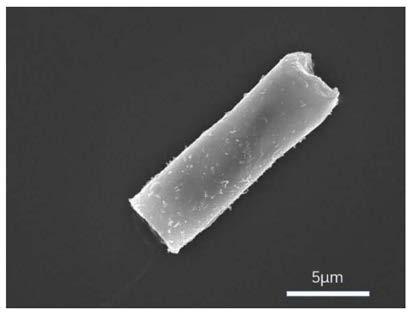

Biocompatible iron-manganese dioxide system micro-nano motor and preparation method thereof

A manganese dioxide, micro-nano technology, applied in microstructure technology, gaseous chemical plating, microstructure devices, etc., can solve the problems of inability to form surface morphology, inaccurate regulation of element composition and content, etc. Compatibility, less damage to human body, effect of reducing manganese content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a biocompatible iron-manganese dioxide system micro-nano motor, comprising the following steps:

[0037] Step 1: Use a polycarbonate film sputtered with a 30-nanometer thick Au metal layer on one side as the working electrode, platinum wire as the auxiliary electrode, and an Ag / AgCl electrode as the reference electrode, and add polyethylenedioxythiophene (PEDOT) to the electrolytic cell. ) electrolyte, using electrochemical workstation to carry out electrochemical deposition of polyethylenedioxythiophene (PEDOT) support outer layer in polycarbonate film, set deposition voltage as 1.0V, deposition charge as 0.2C, deposition time as 108 second; step 2: the polycarbonate film with a side sputtered with a thickness of 30 nanometers of Au metal layer is used as the working electrode, the stainless steel sheet with an area of 10 square centimeters is used as the auxiliary electrode, and the Ag / AgCl electrode is used as the reference electrode, prepared...

Embodiment 2

[0046] A method for preparing a biocompatible iron-manganese dioxide system micro-nano motor, comprising the following steps:

[0047] Step 1: Use a polycarbonate film sputtered with a 45-nm thick Au metal layer on one side as the working electrode, a platinum wire as the auxiliary electrode, and an Ag / AgCl electrode as the reference electrode, and add polyethylenedioxythiophene (PEDOT) to the electrolytic cell. ) electrolyte solution, using electrochemical workstation to carry out electrochemical deposition of polyethylenedioxythiophene (PEDOT) support outer layer in polycarbonate film, set deposition voltage as 1.2V, deposition charge as 0.3C, deposition time as 126 second; step 2: the polycarbonate film with a side sputtered with a thickness of 45 nanometers of Au metal layer is used as the working electrode, the stainless steel sheet with an area of 16 square centimeters is used as the auxiliary electrode, and the Ag / AgCl electrode is used as the reference electrode, prep...

Embodiment 3

[0056] A method for preparing a biocompatible iron-manganese dioxide system micro-nano motor, comprising the following steps:

[0057] Step 1: Use a polycarbonate film sputtered with a 40-nanometer thick Au metal layer on one side as the working electrode, platinum wire as the auxiliary electrode, and an Ag / AgCl electrode as the reference electrode, and add polyethylenedioxythiophene (PEDOT) to the electrolytic cell. ) electrolyte solution, using electrochemical workstation to carry out electrochemical deposition of polyethylenedioxythiophene (PEDOT) support outer layer in polycarbonate film, set deposition voltage as 1.4V, deposition charge as 0.4C, deposition time as 130 second; step 2: the polycarbonate film with a side sputtering 40 nanometers of thickness Au metal layer as the working electrode, the stainless steel sheet with an area of 12 square centimeters as the auxiliary electrode, and the Ag / AgCl electrode as the reference electrode, prepared in step 1 On the basis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com