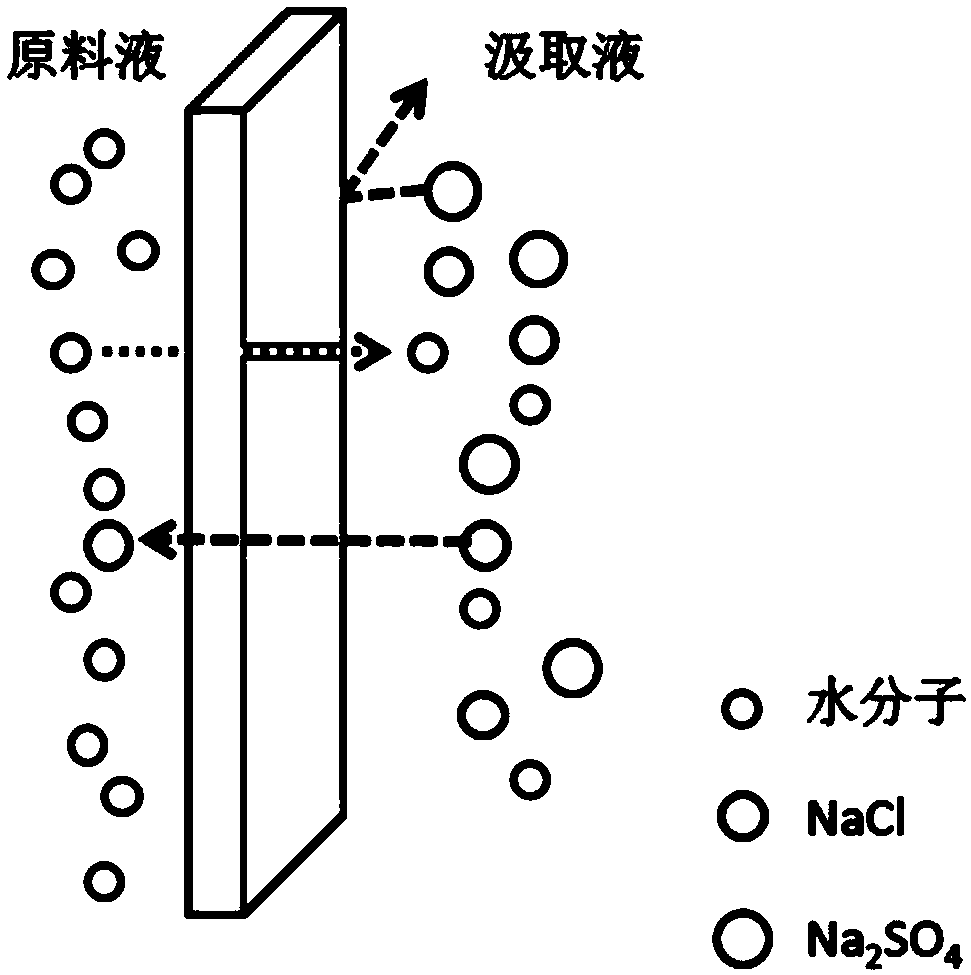

[0036] The preparation method of the forward osmosis membrane with multivalent separation function of the present invention comprises the following steps:

[0037] (1) impregnating the porous support layer in an aqueous phase solution containing two or more reactive amino compounds;

[0038] (2) use a rubber roller to remove excess water phase solution on the surface of the porous support layer after water phase infiltration;

[0039] (3) impregnating the porous support layer treated in step (2) in an organic phase solution of an acid chloride compound containing two or more acid chloride groups;

[0040] (4) make described forward osmosis membrane after heat treatment, washing;

[0041] The porous support layer is one of a polysulfone porous support layer, a polyethersulfone porous support layer, a sulfonated polyethersulfone porous support layer, and a polypropylene porous support layer with a molecular weight cut-off of 30,000 to 50,000.

[0042] The compound containing t...

Embodiment 1

[0067] Use a polyethersulfone porous support membrane with a molecular weight cut-off of 30,000 to 50,000 (ie, a polyethersulfone porous support layer), and contact the front side with a piperazine aqueous phase solution (ie, an aqueous solution) with a concentration of 1 g / L for about 60 seconds. The polyethersulfone support membrane soaked by the phase solution was removed with a rubber roller to remove excess solution. Then this support membrane was contacted with the IsoparE solution of trimesoyl chloride with a concentration of 1g / L for 60 seconds; then the formed polyamide layer was air-dried, placed in an oven at 65°C for 5min, and then heated at 25°C Rinse in deionized water to obtain a composite forward osmosis membrane, and the prepared composite forward osmosis membrane is stored in deionized water.

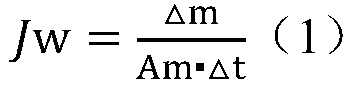

[0068] The performance of the special forward osmosis membrane prepared by the present invention is characterized by the above method, and the draw solution is 1mol / LN...

Embodiment 2

[0071] The preparation method of the composite membrane is the same as in Example 1, except that the piperazine aqueous phase solution is changed to 10 g / L. Using formula (1) to calculate the water flux is 34.15L m -2 h -1 , the salt backmixing flux calculated by formula (2) is 24.34g / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com